A 1.02 μW Autarkic Threshold-Based Sensing and Energy Harvesting Interface Using a Single Piezoelectric Element

Abstract

1. Introduction

2. Background Theory and Conceptualization

2.1. Effect of Energy Harvesting on Sensing

2.2. Related Work in Literature

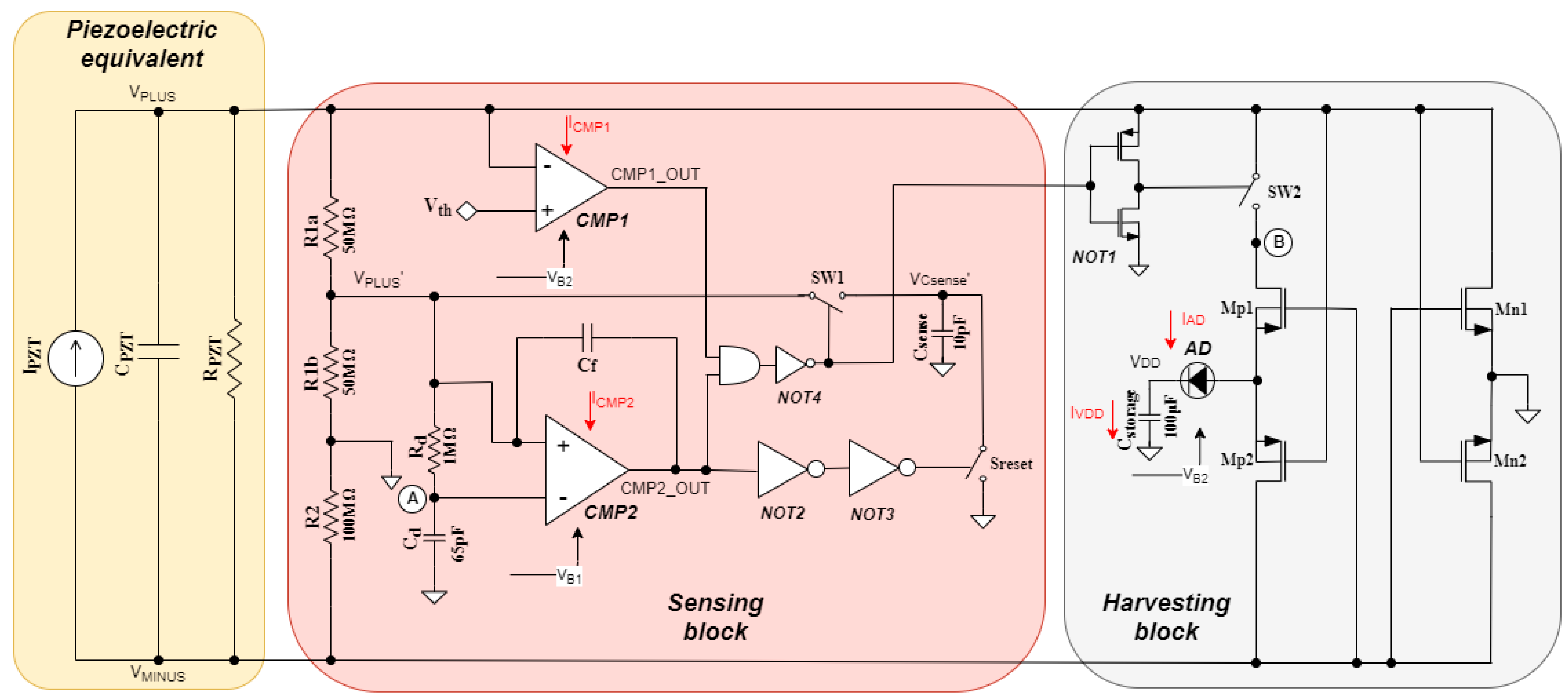

2.3. Proposed System Architecture

3. Proposed Circuit Analysis

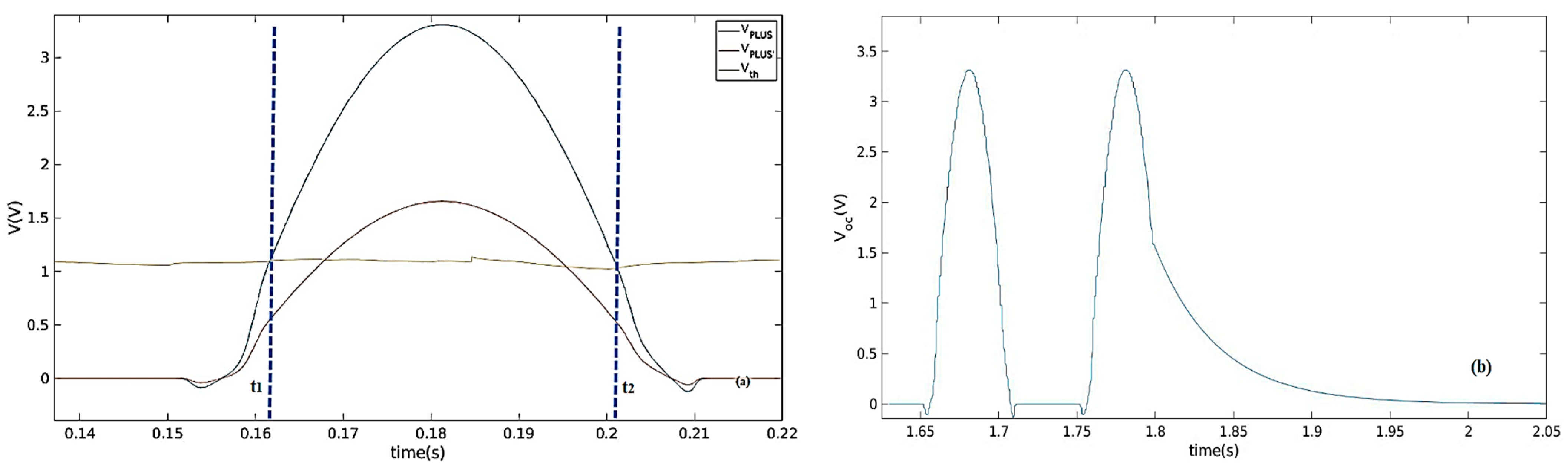

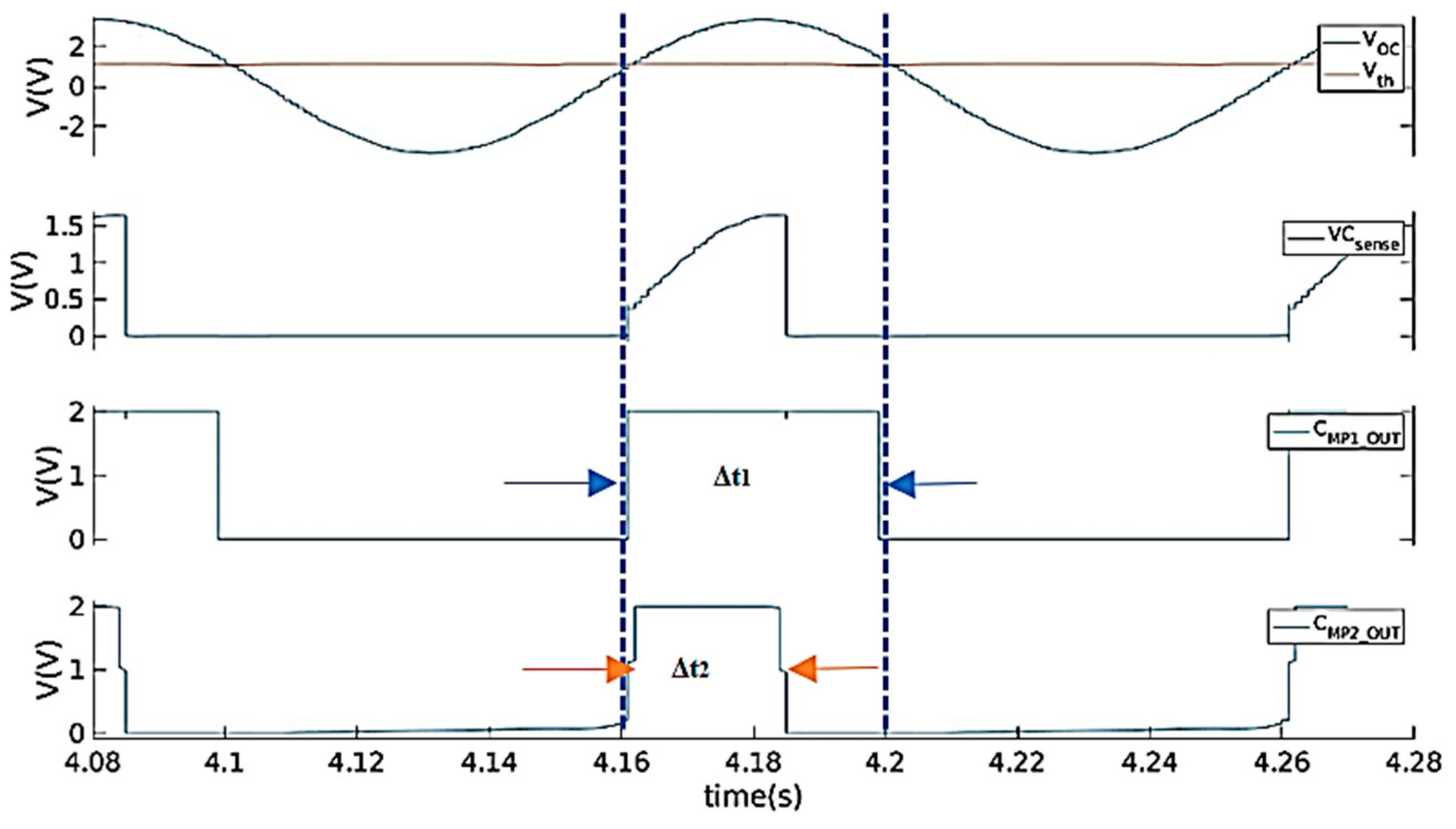

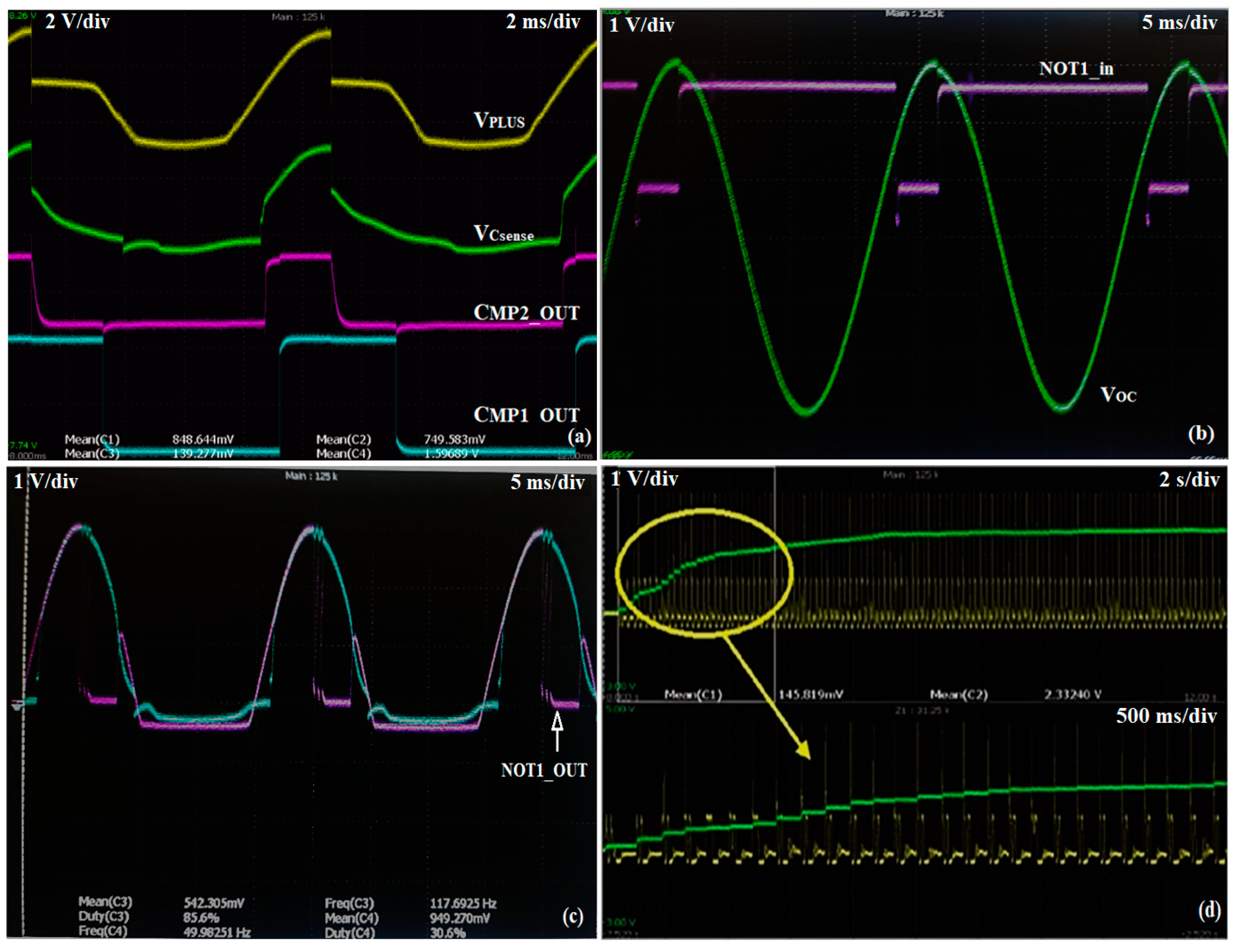

3.1. Sensing Process

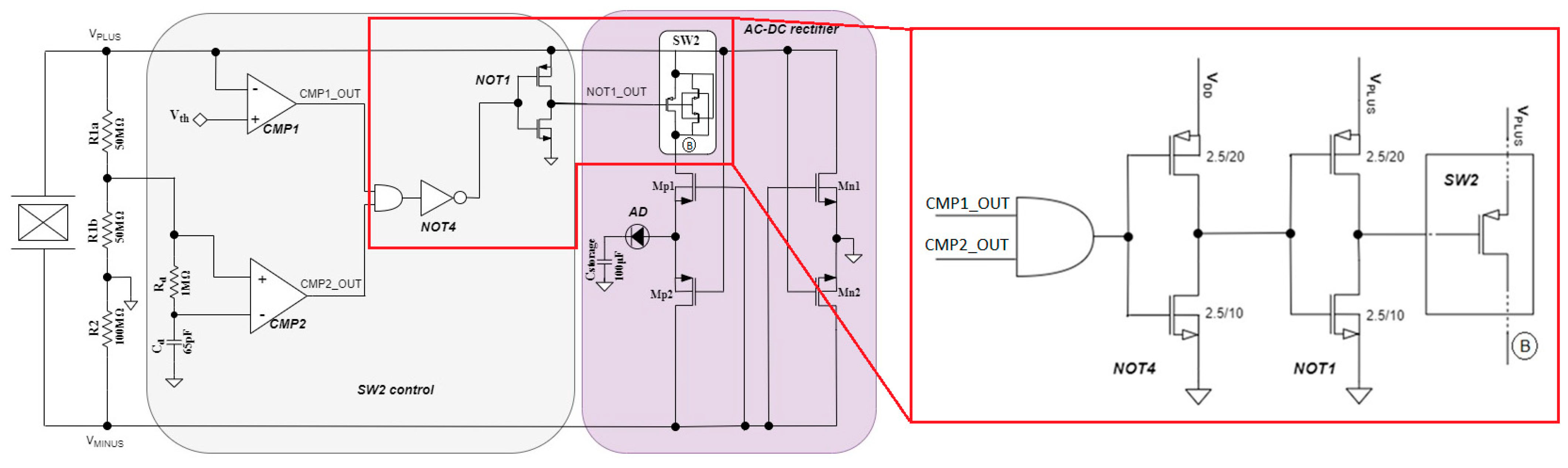

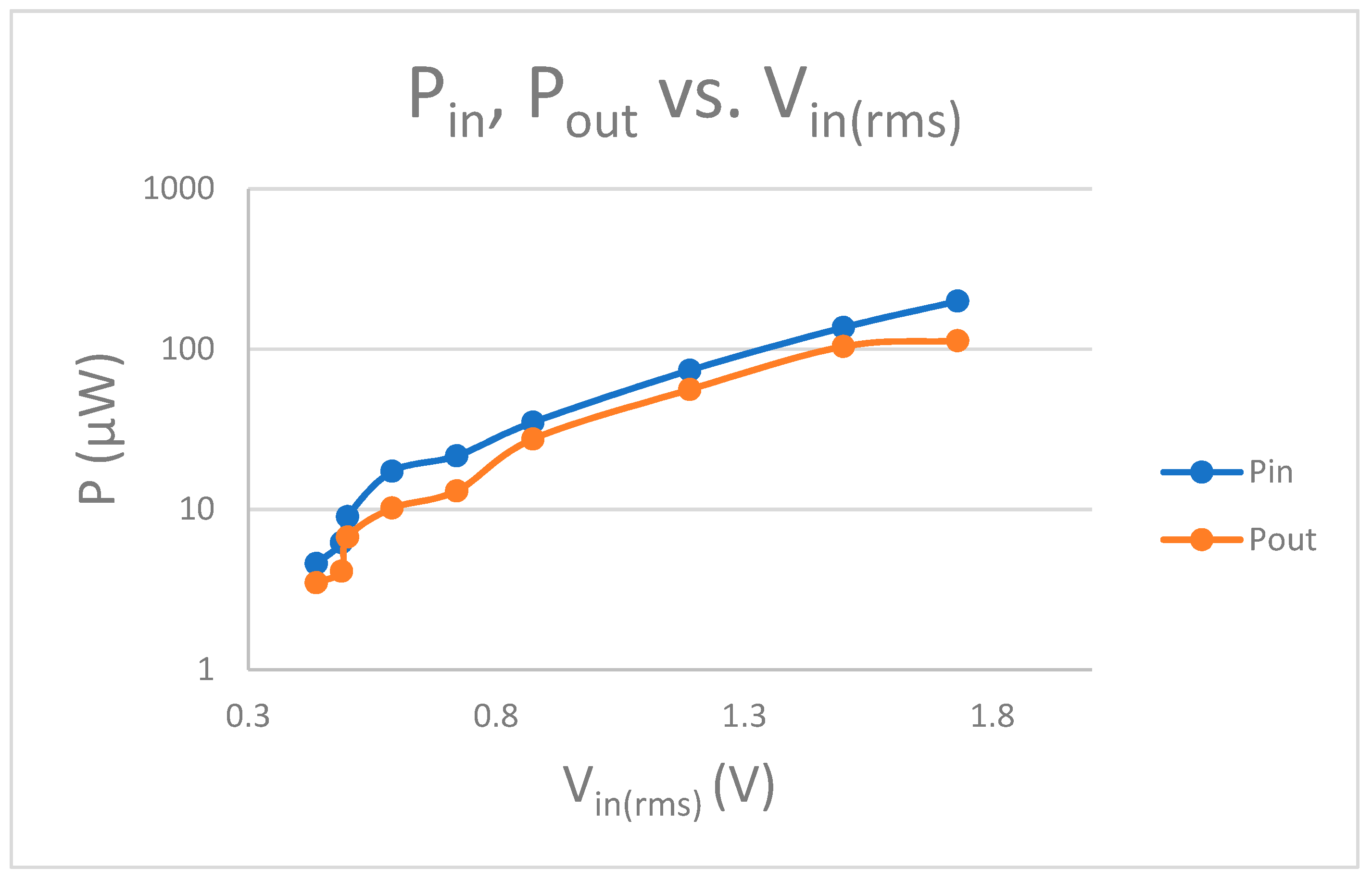

3.2. Energy Harvesting Process

3.3. Start-Up Process

3.4. Simulation Setup and Experimental Results

4. Proof of Concept—Weigh-in-Motion Case Study

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Motlagh, N.H.; Mohammadrezaei, M.; Hunt, J.; Zakeri, B. Internet of Things (IoT) and the Energy Sector. Energies 2020, 13, 494. [Google Scholar] [CrossRef]

- Oh, T.; Islam, S.K.; Mahfouz, M.; To, G. A Low-Power CMOS Piezoelectric Transducer Based Energy Harvesting Circuit for Wearable Sensors for Medical Applications. J. Low Power Electron. Appl. 2017, 7, 33. [Google Scholar] [CrossRef]

- Hassan, A.; El-Shaboury, A.; Mohamed, K.; Askar, M.; Mowafy, O.; Mosaad, Y.; Hassan, A.H.; Mostafa, H. A high-efficiency piezoelectric-based integrated power supply for low-power platforms. Microelectron. J. 2020, 102, 104824. [Google Scholar] [CrossRef]

- Xue, Y.B.; Yang, B.; Peng, L.Z.; Sun, Y.Q. Research on WIM Technology Using Cement-Based Piezoelectric Sensor. In Proceedings of the 2009 First International Conference on Information Science and Engineering, Nanjing, China, 26–28 December 2009. [Google Scholar]

- Jiao, P.; Egbe, K.-J.I.; Xie, Y.; Nazar, A.M.; Alavi, A.H. Piezoelectric Sensing Techniques in Structural Health Monitoring: A State-of-the-Art Review. Sensors 2020, 20, 3730. [Google Scholar] [CrossRef] [PubMed]

- Feng, T.; Aono, K.; Covassin, T.; Chakrabartty, S. Self-Powered Monitoring of Repeated Head Impacts Using Time-Dilation Energy Measurement Circuit. IEEE Trans. Biomed. Circuits Syst. 2015, 9, 217–226. [Google Scholar] [CrossRef] [PubMed]

- Romani, A.; Filippi, M.; Tartagni, M. Micropower Design of a Fully Autonomous Energy Harvesting Circuit for Arrays of Piezoelectric Transducers. IEEE Trans. Power Electron. 2013, 29, 729–739. [Google Scholar] [CrossRef]

- Nabavi, S.; Zhang, L. T-Shaped Piezoelectric Structure for High-Performance MEMS Vibration Energy Harvesting. J. Microelectromechanical Syst. 2019, 28, 1100–1112. [Google Scholar] [CrossRef]

- Kaur, B.; Agnihotri, A.; Thapar, D.; Arora, N. Piezoelectric Energy Harvester Design and Power Conditioning with Solar Integration. In Proceedings of the 2019 3rd International Conference on Electronics, Materials Engineering & Nano-Technology (IEMENTech), Kolkata, India, 29–31 August 2019; pp. 1–6. [Google Scholar]

- Nabavi, S.; Zhang, L. Nonlinear Multi-Mode Wideband Piezoelectric MEMS Vibration Energy Harvester. IEEE Sens. J. 2019, 19, 4837–4848. [Google Scholar] [CrossRef]

- Chew, Z.J.; Ruan, T.; Zhu, M.; Bafleur, M.; Dilhac, J.-M. Single Piezoelectric Transducer as Strain Sensor and Energy Harvester Using Time-Multiplexing Operation. IEEE Trans. Ind. Electron. 2017, 64, 9646–9656. [Google Scholar] [CrossRef]

- Ma, D.; Lan, G.; Xu, W.; Hassan, M.; Hu, W. SEHS: Simultaneous Energy Harvesting and Sensing Using Piezoelectric Energy Harvester. In Proceedings of the 2018 IEEE/ACM Third International Conference on Internet-of-Things Design and Implementation (IoTDI), Orlando, FL, USA, 17–20 April 2018; pp. 201–212. [Google Scholar]

- Jung, B.C.; Huh, Y.C.; Park, J.-W. A Self-Powered, Threshold-Based Wireless Sensor for the Detection of Floor Vibrations. Sensors 2018, 18, 4276. [Google Scholar] [CrossRef] [PubMed]

- Tang, Q.; He, Q.; Li, M.; Dong, C.; Xu, D.; Li, X. Wireless Alarm Microsystem Self-powered by Vibration-threshold Triggered Energy-harvester. IEEE Trans. Ind. Electron. 2015, 63, 1. [Google Scholar] [CrossRef]

- Sandhu, M.M.; Geissdoerfer, K.; Khalifa, S.; Jurdak, R.; Portmann, M.; Kusy, B. Towards Energy Positive Sensing using Kinetic Energy Harvesters. In Proceedings of the 2020 IEEE International Conference on Pervasive Computing and Communications (PerCom), Austin, TX, USA, 23–27 March 2020; pp. 1–10. [Google Scholar]

- Rincon-Mora, G.A. Miniaturized energy-harvesting piezoelectric chargers. In Proceedings of the Proceedings of the IEEE 2014 Custom Integrated Circuits Conference, San Jose, CA, USA, 15–17 September 2014; pp. 1–18. [Google Scholar]

- He, H.-L.; Wang, Y. Simulation of piezoelectric sensor in weigh-in-motion systems. In Proceedings of the 2015 Symposium on Piezoelectricity, Acoustic Waves, and Device Applications (SPAWDA), Jinan, China, 30 October–2 November 2015; pp. 133–136. [Google Scholar]

- Loo, F.J.V.; Visser, G. Vehicle for Dynamic Calibration of a Multiple Sensor Weigh-in-Motion System. In Proceedings of the Fourth International Conference on Weigh-In-Motion, Taipei, Taiwan, 20–23 February 2005. [Google Scholar]

- Kwon, T.M. Signal processing of piezoelectric weight-in-motion systems. In Proceedings of the Fifth IASTED International Conference on Circuits, Signals and Systems (CSS ’07), Anaheim, CA, USA, 25–29 March 2007; ACTA Press: Calgary, AB, Canada, 2007. [Google Scholar] [CrossRef]

- Wahab, N.A.; Salleh, M.K.M.; Othman, N.; Khalid, M.F.A.; Hidayat, N.M. High efficiency CMOS rectifier for energy har-vesting. In Proceedings of the IEEE Industrial Electronics and Applications Conference (IEACon), Kota Kinabalu, Malaysia, 20–22 November 2016. [Google Scholar] [CrossRef]

- Kosmadakis, I.; Konstantakos, V.; Laopoulos, T.; Siskos, S. An automated measurement bench for vibration-based energy harvesting systems. In Proceedings of the 2013 IEEE 7th International Conference on Intelligent Data Acquisition and Advanced Computing Systems (IDAACS), Berlin, Germany, 12–14 September 2013; Volume 1, pp. 15–20. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| CPZT | 22 | nF |

| RPZT | 300 | kΩ |

| fPZT | 10 | Hz |

| IPZT | 12 | μA |

| Vth | 1 | V |

| Cstorage | 100 | μF |

| R1a | 50 | ΜΩ |

| R1b | 50 | ΜΩ |

| R2 | 100 | ΜΩ |

| Parameter | Value | Unit |

|---|---|---|

| VOC(p-p) | 6.6 | V |

| VPLUS(peak) | 3.314 | V |

| VPLUS’(peak) | 1.64 | V |

| VCsense(peak) | 1.638 | V |

| VDD | 2 | V |

| VB1 | 0.3 | V |

| VB2 | 1.0 | V |

| Parameter | Value | Unit |

|---|---|---|

| IC1(avg) @ VDD = 2 V | 8.64 | nA |

| IC2(avg) @ VDD = 2 V | 1.01 | nA |

| IAD(avg) @ VDD = 2 V | 20.93 | nA |

| IVDD(avg) @ VDD = 2 V | 0.51 | μA |

| Power Consumption | 1.02 | μW |

| Parameter | Value | Unit |

|---|---|---|

| fPZT 1 (frequency generator) | 100 | Hz |

| fPZT (piezoelectric cantilever) | 10 | Hz |

| Vth | 1 | V |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agorastou, Z.; Kalenteridis, V.; Siskos, S. A 1.02 μW Autarkic Threshold-Based Sensing and Energy Harvesting Interface Using a Single Piezoelectric Element. J. Low Power Electron. Appl. 2021, 11, 27. https://doi.org/10.3390/jlpea11020027

Agorastou Z, Kalenteridis V, Siskos S. A 1.02 μW Autarkic Threshold-Based Sensing and Energy Harvesting Interface Using a Single Piezoelectric Element. Journal of Low Power Electronics and Applications. 2021; 11(2):27. https://doi.org/10.3390/jlpea11020027

Chicago/Turabian StyleAgorastou, Zoi, Vasileios Kalenteridis, and Stylianos Siskos. 2021. "A 1.02 μW Autarkic Threshold-Based Sensing and Energy Harvesting Interface Using a Single Piezoelectric Element" Journal of Low Power Electronics and Applications 11, no. 2: 27. https://doi.org/10.3390/jlpea11020027

APA StyleAgorastou, Z., Kalenteridis, V., & Siskos, S. (2021). A 1.02 μW Autarkic Threshold-Based Sensing and Energy Harvesting Interface Using a Single Piezoelectric Element. Journal of Low Power Electronics and Applications, 11(2), 27. https://doi.org/10.3390/jlpea11020027