Research on the Value Co-Creation Mechanism of Digital Intelligence Empowerment in Shared Manufacturing Ecosystems: Taking Zhiyun Tiangong as an Example

Abstract

1. Introduction

2. Literature Review

2.1. Research on Shared Manufacturing Platforms

2.2. Research on the Impact of Digital Intelligence Technology on Shared Manufacturing

2.3. Research on VCC in Platform-Based Enterprises

2.4. Research Review

3. Research Design

3.1. Research Methods

3.2. Case Selection

3.3. Data Sources

4. Data Analysis

4.1. Open Coding

4.2. Axial Coding

4.3. Selective Coding

4.4. Theoretical Saturation Test

5. Case Study

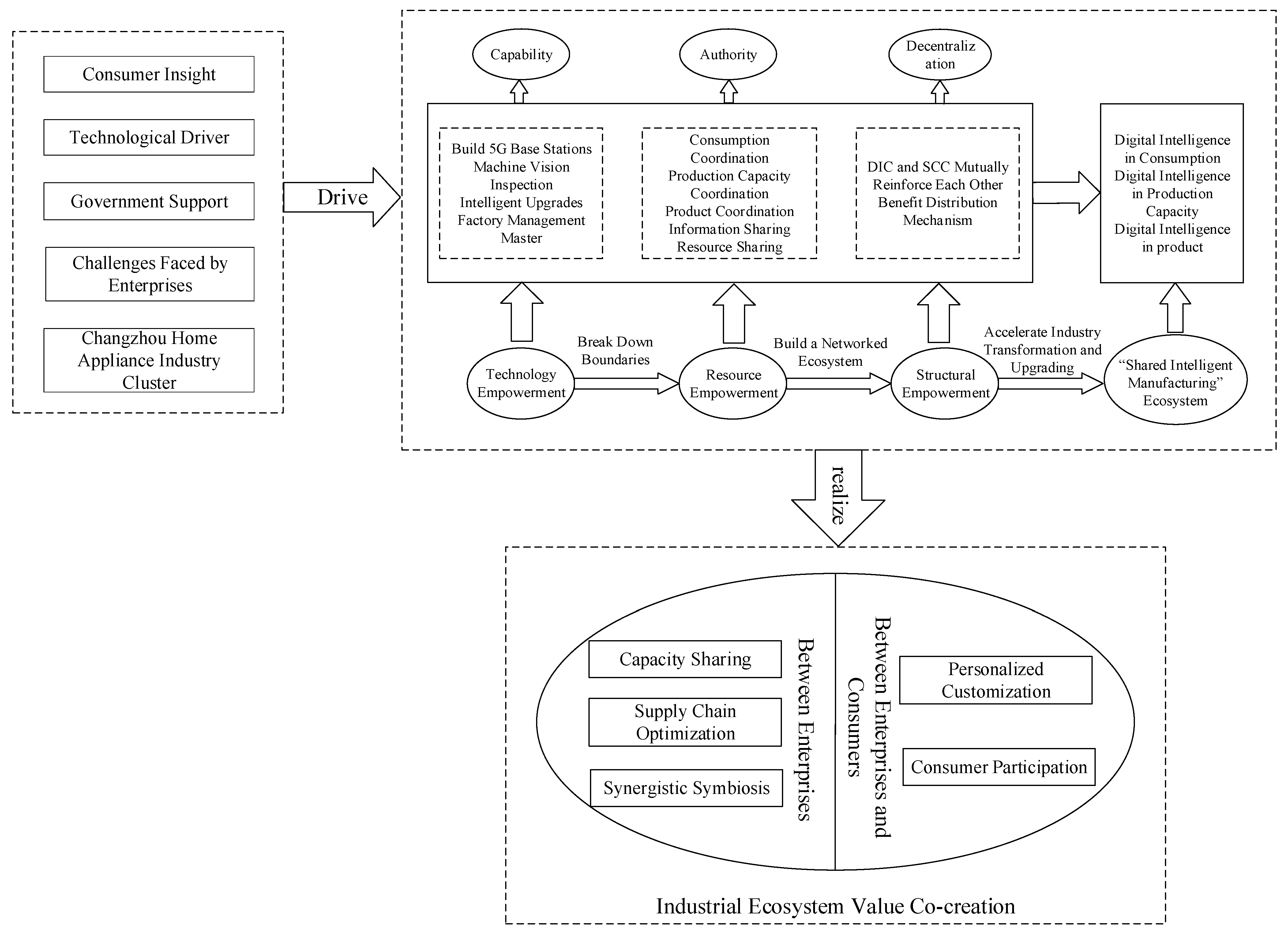

5.1. Internal Driving Forces for Multiple Stakeholders to Join the Platform

“Through deep collaboration with major internet enterprises, we gain consumer insight and leverage AI and big data capabilities to understand consumers’ preferred products. This information is then translated into product definitions, effectively supporting early-stage design and decision-making”.(quotation from a5)

“This division of labor and collaboration leverages 5G + AI technology to assist specific enterprises in achieving digital intelligence transformation across design, production, manufacturing, and marketing processes”.(quotation from a16)

“Government departments in Changzhou, Jiangsu Province, conducted extensive research on this matter and decided to leverage the local information industry’s strengths to build an open industrial big data platform, thereby driving the intelligent and digital transformation of manufacturing”.(quotation from a21)

“In stark contrast to the booming consumer market, traditional manufacturing industries grapple with the dilemma of ‘surplus capacity’. Many factories are still fighting tooth and nail for orders, even resorting to price wars”.(quotation from a43)

“Changzhou Wujin National Hi-Tech Industrial Development Zone, designated as a pilot cluster for robotics and intelligent equipment innovation by the Ministry of Science and Technology, encompasses a complete industrial chain ranging from key components to finished equipment manufacturing and system integration”.(quotation from a43)

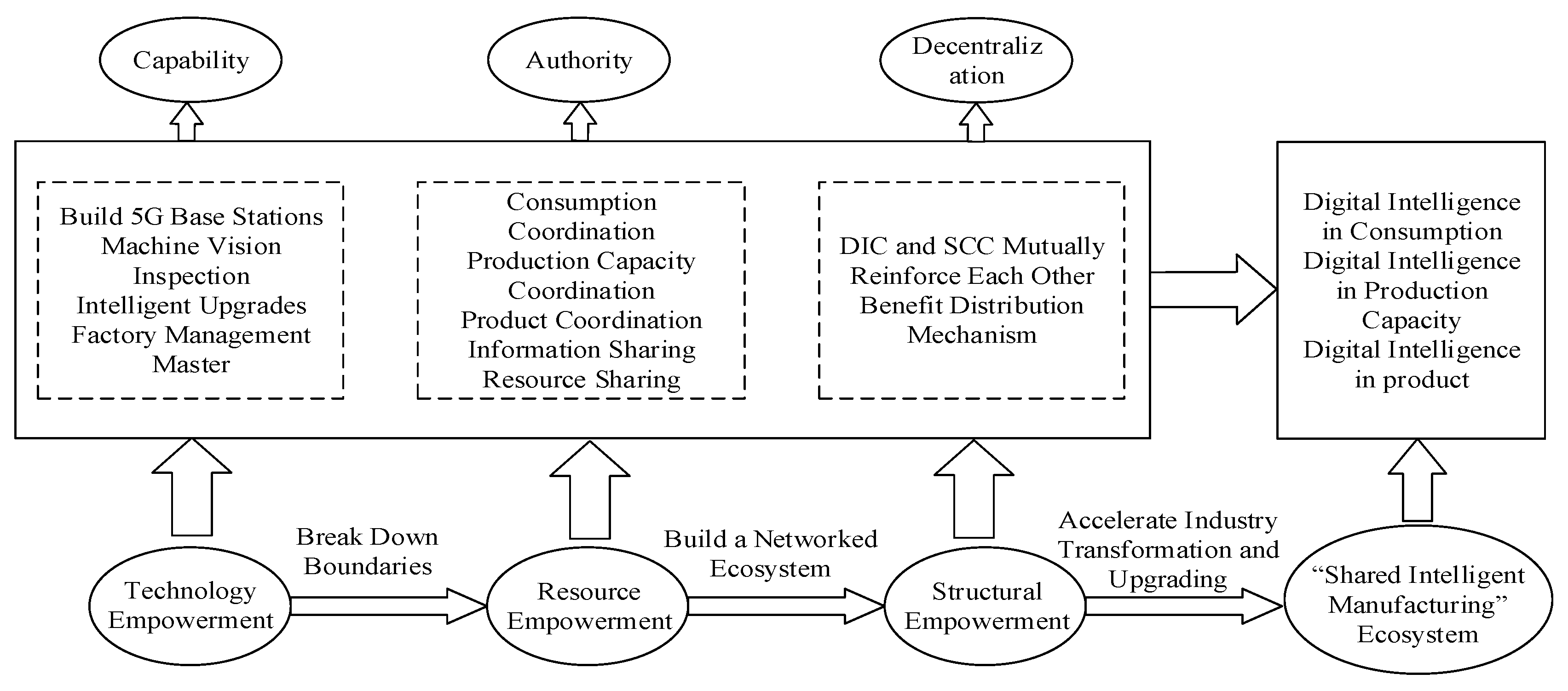

5.2. Technology Empowerment Breaks Down the Boundaries of Traditional Manufacturing Enterprises

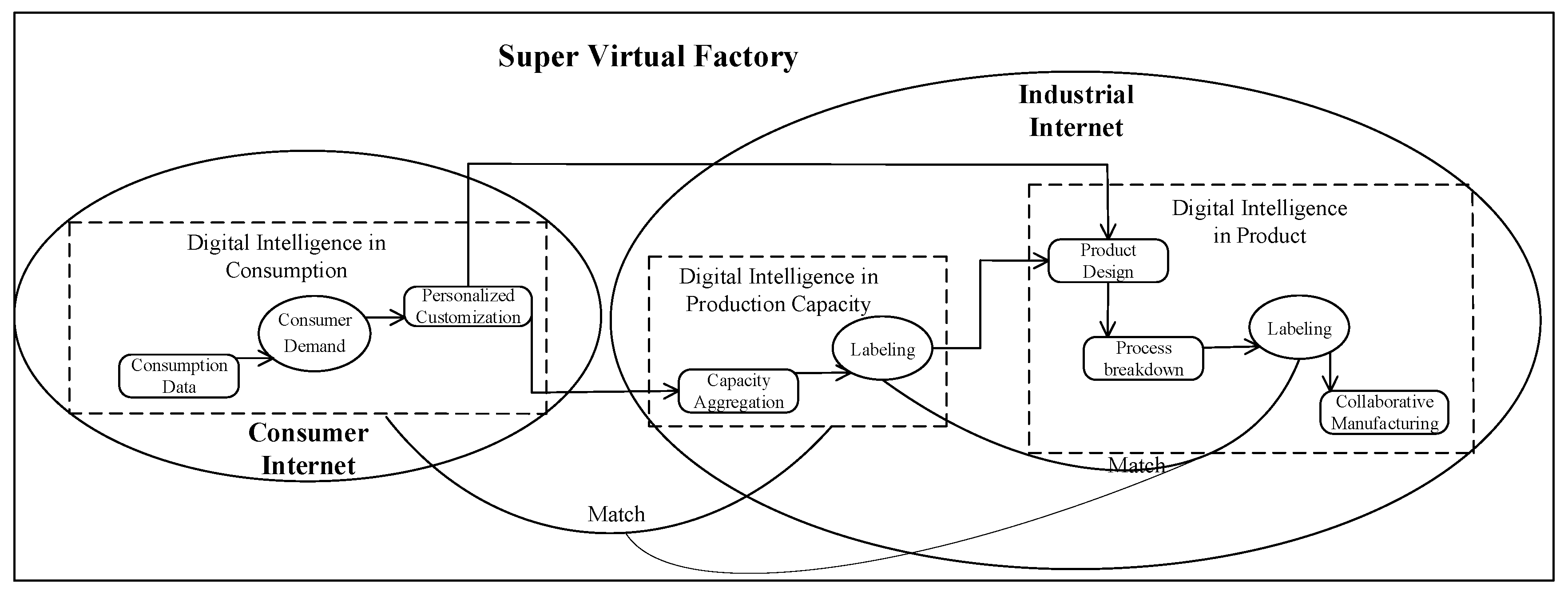

“Currently, the ‘Super Virtual Factory’ has integrated production capacity data from over 1000 enterprises across 18 regions, connecting more than 70,000 pieces of equipment”.(quotation from a89)

“Through a camera, I captured footage of him—his movements during the process, his work rhythms—to observe his daily workflow at each workstation, such as the process of assembling this equipment”.(quotation from a124)

5.3. Resource Empowerment Builds a Collaborative, Networked Supply Chain Ecosystem

“The ‘Super Virtual Factory’ aggregates consumer purchasing demands in the cloud by directly linking various online and offline channels, consolidates orders on the platform, and centrally dispatches them to factories”.(quotation from a69)

“Brands can also access real-time production data and quality management reports from the workshop online, enabling efficient and transparent end-to-end management of the factory”.(quotation from a180)

5.4. Structural Empowerment Accelerates the Transformation and Upgrading of the Home Appliance Industry

“This depends on the specific model we’re working with. Take Weibo, for instance—if I’m only providing design services, and they already have their own production capabilities, then I’m essentially just a designer for them. My compensation would consist of a platform fee plus my service fee”.(quotation from a75)

5.5. Realizing VCC in the Industrial Ecosystem

5.5.1. VCC Among Enterprises

“Zhiyun Tiangong will further accelerate the construction of a new intelligent manufacturing platform characterized by cross-regional integration, coordinated production capacity, and digital intelligence. This initiative will rapidly expand its business footprint, enabling global consumer markets to benefit from China’s high-quality production capabilities. It will enhance the competitiveness of the industrial chain and fundamentally promote industrial upgrading and transformation”.(quotation from a191)

“It has enabled the entire industrial cluster to achieve comprehensive coordination of all factors, synergy across the entire industrial chain, and optimization throughout the entire value chain”.(quotation from a193)

“Through integration and being integrated, we advance the ecological division of labor, achieve complementary value with partners, serve customers, and realize synergistic win-win outcomes.”(quotation from a220)

5.5.2. VCC Between Enterprises and Consumers

“In recent years, products have returned to delivering value and connecting with genuine consumer needs”.(quotation from a184)

6. Discussion

7. Research Conclusions and Outlook

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Guide to Semistructured Interviews

- (1)

- Can the surveillance layout of a factory be applied to a university campus?

- (2)

- Is the product displayed on the big screen the one you designed?

- (3)

- What does your company primarily do?

- (4)

- Your company’s quality inspection technology is quite advanced. Could you coordinate with manufacturing enterprises for inspection?

- (5)

- What about these defective products that are being wasted? Can they be reworked?

- (6)

- You are referring to capacity sharing, right?

- (7)

- Who is responsible for the design aspect?

- (8)

- Is it only suitable for making small household appliances?

- (9)

- If there is a quality issue with this product, which company should be held accountable? Can the source be traced back?

References

- Yu, C.; Xu, X.; Yu, S.; Sang, Z.; Yang, C.; Jiang, X. Shared manufacturing in the sharing economy: Concept, definition and service operations. Comput. Ind. Eng. 2020, 146, 106602. [Google Scholar] [CrossRef]

- Luo, J.; Hu, Y. Value creation of service innovation in manufacturing enterprises empowered by digital intelligence. Comput. Integr. Manuf. Syst. 2025, 31, 1396–1407. [Google Scholar] [CrossRef]

- Hou, L.; Su, J.; Ye, Y. Exploring the Influence of Smart Product Service Systems on Enterprise Competitive Advantage from the Perspective of Value Creation. Sustainability 2023, 15, 13828. [Google Scholar] [CrossRef]

- Peng, C.; Jia, X.; Zou, Y. Does digitalization drive corporate green transformation?—Based on evidence from Chinese listed companies. Front. Environ. Sci. 2022, 10, 963878. [Google Scholar] [CrossRef]

- Mahi, R. Optimizing supply chain efficiency in the manufacturing sector through ai-powered analytics. Int. J. Manag. Inf. Syst. Data Sci. 2024, 1, 41–50. [Google Scholar] [CrossRef]

- Xie, J.; Ma, L.; Yang, Y.; Zhang, X. Research on the Enabling Effect of Digital Intelligence Technology on Sustainable Manufacturing and Circular Economy. Manag. Rev. 2024, 36, 82–95. [Google Scholar] [CrossRef]

- Böckmann, M. The Shared Economy: It is time to start caring about sharing; value creating factors in the shared economy. Univ. Twente Fac. Manag. Gov. 2013, 350. [Google Scholar]

- Hamari, J.; Sjöklint, M.; Ukkonen, A. The sharing economy: Why people participate in collaborative consumption. J. Assoc. Inf. Sci. Technol. 2016, 67, 2047–2059. [Google Scholar] [CrossRef]

- Fang, B.; Ye, Q.; Law, R. Effect of sharing economy on tourism industry employment. Ann. Tour. Res. 2016, 57, 264–267. [Google Scholar] [CrossRef]

- Gawer, A.; Cusumano, M.A. Industry platforms and ecosystem innovation. J. Prod. Innov. Manag. 2014, 31, 417–433. [Google Scholar] [CrossRef]

- Gao, J.; Wang, Y.; Xie, P.; Wei, Z. Collaborative Governance in Sharing Manufacturing Ecosystems: Based on the Problem-Solving Perspective. J. Manag. World 2024, 40, 177–211. [Google Scholar] [CrossRef]

- Helo, P.; Hao, Y.; Toshev, R.; Boldosova, V. Cloud manufacturing ecosystem analysis and design. Robot. Comput.-Integr. Manuf. 2021, 67, 102050. [Google Scholar] [CrossRef]

- Li, X.; Yu, X.; Meng, D.; Xiang, S. Evolving from traditional to sharing manufacturing business ecosystem through open innovation Case study of Shenyang machine tool group. J. Bus. Econ. Manag. 2020, 8, 125–139. [Google Scholar] [CrossRef]

- Jih, C.-Y.; Hung, W.-H. Digital Transformation Research of Taiwan’s Traditional Manufacturing Industry based on the Ecosystem Perspectives. In Proceedings of the International Conference on Electronic Business, Hong Kong, China, 5–8 December 2020; pp. 63–70. [Google Scholar]

- Hein, A.; Weking, J.; Schreieck, M.; Wiesche, M.; Böhm, M.; Krcmar, H. Value co-creation practices in business-to-business platform ecosystems. Electron. Mark. 2019, 29, 503–518. [Google Scholar] [CrossRef]

- Jovanovic, M.; Sjödin, D.; Parida, V. Co-evolution of platform architecture, platform services, and platform governance: Expanding the platform value of industrial digital platforms. Technovation 2022, 118, 102218. [Google Scholar] [CrossRef]

- Wulfert, T.; Strobel, G.; Hoang, H. Let’s join forces: Boundary resources as enablers of value co-creation in e-commerce ecosystems. Electron. Commer. Res. 2024, 24, 1–38. [Google Scholar] [CrossRef]

- Tajvidi, M.; Richard, M.-O.; Wang, Y.; Hajli, N. Brand co-creation through social commerce information sharing: The role of social media. J. Bus. Res. 2020, 121, 476–486. [Google Scholar] [CrossRef]

- Hao, M.; Wang, H.; Gao, K. The multiagent evolutionary game research of enterprise resource sharing on a shared manufacturing platform. Discret. Dyn. Nat. Soc. 2022, 2022, 2322887. [Google Scholar] [CrossRef]

- Benkler, Y. Sharing nicely: On shareable goods and the emergence of sharing as a modality of economic production. JSTOR 2004, 114, 273–358. [Google Scholar] [CrossRef]

- Chen, D.; Yi, S. Research on the Generation and Development of Sharing Manufacturing based on the Long Tail Theory. In Proceedings of the International Conference on Management Science and Engineering Management, Toronto, ON, Canada, 5–8 August 2019; pp. 149–161. [Google Scholar]

- Zhang, X.; Wang, B.; Liu, Y.; Dan, B. Quality Information Disclosure Strategies and Incentive Mechanism in the Supply Chain Based on the Third-party Shared Manufacturing Platform. Chin. J. Manag. Sci. 2024, 32, 278–287. [Google Scholar] [CrossRef]

- Wang, L.; Ma, Z.; Xu, M. Supply-demand bilateral matching model of shared manufacturing platform considering global satisfaction. Comput. Integr. Manuf. Syst. 2024, 30, 32991-18. [Google Scholar] [CrossRef]

- Zhang, X.; Li, J.; Dan, B. Match of the cross-period capacity on the third-party shared manufacturing platform with demand delay. Expert Syst. Appl. 2024, 240, 122479. [Google Scholar] [CrossRef]

- Cao, D.; Zhang, X.; Dan, B. Research on capacity matching strategy of third-party shared manufacturing platform considering order splitting. Chin. J. Manag. Sci. 2025, 33, 225–235. [Google Scholar] [CrossRef]

- Cheng, Y.; Yu, C.; Xu, S.; Zhao, S. A novel supply-demand matching model for shared manufacturing resources. Int. J. Comput. Integr. Manuf. 2024, 38, 1399–1423. [Google Scholar] [CrossRef]

- Jiang, P.; Li, P. Shared factory: A new production node for social manufacturing in the context of sharing economy. Proc. Inst. Mech. Eng. Part. B J. Eng. Manuf. 2020, 234, 285–294. [Google Scholar] [CrossRef]

- Yang, X.; Wu, Y.; Zhang, X.; Zheng, X. Building new paradigm of digital intelligence security for new development pattern. Bull. Chin. Acad. Sci. 2024, 39, 131–142. (In Chinese) [Google Scholar] [CrossRef]

- Yang, B.; Huang, J.; Chen, Y. The relationship between ESG ratings and digital technological innovation in manufacturing: Insights via dual machine learning models. Financ. Res. Lett. 2025, 71, 106362. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, W.; Qin, Q.; Chen, K.; Wei, Y. Intelligent manufacturing management system based on data mining in artificial intelligence energy-saving resources. Soft Comput. 2023, 27, 4061–4076. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, G.; Guo, X.; Zhang, Y. Digital twin-driven service model and optimal allocation of manufacturing resources in shared manufacturing. J. Manuf. Syst. 2021, 59, 165–179. [Google Scholar] [CrossRef]

- Choi, S.; Woo, J.; Kim, J.; Lee, J.Y. Digital twin-based integrated monitoring system: Korean application cases. Sensors 2022, 22, 5450. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Chen, J.; Huang, S.; Liu, Y. Operations Management in the Digitization Era: From Empowering to Enabling. J. Manag. World 2020, 36, 117–128. [Google Scholar] [CrossRef]

- Van Doorn, J.; Lemon, K.N.; Mittal, V.; Nass, S.; Pick, D.; Pirner, P.; Verhoef, P.C. Customer engagement behavior: Theoretical foundations and research directions. J. Serv. Res. 2010, 13, 253–266. [Google Scholar] [CrossRef]

- Prahalad, C.K.; Ramaswamy, V. Co-creation experiences: The next practice in value creation. J. Interact. Mark. 2004, 18, 5–14. [Google Scholar] [CrossRef]

- Donato, H.C.; Farina, M.C.; Donaire, D.; Santos, I.C.D. Value co-creation and social network analysis on a network engagement platform. RAM. Rev. Adm. Mackenzie 2017, 18, 63–91. [Google Scholar] [CrossRef]

- Tchorek, G.; Brzozowski, M.; Dziewanowska, K.; Allen, A.; Kozioł, W.; Kurtyka, M.; Targowski, F. Social capital and value co-creation: The case of a polish car sharing company. Sustainability 2020, 12, 4713. [Google Scholar] [CrossRef]

- Zhang, H.; Xue, K.; Xu, M.; Zheng, X.; Fang, X. The value co-creation mechanisms of incubation-oriented platform ecosystem: A case study of Xiaomi. Sci. Res. Manag. 2021, 42, 71–79. [Google Scholar] [CrossRef]

- Gawer, A. Bridging differing perspectives on technological platforms: Toward an integrative framework. Res. Policy 2014, 43, 1239–1249. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, Z.; Wang, X. Mechanisms for Co-Creating Social Value in Digital Platform Enterprises: A Longitudinal Case Study of the Meituan "Green Mountain" Project. J. Manag. World 2024, 40, 146–171. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, F.-W.; Xia, S.-M.; Cao, D.-M.; Ye, Z.; Shen, C.-R.; Maas, G.; Li, Y.-M. Value co-creation and appropriation of platform-based alliances in cooperative advertising. Ind. Mark. Manag. 2021, 96, 213–225. [Google Scholar] [CrossRef]

- Leone, D.; Schiavone, F.; Appio, F.P.; Chiao, B. How does artificial intelligence enable and enhance value co-creation in industrial markets? An exploratory case study in the healthcare ecosystem. J. Bus. Res. 2021, 129, 849–859. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Mao, J. Conducting rigorous qualitative research by using a structured data analysis method: Review of the forum on case-based and qualitative research in business administration in China (2019). J. Manag. World 2020, 36, 221–227. [Google Scholar]

- Denzin, N.K. The Research Act: A Theoretical Introduction to Sociological Methods; Routledge: Abingdon, UK, 2017. [Google Scholar]

- Jiangsu Zhiyun Tiangong Enterprise Limited. Available online: http://www.svfactory.com.cn/ (accessed on 24 November 2024).

- Glaser, B.G.; Strauss, A.L.; Strutzel, E. The discovery of grounded theory; strategies for qualitative research. Nurs. Res. 1968, 17, 364. [Google Scholar] [CrossRef]

- Cumbajin, E.; Rodrigues, N.; Costa, P.; Miragaia, R.; Frazão, L.; Costa, N.; Fernández-Caballero, A.; Carneiro, J.; Buruberri, L.H.; Pereira, A. A real-time automated defect detection system for ceramic pieces manufacturing process based on computer vision with deep learning. Sensors 2023, 24, 232. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Tran, K.-p.; Thomassey, S.; Zeng, X.; Yi, C. A reinforcement learning based decision support system in textile manufacturing process. In Developments of Artificial Intelligence Technologies in Computation and Robotics: Proceedings of the 14th International FLINS Conference (FLINS 2020); World Scientific Publishing: Singapore, 2020; pp. 550–557. [Google Scholar]

- Yan, P.; Yang, L.; Che, A. Review of supply-demand matching and scheduling in shared manufacturing. Syst. Eng.-Theory Pract. 2022, 42, 811–832. Available online: https://link.cnki.net/urlid/11.2267.n.20220215.1137.002 (accessed on 30 September 2025).

- Tolio, T.A.M.; Monostori, L.; Váncza, J.; Sauer, O. Platform-based manufacturing. CIRP Ann. 2023, 72, 697–723. [Google Scholar] [CrossRef]

| Data Type | Information Type | Data Source | Collection Volume |

|---|---|---|---|

| Primary Data | Field visit interviews | The platform manager of Zhiyun Tiangong introduced the enterprise to us and answered some of our questions. | Took 35 photos and recorded about 13,000 Chinese characters |

| Secondary Data | Corporate website | Basic information and latest news of the enterprise, etc. | About 25,000 Chinese characters |

| News reports | Coverage of the platform’s development and the enterprises it empowers | About 11,000 Chinese characters | |

| Academic publications | Literature Study on Jiangsu Zhiyun Tiangong | About 1000 Chinese characters |

| Primary Sources | Conceptualization | Initial Categorization |

|---|---|---|

| They will have some customized needs, so we are also thinking about how we can customize small quantities of multiple varieties of these products for him with the lowest price. Then we are actually working with Jingdong. (a2) | Customized production and cooperation (A2) | Demand for personalization and customization of products (B1) |

| In the first half of this year, China’s consumption recovery was strong, and with it, personalized and diversified consumption became the trend. (a3) | Consumption recovery and personalization trends (A3) | |

| What about working with Jingdong, which provides us with some consumer data? What about the consumer data? That is to say, through the consumer insights, I will go to analyze some of the consumer behaviors, and actually, we have done some of that sample out. (a10) | Consumer data and sample development (A10) | Consumer behavioral profiling (B2) |

| This division of labor has helped specific enterprises both digitally and intellectually transform themselves in design, production, manufacturing, and marketing through 5G + AI technology. (a16) | 5G + AI technology to help enterprises digital intelligence transformation (A16) | Digital intelligence technology (B4) |

| Among them, Changzhou Mobile has built a high-quality and reliable cloud network infrastructure by taking advantage of 5G and edge cloud. (a17) | 5G and edge cloud infrastructure building (A17) | |

| ‘Super Virtual Factory’ aggregates consumers’ purchasing needs in the cloud by directly linking various channels online and offline, aggregating orders on the platform and uniformly sending them to factories. (a69) | Order aggregation and demand matching (A65) | Capacity synergies (B14) |

| Here’s my machine, which is a camera light source driven by a six-axis robotic arm to take pictures of it, and on this product, it’s going to be photographed every month. (a117) | Six-axis robotic arm photo inspection (A110) | Intelligent inspection and quality control (B19) |

| We provide a set of intelligent machine vision solutions for an intelligent inspection, such as a solution, then during the inspection process, I’m able to go and collect a lot of quality data from it. (a132) | Intelligent machine vision inspection program (A125) | |

| Wang Nan, vice president of Jingdong Group, believes that ecological cooperation, that is, comparative advantage under the industrial synergy, is a win-win situation. (a217) | Industrial synergy and win-win ecology (A207) | Synergistic symbiosis (B27) |

| Main Category | Subcategory | Typical Example |

|---|---|---|

| Consumer Insight (C1) | Personalization and customization of products (B1) Analysis of consumer behavior characteristics (B2) | Through deep cooperation with major Internet enterprises, we gain consumer insights and combine AI and big data capabilities to understand what types of products consumers like. |

| Technological Drive (C2) | Industrial intelligence cloud platform construction (B3) Digital intelligence technology (B4) | Integrating new-generation digital intelligence technologies and methods such as artificial intelligence, machine vision, big data analysis, and consumer data insights, we are digitizing existing manufacturing capacity and consumer demand. |

| Government Support (C3) | Helping to build a “Super Virtual Factory” (B5) Government measures (B6) Policy guidance and financial support (B7) | To build this “Super Virtual Factory”, Zhonglou District in Changzhou City teamed up with a bunch of telecom operators to set up 5G communication base stations and put in 60 million yuan in special funds for digital infrastructure construction. |

| Enterprise Challenges (C4) | Enterprise transformation needs (B8) Supply chain disruption (B9) High idle capacity utilization rate (B10) Difficulties in implementing industrial AI projects (B11) Cost pressures (B12) Impact of the pandemic and response measures (B13) | In stark contrast to the booming consumer market is the dilemma of “excess capacity” in traditional manufacturing. Many factories are still fighting tooth and nail for orders, even resorting to price wars. |

| Changzhou Home Appliance Industry Cluster (C5) | Possesses a complete industrial chain (B28) Focuses on developing the home appliance industry (B29) | As a pilot project approved by the Ministry of Science and Technology for robotics and intelligent equipment innovation clusters, Changzhou Wujin National High-Tech Zone covers the entire industrial chain from key components to complete machine production and system integration. |

| Coordination Mechanisms (C6) | Production capacity coordination (B14) Product coordination (B15) Consumption coordination (B16) | Since we know the basic production capacity of each enterprise, we know which factories have surplus capacity, so I can distribute this surplus capacity and then resume production. |

| Data Integration (C7) | Data source (B17) Data processing (B18) | Bring together the core capabilities and data of different regions, different enterprises, and different processes through a platform, connecting the dots and coordinating the whole. |

| Smart Manufacturing (C8) | Intelligent detection and quality control (B19) Production automation and intelligence (B20) | OCT is a technology that uses high-precision analysis to perform this detection. It works by shining a beam of laser light onto the surface, which then reflects back, allowing the entire internal image to be displayed. |

| Sharing Information and Resources (C9) | Information sharing (B21) Resource sharing (B22) | Zhiyun Tiangong provides assistance for preliminary product design decisions, comprehensive product reports, and application tools, offering comprehensive information such as concept analysis and design evaluation. |

| Value Co-creation between Enterprises and Consumers (C10) | Personalized customization (B23) Consumer participation (B24) | In recent years, commodities have returned to value output, connecting with the true needs of consumers. |

| Value Co-creation among Enterprises (C11) | Capacity sharing (B25) Supply chain optimization (B26) Synergistic symbiosis (B27) | A more efficient supply chain enables greater flexibility in production systems, helping the manufacturing industry solve key issues. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Y.; Zhang, H. Research on the Value Co-Creation Mechanism of Digital Intelligence Empowerment in Shared Manufacturing Ecosystems: Taking Zhiyun Tiangong as an Example. Systems 2025, 13, 969. https://doi.org/10.3390/systems13110969

Pan Y, Zhang H. Research on the Value Co-Creation Mechanism of Digital Intelligence Empowerment in Shared Manufacturing Ecosystems: Taking Zhiyun Tiangong as an Example. Systems. 2025; 13(11):969. https://doi.org/10.3390/systems13110969

Chicago/Turabian StylePan, Yanlei, and Hao Zhang. 2025. "Research on the Value Co-Creation Mechanism of Digital Intelligence Empowerment in Shared Manufacturing Ecosystems: Taking Zhiyun Tiangong as an Example" Systems 13, no. 11: 969. https://doi.org/10.3390/systems13110969

APA StylePan, Y., & Zhang, H. (2025). Research on the Value Co-Creation Mechanism of Digital Intelligence Empowerment in Shared Manufacturing Ecosystems: Taking Zhiyun Tiangong as an Example. Systems, 13(11), 969. https://doi.org/10.3390/systems13110969