Viable and Agile Model for Improving the Quality Area in an Automotive Company in Mexico

Abstract

1. Introduction

1.1. Systems Thinking

- Our object of study will be conceptualized not as an isolated entity, but as part of a larger system or set.

- A global perspective of the system under study is sought.

- The system is understood from its relationship to other systems.

1.2. Literature Review

1.3. Case Study Company

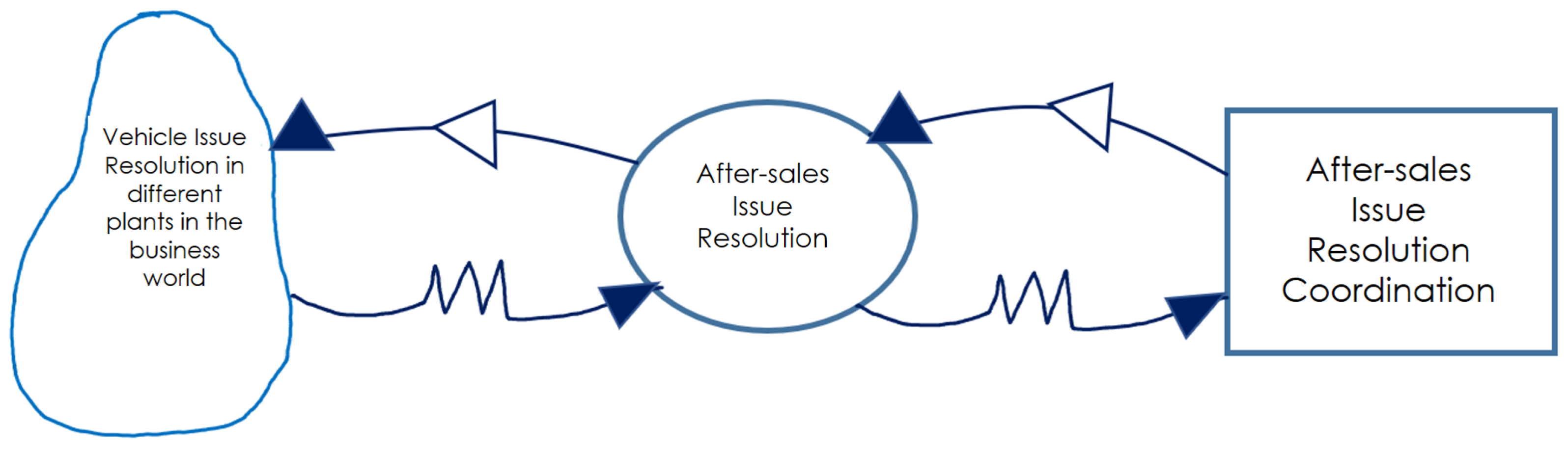

- Vehicle Issue Resolution (VIR): In this division, the team manages issues arising from two sources: presale production issues and customer complaints (post-sale). Its main responsibilities are to analyze the problem and manage activities with different Stellantis areas worldwide, which can help identify the root cause of the problem.

- Incident Program and Resolution Management (QPM): In this division, the team manages issues through a problem platform and manages the corresponding activities for closure.

- Quality System Management (QMS): This division is responsible for managing the quality certification system. Its administration is carried out jointly with different areas of the company in Mexico. For this research, we will focus on the Issue Resolution area, the process of which is described in detail below:

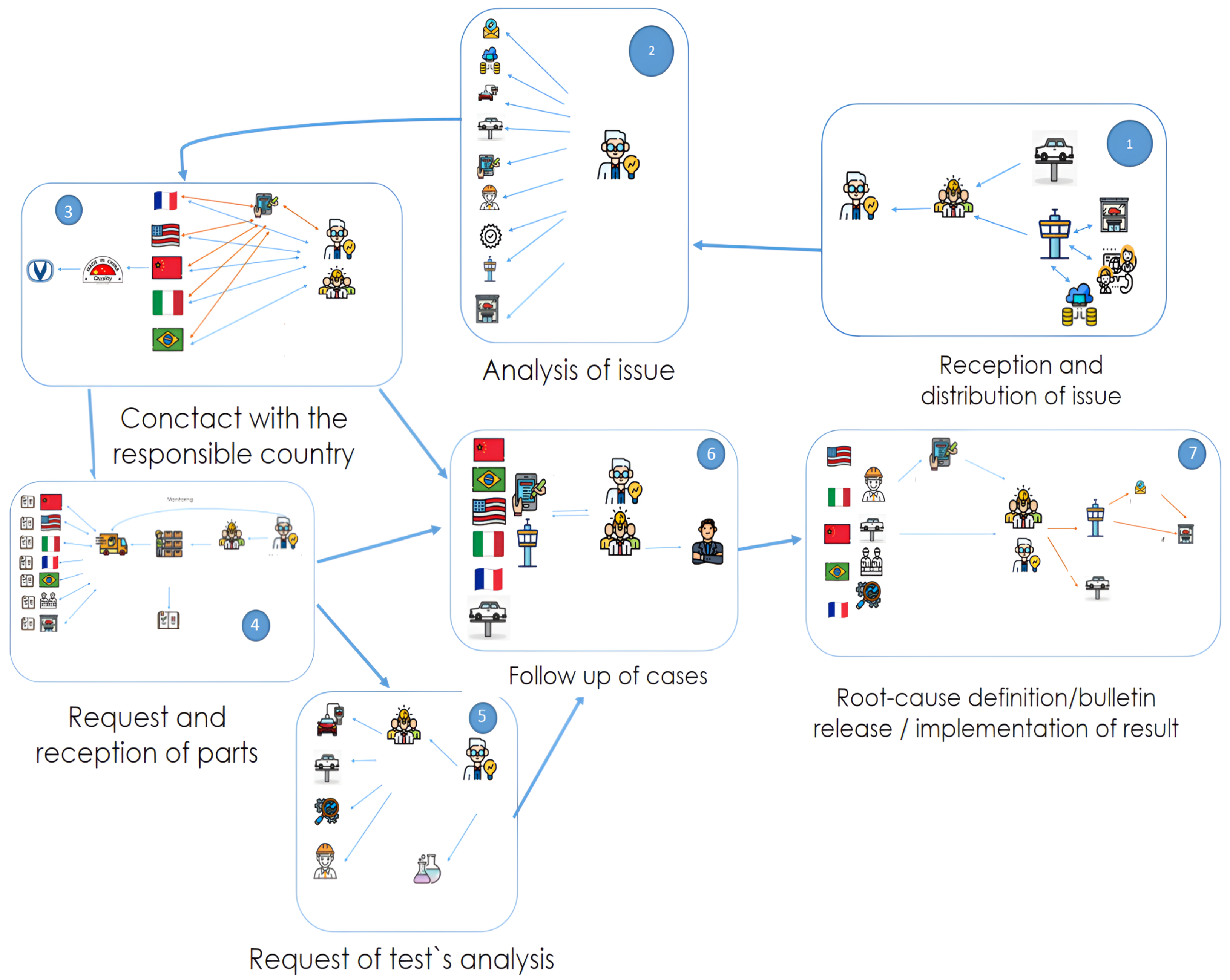

- Initial Detection and Documentation. The first crucial step in this process is the identification of defects. These defects can arise from two sources: defects present in vehicles before sale or defects found in vehicles that have already been sold and are in use by the customer. Once a defect has been identified, detailed documentation begins. This information is essential for analysts to fully understand the problem and take the appropriate actions.

- In-depth Analysis and Global Communication. Subsequently, the Analysts delve into a thorough investigation of each defect. By gathering and analyzing relevant data, they aim to understand the underlying causes of the problem. In many cases, collaboration with experts in other countries is necessary to gain a global perspective and access specialized resources. Effective communication among the various teams involved is essential to ensure the efficiency of the process.

- Obtaining and Analyzing Physical Evidence. To support the conclusions of the analysis, it is often necessary to physically examine the affected parts or components. Through laboratory tests or field tests, engineers can identify failure patterns and determine the root cause of the problem. The logistics of obtaining the required parts is a significant aspect to consider and is carried out in coordination with warehouses and transportation companies.

- Monitoring and Final Resolution. Throughout the process, rigorous monitoring of each case is performed. Analysts, supported by their leaders and representatives from the countries involved, monitor the progress of the investigations and ensure that deadlines are met. Once the root cause of a defect has been identified, the results are communicated to stakeholders, and the necessary corrective actions are implemented. In the case of products already on the market, informative bulletins are issued to inform customers about the implemented solutions.

- The time taken to resolve issues is excessively long.

- There are numerous intermediaries through whom communication must pass to obtain any type of response.

- There is poor management from the Project Leader with their Analysts, as the Leader himself lacks knowledge on how to improve the process.

- Post-sales expenses: These arise from excessive warranty payments as, in the absence of effective solutions, parts are simply replaced with new ones due to the urgency of the customer. Additional costs may also arise from potential customer lawsuits, which could harm the reputation of the brands.

- Pre-sales expenses: These are generated by poor design and delays in vehicle production due to the time required to obtain solutions from the corresponding country.

- Furthermore, there is inadequate identification of the interacting elements within the system and their integration.

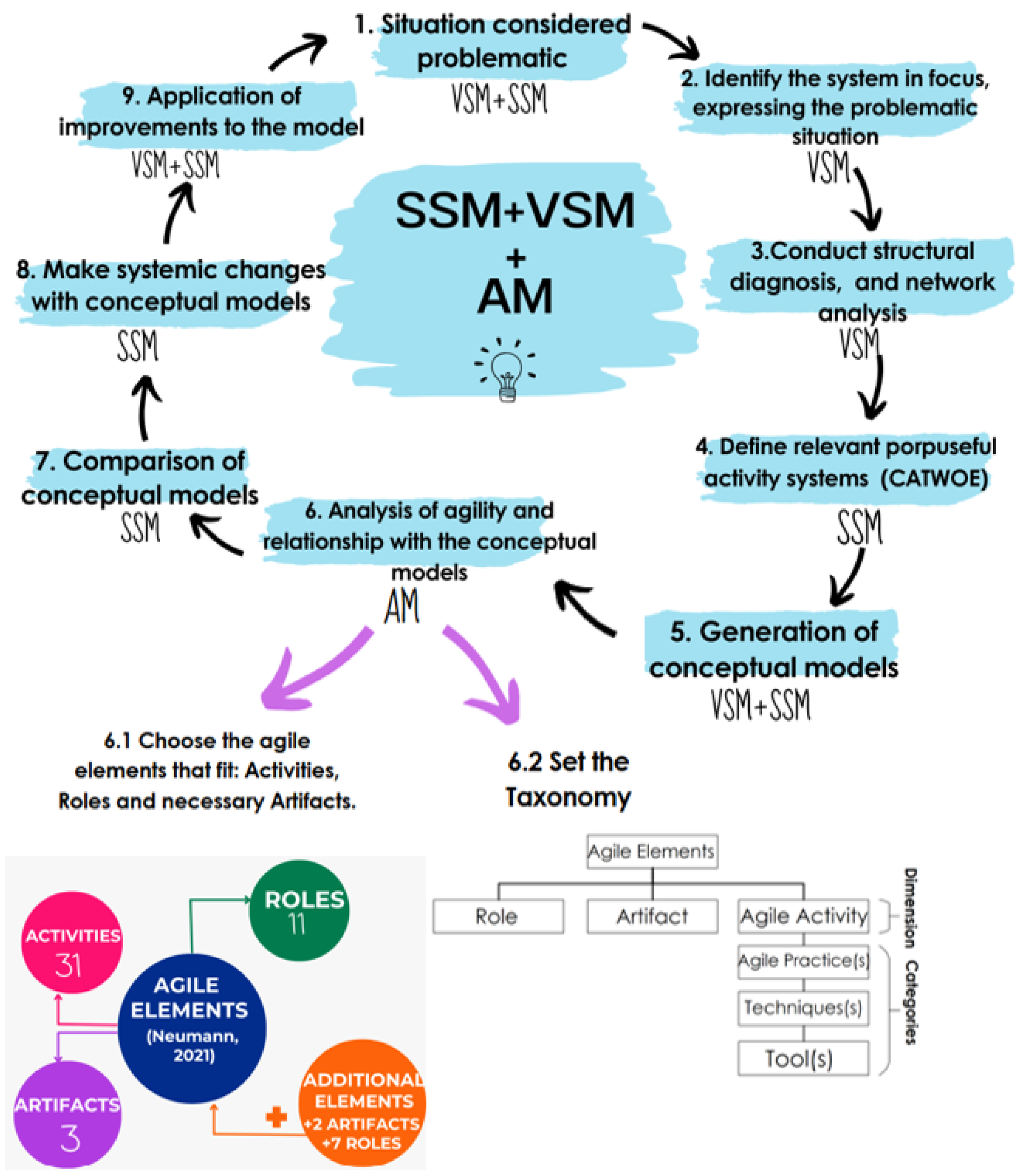

2. Materials and Methods

- Soft Systems Methodology (SSM): Developed by Peter Checkland, SSM is an approach used to address complex and poorly structured problems within organizations and other social systems. It is particularly useful in ambiguous and conflicting situations where the problems are not clearly defined and may be perceived differently by the various stakeholders involved [53].

- Viable System Model (VSM): Developed by Stafford Beer, the VSM is a theory and tool for organizational management and design based on cybernetic principles. The model focuses on how complex systems, such as organizations, can remain viable and adapt to changing environments through self-management and self-regulation [54].

- Agile Methodologies: Agile methodologies focus on iterative value delivery, flexibility, and continuous improvement in uncertain and dynamic contexts [55].

2.1. Constraints of Each Methodology

- VSM contributes a systemic structural foundation and logic to achieve organizational viability.

- SSM enriches the process by incorporating stakeholder perspectives and addressing ambiguity in complex human systems.

- Agile introduces operational agility and practical mechanisms for iterative improvement and rapid adaptation.

2.2. Complementarity of Methodologies

2.3. Stage 1: Situation Considered Problematic

- Input: This refers to everything that enters the system to be processed, such as data, materials, instructions, or signals. Essentially, it serves as the starting point that triggers the process [68].

- Process: At this stage, transformation occurs. The information or material received is analyzed and processed according to predefined rules to produce something useful or necessary [69].

- Output: This represents the result of the process, whether it is a product, a solution to a problem, or processed information ready for use. The quality of the output depends on both the input and the way it has been processed [70].

- Feedback: To ensure continuous improvement, the system reviews its results and reintegrates them as new input. This allows for adjustments and optimization, ensuring stability and control [71].

2.4. Stage 2: Identify the System in Focus, Expressing the Problematic Situation

2.5. Stage 3: Conduct Structural Diagnosis and Network Analysis

2.5.1. Qualitative Analysis

- Analysis of Environmental Complexity: Identify and understand the external variables that can affect the system, such as economic, technological, social, and political factors.

- Mapping of VSM Subsystems: Understand how the different subsystems interact and how each contributes to the overall viability of the system.

- Consideration of Human and Cultural Factors: Integrate informal dynamics, organizational culture, shared values, and internal politics into the analysis, as these elements are crucial for a complete understanding of the system.

- Evaluation of Adaptive Capacity: Identify and analyze the feedback mechanisms that allow the system to adapt and respond to changes in its environment (homeostasis).

- Analysis of Synergy between Subsystems and Environment: Assess how the organization relates to and interacts with its environment, beyond internal interactions among subsystems.

2.5.2. Quatitative Analysis

- Centrality parameters. These parameters in a network allow for the identification of the importance and role of each node within a connection structure. they provided a means to measure the extent to which the network structure contributes to the importance or status of a node within a network. Over the years, many different centrality metrics have been defined [76]. The Centrality Parameters are described in Table 2, including certain features such as variable, definition, equation, and parameters.

- Random Networks. The Table 3 describes the properties of Random Networks including certain elements such as variable, definition, equation, and parameters.

- G(N,L) model: N-labeled nodes are connected with L randomly placed edges.

- G(N,p) model: Each pair of N-labeled nodes is related with a probability p.

| Variable | Definition | Equation | Parameters |

|---|---|---|---|

| Degree (k) | Represents the number of links a node has with other nodes [67]. | : in-degree, : out-degree. | |

| Links (L) | Total number of interactions [67]. | For an undirected network:

| N is the number of nodes. |

| Maximum Links () | Represents the maximum number of possible interactions in the network [67]. | N is the number of nodes. | |

| Average Degree () | The average number of links per node in the network [67]. | For undirected networks:

| N: number of nodes, L: number of links. |

| Density (D) | Determines how dense or sparse the network is [67]. | L: number of links, : maximum number of links. | |

| Clustering Coefficient () | Quantifies how well the neighbors of a vertex are connected [78,79]. | : number of edges between neighbors of node i, : degree of node i. | |

| Betweenness and Closeness () | Measures how often a node is part of the shortest path (Betweenness). Closeness indicates how close a node is to all other nodes in the network [80]. | : total number of shortest paths between s and t, : number of shortest paths passing through v. |

| Variable | Definition | Equation | Parameters |

|---|---|---|---|

| Probability of a random network to have L links () | The probability of a random network to have L links is related to the probability of successfully linking L () and the maximum number of possible links in the network (). | L: number of links : maximum number of links | |

| Expected number of links | Average number of connections expected to be found in the network. | : Probability of a random network to have L links N: number of nodes L: number of links p: probability | |

| Average degree of a random network | Average number of connections (edges) that each node in the network has. | N: number of nodes L: number of links p: probability |

| Variable | Definition | Equation | Parameters |

|---|---|---|---|

| Binomial Distribution | In a random network, the probability that the node (i) has exactly k links [67]. | : The probability that a node has exactly k links [67]. : The binomial coefficient, representing the number of ways to choose k links from possible nodes. N: The total number of nodes in the network. k: The number of links or connections. p: The probability of a link existing between any two nodes. This value is constant in a random network. : The probability that the node does not connect to the remaining nodes. | |

| Poisson Distribution | A special case of the binomial distribution where the probability p gradually decreases towards zero () while the exponent k increases indefinitely () [81]. | : The probability that a node has exactly k links (connections). e: The base of the natural logarithm (approximately 2.71828), representing continuous growth in probabilistic models. : The average degree of the network. k: Number of links or connections. : Factorial of k, which normalizes the distribution to ensure the total probability equals 1. |

| Regime | Equation | Definition |

|---|---|---|

| Subcritical | In this phase, the network consists of numerous small components, and it is impossible to distinguish any particularly large group. | |

| Critical | At this stage, the regime is separated into one where there is still no giant component and another where one exists; however, the nodes are distributed among numerous components, without a single giant component identified. | |

| Supercritical | This is considered the most relevant regime for real systems, as it is the first time a giant component similar to a network is present. | |

| Connected | For sufficiently large p, the giant component absorbs all nodes and components, resulting in . There are no isolated nodes, so the network is fully connected. |

2.6. Stage 4: Define Relevant Purposeful Activity Systems (CATWOE)

- C = “Customers”—the beneficiaries or victims of the transformation process.

- A = ‘Actors’, those who carry out the transformation process.

- T = ‘Transformation’—the conversion of input into output.

- W = ‘World vision’—the world vision that makes this transformation meaningful.

- O = ‘Owners’, those who could stop the transformation.

- E = ‘Environmental constraints’, elements outside the system that are taken for granted.

2.7. Stage 5: Generation of Conceptual Models

- System 1

- System 2

- System 3

- System 3*

- System 4

- System 5

2.8. Stage 6: Analysis of Agility and Relationship with Conceptual Models

- Identification of attenuators and amplifiersOnce the model is formed, an analysis of the attenuators and amplifiers is carried out in each of the identified systems. Attenuators and Amplifiers are tools for managing complexity used in VSM to achieve a balance between the variety of the environment and the responsiveness of the organization [95]. These are defined as follows:

- Attenuators: These are mechanisms whose purpose is to reduce the complexity of the environment by filtering and selecting the aspects that are relevant to the organization.

- Amplifiers: In contrast, amplifiers increase the organization’s capacity to cope with complexity.

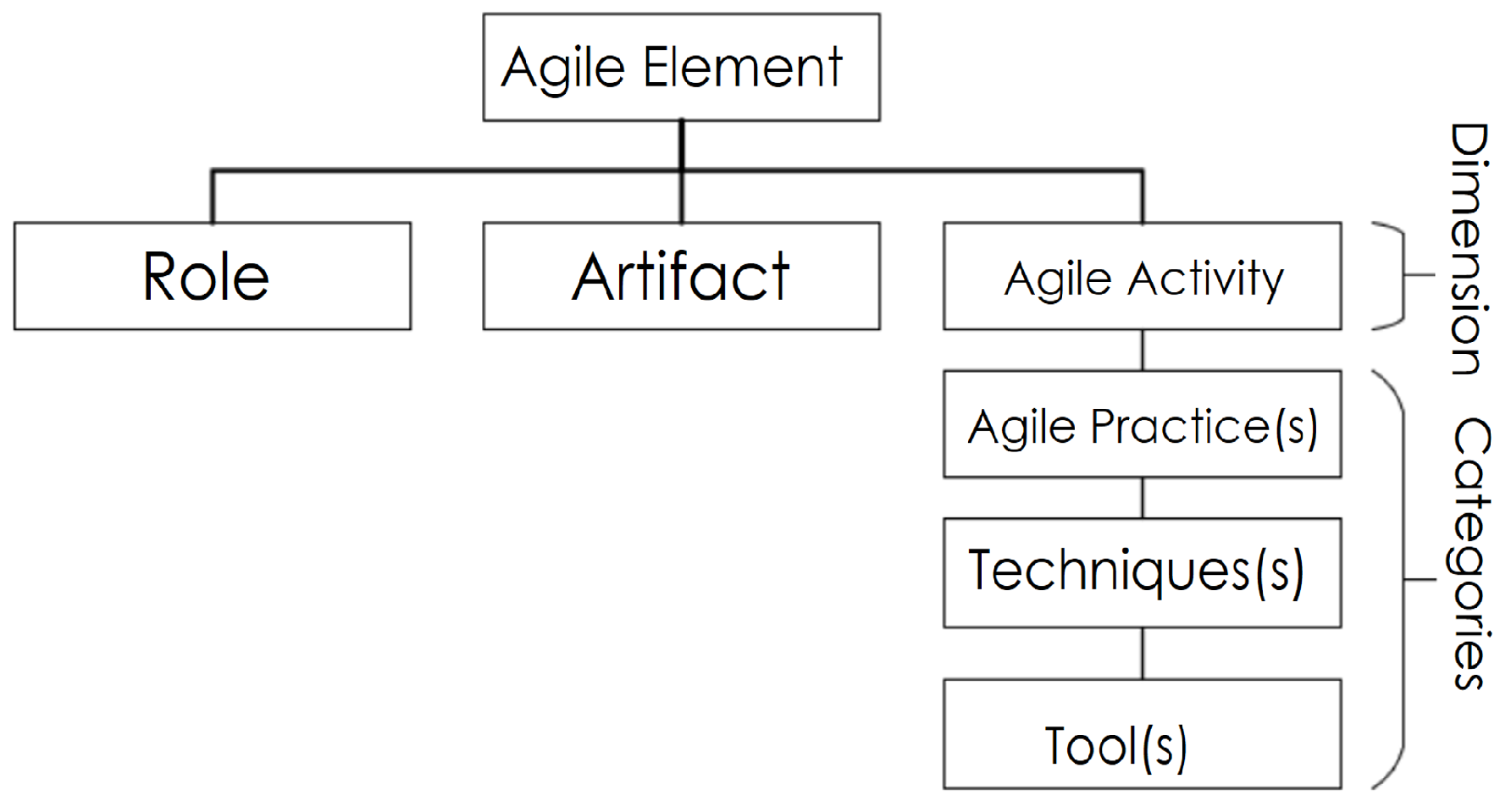

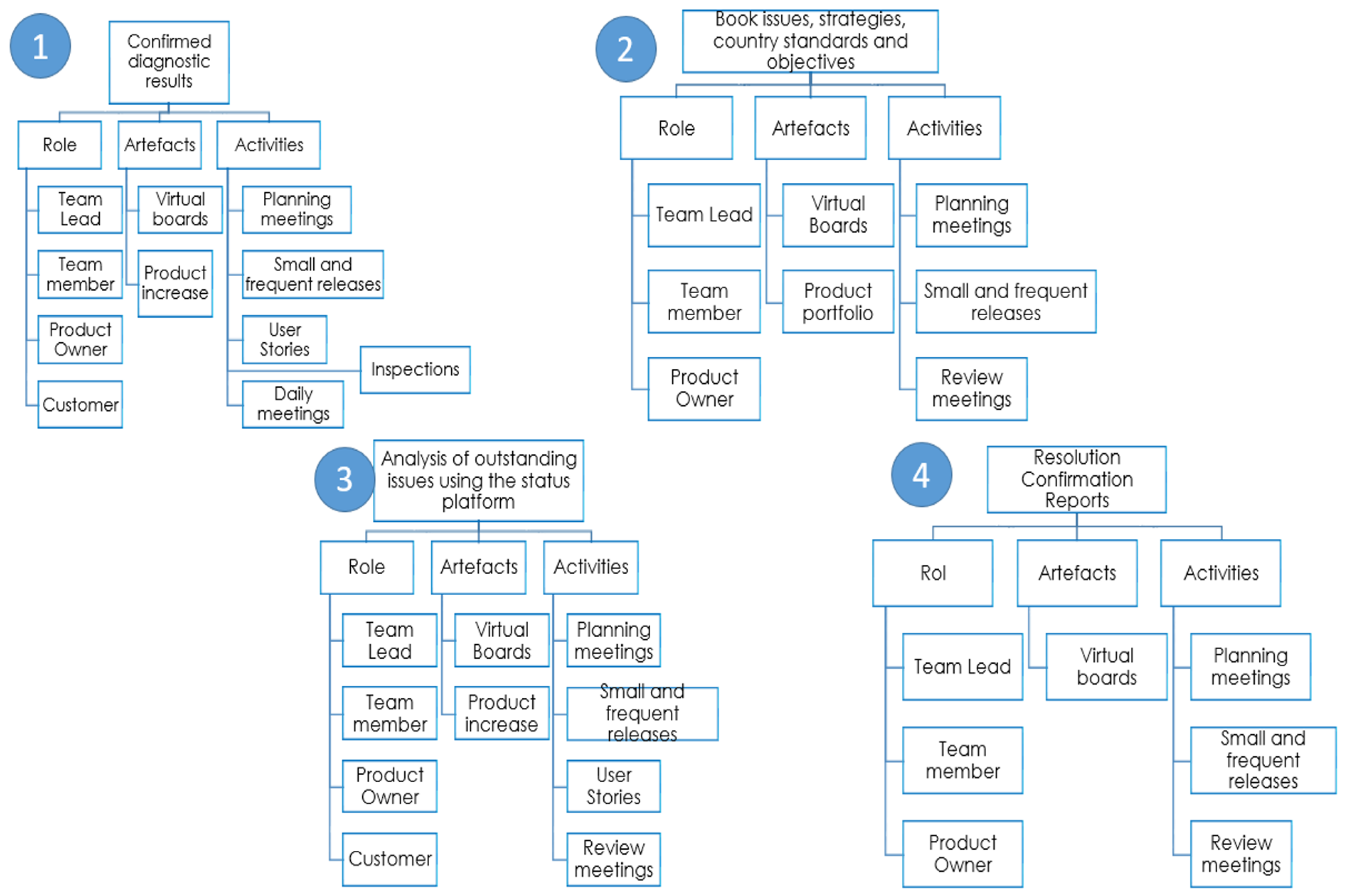

These tools are derived from the Ashby’s Law. It establishes that: “only variety can absorb variety, “where variety is a measure of complexity: “the number of possible states of the system” [96]. This law takes into account both internal and external complexity. When a system is complex, it exhibits a high degree of diversity [97]. In contrast, when it is simple, the diversity is limited.To achieve a balance in varieties, it is necessary to increase variety in management and reduce variety in operations, and the most effective way to allow units and individuals to self-manage (self-organization and self-control) involves providing adequate training and ensuring appropriate information flows within the organization [87]. - Agile Elements IdentificationAgile elements are a set of principles and practices for project management and software development that prioritize flexibility, collaboration, and rapid, continuous delivery of functional products [55]. To select the elements that will function as attenuators or amplifiers, a selection is made from a list of 45 elements, which in turn are divided into three dimensions: activities, roles, and artifacts, created by Neumann in [98]. Additionally, 9 elements have been added Table 6, which will help complement the existing list.To enhance the adaptability and comprehensiveness of the proposed model, 9 additional agile elements were incorporated into the original list of 45 elements. These additions stem primarily from Scrum, a widely recognized agile framework that emphasizes flexibility, collaboration, and continuous improvement in project management and product development [77]. The inclusion of these elements aims to better align the model with real-world practices, particularly in complex, multinational environments like the automotive industry. Regarding the agile elements added: Virtual Boards and Physical Boards promote transparency and continuous task tracking [99,100].The Team Lead adapts agile leadership to hierarchical environments [101], while the Project Sponsor ensures strategic alignment and resource allocation [102]. The Team Member reinforces self-management within cross-functional teams [77], and the Subject Matter Expert provides specialized knowledge for complex projects [103]. The Finance Partner ensures financial decisions are aligned with agile project goals [104]. Finally, the Service Request Manager and Service Delivery Manager integrate agile principles into service management [105]. These additions reflect the evolving nature of agile methodologies, adapting core principles to the specific needs of the automotive industry’s Quality Management processes.

- Agile taxonomy formationIn this stage, the selected elements for each previously chosen attenuator or amplifier are classified, each subsystem must have at least one element of each classification: roles, activities and artifacts, whose function is to ensure that the new structure generated during the creation of the model (done in the previous stage) works properly (Figure 2). To evaluate their impact in detail on the formed taxonomy, these selected elements can be related to the cultural values defined by Hofstede in [106], as well as the competitive value framework of Quinn and Rohrbaugh in [107], through the MoCA model [98]; however, on this occasion it will only be limited to the formation of the taxonomy.

2.9. Stage 7: Comparison of Conceptual Models

2.10. Stage 8: Systemic Changes with Conceptual Models

2.11. Stage 9: Implementation of Improvements to the Model

3. Results

3.1. Stage 1: Situation Considered Problematic

- Input (Complaint, Claim, Evidence): This is the starting point of the system, where a complaint, claim, or evidence is received indicating that something is not working correctly. From a technical perspective, this input serves as a signal that alerts the system to a deviation or issue within the process.

- Diagnosis and Solution Process: Once the issue has been identified, an analysis is performed to determine the best solution. At this stage, the received information is examined, the relevant data is filtered, and the most appropriate course of action is defined to resolve the situation.

- Output (Solution to the Problem): The outcome of the entire process is the implementation of the identified solution. In terms of quality control or management systems, this output aims to correct the detected issue and minimize any errors or negative impacts.

- Feedback (Evaluation and Adjustment): After the solution is implemented, it is essential to assess whether it effectively resolved the problem. If the response was not sufficient, the system receives this feedback and adjusts its approach to improve future outcomes. This feedback mechanism ensures that the process is continuously refined, allowing for ongoing adjustments and improvements.

3.2. Stage 2: Identify the System in Focus, Expressing the Problemnatic Situation

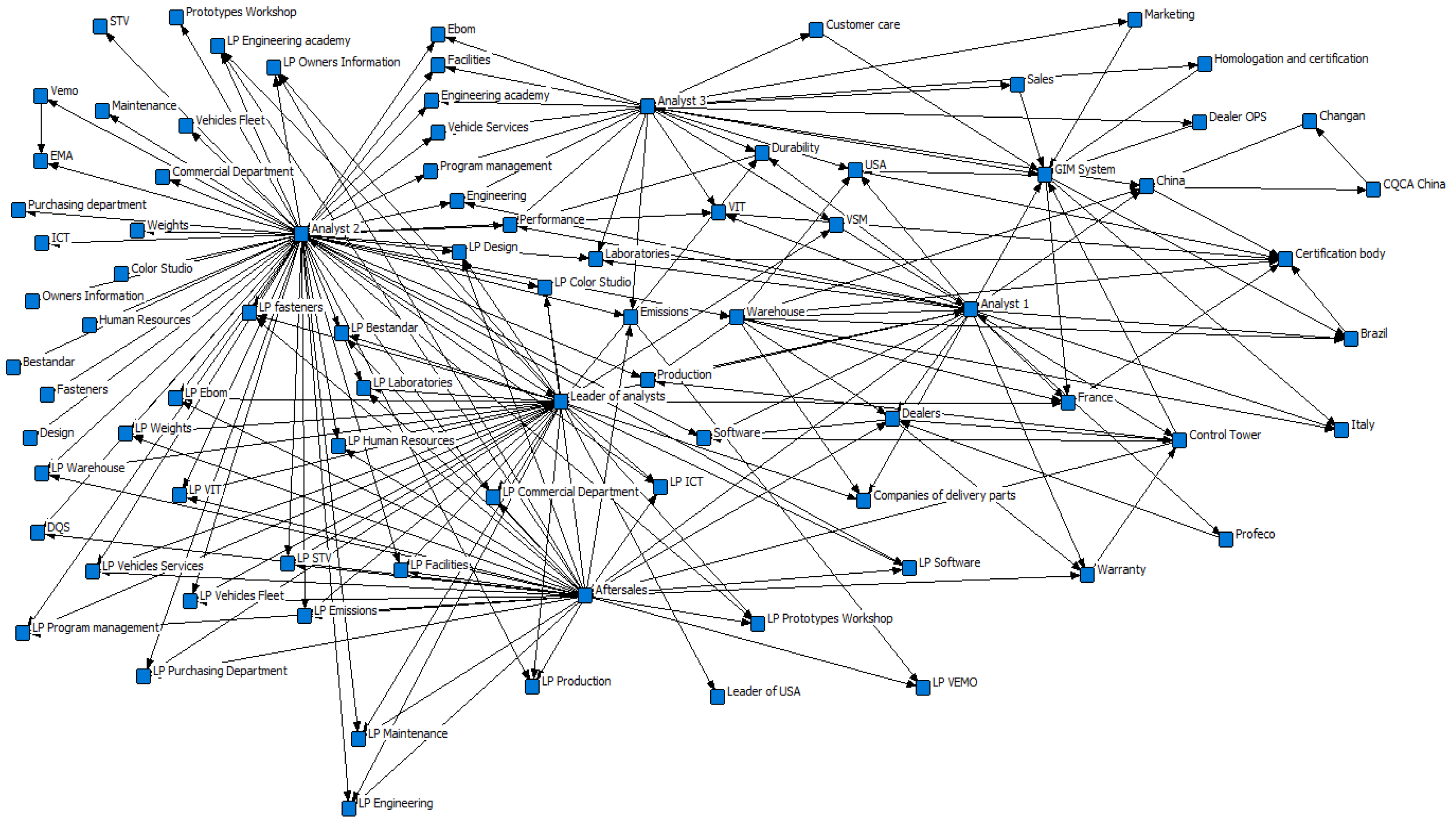

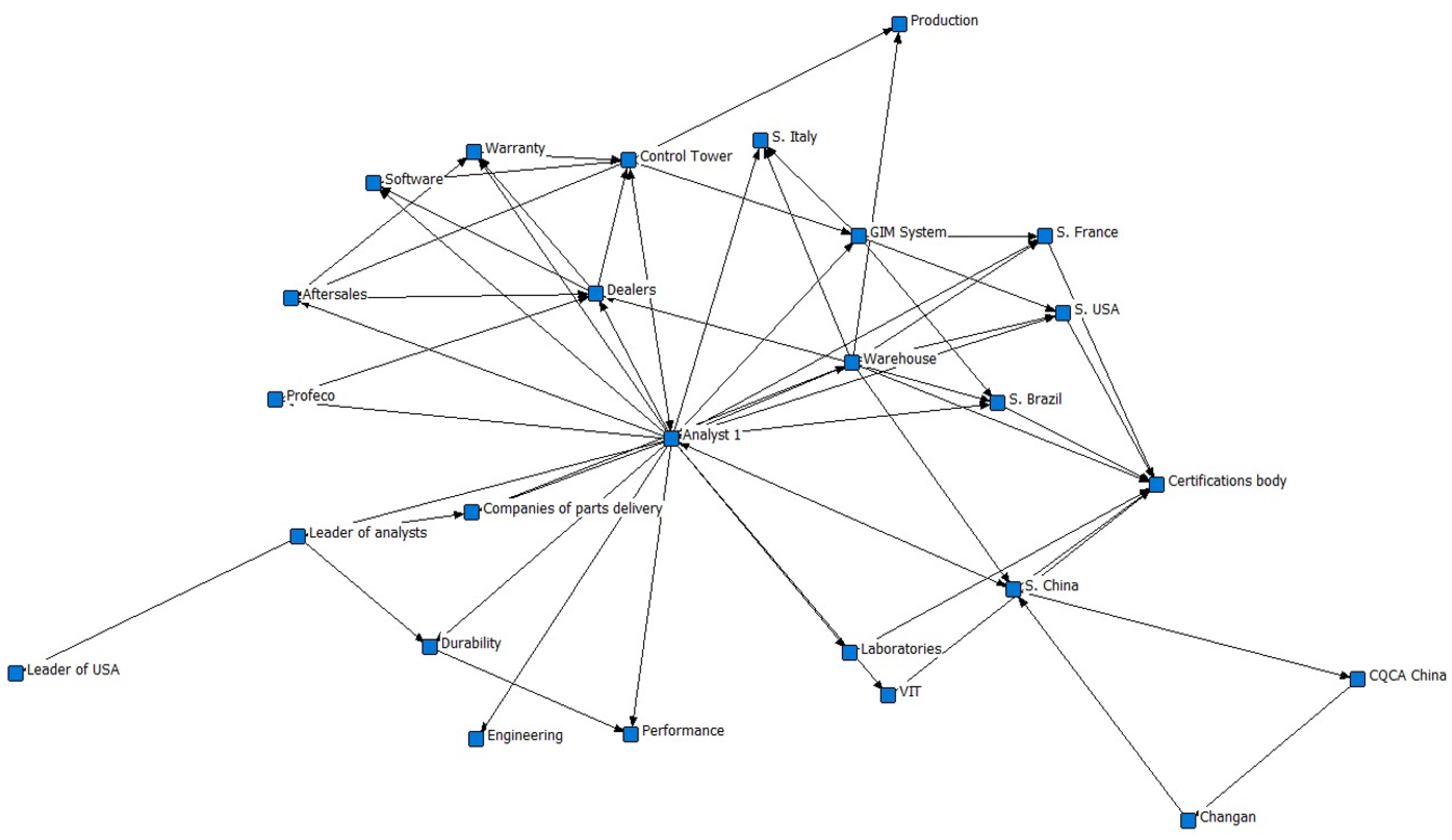

3.3. Stage 3: Conduct Structural Diagnosis and Network Analysis

3.3.1. Qualitative Analysis

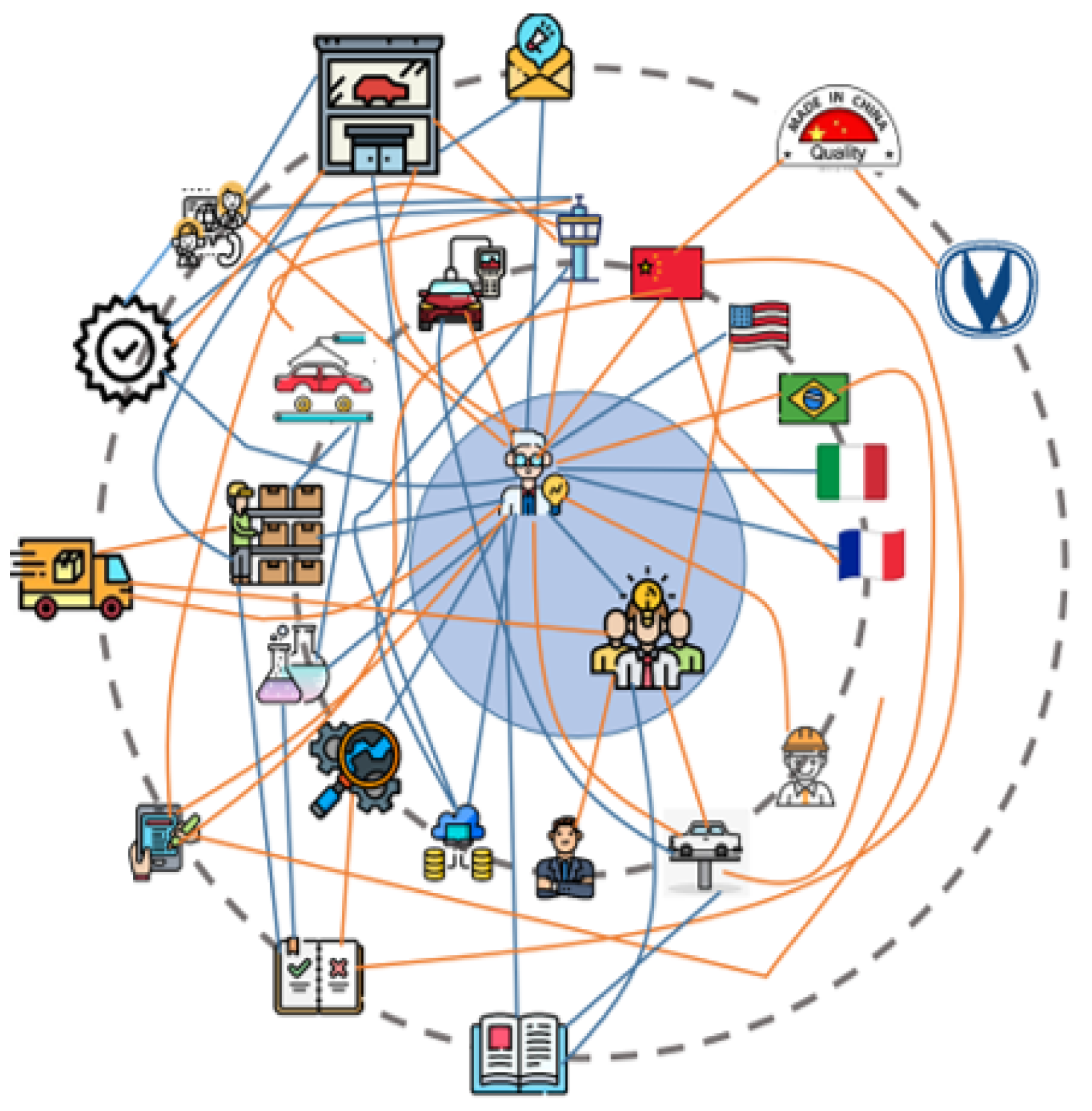

- The members of the Issue Resolution subsystem are only two: Analyst 1 and the Analyst Leader, who perform the necessary activities to achieve the subsystem’s objectives.

- The areas that interact with the Issue Resolution subsystem members, as it is crucial for the main actors to interact with other systems to achieve the objective.

3.3.2. Quantitative Analysis

- Identification of a Network Model Representing Issue Resolution Area

3.4. Stage 4: Define Relevant Activity Systems (CATWOE)

- Root Definition of the Issue Resolution System Based on the above and supported by the phenomenological methodology, the root definition of the Issue Resolution System is proposed as follows. The Issue Resolution System is a company-owned system that promotes systemic value generation through the resolution of problems in sold products, which, if unresolved, could lead to severe consequences for customers and, in turn, create a negative reputation that could directly impact the business and its objectives.

- Relevant Systems Based on the root definition, the relevant systems are derived and framed by the CATWOE. Each relevant system is presented with its own root definition, reflecting an iterative process for the relevant Issue Resolution System.

- –

- Client: The customer is the area that requests support for problem resolution, and two divisions have been identified. Before the sale: The international counterparts (China, Brazil, USA, France, Italy) and the internal areas of the organization that interact in the problem resolution process before the vehicles are marketed.After the Sale: The final customers who purchased vehicles, agencies and the warranty department as they are directly affected by the quality of the product and the efficiency in problem resolution.

- –

- Actors: In the Issue Resolution System, the following are included:Before the Sale: Engineering warehouse, laboratories, information platforms, control tower, design engineering, parts development, Analysts and Analyst Leader.After the Sale: Post-sale, Dealers, Warranty department, PROFECO (Federal Consumer Protection Agency by its acronym in Spanish), Parts shipping companies, and analysis and diagnosis personnel, Analysts, and Analyst Leader.

- –

- Pre-sales transformation: Converting design and production problems into effective solutions before vehicles reach the market.After-sales transformation: Resolving problems detected in vehicles already sold, improving customer satisfaction, and reducing the costs associated with warranties and claims.

- –

- Worldview (Weltanschauung): In the Issue Resolution System, the worldview perceives that, by generating systemic value in the Issue Resolution, the warranty costs generated by faults detected in light vehicles will be reduced to a minimum and this can be measured through customer satisfaction, since it is not only key for retention, but also influences market perception and future sales.

- –

- Owner: The General Management of the organization and the operational management areas (System 3 and System 5), which establish the policies, strategies, and resources necessary for the operation of the Issue Resolution System.

- –

- Environment: National and international regulations, international treaties, response times of foreign counterparts, client expectations, budget limitations, and the technological capacity available for analysis and diagnosis.

3.5. Stage 5: Generation of Conceptual Models

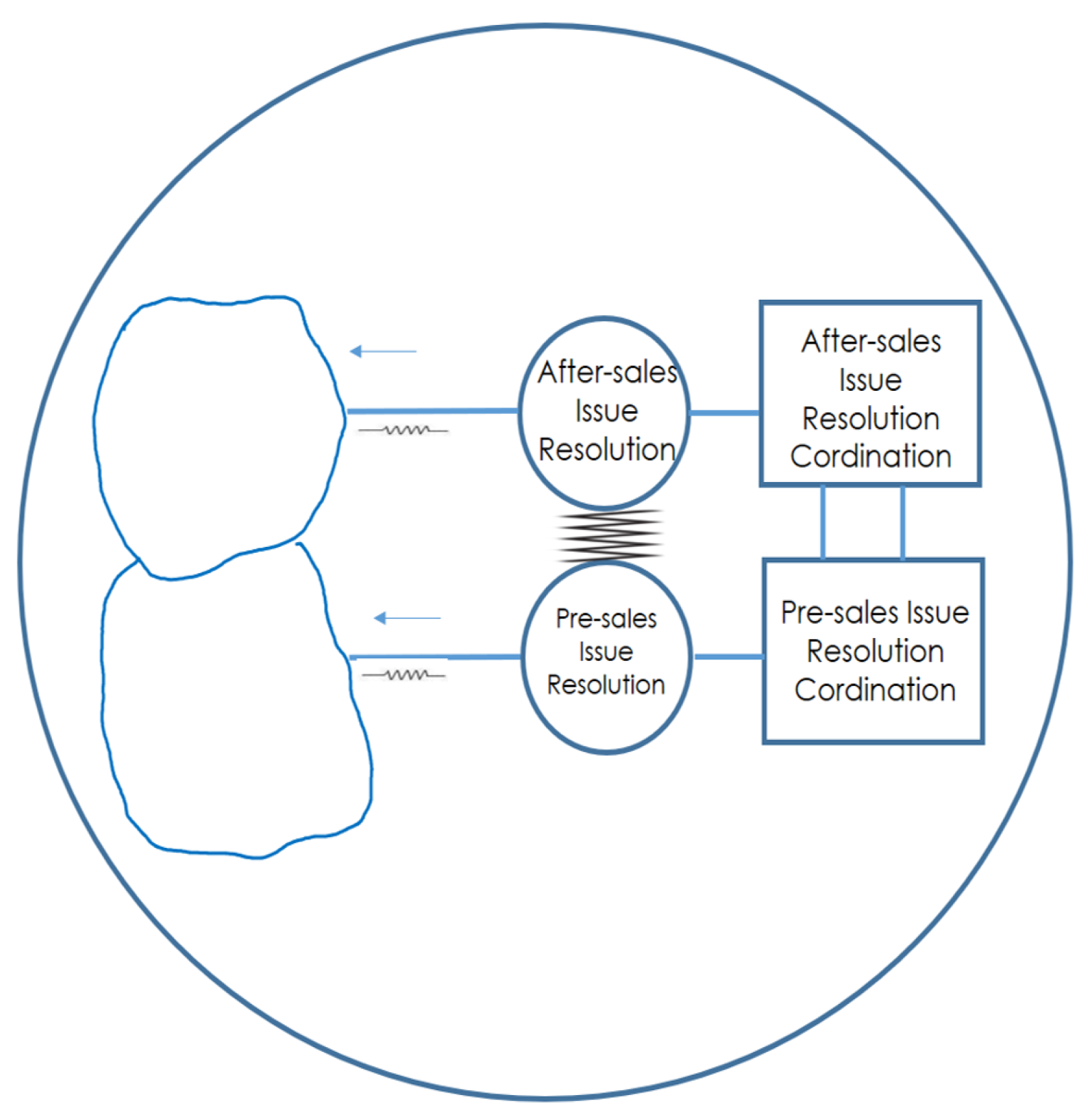

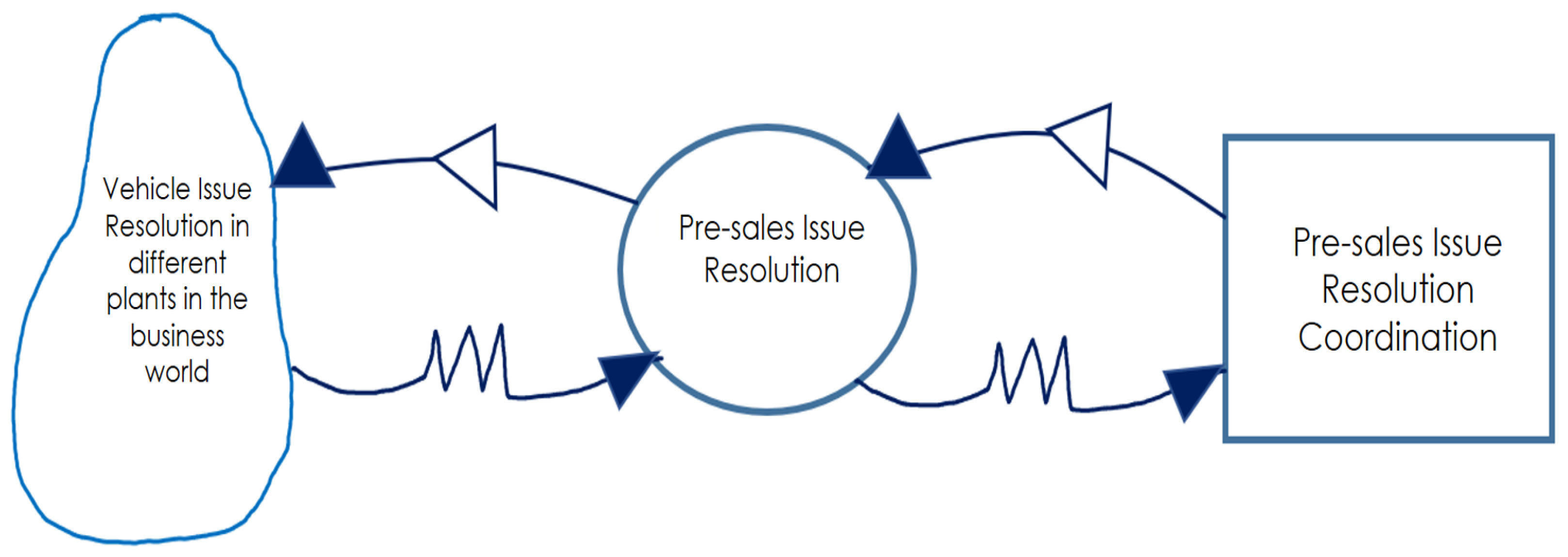

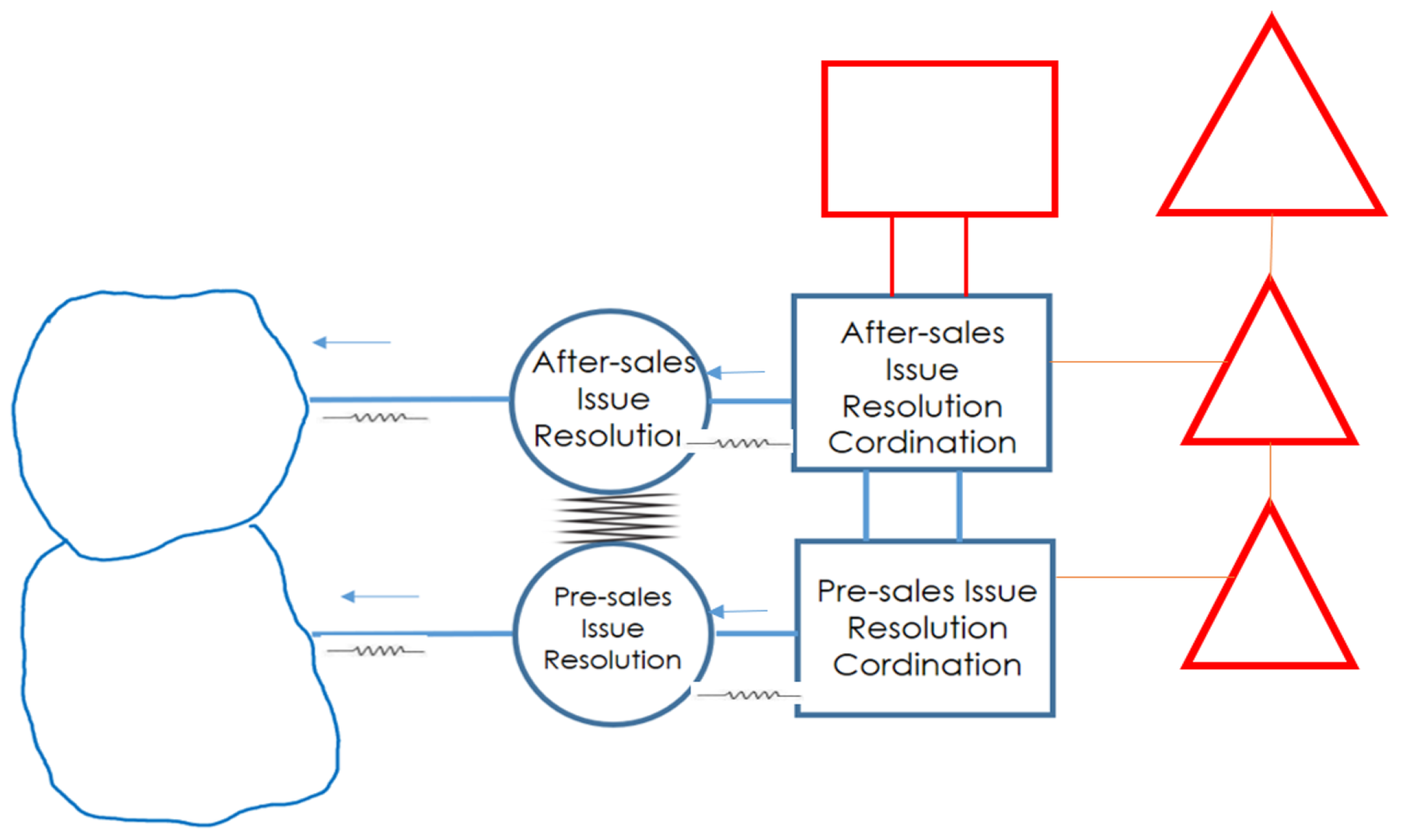

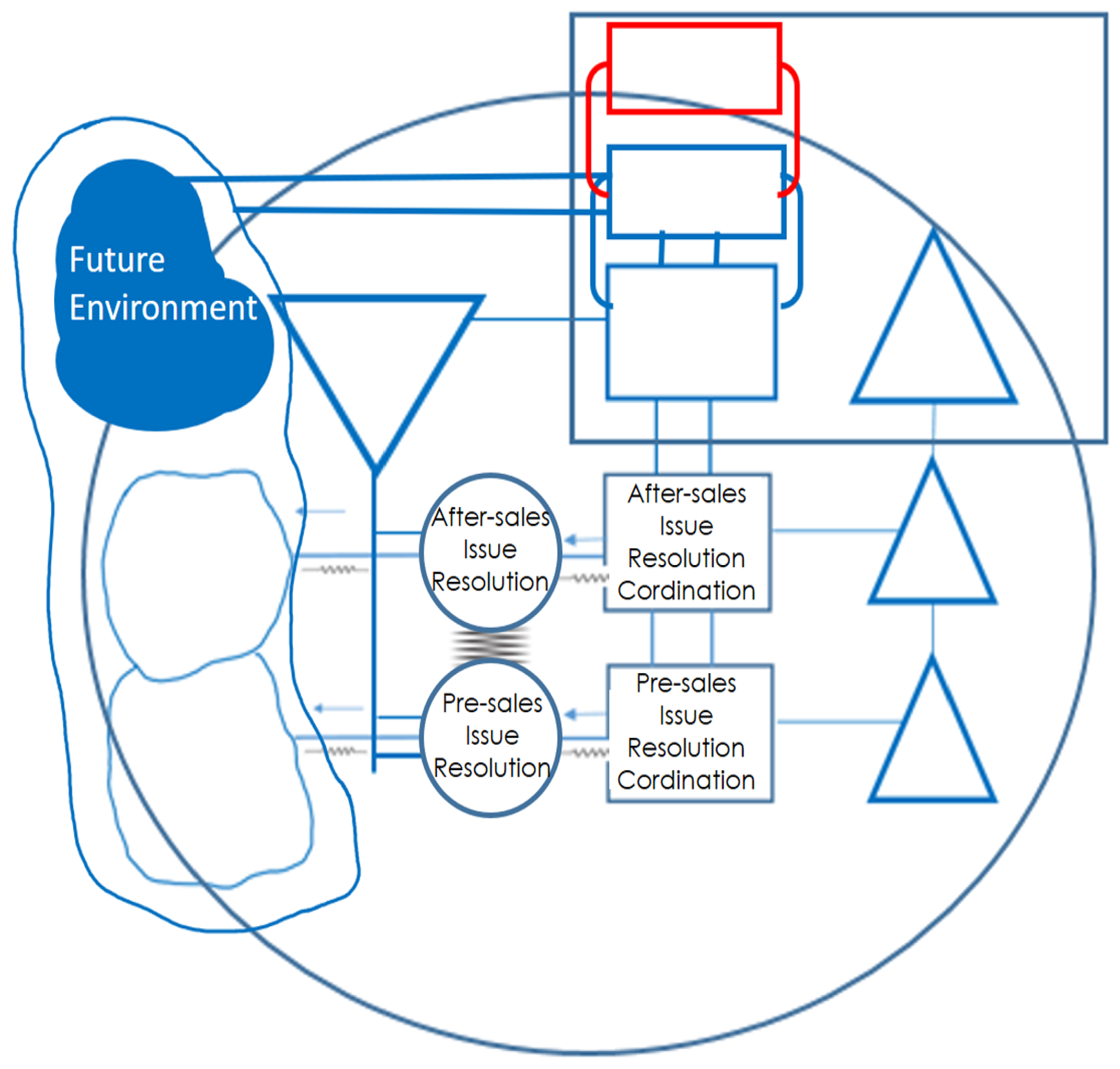

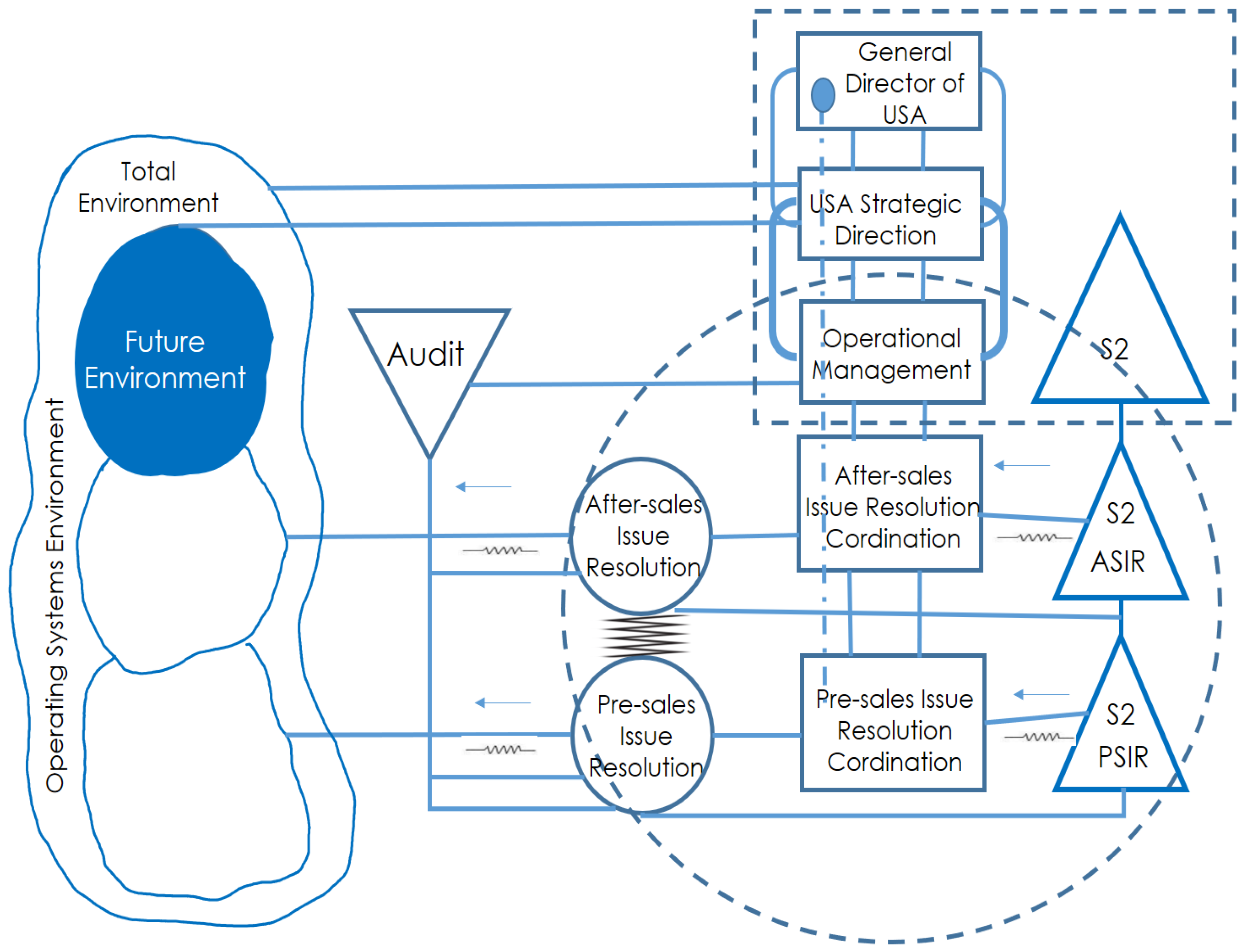

- System 1: Given the type of activities involved in the Problem Resolution area, System 1 consists of two subsystems that support its operation. These subsystems are: (1) Problem resolution before mass production, (2) Problem resolution after mass production (Figure 6).

- Pre-sale Issue Resolution Subsystem Root definition: The pre-sales problem resolution system is the system in charge of receiving the problem, gathering information, managing interactions among countries, analyzing information, detecting root causes, and generating problem solutions, which it provides to the countries of origin where the vehicle to be sold is produced, through synergy with the areas that interact with it, belonging to the same organization, whether national or international. As its root definition indicates, this subsystem presented in Figure 7 is in charge of resolving problems that arise before vehicles go on sale. In order to carry out this activity, the subsystem works with actors such as: Engineering Warehouse, laboratories, company information platforms, control tower, VIT area, engineering (Design and development of parts and components), parts shipping company, durability, performance, counterparts in China, counterparts in Brazil, counterparts in the United States, counterparts in France, counterparts in Italy, the Analyst Leader and the Issues Reception Platform. The operational areas have mechanisms that facilitate adequate interaction with the environment, known as amplifiers. These amplifiers increase the organization’s capacity to transmit information to the outside, or enhance the ability of managers to interact effectively within the same organization. In the Issue Resolution System model, amplifiers and attenuators are defined in the stage of choosing agile elements.

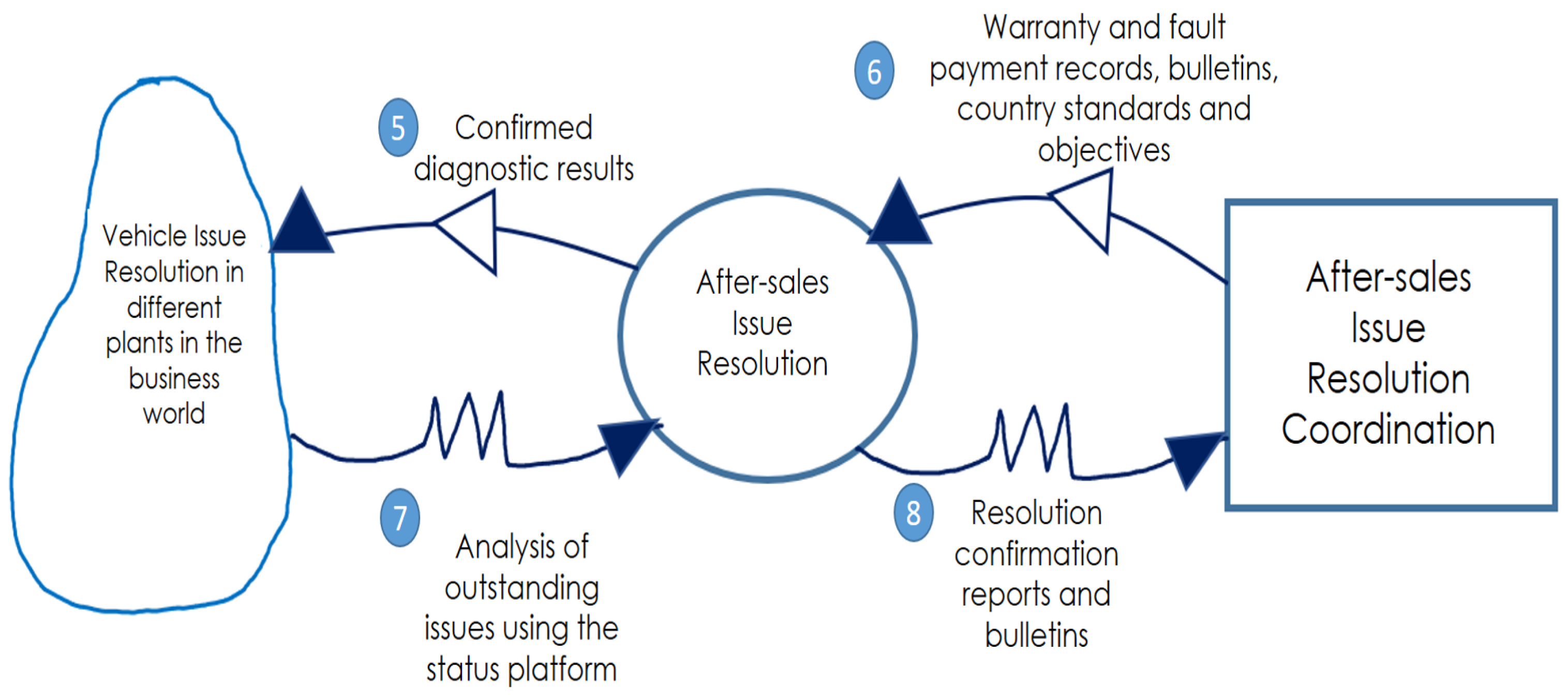

- After-sales Issue Resolution Subsystem Root definition: In the case of the after-sale problem resolution system, it is the system in charge of receiving the problem, gathering information, managing interactions among countries, analyzing information, detecting root causes, generating problem solutions, which is provided to the countries of origin, where the vehicle to be sold was produced, through synergy with the areas that interact, belonging to the same organization, whether national or international. As its root definition indicates, this subsystem presented in Figure 8 is in charge of resolving problems that arise after the vehicles have gone on sale and have been used by the customer. In order to carry out this activity, the subsystem works with actors such as: Engineering Warehouse, laboratories, Own company information platforms, control tower, VIT area, after-sales, agencies, Warranty Department, engineering (design and development of parts and components), PROFECO, parts shipping company, durability, performance, counterparts in China, counterparts in Brazil, counterparts in the United States, counterparts in France, counterparts in Italy, the Analyst Leader and the Issues Reception Platform. The operational areas have mechanisms that facilitate adequate interaction with the environment, known as amplifiers. These amplifiers increase the organization’s capacity to transmit information to the outside, or enhance the ability of managers to interact effectively within the same organization. In the Issue Resolution System model, amplifiers and attenuators are defined in the stage of choosing agile elements.

- System 2: This system is responsible for coordinating the proper functioning of the operating units (S1), for which it receives information from the local systems of each of them. The design of this system is carried out jointly by the heads of the operating departments of each unit, with the support of System 3. System 2 (Figure 9) includes information systems, production scheduling, task scheduling, coordination teams, procedures, national and international regulations, and international treaties. These activities, particularly information systems, act as amplifiers and attenuators among operating departments, their coordination unit, and the general coordinating unit of the system.Subsystem 2 acts as a system that prevents oscillations. This system operates outside the chain of command and is defined as a support system.

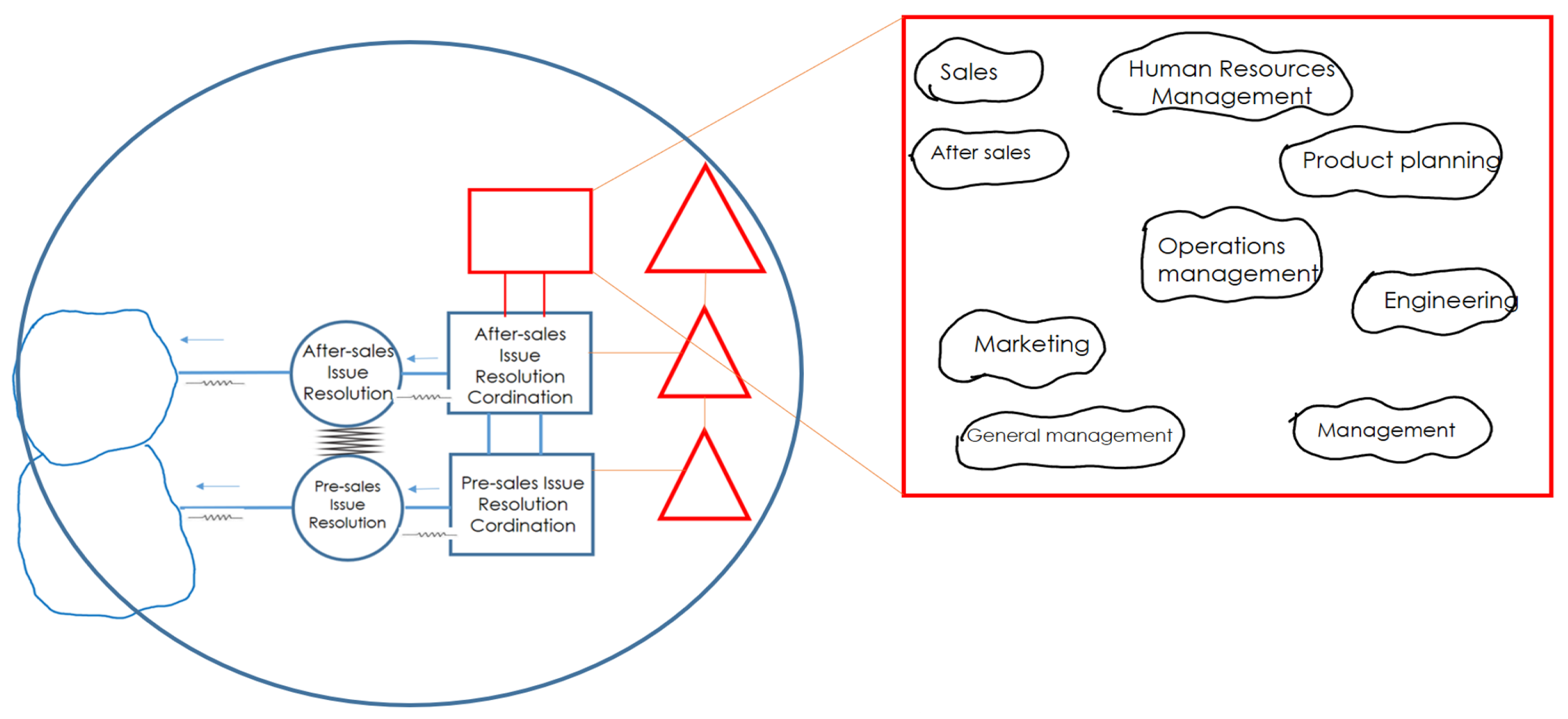

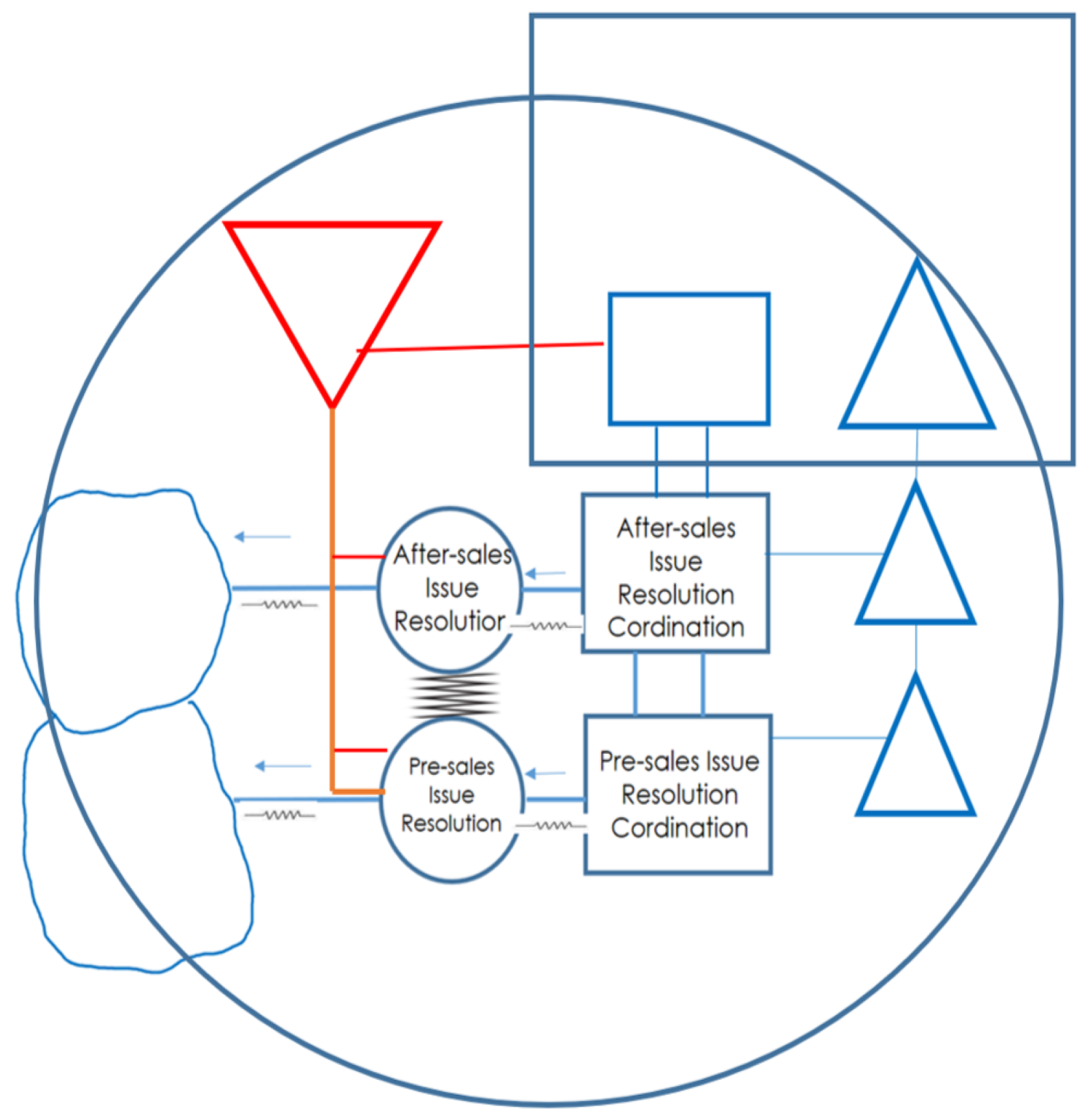

- System 3: It is considered the central axis of the entire system, or the key system for the functioning of the organization. Its responsibility is the present of the organization. This system covers both operational and management activities. In operational activities, it is responsible for ensuring the good performance of the operating units, with a comprehensive view of System 1, from which it receives information on the performance of operations and the fulfillment of objectives. In addition, it distributes financial, material, and human resources to each unit and communicates the instructions and objectives provided by System 4 or System 5. Regarding management activities, Subsystem 3 collaborates with System 4 to implement the necessary changes in System 1, thus ensuring the correct functioning of the organization. In general, this system includes sales activities, human resources management, administration, after sales, product planning, general management, operations management, marketing, and engineering (Figure 10).Subsystem 3 is supported by a mechanism called Homeostases, which acts as a regulatory channel between System 3 and System 4. Through this channel, internal and external information is managed in the past, present, and future, to facilitate decision-making and ensure that the necessary changes to System 1 are implemented in a timely and appropriate manner.

- System 3*: Figure 11 shows how to collect and process information that cannot be transmitted through System 2 or System 3, but which is crucial to the functioning of the Total System. System 3* must ensure the collection of accurate and complete information flowing from System 1 to System 3. This is done through internal and external audits, competitiveness analysis, environmental impact studies, international certifications, global assessments, comparisons of customer satisfaction results, as well as informal data collection mechanisms such as surveys, interviews, and polls.

- System 4: This subsystem (Figure 12) provides the organization with relevant information on the current and future environment. Its function is to provide a strategic direction. The information collected must be transformed into executable actions through strategies that are developed in conjunction with System 3, aimed at System 1, and aligned with the mission, vision, and objectives established by System 5. Information collection is carried out through sensors that monitor the main variables of the environment that impact the system. The functions of this system include market research, incident analysis at both the international and national level, payment monitoring, development and innovation, and strategic planning.As indicated previously, this system maintains a continuous interaction with System 3 through homeostasis, with the purpose of developing strategies that align with the objectives of the Total System, which are presented to System 5 for decision-making.

- System 5: This system (Figure 13) brings decision makers together within the Issue Resolution framework. For this system to operate effectively, it is essential to define the mission, vision, goals, strategic objectives, indicators, values, policies, communication channels, clients, and segments of clients, which will guide and align performance.

3.6. Stage 6: Analysis of Agility and Relationship with Conceptual Models

- Selecting Attenuators and Amplifiers As a first step, the attenuators and amplifiers for the previously formed system are selected.

- –

- For the Pre-sale problem resolution system, the following were identified:The Operation attenuator to deal with the variety of the environment is the ‘Analysis of pending problems using the status platform’ Result of confirmed diagnoses’ where a filter of the most urgent problems is made, to later make a prioritization of the identified problems.The variety amplifier from Operations to the Environment is “The result of confirmed diagnoses”, which presents a list of all the issues identified during the analysis and testing of various types of prototype vehicles.The Management attenuator to deal with the variety of Operation is the ‘Resolution confirmation reports’ where the root cause of the problem is given, along with all the information supporting it. The variety amplifier of the Management towards the Operation is: ’The defect book issued by the coordination, where you can obtain more information on the reported problems, the standards under which one must work in each country of origin, as well as the objectives under which one must work, where time, budget, among others, are specified (Figure 15).

- –

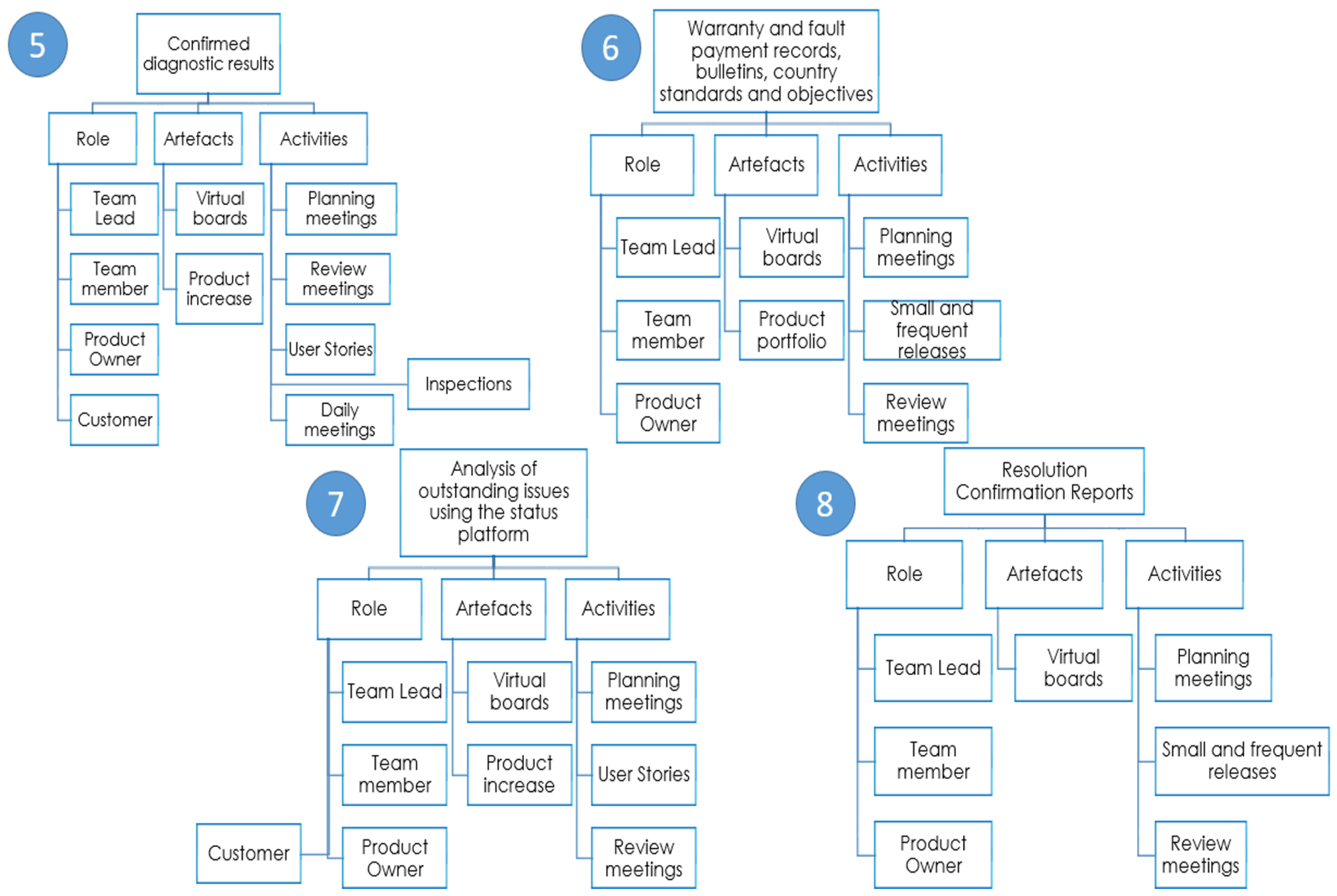

- Regarding the After-Sale problem resolution system, the following are available:The Operation attenuator to deal with the variety of the environment is the ‘Analysis of pending problems using the status platform’ Result of confirmed diagnoses’ where a filter is made of the most urgent problems, to later make a prioritization of the identified problems.The variety amplifier from Operations to the environment is *“The result of confirmed diagnostics”*, which provides a comprehensive list of all issues identified during the analysis and testing of various prototype vehicles.The variety attenuator from Management to handle Operational variety consists of *“Resolution confirmation reports and bulletins”*, which detail the root cause of each issue, along with all supporting information. This consolidated data is then used to alert agencies through official bulletins.The variety amplifier from Management to Operations includes *“Warranty records, failure payments, bulletins, country standards, and objectives”*, offering detailed information on reported issues, financial data related to warranty payments, the frequency of such payments, the affected components, and additional customer-related information. The standards under which one must work in each country of origin, as well as the objectives under which one must work, where time, budget, among others, are specified (Figure 16).The term “agile practice” lacks a standard definition and is not used consistently. Agile methodology guidelines describe various agile practices that differ in their specific implementations. These agile elements were created to be integrated into the process. Such practices must evolve as the environment and circumstances change.Roles define the responsibilities each individual must assume within the system, artifacts are the tools that facilitate the understanding of processes within the systems, and activities are the tasks that guide the team towards an agile level, ensuring that the planned strategy is sustainable. In this case, the elements were selected based on the specific conditions of each context and the roles that each participant is expected to fulfill. The selected elements can be observed in the taxonomy formed, as shown in Figure 17 and Figure 18.

- Forming the taxonomyFigure 17 and Figure 18 show the selection of agile elements for each attenuator or amplifier. The selection of each element was made on the basis of the context from which each system is derived. In taxonomy 1, 2, 3, 4, 5, 6, 7 and 8, it can be seen that the roles chosen were ‘Team member’, ‘Team Leader’, as well as ‘Product owner’. In all cases, Analysts will perform the ‘Team member’ role, while the Analyst Leader will perform the ‘Team Leader’ role. The role of ‘Product Owner’ will be played by the person responsible for each process, and this is found in all the taxonomies formed because their participation in the process must always be taken into account, to know their needs and, in case this requires any adjustment, having them close to the process represents making them part of the process in each movement made.Regarding the selected artifacts, it can be observed that Virtual Boards are present across all taxonomies. This is because, given that the selected company is a multinational, in-person meetings are not always feasible, and virtual boards facilitate this communication. It is also important to note that virtual boards must display all necessary information for everyone involved in the process and should be accessible to all stakeholders whenever they wish to consult them. There is no specific platform defined for this purpose; the selection can be adapted to the company’s resources and needs. The only requirement is that these boards must clearly present the most relevant project information.Another selected artifact was the Product Increment, which refers to the sum of activities previously planned and completed during the last review period. This involves analyzing the agreed-upon activities, identifying which were carried out and which were not, and discussing which will be undertaken in the next session.Additionally, the Product Portfolio was selected, an element that allows for the interactive selection of proposed projects that offer the greatest business value.

4. Discussion

4.1. Qualitative Diagnosis

4.2. Quantitative Diagnosis

4.3. Relevant Systems

4.4. Generation of Conceptual Models

- –

- System 1: Pre-sales (Laboratories, Engineering, Information platforms, Control Tower, VIT, Engineering warehouse), Post-sales ( After-sales service, Dealerships, Warranty department, PROFECO, Parts shipping, Analysis, and Diagnostics) International counterparts: China, Brazil, United States, France, Italy.

- –

- System 2: Information systems, Production and task planning, Coordination teams, National and international regulations, and international treaties.

- –

- System 3: Includes Sales, Human Resources, Administration, After-sales, Product planning, General Management, Operations Management, Marketing, and Engineering. In addition, it manages communication and resource allocation between System 1 and the higher strategic levels.

- –

- System 4: Market research, Innovation, Strategic planning, International incident analysis, Technology monitoring, Payment and risk monitoring. Works in collaboration with System 3 to ensure that the organization is aligned with global trends.

- –

- System 5: Executive Management and General Management, Quality Area Leadership, Corporate Policy Definition, Regulation, and Compliance.

4.5. Systems Approach

4.6. Agility Analysis

- –

- Roles: Team Leader, team member, product owner.

- –

- Artifacts: Virtual boards, product backlog, product increments.

- –

- Activities: Planning and review meetings, inspections, and daily presentations.

5. Conclusions

- Network Structure and Connectivity: The Issue Resolution network exhibits low connectivity, indicating that many key relationships within the system are not well established. The analysis confirmed that this network operates under a Super Critical Regime, meaning that the lack of interconnectivity among actors prevents processes from flowing efficiently.

- Critical Nodes and Systemic Weaknesses: Analyst 1 and the Analyst Leader were identified as central actors (hubs) within the network. If either of them were removed, the system could collapse, leaving critical vehicle quality issues unresolved. Furthermore, 68% of the relationships within the system were found to be conflictual, highlighting the need to improve communication and collaboration among stakeholders.

- Process Optimization Through Agile Approaches: The study proposed integrating agile tools, such as virtual boards, product backlogs, and daily meetings, to improve the flexibility and efficiency of the system. The use of CATWOE analysis helped to better understand the relevant systems within the organization, facilitating the development of conceptual models aligned with the company’s strategic goals.

- Strategic Importance of Issue Resolution in Quality Management: The Issue Resolution process is crucial before and after sales, as its effectiveness directly influences customer satisfaction and warranty costs. Improving connectivity and collaboration within this system will allow for faster and more effective resolution of quality issues, reducing costs, and strengthening company reputation.

5.1. Theoretical Implications

- Innovative methodological integration: This study contributes to the academic literature by introducing an integrated metamethodology that combines the Viable System Model (VSM), the Soft Systems Methodology (SSM), and the Agile Methodologies (AM). This combination addresses the individual limitations of each framework and aligns with [56] concept of creative holism as a strategy to tackle complex systems.

- Expansion of systemic thinking: The research reinforces the value of systemic thinking as a theoretical tool to diagnose complex organizational structures, incorporating both structural and interpretive dimensions.

- Complementarity of Conceptual Frameworks: The proposed model empirically validates the feasibility of combining organizational cybernetics, stakeholder participation in decision making, and operational agility, thus contributing to the evolution of organizational design and complexity management theories.

- Incorporation of network analysis: Theoretically, the study introduces the use of network science and complexity metrics within a systemic framework, enabling a more precise measurement of the viability, interconnectivity, and structural dynamics of the system.

5.2. Practical Implications

- Improvement in quality management: On an operational level, the implementation of the Agile Viable Model (AVM) led to shorter response times in problem solving within the quality department, with a direct impact on customer satisfaction and a reduction in warranty-related costs.

- Optimization of organizational communication: The analysis revealed that 68% of the relationships between actors were conflictual and that key nodes, such as the analyst and their team leader, were poorly connected. The introduction of agile tools such as virtual boards, product logs, and daily stand-up meetings significantly improved collaboration and process transparency.

- Real-world applicability: The model was successfully implemented in a multinational automotive company in Mexico, demonstrating its practical viability and adaptability to complex environments, including distributed manufacturing systems, multicultural teams, and high contextual variability.

- Replicable Toolkit: The research provides a structured step-by-step implementation process that can be replicated in other organizations facing similar challenges in quality management, decision making, and organizational adaptability.

- Development of internal capabilities: The model fosters a culture of continuous learning, self-management, and cross-functional collaboration, aligning human development with a larger organizational strategy.

Study Limitations

- While the proposed meta-methodology—based on the integration of the Viable System Model (VSM), Soft Systems Methodology (SSM), and Agile Methodologies—offers a robust framework for diagnosing and improving complex organizational systems, several limitations must be acknowledged regarding its scope and applicability.

- Limited scope of application: The model was implemented within a single automotive company in Mexico, specifically in the Quality Engineering department. Although the results were promising, the generalizability of the model to other departments, organizations, or industries has not yet been tested. Consequently, its conclusions may not be directly transferable to other settings.

- Contextual dependency: The effectiveness of the methodology is heavily influenced by the socio-cultural and economic environment in which it is applied. This study was conducted in a context characterized by hierarchical organizational structures, centralized decision-making, and the strong role of interpersonal relationships—typical of the Mexican corporate environment. These cultural factors significantly influence communication dynamics, collaboration practices, and team adaptability. Additionally, socio-economic factors such as resource constraints, technological availability, and regulatory frameworks shape how systemic and agile methodologies are implemented and perceived.

- Dependence on organizational culture: The success of the meta-methodology relies substantially on an organization’s openness to change, its collaborative mindset, and stakeholder willingness to participate in iterative and participatory processes. These conditions may not be present in more rigid or traditionally structured environments, limiting the effectiveness of the model.

- Training and knowledge requirements: Implementing the model requires a solid understanding of systems thinking, network analysis, and agile tools. Organizations lacking prior exposure or trained personnel in these areas may face significant barriers to effective implementation.

- Complexity of integration: Although the combination of VSM, SSM, and Agile methodologies enhances theoretical robustness, it also increases operational complexity. Teams unfamiliar with one or more of these approaches may struggle without dedicated training or expert facilitation.

- Perceived abstraction of the VSM: Certain components of the Viable System Model may be seen as overly abstract or theoretical by operational teams, potentially limiting their engagement or understanding unless supported by appropriate contextualization and facilitation.

- Lack of longitudinal evaluation: The outcomes presented reflect a specific moment in time. This study did not include a long-term evaluation of the model’s impact or the sustainability of the improvements introduced. Future research should consider longitudinal assessments to better understand the model’s long-term value.

- Cultural and Economic Transferability: Due to the unique characteristics of the Mexican context, direct application of the model in other cultural or economic settings (e.g., Northern Europe or East Asia) would require thoughtful adaptation. Variations in autonomy, stakeholder involvement, and resistance to change may significantly affect the model’s applicability and outcomes.

- Future studies are encouraged to conduct cross-cultural and cross-sector comparisons to assess how cultural and economic variables influence the model’s effectiveness and adaptability. Such efforts will contribute to the development of a more generalized and context-sensitive framework for organizational transformation.

5.3. Future Directions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Actor A | Actor B |

|---|---|

| Analysts | Control Tower, After-sales, Dealers, Engineering (Design and Development of Parts and Components), Parts Shipping Company, Durability, Performance, Counterpart in China, Counterpart in Brazil, Counterpart in the United States, Issues Reception Platform, Dealers, Manufacturing, Chinese Quality Automotive, Construction, External manufacturer in China and U.S. Leader |

| Control Tower | Manufacturing, Analysts, Issues Reception Platform |

| Engineering Warehouse | Counterpart in China, Counterpart in Brazil, Counterpart in the United States, Counterpart in Italy, Counterpart in France and Manufacturing |

| Dealers | Warranty Department and Control Tower |

| Counterpart in China | Quality and Environmental Standards Certifying Bodies and Chinese Quality Automotive Construction |

| Counterpart in the United States | Quality and Environmental Standards Certifying Bodies |

| Counterpart in Italy | Quality and Environmental Standards Certifying Bodies |

| Counterpart in France | Quality and Environmental Standards Certifying Bodies |

| Counterpart in Brazil | Quality and Environmental Standards Certifying Bodies |

| Issues Reception Platform | Counterpart in China, Counterpart in Brazil, Counterpart in the United States, Counterpart in France and Counterpart in Italy |

| Lead Analyst | Parts Shipping Company, Counterpart in the United States, External manufacturer in China and U.S. Leader |

| Vehicle Specialization Area | Quality and Environmental Standards Certifying Bodies |

| After-sales | Dealers |

| Chinese Quality Automotive Construction | External manufacturer in China |

| External Manufacturer in China | Counterpart in China |

References

- AMIA. Importancia de la Industria Automotriz. Available online: https://www.amia.com.mx/publicaciones/industria_automotriz/ (accessed on 4 February 2025).

- Niewenhuis, P.; Wells, P. The Automotive Industry and the Environment; Woodhead: Sawston, UK, 2003; pp. 3–4. [Google Scholar]

- Stylidis, K.; Wickman, C.; Söderberg, R. Defining perceived quality in the automotive industry: An engineering approach. Procedia CIRP 2015, 36, 165–170. [Google Scholar] [CrossRef]

- Klink, G. Contribution of the automobile industry to technology and value creation. Auto Tech Rev. 2014, 3, 18–23. [Google Scholar] [CrossRef]

- Jackson, M.C. Critical Systems Thinking and the Management of Complexity; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Balankin, A.S.; Susarrey, O.; Márquez Gonzáles, J. Scaling properties of pinned interfaces in fractal media. Phys. Rev. Lett. 2003, 90, 096101. [Google Scholar] [CrossRef] [PubMed]

- Lina, I.R.; Troya, T.I.C.; Matamoros, O.M.; Escobar, J.J.M.; Padilla, R.T. Fractal Characterization of Stochastic Series Fluctuations of Children with Reading Disorders. Nonlinear Dyn. Psychol. Life Sci. 2020, 24, 159. [Google Scholar] [CrossRef]

- Rotmans, J.; van Asselt, M.B. Uncertainty management in integrated assessment modeling: Towards a pluralistic approach. Environ. Monit. Assess. 2001, 69, 101–130. [Google Scholar] [CrossRef]

- Helbing, D. Pluralistic modeling of complex systems. Sci. Cult. 2010, 76, 315–329. [Google Scholar] [CrossRef]

- Meadows, D.H. Thinking in Systems: A Primer; Chelsea Green Publishing: Chelsea, VT, USA, 2008. [Google Scholar]

- Whitchurch, G.G.; Constantine, L.L. Systems theory. In Sourcebook of Family Theories and Methods: A Contextual Approach; Springer: Berlin/Heidelberg, Germany, 1993; pp. 325–355. [Google Scholar] [CrossRef]

- Bertalanffy, L.V. General system theory: Foundations, development, applications. JAMA 1969, 208, 870. [Google Scholar] [CrossRef]

- Hartman, R.; Kvasnička, R.; Čejka, M.; Pilař, L. Design Thinking in Innovation Processes: A Market Segmentation Tool in Social Networks Research. Systems 2024, 12, 444. [Google Scholar] [CrossRef]

- Arnold, R.D.; Wade, J.P. A definition of systems thinking: A systems approach. Procedia Comput. Sci. 2015, 44, 669–678. [Google Scholar] [CrossRef]

- Frank, M.; Zwikael, O.; Boasson, M. Jobs requiring a capacity for engineering systems thinking (CEST): Selection using an interest inventory. Proj. Manag. J. 2007, 38, 36–44. [Google Scholar] [CrossRef]

- Senge, P.M. The Fifth Discipline: The Art and Practice of the Learning Organization; Broadway Business: New York, NY, USA, 2006; p. 445. [Google Scholar]

- Charnley, F.; Lemon, M.; Evans, S. Exploring the process of whole system design. Des. Stud. 2011, 32, 156–179. [Google Scholar] [CrossRef]

- Cabrera, D.; Cabrera, L. What is systems thinking? In Learning, Design, and Technology: An International Compendium of Theory, Research, Practice, and Policy; Springer: Berlin/Heidelberg, Germany, 2023; pp. 1495–1522. [Google Scholar] [CrossRef]

- Leischow, S.J.; Best, A.; Trochim, W.M.; Clark, P.I.; Gallagher, R.S.; Marcus, S.E.; Matthews, E. Systems thinking to improve the public’s health. Am. J. Prev. Med. 2008, 35, S196–S203. [Google Scholar] [CrossRef] [PubMed]

- Bureš, V. A method for simplification of complex group causal loop diagrams based on endogenisation, encapsulation and order-oriented reduction. Systems 2017, 5, 46. [Google Scholar] [CrossRef]

- Ackoff, R.L. The future of operational research is past. J. Oper. Res. Soc. 1979, 30, 93–104. [Google Scholar] [CrossRef]

- Hofmann, P.; Powell, D. The combination of lean thinking and systems thinking in the design of manufacturing systems. In Proceedings of the 2012 IEEE International Conference on Industrial Engineering and Engineering Management, Hong Kong, China, 10–13 December 2012; pp. 56–60. [Google Scholar] [CrossRef]

- Nunes, B.; Betz, F.; Bennett, D.; Shaw, D. A systems approach to analysing environmental decisions in the automotive industry. In Proceedings of the 2011 Proceedings of PICMET ’11: Technology Management in the Energy Smart World (PICMET), Portland, OR, USA, 31 July–4 August 2011. [Google Scholar] [CrossRef]

- Fessina, M.; Zaccaria, A.; Cimini, G.; Squartini, T. Pattern-detection in the global automotive industry: A manufacturer-supplier-product network analysis. Chaos Solitons Fractals 2024, 181, 114630. [Google Scholar] [CrossRef]

- Laimon, M.; Yusaf, T.; Mai, T.; Goh, S.; Alrefae, W. A systems thinking approach to address sustainability challenges to the energy sector. Int. J. Thermofluids 2022, 15, 100161. [Google Scholar] [CrossRef]

- Kim, S.; Connerton, T.P.; Park, C. Exploring the impact of technological disruptions in the automotive retail: A futures studies and systems thinking approach based on causal layered analysis and causal loop diagram. Technol. Forecast. Soc. Change 2021, 172, 121024. [Google Scholar] [CrossRef]

- Dima, I.C. Systemic Approaches to Strategic Management: Examples from the Automotive Industry; IGI Global: New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Holman, D.; Wicher, P.; Lenort, R.; Dolejšová, V.; Staš, D.; Giurgiu, I. Sustainable logistics management in the 21st century requires wholeness systems thinking. Sustainability 2018, 10, 4392. [Google Scholar] [CrossRef]

- Graessler, I.; Grewe, B. Stages of systems engineering: An analysis and characterization of systems engineering approaches. Systems 2025, 13, 53. [Google Scholar] [CrossRef]

- Khan, S.K.; Shiwakoti, N.; Stasinopoulos, P.; Warren, M. Cybersecurity regulations for automated vehicles: A conceptual model demonstrating the “tragedy of the commons”. Transp. Res. Procedia 2025, 82, 3729–3751. [Google Scholar] [CrossRef]

- Rocha, J.M.S.; Rocha, J.M.S. Applying agile practices in automotive engineering: A lean approach for software development and vehicle design. Int. J. Automot. Technol. Manag. 2011, 11, 227–246. [Google Scholar] [CrossRef]

- Ågren, S.M.; Heldal, R.; Knauss, E.; Pelliccione, P. Agile beyond teams and feedback beyond software in automotive systems. IEEE Trans. Eng. Manag. 2022, 69, 3459–3475. [Google Scholar] [CrossRef]

- Kasauli, R.; Knauss, E.; Horkoff, J.; Liebel, G.; de Oliveira Neto, F.G. Requirements engineering challenges and practices in large-scale agile system development. J. Syst. Softw. 2021, 172, 110851. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, K.; Jain, S.K. Assessment of agile manufacturing impact on business performance of Indian manufacturing industry: A PLS-SEM approach. Sustain. Manuf. Serv. Econ. 2022, 1, 100001. [Google Scholar] [CrossRef]

- Alahyari, H.; Gorschek, T.; Svensson, R.B. An exploratory study of waste in software development organizations using agile or lean approaches: A multiple case study at 14 organizations. Inf. Softw. Technol. 2019, 105, 78–94. [Google Scholar] [CrossRef]

- Burggräf, P.; Dannapfel, M.; Adlon, T.; Kahmann, H.; Schukat, E.; Keens, J. Capability-based assembly design: An approach for planning an agile assembly system in automotive industry. Procedia CIRP 2020, 93, 1206–1211. [Google Scholar] [CrossRef]

- Jadoon, G.; Ud Din, I.; Almogren, A.; Almajed, H. Smart and agile manufacturing framework: A case study for automotive industry. Energies 2020, 13, 5766. [Google Scholar] [CrossRef]

- Henschel, S.; Hubalek, K.; Neub, N.; Kößler, F.; Fleischer, J. Implementation of an agile manufacturing system for the lithium-ion-cell production based on individual microenvironments. Procedia CIRP 2024, 130, 619–624. [Google Scholar] [CrossRef]

- El-Khalil, R.; Mezher, M.A. The mediating impact of sustainability on the relationship between agility and operational performance. Oper. Res. Perspect. 2020, 7, 100171. [Google Scholar] [CrossRef]

- Fleischer, J.; Fraider, F.; Kößler, F.; Mayer, D.; Wirth, F. Agile production systems for electric mobility. Procedia CIRP 2022, 107, 1251–1256. [Google Scholar] [CrossRef]

- Brandl, F.J.; Roider, N.; Hehl, M.; Reinhart, G. Selecting practices in complex technical planning projects: A pathway for tailoring agile project management into the manufacturing industry. CIRP J. Manuf. Sci. Technol. 2021, 33, 293–305. [Google Scholar] [CrossRef]

- Sadeghi, K.; Ojha, D.; Kaur, P.; Mahto, R.V.; Dhir, A. Explainable artificial intelligence and agile decision-making in supply chain cyber resilience. Decis. Support Syst. 2024, 180, 114194. [Google Scholar] [CrossRef]

- Cimini, C.; Lagorio, A.; Cavalieri, S. Development and application of a maturity model for industrial agile working. Comput. Ind. Eng. 2024, 188, 109877. [Google Scholar] [CrossRef]

- Hilt, M.J.; Wagner, D.; Osterlehner, V.; Kampker, A. Agile predevelopment of production technologies for electric energy storage systems: A case study in the automotive industry. Procedia CIRP 2016, 50, 88–93. [Google Scholar] [CrossRef]

- Beer, S. Brain of the Firm, 2nd ed.; John Wiley & Sons: Chichester, UK, 1995. [Google Scholar]

- Espejo, R.; Reyes, A. Organizational Systems: Managing Complexity with the Viable System Model; Springer Science & Business Media: Berlin, Germany, 2011; pp. 230–256. [Google Scholar]

- Sánchez, R.N.; Vizhñay, C.V. Analysis of the productivity of pair programming versus solo programming in a university classroom. In Communication, Smart Technologies and Innovation for Society: Proceedings of CITIS 2021; Springer: Singapore, 2022; pp. 733–743. [Google Scholar] [CrossRef]

- Daraojimba, E.C.; Nwasike, C.N.; Adegbite, A.O.; Ezeigweneme, C.A.; Gidiagba, J.O. Comprehensive review of agile methodologies in project management. Comput. Sci. IT Res. J. 2024, 5, 190–218. [Google Scholar] [CrossRef]

- Wafa, R.; Khan, M.Q.; Malik, F.; Abdusalomov, A.B.; Cho, Y.I.; Odarchenko, R. The impact of agile methodology on project success, with a moderating role of Person’s job fit in the IT industry of Pakistan. Appl. Sci. 2022, 12, 10698. [Google Scholar] [CrossRef]

- Zasornova, I.; Lisenko, S.; Zasornov, O. Choosing scrum or kanban methodology for project management in it companies. Comput. Syst. Inf. Technol. 2022, 4, 6–12. [Google Scholar] [CrossRef]

- Iqbal, J.; Omar, M.; Yasin, A. The effects of agile methodologies on software project management in pakistani software companies. Turk. J. Comput. Math. Educ. (TURCOMAT) 2021, 12, 1717–1727. [Google Scholar] [CrossRef]

- Yadav, N.S.; Goar, V.K.; Kuri, M. Agile Methodology-a Perfect Sdlc Model with Some Improvements. J. Crit. Rev. 2020, 7, 2511–2514. [Google Scholar] [CrossRef]

- Checkland, P. Systems Thinking, Systems Practice; John Wiley & Sons: Hoboken, NJ, USA, 1981; pp. 13–312. [Google Scholar]

- Beer, S. Brain of the Firm: The Managerial Cybernetics of Organization; Wiley: Hoboken, NJ, USA, 1972; pp. 113–315. [Google Scholar]

- Beck, K.; Beedle, M.; van Bennekum, A.; Cockburn, A.; Cunningham, W.; Fowler, M.; Thomas, D. Manifesto for Agile Software Development. 2001. Available online: https://agilemanifesto.org/ (accessed on 16 January 2025).

- Jackson, M.C. Systems Thinking: Creative Holism for Managers; Citeseer; John Wiley & Sons, Ltd.: Chichester, UK, 2016; pp. 116–216. [Google Scholar]

- Hildbrand, S.; Bodhanya, S. Exploring the complexity of sugarcane supply chains via systemic approaches. Kybernetes 2017, 46, 310–329. [Google Scholar] [CrossRef]

- Donaires, O.S. Aplicação de abordagem sistêmica na resolução de conflito no desenvolvimento de produtos inovadores. In Proceedings of the Anais do Congresso Brasileiro de Sistemas, Bonito, Spain, 9–11 November 2010. [Google Scholar]

- Kinloch, P.; Francis, H.; Francis, M.; Taylor, M. Supporting crime detection and operational planning with soft systems methodology and viable systems model. Syst. Res. Behav. Sci. Off. J. Int. Fed. Syst. Res. 2009, 26, 3–14. [Google Scholar] [CrossRef]

- Bustard, D.W.; Sterritt, R.; Taleb-Bendiab, A.; Laws, A. Autonomic system design based on the integrated use of SSM and VSM. Artif. Intell. Rev. 2006, 25, 313–327. [Google Scholar] [CrossRef]

- Beer, S. Recursion zero: Metamanagement. Syst. Pract. 1990, 3, 315–326. [Google Scholar] [CrossRef]

- Espejo, R.; Bowling, D.; Hoverstadt, P. The viable system model and the Viplan software. Kybernetes 1999, 28, 661–678. [Google Scholar] [CrossRef]

- Espinosa, A.; Walker, J. Complexity management in practice: A Viable System Model intervention in an Irish eco-community. Eur. J. Oper. Res. 2013, 225, 118–129. [Google Scholar] [CrossRef]

- Perez, J. Disseño y Diagnóstico de Organizaciones Viables: Un Enfoque Sistemico; Universidad de Valladolid: Valladolid, Spain, 2008. [Google Scholar]

- Schwaninger, M. Theories of viability: A comparison. Syst. Res. Behav. Sci. Off. J. Int. Fed. Syst. Res. 2006, 23, 337–347. [Google Scholar] [CrossRef]

- Harwood, S.A. A question of interpretation: The viable system model (VSM). Eur. J. Oper. Res. 2019, 274, 1198–1201. [Google Scholar] [CrossRef]

- Pósfai, M.; Barabási, A.L. Network Science; Cambridge University Press: Cambridge, UK, 2016; pp. 18–451. [Google Scholar]

- Wiener, N. Cybernetics: Or Control and Communication in the Animal and the Machine; MIT Press: Cambridge, MA, USA, 1948; pp. 16–103. [Google Scholar]

- Forrester, J.W. Industrial Dynamics; MIT Press: Cambridge, MA, USA, 1961; pp. 25–39. [Google Scholar] [CrossRef]

- Sterman, J.D. Business Dynamics: Systems Thinking and Modeling for a Complex World; McGraw-Hill: Boston, MA, USA, 2000; pp. 20–26. [Google Scholar]

- Deming, W.E. Out of the Crisis; MIT Press: Cambridge, MA, USA, 1986; pp. 89–91. [Google Scholar] [CrossRef]

- Checkland, P. Systems Thinking, Systems Practice: Includes a 30-Year Retrospective; John Wiley & Sons: Chichester, UK, 2001; p. 416. [Google Scholar]

- Borgatti, S.P.; Everett, M.G.; Freeman, L.C. UCINET for Windows: Software for Social Network Analysis; Analytic Technologies: Lexington, KY, USA, 2002; pp. 56–98. [Google Scholar] [CrossRef]

- Cormen, T.H.; Leiserson, C.E.; Rivest, R.L.; Stein, C. Introduction to Algorithms, 3rd ed.; MIT Press: Cambridge, MA, USA, 2009; pp. 746–764. [Google Scholar]

- Barabási, A.L.; Albert, R. Emergence of scaling in random networks. Science 1999, 286, 509–512. [Google Scholar] [CrossRef]

- Ghosh, R.; Lerman, K. Parameterized centrality metric for network analysis. Phys. Rev. E—Stat. Nonlinear Soft Matter Phys. 2011, 83, 4–6. [Google Scholar] [CrossRef]

- Schwab, J.D.; Kühlwein, S.D.; Ikonomi, N.; Kühl, M.; Kestler, H.A. Concepts in Boolean network modeling: What do they all mean? Comput. Struct. Biotechnol. J. 2020, 18, 571–582. [Google Scholar] [CrossRef]

- Soffer, S.N.; Vazquez, A. Network clustering coefficient without degree-correlation biases. Phys. Rev. E 2005, 71, 057101. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Wang, J.; Li, X.; Li, M.; Di, Z.; Fan, Y. Clustering coefficient and community structure of bipartite networks. Phys. A Stat. Mech. Appl. 2008, 387, 6869–6875. [Google Scholar] [CrossRef]

- Lewis, T.G. Network Science: Theory and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2011; p. 512. [Google Scholar]

- Jolicoeur, P.; Jolicoeur, P. The Poisson distribution. In Introduction to Biometry; Springer: Boston, MA, USA, 1999; pp. 124–133. [Google Scholar]

- Flood, R.L. Solving Problem Solving: A Potent Force for Effective Management; John Wiley & Sons: Chichester, UK, 1995; p. 248. [Google Scholar]

- Bergvall-Kåreborn, B.; Mirijamdotter, A.; Basden, A. Basic principles of SSM modeling: An examination of CATWOE from a soft perspective. Syst. Pract. Action Res. 2004, 17, 55–73. [Google Scholar] [CrossRef]

- Marttunen, M.; Lienert, J.; Belton, V. Structuring problems for Multi-Criteria Decision Analysis in practice: A literature review of method combinations. Eur. J. Oper. Res. 2017, 263, 1–17. [Google Scholar] [CrossRef]

- Salner, M. Beyond Checkland & Scholes: Improving SSM. In Proceedings of the International Conference of the System Dynamics Society, Wellington, New Zealand, 20–23 July 1999. [Google Scholar]

- Rezaee, Z.; Azar, A.; Erz, A.M.B.; Nayeri, M.D. Application of viable system model in diagnosis of organizational structure. Syst. Pract. Action Res. 2019, 32, 273–295. [Google Scholar] [CrossRef]

- Azadeh, A.; Darivandi, K.; Fathi, E. Diagnosing, simulating and improving business process using cybernetic laws and the viable system model: The case of a purchasing process. Syst. Res. Behav. Sci. 2012, 29, 66–86. [Google Scholar] [CrossRef]

- Leonard, A. The viable system model and its application to complex organizations. Syst. Pract. Action Res. 2009, 22, 223–233. [Google Scholar] [CrossRef]

- Espinosa, A.; Walker, J. Complexity Approach to Sustainability, A: Theory and Application; World Scientific: Singapore, 2017; Volume 5. [Google Scholar] [CrossRef]

- Hilder, T. Stafford Beer’s Viable System Model: An Interpretation; Cavendish Software Ltd.: Trowbridge, UK, 1995. [Google Scholar]

- Hayward, P. Facilitating foresight: Where the foresight function is placed in organisations. Foresight 2004, 6, 19–30. [Google Scholar] [CrossRef]

- Sydelko, P.; Espinosa, A.; Midgley, G. Designing interagency responses to wicked problems: A viable system model board game. Eur. J. Oper. Res. 2024, 312, 746–764. [Google Scholar] [CrossRef]

- Hoverstadt, P. The Fractal Organization: Creating Sustainable Organizations with the Viable System Model; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar] [CrossRef]

- Clark, A.; Brocklesby, J.; Elias, A. Enhancing collaborative advantage through critical systems thinking: An augmented viable system model intervention in a cross-sector partnership social policy context. Syst. Res. Behav. Sci. 2024, 42, 142–156. [Google Scholar] [CrossRef]

- Pérez, R.J. Design and Diagnosis for Sustainable Organizations: The Viable System Method; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Ashby, W.R. An Introduction to Cybernetics; Chapman & Hall: London, UK, 1956; p. 295. [Google Scholar]

- Christopher, W.F. Holistic Management: Managing What Matters for Company Success; John Wiley & Sons: Hoboken, NJ, USA, 2007; p. 288. [Google Scholar] [CrossRef]

- Neumann, M. Towards a taxonomy of agile methods: The tree of agile elements. In Proceedings of the 2021 9th International Conference in Software Engineering Research and Innovation (CONISOFT), San Diego, CA, USA, 25–29 October 2021; pp. 79–87. [Google Scholar] [CrossRef]

- Kniberg, H.; Skarin, M. Kanban and Scrum-Making the Most of Both; Lulu Press: Morrisville, NC, USA, 2010. [Google Scholar]

- Mahnic, V. Scrum in software engineering courses: An overview. IEEE Trans. Educ. 2015, 58, 253–258. [Google Scholar] [CrossRef]

- Moe, N.B.; Smite, D.I.K.; Ågerfalk, P.J.; Jørgensen, M. Understanding the dynamics in distributed agile teams. In Proceedings of the 2012 International Conference on Agile Software Development, Malmö, Sweden, 21–25 May 2012; pp. 105–119. [Google Scholar] [CrossRef]

- Hobbs, B.; Petit, Y. Agile methods on large projects in large organizations. Proj. Manag. J. 2017, 48, 3–19. [Google Scholar] [CrossRef]

- Highsmith, J. Agile Project Management: Creating Innovative Products; Pearson Education: London, UK, 2009. [Google Scholar] [CrossRef]

- Stettina, C.J.; Hörz, J. Agile portfolio management: An empirical perspective on the practice in use. Int. J. Proj. Manag. 2015, 33, 140–152. [Google Scholar] [CrossRef]

- Ahmad, M.O.; Markkula, J.; Oivo, M. Kanban in software development: A systematic literature review. In Proceedings of the 2013 39th Euromicro Conference on Software Engineering and Advanced Applications, Santander, Spain, 4–6 September 2013; pp. 9–16. [Google Scholar] [CrossRef]

- Hofstede, G. Culture’s Consequences: Comparing Values, Behaviors, Institutions and Organizations Across Nations; Sage: Thousand Oaks, CA, USA, 2001. [Google Scholar]

- Quinn, R.E.; Rohrbaugh, J. A spatial model of effectiveness criteria: Towards a competing values approach to organizational analysis. Manag. Sci. 1983, 29, 363–377. [Google Scholar] [CrossRef]

- Klatt, K.U.; Marquardt, W. Perspectives for process systems engineering—Personal views from academia and industry. Comput. Chem. Eng. 2009, 33, 536–550. [Google Scholar] [CrossRef]

- Klir, G.J. Architecture of Systems Problem Solving; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Granovetter, M.S. The strength of weak ties. Am. J. Sociol. 1973, 78, 1360–1380. [Google Scholar] [CrossRef]

- Agneessens, F.; Borgatti, S.P.; Everett, M.G. Geodesic based centrality: Unifying the local and the global. Soc. Netw. 2017, 49, 12–26. [Google Scholar] [CrossRef]

- Espinosa, E.O.C.; Mendoza, J.R.R.; Padilla, R.T. Evaluación de programas educativos desde la perspectiva de los sistemas suaves: Propuesta metodológica. Rev. Univ. EAFIT 2009, 45, 30–44. [Google Scholar]

| Actor A | Actor B | Actor C | |

|---|---|---|---|

| Actor A | 0 | 1 | 1 |

| Actor B | 1 | 0 | 1 |

| Actor C | 1 | 1 | 0 |

| ID | Description | Dimension |

|---|---|---|

| 46 | Virtual boards | Activity |

| 47 | Physical Boards | Activity |

| 48 | Team Lead | Role |

| 49 | Project Sponsor | Role |

| 50 | team member | Role |

| 51 | Subject Master Expert | Role |

| 52 | Finance Partner | Role |

| 53 | Service Request Manager | Role |

| 54 | Service Delivery Manager | Role |

| Quality | IR | |

|---|---|---|

| Total actors | 84 | 26 |

| (output degrees) | 210 | 59 |

| (input degrees) | 210 | 59 |

| L | 210 | 59 |

| 3486 | 325 | |

| Density | 0.03 | 0.091 |

| Average grade | 2.5 | 2.231 |

| Centrality Parameters | ||

|---|---|---|

| Parameters | Quality | Issue Resolution |

| Clustering coefficient | 715.371 | 0.286 |

| Weighted clustering coefficient | 14.255 | 0.143 |

| Average distance | 3.178 | 2.619 |

| Betweenness | 39.071 | 16.5 |

| Quality | Issue Resolution | |

|---|---|---|

| N | 84 | 26 |

| 2.5 | 2.231 | |

| 4.43 | 3.258 | |

| Result | ||

| Regime | Super Critical | Super Critical |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceballos Chávez, B.A.; Takeo Nava, J.G.; Moreno Escobar, J.J.; Morales Matamoros, O. Viable and Agile Model for Improving the Quality Area in an Automotive Company in Mexico. Systems 2025, 13, 343. https://doi.org/10.3390/systems13050343

Ceballos Chávez BA, Takeo Nava JG, Moreno Escobar JJ, Morales Matamoros O. Viable and Agile Model for Improving the Quality Area in an Automotive Company in Mexico. Systems. 2025; 13(5):343. https://doi.org/10.3390/systems13050343

Chicago/Turabian StyleCeballos Chávez, Blanca Alhely, José Guillermo Takeo Nava, Jesús Jaime Moreno Escobar, and Oswaldo Morales Matamoros. 2025. "Viable and Agile Model for Improving the Quality Area in an Automotive Company in Mexico" Systems 13, no. 5: 343. https://doi.org/10.3390/systems13050343

APA StyleCeballos Chávez, B. A., Takeo Nava, J. G., Moreno Escobar, J. J., & Morales Matamoros, O. (2025). Viable and Agile Model for Improving the Quality Area in an Automotive Company in Mexico. Systems, 13(5), 343. https://doi.org/10.3390/systems13050343