Abstract

The cyclic process of the circular supply chain (CSC) involves many stakeholders, and how to synergistically promote the active participation of different entities in CSC practices in the complex context of interacting factors is an important condition for moving towards low-carbon sustainable development and realizing the economic benefits as well as the competitive advantages of enterprises. Therefore, based on the technology cycle perspective (recycling, remanufacturing, refurbishing, repairing, and reusing), this study combines text mining and bibliometrics to identify CSC drivers, establish a factor prioritization assessment model, and construct a comprehensive framework for a set of CSC implementation pathways covering multiple subjects and multidimensional factor interaction mechanisms. The results emphasize that the most critical drivers are policies and regulations, resource use efficiency, and consumer awareness and attitudes, with contribution rates of 5.1%, 4.5%, and 4.5%, respectively. On this basis, this paper explores the efficiency-enhancing path strategy for the synergistic implementation of CSC by multiple subjects from the perspectives of the four key subjects of CSC. It puts forward policy recommendations to promote the successful implementation of CSC at the level of mechanism construction and specific operation, to provide theoretical guidance for the cooperation of upstream and downstream subjects.

1. Introduction

For a long time, the production and consumption model of society has followed a linear process of “take-make-dispose” [1]. However, this linear economic model is unsuitable for sustainable development as it generates large amounts of waste. In addition, it depletes available natural resources, leading to scarcity of natural resources and severe pollution of the environment [2]. An important concept that may change this phenomenon is the circular economy (CE). As an economic model based on the principles of regeneration and restoration [3], the CE concept is increasingly recognized as a better alternative to the dominant linear economic model [4], and is evolving to become an important driving force behind sustainable development, both in the literature and in practice [5].

In the CE literature, the supply chain (SC) is recognized as one of the key enablers of CE implementation [5]. The incorporation of CE principles in SC is referred to as circular supply chain (CSC) [4]. Unlike linear SC, CSC activities involve value creation, delivery, and retention [6] by recycling technical/biomaterials to realize the zero-waste vision. Implementing CSC involves numerous stakeholders, each playing a distinct role in CE, from suppliers to manufacturers and consumers [7]. Achieving circularity in SC requires the collective efforts and synergy of all CSC stakeholders [8,9].

SC stakeholders and their interdependent relationships are closely related to CSC in terms of the technology cycle (recovery and recycling of materials) [10], and the mechanisms of stakeholder collaboration and coordination facilitate the realization of CSC [11]. Ahmed et al. [12] go further to position the collaborative relationship of stakeholders in SC as a strategic necessity rather than just an operational choice. In addition, Farooque et al. [4] proposed that the design of CSC should focus on its collaboration and coordination with suppliers, customers, and other stakeholders rather than being limited to finding the challenges of CSC implementation to increase the speed of transition from SC to CE.

In addition to focusing on the collaboration mechanism between CSC subjects, it is also necessary to identify the key influencing factors of different subjects and explore the interactions between these factors and how they affect the subjects to promote the successful practice of CSC. By analyzing the role of the factors and the response mechanism of the subjects, we can accurately design synergistic strategies and transform the theoretical feasibility into operability in practice [13]. Therefore, as one of the driving functions of CSC, “drivers” have received attention from many researchers. However, there is no literature on this topic that identifies and categorizes the influencing factors from the transversal dimension of CSC [14] and explores the dynamic interactions among these factors in depth. Moreover, it is observed that the literature on the effective adoption of the strategic framework of circular supply chain management (CSCM) practices to promote overall firm competitiveness is still in its infancy [5]).

In summary, relevant studies still have the following limitations: (1) existing literature mostly focuses on the vertical challenges (e.g., technical/policy barriers) of CSC implementation. However, it does not systematically identify and categorize the influencing factors from the horizontal dimension (suppliers, manufacturers, users, etc.), resulting in the subject-specific driving mechanism not being deconstructed. (2) Theoretical gaps in the dynamic interaction between factors. (3) Existing CSC practice frameworks are mostly conceptual proposals, lacking a systematic approach that integrates multi-subject collaboration mechanisms, dynamic factor weights, and competitiveness enhancement paths.

In this regard, this paper focuses on the following issues: (1) Systematically identifying and counting CSC drivers and categorizing the factors regarding subject relevance through a technology cycle perspective. (2) Quantitatively assessing the priority of the driving factors and their differential impact on the enthusiasm of multiple subjects to participate. (3) Constructing a multi-subject CSC pathway framework and provide specific multi-subject collaborative optimization pathways and strategies.

The main contributions of this paper are as follows: (1) Enriching the theoretical connotation of CSCM. From a multi-subject perspective, this paper identifies and categorizes the factors as subjects and explores in depth the dynamic interactions among these factors, which solves the problem of confusing factor–subject coupling effects in previous studies. (2) Expanding research methods. This paper constructs an assessment model to prioritize CSC driving factors, which helps identify the driving effects of factors on each subject, to better grasp the differences in the response of the same subject to different factors, and to drive the subject to actively participate in CSC practices to promote the realization of the dual-carbon goal. (3) This paper provides decision-making support on cooperation strategies for CSC participants. This paper fully grasps the correlation between the CSC technology cycle and the key subjects, analyzes the influence of the subjects on the CSC technology cycle, considers the dual-objective optimization strategy of maximizing the economic benefits and minimizing the wastes, and proposes the framework of the CSC pathway for the satisfaction of multiple subjects. It provides theoretical guidance and a decision-making basis for promoting the participation enthusiasm and collaboration synergy of each subject.

2. Theoretical Background

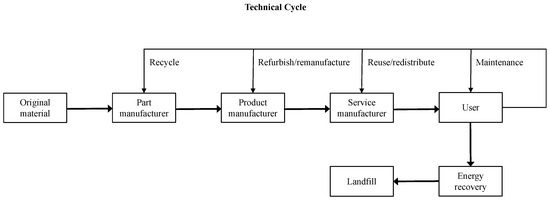

CE is often defined as industrial production systems that are restorative and regenerative through intent and design [15]. Products are designed and optimized through disassembly, reuse, refurbishment, or recycling cycles, and value is extracted from materials recovered from end-of-life products, rather than extracting resources [3]. Researchers have categorized recycled materials into biological and technological cycles [3]. The biological cycle involves controlling the flow of renewable materials or biological inputs to ensure the regeneration of biosphere components. The technological cycle is the control of a finite inventory of materials so that products obtained through the process can be shared, reused, remanufactured, or recycled, recovering materials and creating a cycle [16]. Among other things, “technical nutrients” are designed for reuse, refurbishment, remanufacturing, and recycling for multiple consecutive production cycles and uses at the highest quality [3] (Figure 1).

Figure 1.

Circular Economy Model—Technology Cycle. Source: Adapted from [3].

Figure 1 illustrates how initial materials undergo a reverse flow, enabling their reintegration at the start of the chain. When all reuse possibilities of the material have been exhausted, the energy potential of the material is harnessed, and the waste is transported to a landfill. From the perspective of the CE technology cycle, integrating CE into supply chain management (SCM) can provide significant sustainability advantages [17]. Therefore, SCM is important in terms of innovation and the ability to transition to CE [18].

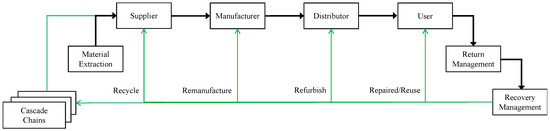

CSC is defined as the embodiment of the CE principle in SC [18], emphasizing regeneration and restoration functions [19]. It systematically recovers technical materials and regenerated biomaterials through whole-system innovations in business models and SC functions from product/service design to end-of-life and waste to realize a zero-waste vision that involves all stakeholders in the product/service lifecycle, including the part/product manufacturer, the service provider, the consumer, and the user [4]. Figure 2 illustrates our systematic understanding of the overall structure of the CSC, where the core stakeholders and key technology streams are the starting perspectives for our research. The figure illustrates the main flows of the CSC from raw material sourcing to recycling strategy execution. This structure emphasizes the need for forward and reverse logistics integration, aiming at a closed-loop flow of resources and uncertainty control in the return process through product design to support diversified use and recycling patterns. In addition, the cascade chains here emphasize CSC’s vision of managing the goal of zero waste by working with other organizations to ensure that materials, components, and products that could not be recycled by the original manufacturer can become a source of raw materials for other companies. These cascades can even effectively deal with so-called “production residues”, which can be extremely valuable to other partners in the SC [10].

Increasingly complex, expanding in scope, and as an enabler of corporate response to CE sustainability requirements, CSC deserves more attention and a fuller understanding [20]. Despite the enormous opportunities for CSC, the transformation faces many obstacles [3]. The challenge is that economic gains can only be realized if multiple players across business and research collaborate and reimagine key material flows and manufacturing processes with the support of policymakers and innovation [3,15]. However, the challenges posed by environmental legislation and the need to reduce costs have driven the implementation of CSCM and efforts towards better structuring of CSC systems with a greater focus on circular stakeholder collaboration. Therefore, there is a need to understand the key drivers of CSC that lead to better economic, environmental, and social outcomes.

Figure 2.

Circular supply chain structure. Source: Adapted from [21].

3. Methodology

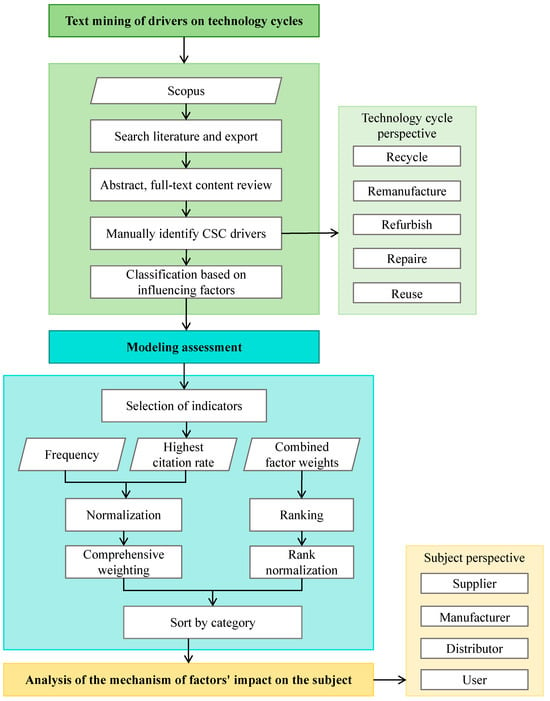

As shown in Figure 3, this paper, from a technology cycle perspective, constructs a CSC implementation path for multiple subjects through the following steps. Step 1: all the drivers of CSC are identified and categorized using text mining and analysis methods. The required data comes from related research literature. Step 2: build an assessment model to prioritize the drivers of CSC. Step 3: apply text analysis methods to identify the driving factors under different subjects, analyze the interaction mechanism between these factors and the way they affect the subjects, and accordingly propose a development path for the collaborative implementation of CSC by multiple subjects.

Figure 3.

Flowchart of research methodology.

3.1. Text Mining of Drivers Based on Technology Cycles

In order to drive multiple subjects to actively participate in CSC implementation, it is first necessary to systematically identify all CSC drivers, and this paper chooses literature review and text mining methods in this segment. The specific steps are as follows.

3.1.1. Data Sources

Papers for inclusion in the study were screened according to the following pre-specified criteria.

- Locates research by searching potential literature through the Scopus database. Scopus is not only a widely used and recognized database in academia [22,23,24] but it is also considered the largest source of abstracts and scholarly citations [25].

- Searched for the keyword “circular supply chain” in the paper title. In contrast, the Boolean phrase inserted in the paper title, abstract, and keywords was as follows, “driver” OR “pressure” OR “trigger” OR “priority” OR “facilitator”. The phrase was searched across all publications without restrictions, aiming to capture relevance in titles, abstracts, and full texts.

- Literature included in this study should be written in English as English is the most spoken language by researchers worldwide.

- No publication date restriction was defined for this study, as a search in the Scopus database revealed a lack of publications before 2011 when using the above criteria.

- To gain a deeper understanding of the work accomplished in this area of work, the types of publications included in this study included journal papers, conference papers, book chapters, and review papers, excluding editorials.

- Additionally, we excluded articles that required payment for access, as our study was not financially supported to cover these costs.

3.1.2. Data Filtering

This step aims to document the reviewer’s decision-making process for transparency and evaluation, while also facilitating updates to the systematic review [26]. The criteria are listed below.

- Relevant—a paper is considered relevant when it meets the following three criteria:

- The material must address CSC as a major topic.

- The material must address the key technical processes of CSC.

- The material must address the influencing factors of CSC implementation.

- Relevance: Those papers that were not relevant to this study were excluded by reviewing all remaining papers.

The abstracts of 111 papers were investigated to determine if their content was relevant to the scope of this study. It was found that 68 papers met all four of the appropriate criteria. The remaining 43 papers were excluded and will not be considered in the remainder of this study. Upon reviewing the full texts, we found that several papers were not relevant to this study, contrary to what their abstracts suggested. Therefore, a total of 25 articles were removed from the survey during the review stage of the full text, leaving 43 papers for the remainder of this study. In addition, the process utilized forward and backward snowballing techniques as suggested by Thomé et al. [27]. This allowed us to obtain an additional 3 papers relevant to this study. Finally, this study consisted of 46 documents, and the sample of articles was considered sufficient.

3.1.3. Data Analysis and Synthesis

This step is to identify the drivers. Most of the factors that drive CSC implementation are indirectly obtained in the text, so this study uses linguistic analysis to manually identify the content of linguistic expressions, such as what leads to a successful transition from SC to CE and what affects (drives or hinders) CSC implementation. Through the above steps, this study attempts to comprehensively uncover the drivers of CSC implementation in the technology cycle.

This study uses an Excel spreadsheet to extract data containing general information (title, author, name of source publication), drivers, frequency of occurrence of factors, and average annual citation rate of the article. To ensure reliability at all stages of the formal analysis, all researchers engaged in exhaustive discussions during the analysis until a consensus was reached.

3.2. Establishing an Evaluation Model of Driving Factors

After systematically identifying all CSC drivers, there is a need to identify the key drivers or to recognize the importance of different drivers, so this study developed an evaluation model with three indicators.

The first indicator is the frequency of the driver, , which aims to demonstrate the prevalence of the driver based on the frequency of the factor appearing in all articles (counted only once per article). The larger the value, the more important the driver [28]. The second evaluation metric is the number of citations, , of the literature with the driver, which represents the authority and importance of the driver, i.e., the average number of citations per year of the most highly cited literature among all the literature. Citation rate is the most representative, simple, standardized, and objective measure of academic influence [29]. By combining these two indicators, the importance of the driver is evaluated. In addition, a third evaluation metric is introduced, , which is the combined weight of the drivers in the existing literature, to better quantify the importance of the drivers [30]. All the drivers were mined from the 46 papers, and and were used to assess the importance of the drivers and rank them comprehensively (Table 1).

Table 1.

Indicator data processing.

Weight allocation note: since these two indicators for the quantitative evaluation of drivers are equally important and both are positive indicators, it is more appropriate to choose an equal weight assignment in this paper.

The results of the study ranked the drivers according to the -value and combined with a third indicator, .

4. Results and Discussion

This section first presents the results of the content analysis, where the content of the selected 46 articles was identified, categorized, and counted using text mining methods based on a technology cycle perspective. Next, this section applies the evaluation model to evaluate and analyze the specific driver indicators for different categories. Finally, this section presents a multi-object CSC framework consisting of different CSC interest subjects and their drivers and discusses the creation of value through the linkages between different subjects and drivers.

4.1. Categorization of Drivers

Organizational voluntary participation in CSCM practices is related to the drivers of CSC [31]. Therefore, to coordinate the participation of many stakeholders in CSCM implementation, this study cuts through the technology cycle perspective and content analyzes 46 pieces of literature to count and categorize all drivers. A foundation is laid for subsequent driver prioritization assessment. Fifty-nine drivers were identified based on the statistics of the 46 selected papers. The 47 drivers were retained by removing duplicate expressions and factors with the least correlation with CSC. Based on the characteristics of the drivers, these 47 factors were categorized into 10 groups: social, policy, organizational, economic, environment, supply chain, technology, information, infrastructure, and Circular Design and Services. Table 2 explains in detail the meaning of the various types of CSC drivers in the technology cycle.

Table 2.

CSC drivers and explanations in the technology cycle.

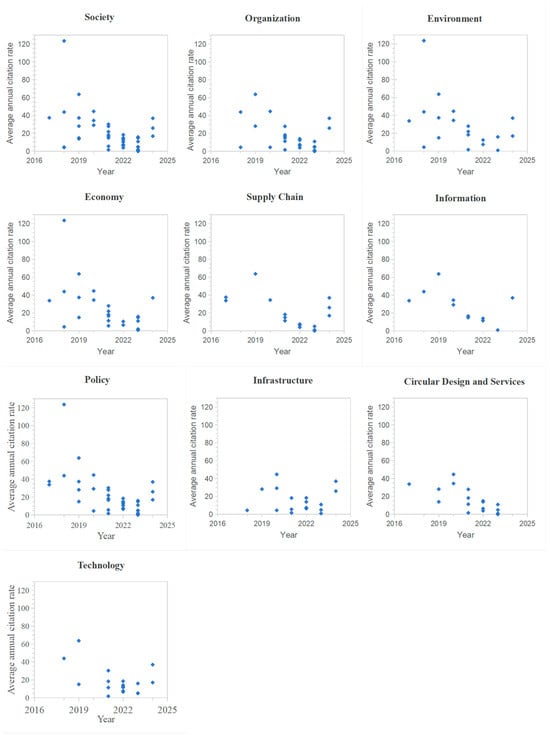

Figure 4 illustrates these 10 categories, with each dot representing a CSC driver discussed in an article. The specific location of each dot is based on the year of publication and the article’s average annual citation rate. A high frequency of discussion means that the drivers in this literature have received widespread attention in the academic community and may be considered core drivers. A high citation rate, on the other hand, indicates that this literature is authoritative and influential in the field, providing key insights into the drivers.

Figure 4.

Classification of 46 papers. Source of data: Appendix A (Table A1).

As depicted in Figure 4, the most discussed categories of drivers among the 46 studies were social, governmental, organizational, and economic. The highly cited literature is then concentrated on the years 2018 to 2020. These results illustrate the importance and authority of these drivers. Specifically, they are as follows.

Several scholars have examined the role of various influencing factors on CSC and conducted impact factor assessments using the Best Worst Method (BWM). These factors include effective and supportive government regulations, financial assistance, ISO certification, commitment to sustainability in recycling practices, the potential for employment, information technology, Industry 4.0 technology, stakeholder cooperation and collaboration, CE awareness training, environmental responsibility, and transparency of SC [49,65,66].

Among other things, the transparency and visibility of SC are influenced by factors such as information sharing, stakeholder cooperation and collaboration, effective communication, research and development intensity (R&D intensity), Industry 4.0 technology, blockchain technology, and information technology. Lahane et al. [5] used content analysis to identify the drivers of CSC, and they found that the main drivers of CSCM factors include factors such as government support and legislation, economic efficiency, resource scarcity, consumer environmental awareness, top management support, industry cooperation, innovation strategies, environmental policies, and regulatory practices. To explore the influence of these factors, this study finds that government policies and regulations are one of the most significant factors driving the successful implementation of CSC. The factors that do not depend on any other drivers in the overall SC system are government support and top management involvement, which play a leading role in the shift to CE through the adoption of circular practices in SC. The technology-based factors have a positive impact on the closed-loop flow of material flows in SC, achieving environmental sustainability as well as an overall sustainable closed-loop supply chain (CLSC).

Other scholars have used the Delphi method and improved explanatory structural models to analyze the influences that drive CSCM practices. Legislation and regulation, government subsidies, shared information, system coupling, joint decision-making, CE awareness training, collaborative relationships, cascading and reuse, SC transparency, financial attractiveness, customer needs, technological innovations, product design, recognition of CE revenue growth potential, R&D teams, and development of CE culture were identified as the important factors that promote firms to adopt CSCM practices. These factors are all related to society, policy, organization, economy, environment, SCM, circular design and services, information, technology, and infrastructure [33,49,60,67,68].

Regarding the frequency of influencing factors, CE awareness training is the most discussed factor in the literature, followed by policies and regulations, and the development of CE skills and competencies.

4.2. Statistical Ranking of Drivers

After systematically counting and clarifying the drivers and their classification system, the relative importance of the factors needs to be further assessed to guide the optimization path of the CSC’s multi-subject collaborative practice. Based on Section 4.1, the drivers in the CSC technology cycle that motivate different stakeholders to implement CSCM were obtained: suppliers (recycling), manufacturers (remanufacturing), distributors (refurbishment), and users (repair and reuse). Among these, circular design and services is the main driver in the recycling, remanufacturing, and refurbishment phases. In addition, the other nine categories of factors are present throughout the cycle, but their roles and focus differ at each stage. Therefore, the evaluation model was applied in Section 4.2 to evaluate and analyze the indicators of each type of driver (Table 3) in order to determine the importance of the drivers.

Table 3.

Classification of drivers.

As shown in Table 3, the combined social, organizational, supply chain, environmental, economic, and policy indicators are relatively high, with 22%, 15%, 12%, 12 %, 11%, and 7% importance, respectively. The factors in these categories are listed in Table 4, Table 5, Table 6, Table 7, Table 8 and Table 9 (see Table A2, Table A3, Table A4 and Table A5. for the influence mechanisms of these factors).

Table 4.

Assessment results of social factors.

Table 5.

Assessment results of organizational factors.

Table 6.

Assessment results of supply chain factors.

Table 7.

Assessment results of environmental factors.

Table 8.

Assessment results of economic factors.

Table 9.

Assessment results of policy factors.

Table 4 reflects social factors’ influence on CSC through awareness of sustainable development and employment opportunities, accounting for 32% and 19% of the total, respectively. Among them, sustainability awareness is one of the key factors to promote CSC. Once enterprises and the public realize the advantages and sustainability of CSC through CE campaigns, enterprises can collaborate on CE practices and transform their SC to CE. In addition, the employment opportunities created by CSC can also contribute to the market popularization of the CE concept. The increase in CSCM practices is directly proportional to the rise in consumer demand, and this trend can be attributed to the spread of sustainability awareness. Social factors positively influence environmental commitment and green economy incentives and encourage small and medium enterprises and SCs to transition to CE [48]. Based on the development of CSC, this study suggests that utilizing social categories can help firms advance the implementation of CSCM practices, for example, the pressure from end consumers and upstream customers to be environmentally friendly has prompted firms to adopt CSCM to meet the market demand for environmentally friendly products to maintain their competitiveness in the market.

Organizational factors drive CSCM implementation, as shown in Table 5 [54]. The lack of necessary knowledge and skills within the organization may hinder the transition to CE. In particular, CSCM requires a higher level of technical competence and expertise regarding issues such as servitization, cooperative competition, and process redesign [69]. In addition, the commitment and involvement of top management can help to raise CE awareness among employees and promote organizational training on CE principles and models as well as professional skills. Through training, the longevity, reliability, and durability of remanufactured/recyclable products increase, which is critical to the success of a company’s CSC implementation [70].

The drivers of the supply chain categories are presented in Table 6. Of these, supply chain visibility accounts for about 20%, second only to supply chain flexibility. Supply chain visibility is critical for all participants in the CSC to enhance transparency, reduce risk, and improve efficiency in the closed-loop supply chain. In addition, visibility will help build long-term relationships with suppliers and logistics partners and create brand loyalty for customers [66,71]. In CSC, aligning resources, structure, and operational flexibility can reduce supply risk and increase product and process flexibility, which relies on technological advancements.

As shown in Table 7, environmental benefits contribute to the successful implementation of CSCM [6]. This involves minimizing the negative environmental impacts of company activities, decreasing the environmental footprint of products, and conserving resources [69,72].

In Table 8, the driver “business and profit” has the highest index weight, followed by awareness of cost reduction potential. Business and profitability includes sustained business growth and financial returns [49]. CE reduces production waste and, thus, reduces costs and improves profitability, which helps to maintain existing customers and attract new ones. Once management and employees foresee the business opportunities involved, they will actively adopt CSC practices.

To summarize, there are three main ways in which economic-type factors influence CSC practices, where one is that financial costs and benefits are the key factors driving the adoption of CE practices by SCs. Another is that competitive pressures motivate firms to adopt sustainable practices to gain a better reputation in the industry, thereby realizing a competitive advantage to expand market share and increase profits. These financial benefits further incentivize firms to continue to implement CSCM. Finally, investment in technology provides financial growth by facilitating technological advancement, which in turn protects the continued implementation of CSC.

As shown in Table 9, policy support helps drive CSC implementation [73]. The government’s legislative regulation and financial assistance play a key role in the adoption of CE practices by firms in their SC processes [74].

In Table 3, Table 4, Table 5, Table 6, Table 7, Table 8 and Table 9, consumer awareness and attitudes, product quality enhancement, resource efficiency, business and revenue, environmental benefits, employment potential, and policies and regulations have high citations in the literature, which indicates the relative importance of these factors in driving CSC implementation. Industry competitive pressures and CE awareness training appear in many studies. Although these articles usually have low citation rates, most of the literature still cannot deny the importance of these factors in driving the transition from SC to CE.

Policies and regulations, development of CE skills and competencies, consumer awareness and attitudes, business and profitability, improved resource utilization efficiency, and supply chain visibility performed well on both indicators, confirming that these factors should be considered. Strong correlations were observed between these factors. For example, for organizations, the development of CE skills and competencies is a prerequisite for SCs to make the transition to CE, which improves resource utilization by facilitating a closed-loop flow of resources. Consumer awareness and attitudes define the norms and standards for the industry, driving policy norms and requiring businesses to adopt circular and sustainable practices. CSC is, therefore, the inevitable choice for the future of environmental SC.

Increased public environmental awareness can effectively improve resource utilization efficiency. Improving resource utilization efficiency is the most direct and effective way to drive the success of CSCM implementation [47]. Therefore, the categorization here only clearly highlights some key factors and does not imply that the rest are unimportant. Up to now, this study has obtained the results of the evaluation of carbon emission impact factors by two indicators.

Alongside Table 10, a third indicator was introduced, representing the combined weight of importance of certain factors driving CSCM practice, denoted as . The table covers certain drivers decomposed in the literature and a more in-depth textual analysis was used to obtain a standardized ranking of how they drive CSCM practice.

Table 10.

Normalized ranking of drivers in the literature.

Table 5 shows that the significance of the CE awareness training factor obtained through frequency and citation statistics should be emphasized, but it is not reflected in Table 10. Existing literature suggests that CE awareness training is crucial as it influences the behavior and decision-making of all SC subjects [72]. Within the organization, to improve the implementation of CSC, the training of employees, especially SC management, on the awareness and knowledge of CE principles is needed to drive the organization to act responsibly on environmental issues both vertically and horizontally [65]. In addition, training programs focusing on CE models and principles can encourage employees to design SC eco-innovation solutions that drive CSC implementation success and increase the organization’s competitive advantage by improving SC eco-efficiency.

Thus, a third indicator can weaken or strengthen the significance of a given factor. It can also be concluded that the main drivers of several indicators are significant. The most prominent of these is the policy factor. Most of the studies measured the impact of policies and regulations on the adoption of CSC practices by companies. According to Table 9, the total value of policies and regulations reaches 2.31, and the mean of these two indicators exceeds 0.7. The policy factor is used in most of the literature for the analysis, and the high citation rate of these articles explains the acceptance of this influencing factor in this field of research. In Table 10, Dohale et al. [60] use a new Neutral Interpretive Structural Modeling (N-ISM) approach to analyze the drivers of CSC, and the results show that a standardized ranking of 1 for supportive legislative frameworks is the most influential driver of CSC. Faisal [62] used an Interpretive Structural Model (ISM) analysis to derive a standardized ranking of 1 for the importance of government regulatory interventions as a driver of CSCM as well, which could adequately explain the importance of this factor. The reason for this is the weak enforcement of laws to promote circularity and weak policy structures in developing economies [75]. The successful implementation of CSCM, on the other hand, requires defining the responsibilities of each participant in the SC and stipulating the roles and cooperative relationships between the government, SC, third-party waste collectors and customers. Therefore, governments at all levels need to develop clear legislation to promote CSCM, which is necessary to set standards for recycled products, define ownership responsibilities and encourage SCs to adopt CE principles.

4.3. Key Drivers and Path Construction of CSC from a Multiple Subject Perspective

After identifying and statistically ranking all the drivers, this paper extracts the key drivers under different subjects in this section. Given the heterogeneous effects of drivers on subjects, it is also necessary to construct a multi-subjects CSC pathway framework to facilitate the transformation of “factor-driven” to “multi-subject synergistic action”.

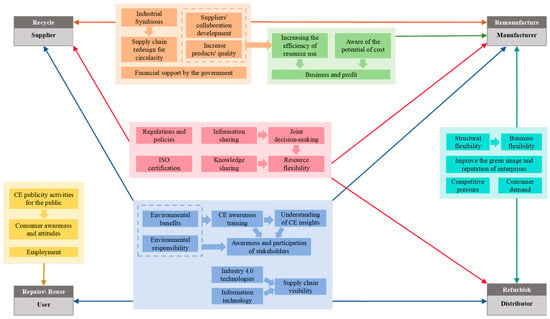

The CSC model proposed by Farooque et al. [4] identifies four key subjects (i.e., suppliers, manufacturers, distributors, and users) as described by MacArthur [3]. Based on the factors derived from the statistics and categorization in Section 4.1 and Section 4.2, the drivers were grouped into four categories by subject, as shown in Table 11. Each material flow link of CSC is directly affected by one of the ten types of drivers, focusing on the interrelationship between different subjects and drivers. Therefore, by analyzing the mechanism of each factor on the main body, the construction path for the successful implementation of CSC by different main bodies is proposed. The pathway diagram in Figure 5 clearly demonstrates how the key aspects of CSC, from raw material supply to the final consumer, are interconnected and facilitate the practice of CE through a range of strategies and practices. The four subjects studied act directly on all components of the CSC and influence value creation in general, with the practice paths of the different subjects indicated by solid lines with different representative colors. However, there are interaction mechanisms between the drivers that will indirectly influence the other subjects, as shown by the widened arrows in Figure 5.

Table 11.

Subjective classification of drivers.

Figure 5.

CSC Implementation Path for Multiple Subjects.

In CSC, factors like stakeholder awareness, environmental responsibility, supply chain visibility, reverse logistics infrastructure, Industry 4.0, and information technology collectively drive the transformation of all entities toward CSC. These factors interact with each other by improving resource efficiency, reducing costs, enhancing transparency, and promoting innovation, which together drive the development of CSC. Among them, environmental efficiency and environmental responsibility are the key factors driving the development of CSC, while SC visibility, Industry 4.0 technology, information technology and reverse logistics infrastructure provide technical support and infrastructural guarantee for CSC.

Given that closed-loop management in SC requires strategic orientation, it is by nature a more systemic process than a linear one. Therefore, the involvement of various stakeholders in the SC is needed to facilitate the coordination and efficiency of the whole system. As a CE enabler, I4.0 technologies will facilitate stakeholder engagement to optimize the recycling process by engaging in product lifecycle management through real-time data analytics and predictive maintenance. For example, Moktadir et al. [76] emphasized that technological advances facilitate the implementation of the CSCM Convention by improving resource utilization and reducing and recycling waste from operations. However, technology alone does not guarantee successful CSC implementation. Calzolari et al. [67] suggest that the CE model implies the need for partnerships. Stakeholder collaboration is an important prerequisite for the implementation of CSCM practices through technology transfer and organizational learning, which are the main requirements for improving the efficiency of resource use and the use of technology [77]. Although stakeholder cooperation and collaborative relationships are important for all subjects, such relationships may be most critical in the manufacturer segment. Since manufacturers are at the heart of SC and are responsible for transforming recycled materials into remanufactured products, this process will affect the efficiency and effectiveness of the overall CSC.

As shown in Figure 5, employment, consumer awareness attitudes, and CE campaigns aimed at the public have a driving effect on users. These factors are interrelated and work together. In particular, CE awareness campaigns increase consumer awareness, which in turn influences their purchasing attitudes, and increased consumer demand for recycled products in turn motivates firms to invest in CSC, which in turn creates jobs. This positive feedback loop helps to promote the widespread implementation of CSC.

Unlike users, manufacturers play a central role in CSC, which is a key link between suppliers and distributors. Factors such as improving resource use efficiency, business, and profitability, realizing the potential for cost reduction, structural flexibility, and clean technology act directly on the manufacturer to drive CSC implementation. Of these, improving resource use efficiency directly reduces costs and improves profits [45]. Since remanufacturing is usually less costly than producing new products from raw materials, manufacturers have the greatest potential to reap economic benefits from remanufacturing and recycling. This leads to the fact that improving resource use efficiency may have the most significant impact on manufacturers.

As services and managers in CSC, factors such as policies and regulations, ISO certification, lean tools, resource flexibility, innovation capacity, development of CE skills and competencies, information sharing, and knowledge sharing work to drive suppliers, manufacturers, and distributors to implement CSC. Consistent with previous research, the framework suggests that policies and regulations are the key factors [78] that are activating sustainable development actions [79]. Thus, policies and regulations, and ISO certification provide external drivers, while other factors provide the internal resources and capabilities that subjects need to implement CSC. In addition, information and knowledge sharing can facilitate SC partnerships and enhance an organization’s competitive advantage [58]. This can be achieved by increasing R&D intensity and innovation capacity. Because firms are concerned with long-term growth and providing new economic possibilities, in this regard, they are complementary tools to facilitate these information and knowledge-sharing practices for CSC and economic growth purposes. For example, Chen et al. [80] emphasize that innovation capabilities help to address data fragmentation among stakeholders.

In CSC, suppliers and manufacturers are key players in the implementation of industrial symbiosis. Industrial symbiosis focuses more on resource recycling and efficiency improvement in the production chain [55]. Resource efficiency and environmental performance are improved by sharing resources, exchanging by-products, and synergizing the use of infrastructure between firms. Therefore, it is mainly reflected in the supplier and manufacturer chain. In turn, the development of supplier partnerships contributes to the role of industrial symbiosis in driving CSC. Since the supplier is the starting point of CSC, its good relationship with the partner is crucial to ensure the smooth operation and efficiency of the whole SC [71]. Also, this partnership indirectly affects the interests of distributors and users. In addition, improving product quality, government financial support, and cycle-oriented SC redesign are also common key drivers for both subjects.

Cascading and reuse are now key drivers for manufacturers and distributors to implement CSC, as remanufacturing is an important means of achieving cascading and reuse by allowing manufacturers to produce new products from recycled materials and to convert the product to a reusable state through repair or refurbishment activities once it has reached its end life. In this context, cascading and reuse strengthen the relationship between SC subjects and the environment, enhancing operational flexibility and resource use efficiency, including recovery, reuse, and recycling [33,48]. In addition, to successfully implement CSC, firms need to reduce business risks on the supply side [45]. Manufacturers need to follow market trends and consumer preferences to adjust product lines, develop new products, and implement remanufacturing processes. In turn, distributors need to adjust their logistics strategies based on data and provide timely repairs and services to support product reuse. Therefore, although business flexibility is important for all subjects of SC, it is especially critical for manufacturers and distributors.

This research primarily highlights how certain key factors impact different subjects, without suggesting that other factors are unimportant in influencing these subjects. In addition to this, while the relationships shown by the dashed arrows in Figure 5 represent the main influences identified in the literature, other relationships between different factors may also occur so that the critical success factors affecting a single CSC subject act as a whole and as one of the enablers and relationships of CSC affecting other components. For example, I4.0 technologies have emerged as a key enabler for ensuring SC visibility [81]. In turn, SC visibility will help develop long-term relationships with suppliers and logistics partners [71]. By establishing cooperative relationships, SC parties are more willing to share key data and knowledge, which is the basis of Industry 4.0 technologies. Thus, Industry 4.0 technologies provide tools for enhanced visibility, increased visibility strengthens collaborative relationships, and strong collaborative relationships further facilitate the application and optimization of Industry 4.0 technologies. This mutually reinforcing relationship helps build a more efficient, transparent, and responsive SC that delivers greater value and competitive advantage to all involved. Driving the CSC to be successfully implemented. Finally, it is suggested that exploratory relationships, which are less described in the literature, could be discussed in future research.

5. Conclusions and Recommendations

Unlike previous studies that focus only on drivers, this study systematically analyzes the interactions between factors and their complex mechanisms of action on multiple subjects from a technology cycle perspective and creates a CSC implementation pathway framework to provide strategies for supply chains to successfully transition to CE. The results show that environmental benefits, environmental responsibility, and stakeholder awareness and participation are the most important factors influencing the implementation of CSC by all subjects, with contribution rates of 16.3%, 9.8%, and 9.4%, respectively.

Based on the CSC pathway framework for multiple actors, the following recommendations are made.

For suppliers and manufacturers, improving product quality and government financial support are their common main drivers, with contribution rates of 30.8% and 12.9%, respectively. Among them, government finance is an important external driver. By providing fiscal incentives, such as tax breaks, subsidies, and financial support, the government can provide economic support and motivation for each segment and promote the development of CE. However, the most direct impact of such incentives is reflected in the manufacturer and supplier segments, as they involve larger capital investments and adjustments in production processes. For manufacturers and suppliers with capital-intensive and complex production processes, governments should develop targeted financial incentives, including tax breaks and subsidies, and prioritize support for key areas such as remanufacturing and recycling technologies, to reduce cost burdens and maximize the effects of circular economy implementation.

For manufacturers and distributors, the green image and reputation of the company, and competitive pressure are important factors driving their collaboration in recycling practices, contributing 20.7% and 18.3% to their collaboration, respectively. There is a mutual positive effect between the two factors. As two entities directly facing the final market, manufacturers and distributors can work together to cope with the competition in the industry by sharing resources, joint research and development, and establishing strategic alliances.

For suppliers, manufacturers, and distributors, policies and regulations are the main factors driving their joint participation in CSC with a contribution rate of 25.7%. Resource flexibility, however, is key, ranking fourth among the three factors with a contribution rate of 10.8%. By adapting resource flexibility, suppliers can design and supply sustainable resources and effectively participate in the recycling process, manufacturers can quickly access and switch resources to adapt to changing market demands, and distributors further enhance the overall efficiency of the supply chain by flexibly deploying inventories and responding quickly to the market.

For suppliers, manufacturers, distributors, and users, environmental efficiency and environmental responsibility are the key factors driving the participation of all actors in the implementation of CSC, with a contribution rate of 16.3% and 9.8%, respectively. The world’s progressive awareness of the need to build a sustainable economy and environment in the future has prompted companies to adopt circular business models and a willingness to minimize adverse environmental impacts. At the same time, consumer concern for responsible environmental sustainability is growing, prompting consumers to reuse or repair products, which also motivates businesses to adopt more sustainable practices.

For business managers, CSC closed-loop capabilities should be built to maximize value. (1) Cross-entity technology synergy: for the product quality contribution rate (30.8%) to establish a supplier–manufacturer synergy strategy, enterprises, and suppliers to form a product modularization design an alliance to share detachable components to reduce the cost of recycling and build a reverse logistics network with distributors to share logistics costs. (2) Green value integration: utilizing the contribution rate of competitive pressure (18%) to promote upstream and downstream joint green certification and jointly create industry standards. It has also set up a “trade-in” closed-loop marketing area to increase the recycling rate. (3) Data-driven governance: by deploying a blockchain traceability system to track carbon footprints in real-time, we can ensure that the actions of each subject can be traced and accelerate the transition of CSC from “fuzzy promises” to “data contracts”.

For policymakers, the dynamic regulation of policies should be strengthened. (1) Optimize the financial incentive mechanism: for remanufacturing and recycling technologies, implement stepwise tax credits and utilization rate-linked subsidies. (2) Strengthen the technology-market double-binding: gradually implement product modularization design certification (requiring a ≥70% detachable rate of key components) and make it a precondition for government procurement and export licensing. (3) Build a cross-regional quota trading market: allow manufacturers to sell remanufacturing carbon emission reductions to energy-consuming industries to form a closed-loop incentive.

The above explanations suggest that the interactions between different factors and their impacts on different subjects still exist in research gaps, and this study explores and enhances the literature by filling these gaps. This provides important insights for policymaking related to the transformation of GSCs to CEs. Particularly in emerging economies, where supply chains are growing in size, there is an urgent need for multiple subjects to collaborate to achieve efficient closure of the supply chain given its continued expansion and transformation. A set of collaborative pathways must be constructed to harmonize economic development with environmental issues to ensure the sustainability of supply chains in the face of rapid economic development. This also provides a concrete path for practitioners who wish to utilize CSC to gain a competitive advantage and improves the participation of multiple actors and the coordination of collaboration.

Author Contributions

M.C.: Writing—original draft, Methodology, Investigation, Formal analysis, Data curation, and Conceptualization. T.W.: Writing—review and editing, Validation, Supervision, Resources, Project administration, and Funding acquisition. Q.Z.: Writing—review and editing, Validation, and Formal analysis. Y.H.: Writing—review and editing, Validation. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (72464007).

Data Availability Statement

The data supporting this study’s findings are available from the corresponding author upon request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Appendix A

Table A1.

Forty-six papers selected.

Table A1.

Forty-six papers selected.

| Literature (Author/Time) | Social | Policy | Organizational | Economic | Environment | Supply Chain | Technology | Information | Infrastructure | Circular Design and Services |

|---|---|---|---|---|---|---|---|---|---|---|

| [67] (Calzolari et al., 2023) | √ | √ | √ | √ | √ | |||||

| [35] (Ouro-Salim & Guarnieri, 2023) | √ | √ | √ | |||||||

| [6] (Amir et al., 2023) | √ | √ | √ | √ | √ | |||||

| [36] (Avikal et al., 2023) | √ | √ | √ | √ | √ | |||||

| [60] (Dohale et al., 2023) | √ | √ | √ | √ | √ | √ | ||||

| [51] (Dwivedi et al., 2023) | √ | √ | √ | √ | √ | √ | ||||

| [37] (Mishra et al., 2023) | √ | √ | √ | |||||||

| [62] (Faisal, 2023) | √ | √ | √ | √ | √ | |||||

| [40] (Ada et al., 2023) | √ | √ | √ | √ | √ | √ | √ | √ | ||

| [41] (Shaharudin et al., 2023) | √ | |||||||||

| [55] (Khan & Ali, 2022) | √ | √ | √ | √ | √ | √ | √ | |||

| [65] (Kayikci et al., 2022) | √ | √ | √ | √ | √ | |||||

| [33] (Khan et al., 2022) | √ | √ | √ | √ | ||||||

| [58] (Ersoy et al., 2022) | √ | √ | ||||||||

| [38] (Kayikci et al., 2021) | √ | √ | √ | √ | √ | √ | √ | |||

| [80] (Chen et al., 2022) | √ | √ | √ | √ | ||||||

| [47] (Lu et al., 2024) | √ | √ | √ | √ | √ | |||||

| [68] (Gebhardt et al., 2022) | √ | √ | √ | |||||||

| [66](Orji et al., 2022) | √ | √ | √ | √ | √ | √ | √ | √ | ||

| [32] (Dossa et al., 2022) | √ | √ | √ | |||||||

| [48] (Centobelli et al., 2021) | √ | √ | √ | √ | √ | √ | ||||

| [44] (Mehmood et al., 2021) | √ | √ | √ | √ | ||||||

| [61] (Chen et al., 2021) | √ | √ | √ | √ | ||||||

| [78] (Sawe et al., 2021) | √ | √ | √ | √ | ||||||

| [71] (Nag et al., 2021) | √ | √ | √ | √ | √ | |||||

| [42] (Calzolari et al., 2021) | √ | √ | √ | √ | √ | |||||

| [72] (Lahane & Kant, 2021) | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| [56] (Bressanelli et al., 2021) | √ | √ | √ | |||||||

| [63] (Lahane et al., 2021) | √ | √ | √ | √ | √ | √ | √ | |||

| [49] (Tseng et al., 2024) | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| [43] (Saroha et al., 2020) | √ | √ | √ | |||||||

| [5] (Lahane et al., 2020) | √ | √ | √ | √ | √ | √ | √ | |||

| [52] (Hussain & Malik, 2020) | √ | √ | √ | √ | √ | √ | ||||

| [59] (Alamerew & Brissaud, 2020) | √ | √ | √ | √ | ||||||

| [82] (Khan et al., 2020) | √ | √ | √ | √ | ||||||

| [50] (Ripanti & Tjahjono, 2019) | √ | √ | ||||||||

| [64] (Sandvik & Stubbs, 2019) | √ | √ | √ | √ | √ | |||||

| [57] (Manavalan & Jayakrishna, 2019) | √ | √ | √ | √ | √ | |||||

| [34] (Braun et al., 2018) | √ | √ | √ | √ | ||||||

| [69] (Govindan & Hasanagic, 2018) | √ | √ | √ | √ | ||||||

| [31] (Levering & Vos, 2019) | √ | √ | ||||||||

| [45] (Masi et al., 2017) | √ | √ | √ | √ | √ | √ | ||||

| [53] (Zeng et al., 2017) | √ | √ | √ | |||||||

| [39] (Caldera et al., 2019) | √ | √ | √ | √ | ||||||

| [46] (Moktadir et al., 2018) | √ | √ | √ | √ | √ | √ | √ | |||

| [54] (Tura et al., 2019) | √ | √ | √ | √ | √ | √ | √ | √ |

Table A2.

Summary of influencing factors.

Table A2.

Summary of influencing factors.

| Type | Factors | Source | Interpretation |

|---|---|---|---|

| Social | ISO certification | [66] | ISO certification means encouraging the implementation of CSC’s global quality standards |

| Employment | [69] | One of the features that motivated the government to implement CE was the prospect of increased employment | |

| Consumer demand | [51] | Organizations will be motivated to maintain CE practices if the demand for green products still exists | |

| Consumer awareness and attitudes | [82] | Consumer attitudes are a key factor in creating demand for recycled products and motivate companies to adopt recycling measures | |

| Cooperation and Collaboration of stakeholders | [62] | Stakeholder collaboration is a prerequisite for SCM success | |

| Improve the green image and reputation of enterprises | [57] | Good brand reputation is a positive impact in SC, bringing environmental, social and economic benefits | |

| CE publicity activities for the public | [36] | Promote the idea of implementing CE principles in SC in the market to increase public participation | |

| Understanding of circular economy insights | [52] | Mutual understanding of CE principles and insights by management and staff facilitates transition to CSCs | |

| Awareness and participation of stakeholders | [35] | The transition to CE requires the active participation of stakeholders, organizations and governments | |

| Policy | Regulations and policies | [53] | Compliance is the main driver for CE, and the main reason companies adopt CE practices is to avoid sanctions |

| Financial support by the government | [60] | The government should provide appropriate subsidies for the implementation of CSC to attract more industry participation |

Table A3.

Summary of influencing factors.

Table A3.

Summary of influencing factors.

| Type | Factors | Source | Interpretation |

|---|---|---|---|

| Organizational | Commitment and involvement of top management | [82] | Top management commitment is critical to the adoption of circular practices and the shift from SC to CE |

| Inclusive Communication | [78] | Effective communication is important because it provides employees with the opportunity to share their ideas, which in turn helps to develop and implement CE within the organization. | |

| Joint decision-making | [42] | Reuse, remanufacturing and recycling feedback loops, often requiring cooperation and joint decision-making by a larger number of participants in the same SC | |

| Recycling capacity | [71] | Product recyclability reflects the way a company manages the refurbishment or remanufacturing of its products/components | |

| Manufacturing capabilities | [41] | Manufacturing capabilities play an important role in determining the degree of CLSC orientation of a firm | |

| CE awareness training | [78] | CE needs to provide adequate awareness training for its employees; insufficient training can result in employees being unable and unwilling to participate in the change process | |

| Development of skills and capabilities for circular economy | [40] | Almost all stages of the SC process are driven by various sub-factors, such as increasing levels of worker knowledge and diversification of skills | |

| Increase products’ quality | [36] | Quality control of products is one of the important factors for the success of CSC implementation, i.e., maintaining the quality of remanufactured/recyclable products | |

| Environment | Environmental benefits | [44] | The impact of environmental protection on the adoption of CE and the economic benefits ranked as one of the top favorites |

| Increasing the efficiency of resource use | [45] | Improvements in resource and energy efficiency result in cost savings and, thus, contribute to the competitiveness of the enterprise, which is critical to the success of the enterprise in achieving CSC | |

| Environmental responsibility | [40] | Responsibilities related to the social and environmental aspects of sustainable development are key factors driving the application of the CE strategy throughout the SC |

Table A4.

Summary of influencing factors.

Table A4.

Summary of influencing factors.

| Type | Factors | Source | Interpretation |

|---|---|---|---|

| Supply Chain | Suppliers’ collaboration development | [66] | Supplier partnership development is critical to the success of both forward and reverse flows and facilitates CSC adoption |

| Resource flexibility | [38] | Resource flexibility contributes to sustainable development goals by reducing product life cycle costs and enabling the reuse of waste and water | |

| Structural flexibility | [52] | The CSC process is realized through greater flexibility in the SC structure, thus breaking down “linear lock-in” and geographic barriers | |

| Business flexibility | [45] | By increasing the flexibility of processes and products, organizations can reduce the business risk of SC. | |

| Adoption of CE culture throughout the supply chain | [49] | To implement CSCM, commitment from leadership must be supported by a strong culture that translates commitment into clear plans and actions | |

| Supply chain visibility | [82] | Implement traceability systems for effective and efficient tracking of materials/products and further recovery of products at the end of their use or functional life | |

| Economic | Competitive pressure | [42] | Even in the absence of coercive or regulatory pressures, companies continue to adopt CE practices, either by emulating industry peers or seeking opportunities for competitive advantage |

| Business and profit | [32] | Financial costs and benefits are one of the main drivers for organizations to adopt CE practices in SC | |

| Aware of the potential of cost | [37] | Reverse supply chain members are concerned with effectiveness and efficiency, including satisfaction with principal and low operating costs | |

| Investment in technology | [57] | Investments in technology help organizations to improve operational efficiency and, thus, become more proficient in CSC implementation | |

| Information | Information sharing | [35] | Circular business models require the exchange of information at multiple stages from design and production to distribution, use, maintenance and recycling |

| Knowledge sharing | [78] | Knowledge sharing can improve the success of CE in SME business processes |

Table A5.

Summary of influencing factors.

Table A5.

Summary of influencing factors.

| Type | Factors | Source | Interpretation |

|---|---|---|---|

| Technology | Industry 4.0 technologies | [56] | Industry 4.0 technologies play a key role in SCM, improving the quality and integrity of information and promising great advances in reverse logistics |

| Blockchain technology | [55] | Blockchain technology drives adoption of CE principle practices in SC to ensure security, transparency and visibility of SCs | |

| Information technology | [65] | Information technology provides the necessary networks, connectivity, sustainable compatibility and improved traceability of information in vertical and horizontal cycles and sustainable SC ecosystems | |

| Cleaner technology | [38] | Clean technology helps SC reduce carbon footprint in sustainable transition to CE | |

| Infrastructure | Innovation capacity | [34] | Effective extension of existing SCs to CE requires systemic changes in technological and non-technological innovations |

| Research and Development (R&D) intensity | [61] | An organization’s R&D intensity activities are an important tool for promoting CSCM adoption | |

| Availability of trained R&D team | [55] | Competent R&D team brings innovation, continuous improvement and SC sustainability | |

| Strong reverse logistics (RL) infrastructure | [38] | Green infrastructure is building lasting, cost-effective recycling networks that can effectively manage sustainability by conserving natural resources | |

| Lean tools | [72] | Lean tools, as a continuous improvement concept and an effective gatekeeper for recycling used/end-use products, can help companies reduce resource consumption in CSC | |

| Circular Design and Services | Cascading and reusing | [6] | For CSC, the vision of zero waste can be achieved by further developing the cascading application chains, not discarded |

| Industrial Symbiosis | [5] | Industrial symbiosis, a strategy that promotes cooperation between companies and resource recycling, is one of the key drivers of CSC | |

| Supply chain redesign for circularity | [62] | In order to realize the SC cycle, SC needs to be redesigned and consider incorporating CE principles into the early stages of the product design process | |

| Product design | [64] | Design for enhanced recyclability means designing products with high durability, long life or recyclability. The design phase is critical to achieving recycling |

References

- Kazancoglu, Y.; Kazancoglu, I.; Sagnak, M. A new holistic conceptual framework for green supply chain management performance assessment based on circular economy. J. Clean. Prod. 2018, 195, 1282–1299. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular economy: The concept and its limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- MacArthur, E. Towards the circular economy. J. Ind. Ecol. 2013, 2, 23–44. [Google Scholar]

- Farooque, M.; Zhang, A.; Thürer, M.; Qu, T.; Huisingh, D. Circular supply chain management: A definition and structured literature review. J. Clean. Prod. 2019, 228, 882–900. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R.; Shankar, R. Circular supply chain management: A state-of-art review and future opportunities. J. Clean. Prod. 2020, 258, 120859. [Google Scholar] [CrossRef]

- Amir, S.; Salehi, N.; Roci, M.; Sweet, S.; Rashid, A. Towards circular economy: A guiding framework for circular supply chain implementation. Bus. Strategy Environ. 2023, 32, 2684–2701. [Google Scholar] [CrossRef]

- Lee, Y.; Hu, J.; Lim, M.K. Revisiting circular economy indicators: A circular supply chain perspective. J. Purch. Supply Manag. 2024, 30, 100941. [Google Scholar] [CrossRef]

- Batista, L.; Bourlakis, M.; Smart, P.; Maull, R. In search of a circular supply chain archetype–a content-analysis-based literature review. Prod. Plan. Control 2018, 29, 438–451. [Google Scholar] [CrossRef]

- Sudusinghe, J.I.; Seuring, S. Supply chain collaboration and sustainability performance in circular economy: A systematic literature review. Int. J. Prod. Econ. 2022, 245, 108402. [Google Scholar] [CrossRef]

- Luthra, S.; Sharma, M.; Kumar, A.; Joshi, S.; Collins, E.; Mangla, S. Overcoming barriers to cross-sector collaboration in circular supply chain management: A multi-method approach. Transp. Res. Part E Logist. Transp. Rev. 2022, 157, 102582. [Google Scholar] [CrossRef]

- Momeni, M.A.; Jain, V.; Govindan, K.; Mostofi, A.; Fazel, S.J. A novel buy-back contract coordination mechanism for a manufacturer-retailer circular supply chain regenerating expired products. J. Clean. Prod. 2022, 375, 133319. [Google Scholar] [CrossRef]

- Ahmed, H.; Al Bashar, M.; Taher, M.A.; Rahman, M.A. Innovative Approaches To Sustainable Supply Chain Management In The Manufacturing Industry: A Systematic Literature Review. Glob. Mainstream J. Innov. Eng. Emerg. Technol. 2024, 3, 1–13. [Google Scholar] [CrossRef]

- Zhang, A.; Wang, J.X.; Farooque, M.; Wang, Y.; Choi, T.M. Multi-dimensional circular supply chain management: A comparative review of the state-of-the-art practices and research. Transp. Res. Part E Logist. Transp. Rev. 2021, 155, 102509. [Google Scholar] [CrossRef]

- Ayati, S.M.; Shekarian, E.; Majava, J.; Wæhrens, B.V. Toward a circular supply chain: Understanding barriers from the perspective of recovery approaches. J. Clean. Prod. 2022, 359, 131775. [Google Scholar] [CrossRef]

- Aminoff, A.; Kettunen, O. Sustainable supply chain management in a circular economy—Towards supply circles. In Sustainable Design and Manufacturing 2016; Springer International Publishing: Cham, Switzerland, 2016; pp. 61–72. [Google Scholar]

- McDonough, W.; Braungart, M. Remaking the Way We Make Things: Cradle to Cradle; North Point Press: New York, NY, USA, 2002; ISBN 1224942886. [Google Scholar]

- Nasir, M.H.A.; Genovese, A.; Acquaye, A.A.; Koh, S.C.L.; Yamoah, F. Comparing linear and circular supply chains: A case study from the construction industry. Int. J. Prod. Econ. 2017, 183, 443–457. [Google Scholar] [CrossRef]

- De Angelis, R.; Howard, M.; Miemczyk, J. Supply chain management and the circular economy: Towards the circular supply chain. Prod. Plan. Control 2018, 29, 425–437. [Google Scholar] [CrossRef]

- Montag, L. Circular economy and supply chains: Definitions, conceptualizations, and research agenda of the circular supply chain framework. Circ. Econ. Sustain. 2023, 3, 35–75. [Google Scholar] [CrossRef]

- Batista, L.; Bourlakis, M.; Liu, Y.; Smart, P.; Sohal, A. Supply chain operations for a circular economy. Prod. Plan. Control 2018, 29, 419–424. [Google Scholar] [CrossRef]

- Nuss, C.; Sahamie, R.; Stindt, D. The reverse supply chain planning matrix: A classification scheme for planning problems in reverse logistics. Int. J. Manag. Rev. 2015, 17, 413–436. [Google Scholar] [CrossRef]

- Falagas, M.E.; Pitsouni, E.I.; Malietzis, G.A.; Pappas, G. Comparison of PubMed, Scopus, web of science, and Google scholar: Strengths and weaknesses. FASEB J. 2008, 22, 338–342. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Pinho, C.; Mendes, L. IT in lean-based manufacturing industries: Systematic literature review and research issues. Int. J. Prod. Res. 2017, 55, 7524–7540. [Google Scholar] [CrossRef]

- Sehnem, S.; Vazquez-Brust, D.; Pereira, S.C.F.; Campos, L.M. Circular economy: Benefits, impacts and overlapping. Supply Chain. Manag. Int. J. 2019, 24, 784–804. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a systematic review. In The Sage Handbook of Organisational Research Methods; Sage: Newcastle upon Tyne, UK, 2009; pp. 671–689. [Google Scholar]

- Thomé, A.M.T.; Scavarda, L.F.; Scavarda, A.J. Conducting systematic literature review in operations management. Prod. Plan. Control 2016, 27, 408–420. [Google Scholar] [CrossRef]

- Jung, H.; Lee, B.G. Research trends in text mining: Semantic network and main path analysis of selected journals. Expert Syst. Appl. 2020, 162, 113851. [Google Scholar] [CrossRef]

- Wallin, J.A. Bibliometric methods: Pitfalls and possibilities. Basic Clin. Pharmacol. Toxicol. 2005, 97, 261–275. [Google Scholar] [CrossRef]

- Tian, M.; Hu, Y.J.; Wang, H.; Li, C. Regional allowance allocation in China based on equity and efficiency towards achieving the carbon neutrality target: A composite indicator approach. J. Clean. Prod. 2022, 342, 130914. [Google Scholar] [CrossRef]

- Levering, R.; Vos, B. Organizational drivers and barriers to circular supply chain operations. In Operations Management and Sustainability: New Research Perspectives; Palgrave Macmillan: London, UK, 2019; pp. 43–66. [Google Scholar] [CrossRef]

- Dossa, A.A.; Gough, A.; Batista, L.; Mortimer, K. Diffusion of circular economy practices in the UK wheat food supply chain. Int. J. Logist. Res. Appl. 2022, 25, 328–347. [Google Scholar] [CrossRef]

- Khan, S.; Haleem, A.; Khan, M.I. A grey-based framework for circular supply chain management: A forward step towards sustainability. Manag. Environ. Qual. Int. J. 2022, 33, 1476–1501. [Google Scholar] [CrossRef]

- Braun, A.T.; Kleine-Moellhoff, P.; Reichenberger, V.; Seiter, S. Case study analysing potentials to improve material efficiency in manufacturing supply chains, considering circular economy aspects. Sustainability 2018, 10, 880. [Google Scholar] [CrossRef]

- Ouro-Salim, O.; Guarnieri, P. Drivers and barriers in the institutionalisation of circular economy practices in food supply chains: A review. Bus. Strategy Dev. 2023, 6, 764–784. [Google Scholar] [CrossRef]

- Avikal, S.; Pant, R.; Barthwal, A.; Ram, M.; Upadhyay, R.K. Factors implementing sustainable circular economy in agro-produce supply chain: DEMATEL-DANP-based approach. Manag. Environ. Qual. Int. J. 2023, 34, 1158–1173. [Google Scholar] [CrossRef]

- Mishra, A.; Dutta, P.; Jayasankar, S.; Jain, P.; Mathiyazhagan, K. A review of reverse logistics and closed-loop supply chains in the perspective of circular economy. Benchmarking Int. J. 2023, 30, 975–1020. [Google Scholar] [CrossRef]

- Kayikci, Y.; Kazancoglu, Y.; Lafci, C.; Gozacan-Chase, N.; Mangla, S.K. Smart circular supply chains to achieving SDGs for post-pandemic preparedness. J. Enterp. Inf. Manag. 2021, 35, 237–265. [Google Scholar] [CrossRef]

- Caldera, H.T.S.; Desha, C.; Dawes, L. Evaluating the enablers and barriers for successful implementation of sustainable business practice in ‘lean’SMEs. J. Clean. Prod. 2019, 218, 575–590. [Google Scholar] [CrossRef]

- Ada, E.; Sezer, M.D.; Khaleel, R. Towards the Smart Sustainable and Circular Food Supply Chains Through Digital Technologies. Int. J. Math. Eng. Manag. Sci. 2023, 8, 374–402. [Google Scholar] [CrossRef]

- Shaharudin, M.R.; Zailani, S.; Tan, K.C.; Cross, J.; Hotrawaisaya, C. Fostering closed-loop supply chain orientation by leveraging strategic green capabilities for circular economy performance: Empirical evidence from Malaysian electrical and electronics manufacturing firms. Environ. Dev. Sustain. 2023, 1–38. [Google Scholar] [CrossRef]

- Calzolari, T.; Genovese, A.; Brint, A. The adoption of circular economy practices in supply chains–An assessment of European Multi-National Enterprises. J. Clean. Prod. 2021, 312, 127616. [Google Scholar] [CrossRef]

- Saroha, M.; Garg, D.; Luthra, S. Pressures in implementation of circular supply chain management for sustainability: An analysis from Indian industries perspective. Manag. Environ. Qual. Int. J. 2020, 31, 1091–1110. [Google Scholar] [CrossRef]

- Mehmood, A.; Ahmed, S.; Viza, E.; Bogush, A.; Ayyub, R.M. Drivers and barriers towards circular economy in agri-food supply chain: A review. Bus. Strategy Dev. 2021, 4, 465–481. [Google Scholar] [CrossRef]

- Masi, D.; Day, S.; Godsell, J. Supply chain configurations in the circular economy: A systematic literature review. Sustainability 2017, 9, 1602. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Rahman, T.; Rahman, M.H.; Ali, S.M.; Paul, S.K. Drivers to sustainable manufacturing practices and circular economy: A perspective of leather industries in Bangladesh. J. Clean. Prod. 2018, 174, 1366–1380. [Google Scholar] [CrossRef]

- Lu, H.; Zhao, G.; Liu, S. Integrating circular economy and Industry 4.0 for sustainable supply chain management: A dynamic capability view. Prod. Plan. Control 2024, 35, 170–186. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Esposito, E.; Passaro, R. Determinants of the transition towards circular economy in SMEs: A sustainable supply chain management perspective. Int. J. Prod. Econ. 2021, 242, 108297. [Google Scholar] [CrossRef]

- Tseng, M.L.; Tran, T.P.T.; Fujii, M.; Lim, M.K.; Negash, Y.T. Modelling hierarchical circular supply chain management enablers in the seafood processing industry in Vietnam under uncertainties. Int. J. Logist. Res. Appl. 2024, 27, 30–58. [Google Scholar] [CrossRef]

- Ripanti, E.F.; Tjahjono, B. Unveiling the potentials of circular economy values in logistics and supply chain management. Int. J. Logist. Manag. 2019, 30, 723–742. [Google Scholar] [CrossRef]

- Dwivedi, A.; Chowdhury, P.; Paul, S.K.; Agrawal, D. Sustaining circular economy practices in supply chains during a global disruption. Int. J. Logist. Manag. 2023, 34, 644–673. [Google Scholar] [CrossRef]

- Hussain, M.; Malik, M. Organizational enablers for circular economy in the context of sustainable supply chain management. J. Clean. Prod. 2020, 256, 120375. [Google Scholar] [CrossRef]

- Zeng, H.; Chen, X.; Xiao, X.; Zhou, Z. Institutional pressures, sustainable supply chain management, and circular economy capability: Empirical evidence from Chinese eco-industrial park firms. J. Clean. Prod. 2017, 155, 54–65. [Google Scholar] [CrossRef]

- Tura, N.; Hanski, J.; Ahola, T.; Ståhle, M.; Piiparinen, S.; Valkokari, P. Unlocking circular business: A framework of barriers and drivers. J. Clean. Prod. 2019, 212, 90–98. [Google Scholar] [CrossRef]

- Khan, F.; Ali, Y. Implementation of the circular supply chain management in the pharmaceutical industry. Environ. Dev. Sustain. 2022, 24, 13705–13731. [Google Scholar] [CrossRef] [PubMed]

- Bressanelli, G.; Pigosso, D.C.; Saccani, N.; Perona, M. Enablers, levers and benefits of Circular Economy in the Electrical and Electronic Equipment supply chain: A literature review. J. Clean. Prod. 2021, 298, 126819. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. An analysis on sustainable supply chain for circular economy. Procedia Manuf. 2019, 33, 477–484. [Google Scholar] [CrossRef]

- Ersoy, P.; Börühan, G.; Kumar Mangla, S.; Hormazabal, J.H.; Kazancoglu, Y.; Lafcı, Ç. Impact of information technology and knowledge sharing on circular food supply chains for green business growth. Bus. Strategy Environ. 2022, 31, 1875–1904. [Google Scholar] [CrossRef]

- Alamerew, Y.A.; Brissaud, D. Modelling reverse supply chain through system dynamics for realizing the transition towards the circular economy: A case study on electric vehicle batteries. J. Clean. Prod. 2020, 254, 120025. [Google Scholar] [CrossRef]

- Dohale, V.; Ambilkar, P.; Kumar, A.; Mangla, S.K.; Bilolikar, V. Analyzing the enablers of circular supply chain using Neutrosophic-ISM method: Lessons from the Indian apparel industry. Int. J. Logist. Manag. 2023, 34, 611–643. [Google Scholar] [CrossRef]

- Chen, X.; Chen, L.; Jiang, M.; Yan, J. Does R&D intensity promote the adoption of circular supply chain management? Evidence from China. Ind. Mark. Manag. 2021, 99, 153–166. [Google Scholar] [CrossRef]

- Faisal, M.N. Role of Industry 4.0 in circular supply chain management: A mixed-method analysis. J. Enterp. Inf. Manag. 2023, 36, 303–322. [Google Scholar] [CrossRef]

- Lahane, S.; Prajapati, H.; Kant, R. Evaluating and ranking the circular supply chain implementation enablers. J. Eng. Res. 2021, 2021, 1–10. [Google Scholar] [CrossRef]

- Sandvik, I.M.; Stubbs, W. Circular fashion supply chain through textile-to-textile recycling. J. Fash. Mark. Manag. Int. J. 2019, 23, 366–381. [Google Scholar] [CrossRef]

- Kayikci, Y.; Kazancoglu, Y.; Gozacan-Chase, N.; Lafci, C. Analyzing the drivers of smart sustainable circular supply chain for sustainable development goals through stakeholder theory. Bus. Strategy Environ. 2022, 31, 3335–3353. [Google Scholar] [CrossRef]

- Orji, I.J.; U-Dominic, C.M.; Okwara, U.K. Exploring the determinants in circular supply chain implementation in the Nigerian manufacturing industry. Sustain. Prod. Consum. 2022, 29, 761–776. [Google Scholar] [CrossRef]

- Calzolari, T.; Bimpizas-Pinis, M.; Genovese, A.; Brint, A. Understanding the relationship between institutional pressures, supply chain integration and the adoption of circular economy practices. J. Clean. Prod. 2023, 432, 139686. [Google Scholar] [CrossRef]

- Gebhardt, M.; Spieske, A.; Birkel, H. The future of the circular economy and its effect on supply chain dependencies: Empirical evidence from a Delphi study. Transp. Res. Part E Logist. Transp. Rev. 2022, 157, 102570. [Google Scholar] [CrossRef]

- Govindan, K.; Hasanagic, M. A systematic review on drivers, barriers, and practices towards circular economy: A supply chain perspective. Int. J. Prod. Res. 2018, 56, 278–311. [Google Scholar] [CrossRef]