System-Theoretic Process Analysis (STPA) for Hazard Analysis in Complex Systems: The Case of “Demand-Side Management in a Smart Grid”

Abstract

1. Introduction

1.1. Background

- Demand-side load management, forecasting, and peak-load saving

- Smart metering

- Smart appliance and home automation

1.2. Accident Models in Systems

2. Methods and Materials

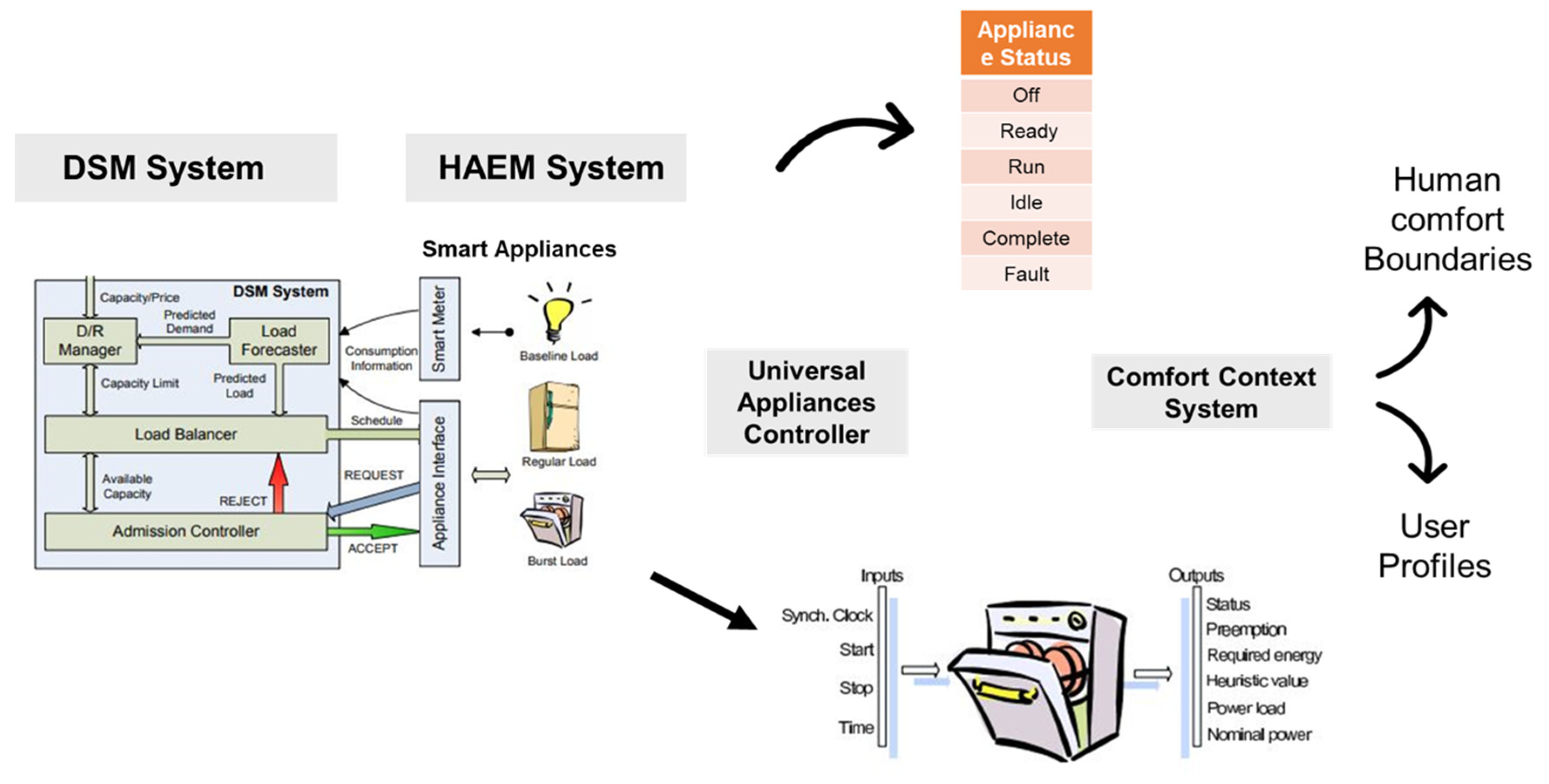

2.1. Demand Side Load Management System in Smart Homes (SHs)

- (1)

- Demand-Side Management-Management System (DSM-MS)

- (2)

- Home Automated Energy Manager

- (3)

- Comfort Context

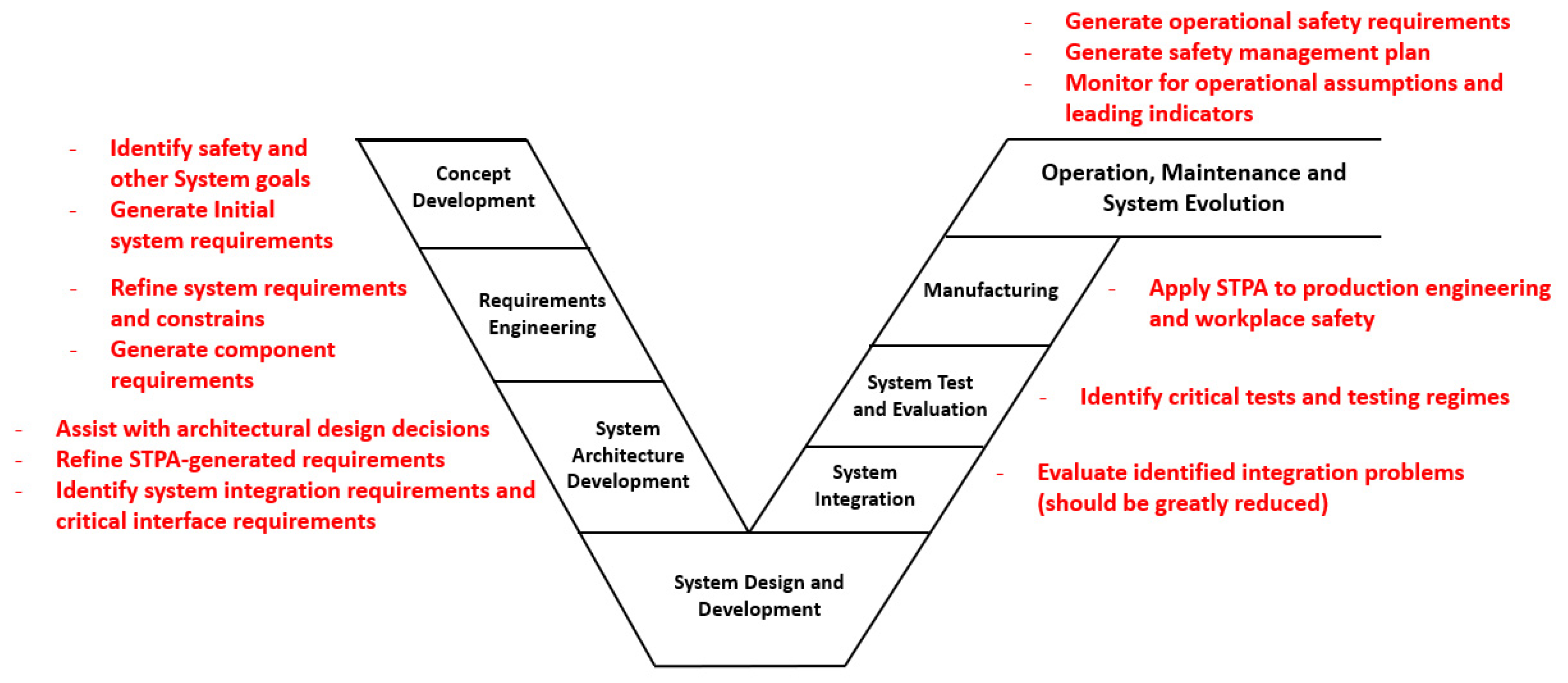

2.2. STPA Method

- 1.

- Define the purpose of analysis—system losses, system level hazards, and corresponding safety constraints are defined.

- 2.

- Model of the control structure—a hierarchical control structure of the system is composed of a series of connected feedback and control loops.

- 3.

- Identify unsafe control actions (UCAs)—these are the control actions which under worst-case circumstances will result in a hazard.

- 4.

- Identify loss scenarios—these are the scenarios that result from the combination of several causal factors (CFs) that may lead to UCAs and potential loss.

3. STPA Results

3.1. Purpose of the Analysis

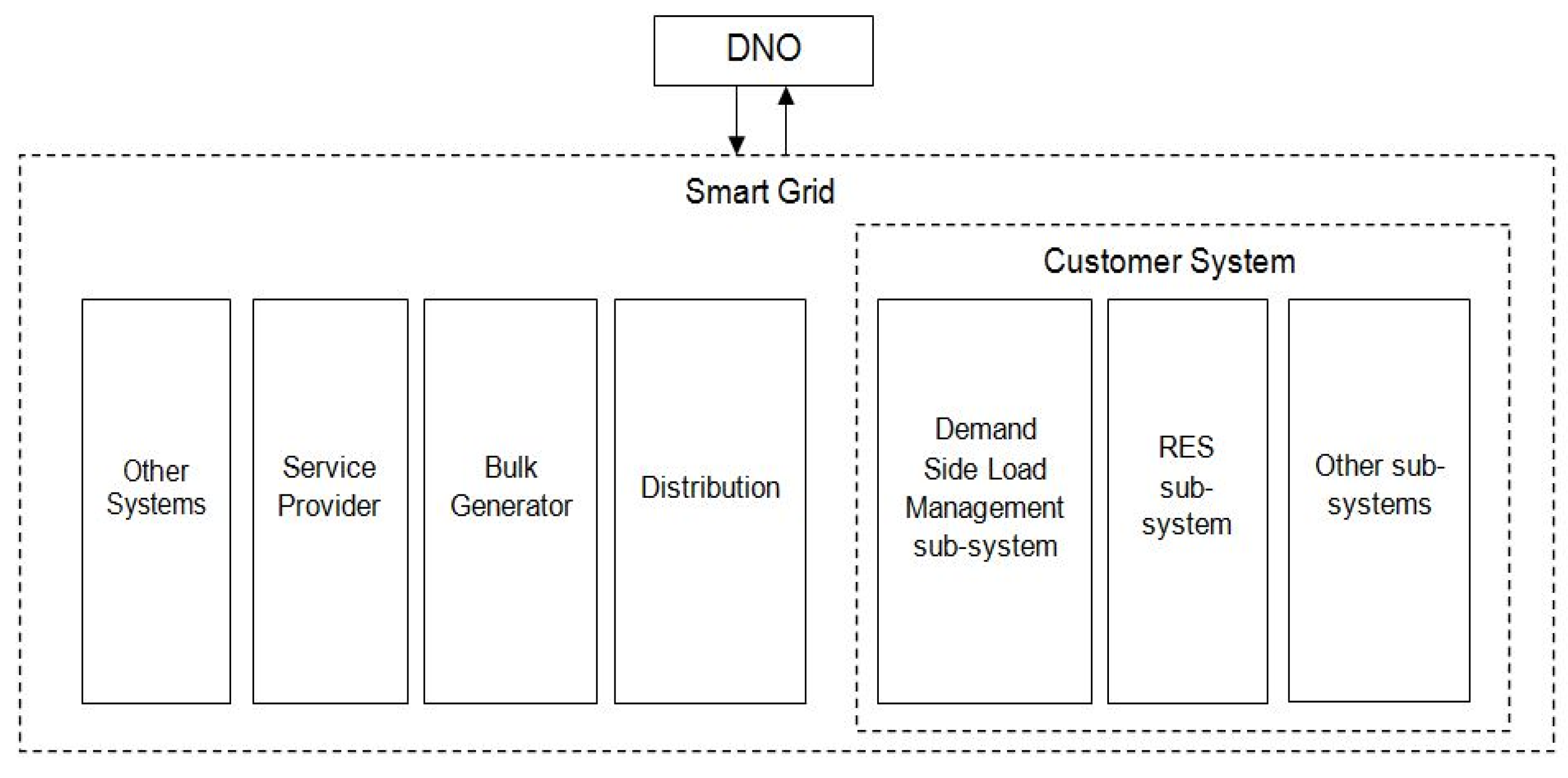

3.2. Modelling the Control Structure

3.3. Identifying Unsafe Control Actions

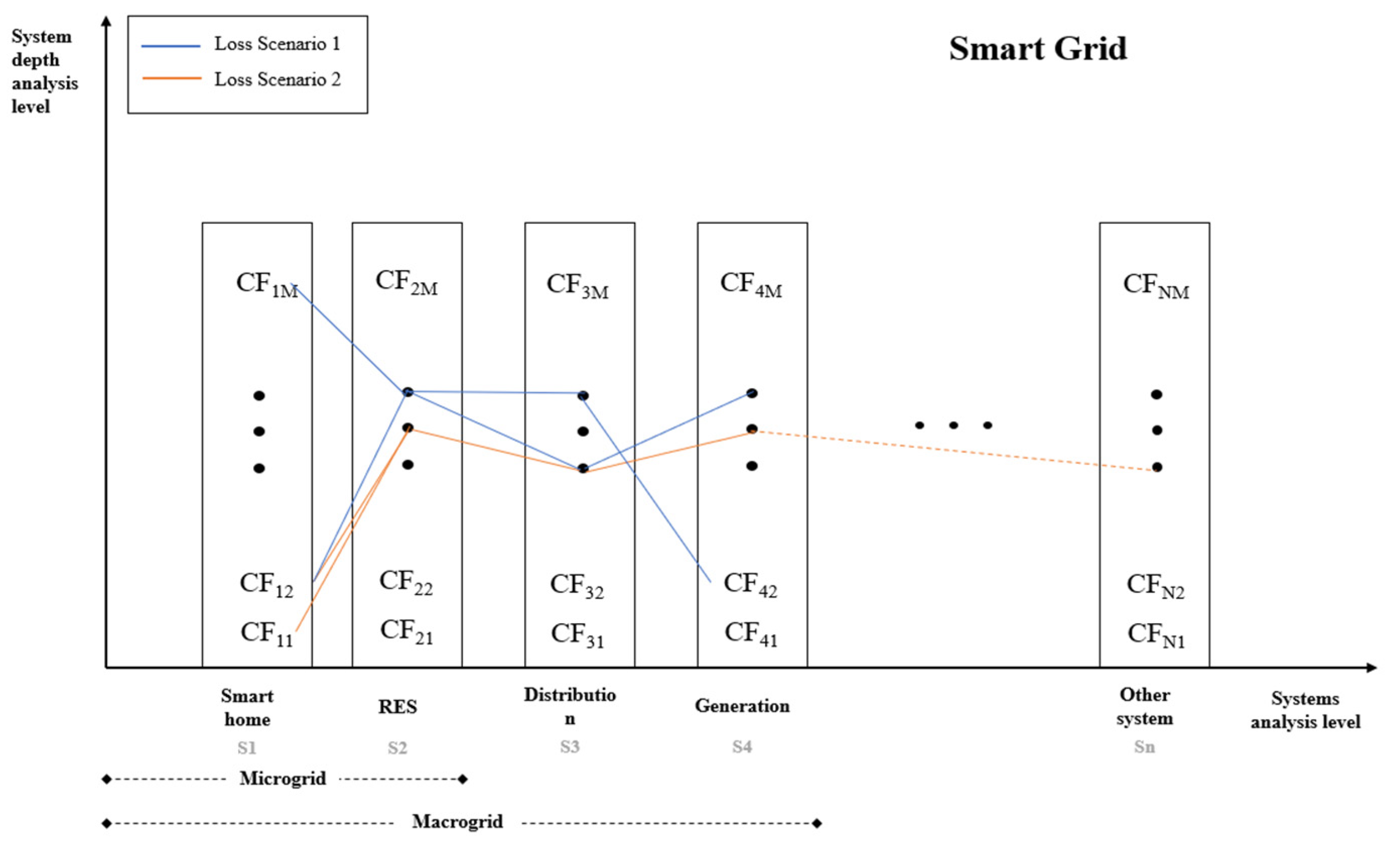

3.4. Loss Scenarios

- (i)

- Unsafe controller behavior

- (ii)

- Inadequate feedback and information

- (iii)

- Scenarios in which control actions are improperly executed or not executed

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| STAMP | Systems-Theoretic Accident Model and Processes |

| STPA | System-Theoretic Process Analysis |

| SG | Smart Grid |

| FTA | Fault Tree Analysis |

| HAZOP | Hazard and operability study |

| FMEA | Failure Mode and Effects Analysis |

| UCA | Unsafe Control Action |

| CFA | Causal Factor Analysis |

| DSM | Demand-Side Management |

| DNO | Distributed Network Operator |

| DRM | Demand Response Manager |

References

- European Commission. Energy Technologies Information System (SETIS): Smart Electricity Grid. 2012. Available online: http://setis.ec.europa.eu/smart-electricity-grids (accessed on 10 March 2020).

- Chondrogianni, D.; Karatzas, S.; Stephanedes, Y. A Process-Centric Approach for System-of-Systems Integration in Smart Cities. 2018. Available online: http://3ftfah3bhjub3knerv1hneul-wpengine.netdna-ssl.com/wp-content/uploads/2018/12/Chondrogianni-V.-Dimitra-Karatzas-Stylianos-Stephanedes-Yorgos.pdf (accessed on 5 September 2019).

- NIST. NIST Framework and Roadmap for Smart Grid Interoperability Standards Release 1.0; Office of the National Coordinator for Smart Grid Interoperability, National Institute of Standard and Technology: Gaithersburg, MD, USA, 2010. [Google Scholar]

- Mohagheghi, S.; Yang, F.; Falahati, B. Impact of demand response on distribution system reliability. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–28 July 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 1–7. [Google Scholar]

- Nordgård, D.E.; Sand, K.; Wangensteen, I. Risk assessment methods applied to electricity distribution system asset management. In Reliability, Risk and Safety: Theory and Applications; ESREL: Prague, Czech Republic, 2009; pp. 429–436. [Google Scholar]

- Brown, R.E. Electric Power Distribution Reliability; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Falaghi, H.; Haghifam, M.R.; Tabrizi, M.O. Fault indicators effects on distribution reliability indices. In Proceedings of the CIRED 2005—18th International Conference and Exhibition on Electricity Distribution, Turin, Italy, 6–9 June 2005; IET: London, UK, 2005; pp. 1–4. [Google Scholar]

- Holmgren, Å.J. Using graph models to analyze the vulnerability of electric power networks. Risk Anal. 2006, 26, 955–969. [Google Scholar] [CrossRef] [PubMed]

- Qureshi, Z. A review of accident modelling approaches for complex socio-technical systems. In Proceedings of the Twelfth Australian Workshop on Safety Critical Systems and Software and Safety-Related Programmable Systems, Adelaide, Australia, 30–31 August 2007; Australian Computer Society, INC.: Darlinghurst, Australia, 2007; Volume 86, pp. 47–59. [Google Scholar]

- I.E.C. 60812:2006 Analysis Techniques for System Reliability-Procedure for Failure Mode and Effects Anaysis (FMEA). 2006. Available online: http://www.iec.chAugust2014 (accessed on 18 April 2020).

- Ericson, C.A. Fault tree analysis-a history. In Proceedings of the 17th International System Safety Conference, Orlando, FL, USA, 16–21 August 1999. [Google Scholar]

- McDermid, J.A.; Nicholson, M.; Pumfrey, D.J.; Fenelon, P. Experience with the application of HAZOP to computer-based systems. In Proceedings of the 10th Annual Conference on Computer Assurance (COMPASS’95), Systems Integrity, Software Safety and Process Security, Gaithersburg, MD, USA, 26–30 June 1995; pp. 37–48. [Google Scholar]

- Hollnagel, E.; Woods, D.D.; Leveson, N. Resilience Engineering: Concepts and Precepts; Ashgate Publishing, Ltd.: Farnham, UK, 2006. [Google Scholar]

- Fleming, C.H.; Spencer, M.; Leveson, N.G.; Wilkinson, C. Safety Assurance in NextGen Technical Report; NASA Technical Report NASA/CR-2012-217553; NASA: Washington, DC, USA, 2012. [Google Scholar]

- Fleming, C.H.; Spencer, M.; Thomas, J.; Leveson, N.; Wilkinson, C. Safety assurance in NextGen and complex transportation systems. Saf. Sci. 2013, 55, 173–187. [Google Scholar] [CrossRef]

- Rasmussen, J. Risk management in a dynamic society: A modelling problem. Saf. Sci. 1997, 27, 183–213. [Google Scholar] [CrossRef]

- Leveson, N. A new accident model for engineering safer systems. Saf. Sci. 2004, 42, 237–270. [Google Scholar] [CrossRef]

- Leveson, N. Engineering a Safer World: Systems Thinking Applied to Safety; The MIT Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Pereira, S.J.; Lee, G.; Howard, J. A system-theoretic hazard analysis methodology for a non-advocate safety assessment of the ballistic missile defense system. In Proceedings of the AIAA Missile Sciences Conference, Monterey, CA, USA, 14–16 November 2006. [Google Scholar]

- Thomas, J.; Leveson, N.G. Performing hazard analysis on complex, software and human-intensive systems. In Proceedings of the 29th ISSC Conference about System Safety, Las Vegas, NV, USA, 8–12 August 2011. [Google Scholar]

- Ishimatsu, T.; Leveson, N.G.; Thomas, J.; Katahira, M.; Miyamoto, Y.; Nakao, H. Modeling and hazard analysis using STPA. In NASA 2010 IV&V Annual Workshop; NASA: Washington, DC, USA, 2010. [Google Scholar]

- Chassiakos, A.; Karatzas, S. Systems-theoretic process analysis in buildings energy risk management. In Proceedings of the European Conference on Computing in Construction, Crete, Greece, 10–12 July 2019. [Google Scholar] [CrossRef]

- Cameron, I.; Mannan, S.; Németh, E.; Park, S.; Pasman, H.J.; Rogers, W.; Seligmann, B. Process hazard analysis, hazard identification and scenario definition: Are the conventional tools sufficient, or should and can we do much better? Process. Saf. Environ. Prot. 2017, 110, 53–70. [Google Scholar] [CrossRef]

- Lai, J.; Zhou, H.; Hu, W.; Zhou, D.; Zhong, L. Smart Demand Response Based on Smart Homes. Math. Probl. Eng. 2015, 2015, 912535. [Google Scholar] [CrossRef]

- Nichols, J.; Myers, B.A.; Higgins, M.; Hughes, J.; Harris, T.K.; Rosenfeld, R.; Pignol, M. Generating remote control interfaces for complex appliances. In Proceedings of the 15th Annual ACM Symposium on User Interface Software and Technology, Paris, France, 27–30 October 2002; ACM: New York, NY, USA, 2002; pp. 161–170. [Google Scholar]

- Karnouskos, S.; De Holanda, T.N. Simulation of a smart grid city with software agents. In Proceedings of the 2009 Third UKSim European Symposium on Computer Modeling and Simulation, Athens, Greece, 25–27 November 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 424–429. [Google Scholar]

- Latifi, M.; Khalili, A.; Rastegarnia, A.; Zandi, S.; Bazzi, W.M. A distributed algorithm for demand-side management: Selling back to the grid. Heliyon 2017, 3, e00457. [Google Scholar] [CrossRef] [PubMed]

- Al-Sumaiti, A.S.; Ahmed, M.H.; Salama, M.M.A. Smart Home Activities: A Literature Review. Electr. Power Compon. Syst. 2014, 42, 294–305. [Google Scholar] [CrossRef]

- Leveson, N. System Safety Engineering: Back to the Future; Massachusetts Institute of Technology: Cambridge, MA, USA, 2002. [Google Scholar]

- Leveson, N.; Thomas, J. STPA Handbook. 2018. Available online: https://psas.scripts.mit.edu/home/get_file.php?name=STPA_handbook.pdf (accessed on 16 March 2020).

- Studienprojekt. Software Engineering Group of the University of Stuttgart. 2014. Available online: www.xstampp.de (accessed on 2 September 2019).

- Available online: https://www.volpe.dot.gov/infrastructure-systems-and-technology/advanced-vehicle-technology/safetyhat-transportation-system (accessed on 16 March 2020).

- Abdulkhaleq, A.; Wagner, S. XSTAMPP: An eXtensible STAMP Platform as Tool Support for Safety Engineering. In Proceedings of the 2015 STAMP Conference, Boston, MA, USA, 23–26 March 2015. [Google Scholar] [CrossRef]

- Merrett, H.C.; Horng, J.J.; Piggot, A.; Qandour, A.; Tong, C.W. Comparison of STPA and Bow-tie Method Outcomes in the Development and Testing of an Automated Water Quality Management System. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 273, p. 02008. [Google Scholar]

- Leveson, N. A systems approach to risk management through leading safety indicators. Reliab. Eng. Syst. Saf. 2015, 136, 17–34. [Google Scholar] [CrossRef]

| No. | Hazard Description | Related Accidents |

|---|---|---|

| 1 | Smartgrid cannot meet unexpected demands | 1, 3 |

| 2 | Smartgrid cannot satisfy local energy demands | 2 |

| 3 | Smartgrid cannot keep customers comfortable per their preferences | 2 |

| No. | Accident Description |

|---|---|

| 1 | Power shortages |

| 2 | Customer Loss |

| 3 | Grid equipment loss (capacitors, lines, etc.) |

| No. | Control Action Description |

|---|---|

| 1 | capacity demand |

| 2 | provide the capacity limits |

| 3 | predict required loads |

| 4 | schedule load requests |

| 5 | accept load request |

| 6 | reject load request |

| 7 | send operational status (start/stop/Synch. Clock) commands |

| 8 | send load requests |

| 9 | set comfort boundaries |

| No. | Responsibilities | Process | Feedback |

|---|---|---|---|

| 1 | Demand/Response Manager (DRM) asks for excess capacity from the Distributed Network Operator (DNO) | Excess capacity is required | Excess capacity |

| 2 | DRM informs Load Balancer (LB) about the capacity limits | Capacity is adjusted | Available capacity Predicted demand |

| 3 | Load Forecaster (LF) provides load forecasts | Loads are forecasted | Load schedule, Energy required, preemption, power load |

| 4 | LB provide informs about available capacity | Capacity available to cover loads | Rejected requests |

| 5 | LB schedules loads request | Loads are scheduled | rejected requests, heuristic value, dependency matrix, |

| 7 | Admission Control (AC) manages incoming requests from UAC | Load requests acceptance/rejection | available capacity, requests |

| 8 | Universal Appliances Controller (UAC) sends start/stop/synch. clock commands to adaptors | Operation management of appliances | load request |

| 9 | UAC sends load request to AC | Load request | direct consumption, indirect consumption, operational status |

| 10 | Comfort Context set comfort boundaries | Meet customer preferences | environmental conditions, operational status |

| 11 | DNO provides excess capacity | Excess capacity is delivered | Required capacity |

| Unsafe Control Actions | ||||

|---|---|---|---|---|

| Control Action | Not Given | Provided Incorrectly | Wrong Timing or Order | Stopped Too Soon or Applied Too Long |

| excess capacity demand | DRM does not demand excess capacity while there is a need to cover more loads (2, 3) | DRM demands more excess capacity than the actual required capacity for appliances to operate in the defined time horizon ahead (1) | DRM demands excess capacity too late (>TBD) after request (2, 3) | DRM stops Demanding for excess capacity while overload still remains (2,3) |

| DRM demands less excessive capacity than the actual required capacity for appliances to operate in the defined time horizon ahead (2,3) | ||||

| DRM demands excessive capacity while the appliances can operate sufficiently in the defined time horizon ahead (1) | ||||

| provide the capacity limits | DRM does not provide capacity limits when these have been modified (2, 3) | DRM provides capacity limits other than these required (1, 2, 3) | DRM provides capacity limits too late (>TBD) after the capacity change (1, 2, 3) | |

| predict required loads | LF does not provide accurate load prediction while there is a change to the load schedule (2, 3) | LF makes an inaccurate load prediction while appliances operation requirements can be met sufficiently according to the schedule (1) | LF provides a load prediction too late (>TBD) after the change on the load schedule (2, 3) | |

| accept load request | AC does not response while there is a request for an appliance to operate (2, 3) | AC accepts load requests while it cannot be covered by the available capacity (1, 2, 3) | AC accepts load request too late (>TBD) after the received request (2, 3) | |

| AC accepts load request while there is another request with higher priority (2, 3) | ||||

| reject load request | AC does not response while there is a request for an appliance to operate (2, 3) | AC rejects load request while it can be covered by the available capacity (2, 3) | AC rejects load request too late (>TBD) after the received request (2, 3) | |

| send operational status (start/stop/Synch. clock) commands | UAC does not send actuation demand while the appliance must start operating (2, 3) | UAC sends appliance operational content different from the actual appliance status (1, 2, 3) | UAC sends too late (>TBD) secs the status after it has been changed (1, 2, 3) | |

| send load requests | UAC does not send load requests while an appliance must start operating (2, 3) | UAC send load requests for another appliance instead of the appliance must start operating (2, 3) | UAC stops sending load requests for an appliance while its request is not accepted yet (2, 3) | |

| set comfort boundaries | Context Module does not adjust comfort boundaries taking into account environmental conditions (3) | Comfort Context set comfort boundaries not in line with user preferences (3) | Comfort Context adjust comfort boundaries too late(>TBD) after preferences are modified (3) | Comfort Context stops adjusting comfort boundaries although preferences change (3) |

| Comfort Context set comfort boundaries not inline to the actual env. conditions (3) | Comfort Context adjust comfort boundaries too late(>TBD) secs after environmental conditions change (3) | Comfort Context stops adjusting comfort boundaries although conditions change (3) | ||

| schedule load requests | LB schedule loads with total power consumption at each time frame more than the given capacity limit (1) | |||

| LB schedules a load to start while it should not according to the corresponding appliance operational status (1) | ||||

| LB schedule loads with total power consumption at each time frame less than the given capacity limit (2, 3) | LB schedules a load prior to the one with higher priority. (2, 3) | |||

| LB schedules a load that cannot be covered by the capacity at the specific defined time (2, 3) | LB schedules a load prior to the one to which is dependent (2, 3) | |||

| Each appliance load is scheduled in an operation period in such a way that appliance is operated for less than the required time to complete an operational cycle (2, 3) | ||||

| Each load is scheduled more than one time (1) | ||||

| No. | Unsafe Control Actions | Resulting Safety Constraints |

|---|---|---|

| 1 | DRM does not demand excess capacity while there is a need to cover more loads | DRM must demand excess capacity when there is a need to meet consumption needs |

| 2 | DRM demands more excessive capacity than the actual required for appliances to operate in the defined time horizon ahead | DRM must demand the exact capacity required for the consumption of the appliances to operate efficiently in the defined time frame |

| 3 | DRM demands excess capacity too late (>TBD) after request | DRM must demand excess capacity TBD secs after excessive load is identified |

| 4 | DRM stops demanding for excessive capacity while overload remains | DRM must continue to demand for excessive capacity while there is over consumption in the respective time frame |

| 5 | DRM demands less capacity than the actual required for appliances to operate in the defined time horizon ahead | DRM must demand the required capacity to cover the over-consumption in a time frame |

| 6 | DRM demands excess capacity while the appliances can operate sufficiently in the defined time horizon ahead | DRM must not demand excess capacity while there is no overconsumption in a time frame |

| 7 | DRM does not provide capacity limits when these have been changed | DRM must provide capacity limits when thesehave been modified |

| 8 | DRM provides capacity limits other than the actual | DRM must provide capacity limits based on the actual conditions in premises |

| 9 | DRM provides new capacity limits too late (>TBD) after the capacity change | DRM must provide new capacity limits within TBD secs after capacity change has been identified |

| 10 | LF does not make new load prediction while there is a change to the load schedule | LF must adjust load predictions when there is a load schedule change |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karatzas, S.; Chassiakos, A. System-Theoretic Process Analysis (STPA) for Hazard Analysis in Complex Systems: The Case of “Demand-Side Management in a Smart Grid”. Systems 2020, 8, 33. https://doi.org/10.3390/systems8030033

Karatzas S, Chassiakos A. System-Theoretic Process Analysis (STPA) for Hazard Analysis in Complex Systems: The Case of “Demand-Side Management in a Smart Grid”. Systems. 2020; 8(3):33. https://doi.org/10.3390/systems8030033

Chicago/Turabian StyleKaratzas, Stylianos, and Athanasios Chassiakos. 2020. "System-Theoretic Process Analysis (STPA) for Hazard Analysis in Complex Systems: The Case of “Demand-Side Management in a Smart Grid”" Systems 8, no. 3: 33. https://doi.org/10.3390/systems8030033

APA StyleKaratzas, S., & Chassiakos, A. (2020). System-Theoretic Process Analysis (STPA) for Hazard Analysis in Complex Systems: The Case of “Demand-Side Management in a Smart Grid”. Systems, 8(3), 33. https://doi.org/10.3390/systems8030033