Abstract

In this work, a multi-independent-output, multi-string, high-efficiency, boost-converter-based white LED (WLED) driver architecture is proposed. It utilizes a single inductor main switch with a common maximum duty cycle controller (MDCC) in the feedback loop. A simple pulse skipping controller (PSC) is utilized in each high-side switch of the multiple independent outputs. Despite the presence of multiple independent outputs, a single over-voltage protection (OVP) circuit is used at the output to protect the circuit from any voltage above 27 V. An open circuit in any of the strings is addressed, in addition to the LED’s short-circuit conditions. Excellent current matching between strings is achieved, despite the low ON-resistance () of transistors used in the 40 nm process. Most circuits are designed in digital CMOS logic to overcome the extreme process variations in the 40 nm node. Compared to a single output parallel strings topology, a improvement in efficiency is achieved relative to extremely unbalanced strings. Three strings are used in this proposal, but more strings can be supported with the same topology. Each string is driven by a 25 mA current sink. An input voltage of 3.2–4.2 V and an output voltage up to 27 V are supported.

1. Introduction

By examining modern smart portable devices, one can find plenty of voltage domains which intended to serve different modules and sub-modules inside those devices [1,2]. The straightforward way to serve all these modules and sub-modules is to have a dedicated voltage converter/regulator from the main battery to each one of them. This is not an optimal design, since it would require each converter to have its external passive components and controller in addition to mitigating the EMI among the different inductors. Multi-output converters are therefore becoming very popular in modern devices. These converters may be of linear, switching, step-down, or step-up type with digital or analog voltage or current control. There are different ways these outputs can be related to each other and controlled [3]. The most versatile form is a multi-output model that can serve different loads independently, along with common control parts to ensure compactness, higher efficiency, and re-use of the resources.

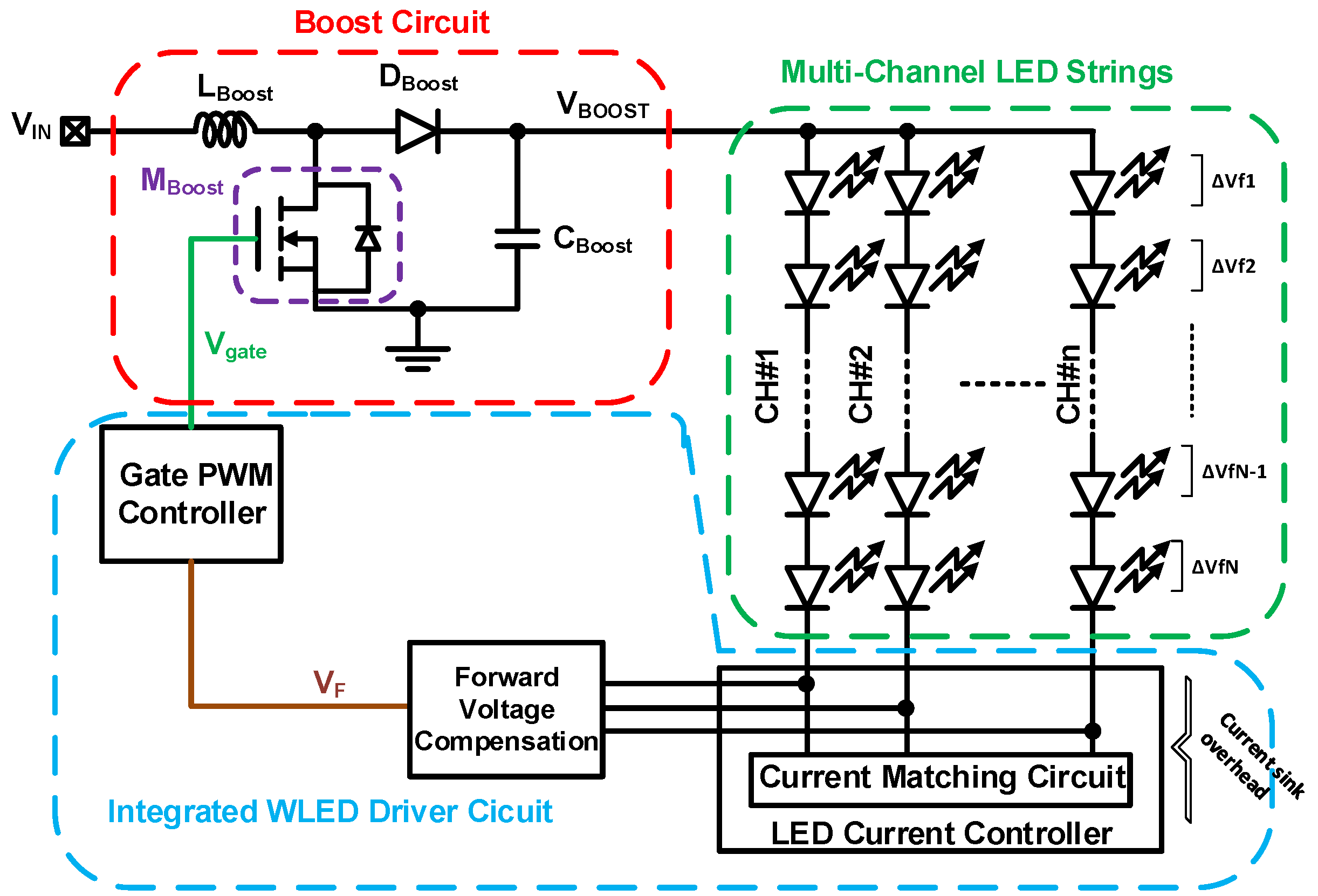

The WLED driver ideally operates in a similar manner to a voltage-regulated boost converter, except it regulates the output current through the string of LEDs with high power efficiency, especially in portable devices. Besides, there is a need for an accurate current within any string and among the different strings to guarantee consistency in brightness [4]. A multi-string WLED driver is a natural application of multi-independent-output converters. The traditional architecture of multi-string WLED drivers has all strings connected to the same output node, which is , as shown in Figure 1. Despite its simple architecture with a common controller, single OVP circuitry, and a minimum number of switches per string [5,6,7,8], it suffers from lower power efficiency and current mismatching among strings. This is particularly true in an asymmetrical string arrangement and low process nodes, such as a 40 nm process node. Even with a symmetrical string arrangement, white LEDs typically have different forward voltage () drops. Practically, the value of varies between 2 and 4 V, even if these WLEDs come from the same batch at the manufacturing facility. Additionally, the drop in each of these WLEDs is a function of temperature [9,10,11]. Therefore, a multi-string driver with the same number of WLEDs per string may require different voltages to satisfy all WLEDs in the string plus the current sink overhead.

Figure 1.

Typical architecture of a multi-string, boost-based WLED driver.

To overcome the disadvantages above of the typical architecture, multiple independent output WLED drivers are becoming the mainstream topology [12,13]. However, this comes with a potentially higher number of switches per string, more complex control circuitry, and multiple circuits (one per output) for common features such as over-voltage protection (OVP).

This work proposes a single-inductor, multiple-independent-output, multi-string architecture using a 40 nm CMOS process node. Using a single inductor, a minimum number of switches per string, and a simple and common controller, excellent current matching among strings is achieved. This solution requires a single OVP circuit for all independent outputs. Furthermore, the proposed solution has high power efficiency, almost all-digital design methodology, easy digital dimming, and expandable design when increasing the number of strings. The rest of the paper is organized as follows: Section 2 discusses the basic operational principles of the proposed architecture, including a performance evaluation. Section 3 describes the individual circuits comprising the proposed architecture. Section 4 summarizes the simulation setups and results. Finally, conclusions are covered in Section 5.

2. Proposed Architecture, Basic Operational Principles, and Performance Evaluation

The proposed architecture and its basic operation are described in Section 2.1. Section 2.2 presents the most popular published current drivers.

2.1. The Proposed Architecture and Its Basic Operation

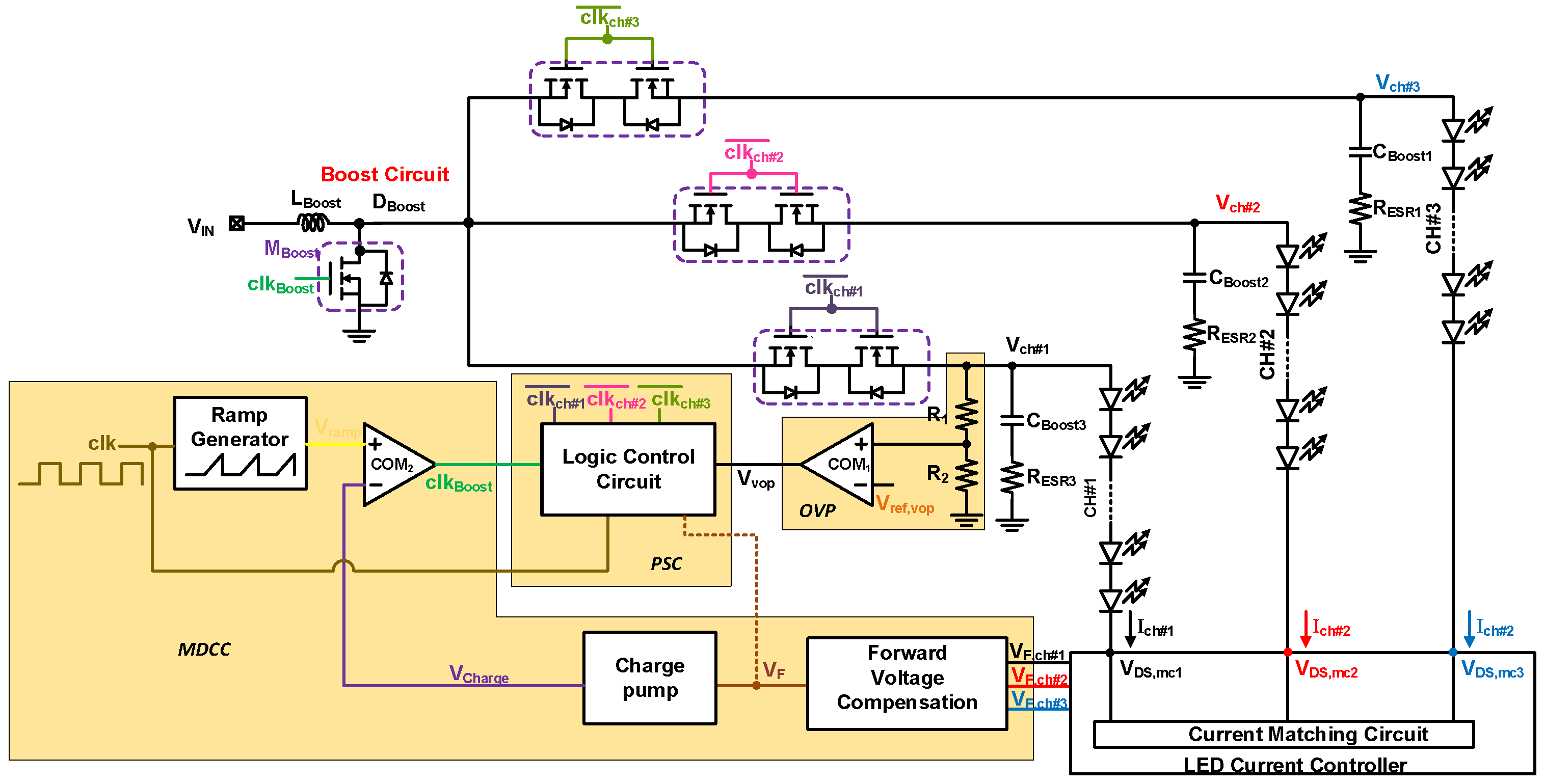

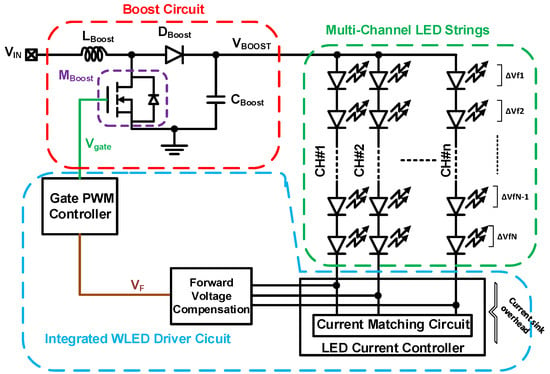

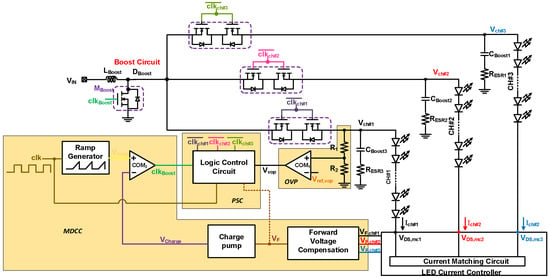

Figure 2 shows the overall block diagram of the proposed architecture. This WLED driver is based on a boost converter with a single common inductor (); a common main switch (); a high-side switch; an output capacitor for each independent output (string); a current matching circuit; and a maximum duty cycle controller (MDCC) that consists of a forward voltage compensation circuit, a charge pump, a PWM block to control, and a drive for the main switch. A simple pulse skipping controller (PSC) is used to control the gates of the high-side switches. For optimal power efficiency of 18 WLEDs, typically enough for a smartphone backlight, WLEDs are arranged as three strings; each has 6 WLEDs [4].

Figure 2.

The proposed architecture.

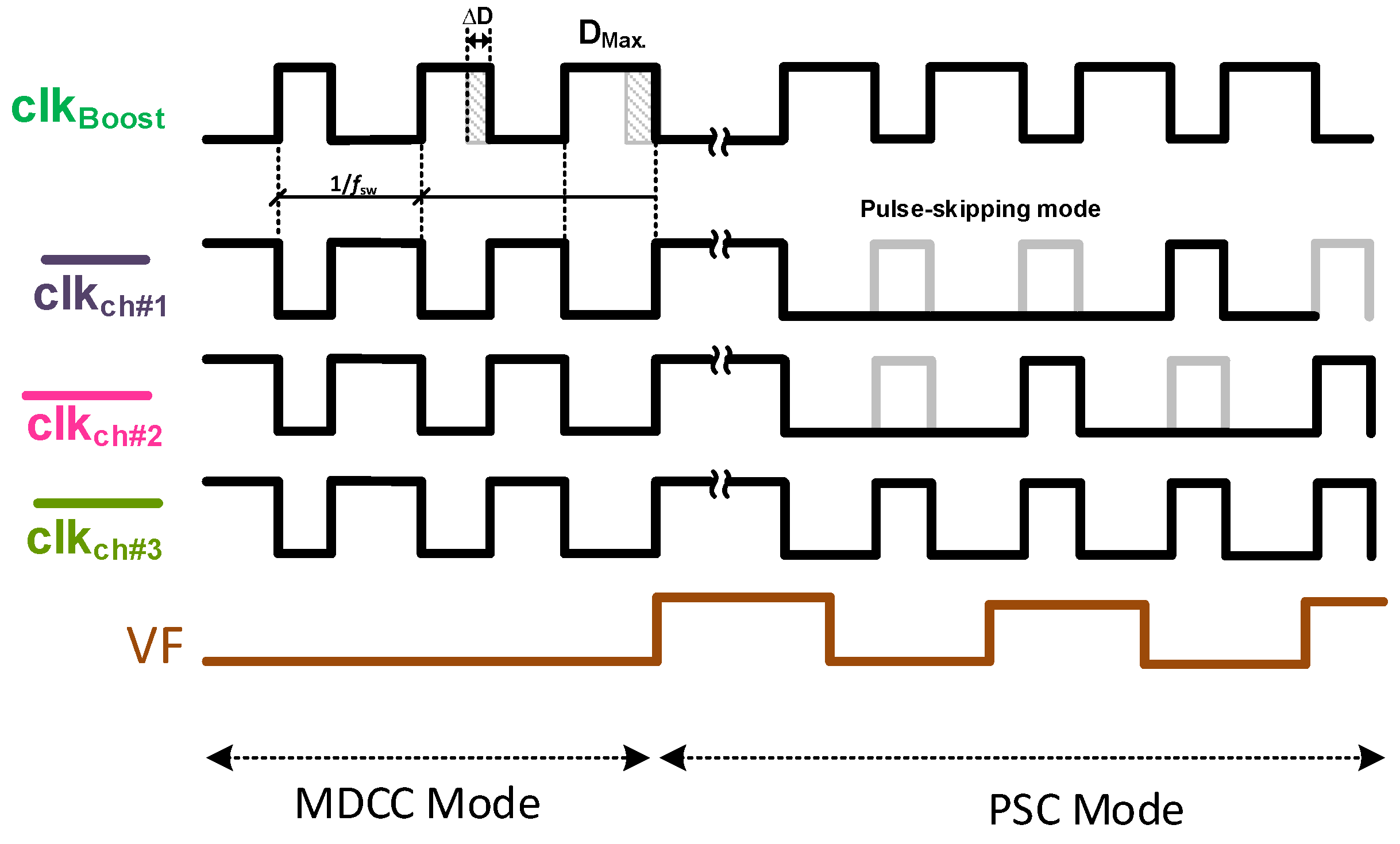

There are two modes of operation: MDCC mode and PSC mode. In the MDCC mode of operation, the MDCC controller produces the signal that drives the main switch to the maximum duty cycle () needed for all strings to be conductive. In this mode, the main switch is driven by duty cycle D and high-side switches are driven by 1D. Arriving at suggests that all strings have reached the targeted current . At that moment, the PSC mode of operation starts pulse-skipping on the individual high-side switches to get rid of any extra voltage/current accumulated during the initial startup procedure (prior to reaching ). A constant value of zero for the signal indicates the MDCC mode of operation; a pulsating value indicates the pulse-skipping mode. If any of the strings’ current sinks’ overheads drops below the reference voltage (), which is equivalent to , back to zero, the MDCC mode starts again and this continues forever.

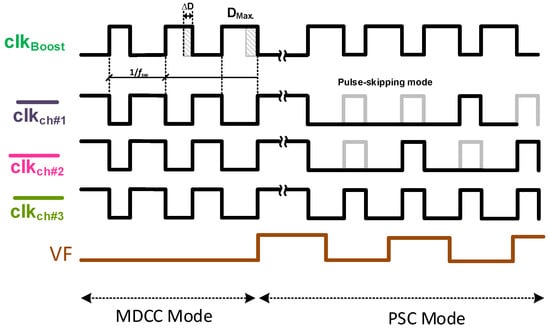

Figure 3 illustrates the timing of the different gate pulse drivers for the main and high-side switches. It shows how the PSC starts pulse skipping mode on the high-side switches once the has been reached at the main switch using MDCC. These waveforms reflect a scenario where the total voltage drop of WLEDs () in string 1 is the lowest and that in string 3 is the highest.

Figure 3.

Main and high-side switches’ gate pulse drives.

If an open circuit condition has been detected, the OVP indicator stops switching, and the system starts all over again at the beginning of the next cycle. In the case of any WLED short-circuit, the system keeps working as if nothing has happened. This is true since the system is designed to work with unbalanced strings, so it acts as if that string is one WLED less in the count.

2.2. Current Matching

In this subsection, the most popular published art current drivers are investigated, along with their shortcomings. The proposed current driver, along with its advantages over published art, is expanded in the following section.

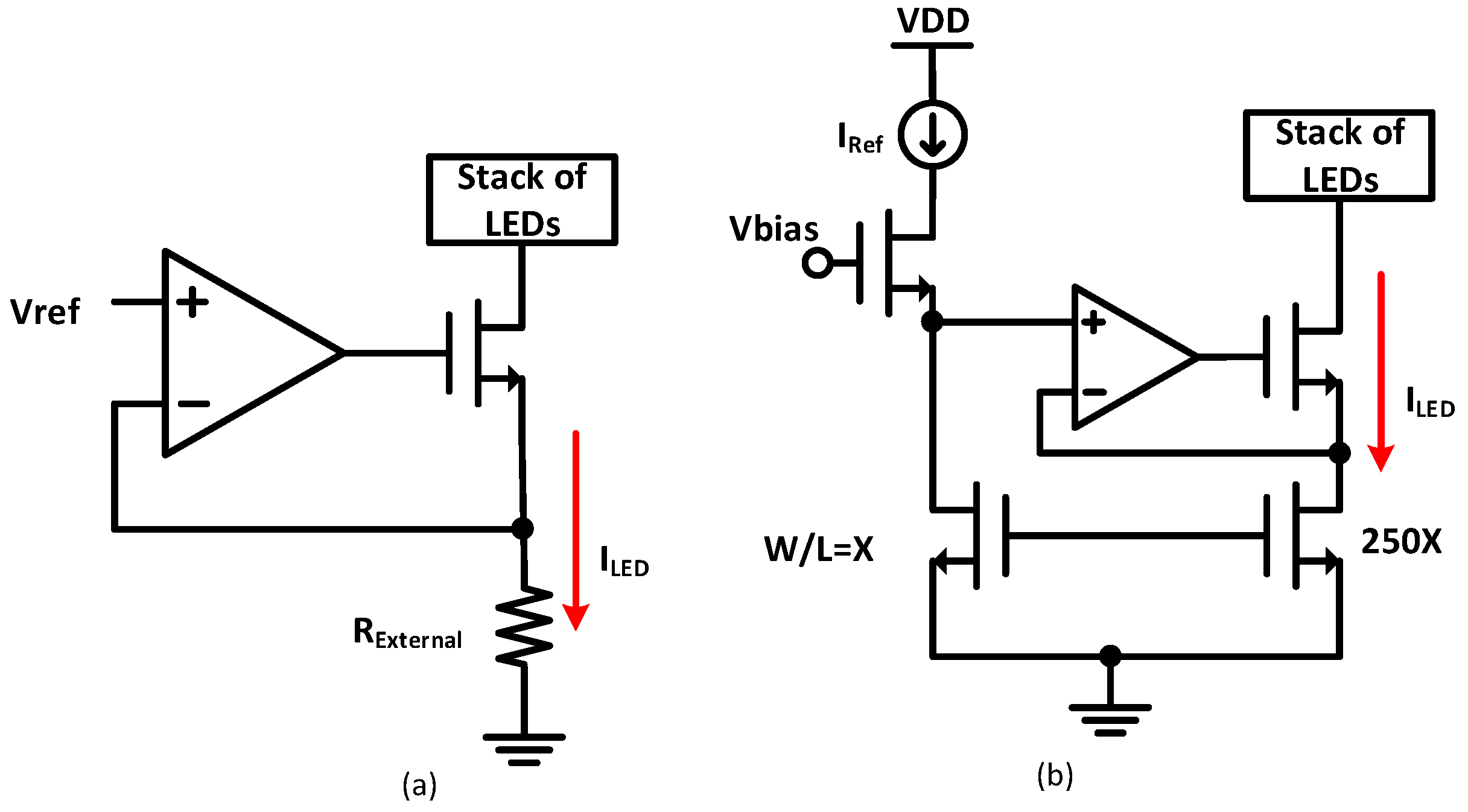

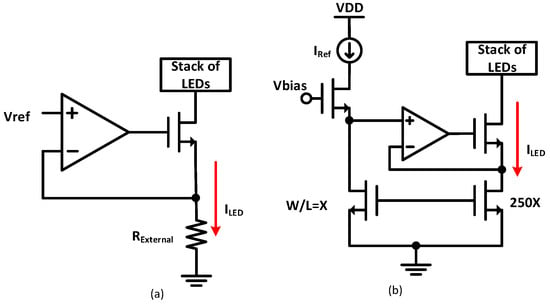

There exists more than one design for regulated current sinks placed in series with the WLEDs in each string [12,13]. Figure 4 depicts two possibilities. Figure 4a shows a regulated current sink using a high gain amplifier, a pass transistor, and an external resistor. In this case, the current that passes through each string of WLEDs would be . Adding a resistor would cause efficiency degradation due to a power loss of . The parasitic resistance of the pin should also be estimated and included in the calculations to have more accurate current values. To overcome the parasitic effect, needs to be large which causes more power dissipation. On the other hand, if the resistor is integrated into the same IC, it would have large tolerance due to the process and temperature variation, which may lead to error in the driving current and consequently change in the color brightness.

Figure 4.

Current regulators: (a) amplifier-boosted current sink with external resistance (b) amplifier-boosted cascode current sink.

Figure 4b shows a cascode mirror with an amplifier forcing both drain-to-source voltages to be equal without using resistive elements. However, the current ratio between the reference current (A) and the WLED current (25 mA) is 250×. This big ratio degrades the current accuracy. The result could be worse than using the resistor due to the mismatch between the two transistors and process variation. The overhead needed to operate the transistors in the saturation region may require around 200–300 mV for each transistor. That adds up to a voltage higher than the voltage across the resistor. This consequently degrades the power efficiency even more.

3. Proposed WLED Driver Circuit Description

In this section, a description of each individual circuit is given. We start with the LED strings, the current matching, and the dimmer circuit; then, we move step by step toward the controller circuity and end up at the power stage switch drivers (both main and high-side switches).

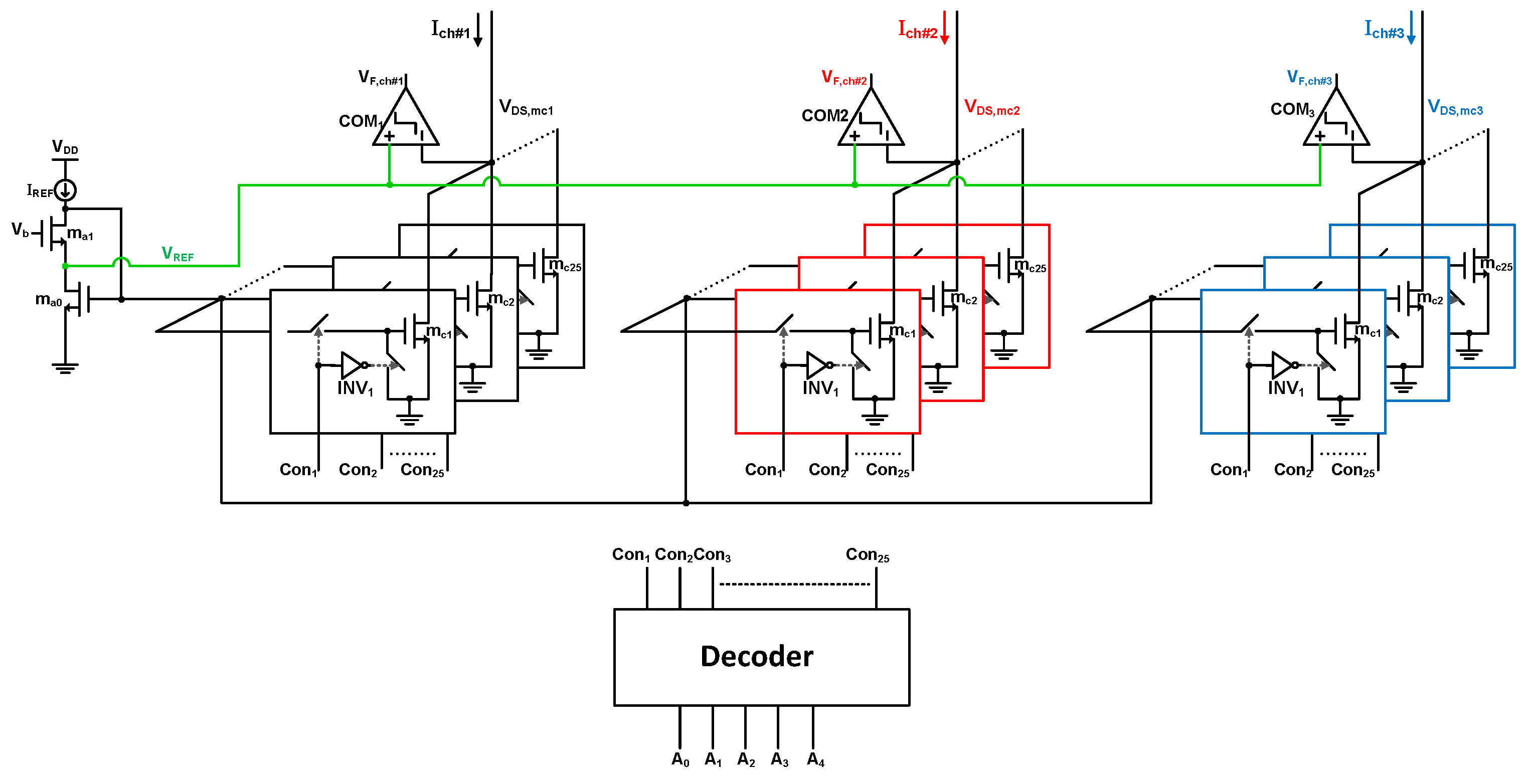

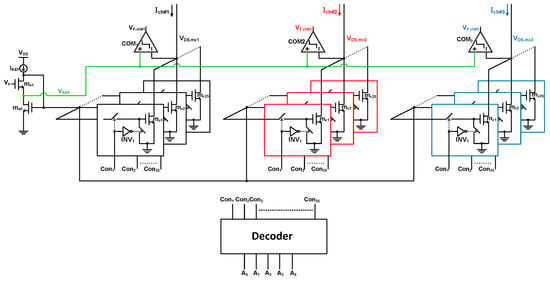

3.1. Current Matching and Dimmer

Figure 5 shows a schematic diagram of both current matchings along with the forward voltage compensation circuits. The current matching circuit consists of a current mirror to produce multiple current sinks, one per string. The reference current which is generated by a bandgap circuit (not shown) is used to bias transistors and to generate the reference voltage of comparators , , and . This is designed to be around 250 mV. Note that the comparators are utilized to force the same current in each string (, and ). This is accomplished when the of each transistor matches the reference voltage . Since mismatch is the biggest factor that could cause a mismatch in the current mirror, this method ensures that it never happens. Each string current sink is composed of 25 segments to allow dimming and brightness control of 25 steps (1 mA each). A minimum of a 5-bit decoder is needed to attain a step of 1 mA. The insertion and deletion of the 25 current segments in each string is done via the 5-bit input to the 25-output decoder, as shown in Figure 5.

Figure 5.

Current matching circuit with dimming capability.

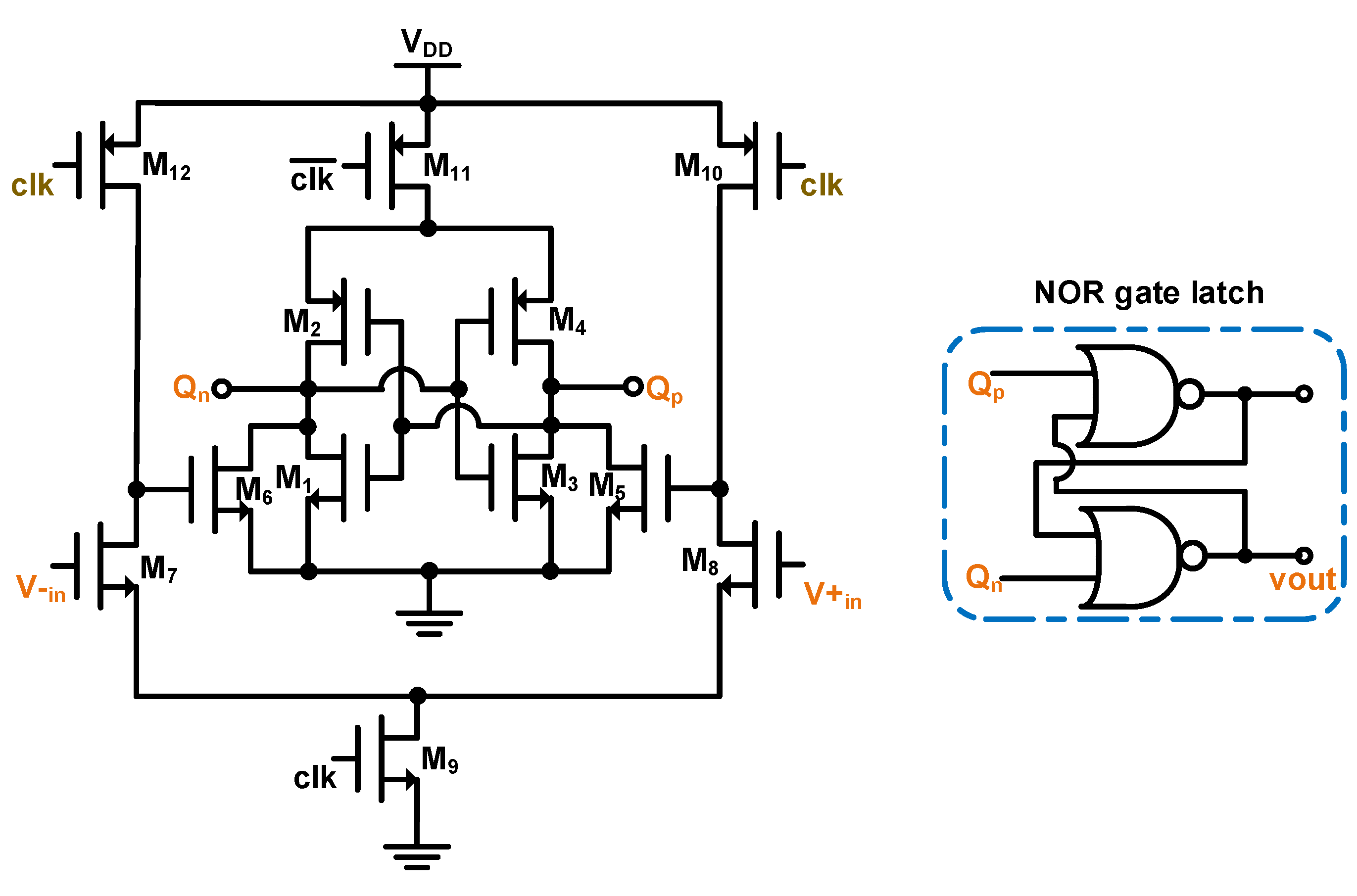

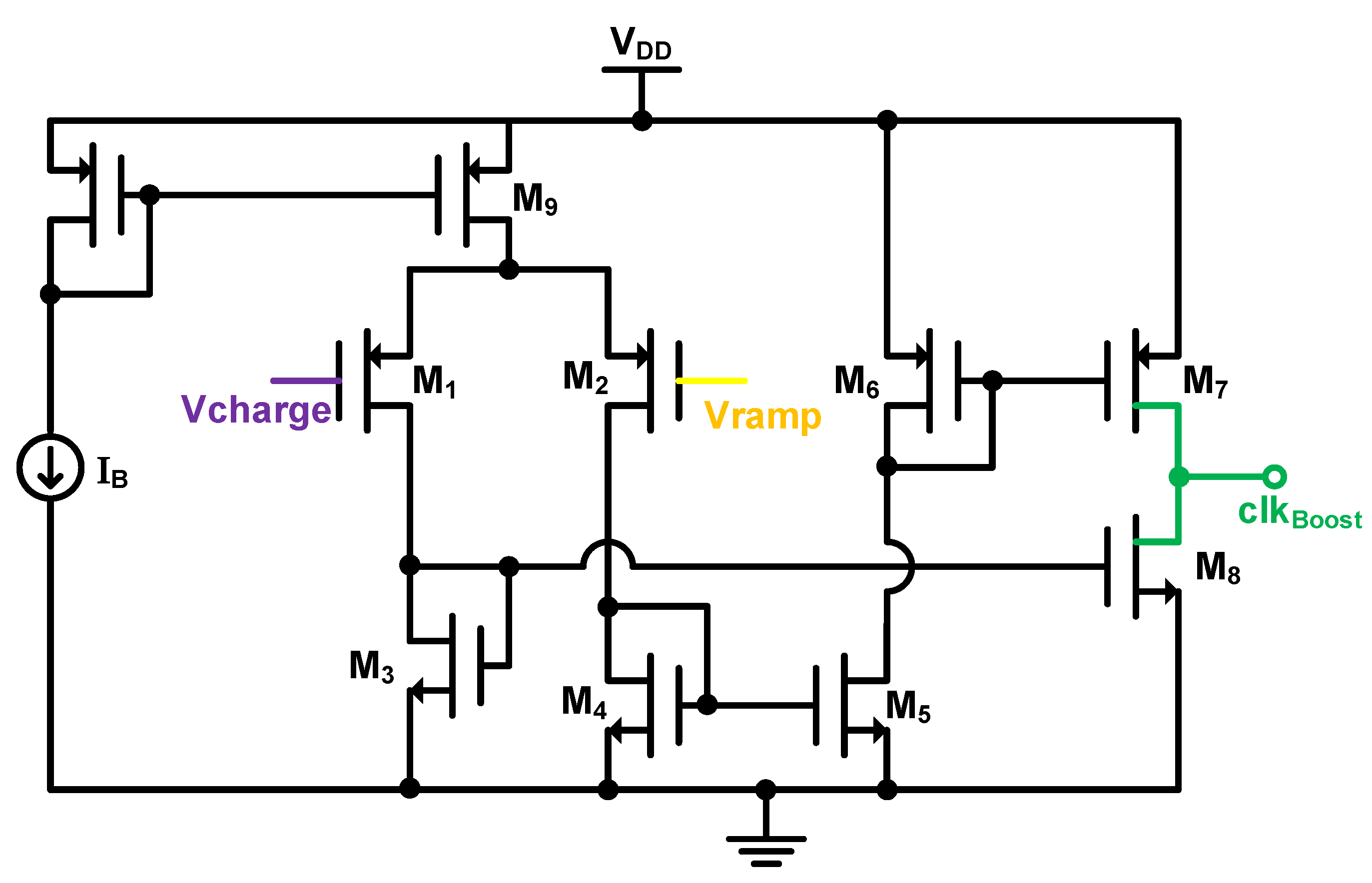

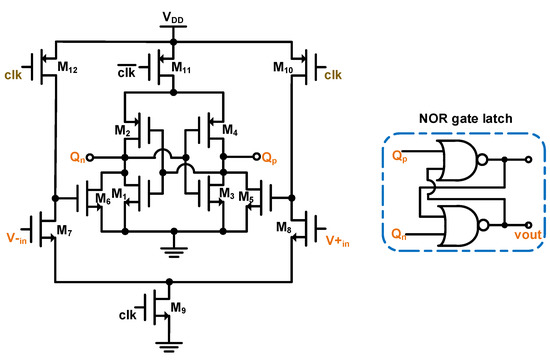

The comparators used in this current matching circuit are of clocked-latch type, also known as double-tail comparators [14], as depicted in Figure 6. Unlike the traditional four stack comparator, this comparator has three stacks of MOS transistors to operate under lower supply voltage. It is intended to be ultra-low power (zero static power consumption) and not necessarily high performance. Since the clock is already available for switching frequency, it was used here even to save more power. The clock triggers the comparator to sample both reference and current sink voltages. The second stage of that comparator (the NOR gate latch) drives the following stage with sharp edges.

Figure 6.

Clocked latch comparator.

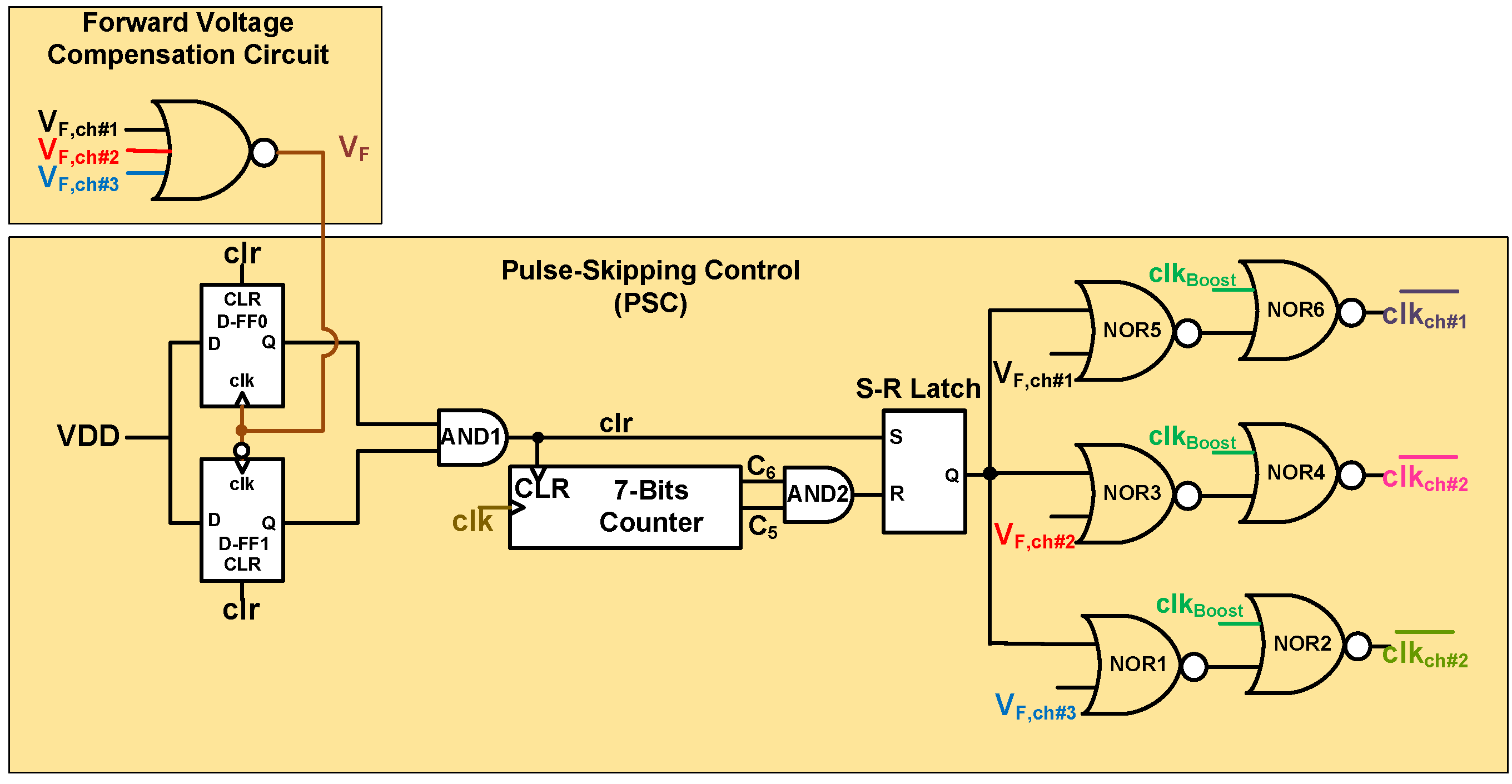

3.2. Forward Voltage Compensation and PSC Circuits

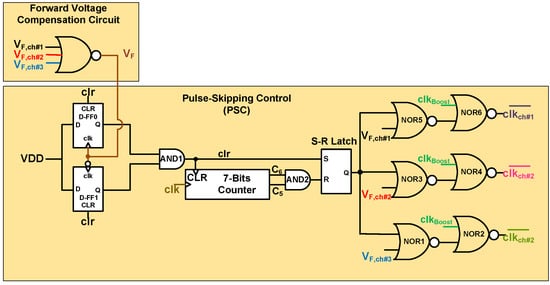

Figure 7 shows forward voltage compensation and PSC circuits. In this circuit, the signal indicates the mode of operation (MDCC or PSC) the WLED driver has at any time. When oscillates, it means the PSC mode of operation, while is a fixed value, indicating the MDCC mode of operation. Recall that in MDCC mode, we search for , and in PSC mode, we do pulse skipping to reach steady-state operation (to maintain targeted LED current). When all current sinks reach their targeted values, the , , and reach the value of zero. The output of the 3-input NOR gate becomes high. At that point, has been reached, and PSC mode begins. To distinguish this state, a watchdog circuit is used to check whether stays in oscillatory mode or goes out of oscillatory mode. If the counter counts around 100 cycles, it means the is out of oscillatory mode, and it consequently resets the R-S latch, and the search starts again.

Figure 7.

Forward voltage compensation and PSC circuits.

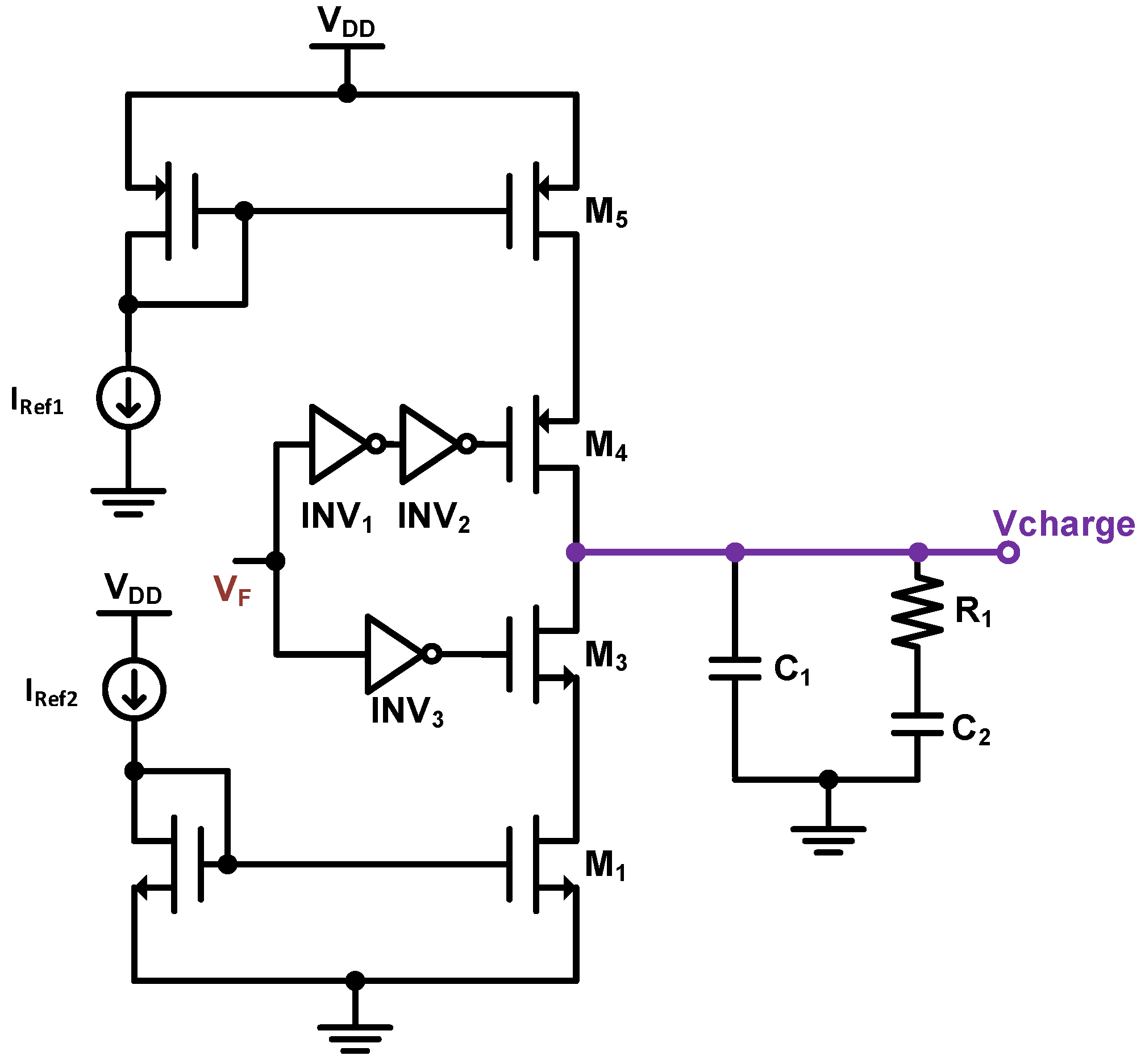

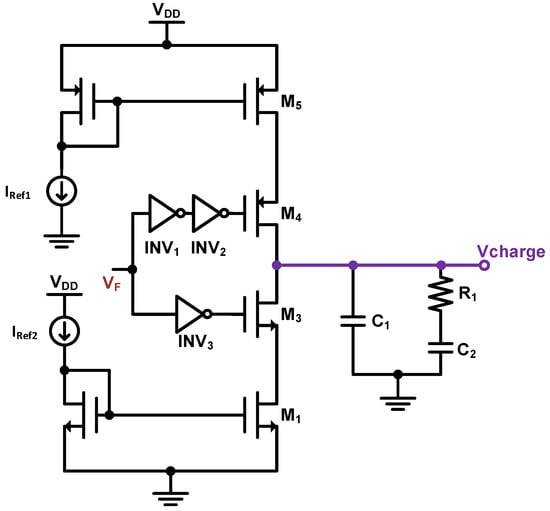

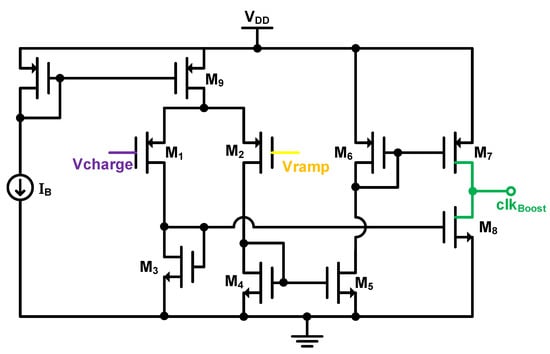

3.3. Charge Pump Circuit and Ramp Generator

The single-ended charge pump circuit, which is part of MDCC, is shown in Figure 8. It integrates the pulses from the signal and generates a control signal to be used in the PWM comparator. and function like a current source and a current sink, respectively. Signal drives PMOS pass device , and an inverted version of drives the NMOS pass device . The R1–C2 combination circuit adds a zero to the charge pump compensation circuit to enhance the phase margin, and thus the stability of the system.

Figure 8.

Charge pump circuit.

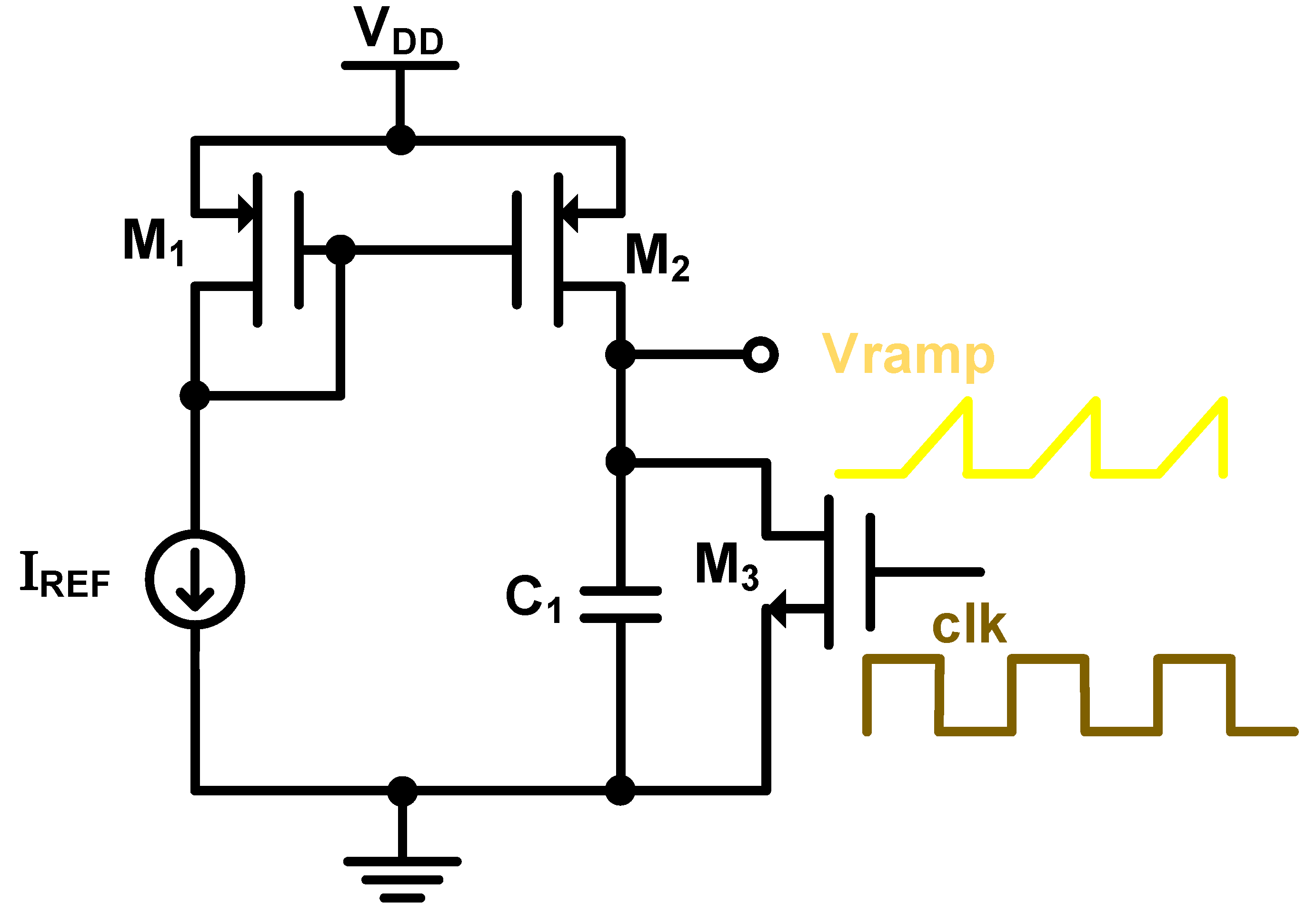

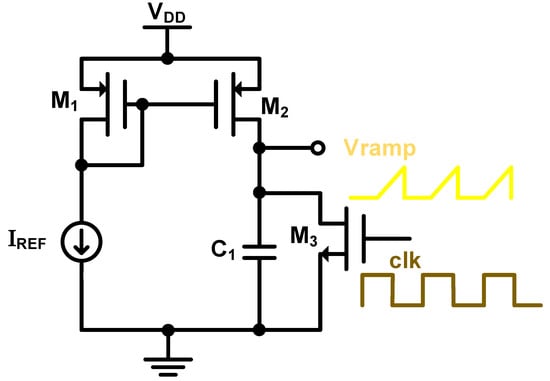

Figure 9 depicts a ramp generator circuit to be used at the other terminal of the PWM comparator. It consists of a simple current source (), a capacitor , and a clock-driven switch . The clock is running at the switching frequency of the boost converter, which is 1 MHz.

Figure 9.

Ramp generator circuit.

3.4. The PWM Comparator

The PWM comparator used as part of MDCC is shown in Figure 10. It takes and signals as its inputs and generates the signal at its output to drive the main switch of the boost converter. The duty cycle of this clock represents the generated in the MDCC mode of operation. The duty cycle complement (1D) drives the high-side switches in the MDCC mode of operation.

Figure 10.

PWM comparator circuit.

4. Simulation Results

The simulation was conducted with ADS CAD tools using 40 nm 1P9M TSMC CMOS technology. A standard 40 nm CMOS process has been used. In this process, the parasitic effects, including pad parasitic, were expected to have minimal effect as the selected switching frequency (1 MHz) was well below the unity-gain frequency ( GHz) [15].

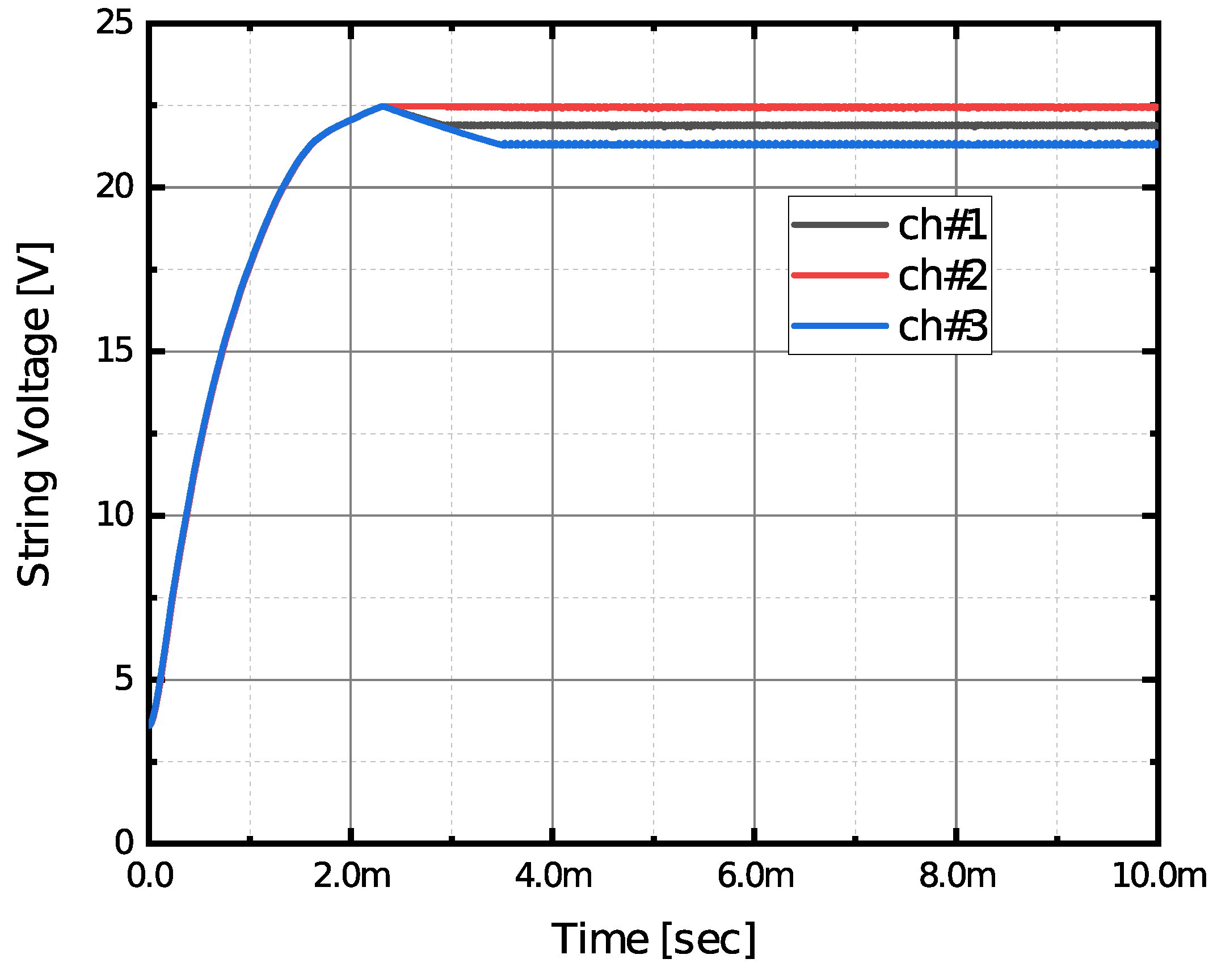

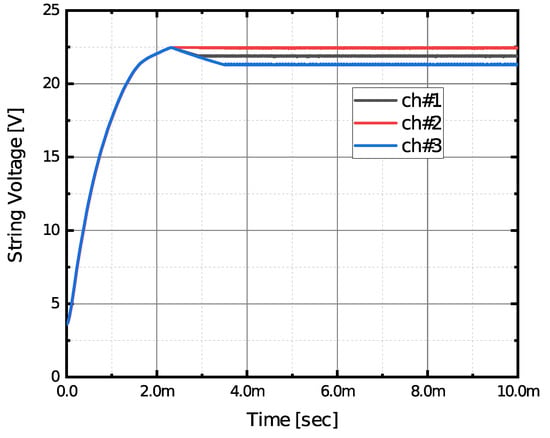

Figure 11 shows the three different independent output voltages generated based on the need to cover both WLEDs’ voltage drops and the current sink overhead of each string. Clearly, the magnitude of the output voltages is different in each string, as it is impossible to have exact voltages even if all strings are balanced (having the same number of WLEDs), as explained before.

Figure 11.

Three independent output voltages—one per string.

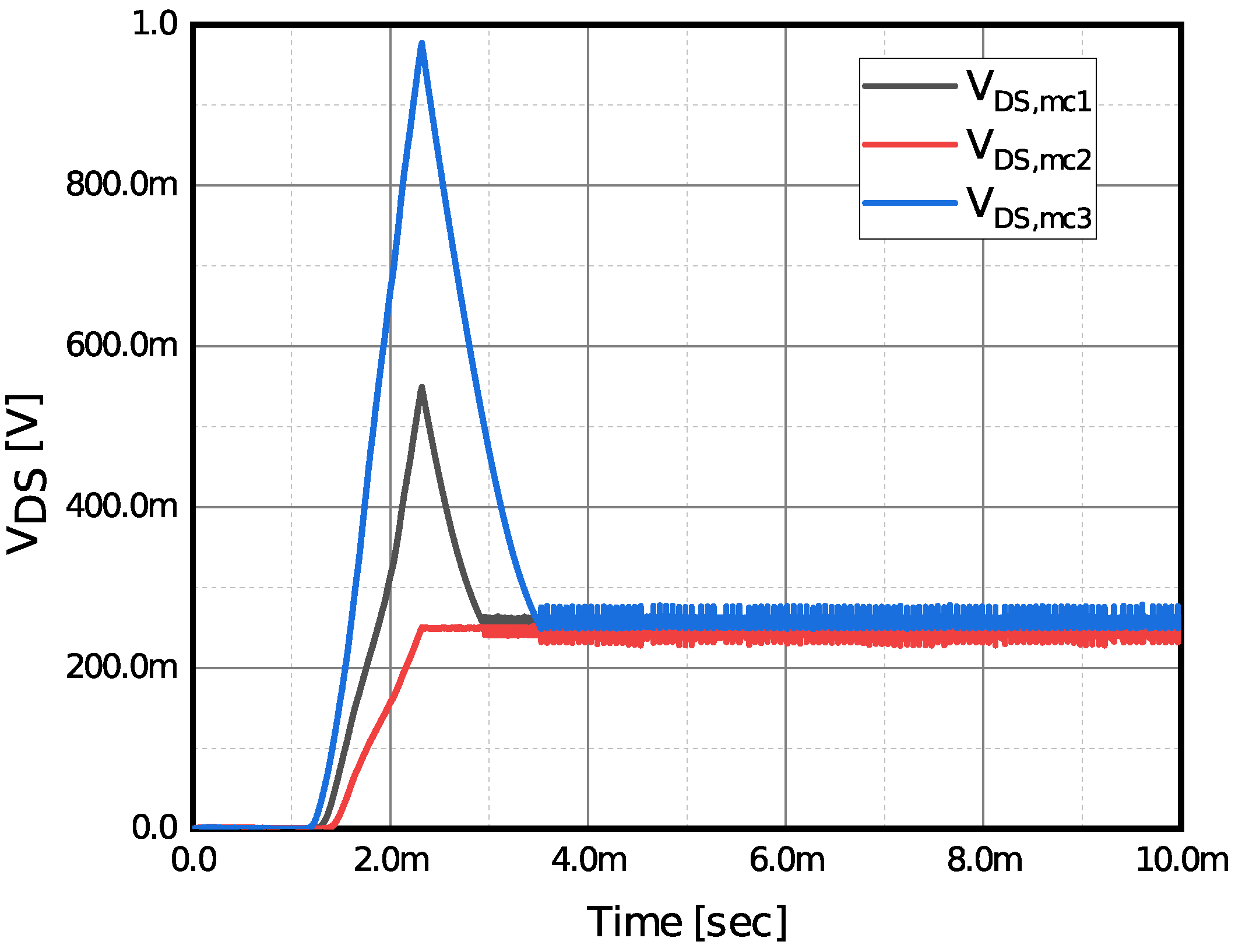

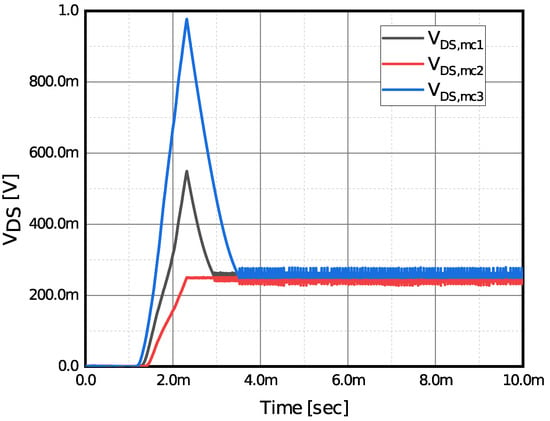

Figure 12 shows the current sinks’ overhead voltages, one per string. Clearly, in the beginning, the overhead was higher than 250 mV, for the two strings with the lowest voltages needed to satisfy all WLEDs and their respective overhead current sinks. The lowest overhead voltage belonged to the highest voltage needed until was reached. Once reached the proper value, the higher overhead voltages started going down as the PSC mode started, until all overheads reached a steady-state value of around 250 mV.

Figure 12.

The current sink voltages—one per string.

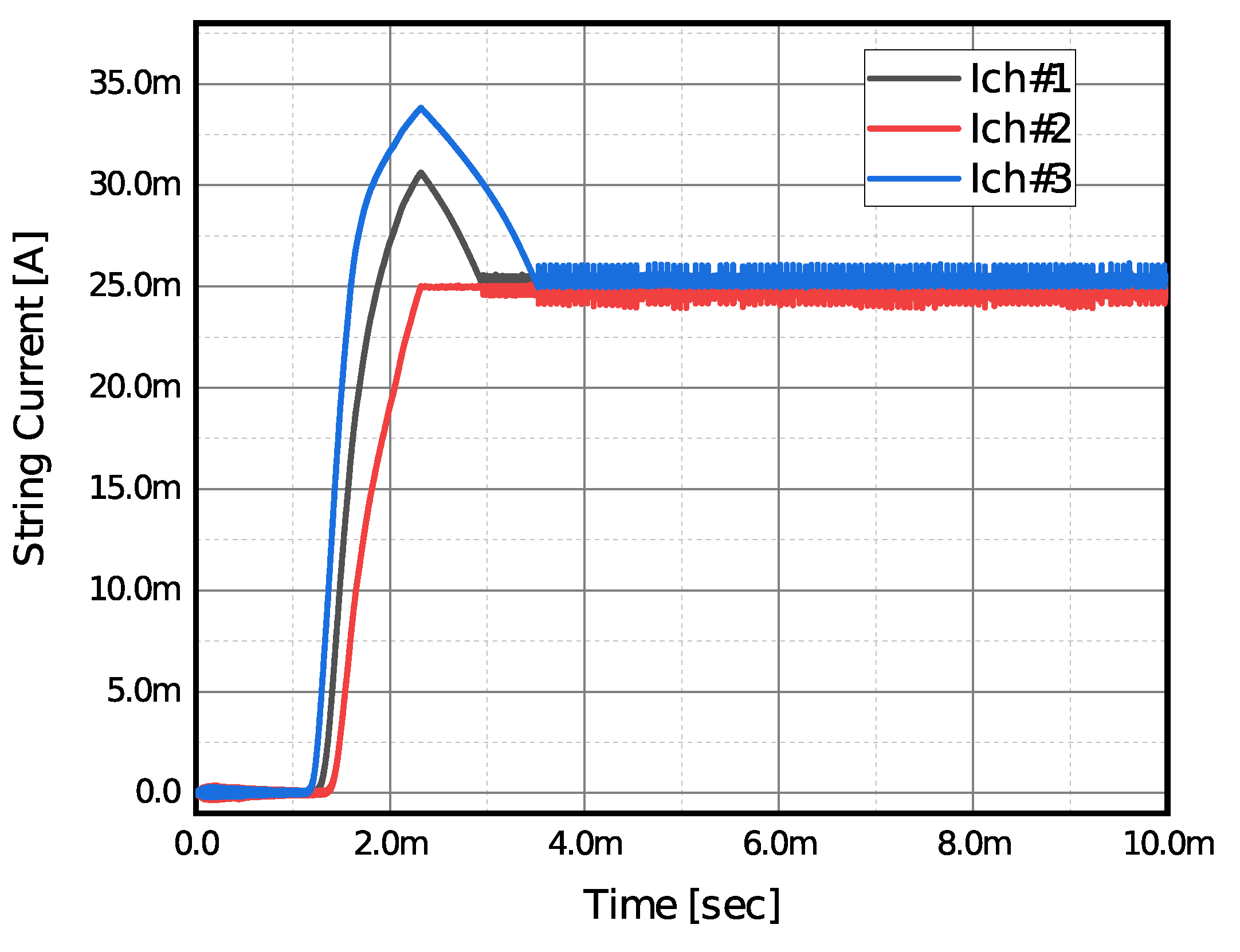

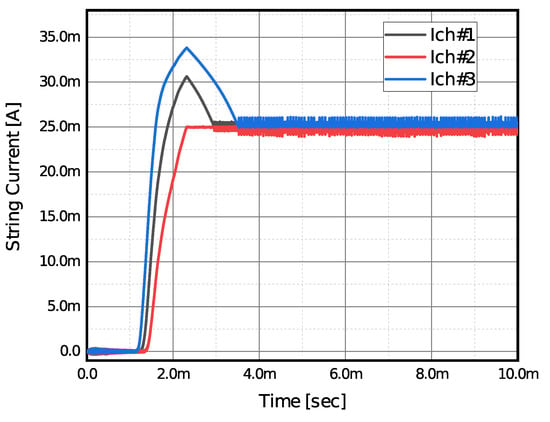

Figure 13 shows the currents in each string. The steady-state value is equal to the targeted value of 25 mA in each string. Of course, the steady-state value can be 1 to 25 mA as per the decoder input, as explained before. The lowest voltages of the three strings show higher currents compared to the highest voltage string while searching for in the MDCC mode of operation. Once the has been reached, the higher current starts going down (PSC mode starts) and continues until it reaches a steady-state of the targeted value of 25 mA.

Figure 13.

Current in each string.

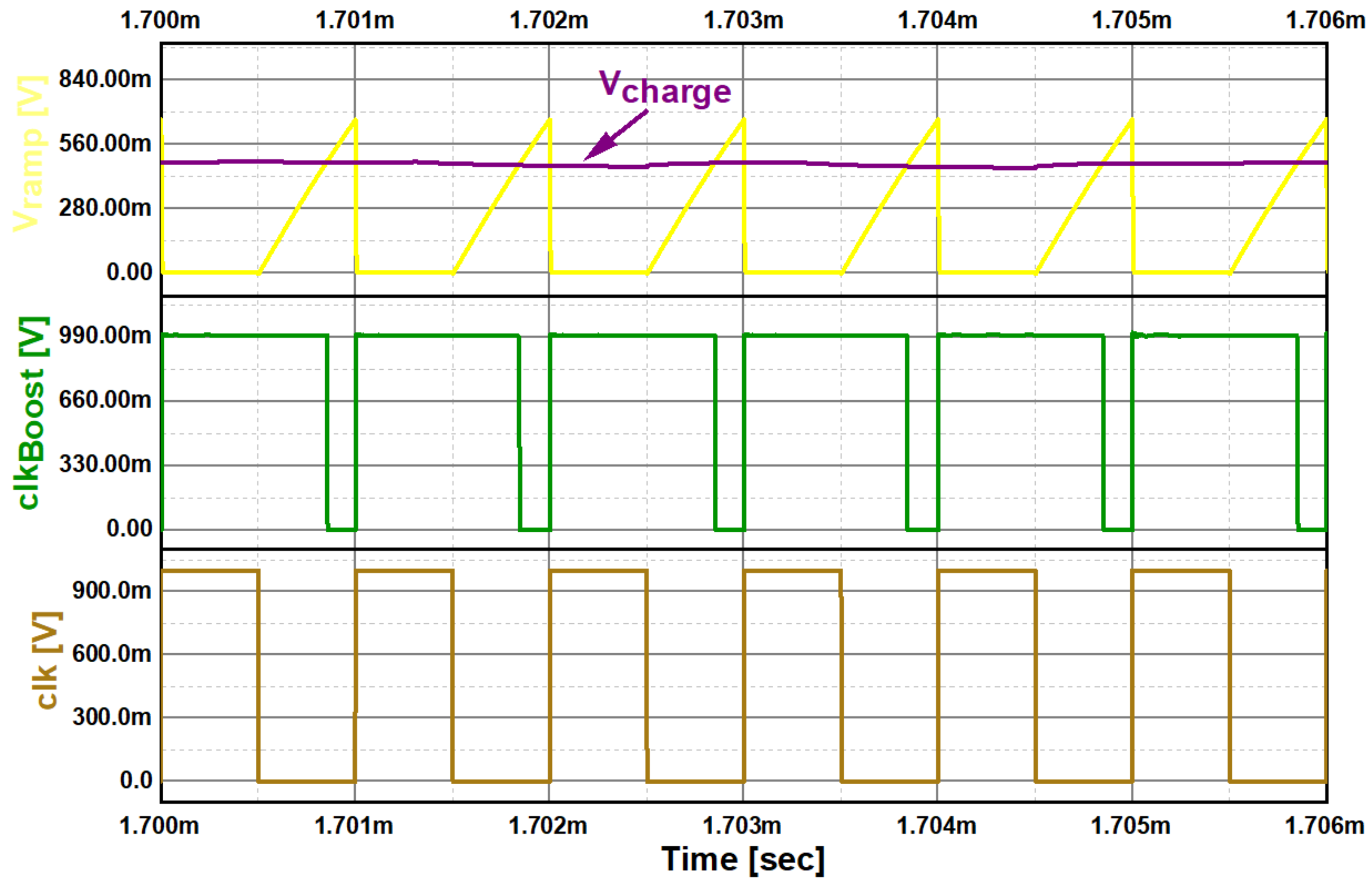

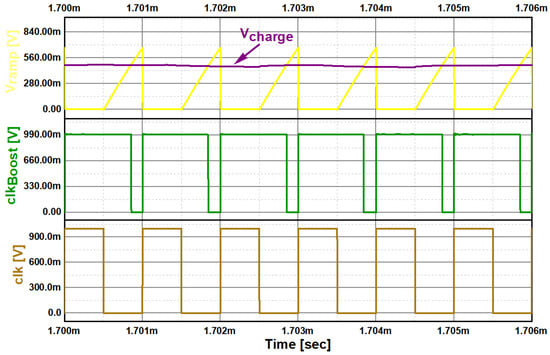

Figure 14 shows the control signal (), the ramp signal (), the duty cycle signal (), and the clock signal (). As mentioned before, the signal stays high beyond the minimum 50% until the becomes smaller than the signal. Note that the is only active when the signal is low and its switching period is s.

Figure 14.

Main clock, duty cycle, and ramp signal.

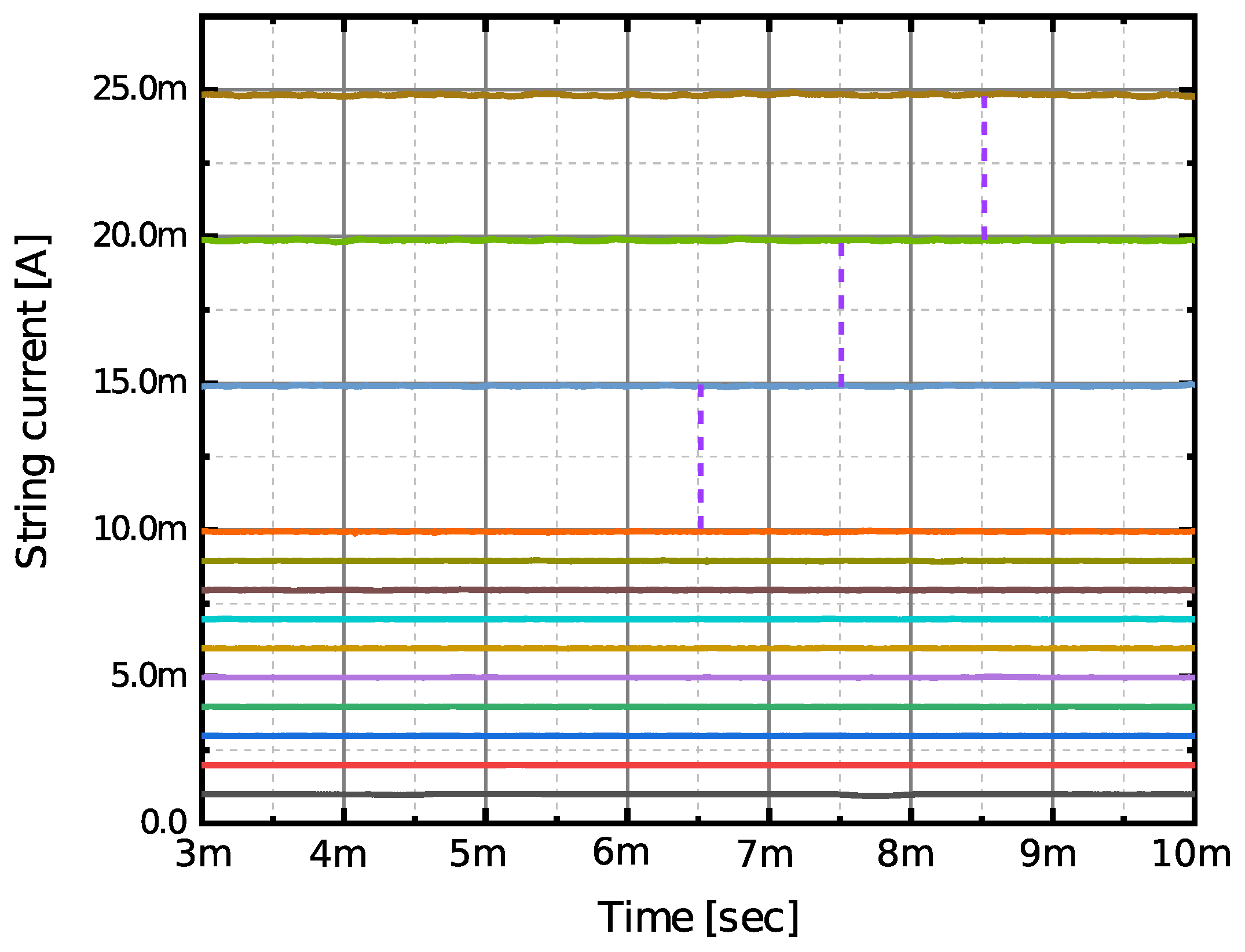

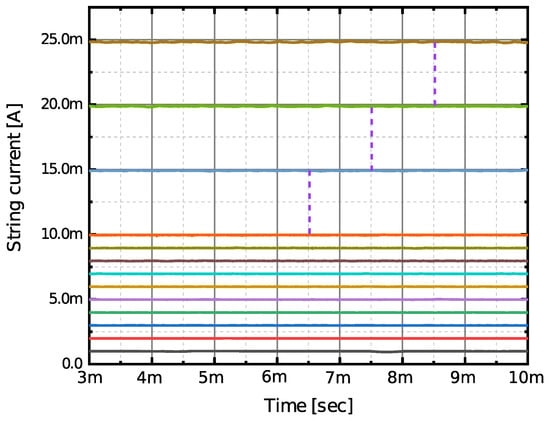

Figure 15 demonstrates the capability of setting the current value to any of the 25 possible options. Each segment carried 1 mA of current. The time simulation stepped up the current by 1 mA until we reached the 10 mA mark. After that, 5 mA steps were implemented until the 25 mA mark was reached.

Figure 15.

The 25 possible options for the string currents.

Literature Feature Comparison

Table 1 shows a list of helpful and necessary features of the multi-output WLED drivers. A brief comparison is drawn amongst the different architectures and that of this work in terms of key features. It is clear from the table that the proposed architecture is the only one among all those shown that supports both modes of operation (CCM and DCM). With multiple independent outputs, most architectures require separate OVP circuits, one per output. The proposed architecture allows the usage of a single OVP circuit for all outputs. This is attainable because the used controller waits for the highest output to reach its final value (without exceeding the voltage limit) before enabling the pulse-skipping mode in which the other two outputs reach their lower final values.

Table 1.

A comparison of architectures from the literature and our architecture.

Despite all the benefits of having a simple node, it has greater challenges in building current drivers due to smaller output (channel) resistance, , which is crucial in making highly accurate current sinks. This problem is taken care of in the proposed solution by using feedback controllers MDCC and PSC that force the same string WLED current via forcing the same over-drive voltage () of all current sinks. This way, the proposed architecture uses the most advanced node along with all its benefits, and remedies its most unwanted disadvantage. Many published architectures utilize multiple switches per independent output and clocks to pack different outputs within the zero-current period in the DCM model. This may demand timing synchronization, hence a need for accuracy or otherwise potential errors and malfunctioning. The proposed work does not use inter-dependent timing signals and hence does not need any synchronization among them. This leads to a more durable solution that can tolerate more imperfections in the manufacturing process, temperature, and supply voltage variations, in addition to any other limitations that may impose themselves, such as a maximum number of outputs (strings) that can be supported.

This naturally leads to the conclusion that this proposed circuit is the simplest among all listed architectures. Dimming and dimming resolution are easily adapted and implanted in the proposed architecture. Dimming accuracy or resolution can also be modified and improved in the proposed architecture. Switching frequency is the constant frequency used in the converter within the WLED driver. It is worthy to note that all integrated circuits reviewed in Table 1 use a switching frequency around 1 MHz to help reduce the passive components’ size. Therefore, a switching frequency of 1 MHz clk is utilized in this work.

The input voltage range of the proposed architecture matches the most popular battery’s usable voltage range ( V to V). The output voltage depends on the number of WLEDs per string. Since a boost converter is used, a conversion ratio of no more than six is used to keep the system efficiency higher by running in CCM mode. A typical low-power WLED current is around 20 to 25 mA. This architecture supports current segmentation from 1 to 25 mA in each string. Efficiency is probably the most crucial metric in the WLED driver: since the output voltage is high, WLED currents are not small either. In all aspects of the design, power-savings and selection of ultra-low-power components are prioritized. A good example is the double-tail comparators used in the current matching circuit, where the comparator static power has a value of zero.

5. Conclusions

In this work, a multi-independent-output, multi-string, high-efficiency, boost-converter-based white LED (WLED) driver architecture was proposed. The feedback loop utilizes a single inductor main switch with a common maximum duty cycle controller (MDCC). A simple pulse skipping controller (PSC) is utilized in each high-side switch of the multiple independent outputs. An open circuit in any of the strings is also addressed in addition to any LED short circuit condition. Increasing the number of independent output strings can be done so long as the power stage is appropriately scaled. Although a three-string design is demonstrated, a lesser number of output strings (e.g., single-output) can be easily accommodated by merely disabling the relevant feedback signal (i.e.,) of the removed channel. In the proposed design, each string is driven by a 25 mA current sink. An input voltage of 3.2–4.2 V and an output voltage of up to 27 V are supported. Excellent current matching between strings is achieved, despite the low on-resistance of transistors used in the 40 nm process. Despite the presence of multiple independent outputs, a single over-voltage protection (OVP) circuit is used at the output to protect the circuit from any voltage above 27 V. The proposed design does not rely on time multiplexing; hence, it supports both modes of operation, CCM and DCM. A improvement in efficiency is achieved relative to extremely unbalanced strings. Future work will include fabrication with an on-chip oscillator to generate the 1 MHz clk in a 40 nm 1P9M TSMC CMOS node.

Author Contributions

Conceptualization, H.H.A.; methodology, F.R.S. and I.A.; software, F.R.S.; validation, H.H.A., F.R.S. and I.A.; writing—original draft preparation, H.H.A., F.R.S. and I.A.; writing—review and editing, H.H.A., F.R.S. and I.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available in article.

Acknowledgments

The authors would like to thank EUROPRACTICE for their kind support by providing the technology files.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CMOS | Complementary Metal-Oxide-Semiconductor |

| WLED | White Light-Emitting Diode |

| MDCC | Maximum Duty Cycle Controller |

| PSC | Pulse Skipping Controller |

| OVP | Over-Voltage Protection |

| CCM | Continuous Conduction Modes |

| DCM | Discontinuous Conduction Modes |

References

- Huh, Y. Future direction of power management in mobile devices. In Proceedings of the IEEE Asian Solid-State Circuits Conference 2011, Jeju, Korea, 14–16 November 2011; pp. 1–4. [Google Scholar]

- Pramanik, P.K.D.; Sinhababu, N.; Mukherjee, B.; Padmanaban, S.; Maity, A.; Upadhyaya, B.K.; Holm-Nielsen, J.B.; Choudhury, P. Power consumption analysis, measurement, management, and issues: a state-of-the-art review of smartphone battery and energy usage. IEEE Access 2019, 7, 182113–182172. [Google Scholar] [CrossRef]

- Erickson, R.W.; Maksimovic, D. Fundamentals of Power Electronics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Ahmad, H.H.; Shahroury, F.R. Design of a High Efficiency WLED Driver in 40 nm CMOS Technology. In Proceedings of the 2020 32nd International Conference on Microelectronics (ICM), Aqaba, Jordan, 14–17 December 2020; pp. 1–4. [Google Scholar]

- Kang, E.C.; Yeon, J.E.; Kim, D.S.; Kwon, D. Sequential low-voltage detecting method for multistring LED BLU circuit. Electron. Lett. 2010, 46, 839–840. [Google Scholar] [CrossRef]

- Kang, E.C.; Kwon, D.; Yeon, J.E.; Kim, D.S.; Oh, W. A new low voltage detecting method for multi-string LED BLU circuit. In Proceedings of the 2009 13th European Conference on Power Electronics and Applications, Barcelona, Spain, 8–10 September 2009; pp. 1–6. [Google Scholar]

- Hong, S.i.; Han, J.W.; Kim, D.H.; Kwon, O.K. A double-loop control LED backlight driver IC for medium-sized LCDs. In Proceedings of the 2010 IEEE International Solid-State Circuits Conference-(ISSCC), San Francisco, CA, USA, 2010, 7–11 February; pp. 116–117.

- Hu, Y.; Jovanovic, M.M. LED driver with self-adaptive drive voltage. IEEE Trans. Power Electron. 2008, 23, 3116–3125. [Google Scholar] [CrossRef]

- Carraro, G. Solving high-voltage off-line HB-LED constantcurrent contro-circuit issues. In Proceedings of the APEC 07—Twenty-Second Annual IEEE Applied Power Electronics Conference and Exposition, Anaheim, CA, USA, 25 February–1 March 2007; pp. 1316–1318. [Google Scholar]

- Tsao, J. Solid-state lighting: lamps, chips, and materials for tomorrow. IEEE Circuits Devices Mag. 2004, 20, 28–37. [Google Scholar] [CrossRef]

- Tsao, J.Y. Light Emitting Diodes (LEDs) for General Illumination; Optoelectronics Industry Development Association: Washington, DC, USA, 2002; pp. 289–290. [Google Scholar]

- Chen, H.; Zhang, Y.; Ma, D. A SIMO parallel-string driver IC for dimmable LED backlighting with local bus voltage optimization and single time-shared regulation loop. IEEE Trans. Power Electron. 2011, 27, 452–462. [Google Scholar] [CrossRef]

- Kim, H.C.; Yoon, C.S.; Jeong, D.K.; Kim, J. A single-inductor, multiple-channel current-balancing LED driver for display backlight applications. IEEE Trans. Ind. Appl. 2014, 50, 4077–4081. [Google Scholar] [CrossRef]

- Schinkel, D.; Mensink, E.; Klumperink, E.; Van Tuijl, E.; Nauta, B. A double-tail latch-type voltage sense amplifier with 18ps setup+ hold time. Digest of technical papers. In Proceedings of the IEEE International Solid-State Circuits Conference, San Francisco, CA, USA, 11–15 February 2007; pp. 314–605. [Google Scholar]

- Dimitrov, V.; Heng, J.; Timp, K.; Dimauro, O.; Chan, R.; Hafez, M.; Feng, J.; Sorsch, T.; Mansfield, W.; Miner, J.; et al. Small-signal performance and modeling of sub-50 nm nMOSFETs with fT above 460-GHz. Solid-State Electron. 2008, 52, 899–908. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, A.T.; Sin, J.K.; Chan, P.C. Scalability of quasi-hysteretic FSM-based digitally controlled single-inductor dual-string buck LED driver to multiple strings. IEEE Trans. Power Electron. 2013, 29, 501–513. [Google Scholar] [CrossRef] [Green Version]

- Modepalli, K.; Parsa, L. A scalable N-color LED driver using single inductor multiple current output topology. IEEE Trans. Power Electron. 2015, 31, 3773–3783. [Google Scholar] [CrossRef]

- Li, S.; Guo, Y.; Tan, S.C.; Hui, S. An off-line single-inductor multiple-output LED driver with high dimming precision and full dimming range. IEEE Trans. Power Electron. 2016, 32, 4716–4727. [Google Scholar] [CrossRef]

- Yang, W.H.; Yang, H.A.; Huang, C.J.; Chen, K.H.; Lin, Y.H. A high-efficiency single-inductor multiple-output buck-type LED driver with average current correction technique. IEEE Trans. Power Electron. 2017, 33, 3375–3385. [Google Scholar] [CrossRef]

- Guo, Y.; Li, S.; Lee, A.T.; Tan, S.C.; Lee, C.K.; Hui, S.R. Single-stage AC/DC single-inductor multiple-output LED drivers. IEEE Trans. Power Electron. 2015, 31, 5837–5850. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).