1. Introduction

Characteristics of human beings vary, cognitively and physically, which impacts end user performance, product performance, and user satisfaction. In particular, human physical capabilities can differ significantly based on anthropometry, force, tactility, maneuverability, and reach, which impacts product interaction outcomes. It is critical to identify these aspects of human variability early in the design process to ensure that design components consider the requirements and limitations of the user population. While there are existing approaches that aid in quantifying the variability of different human characteristics, structured design methods informed by this information are limited. Without understanding how physical capabilities impact product interactions such as grasping, pushing, and pulling, these capabilities may not be appropriately integrated into the design process, thereby compromising human performance. This paper presents and evaluates a method developed to define the functional interactions between humans and products and provides a basis to map functional capacities of musculoskeletal regions to product applications. This information can be used to improve safety and reduce the potential for human error during physical interactions.

The impact that human variability has on product usability is extensive. Usability applies to all aspects of a system in which a human would interact; it includes learnability (system is easy to learn), efficiency (system is efficient), memorability (system is easy to remember), errors (system has low error rate), and satisfaction (system is pleasant to use) [

1]. While human variability encompasses many dimensions, the focus of the presented literature and the proposed methodology will be on physical constraints, which may limit functional device interaction. In order to comprehensively describe these constraints, user-centered and universal design, human variability, and end user errors will be discussed.

1.1. User-Centered Design

User-centered design encompasses several design techniques that aim to comprehensively account for the needs of users at different phases and by different means (qualitative and quantitative) throughout the design process. The International Standards Organization (ISO) defines user-centered design through six principals: (1) the design is based upon an explicit understanding of users, tasks, and environments; (2) users are involved throughout design and development; (3) the design is driven and refined by the user-centered evaluation; (4) the process is iterative; (5) the design addresses the whole user experience; and (6) the design team includes multidisciplinary skills and perspectives [

2]. The application of user-centered design is essential to adequately design for the intended population. Failure to consider user-centered design principals in consumer products often results in a “bad design” as defined by Norman [

3], leading to user dissatisfaction, use error, and compromised safety. The limitations associated with adequately applying these ISO principles is the qualitative nature of the principles, which makes them hard to objectively measure, thus limiting their integration into quantitative models. Moreover, they require subjective human input that is usually collected through participatory design approaches such as interviews, focus groups, surveys, etc., consisting of feedback from individuals and small groups. Thus, the designs derived are often not generalizable or representative of the entire user population, without comprehensive statistical representation of the population variability.

1.2. Universal Design

A commonly applied subset of user-centered design is universal design. Universal design has been applied in several applications to narrow, evaluate, and select the best, most accessible product options for the population [

4,

5,

6]. Universal design principals are listed in seven concepts, as described by Connell et al. [

7]; equitable use, flexibility in use, simple and intuitive use, perceptible information, tolerance and balance, low physical effort, size and space for approach, and use. Universal design has been used qualitatively and quantitatively to assess and measure the accessibility of the design.

Universal design was established with the intention to produce designs that are appropriate for all users; however, design methods and principals are broad and often are not applied prescriptively enough to truly design for all users [

4]. In many instances, user groups contain small sample sizes and results are generalized for an entire subset of the population [

8]. Moreover, universal design principals are qualitative in nature, which requires human interpretations that can lead to bias and subjectivity in designs that are intended for all people. There is a need to expand the representativeness of universal design in the population and remove subjectivity in the design process.

1.3. Human Variability

Design for human variability (DfHV) attempts to address the subjective nature of user-centered design by focusing on quantifying and integrating human physical attributes in to the design process. Garneau, Nadadur, and Parkinson [

9] define DfHV as “the design of artifacts, tasks, and environments that are robust to the variability in their users.” Human variability is described as the anthropometric differences in human beings [

10], based on the measurement of the human body [

11]. The majority of the DfHV applications include the use of large anthropometric databases such as National Health and Nutrition Survey (NHANES) I, II, and III and the Army Anthropometric Survey (ANSUR) I and II. Garneau and Parkinson [

12] present a major limitation associated with DfHV methods, which discusses the risk associated with the use of outdated military databases as a source of optimization for design and fit when these databases do not currently reflect the increase on body mass of human beings within the US population. Moreover, human factors methods are traditionally applied to the design of work or the fit of the person to a product [

13,

14,

15]. These methods rely on adjustability of products and humans to fit workspaces and human parameters to guide the dimensions of products, respectively [

15,

16,

17,

18]. Current methods only address static applications or dynamic interactions that are static-driven and lack standardization often requiring experts or thoroughly trained engineers, e.g., master’s degree, to implement these techniques. Furthermore, static-driven dynamic interactions usually require modeling several static postures to capture each instance (initial and final position) of a dynamic interaction.

The connection between anthropometry and ergonomics is extremely important for product design to maximize perceived quality and usefulness of a product. Moreover, poor interactions increase the occurrence of safety issues and human errors due to functional use of products resulting in musculoskeletal disorders, permanent injuries, etc. The original intent of accommodating human parameters in design was to ensure universal operation and design for all users in the population [

11,

14]. The application of anthropometrics may impact the size and shape of components in a product or design, which could provide a better fit for the end user.

1.4. Use Errors

As mentioned previously, inappropriate design accommodation for end users can also lead to use errors during device interaction. Use errors occur at points of user interaction with artifacts, which may include artifact systems consisting of hardware or software elements. Use errors are defined in four forms of error: slips (attention failures), lapses (memory failures), mistakes (performance (rule-based), and planning (knowledge-based) errors [

19]. These errors may occur at points of interaction in the output (information provided to user) or input (user performs action on system) state of a system [

20]. End use errors impact a product’s market success. In addition, products that predispose end users to use errors are not easily correctable through labeling and may present end users with negative safety consequences [

20]. It is essential to build corrective models between the designer model and the user model while satisfying the functional requirements of the product [

3].

1.5. Human Interaction Factors

Interaction variability is introduced in this paper to address the aforementioned methodological gaps in existing approaches to integrate human variability into design. This concept focuses on an objective perspective that informs the customization of products based on interactions between the product and physical human parameters. The method relies on the underlying assumption that user preferences and/or needs are dependent on accommodation. Accommodation in this work is defined as consideration of human parameters and their functional capacities during product use. Currently, there is a lack of structured methods for mapping human and product component interactions in consumer products (e.g., cell phone, sunglasses, utensil, glucometer, helmet, shoes, remote control, hair dryer, etc.) [

21,

22,

23,

24,

25]. The Interaction Variability method seeks to address the baseline necessity of users for product interaction instead of solely customer preference, since customers may not always be sensitive to their musculoskeletal needs.

This proposed method intends to address product design limitations by identifying interaction variability from a biomechanics viewpoint at the musculoskeletal level. Interaction variability, the main theoretical contribution of this work, is integrated into a novel multidisciplinary method. This work presents a structured, classification scheme for identifying interactions between product and human interfaces based on product functions for static and dynamic applications. Moreover, this method is validated in this work and developed for application in the design conceptualization phase of the product design process (PDP). The fundamental contribution and emphasis of this work, compared to traditional methods, lies in a distinct focus surrounding the dynamics of interactions. The interaction variability method seeks to standardize the selection and evaluation of human product interaction factors during the design process amongst designers, product design engineers, human factors/biomechanics engineers, and user experience (UX) researchers. The physical constraints of human dimensions, which may limit component or device interaction, are identified. Lastly, this work presents a structured design method facilitating the selection of interaction spaces, which enable mass customization, and product platform approaches, all enabling mass production, which is explored in tangential analyses.

2. Materials and Methods

2.1. Method Overview

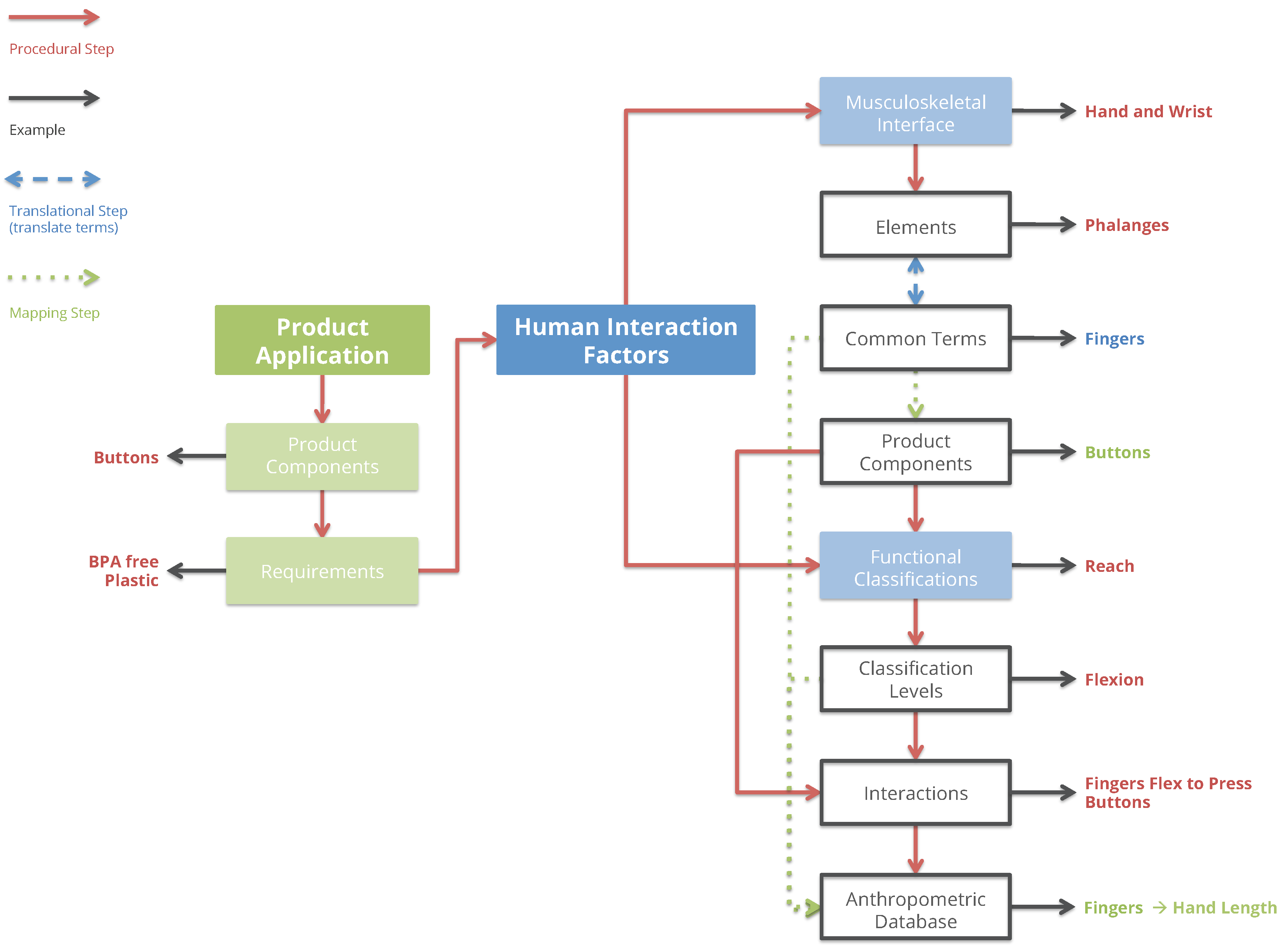

A two-step structured design methodology that focuses on mapping human and product interactions is presented,

Figure 1. The first step consists of identifying specific applications, emphasizing products that are inherently limited by human interaction factors (e.g., helmet, backpack, glucometer). All product components (parts of the whole product application) and requirements (i.e., primary function) are identified for the product application. The second step includes identifying human interaction factors required for product interaction. Identifying interaction factors include observing active musculoskeletal interfaces (static regions of the body) and functional classifications (dynamic functionality of static regions). The second step facilitates the generation of design variables related to human factor interactions through mappings of relevant musculoskeletal interfaces and functional classifications to anthropometric databases,

Figure 1.

The process for identifying human interaction factors is presented in two primary processes (1) musculoskeletal interface identification and (2) functional classification identification.

Figure 1 provides a detailed process for the human interaction factors process. The procedural transition step indicates that the interaction is sequential with precedence relationships. The translational transition step occurs when a conversion of syntax is being performed, i.e., phalanges

fingers. The mapping transition step identifies the specific interface elements, functional classification level, and product components that interact, i.e., fingers map to buttons. In addition, the mapping step provides a linkage to the anthropometric values based on the common term for the musculoskeletal interface and classification level of the functional classification. Finally, the black arrows represent examples of each term presented in this method.

2.2. Product Application

Fundamental characteristics of product applications require static or dynamic interactions and characterization to be effectively evaluated in this method. A static application has the capacity to carry out the primary function of a product application without additional interactions, after an initial interaction. For example, the primary function of a lamp is to illuminate a space. After the initial interaction of turning on the lamp, it will perform its function without additional interactions. In essence, many static applications have two or less states, in our example of the lamp the states are “lamp on” or “lamp off”. Other examples of static applications include: chair, glasses, non-accessible containers, etc.

A dynamic application does not have the capacity to carry out the primary function of a product application, without additional interactions after an initial interaction. In many instances dynamic applications have one or more primary functions. For example, a water bottle has two primary functions: (1) to hold, store, or contain liquid and (2) to provide access to liquid. The first function can be accomplished without interaction while the second function requires interaction. There are three states in this dynamic application “bottle closed,” “bottle open,” and “liquid released.” After state three, the water bottle will return to one of the previous states. If weight and proportion of liquid are considered in the primary function of the device then more states may be important such as the decrease in liquid and weight and the effectiveness of the container, i.e., bottle half full. Other examples of dynamic applications include: tablet, glucometer, vacuum cleaner, etc.

Correct identification of product components as a part, assembly, or sub-assembly within a product is essential to correctly identify component-to-component interactions and human component interactions. Correct categorization of static and dynamic interactions is essential for the conceptualization of human component interactions. Performance requirements for products must typically satisfy regulations for safety reasons. Consideration of product performance requirements assists in optimal product design based on interactions (component and human) and product functionality.

2.3. Human Interaction Factors

Human beings interact with artifacts in the world on a consistent and regular basis. These interactions can be described at the basic level of human extremities manipulating objects that are motionless or have motor capabilities. Anthropometry and anatomy enables the description of the biomechanics or human extremities from a static and dynamic perspective.

2.3.1. Musculoskeletal Interface (Static Region)

The musculoskeletal system consists of the human skeletal system and the muscles that support the skeletal structure. There are twelve musculoskeletal areas in the human being. Areas include the braincase, face, ear, throat, vertebral column, thorax, pectoral girdle, arm, hand and wrist, pelvic girdle, leg, and foot [

26]. Each area acts as a system with a subset of bones. For example, the hand and wrist consists of 54 bones including phalanges, metacarpals, and the bones that make up the carpal system [

26]. For this work, musculoskeletal areas are referred to as musculoskeletal interfaces. The musculoskeletal interfaces represent static regions of the human body because they do not vary instantaneously with respect to their physical dimensions (width, length, etc.)

Subsets of the interfaces (body parts, e.g., hand and wrist) are considered the elements (bones/muscles, e.g., phalanges) of the interface. It is essential to specify which musculoskeletal interfaces and specified elements are relevant for product design. Once elements are specified at the appropriate level of detail, element terms will be translated into common terms for identification in anthropometric databases, for example phalangesfingers. After identifying common terms, product components that human elements interact with are identified. Relevant product components of the product are identified through the intended interactions defined by the design requirements. Next, all interactions are identified. Detailed interactions should be captured to ensure translated elements and product component interactions are captured and conveyed intuitively for the layperson. For example, thumb (translated element) presses and holds button (product component).

The process map for identifying the interactions between elements and human parameters,

Figure 1, encompasses identified musculoskeletal interfaces and product components that are relevant to selected product applications. Procedural transition indicates a sequential interaction with precedence relationships. Translational transition occurs with the conversion of syntax, i.e., phalanges

fingers. Mapping transition characterizes element and product component interaction, i.e., fingers map to buttons.

2.3.2. Functional Classifications (Dynamic Functionality of Static Regions)

After identifying musculoskeletal and product component interactions, functional interactions are defined. Human actions are classified in four categories.

- 1.

Reach. Extension, flexion, and retraction of the limbs in relation to the specific limb when active.

- 2.

Application of force. Force exerted by the human being in relation to the interaction with an object.

- 3.

Initiation of tyactility. Sensory system that is activated to distinguish surfaces and textures through touch.

- 4.

Maneuverability. Ability of the joints and axes of rotation in different limbs and body parts, including deviations of the wrist, arms, and lower limbs including legs, ankles, and feet.

Functional classifications and respective classification levels are represented in

Table 1. Functional classifications of reach and force were derived from anthropometric databases while tactility and maneuverability were conceptualized in this method. Tactility and maneuverability draw from concepts related to feedback analyzed by the sensory system and the degree of joint fluctuation in a three-dimensional space, respectively. Data and descriptions of all classification levels were derived from anthropometric databases with the exception of twist and turn (force), sense (tactility), and rotation (maneuverability). Interactions that occur at each classification level of the relevant functional classifications will be identified. Functional classifications represent dynamic functionality for static regions of the musculoskeletal interfaces. Dynamic functions represent actions of the static regions that allow interaction to occur.

2.3.3. Mapping to Anthropometric Databases

The identification of the musculoskeletal interfaces and functional classifications allow for the mapping of the identified human parameters to anthropometric databases. The anthropometric databases provide static and dynamic measurements for human parameters, which enables the seamless mapping of musculoskeletal interfaces and functional classifications, respectively. The identified measurements are critical to the optimization model for the prediction of product components dimensions.

Anthropometric databases provide measurements that give insight to the population variability for different body part sizes. Once the appropriate anthropometrics are identified, the distributions of each measurement can be observed to obtain an idea of the shape of the distribution. Most anthropometric databases have an underlying assumption of normality in the distribution. However, the spread of each body part parameter is variable. The most important aspect of obtaining anthropometrics is identifying the correct mapping relationship between the anthropometric value and the musculoskeletal interface or functional classification. The variability ranges for the functional classification levels are determined from federal databases (i.e., NHANES), scholarly research (i.e., Bodyspace by Stephen Pheasant), and anthropometric databases (i.e., ANSUR) [

14,

27,

28]. For example, NHANES defines physical measures (weight, height, etc.) of people in the population based on physical examinations; the US Department of Defense (DoD) databases define anthropometric data for military personnel; National Institute for Occupational Safety and Health (NIOSH) funds research projects that produce anthropometric data-sets for workforce populations to assist in the reduction of workplace injuries; ANSUR defines anthropometric data for army personnel, and NASA databases provides space flight standards for human–system integration from multiple perspectives [

14,

27,

28].

Once an application is selected and a target population is identified, one of the previously mentioned US anthropometric databases can be used to obtain body measurement values for men, woman, and children. There are also international anthropometric databases for products that are expected to be available internationally. In applying most anthropometric database measurements, the designer selects the 5th, 50th, or 95th percentiles of the desired populations based on the population needs. This almost always leaves out some portion of the population [

29].

2.4. Design Validation Study

This method was empirically validated for product component dissection and anatomical and anthropometric references to static musculoskeletal interfaces and related functional classifications,

Table 2. Validation of human interaction factors is necessary to ensure standardization and repeatability among a sample of the target population (designers). Study subjects followed the design process detailed in

Figure 1.

2.4.1. Product Selection

Subjects were presented with a dynamic (primary function is not performed after initial interaction) and static (primary function is performed after initial interaction) application. Selected product applications include: sunglasses and a water bottle representing static and dynamic applications, respectively. Product applications with minimal complexity and common knowledge of use were selected to ensure that prior knowledge of the application would not influence the study outcome. Sunglasses have components that are commonly agreed upon by design engineers from a manufacturing perspective. Typical components include lens (2), a frame, arms (2), and some affixing mechanism. Water bottles components include a cap or top and a body to store the water. Thus, the first goal of this study was to determine whether experienced design engineers could identify common product components consistently. This process was repeated for components in static and dynamic applications measuring the consistency amongst the components identified.

2.4.2. Study Protocol

This research complied with the American Psychological Association Code of Ethics and was approved by the Institutional Review Board under project [943186-2] Design Methodology Study. Informed consent was obtained from each enrolled subject. Subjects were provided with formal definitions of static and dynamic applications. In addition, subjects were allowed to use the Internet and/or a medical dictionary to complete musculoskeletal constructs.

At the start of the study, a series of interactions was demonstrated for both the dynamic and static product application. Subjects were eligible for enrollment in the study if they were an upper level undergraduate engineering student with at least 1 advanced (300 or 400 level course) engineering design course and a basic knowledge of the human anatomy. This study enrolled 16 subjects over a 2-week enrollment period.

An interaction was demonstrated for both product types (dynamic and static). The water bottle interaction,

Figure 2, was initiated with a closed cap water bottle placed on a flat surface. The sunglasses interaction,

Figure 3, was initiated with sunglasses on a desk with arms expanded. Subjects were asked to complete a series of tasks identifying the relevant interfaces of the human anatomy and the individual components of the product that are required for human interaction. Each interaction is described in the respective category.

(a) Dynamic interaction scenario: Water bottle application.

Pick up the water bottle with a loose grip. Then, apply a tight grip to the container and lid with two hands in opposite directions apply the torque necessary to unscrew the cap. Remove cap and drink from the container.

(b) Static interaction scenario: Sunglasses application.

Pick up the sunglasses, in an expanded arm state, with a two-handed pinch grip between the thumb and index finger. Place the lenses in alignment with the pupils and the arms between the braincase and ear.

2.4.3. Materials

Subjects were provided with a series of interactive handouts that they could view at any point in the study. Diagrams of the sunglasses and water bottle applications were provided to each subject. Each subject was provided the supplemental tools necessary to perform the mapping tasks, which consisted of a series of blank tables provided for each task and sub-task described below. Subjects were also allowed to ask the experimenter any questions regarding the tables provided, interactions, and term clarification, demonstration, or definition. The materials were available via Smart Board screens and consisted of the human skeletal and select relevant anthropometric databases.

- 1.

Task One: Identify table parameters from source information.

- (a)

Subjects were provided with Table 9.2 from Steele and Bramblett [

26] and asked to identify and complete the musculoskeletal interfaces, elements, and common terms constructs of the

Figure 1. Subjects were provided access, via an electronic touch screen smart board interface and handouts, to select anthropometric databases and medical dictionaries to complete these three constructs.

- (b)

Subjects were provided with a table version of the functional classifications,

Table 1. Based on the musculoskeletal interfaces identified, subjects were asked to identify the functional classifications and levels that are active during the demonstrated interaction between the musculoskeletal interface and the product component. Subjects were provided access to the same resources available in Task 1 (a).

- 2.

Task Two: Determining mappings and interactions.

- (a)

Subjects were asked to segment the product applications in terms of physical components that require human or user interaction to accomplish the demonstrated interactions. After this, each subject completed the product components handout that was later translated to the product component column of the musculoskeletal interface mapping table. The subject then described and wrote the interaction, in the interaction column of the mapping table that occurred between the product component and the common term,

Figure 1. This process was repeated for the functional classifications and levels identified in Task 1 (b). The interactions described in this part of the study were based the interaction between the product component, musculoskeletal interface, and the classification level for each functional classification required to complete the demonstrated interaction for each product application.

- (b)

Subjects were provided with anthropometric measurements tables and asked to determine the specific measurements related to the common terms followed by those related to the classification levels. If expected measurements were not available then subjects were asked to provide the needed measurement. Subjects were also allowed to ask clarifying questions related to the anthropometric terms.

- 3.

Task Three: Identify application type.

2.4.4. Construct Validation

Construct (musculoskeletal interfaces and functional classifications) integration along with concepts identifying interactions were explored as part of this study. Validation assessment evaluated interactions developed as a result of translated element and classification level mappings with product components. In addition, the accuracy of the mappings of translated elements and classification levels with measurements are also included. Simultaneously, the entire construct for

Figure 1 and

Table 1 was validated.

Theoretical structural validity is the correctness of the method constructs separately and integrated [

30]. This form of validity is demonstrated for each construct separately as defined in [

30] and the integration of the constructs, highlighted in gray, are verified in the present study [

31],

Table 2. Construct integration refers to integration of a construct either modified or unaltered into the method.

The correction rate of the subjects was calculated and analyzed based on the acceptable performance range of 75% to 95% correctness. A range is considered acceptable when a level is not specified, which may prove difficult because a correction rate that is too high (100%) is unreasonable while a correction rate that is too low (50%) may cause system or method failure [

40,

41].

2.4.5. Data Analysis

The data collected from subjects were analyzed based on consensus data where an acceptable performance range was 75% to 95% correctness [

40] where 50% correctness is suspected to cause system or method failure. This analysis assessed the statistical significance of consensus values obtained from the method measures compared to 50% correctness. The consensus rates are calculated for each measure, where the denominator is the population size and the numerator is the subject response to a measure. Percent correctness is the number of subjects that correctly labeled an item divided by the number of subjects. Correctness is defined based on formal definitions from engineering design, manufacturing, and biomechanics related to product components and human dynamic actions. Rate calculations have been applied in clinical and product bench marking methods [

42,

43].

One-tailed binomial sign tests were conducted to understand the significance of the consensus rates. Tests were performed at the 90% confidence level, where the proportion estimated was 50% consensus. The 50% consensus was selected as a benchmark rate because values at or below 50% are expected to be too low to indicate consensus among the designer population [

40]. The goal of the statistical analysis was to determine whether the consensus rates achieved were significantly different from the proportion estimate. Other analyses preformed include a Chi-Squared goodness of fit test (95% CI,

p > 0.05) for normality assessment and summary statistics including count and percentage based on consensus. The software used to analyze the data included R (Project for Statistical Computing) and Microsoft Excel

®.

2.4.6. Product Application

Each product application (sunglasses and water bottle) was analyzed based on the application type through the aforementioned analysis methods. Count evaluated the number of people in the population that identified the component correctly, regardless of syntax. Moreover, count also included the number of subjects that used the same syntax to describe the product component. The percent consensus includes the number of subjects that obtained the same answer divided by the subject sample size, which then was assessed for significance through a one-tailed binomial sign test.

2.4.7. Human Interaction Factors

A binomial sign test and summary statistics were also applied to musculoskeletal interface and functional classification mapping. The interaction syntax was not evaluated for consistency or structure but for correctness because it varied drastically and requires further assessment through a textual clustering method. Count was used to assess the number of subjects that correctly identified each mapping step in the musculoskeletal interface and functional classification process, respectively. The percent consistency was then tabulated based on the number of subjects that answered each step in the mapping process. The number of subjects that identified the same components divided by the total number of subjects that responded determined the percent consistency for each mapping. The result section outlines the one-tailed binomial sign test outcomes and summary statics results for mappings that achieved high and low consistency amongst subjects.

4. Discussion

The interaction variability method was introduced in this study. The study was designed in a manner to validate the structure of the method and assess consistency amongst subjects with a design background. Moreover, this study provided insights for the redesign of components based on product component labeling and incomplete product architecture dissection within the sample group. While incomplete product architecture dissection impacted anthropometric mappings, the overwhelming inability to comprehensively map anthropometric measures may indicate design intent was not focused on the human product interaction. Instead these products, like many products on the market, were driven by the product function suggesting the need for redesign or at least consideration of the user experience in the design of the product. The product applications and overall interactions demonstrated were selected due to their simplicity. Even with the de-emphasis on product application complexity, all subjects took the full 2 h to complete the study, suggesting the need for additional separate sessions to train designers. A general observation of this study reveals subjects inability to completely identify user interactions with very simple product applications and interactions. Adding complexity to either the product application or the series of interactions would distract from the goals of this study, which were to measure designer consistency and assess the comprehensiveness and effectiveness of this method for interaction variability.

The revelation that all subjects did not identify comprehensively all possible interactions, resulting in lower consistency percentages, touches on a bigger theme of inconsistently and subjectivity in the application of design and human factors methods. Although consensus was not achieved for each individual measure, validity of the interaction variability method was demonstrated overall since subjects identified measures in accordance with constructs and method procedures outlined in

Figure 1. Additional studies are required to assess the reliability of this method. Training is necessary to develop a baseline skill set in designers that will enable them to think beyond their experiences or a small sample size since diversity in population segments can not always be achieved [

8,

40]. Moreover, since subjects failed to identify all possible anthropometrics and musculoskeletal interfaces associated with the series of interactions, they were unable to identify interaction variability in those cases. While physical interactions are often easier to identify at a surface level, developing a trained eye allows for standardization. While cognitive predictions of interactions are more susceptible to ambiguity, culture differences, and subjectivity, physical predictions of interaction are also vulnerable to these factors. Moreover, both physical and cognitive perspectives can lead to human error when left unaddressed [

44].

Subjects were randomly asked to describe product applications as dynamic and static after a definition was provided. Subjects were able to consistently identify static and dynamic applications at a significant consensus rate, 87% ( p < 0.1). This indicates that subjects had a strong understanding of the definitions with regard to product applications. Subjects were allowed to use the Internet and/or medical dictionary to complete musculoskeletal constructs. However, no subjects took advantage of these resources.

The tasks related to product components labeling also achieved significant consensus amongst subjects for the cap and bottle components of the water bottle application. On the other hand, the consensus percentage amongst subjects for the labeling components in the sunglasses application was significant for the lens, frame, and arms but failed to achieve significant consensus for labeling the screw and screw frame. This indicates that products with more components have a higher likelihood of inconsistency and reduction in consensus amongst designers when defining components. It also seemed that many subjects overlooked the details of the glasses, which may indicate that designer’s ability to accurately assess components that impact the user experience is diminished with product complexity. Inconsistency in consensus for these basic applications could indicate a need for additional training in product decomposition and manufacturing prior to use of the method.

The range of consistency for the sunglasses and water bottle applications began to vary significantly in relation to identifying musculoskeletal interfaces that interact with each application. For the water bottle, subjects identified all direct and indirect interactions of the hand and wrist musculoskeletal region at ≥50%. In many instances, subjects consistently identified the wrist system over the palm of the hand even though the wrist indirectly interacts with the water bottle and the palm directly interacts. In fact, the face musculoskeletal region, which includes the mouth interface, has a direct interaction with the bottle based on the presented interaction; however, only 28.1% consensus, on average, was achieved amongst subjects. This is surprising because other indirect interactions with arm musculoskeletal regions almost doubled the consistency of the face musculoskeletal region with 50.8% consensus, although insignificant. One limitation that could be improved would be to obtain a more robust indication of consensus in the engineering design population by increasing the sample size.

For the sunglasses application, consistency among the identification of direct musculoskeletal regions including the fingers, ear, and bridge received 72.9% consensus. While other non-common musculoskeletal regions with direct interaction including the cheek, temple, and upper face of the braincase received only 12.5% consensus amongst subjects.

Consistency ranges amongst the functional classifications were more consistent overall with subjects correctly identifying all dynamic actions of the musculoskeletal regions with 64.3% consensus for the water bottle application and 68.8% consensus amongst the sunglasses. The linkages of the dynamic and static interactions to the anthropometric databases were much lower overall. However, for direct interactions, musculoskeletal interfaces consensus amongst subjects ranged from 12.5% to 87.5% and for indirect interactions the range shifted left at 6.3% to 68.8%. It appears that subjects understood the actions of musculoskeletal interfaces during the interaction but could not identify which musculoskeletal interfaces were actually interfacing with the product application.

Limitations

The interaction variability method aims to comprehensively capture the biomechanics of human–product interactions for the purpose of improved user-centered design. However, the development of this method relies on an assumption that limits its application. Specifically, it is assumed that a baseline understanding of human factors, ergonomics, and biomechanics will enable designers to comprehensively capture important human interaction factors and anthropometric measures. This assumption may negatively impact consensus and should not be generalized across all designer populations. Another limitation is the lack of control for designer subjectivity with regard to the identification of important factors and measures. There also may be some ambiguity in the mapping steps of the human interaction factors that create opportunities for unidentified interactions. Moreover, this method requires the segmentation of complex interactions to the simplest state forms of interactions to properly capture all relevant human interaction factors. This limitation creates variability based on the designers’ approach to defining interactions. The time required to apply this method, 2 h or more without training, also poses a limitation. Effective training and assessment tools are required to establish sufficient baseline knowledge, which poses a limitation to controlling variability in the application of this method, and increase efficiency with respect to the time required for the application of this method. A key challenge lies in the effort to control designer variability in the identification of important human interaction factors without negatively impacting designer creativity.

This study could have been improved with a larger sample population of students. Students were sampled from a mechanical engineering undergraduate program, which has sparse biomechanical curriculum integration. The limited biomechanical curriculum in the sampled population may have contributed to the variance in consensus in the application of the Interaction Variability method. Instructions and reference materials (skeletal diagrams and anthropometric data sets) were also provided to subjects to restrict or control the addition of irrelevant options. Extended sampling time could have been applied to gain a more robust data set of the population. Gaining an accurate assessment of students’ prior knowledge of human anatomy and product development skills would have been important for assessing whether students understood the differences between primary and secondary interactions. Incorporating a detailed written/visual guide for the interaction being assessed could also improve consensus outcomes for students who have different learning styles. This process could also assist subjects in the strategic structuring of syntax to describe the interaction that was correctly mapped. Another alternative to increase the potential for a correct or common syntax structure for interactions is a fill in the blank format, which ensures that each participant clearly understood the identified mappings.

Other recommendations to address UX in the design of consumer products are to incorporate multi-methodological approaches [

45,

46]. These approaches have been effective in other industries, such as vehicle design and construction, by establishing “in-line” comparative analysis and “holistic systems-thinking approaches” [

45,

46]. In-line comparative analysis enables researchers to compare distinct method sections within the overall method for effectiveness [

45]. Moreover, holistic systems-thinking approaches facilitate researchers’ ability to think cross functionally and interdisciplinary about distinct methodologies that can effectively capture contributing factors that impact the UX [

46]. Investigations such as these enable designers to address multiple distinct areas of design in a clear structured way without neglecting key information that impacts the user population.

5. Conclusions

The results of this study were insightful, as many designers interested in product design have not considered the interactions that humans have with consumer products designed for human use. This method demonstrates consensus in the identification of static and dynamic product applications and product component labeling. The concept of static and dynamic product applications characterized by interactions were introduced and defined in the paper. Human interaction factors, including musculoskeletal interfaces and functional classifications, demonstrated consensus only in mapping primary interactions (musculoskeletal interface physically contacts product component) with the exception of key secondary interactions (bold lines in tables). Secondary interactions occur at the point of dynamic interaction with the product component. The population demonstrated consensus in identifying wrist deviation and rotation and upperarm and forearm extension and elevation. However, consensus was largely not achieved in identifying other secondary human interaction factors and in determining anthropometric values.

Designers could use this method to identify and target specific interactions between musculoskeletal interfaces and product components to improve usability and reduce the risk of human error. Additional investigations are necessary to assess the reliability of the consensus values achieved in relation to musculoskeletal and product component interface interactions. Common musculoskeletal interfaces with direct or indirect interactions are easily identifiable and achieved consensus at significant rates amongst the subjects. However, anatomical regions that are not commonly understood among the study population (mechanical engineers) were not considered and may be important in the design process. Future work should explore the impact of identifying human component interactions on manufacturing decisions for mass customization. This work has several implications for direct impacts on product design improvement, redesign, and user accommodation, which may be computationally modeled prior to production.