Research on the Evaluation and Selection of AIoT Suppliers from an ESG Perspective

Abstract

1. Introduction

2. The Evaluation and Selection of AIoT Suppliers

2.1. The Connotation of AIoT Suppliers

- (a)

- Hardware Manufacturing: Producing sensors, embedded chips, smart devices (e.g., intelligent cameras, robots), and other equipment. Such hardware often features environmental sensing, data collection, and communication with cloud platforms or other devices.

- (b)

- Software Development: Designing AI algorithms, machine learning models, data analytics platforms, IoT operating systems, and related applications. This software usually processes data collected from IoT devices and further employs AI for intelligent analysis and decision-making support.

- (c)

- System Integration: Combining diverse hardware devices and software platforms to deliver turnkey solutions like smart logistics, smart warehousing, and smart manufacturing applications.

- (d)

- Service Provision: Offering professional services such as technical support, system maintenance, and data analytics, which will be able to help clients maximize the value of AIoT technologies.

2.2. Supplier Evaluation and Selection

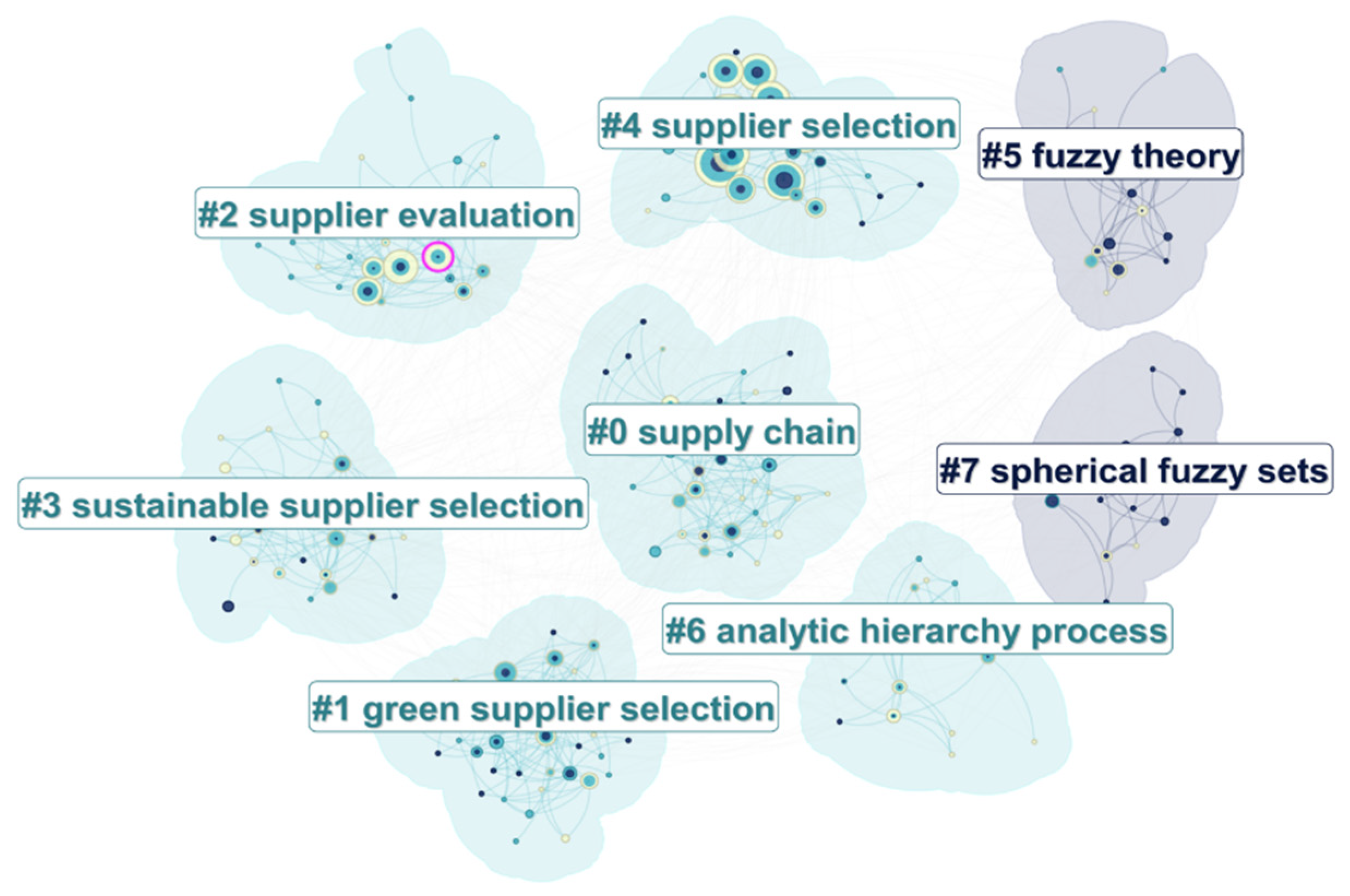

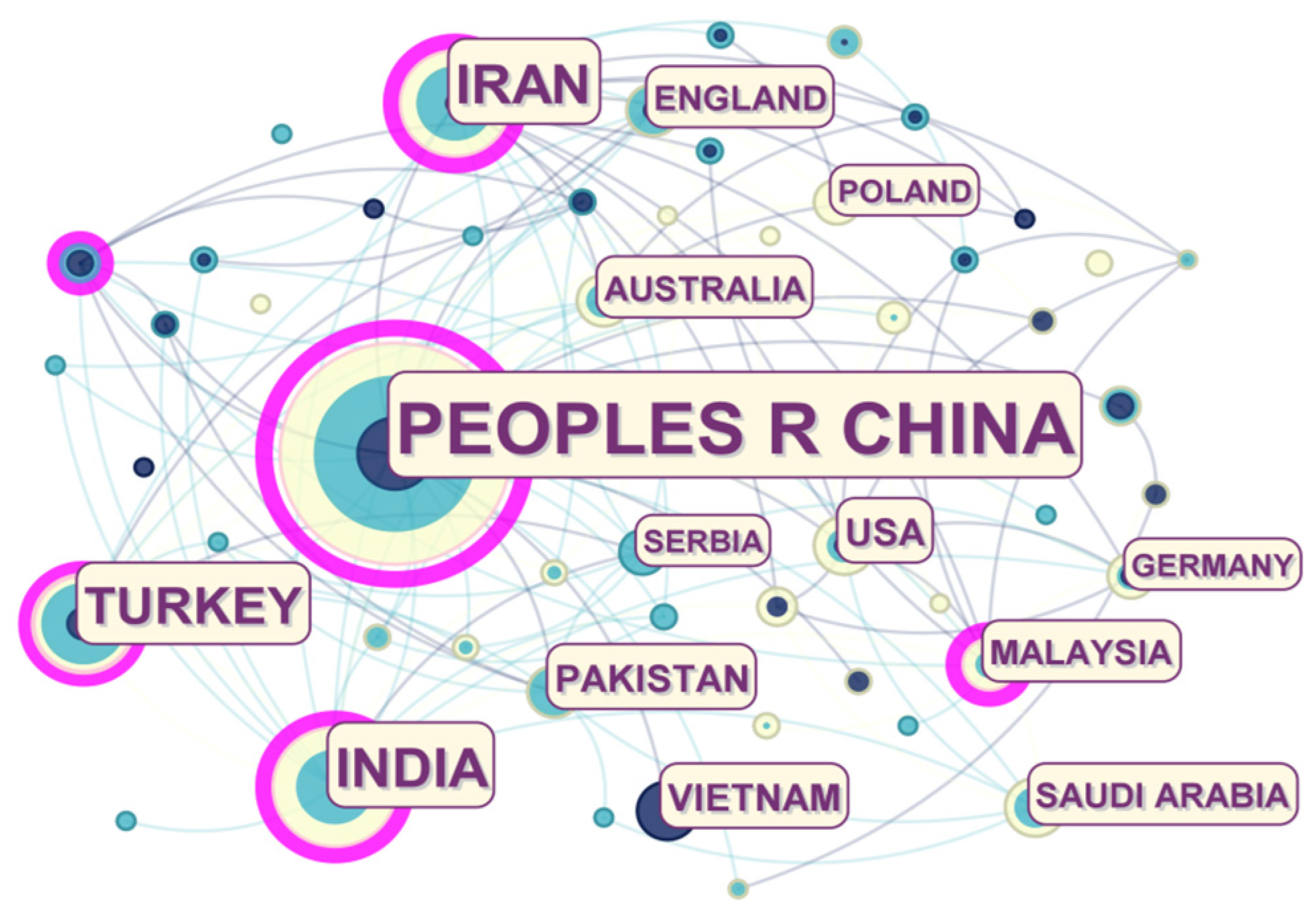

2.2.1. Bibliometric Analysis

2.2.2. Literature Summary

2.3. Evaluation Criteria for AIoT Supplier

3. The Impact of ESG Standards on Supplier Evaluation

3.1. Environmental Influence

3.2. Social Responsibility

- (a)

- Workplace Safeguards: Ensuring occupational health and safety standards, comprehensive employee training, and rigorous management of workplace hazards with emergency protocols.

- (b)

- Labor Ethics: Prohibiting forced or child labor while enforcing non-discrimination and pay equity policies.

- (c)

- Employee Welfare: Mandating transparent compensation systems and guaranteed benefits.

3.3. Governance

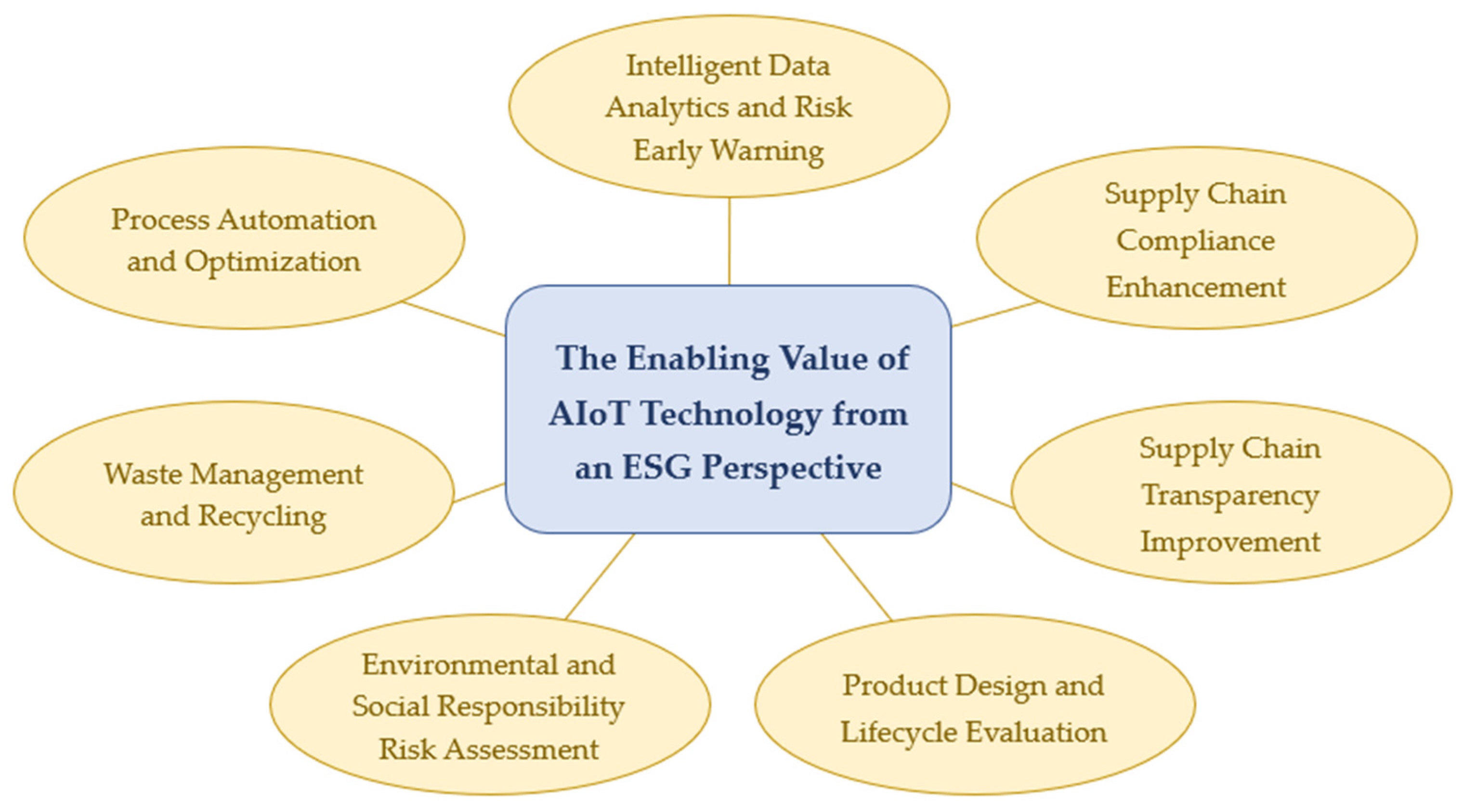

4. The Enabling Value of AIoT Technology from an ESG Perspective: A Case Study of the NEV Industry

4.1. Intelligent Data Analytics and Risk Early Warning

4.2. Process Automation and Optimization

4.3. Waste Management and Recycling

4.4. Environmental and Social Responsibility Risk Assessment

4.5. Product Design and Lifecycle Evaluation

4.6. Supply Chain Transparency Improvement

- (a)

- Enabling cross-verification of business information across supply chain nodes;

- (b)

- Supporting precise tracking of material provenance, manufacturing processes, logistics, and inventory management;

- (c)

- Establishing interconnected audit trails throughout operational workflows [48].

4.7. Supply Chain Compliance Enhancement

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, N.; Pan, H.; Feng, Y.; Du, S. How do ESG practices create value for businesses? Research review and prospects. Sustain. Account. Manag. Policy J. 2024, 15, 1155–1177. [Google Scholar] [CrossRef]

- Li, Y.; Tsang, Y.P.; Lee, C.K.M.; Wu, C.H. Multi-criteria group decision analytics for sustainable supplier relationship management in a focal manufacturing company. J. Clean. Prod. 2024, 476, 143690. [Google Scholar] [CrossRef]

- Govindan, K.; Aditi; Kaul, A.; Darbari, J.D.; Jha, P.C. Analysis of supplier evaluation and selection strategies for sustainable collaboration: A combined approach of best–worst method and TOmada de Decisao Interativa Multicriterio. Bus. Strategy Environ. 2023, 32, 4426–4447. [Google Scholar] [CrossRef]

- Aliahmadi, A.; Nozari, H.; Ghahremani-Nahr, J. AIoT-based sustainable smart supply chain framework. Int. J. Innov. Manag. Econ. Soc. Sci. 2022, 2, 28–38. [Google Scholar] [CrossRef]

- Mulligan, C.; Morsfield, S.; Cheikosman, E. Blockchain for sustainability: A systematic literature review for policy impact. Telecommun. Policy 2024, 48, 102676. [Google Scholar] [CrossRef]

- Chen, M.C.; Pang, S.S.; Su, S.Y. Sustainable global semiconductor supply chain network design considering ESG. Technol. Soc. 2025, 81, 102829. [Google Scholar] [CrossRef]

- Nozari, H.; Szmelter-Jarosz, A.; Ghahremani-Nahr, J. Analysis of the challenges of Artificial Intelligence of Things (AIoT) for the smart supply chain (Case study: FMCG industries). Sensors 2022, 22, 2931. [Google Scholar] [CrossRef]

- Muhammed, D.; Ahvar, E.; Ahvar, S.; Trocan, M.; Montpetit, M.J.; Ehsani, R. Artificial Intelligence of Things (AIoT) for smart agriculture: A review of architectures, technologies and solutions. J. Netw. Comput. Appl. 2024, 228, 103905. [Google Scholar] [CrossRef]

- Xu, X.; Gu, J.; Yan, H.; Liu, W.; Qi, L.; Zhou, X. Reputation-Aware supplier assessment for blockchain-enabled supply chain in Industry 4.0. IEEE Trans. Ind. Inform. 2023, 19, 5485–5494. [Google Scholar] [CrossRef]

- Saxena, A.; Singh, R.; Gehlot, A.; Akram, S.V.; Twala, B.; Singh, A.; Montero, E.C.; Priyadarshi, N. Technologies empowered environmental, social, and governance (ESG): An Industry 4.0 landscape. Sustainability 2023, 15, 309. [Google Scholar] [CrossRef]

- Zhao, C.; Zou, X.; Wei, X.; Zhou, X.; Meng, G.; Zhang, M. Mechanical intelligent energy harvesting: From methodology to applications. Adv. Energy Mater. 2023, 13, 2300557. [Google Scholar] [CrossRef]

- Asif, M.; Searcy, C.; Castka, P. ESG and Industry 5.0: The role of technologies in enhancing ESG disclosure. Technol. Forecast. Soc. Change 2023, 195, 122806. [Google Scholar] [CrossRef]

- Hou, K.M.; Diao, X.; Shi, H.; Ding, H.; Zhou, H.; de Vaulx, C. Trends and challenges in AIoT/IIoT/IoT implementation. Sensors 2023, 23, 5074. [Google Scholar] [CrossRef] [PubMed]

- Giri, B.C.; Molla, M.U.; Biswas, P. Pythagorean fuzzy DEMATEL method for supplier selection in sustainable supply chain management. Expert Syst. Appl. 2022, 193, 116396. [Google Scholar] [CrossRef]

- Dang, T.T.; Nguyen, N.A.T.; Nguyen, V.T.T.; Dang, L.T.H. A two-stage multi-criteria supplier selection model for sustainable automotive supply chain under uncertainty. Axioms 2022, 11, 228. [Google Scholar] [CrossRef]

- Chai, N.; Zhou, W.; Jiang, Z. Sustainable supplier selection using an intuitionistic and interval-valued fuzzy MCDM approach based on cumulative prospect theory. Inf. Sci. 2023, 626, 710–737. [Google Scholar] [CrossRef]

- Nguyen, T.L.; Nguyen, P.H.; Pham, H.A.; Nguyen, T.G.; Nguyen, D.T.; Tran, T.H.; Le, H.C.; Phung, H.T. A novel integrating data envelopment analysis and spherical fuzzy MCDM approach for sustainable supplier selection in steel industry. Mathematics 2022, 10, 1897. [Google Scholar] [CrossRef]

- Kamacı, H.; Petchimuthu, S. Some similarity measures for interval-valued bipolar q-rung orthopair fuzzy sets and their application to supplier evaluation and selection in supply chain management. Environ. Dev. Sustain. 2022, 1–40. [Google Scholar] [CrossRef]

- Shang, Z.; Yang, X.; Barnes, D.; Wu, C. Supplier selection in sustainable supply chains: Using the integrated BWM, fuzzy Shannon entropy, and fuzzy MULTIMOORA methods. Expert Syst. Appl. 2022, 195, 116567. [Google Scholar] [CrossRef]

- Song, J.; Jiang, L.; Liu, Z.; Leng, X.; He, Z. Selection of third-party reverse logistics service provider based on intuitionistic fuzzy multi-criteria decision making. Systems 2022, 10, 188. [Google Scholar] [CrossRef]

- Jessin, T.A.; Rajeev, A.; Rajesh, R. Supplier selection framework to evade pseudo-resilience and to achieve sustainability in supply chains. Int. J. Emerg. Mark. 2023, 18, 1425–1452. [Google Scholar] [CrossRef]

- Afrasiabi, A.; Tavana, M.; Di Caprio, D. An extended hybrid fuzzy multi-criteria decision model for sustainable and resilient supplier selection. Environ. Sci. Pollut. Res. 2022, 29, 37291–37314. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Ju, Y.; Martinez, L.; Tu, Y. Sustainable battery supplier evaluation of new energy vehicles using a distributed linguistic outranking method considering bounded rational behavior. J. Energy Storage 2022, 48, 103901. [Google Scholar] [CrossRef]

- Singh, R.R.; Zindani, D.; Maity, S.R. A novel fuzzy-prospect theory approach for hydrogen fuel cell component supplier selection for automotive industry. Expert Syst. Appl. 2024, 246, 123142. [Google Scholar] [CrossRef]

- Fang, J.; Zhou, W.; Xiong, L. Multi-criteria decision making approach for supplier selection and order allocation in a digital supply chain resilience. Ann. Oper. Res. 2024, 1–37. [Google Scholar] [CrossRef]

- Lin, C.; Chen, J.; Feng, C.; Li, X. Optimizing supplier selection for prefabricated components: A comprehensive evaluation. In Engineering, Construction and Architectural Management; Emerald Publishing Limited: Leeds, UK, 2024. [Google Scholar] [CrossRef]

- Ahamed, N.; Dey, G.; Ahmed, T.; Rahman, R.; Taqi, H.M.M.; Ahmed, S. Embracing sustainability in green supplier evaluation: A novel integrated multi-criteria decision-making framework. Contemp. Math. 2024, 5, 1891–1917. [Google Scholar] [CrossRef]

- Rahardjo, B.; Wang, F.K.; Lo, S.C.; Chou, J.H. A hybrid multi-criteria decision-making model combining DANP with VIKOR for sustainable supplier selection in electronics industry. Sustainability 2023, 15, 4588. [Google Scholar] [CrossRef]

- Görçün, Ö.F.; Aytekin, A.; Korucuk, S.; Tirkolaee, E.B. Evaluating and selecting sustainable logistics service providers for medical waste disposal treatment in the healthcare industry. J. Clean. Prod. 2023, 408, 137194. [Google Scholar] [CrossRef]

- Amid, A.; Ghodsypour, S.H.; O’Brien, C. A weighted max–min model for fuzzy multi-objective supplier selection in a supply chain. Int. J. Prod. Econ. 2011, 131, 139–145. [Google Scholar] [CrossRef]

- Jadidi, O.; Zolfaghari, S.; Cavalieri, S. A new normalized goal programming model for multi-objective problems: A case of supplier selection and order allocation. Int. J. Prod. Econ. 2014, 148, 158–165. [Google Scholar] [CrossRef]

- Rasmussen, A.; Sabic, H.; Saha, S.; Nielsen, I.E. Supplier selection for aerospace & defense industry through MCDM methods. Clean. Eng. Technol. 2023, 12, 100590. [Google Scholar]

- Boukrouh, I.; Tayalati, F.; Azmani, A. A comprehensive framework for supplier selection: Using subjective, objective, and hybrid multi-criteria decision-making techniques with sensitivity analysis. IEEE Access 2024, 12, 145550–145569. [Google Scholar] [CrossRef]

- Hallak, J. Optimizing construction supplier selection in conflict-affected regions: A hybrid multi-criteria framework. Oper. Manag. Res. 2024, 17, 1270–1294. [Google Scholar] [CrossRef]

- Orji, I.J.; Ojadi, F. Investigating the COVID-19 pandemic’s impact on sustainable supplier selection in the Nigerian manufacturing sector. Comput. Ind. Eng. 2021, 160, 107588. [Google Scholar] [CrossRef]

- Pamucar, D.; Torkayesh, A.E.; Biswas, S. Supplier selection in healthcare supply chain management during the COVID-19 pandemic: A novel fuzzy rough decision-making approach. Ann. Oper. Res. 2023, 328, 977–1019. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Gupta, H.; Khan, S.A.; Jabbour, C.J.C.; Rehman, S.T.; Kusi-Sarpong, H. Sustainable supplier selection based on industry 4.0 initiatives within the context of circular economy implementation in supply chain operations. Prod. Plan. Control 2023, 34, 999–1019. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, Y.; Yang, G. Smart supply chain management in Industry 4.0: The review, research agenda and strategies in North America. Ann. Oper. Res. 2023, 322, 1075–1117. [Google Scholar] [CrossRef]

- Ali, Z.; Mahmood, T.; Gwak, J.; Jan, N. A novel extended Portuguese of interactive and multi-criteria decision making and Archimedean Bonferroni mean operators based on prospect theory to select green supplier with complex q-rung orthopair fuzzy information. CAAI Trans. Intell. Technol. 2023, 8, 177–191. [Google Scholar] [CrossRef]

- Ghadimi, P.; Dargi, A.; Heavey, C. Making sustainable sourcing decisions: Practical evidence from the automotive industry. Int. J. Logist. 2017, 20, 297–321. [Google Scholar] [CrossRef]

- Masudin, I.; Habibah, I.Z.; Wardana, R.W.; Restuputri, D.P.; Shariff, S.S.R. Enhancing supplier selection for sustainable raw materials: A comprehensive analysis using analytical network process (ANP) and TOPSIS methods. Logistics 2024, 8, 74. [Google Scholar] [CrossRef]

- Lou, S.; You, X.; Xu, T. Sustainable supplier evaluation: From current criteria to reconstruction based on ESG requirements. Sustainability 2024, 16, 757. [Google Scholar] [CrossRef]

- Liang, D.; Cao, W.; Zhang, Y.; Xu, Z. A two-stage classification approach for AI technical service supplier selection based on multi-stakeholder concern. Inf. Sci. 2024, 652, 119762. [Google Scholar] [CrossRef]

- Nabeeh, A.; Abdel-Basset, M.; El-Ghareeb, H.A.; Aboelfetouh, A. Neutrosophic multi-criteria decision making approach for IoT-based enterprises. IEEE Access 2019, 7, 59559–59574. [Google Scholar] [CrossRef]

- Ding, S.; Ward, H.; Tukker, A. How Internet of Things can influence the sustainability performance of logistics industries—A Chinese case study. Clean. Logist. Supply Chain 2023, 6, 100094. [Google Scholar] [CrossRef]

- Singh, A.; Mishra, N.; Ali, S.I.; Shukla, N.; Shankar, R. Cloud computing technology: Reducing carbon footprint in beef supply chain. Int. J. Prod. Econ. 2015, 164, 462–471. [Google Scholar] [CrossRef]

- Dumée, L.F. Circular materials and circular design—Review on challenges towards sustainable manufacturing and recycling. Circ. Econ. Sustain. 2022, 2, 9–23. [Google Scholar] [CrossRef]

- Francisco, K.; Swanson, D. The supply chain has no clothes: Technology adoption of blockchain for supply chain transparency. Logistics 2018, 2, 2. [Google Scholar] [CrossRef]

| No. | Keywords | Frequency | No. | Keywords | Frequency |

|---|---|---|---|---|---|

| 1 | supplier selection/evaluation | 176 | 11 | management | 41 |

| 2 | decision making | 138 | 12 | framework | 41 |

| 3 | model | 109 | 13 | order allocation | 37 |

| 4 | supply chain (management) | 84 | 14 | dea | 24 |

| 5 | topsis | 70 | 15 | sustainable/green supplier selection | 23 |

| 6 | performance (evaluation) | 69 | 16 | system | 22 |

| 7 | fuzzy | 68 | 17 | group decision making | 22 |

| 8 | ahp | 65 | 18 | sets | 20 |

| 9 | criteria | 62 | 19 | aggregation operators | 17 |

| 10 | mcdm | 57 | 20 | sustainability | 15 |

| No. | Method | Frequency | Representative Study |

|---|---|---|---|

| 1 | TOPSIS | 70 | Giri (2022) [14] |

| 2 | Fuzzy Theory | 68 | Dang (2022) [15] |

| 3 | AHP | 65 | Chai (2023) [16] |

| 4 | DEA | 24 | Nguyen (2022) [17] |

| 5 | Aggregation Operators | 17 | Kamacı (2022) [18] |

| 6 | VIKOR | 12 | Shang (2022) [19] |

| 7 | Entropy | 11 | Song (2022) [20] |

| 8 | ANP | 11 | Jessin (2023) [21] |

| 9 | BWM | 10 | Afrasiabi (2022) [22] |

| 10 | Prospect Theory | 7 | Liang (2022) [23] |

| Dimension | Concrete Criteria | Explanation |

|---|---|---|

| Economic | Price | Assess price reasonableness and market competitiveness of products/services |

| Quality | Evaluate product/service reliability and consistency to avoid quality-related additional costs | |

| Delivery Time | Verify ability to meet delivery timelines and maintain project schedules | |

| Service | Examine support services including after-sales support and training provisions | |

| Technical Capability | Assess industry-leading technical capabilities and cutting-edge support, evaluate compatibility of AIoT solutions with existing enterprise IT architecture for seamless integration | |

| Financial Capability | Measure financial stability and cash flow reliability | |

| Market Competitiveness | Evaluate co-development capability, assess innovative solution provision, and verify rapid response to market dynamics and customer needs | |

| Environmental | Carbon Footprint Management | Evaluate sustainability performance in green transportation and production across the supply chain |

| Material Management | Audit raw material classifications and productivity metrics | |

| Resources Management | Measure water, electricity, and natural gas consumption and utilization efficiency | |

| Waste and Pollution Management | Assess environmental impact, pollution control, and waste recycling measures | |

| Environmental Management System | Review environmental protection measures and management systems | |

| Green Product | Evaluate product environmental friendliness and recyclability | |

| Green Image | Investigate market reputation regarding environmental responsibility | |

| Green Innovation | Measure eco-innovation capabilities and green technology R&D | |

| Green Transportation | Audit circular packaging solutions and low-carbon transportation | |

| Social | Conflict Mineral | Verify conflict-free mineral sourcing and human rights compliance |

| Occupational Health and Security | Examine employee health/safety protections and workplace conditions | |

| Staff Right and Interest | Assess employee treatment including compensation, benefits, and development opportunities | |

| Non-discrimination and Equality | Evaluate understanding and respect for diverse cultural backgrounds in global operations | |

| Child Labor and Forced Labor | Verify compliance with forced labor prohibitions | |

| Community Impact | Evaluate social program support and community rights compliance | |

| Governance | Fair Trade & Competition | Verify bid-rigging/market manipulation absence and conflict-of-interest disclosures |

| Internal Management & Compliance | Audit internal control effectiveness and anti-corruption compliance | |

| Data Security and Protection | Examine data protection mechanisms and client data security | |

| Business Ethics | Review trade secret/IP protections and ethical code adherence | |

| Supply Chain Transparency | Assess willingness to provide transparent supply chain information regarding environmental/social impacts | |

| Collaborative Capacity | Test co-development capabilities, contract fairness, and long-term partnership commitment |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, X.; Lou, S. Research on the Evaluation and Selection of AIoT Suppliers from an ESG Perspective. Systems 2025, 13, 422. https://doi.org/10.3390/systems13060422

You X, Lou S. Research on the Evaluation and Selection of AIoT Suppliers from an ESG Perspective. Systems. 2025; 13(6):422. https://doi.org/10.3390/systems13060422

Chicago/Turabian StyleYou, Xiaoyue, and Shuqi Lou. 2025. "Research on the Evaluation and Selection of AIoT Suppliers from an ESG Perspective" Systems 13, no. 6: 422. https://doi.org/10.3390/systems13060422

APA StyleYou, X., & Lou, S. (2025). Research on the Evaluation and Selection of AIoT Suppliers from an ESG Perspective. Systems, 13(6), 422. https://doi.org/10.3390/systems13060422