Supply Chain Capability and Performance Under Environmental Uncertainty: The Mediating Role of Multidimensional Resilience

Abstract

1. Introduction

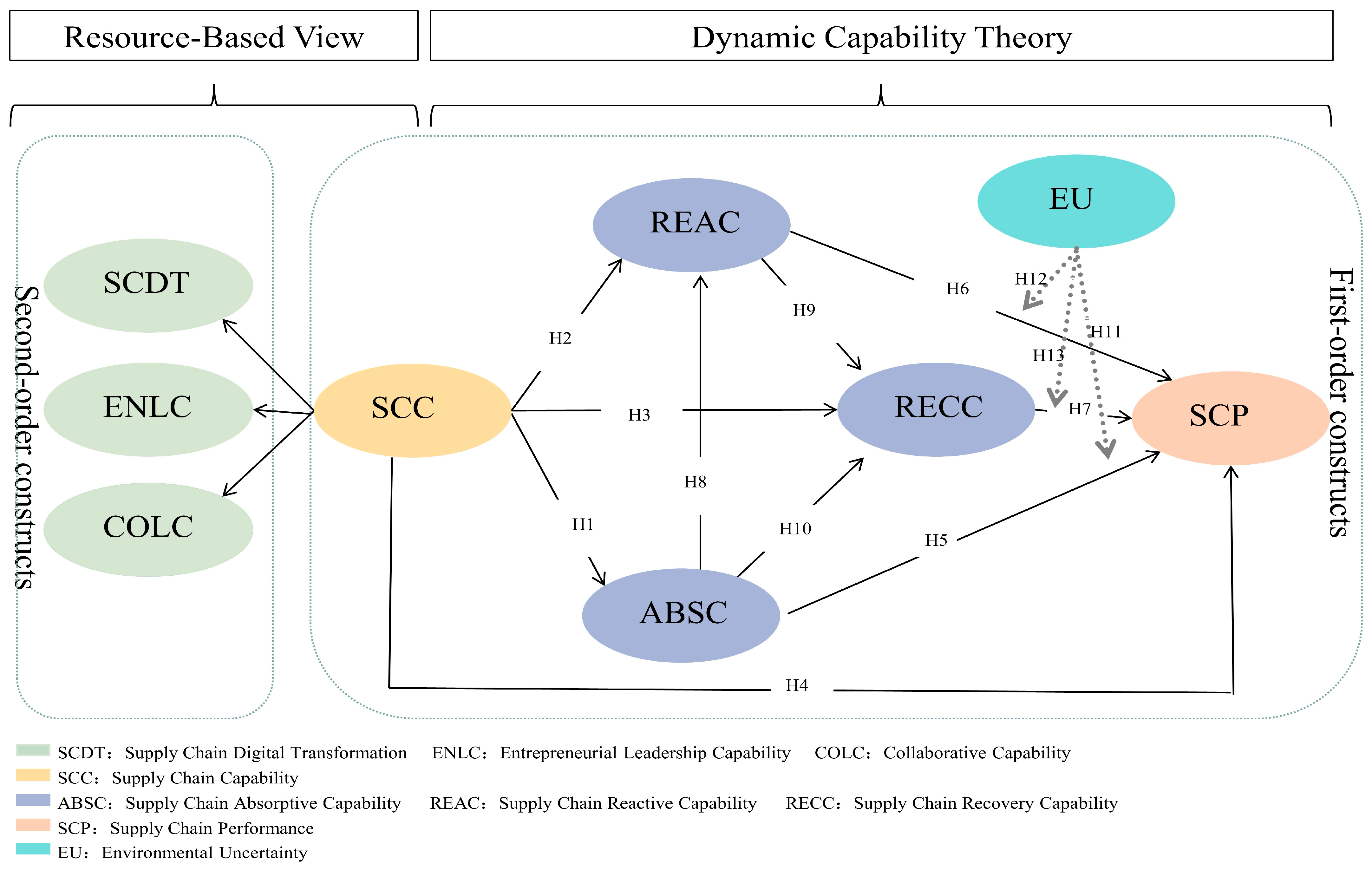

2. Literature Review and Research Hypotheses

2.1. Supply Chain Resilience

2.2. Integration of the Resource-Based View and Dynamic Capability Theory

2.3. Research Hypotheses

3. Methodology

3.1. Questionnaire Management and Sampling Process

3.2. Questionnaire Structure and Distribution

3.3. Common Method Bias

3.4. Demographic Characteristics

4. Results and Discussion

4.1. Confirmatory Factor Analysis

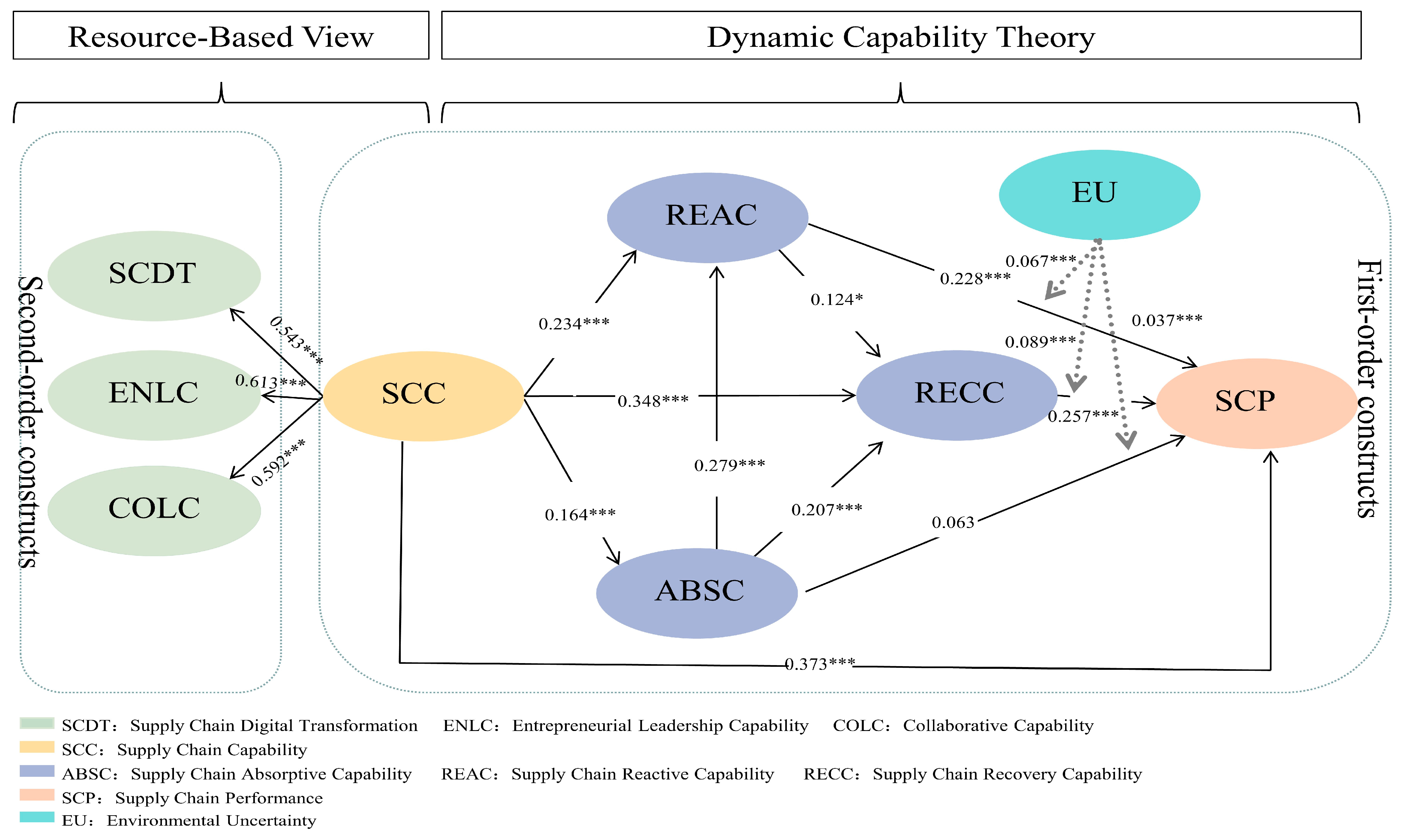

4.2. Structural Model Testing

4.3. Mediating Effects

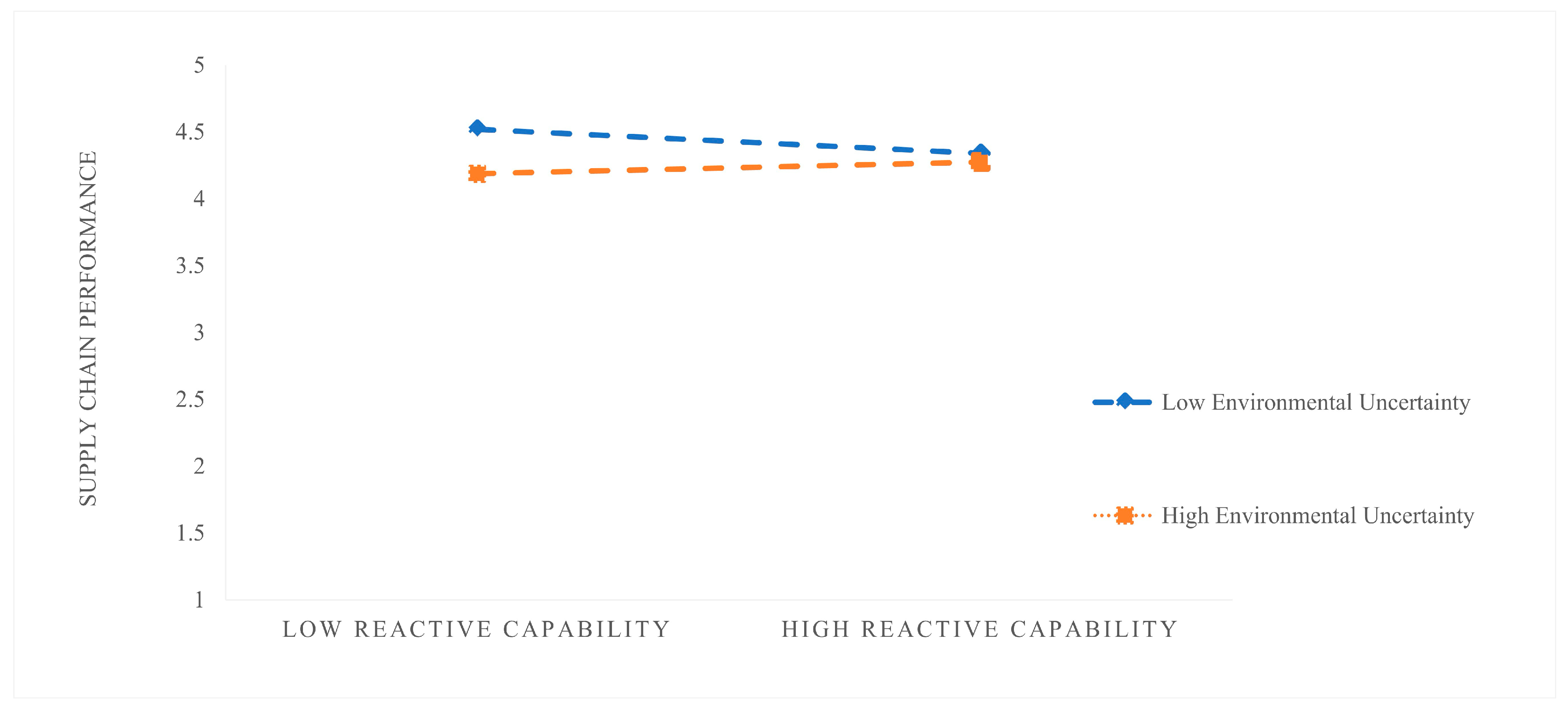

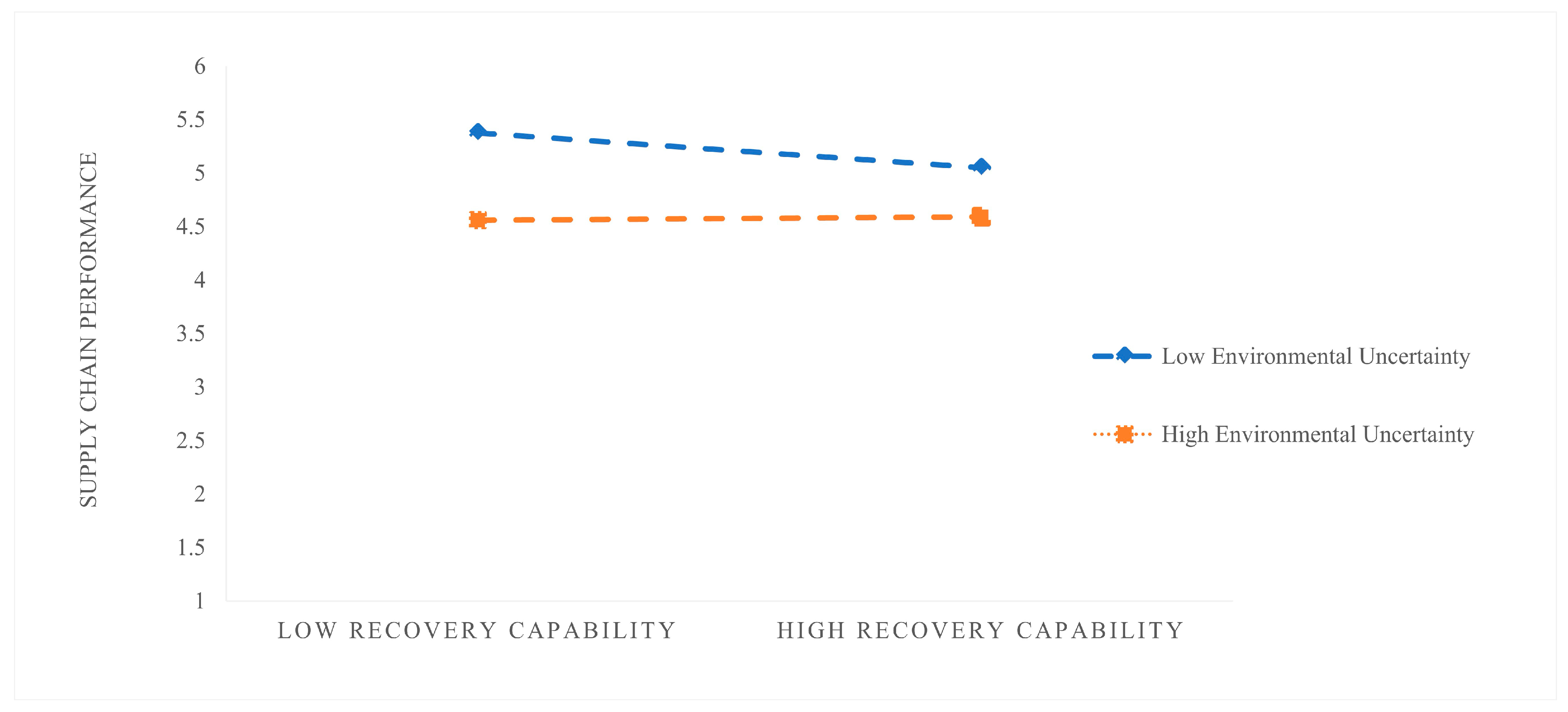

4.4. Moderating Effects

4.5. Discussion of Results

5. Conclusions

5.1. Theoretical Contributions

5.2. Implications for Management

5.3. Limitations and Future Research

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RBV | Resource-based view |

| DCT | Dynamic capability theory |

| SCDT | Supply chain digital transformation |

| ENLC | Entrepreneurial leadership capability |

| COLC | Collaborative capability |

| SCC | Supply chain capability |

| ABSC | Supply chain absorptive capability |

| REAC | Supply chain reactive capability |

| RECC | Supply chain recovery capability |

| SCP | Supply chain performance |

| EU | Environmental uncertainty |

Appendix A

Appendix A.1

| Construct | ID | Measurement | Source |

|---|---|---|---|

| SCDT | SCDT1 | We aim to digitalize everything that can be digitalized | Frank et al., 2019; Nasiri M et al., 2020 [66,67] |

| SCDT2 | We collect large amounts of data from different sources | ||

| SCDT3 | We aim to create stronger networking between the different business processes with digital technologies | ||

| SCDT4 | We aim to enhance an efficient customer interface with digitality | ||

| SCDT5 | We aim at achieving information exchange with digitality | ||

| ENLC | ENLC1 | The leader proposes radical improvements to products and services | Haq M Z, Aslam H, 2023 [68] |

| ENLC2 | The leader generates ideas for entirely new products and services | ||

| ENLC3 | The leader exhibits a willingness for risk-taking in pursuit of innovation | ||

| ENLC4 | The leader develops creative solutions to address challenges | ||

| ENLC5 | The leader demonstrates passion for the company’s mission | ||

| ENLC6 | The leader articulates a vision for the future of the company | ||

| ENLC7 | The leader challenges conventional approaches to encourage innovation | ||

| ENLC8 | The leader questions current business practices to drive change | ||

| COLC1 | We collaborate with key suppliers to accomplish shared objectives | ||

| COLC2 | We jointly establish strategic goals with our supply chain partners | Mandal S et al., 2016; Gani MO et al., 2023 [69,70] | |

| COLC | COLC3 | We equitably distribute both risks and rewards with our supply chain partners | |

| COLC4 | We engage with key supply chain members to achieve mutual advantages | ||

| ABSC1 | We can allocate redundant resources in advance to ensure preparedness before disruptions occur | ||

| ABSC | ABSC2 | We can enhance data transparency to attain a comprehensive level of visibility | Zhao et al., 2023; Liu et al., 2018; Ma, X., 2023 [71,72,73] |

| ABSC3 | We have successfully sustained strong situational awareness and effectively anticipated potential crises | ||

| ABSC4 | We offer employees guidance on the essential actions to implement when facing a risk event | ||

| REAC | REAC1 | We can effectively make informed risk management decisions when disruptions arise | |

| REAC2 | We can swiftly respond to disruptions within the supply chain, ensuring timely mitigation | ||

| REAC3 | We consistently ensure supply chain connectivity and seamless collaboration during disruptions | ||

| REAC4 | We can easily adjust our products and services during supply chain disruptions | ||

| RECC | RECC1 | We can rapidly and effectively restore normal operations following a disruption | |

| RECC2 | Following a disruption, we have successfully reallocated resources and formulated new business strategies to ensure supply chain continuity | ||

| RECC3 | We can derive valuable insights from disruptions and enhance supply chain operations post-disturbance | ||

| RECC4 | We can strategically plan our market focus based on our scale and technological strength after supply chain disruptions | ||

| SCP | SCP1 | We have successfully reduced operational expenses, enhancing cost efficiency | |

| SCP2 | We can enhance investment returns and improve overall financial performance | ||

| SCP3 | We can effectively reduce lead times, enhancing operational efficiency and responsiveness | ||

| SCP4 | We can effectively fulfill customers’ varied product demands, ensuring adaptability and satisfaction | ||

| EU | EU1 | Our customers frequently demand innovative products and services | Wang, L. et al., 2011 [74,75] |

| EU2 | The competitive landscape in our market is constantly evolving | ||

| EU3 | The industry experiences a notably high rate of business failures | ||

| EU4 | Products and services in our market become obsolete at a rapid pace |

References

- Panwar, R.; Pinkse, J.; De Marchi, V. The future of global supply chains in a post-COVID-19 world. Calif. Manag. Rev. 2022, 64, 5–23. [Google Scholar] [CrossRef]

- Grzybowska, K.; Stachowiak, A. Global changes and disruptions in supply chains—Preliminary research to sustainable resilience of supply chains. Energies 2022, 15, 4579. [Google Scholar] [CrossRef]

- Hsu, C.; Zeng, J.; Chang, A.; Cai, S. Deploying Industry 4.0 Enablers to Strengthen Supply Chain Resilience to Mitigate Ripple Effects: An Empirical Study of Top Relay Manufacturer in China. IEEE Access 2022, 10, 114829–114855. [Google Scholar] [CrossRef]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Ivanov, D. Two views of supply chain resilience. Int. J. Prod. Res. 2024, 62, 4031–4045. [Google Scholar] [CrossRef]

- Shen, Z.M.; Sun, Y. Strengthening supply chain resilience during COVID-19: A case study of JD. com. J. Oper. Manag. 2023, 69, 359–383. [Google Scholar] [CrossRef]

- Alikhani, R.; Torabi, S.A.; Altay, N. Retail supply chain network design with concurrent resilience capabilities. Int. J. Prod. Econ. 2021, 234, 108042. [Google Scholar] [CrossRef]

- Sawik, T. Stochastic optimization of supply chain resilience under ripple effect: A COVID-19 pandemic related study. Omega 2022, 109, 102596. [Google Scholar] [CrossRef]

- Dabić, M.; Stojčić, N.; Simić, M.; Potocan, V.; Slavković, M.; Nedelko, Z. Intellectual agility and innovation in micro and small businesses: The mediating role of entrepreneurial leadership. J. Bus. Res. 2021, 123, 683–695. [Google Scholar] [CrossRef]

- Belhadi, A.; Kamble, S.S.; Venkatesh, M.; Jabbour, C.J.C.; Benkhati, I. Building supply chain resilience and efficiency through additive manufacturing: An ambidextrous perspective on the dynamic capability view. Int. J. Prod. Econ. 2022, 249, 108516. [Google Scholar] [CrossRef]

- Yang, M.; Fu, M.; Zhang, Z. The adoption of digital technologies in supply chains: Drivers, process and impact. Technol. Forecast. Soc. Change 2021, 169, 120795. [Google Scholar] [CrossRef]

- Naghshineh, B.; Carvalho, H. The implications of additive manufacturing technology adoption for supply chain resilience: A systematic search and review. Int. J. Prod. Econ. 2022, 247, 108387. [Google Scholar] [CrossRef]

- Hennelly, P.A.; Srai, J.S.; Graham, G.; Fosso Wamba, S. Rethinking supply chains in the age of digitalization. Prod. Plan. Control 2020, 31, 93–95. [Google Scholar] [CrossRef]

- Sawyerr, E.; Harrison, C. Developing resilient supply chains: Lessons from high-reliability organisations. Suppl. Chain Manag. Int. J. 2020, 25, 77–100. [Google Scholar] [CrossRef]

- Maharjan, R.; Kato, H. Resilient supply chain network design: A systematic literature review. Transp. Rev. 2022, 42, 739–761. [Google Scholar] [CrossRef]

- Chowdhury, M.; Quaddus, M. Supply chain resilience: Conceptualization and scale development using dynamic capability theory. Int. J. Prod. Econ. 2017, 188, 185–204. [Google Scholar] [CrossRef]

- Holling, C.S. Resilience and stability of ecological systems. Annu. Rev. Ecol. Syst. 1973, 4, 1–23. [Google Scholar] [CrossRef]

- Hosseini, S.; Ivanov, D.; Dolgui, A. Review of Quantitative Methods for Supply Chain Resilience Analysis. Transp. Res. Part E Logist. Transp. Rev. 2019, 125, 285–307. [Google Scholar] [CrossRef]

- Abourokbah, S.H.; Mashat, R.M.; Salam, M.A. Role of absorptive capacity, digital capability, agility, and resilience in supply chain innovation performance. Sustainability 2023, 15, 3636. [Google Scholar] [CrossRef]

- Kogler, C.; Beiglböck, A.; Rauch, P. An empirical study of the resilience in Austrian wood transport. Transp. Res. Part A Policy Prac. 2025, 191, 104303. [Google Scholar] [CrossRef]

- Drozdibob, A.; Sohal, A.; Nyland, C.; Fayezi, S. Supply chain resilience in relation to natural disasters: Framework development. Prod. Plan. Control 2023, 34, 1603–1617. [Google Scholar] [CrossRef]

- Iftikhar, A.; Ali, I.; Stevenson, M. The silver lining of supply chain complexity: Building supply chain resilience and robustness through exploitation and exploration. Supply Chain Manag. Int. J. 2024, 29, 244–259. [Google Scholar] [CrossRef]

- Peker, I.; Ar, I.M.; Erol, I.; Searcy, C. Leveraging blockchain in response to a pandemic through disaster risk management: An IF-MCDM framework. Oper. Manag. Res. 2023, 16, 642–667. [Google Scholar] [CrossRef]

- Wieland, A.; Wallenburg, C.M. The influence of relational competencies on supply chain resilience: A relational view. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 300–320. [Google Scholar] [CrossRef]

- Leoni, L.; Ferraro, S.; Cantini, A.; Rinaldi, R.; De Carlo, F. MaMoReS: A Robust Tool for Evaluating Supply Chain Resilience Through Systematic Literature and Network Analysis. Appl. Sci. 2024, 14, 9568. [Google Scholar] [CrossRef]

- Bag, S.; Rahman, M.S.; Chiarini, A. Building Sustainable Supply Chain Resilience: Insights from a Mixed-Method Study. Bus. Strateg. Environ. 2025, 34, 2103–2127. [Google Scholar] [CrossRef]

- Zhu, X.; Wu, Y.J. How does supply chain resilience affect supply chain performance? The mediating effect of sustainability. Sustainability 2022, 14, 14626. [Google Scholar] [CrossRef]

- Ferreira, N.C.; Ferreira, J.J. The field of resource-based view research: Mapping past, present and future trends. Manag. Decis. 2025, 63, 1124–1153. [Google Scholar] [CrossRef]

- McDougall, N.; Wagner, B.; MacBryde, J. Leveraging competitiveness from sustainable operations: Frameworks to understand the dynamic capabilities needed to realise NRBV supply chain strategies. Supply Chain Manag. Int. J. 2022, 27, 12–29. [Google Scholar] [CrossRef]

- Stadtfeld, G.M.; Gruchmann, T. Dynamic capabilities for supply chain resilience: A meta-review. Int. J. Logist. Manag. 2024, 35, 623–648. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, H.; Siddik, A.B.; Zheng, Y.; Sobhani, F.A. Understanding corporate green competitive advantage through green technology adoption and green dynamic capabilities: Does green product innovation matter? Systems 2023, 11, 461. [Google Scholar] [CrossRef]

- Kähkönen, A.K.; Evangelista, P.; Hallikas, J.; Immonen, M.; Lintukangas, K. COVID-19 as a trigger for dynamic capability development and supply chain resilience improvement. Int. J. Prod. Res. 2023, 61, 2696–2715. [Google Scholar] [CrossRef]

- Pu, G.; Cui, Z.; Qiao, J. Management antecedents of supply chain resilience: An integrating perspective. J. Conting. Crisis Manag. 2024, 32, e12551. [Google Scholar] [CrossRef]

- Asamoah, D.; Agyei-Owusu, B.; Andoh-Baidoo, F.K.; Ayaburi, E. Inter-organizational systems use and supply chain performance: Mediating role of supply chain management capabilities. Int. J. Inf. Manag. 2021, 58, 102195. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. The evolution of resilience in supply chain management: A retrospective on ensuring supply chain resilience. J. Bus Logist. 2019, 40, 56–65. [Google Scholar] [CrossRef]

- Li, W.; Xiao, X.; Yang, X.; Li, L. How Does Digital Transformation Impact Green Supply Chain Development? An Empirical Analysis Based on the TOE Theoretical Framework. Systems 2023, 11, 416. [Google Scholar] [CrossRef]

- Mutambik, I. The Role of Strategic Partnerships and Digital Transformation in Enhancing Supply Chain Agility and Performance. Systems 2024, 12, 456. [Google Scholar] [CrossRef]

- Rehman, K.U.; Aslam, F.; Mata, M.N.; Martins, J.M.; Abreu, A.; Morão Lourenço, A.; Mariam, S. Impact of entrepreneurial leadership on product innovation performance: Intervening effect of absorptive capacity, intra-firm networks, and design thinking. Sustainability 2021, 13, 7054. [Google Scholar] [CrossRef]

- Hong, J.; Zheng, R.; Deng, H.; Zhou, Y. Green supply chain collaborative innovation, absorptive capacity and innovation performance: Evidence from China. J. Clean. Prod. 2019, 241, 118377. [Google Scholar] [CrossRef]

- Barakat, M.; Wu, J.S.; Tipi, N. Empowering Clusters: How Dynamic Capabilities Drive Sustainable Supply Chain Clusters in Egypt. Sustainability 2023, 15, 16787. [Google Scholar] [CrossRef]

- Alherimi, N.; Saihi, A.; Ben-Daya, M. A Systematic Review of Optimization Approaches Employed in Digital Warehousing Transformation. IEEE Access 2024, 12, 145809–145831. [Google Scholar] [CrossRef]

- Goldsby, T.J.; Kuratko, D.F.; Goldsby, M.G. Developing an entrepreneurial mindset in supply chain managers: Exposing a powerful potential. J. Bus. Logist. 2024, 45, e12372. [Google Scholar] [CrossRef]

- Mustapha, S.A.; Agha, M.S.A.; Masood, T. The role of collaborative resource sharing in supply chain recovery during disruptions: A systematic literature review. IEEE Access 2022, 10, 115603–115623. [Google Scholar] [CrossRef]

- Rezaei, S.; Behnamian, J. A survey on competitive supply networks focusing on partnership structures and virtual alliance: New trends. J. Clean. Prod. 2021, 287, 125031. [Google Scholar] [CrossRef]

- Gaudenzi, B.; Pellegrino, R.; Confente, I. Achieving supply chain resilience in an era of disruptions: A configuration approach of capacities and strategies. Supply Chain Manag. Int. J. 2023, 28, 97–111. [Google Scholar] [CrossRef]

- Stentoft, J.; Mikkelsen, O.S.; Wickstrøm, K.A. Supply chain resilience and absorptive capacity: Crisis mitigation and performance effects during Covid-19. Supply Chain Manag. Int. J. 2023, 28, 975–992. [Google Scholar] [CrossRef]

- Roh, J.; Tokar, T.; Swink, M.; Williams, B. Supply chain resilience to low-/high-impact disruptions: The influence of absorptive capacity. Int. J. Logist. Manag. 2022, 33, 214–238. [Google Scholar] [CrossRef]

- Sardana, D.; Terziovski, M.; Gupta, N. impact of strategic alignment and responsiveness to market on manufacturing firm’s performance. Int. J. Prod. Econ. 2016, 177, 131–138. [Google Scholar] [CrossRef]

- Jafari, M.; Khanachah, S.N.; Akhavan, P. Horizontal integration through knowledge sharing in the supply chain under uncertainty. IEEE Trans. Eng. Manag. 2024, 71. [Google Scholar] [CrossRef]

- Ma, S.; He, Y.; Gu, R. Low-carbon tourism supply chain network optimisation with vertical and horizontal cooperations. Int. J. Prod. Res. 2023, 61, 6251–6270. [Google Scholar] [CrossRef]

- Rasoulian, S.; Grégoire, Y.; Legoux, R.; Sénécal, S. Service crisis recovery and firm performance: Insights from information breach announcements. J. Acad. Mark. Sci. 2017, 45, 789–806. [Google Scholar] [CrossRef]

- Phan, V.D.V.; Huang, Y.F.; Hoang, T.T.; Do, M.H. Evaluating barriers to supply chain resilience in vietnamese SMEs: The fuzzy VIKOR approach. Systems 2023, 11, 121. [Google Scholar] [CrossRef]

- Liu, H.M.; Yang, H.F. Managing network resource and organizational capabilities to create competitive advantage for SMEs in a volatile environment. J. Small Bus. Manag. 2019, 57, 155–171. [Google Scholar] [CrossRef]

- Paul, S.K.; Sarker, R.; Essam, D. A reactive mitigation approach for managing supply disruption in a three-tier supply chain. J. Intell. Manuf. 2018, 29, 1581–1597. [Google Scholar] [CrossRef]

- Cheong, S.M.; Assenova, V.A. Absorptive capacity facilitates adaptation to novel environmental disasters. PLoS ONE 2021, 16, e0259368. [Google Scholar] [CrossRef] [PubMed]

- Katsaliaki, K.; Galetsi, P.; Kumar, S. Supply chain disruptions and resilience: A major review and future research agenda. Ann. Oper. Res. 2022, 319, 965–1002. [Google Scholar] [CrossRef] [PubMed]

- Shekarian, M.; Mellat Parast, M. An Integrative approach to supply chain disruption risk and resilience management: A literature review. Int. J. Logist. Res. Appl. 2021, 24, 427–455. [Google Scholar] [CrossRef]

- Nayal, K.; Raut, R.D.; Queiroz, M.M.; Priyadarshinee, P. Digital supply chain capabilities: Mitigating disruptions and leveraging competitive advantage under COVID-19. IEEE Trans. Eng. Manag. 2023, 71, 10441–10454. [Google Scholar] [CrossRef]

- Huo, B.; Haq, M.Z.U.; Gu, M. The impact of information sharing on supply chain learning and flexibility performance. Int. J. Prod. Res. 2021, 59, 1411–1434. [Google Scholar] [CrossRef]

- Wang, X.; Sun, M. Enhancing SMEs resilience through digital innovation: A stage-based analysis. Eur. J. Innov. Manag. 2024. [Google Scholar] [CrossRef]

- Lyu, T.; Geng, Q.; Yu, D. Research on the relationship between network insight, supply chain integration and enterprise performance. Systems 2022, 11, 10. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S. Supply Chain Integration Capability, Intra-Cluster Co-Opetition Strategy, and Breakthrough Innovation: The Moderating Effect of Environmental Turbulence. Systems 2024, 12, 455. [Google Scholar] [CrossRef]

- Flynn, B.B.; Sakakibara, S.; Schroeder, R.G.; Bates, K.A.; Flynn, E.J. Empirical research methods in operations management. J. Oper. Manag. 1990, 9, 250–284. [Google Scholar] [CrossRef]

- Wong, C.Y.; Boon-itt, S.; Wong, C.W. The contingency effects of environmental uncertainty on the relationship between supply chain integration and operational performance. J. Oper. Manag. 2020, 66, 406–421. [Google Scholar] [CrossRef]

- Frank, A.G.; Mendes, G.H.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Change 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Nasiri, M.; Ukko, J.; Saunila, M.; Rantala, T. Managing the digital supply chain: The role of smart technologies. Technovation 2020, 96, 102121. [Google Scholar] [CrossRef]

- Haq, M.Z.U.; Aslam, H. Impact of entrepreneurial leadership on supply chain performance: The mediating role of supply chain resilience. J. Manuf. Technol. Manag. 2023, 34, 694–712. [Google Scholar] [CrossRef]

- Mandal, S.; Sarathy, R.; Korasiga, V.R.; Bhattacharya, S.; Dastidar, S.G. Achieving supply chain resilience: The contribution of logistics and supply chain capabilities. Int. J. Disaster Resil. Built Environ. 2016, 7, 544–562. [Google Scholar] [CrossRef]

- Gani, M.O.; Takahashi, Y.; Bag, S.; Rahman, M.S. Firms’ dynamic capabilities and supply chain risk management: A B2B perspective. Benchmarking Int. J. 2023, 30, 4119–4139. [Google Scholar] [CrossRef]

- Zhao, N.; Hong, J.; Lau, K.H. Impact of supply chain digitalization on supply chain resilience and performance: A multi-mediation model. Int. J. Prod. Econ. 2023, 259, 108817. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.L.; Shang, K.C.; Lirn, T.C.; Lai, K.H.; Lun, Y.V. Supply chain resilience, firm performance, and management policies in the liner shipping industry. Transp. Res. Part A Policy Pract. 2018, 110, 202–219. [Google Scholar] [CrossRef]

- Ma, X.; Huang, M.; Yang, M. Study on influencing factors of supply chain resilience: Based on SEM and fsQCA methods. Syst. Eng. Theory Pract. 2023, 9, 2484–2501. [Google Scholar]

- Bstieler, L. The moderating effect of environmental uncertainty on new product development and time efficiency. J. Prod. Innov. Manag. 2005, 22, 267–284. [Google Scholar] [CrossRef]

- Wang, L.; Yeung, J.H.Y.; Zhang, M. The impact of trust and contract on innovation performance: The moderating role of environmental uncertainty. Int. J. Prod. Econ. 2011, 134, 114–122. [Google Scholar] [CrossRef]

- Xue, J.; Li, G.; Ivanov, D. Digital transformation in the blockchain era: Balancing efficiency and resilience in operations management. Int. J. Prod. Econ. 2025, 282, 109525. [Google Scholar] [CrossRef]

- Gottfried, J. Practices in data-quality evaluation: A large-scale review of online survey studies published in 2022. Adv. Methods Pract. Psychol. Sci. 2024, 7, 25152459241236414. [Google Scholar] [CrossRef]

- Kline, R.B. The mediation myth. Basic Appl. Soc. Psychol. 2015, 37, 202–213. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879. [Google Scholar] [CrossRef] [PubMed]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Byrne, B.M.; Shavelson, R.J.; Muthén, B. Testing for the equivalence of factor covariance and mean structures: The issue of partial measurement invariance. Psychol. Bull. 1989, 105, 456. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Structural equation models with unobservable variables and measurement error: Algebra and statistics. J. Market. Res. 1981, 18, 382–388. [Google Scholar] [CrossRef]

- Hu, L.T.; Bentler, P.M. Cutoff criteria for fit indexes in covariance structure analysis: Conventional criteria versus new alternatives. Struct. Equ. Model. A Multidiscip. J. 1999, 6, 1–55. [Google Scholar] [CrossRef]

- O’brien, R.M. A caution regarding rules of thumb for variance inflation factors. Qual. Quant. 2007, 41, 673–690. [Google Scholar] [CrossRef]

- Saenz, M.J.; Revilla, E.; Knoppen, D. Absorptive capacity in buyer–supplier relationships: Empirical evidence of its mediating role. J. Supply Chain Manag. 2014, 50, 18–40. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chaudhuri, R.; Vrontis, D. Examining the impact of adoption of emerging technology and supply chain resilience on firm performance: Moderating role of absorptive capacity and leadership support. IEEE Trans. Eng. Manag. 2022, 71, 10373–10386. [Google Scholar] [CrossRef]

- Negri, M.; Cagno, E.; Colicchia, C.; Sarkis, J. Integrating sustainability and resilience in the supply chain: A systematic literature review and a research agenda. Bus. Strateg. Environ. 2021, 30, 2858–2886. [Google Scholar] [CrossRef]

- Yadav, U.S.; Tripathi, R. Impact of innovation, entrepreneurial orientation and entrepreneurial leadership on supply chain resilience in handicraft industry: Moderating role of supply chain orientation. Benchmark. Int. J. 2025, 32, 1559–1601. [Google Scholar] [CrossRef]

- Cotta, D.; Klink, L.; Alten, T.; Al Madhoon, B. How do supply chain managers perceive the relationship between resilience and sustainability practices? An exploratory study. Bus. Strateg. Environ. 2023, 32, 3737–3751. [Google Scholar] [CrossRef]

- Cui, L.; Jin, Z.; Li, Y.; Wang, Y. Effects of control mechanisms on supply chain resilience and sustainability performance. Aust. J. Manag. 2023, 48, 323–340. [Google Scholar] [CrossRef]

- Gu, M.; Yang, L.; Huo, B. The impact of information technology usage on supply chain resilience and performance: An ambidexterous view. Int. J. Prod. Econ. 2021, 232, 107956. [Google Scholar] [CrossRef] [PubMed]

- Al-Swidi, A.K.; Al-Hakimi, M.A.; Al-Hosam, A.; Al Koliby, I.S. When does entrepreneurial leadership enhance supply chain resilience? A three-way interaction analysis. J. Enterp. Inf. Manag. 2024, 37, 1788–1808. [Google Scholar] [CrossRef]

- Mubarik, M.S.; Bontis, N.; Mubarik, M.; Mahmood, T. Intellectual capital and supply chain resilience. J. Intellect. Cap. 2022, 23, 713–738. [Google Scholar] [CrossRef]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Yamin, M.A. Investigating the drivers of supply chain resilience in the wake of the COVID-19 pandemic: Empirical evidence from an emerging economy. Sustainability 2021, 13, 11939. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. Cloud supply chain: Integrating Industry 4.0 and digital platforms in the “Supply Chain-as-a-Service”. Transp. Res. Part E Logist. Transp. Rev. 2022, 160, 102676. [Google Scholar] [CrossRef]

- Bahrami, M.; Shokouhyar, S. The role of big data analytics capabilities in bolstering supply chain resilience and firm performance: A dynamic capability view. Inf. Technol. People 2022, 35, 1621–1651. [Google Scholar] [CrossRef]

- Wehrle, M.; Lechler, S.; von der Gracht, H.A.; Hartmann, E. Digitalization and its Impact on the Future Role of SCM Executives in Talent Management–An international cross-industry Delphi study. J. Bus. Logist. 2020, 41, 356–383. [Google Scholar] [CrossRef]

- Cohen, M.; Cui, S.; Doetsch, S.; Ernst, R.; Huchzermeier, A.; Kouvelis, P.; Tsay, A.A. Bespoke supply-chain resilience: The gap between theory and practice. J. Oper. Manag. 2022, 68, 515–531. [Google Scholar] [CrossRef]

- Aslam, H.; Khan, A.Q.; Rashid, K.; Rehman, S.U. Achieving supply chain resilience: The role of supply chain ambidexterity and supply chain agility. J. Manuf. Technol. Manag. 2020, 31, 1185–1204. [Google Scholar] [CrossRef]

- Polyviou, M.; Wiedmer, R.; Chae, S.; Rogers, Z.S.; Mena, C. To concentrate or to diversify the supply base? Implications from the US apparel supply chain during the COVID-19 pandemic. J. Bus. Logist. 2023, 44, 502–527. [Google Scholar] [CrossRef]

| Construct | Item | Mean | SD | Factor Loading | Cronbach’s Alpha | AVE | CR | |

|---|---|---|---|---|---|---|---|---|

| SCC | SCDT | SCDT1 | 3.98 | 1.809 | 0.808 | 0.913 | 0.678 | 0.913 |

| SCDT2 | 3.91 | 1.79 | 0.822 | |||||

| SCDT3 | 3.99 | 1.825 | 0.821 | |||||

| SCDT4 | 3.99 | 1.865 | 0.828 | |||||

| SCDT5 | 3.96 | 1.866 | 0.839 | |||||

| ENLC | ENLC1 | 3.7 | 1.843 | 0.843 | 0.956 | 0.733 | 0.956 | |

| ENLC2 | 3.69 | 1.806 | 0.865 | |||||

| ENLC3 | 3.69 | 1.784 | 0.844 | |||||

| ENLC4 | 3.6 | 1.881 | 0.876 | |||||

| ENLC5 | 3.84 | 1.893 | 0.779 | |||||

| ENLC6 | 3.65 | 1.863 | 0.894 | |||||

| ENLC7 | 3.68 | 1.805 | 0.878 | |||||

| ENLC8 | 3.74 | 1.821 | 0.863 | |||||

| COLC | COLC1 | 4.05 | 1.737 | 0.725 | 0.838 | 0.565 | 0.838 | |

| COLC2 | 4.03 | 1.717 | 0.753 | |||||

| COLC3 | 4.1 | 1.722 | 0.761 | |||||

| COLC4 | 4.06 | 1.715 | 0.766 | |||||

| ABSC | ABSC1 | 3.97 | 1.817 | 0.736 | 0.838 | 0.565 | 0.839 | |

| ABSC2 | 3.95 | 1.835 | 0.781 | |||||

| ABSC3 | 4.02 | 1.8 | 0.74 | |||||

| ABSC4 | 3.96 | 1.852 | 0.749 | |||||

| REAC | REAC1 | 4 | 1.806 | 0.733 | 0.831 | 0.551 | 0.831 | |

| REAC2 | 3.97 | 1.834 | 0.772 | |||||

| REAC3 | 4.04 | 1.778 | 0.718 | |||||

| REAC4 | 3.98 | 1.842 | 0.746 | |||||

| RECC | RECC1 | 4.59 | 1.732 | 0.74 | 0.853 | 0.593 | 0.853 | |

| RECC2 | 4.53 | 1.743 | 0.785 | |||||

| RECC3 | 4.47 | 1.724 | 0.784 | |||||

| RECC4 | 4.57 | 1.718 | 0.77 | |||||

| SCP | SCP1 | 5.09 | 1.547 | 0.756 | 0.837 | 0.563 | 0.837 | |

| SCP2 | 4.99 | 1.449 | 0.716 | |||||

| SCP3 | 5.03 | 1.552 | 0.762 | |||||

| SCP4 | 5.04 | 1.528 | 0.765 | |||||

| EU | EU1 | 4.64 | 1.664 | 0.792 | 0.894 | 0.678 | 0.894 | |

| EU2 | 4.59 | 1.718 | 0.823 | |||||

| EU3 | 4.58 | 1.7 | 0.841 | |||||

| EU4 | 4.6 | 1.71 | 0.836 | |||||

| SDTC | ENLC | COLC | ABSC | REAC | RECC | SCP | EU | |

|---|---|---|---|---|---|---|---|---|

| SDTC | 0.823 | |||||||

| ENLC | 0.303 | 0.856 | ||||||

| COLC | 0.368 | 0.39 | 0.752 | |||||

| ABSC | 0.114 | 0.131 | 0.04 | 0.752 | ||||

| REAC | 0.198 | 0.169 | 0.161 | 0.329 | 0.742 | |||

| RECC | 0.249 | 0.3 | 0.239 | 0.218 | 0.306 | 0.77 | ||

| SCP | 0.312 | 0.386 | 0.296 | 0.25 | 0.447 | 0.516 | 0.75 | |

| EU | 0.176 | 0.244 | 0.209 | 0.116 | 0.21 | 0.44 | 0.307 | 0.823 |

| Hypotheses | Constructs | Standardized Estimate | S.E. | C.R. | p | Hypothesis Supported |

|---|---|---|---|---|---|---|

| H1 | SCC → ABSC | 0.164 | 0.293 | 4.754 | *** | Supported |

| H2 | SCC → REAC | 0.234 | 0.086 | 3.799 | *** | Supported |

| H3 | SCC → RECC | 0.348 | 0.089 | 5.247 | *** | Supported |

| H4 | SCC → SCP | 0.373 | 0.085 | 5.422 | *** | Supported |

| H5 | ABSC → SCP | 0.063 | 0.039 | 1.379 | / | Not Supported |

| H6 | REAC → SCP | 0.228 | 0.042 | 4.847 | *** | Supported |

| H7 | RECC → SCP | 0.257 | 0.047 | 4.999 | *** | Supported |

| H8 | ABSC → REAC | 0.279 | 0.048 | 5.522 | *** | Supported |

| H9 | REAC → RECC | 0.124 | 0.048 | 2.485 | * | Supported |

| H10 | ABSC → RECC | 0.207 | 0.046 | 4.161 | *** | Supported |

| Second-order constructs | SCDT | 0.543 | 0.104 | 7.967 | *** | Supported |

| ENLC | 0.613 | 0.161 | 7.939 | *** | Supported | |

| COLC | 0.592 | 0.098 | 7.939 | *** | Supported |

| Hypotheses | Constructs | Standardized Estimate | Lower | Upper | p | Percentage of Effect (%) |

|---|---|---|---|---|---|---|

| Direct effect | ||||||

| H4 | SCC → SCP | 0.373 | 0.258 | 0.492 | ** | 64.421 |

| Indirect effect | ||||||

| H1a | SCC → ABSC → SCP | 0.018 | −0.01 | 0.047 | / | |

| H2a | SCC → REAC → SCP | 0.053 | 0.029 | 0.089 | *** | 9.154 |

| H3a | SCC → RECC → SCP | 0.089 | 0.031 | 0.096 | ** | 15.371 |

| H1b | SCC → ABSC → REAC → SCP | 0.019 | 0.01 | 0.034 | ** | 3.282 |

| H1c | SCC → ABSC → RECC → SCP | 0.016 | 0.007 | 0.03 | *** | 2.763 |

| H3b | SCC → REAC → RECC → SCP | 0.007 | 0.002 | 0.017 | ** | 1.209 |

| H1d | SCC → ABSC → REAC → RECC → SCP | 0.003 | 0.001 | 0.007 | ** | 0.518 |

| Total indirect effect | 0.206 | 0.126 | 0.235 | *** | 35.579 | |

| Total effect | 0.579 | 0.486 | 0.664 | ** | 100 |

| Hypotheses | Variable | Coeff | SE | T | p-Value | LLCI | ULCI |

|---|---|---|---|---|---|---|---|

| H11 | ABSC × EU → SCP | 0.0372 | 0.0215 | 1.7324 | 0.0837 | −0.005 | 0.0794 |

| H12 | REAC × EU → SCP | 0.0667 | 0.0221 | 3.0184 | 0.0026 | 0.0233 | 0.1101 |

| H13 | RECC × EU → SCP | 0.0891 | 0.0247 | 3.6078 | 0.0003 | 0.0406 | 0.1376 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Liu, Y.; Li, J. Supply Chain Capability and Performance Under Environmental Uncertainty: The Mediating Role of Multidimensional Resilience. Systems 2025, 13, 618. https://doi.org/10.3390/systems13080618

Wang J, Liu Y, Li J. Supply Chain Capability and Performance Under Environmental Uncertainty: The Mediating Role of Multidimensional Resilience. Systems. 2025; 13(8):618. https://doi.org/10.3390/systems13080618

Chicago/Turabian StyleWang, Jiaqi, Yanfeng Liu, and Jing Li. 2025. "Supply Chain Capability and Performance Under Environmental Uncertainty: The Mediating Role of Multidimensional Resilience" Systems 13, no. 8: 618. https://doi.org/10.3390/systems13080618

APA StyleWang, J., Liu, Y., & Li, J. (2025). Supply Chain Capability and Performance Under Environmental Uncertainty: The Mediating Role of Multidimensional Resilience. Systems, 13(8), 618. https://doi.org/10.3390/systems13080618