Abstract

Truck congestion around international ports poses persistent challenges for safety, efficiency, environmental performance, and accessibility, particularly during container terminal disruptions when long queues of trucks accumulate. Traditional responses often address isolated components of the problem and fail to capture the interdependencies of sociotechnical systems, where multiple actors pursue partly conflicting goals. This study explores the usefulness of combining Sociotechnical Systems (STS) principles with the Systems-Theoretic Accident Model and Processes (STAMP) to analyze such complexity more holistically. Using the case of truck re-routing procedures during terminal closures at the Port of Rotterdam, structured interviews and document analyses were used to apply parallel STS and System-Theoretic Process Analyses (STPA). The STS analysis identified misalignments among procedures, actor intentions, infrastructure, and communication practices, clarifying why diversion protocols often fail in practice. The STPA complemented this diagnosis by modeling control relationships and feedback loops, identifying 92 unsafe control actions and 407 loss scenarios that informed 16 design recommendations. Together, the two approaches demonstrate how sociotechnical and control-theoretic perspectives can be combined to generate both diagnostic and prescriptive insights. The study highlights the potential of a combined STS–STPA framework as a transferable analytical tool for understanding and redesigning complex transport systems.

Keywords:

STAMP; sociotechnical systems; port; container terminal; evacuation; hybrid systems method 1. Introduction

Truck congestion around international ports remains a persistent challenge with wide-ranging impacts on road safety, productivity, environmental performance, and port accessibility [1,2,3]. Congestion often arises during major disruptions to container handling at terminals or depots, when long queues of trucks accumulate while waiting to deliver or collect containers [4]. With container ships growing in capacity and port operations becoming increasingly interdependent and complex, the impacts of these disruptions are amplified [5].

Traditional responses, such as expanding infrastructure or applying logistical optimization models, have produced limited results since they tend to focus on isolated system components rather than addressing the complex interactions that cause congestion [6,7]. Although numerous studies have modelled traffic flow and gate operations or proposed appointment systems and digital platforms to manage truck arrivals, these efforts remain largely reductionist. They rarely capture how social, organizational, and technical factors interact to produce emergent congestion dynamics. There is therefore a need for systems-based approaches that recognize the sociotechnical nature of port traffic: a network of terminal operators, port authorities, truck drivers, cargo owners, and regulators whose goals and actions interact in dynamic and sometimes conflicting ways.

Two perspectives offering complementary insights into such complexity are: sociotechnical systems (STS) theory, which highlights the importance of alignment among social, organizational, and technical system elements; and control-theoretic approaches, such as the Systems-Theoretic Accident Model and Processes (STAMP), which focuses on the quality of control relationships and feedback loops within complex systems. Despite their shared concern for system behavior, these paradigms have largely evolved in parallel, and their combined potential has rarely been explored in the context of port operations or wider transport systems. This constitutes a research gap: while prior work has either examined social coordination or modelled technical control, few studies have investigated how these perspectives might be combined to better understand and manage complex port traffic systems.

The current study addresses this gap by exploring how combining STS with the control-theoretic approach could support the redesign of truck re-routing procedures during container terminal closures in the Port of Rotterdam. By combining the diagnostic strength of STS with the prescriptive rigor of STAMP the study aims to evaluate the usefulness of a hybrid systems framework for analysing port truck congestion holistically, rather than to generalise specific empirical findings. The following section reviews the literature on STS and STAMP to clarify their theoretical foundations and explores how their combined use can enhance the analysis and management of complex port traffic systems. The remainder of this paper is structured as follows: Section 2 reviews existing approaches to managing port truck congestion and the literature on STS and STAMP; Section 3 describes the methods and case context; Section 4 presents the analytical results; Section 5 discusses their implications and limitations; and Section 6 concludes with reflections on future research.

2. Literature Analysis

While a substantial body of work has examined operational or infrastructural solutions to truck congestion, few studies have adopted a systemic perspective that integrates both sociotechnical and control-theoretic insights. This section reviews existing approaches to managing port truck congestion, before outlining the conceptual foundations of STS theory and principles of STAMP and its analytical method STPA. It then considers how combining these paradigms could support a more holistic understanding of complex port traffic systems.

2.1. Existing Approaches to Managing Port Truck Congestion

Truck congestion in and around container ports has been a long-standing concern in both research and practice, with implications for operational efficiency, air quality, and safety. The dominant strategies proposed in the literature can be grouped into three broad categories: infrastructure expansion, logistical optimization, and policy or scheduling measures. Infrastructure-based approaches, such as expanding gate capacity, redesigning access roads, or adding waiting areas, aim to absorb peak flows but often shift congestion elsewhere or offer only temporary relief [8,9]. Operational approaches—such as truck appointment scheduling, dynamic scheduling, and simulation-based queuing optimization—seek to smooth truck arrivals and departures [10,11].

While these strategies have improved local throughput, they remain focused on individual system components or subsystems, and fail to address underlying coordination challenges or conflicting interests of stakeholders [12]. A meta-review of 71 studies of port truck congestion classified methods according to technical scope and concluded that most focus on single actors or processes such as terminal gate operations or haulier dispatching, rather than the port ecosystem as a whole [9]. Similar criticisms can be made of more recent optimization research suggesting that truck flows can be centrally scheduled with perfect information [10]. The challenge for reductionist or technocentric approaches to resolving port truck congestion is that congestion patterns are highly sensitive to complex behavioral and organizational factors, such as drivers’ preferences, contractual obligations, or information asymmetries between terminals and logistics companies [12,13,14]. For instance, even well-designed appointment systems may fail when stakeholders lack incentives or digital capacity to participate.

There is therefore a need for system-oriented and sociotechnical perspectives that explicitly account for human, organizational, and technological interdependencies in port traffic management [15]. Yet work examining port truck congestion through a sociotechnical or control-theoretic lens has been limited [16,17]. This gap motivates the present study’s combination of Sociotechnical Systems (STS) theory and the Systems-Theoretic Accident Model and Processes (STAMP), as a way of better understanding and redesigning complex port traffic systems.

2.2. Sociotechnical Systems (STS) Perspective

The STS perspective originated from mid-20th-century studies of industrial organizations showing that technological innovations often failed when implemented without regard for social and organizational context [18]. According to STS theory effective system design requires the joint optimization of social and technical subsystems, recognizing that changes to one dimension inevitably affect the others [19]. STS research has articulated a set of design principles and analytical frameworks that allow system designers to capture and account for interdependencies among system dimensions [20,21,22]. Principles have been used to ensure technology fits with the goals, culture and processes of people in the system into which it will be introduced [22], to develop design ideas for sociotechnical systems [23], and to analyze incidents or accidents and inform future system developers [24]. A sociotechnical analysis framework has also been used to help analyze and optimize systems in line with sociotechnical theory and principles [25]. Existing or proposed systems can be analyzed using a framework that structures the identification of explicit combinatorial influences among six types of system dimension:

- Human (e.g., roles, behaviors, competencies);

- Intentional (e.g., goals and motives);

- Technological (e.g., digital tools, interfaces);

- Procedural (e.g., formal processes, rules);

- Cultural (e.g., norms, shared beliefs);

- Infrastructural (e.g., physical constraints like road layouts).

Problems often arise not just from a flaw in one dimension, but from misalignments among two or more dimensions, e.g., a procedure requiring real-time updates can be poorly aligned with a culture that discourages information sharing. Mapping misalignments sociotechnical dimensions can highlight opportunities for meaningful system improvement [24,25].

As trends such as globalization, digitalization and connectivity increase interdependencies between people and structures in transport systems, sociotechnical systems approaches are becoming increasingly relevant. Empirical applications in diverse sectors (e.g., aviation, healthcare, energy), consistently show that system failure often stem from misalignments across these dimensions [25]. In transport contexts, STS approaches have helped explain that technical interventions such as automated gate systems or traffic control platforms can fail inadequately aligned with workflows, information flows, or informal norms among actors [23]. Mapping such misalignments can reveal leverage points for meaningful redesign, making STS particularly relevant to the multi-actor, interdependent environment of port logistics.

2.3. System-Theoretic Accident Model and Processes (STAMP)

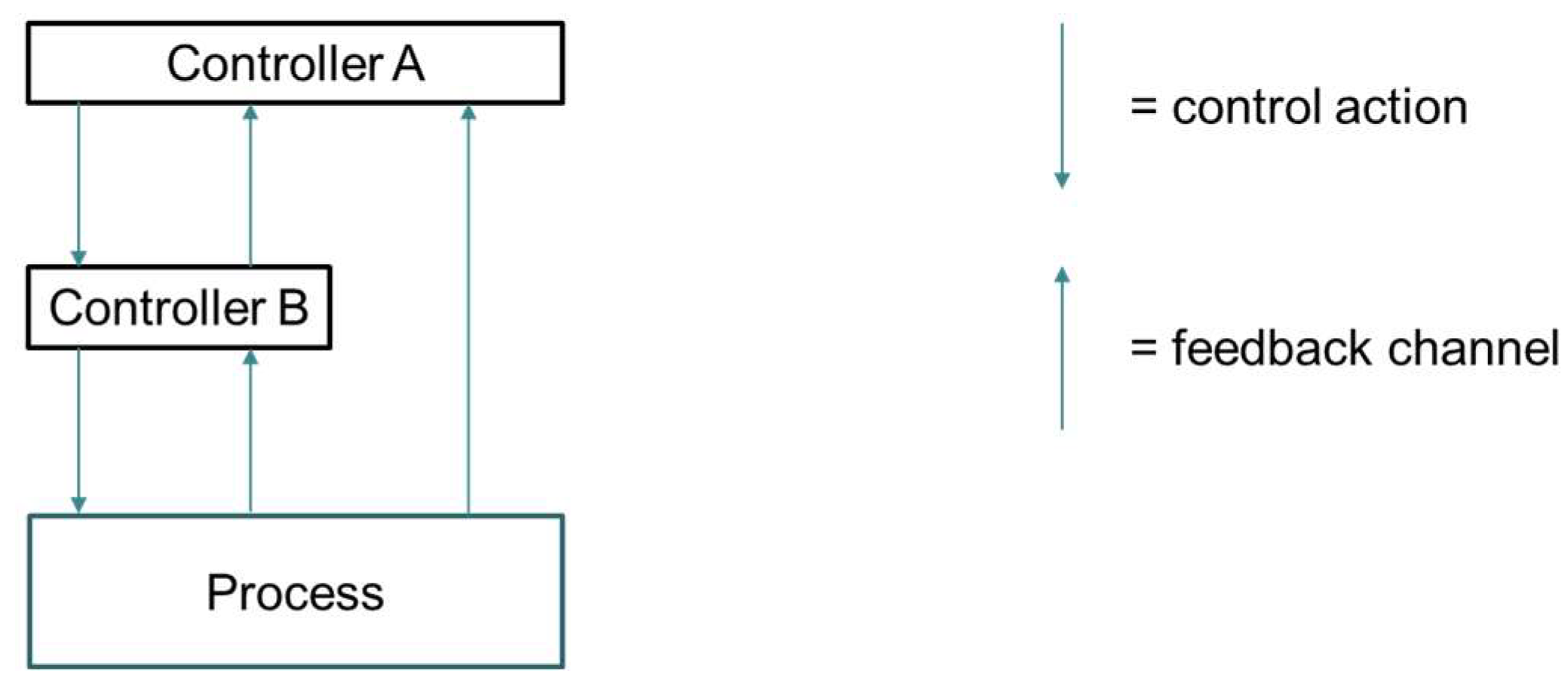

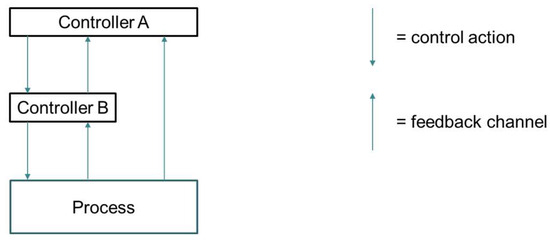

Developed by Leveson (2004), STAMP reconceptualizes system-level outcomes as resulting from control and feedback relations within complex systems [26]. Rather than tracing linear cause-effect chains, STAMP models systems as hierarchical control structures in which outcomes depend on the adequacy of control actions, feedback, and process models maintained by human and technical controllers. In Figure 1, for example, Controller A carries out control actions that influence Controller B, which in turn influences a process.

Figure 1.

Structure of control loops, adapted from [26].

Controller A could be, for example, an office-based manager instructing an on-site team (Controller B) responsible for diverting trucks (Process). According to STAMP each “controller” will have a mental or digital representation of (i) the state of the controller or process they are controlling, and (ii) a set of appropriate actions that can be used to influence it. Human controllers will also have ideas about what the likely effects of control actions will be. Each of these aspects of the controller’s process model evolves in response to information about the process being controlled (feedback).

In the above example the actions of the office-based manager (Controller A) will be informed by feedback on the effects of their previous instructions on the on-site team (Controller B) and the trucks being diverted (Process). Since a controller can be technical, human, or a social organization, the key components of any complex sociotechnical system can be linked together by control loops.

Control over a system requires that controllers coordinate control actions to achieve a purpose, and that each controller receives meaningful, timely and accurate feedback and has a sufficient model of the processes being controlled. Models of control structure help understand how controllers collectively control the quality of system’s output. Although rooted in safety engineering, STAMP has been increasingly applied to broader sociotechnical contexts, including maritime and railway systems [27,28]. Of the analytical methods associated with STAMP, System-Theoretic Process Analysis (STPA) is applied most widely and is suited to the identification of design flaws, component interactions, and human factors that can lead to undesirable outcomes in existing systems [29,30]. A main strength is that it indicates ways to explicitly account for critical but often hidden dependencies among human, organizational, and technical elements [31].

Recent studies explore hybrid approaches that combine STAMP with human factors frameworks such as the Human Factors Analysis and Classification System (HFACS), to capture both control structures and behavioral causes of system breakdowns [32]. These developments reflect a growing recognition that control-theoretic approaches can complement sociotechnical theory by providing prescriptive methods for redesign once misalignments are diagnosed.

2.4. Combining STS and STAMP to Identify Redesign Solutions for Complex Port Systems

STS and STAMP share a systems view but whereas STS focuses on why sociotechnical interactions produce certain outcomes, STAMP explains how control and feedback mechanisms sustain or disrupt system performance. A hybrid approach combining STS and STAMP could provide both diagnostic and prescriptive capabilities by linking actor misalignments revealed through STS analysis to deficient control structures identified through STPA. Such an approach would also be practical, since both depend on data collected using qualitative methods such as interviews, observations or document surveys. In the context of truck re-routing during terminal closures, combining STS and STAMP can address the limitations of existing studies, which either identify bottlenecks but overlook interdependencies among human and technical actors, or capture stakeholder dynamics but fail to identify concrete design interventions.

The aim of this study was therefore to explore whether a hybrid diagnostic-prescriptive systems analysis using STS and STAMP could inform technically robust and socially sustainable redesign of truck re-routing procedures during container terminal closures in an area of the Port of Rotterdam. Specifically, STPA was used to structure a series of explorative interviews with port management experts about the system involved in re-routing trucks on closure of container terminals. The results were analysed using both STS and STPA frameworks to (i) identify misalignments among infrastructure, technology, procedures, and actor behavior, and (ii) account for them by generating redesign strategies addressing explicit feedback and control challenges in the sociotechnical system.

3. Methods

STS and STPA were chosen for their potential to allow for a dual diagnostic-prescriptive systems analysis, as described in Section 2.4. Both methods are usefully informed by qualitative methods [25,29]. According to a body of work on decision-making in real-world systems, much insight can be generated by treating experts not as biased informants but as windows onto the complex system they are central to, providing high-fidelity insights into coordination, trade-offs, assumptions and adaptive decision processes in situ [33]. An emphasis was therefore placed on obtaining rich accounts of the system through the eyes of central actor representatives in the form of two port management experts possessing comprehensive oversight of the truck-re-routing procedures, including coordination with terminal operators, traffic controllers, and inspectors. In line with purposive expert sampling used in systems and safety research, the aim was depth to elicit detailed knowledge of decision-making processes, control structures, and inter-organizational coordination. Each interviewee therefore participated in three extended sessions involving document review and scenario walkthroughs. Views of the port managers were also supplemented by document reviews, as described in Section 3.2.

3.1. Case Study: Truck Rerouting in the Port of Rotterdam

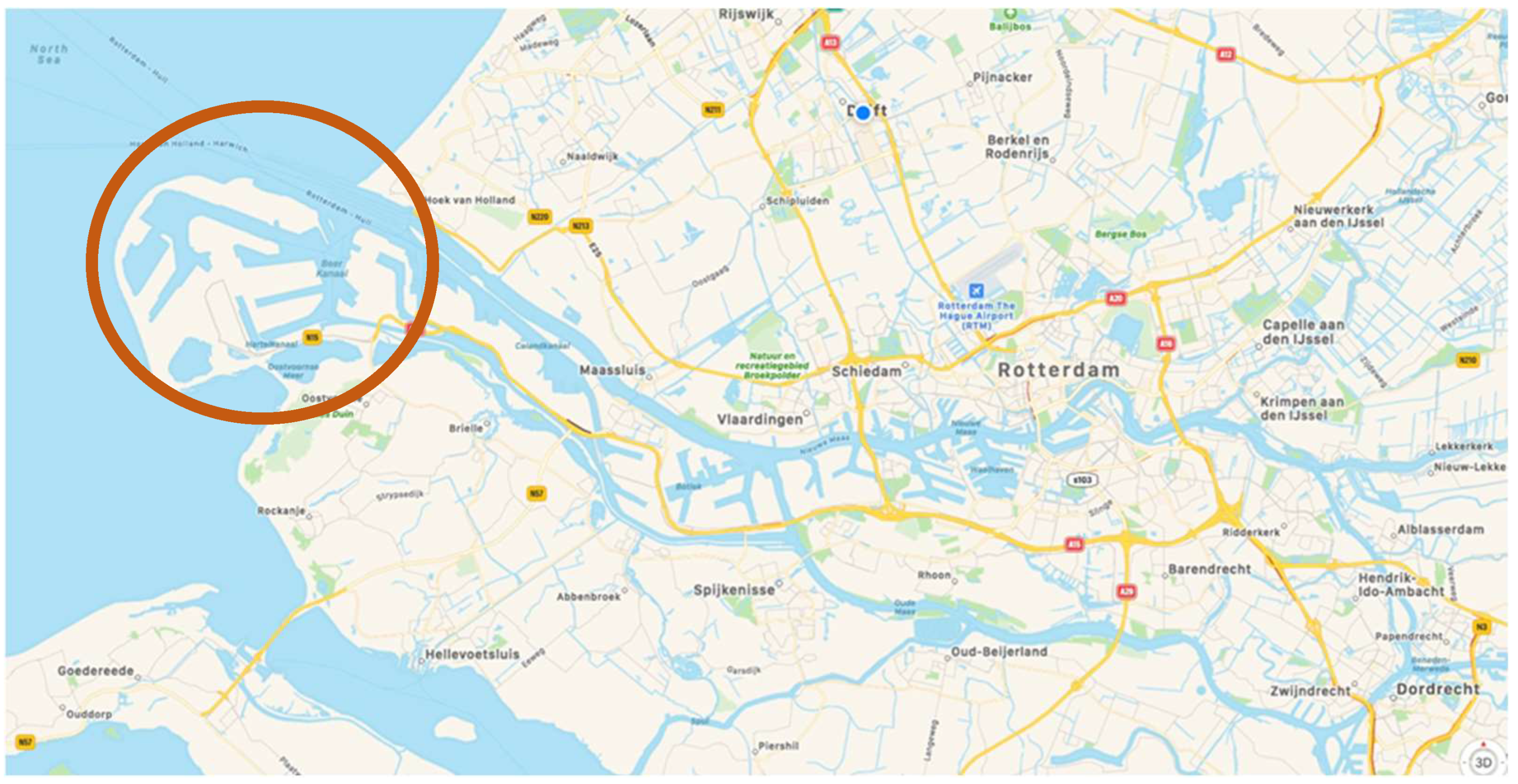

The system under study comprises the social and technological components involved in diverting container trucks away from terminal entrances during the planned or unplanned closure of container terminals in the Maasvlakte harbor area of the Port of Rotterdam (PoR; see Figure 2).

Figure 2.

Maasvlakte harbor area (circled) in relation to the broader Rotterdam region.

This harbor area hosts multiple major container terminals that receive truckloads arriving via the Dutch and broader European road networks. Trucks typically deliver containers for transfer to ships; however, terminal operations may be disrupted by planned maintenance or unforeseen events such as high wind conditions, IT system failures, or public health measures (e.g., Covid-19 restrictions). When a terminal is forced to close, port authorities must quickly divert or evacuate trucks already en route or queued near the terminal.

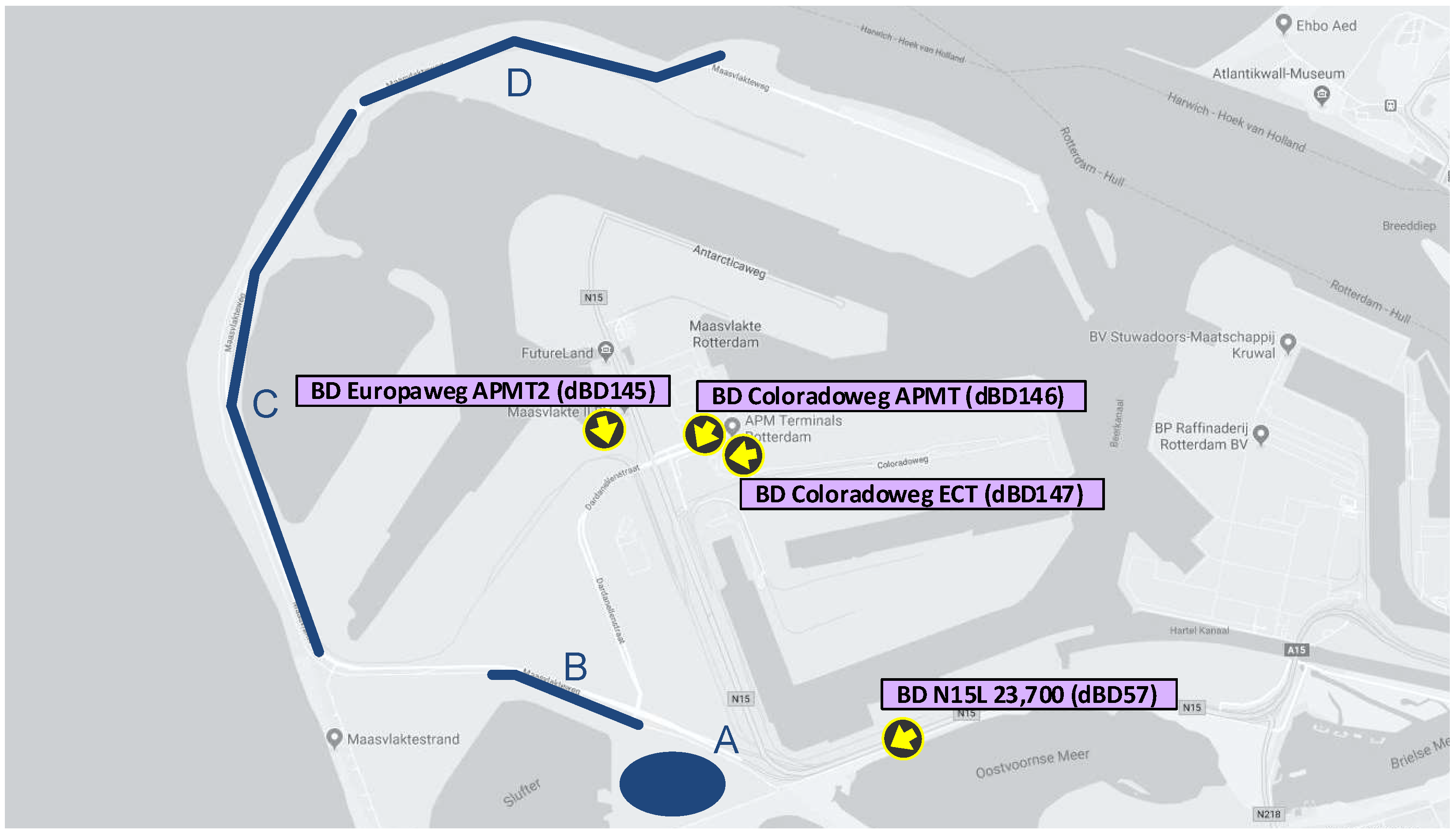

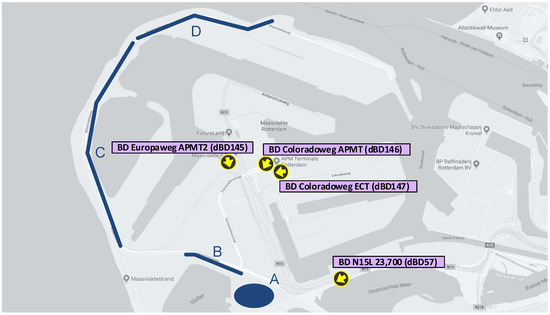

To manage these situations, designated holding areas—known in evacuation protocols as landing zones (LZs)—are used to temporarily buffer truck traffic. If LZs within terminal premises reach capacity, overflow buffering is handled by additional areas located outside the terminal gates, some distance away. Figure 3 shows the locations of the primary LZs (A, B, C, D) relative to the ECT, APMT, and APMT2 container terminals (indicated in purple). When one or more of these terminals closes or reaches capacity, trucks are first diverted to LZ A, which can accommodate approximately 500 trucks. Once LZ A reaches saturation, additional traffic is redirected: trucks destined for ECT, APMT, and APMT2 are sent to LZ B, while those bound for more distant terminals are forwarded to LZ C.

Figure 3.

Locations of truck landing zones A, B, C, D (blue) and nearby container terminals (purple) in the Maasvlakte area.

The focal point of this study is the operation of buffer area A during closures of ECT, APMT, and APMT2. Re-routing procedures specify the actions to be taken in such events, including

- the allocation of truck traffic to specific buffer areas;

- activation of tailored messages on Variable Message Signs (VMS) along approach roads; and

- coordinated responsibilities for personnel in operational roles to facilitate the diversion process.

Leading up to this study in 2021, implementation of these procedures had encountered challenges. In practice, port managers had observed that many truck drivers disregarded diversion instructions and continued toward the closed terminals. Some parked illegally on roads near the terminal entrance. While many were forced to turn around, the problem seemed intractable as traffic would continue to build up on roads near the terminal entrances. As a result, terminal closures often caused congestion, jeopardizing safety, and compromising access to roads and other, open terminals in the wider Maasvlakte area.

3.2. Document Review and Site Visits

Documents, traffic management plans, different Scenario documents, driver surveys conducted by PoR, and local and harbour maps were collected and reviewed as part of preparation for interviews and as part of the analysis using STS principles and framework and STPA. Two of the authors had visited the port area.

3.3. Data Collection and Analysis with STS and STPA

At the start of 2021, the research team conducted a series of three structured digital interviews with two senior representatives of port management. Both participants were experienced in managing truck buffer scenarios and were knowledgeable about the behaviors and perspectives of the various actors involved in terminal operations and re-routing procedures. The interviews were attended by each of the three researchers and were spaced approximately three to four weeks apart. Each session lasted around two hours. The interviews were structured and analyzed according to the System-Theoretic Process Analysis (STPA) methodology briefly, as follows [29]:

3.3.1. STPA Analysis

Interview 1: System definition and actor mapping. The first interview focused on collaboratively defining the system under analysis and identifying the key actors, their roles, and the relationships between them. This was foundational for constructing an initial model of the system’s control structure. To support later application of sociotechnical systems (STS) analysis, we supplemented the STPA framework with an additional prompt aimed at eliciting the goals and motives of each actor group—an element typically not captured by STPA but central to STS approaches [20].

Interview 2: Control dynamics, hazards, and loss scenarios. Between the first and second interviews, the researchers developed a preliminary control structure model using the initial findings. This model was presented to the port experts during the second interview and iteratively developed in collaboration with them. Additional questions were posed to identify relevant system losses, hazards, and “unsafe”1 control actions, in line with STPA procedures [29]. Toward the end of the second session, discussions expanded to include the nature of communication and coordination between actors during both routine operations and various types of terminal closure events. Data from this interview—along with notes from the first interview and supporting procedural documents—served as the foundation for constructing loss scenarios, which describe how specific “unsafe” conditions can emerge from control failures.

Interview 3: Validation and Refinement of Loss Scenarios. The third and final interview was used to present and validate the set of developed loss scenarios. These were reviewed collaboratively with the participants and further elaborated through discussion, ensuring that the models and scenarios accurately reflected real-world practices and challenges in the Maasvlakte operational context.

3.3.2. STS Analysis

Although the interviews were structured around STPA, the responses were suitable for analysis using the sociotechnical framework proposed by Davis et al. (2014) [25]. This supplementary analysis was conducted through a focused review of audio recordings, in which a single researcher annotated observations related to the six sociotechnical dimensions: human, procedural, intentional, technological, cultural, and infrastructural. Notes were developed using an interpretive application of sociotechnical theory and design principles [25]. Specifically, influences on re-routing events were analyzed through the lens of the six sociotechnical dimensions—Human, Procedural, Intentional, Technological, Cultural, and Infrastructural—and particular attention was given to combinatorial misalignments across these dimensions. For instance, the intended process during a terminal closure was for port management to contact the traffic control center, which would then activate messages on Variable Message Signs (VMS) to divert inbound truck traffic to designated landing zones (LZs). This sequence implies multiple dimensions: Procedural (the formal re-routing plan), Intentional (intention behind the re-routing plan), Human (port and traffic controllers, their role, experience with re-routing, etc.), Technology (telephone systems, VMS), and Infrastructure (road networks). The analysis involved examining how these elements aligned or interacted in practice compared to how they were intended to function. Misalignments were noted when two or more components failed to support one another. For example, a VMS with poor visibility represents a technological constraint that undermines both the procedural intent and human action. Similarly, a poorly worded VMS message may point to a procedural deficiency—such as vague or ambiguous guidance in the re-routing protocol—or to gaps in the training of traffic control staff, thereby misaligning procedures, people, and technology. By identifying such cross-dimensional mismatches, the analysis aimed to surface latent vulnerabilities in the current system and highlight opportunities for more coherent and resilient redesign.

Participants were fully informed about the study objectives, procedures, voluntary participation, anonymity protections, and data rights prior to the interviews.

ChatGPT4.0 was used to help structure presentation of the study this article, but not used in execution or analysis of the research otherwise.

4. Results

In the event of terminal closure, truck drivers en route to closed or imminently closing terminals are intended to be diverted to designated buffer areas. This strategy aims to maintain access to open terminals for other drivers and prevent road congestion (Figure 3). However, in practice, diversion compliance is inconsistent: some drivers remain parked near closed terminals or stop on surrounding roads, contributing to traffic obstructions and unsafe conditions. To identify systemic causes of this breakdown, we conducted STS and STPA analyses of the re-routing procedure. For both analyses the system was defined as the combined people, procedures, technologies, and infrastructures working to achieve safe, orderly, efficient and fair contingency parking on temporary closure of a container terminal due to IT malfunction, storm or other risk.

4.1. STS Analysis

The sociotechnical systems analysis identified several critical misalignments across the six STS dimensions that undermine the effectiveness of the re-routing procedure.

4.1.1. Misalignment Between Procedures and Actor Intentions

While the re-routing procedure aligned well with the overarching goals of terminal operators, to reduce congestion and enhance safety in the terminal, it was less well aligned with the key goals of other system actors, particularly truck drivers. One major source of misalignment concerned fair treatment: the procedure did not ensure that drivers were processed at re-opened terminals in the order of their arrival at the port. As a result, drivers perceived the procedure as unfair and sought alternative strategies to maintain competitive advantage—such as parking near terminal gates rather than diverting. This behavioral adaptation led to unintended consequences, including roadside queuing, obstructed routes, and increased overtaking behavior, directly undermining the safety intention behind the procedure. The extent to which actor goals aligned or conflicted with the re-routing procedure is summarized in Table 1.

Table 1.

Alignment of re-routing procedure with goals of key actor groups.

Overall, Table 1 highlights a marked asymmetry in how the re-routing procedure served different actor groups. While the procedure met operational objectives of terminal and port management related to congestion control and road safety, it failed to align with the real-world priorities of truck drivers and in practice undermined the intended safety outcomes. Adaptive behaviors of drivers effectively re-created congestion in less controlled spaces, demonstrating how partial goal alignment can generate new systemic risks.

4.1.2. Misalignment Between Procedures and Infrastructure

The effectiveness of the re-routing procedure was also constrained by the physical layout of the road network and buffer areas. The existing infrastructure did not support channeling trucks into queues based on their order of arrival, especially when LZs were shared by trucks destined for different terminals. Moreover, the geometry of road access meant that trucks diverted to buffer areas had to drive away from their target terminal, misaligning with driver expectations. Critically, it was not feasible to physically enforce driver compliance by closing access roads to the terminals, as these same roads had to remain open to vehicles bound for other operational terminals. This infrastructural limitation reduced the enforceability of diversion instructions, allowing for discretionary driver behavior. Some drivers would bypass diversion signs to verify terminal status firsthand or gain early positioning.

4.1.3. Misalignment Between Procedures, Culture, and Technology

A further misalignment was observed between formal procedures and the cultural-technological practices of truck drivers. Drivers frequently used social media platforms such as WhatsApp or Facebook to coordinate with their peers, reflecting a long-standing culture of peer-to-peer communication. Social media was used as a tool not only for information sharing but for strategic collaboration. For example, drivers would coordinate actions, perhaps parking on specific side roads to improve group positioning for terminal re-entry. At the time of the study, port management had not leveraged social media to communicate directly with drivers, nor was there deployment of sensor- or camera-based monitoring to track truck locations. As a result, management lacked real-time situational awareness of traffic behaviors, while drivers demonstrated high adaptability through informal, decentralized networks and use of newer communication technologies. This asymmetry in technological use and communication modes—hierarchical and analog on one side, distributed and digital on the other—contributed to a disconnect between the intended re-routing process and its real-world implementation.

Thus, STS analysis confirmed that the shortcomings of the re-routing procedure were not isolated to any single component, but systemic. Goal misalignments among actors were reinforced by infrastructural constraints that limited enforceability, and by cultural-technological mismatches that shaped how information was shared and acted upon. These misalignments served to undermine a seemingly robust procedural intervention. To better understand how interacting misalignments generated undesirable system outcomes, and to identify explicit opportunities for redesign, the next section applies STPA to analyse the port manager interviews.

4.2. STPA Analysis

We applied Systems-Theoretic Process Analysis (STPA) to identify how well the control structure of the re-routing system prevents losses during terminal closures.

4.2.1. Losses, Hazards and System-Level Constraints

Port management identified three key system-level losses to be avoided:

- L1—Delays to ship departures;

- L2—Road safety risks (collisions or near misses);

- L3—Damage to the port authority’s reputation for fairness.

Next we derived a set of hazards (e.g., unsafe queues, illegal parking, fairness perception failures) and the associated system constraints they imply; it is these constraints that must be effectively enforced to avoid the losses. Examples of system constraints are that trucks should not queue in ways that obstruct access to other terminals, and it should be evident to drivers that entry to reopened terminals occurs in fair order. A full list of hazards and system constraints is given in Appendix A.

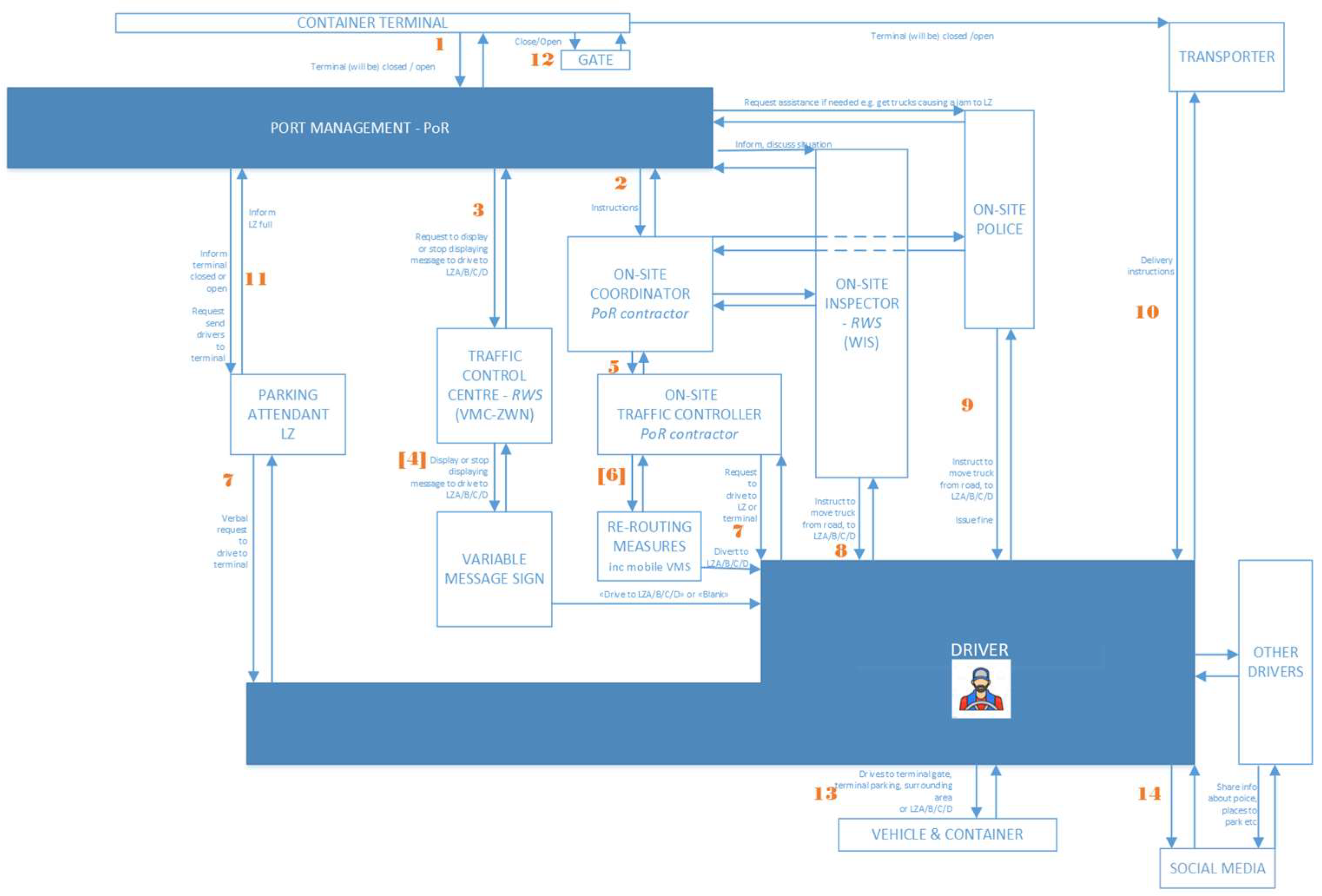

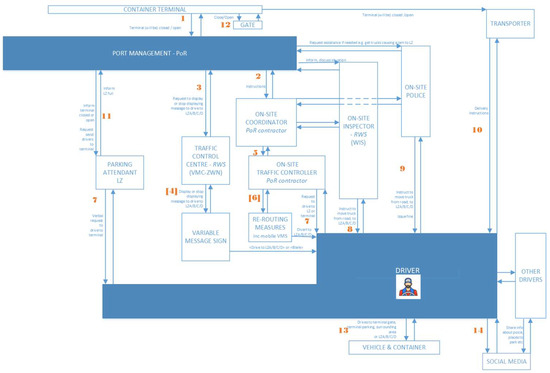

4.2.2. Control Structure and Unsafe Control Actions

The system control structure shown in Figure 4 was analysed to identify 92 unsafe control actions (UCA) across communication and coordination links among system actors. Each UCA represented an “unsafe”, omitted, poorly timed or poorly executed action that could violate a system constraint. The full list of UCAs is given in Appendix B.

Figure 4.

System control structure. LZ = Landing Zone, RWS = state road administration; PoR = Port of Rotterdam; VMS = variable message sign; WIS = state road inspector, VMC-ZWN = regional traffic control center dealing with traffic on roads leading to and from PoR. For further explanation, see text.

The control structure revealed a highly layered system in which information and authority flowed through multiple intermediaries. While the Port of Rotterdam formally initiated strategic re-routing decisions, its feedback channels to drivers are fragmented and indirect and therefore delayed, mediated through traffic control units, visual message signs, and contractors. This structural distance could also help explain why local behaviors often diverged from central intentions. Limited direct communication and feedback loops mean that policy adjustments are not easily informed by real-time driver behavior, increasing the potential for local adaptations and emergent risks that were not anticipated in procedural design.

4.2.3. Loss Scenarios and Design Recommendations

For each UCA, we developed loss scenarios by asking why they could occur in control theoretic terms. For example, “Container terminal fails to tell port management that it will re-open” was an unsafe control action as it would have led to delayed re-entry of trucks and delayed ship departure (L1). This UCA could be explained by ten envisaged loss scenarios, e.g., “Terminal does not think that PoR needs to know it will re-open or has re-opened” and “Terminal believes PoR already knows terminal will re-open”. In this way 407 loss scenarios were identified, clustered into four categories:

- Unsafe controller actions (51.6%);

- Inadequate feedback/information (26.3%);

- Faulty control paths (14.2%);

- Failures in the process being controlled (7/9%).

Most loss scenarios were attributed to unsafe controller actions or inadequate feedback and information flow. This underscores that i) operational risks were primarily behavioral and organizational, arising from how decisions were made or implemented, rather than from hardware or procedural errors; and ii) that visibility across actors was limited and situational awareness unevenly distributed.

Finally, from the 407 loss scenarios, we derived 29 preliminary design recommendations, which we synthesized further into 16 final design recommendations (Table 2).

Table 2.

Summary of final set of 16 design recommendations—suggestions on how to avoid loss scenarios.

The design recommendations translate diagnostic insights into concrete improvements that strengthen information symmetry, shared situational awareness, and cross-level feedback between the Port of Rotterdam, terminal operators, coordinators, and drivers. Collectively, they point to the need for a control architecture that integrates real-time data visibility, fair and transparent procedures, and mechanisms for mutual confirmation of actions among actors. The analysis demonstrates that the core vulnerability of the current system lies not in the absence of procedures, but in the disconnection between control and communication.

5. Discussion

5.1. Comparison of STPA Recommendations and STS Results

The STS and STPA analyses were clearly complementary. While the STS framework identified why the re-routing procedure broke down in terms of misalignments between actor goals, infrastructure constraints, cultural practices, and technological gaps, the STPA analysis suggests how those breakdowns could be corrected through redesign of control actions and feedback structures. This is made more explicit by the summary in Table 3.

Table 3.

Linking STS findings to STPA design recommendations.

An analytical approach combining STS and STPA has demonstrated that system improvement requires both understanding and intervention. The STS framework exposed the misaligned goals, infrastructural constraints, and cultural–technological asymmetries that manifest as undesirable responses to implemented procedures, while STPA both complemented these diagnostic insights, and suggested how to translate them into actionable redesigns of control and feedback structures. Together, STS and STPA revealed that failures in the re-routing system were unlikely to be resolved by simply improving procedures, but by addressing fragmented control and limited mutual observability among actors.

Combined analysis also exposed a limitation: while STPA effectively operationalized technical and procedural redesigns, it only partially captured the social and cultural dynamics identified in the STS analysis—particularly the asymmetry relating to the informal coordination among drivers. This suggests that even a strengthened control architecture will remain brittle unless it explicitly incorporates human adaptability, informal communication channels, and fairness perceptions as integral design parameters. Thus, the combined framework provides an improved analytical lens and suggests that technical feedback loops can correct control deficiencies, but that sustainable resilience may depend on fully aligning those loops with the social systems through which port operations actually function.

5.2. Implications for Sociotechnical Design

The findings of this exploratory study support that there is value in combining STS and STPA to diagnose systemic failures and develop prescriptive redesigns in complex sociotechnical systems. First, the STS analysis identified a range of misalignments across sociotechnical dimensions, including disconnects between formal procedures and the goals of truck drivers, infrastructural constraints that limited physical enforcement, and cultural-technical mismatches in communication practices between drivers and port management. These diagnostic insights helped explain why, despite the existence of formal re-routing protocols, drivers frequently disregard diversion instructions, seeking instead to position themselves advantageously for terminal re-entry. This behavioral adaptation undermines the safety and fairness goals of the system, leading to congestion, unsafe road conditions, and diminished legitimacy of the diversion procedures.

Second, the STPA analysis complemented these findings by identifying actionable control flaws and specifying redesign strategies to mitigate risks. Note that many of the 16 design recommendations correspond directly to the failures highlighted in the STS analysis. For example, the recommendation to implement a fair-order process (Recommendation #2) directly responds to the STS-identified misalignment between procedure design and driver expectations. While STS emphasized the importance of aligning procedures with actor goals and sociocultural practices, STPA brought precision to how these dynamics could be governed through improved feedback loops, coordination mechanisms, and role-specific responsibilities. As expected, STPA also went beyond individual component failures to re-engineer control structures—providing a roadmap for system-wide resilience.

Together, the STS-STPA approach therefore fulfilled the dual aim of this study: (1) understanding why truck re-routing procedures fail in real-world scenarios, and (2) identifying concrete, implementable redesigns to improve performance. The integration enabled us to bridge the gap between diagnostic insight (why the system fails) and prescriptive guidance (how it can be improved), yielding solutions that are both technically robust and socially grounded. This dual-perspective framework offers a promising template for redesigning other sociotechnical control systems facing similar challenges.

Finally, we wish to highlight two points. First, rather than embedding cultural or normative constructs directly into control loops, we have treated STS and STPA as complementary lenses: STS provided explanatory insight into sociotechnical misalignments, while STPA offered a structured means of redesigning control and feedback mechanisms. This approach has preserved the conceptual integrity of each paradigm while enabling mutual enrichment through the comparison of their findings. Second, the study has been on the Maasvlakte area of the Port of Rotterdam, which has unique road geometries, governance structures, and regulatory arrangements. The findings should be interpreted as analytically transferable rather than statistically generalizable. While contextual factors such as seasonality, traffic demand peaks, or temporary COVID-19 measures may have influenced specific driver behaviors, the system relationships analyzed—control dependencies, feedback gaps, and goal misalignments—represent structural features that are likely to recur in other large ports. Future research could examine how similar sociotechnical dynamics manifest under different regulatory and cultural conditions, enabling comparative validation of the proposed framework.

6. Conclusions

Sociotechnical systems (STS) and Systems-Theoretic Process Analysis (STPA) can be usefully combined to understand truck re-routing challenges emerging on container terminal closure in a busy international port. A main advantage is that sociotechnical misalignments can be traced to specific feedback gaps, information delays, or organizational blind spots, which can then be addressed through coordinated redesign. The STS-STPA approach allows the generation of solutions that are more likely to be both technically feasible and socially viable—including fair-order mechanisms, real-time status sharing, and better synchronization across actors. Combining STS and STPA holds significant promise for guiding system redesigns that improve resilience, equity, and operational safety. More elaborate demonstrations of this approach in other transport or infrastructure domains could help validate its broader relevance.

These conclusions can be made while accepting the study’s limitations. A key limitation is that in-depth interviews were conducted with only two port-management experts, representing a management-level perspective on the re-routing procedure. This narrow sampling reflects the study’s focus on decision-making and control structures rather than on stakeholder perceptions. While this approach aligns with expert sampling conventions in complex systems and safety research, it may have underrepresented informal work practices and trust dynamics at the operational level. Triangulation with port documents, traffic-control procedures, and driver survey responses discussed at interviews helped to mitigate this risk. Nevertheless, future research should include participatory workshops or multi-stakeholder focus groups to cross-validate the STPA findings and incorporate perspectives from drivers, transport companies, and enforcement personnel. This would serve to verify researcher findings and add understanding regarding real-time control decision-making, feedback challenges, or trust dynamics across actors.

Author Contributions

Conceptualization, R.O.P., B.R. and S.R.; methodology, formal analysis, Writing—Original draft preparation, R.O.P.; review and editing, R.O.P.; project administration, R.O.P., B.R. and S.R. All authors have read and agreed to the published version of the manuscript.

Funding

The SAFEWAY project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No 769255. This paper reflects only the views of the authors. Neither the Innovation and Networks Executive Agency (INEA) nor the European Commission is in any way responsible for any use that may be made of the information it contains.

Data Availability Statement

The data analyzed for this article are not readily available for reasons of confidentiality.

Conflicts of Interest

Author Semaneh Rezvani was employed by the company Demo Consultants Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Appendix A. Loss, Hazards and System Constraints

Loss

Port management representatives identified three types of loss (L) that it was important for the system to avoid:

- L-1

- Delay to ship departure

- L-2

- Material or personal injury due to road traffic collision

- L-3

- Port authority get a reputation for unfair practice

Hazards

Hazards are system states that increase the risk of losses occurring. The following hazards (H) and subhazards (SH) were identified for the system under study:

- H-1

- Truck queue outside one container terminal reduces access to another [can lead to L-1, L-2, L-3]

- SH-1.1

- Trucks approach closed terminal instead of buffer area [can lead to H-1]

- SH-1.2

- Too many trucks arrive at open terminal just before it is closed [H-1]

- SH-1.3

- Too high rate of trucks arriving at terminal after it is re-open [H-1]

- H-2

- Trucks parked on main roads or side roads surrounding a container terminal [L-1, L-2, L-3]

- H-3

- Trucks turning around in a road leading to a closed container terminal [L-1, L-2]

- H-4

- It is not evident to truck drivers in buffer area that all trucks will enter re-opened terminal in order of arrival at port [L-3]

- SH-4.1

- Drivers/firms do not see that all trucks will enter re-opened terminal in order of arrival at port [L-3]

- SH-4.2

- Drivers in buffer area do not see that trucks not using buffer area cannot enter terminal before them [L-3]

- SH-4.3

- Drivers in buffer area do not see that trucks arriving at port just after terminal re-opening will not enter terminal before them [L-3]

- H-5

- Trucks in buffer area do not start to approach terminal once it is re-opened [L-1]

System constraints

We considered constraints that need to be upheld by the system in order to prevent loss. Systems constraints are derived from hazards and sub-hazards:

- SC-0

- <X trucks queue on road outside a container terminal [H-1]

- SC-1

- Drivers do not drive to a closed terminal instead of a buffer area [SH-1.1]

- SC-2

- <Y trucks head towards a terminal less than Z minutes before it closes [SH-1.2]

- SC-3

- Rate of trucks [no. of trucks/min] heading towards a re-open terminal limited [SH-1.3]

- SC-4

- Trucks do not park on roads near terminal that is closed, about to close or re-open [H-2]

- SC-5

- Trucks do not enter road leading to a terminal that is closed or about to close [H-3]

- SC-7

- Evident to drivers/firms that trucks enter re-opened terminal in order of arrival at buffer area [SH-4.1]

- SC-8

- Evident to drivers that trucks not buffering do not enter the terminal before trucks that have diverted [SH-4.2]

- SC-9

- Evident to drivers that trucks arriving at port do not enter re-open terminal before trucks coming from buffer area [SH-4.3]

- SC-10

- Trucks progress to correct terminal once it is re-opened [H-5]

Appendix B

Table A1.

Unsafe Control Actions (UCA) with corresponding Safety Constraints (SC).

Table A1.

Unsafe Control Actions (UCA) with corresponding Safety Constraints (SC).

| Unsafe Control Actions Identified (UCA) | |||

|---|---|---|---|

| Control Action (cf Figure 4) | Not Providing Action Causes Hazard | Providing Action Causes Hazard | Too Early, Late, Out of Order |

| 1 Container Terminal to PoR: terminal will close | UCA-1: Container Terminal does not tell PoR that it will close (SC-0,1,2,5,7,8,9) | UCA-2: Container Terminal tells PoR that it will close when it will not (SC-10) | UCA-3: Container Terminal gives PoR insufficient warning that it will close (SC-0,1,2,5) |

| 1 Container Terminal to PoR: terminal will open | UCA-4: Container Terminal does not tell PoR that it will open (SC-10) | UCA-5: Container Terminal tells PoR that it will open when it will not (SC-0,1,2,5) | UCA-6: Container Terminal gives PoR insufficient warning that it will open (SC-10) |

| 2 PoR to On-site Coordinator: instructions on terminal closure | UCA-15: PoR does not give on-site Coordinator instructions to divert from terminal when it closes (SC-0,1,2,4,5) | UCA-16: PoR gives on-site Coordinator instructions to divert drivers from terminal when it will remain open (SC-10) | UCA-17: PoR gives on-site Coordinator instructions too late to divert drivers from terminal (SC-0,1,2,4,5) |

| UCA-19: PoR gives on-site Coordinator inadequate instructions on how to divert drivers from terminal when it closes (SC-0,1,2,4,5,7,8,9,10) | |||

| 2 PoR to On-site Coordinator: instructions on terminal opening | UCA-20: PoR does not give on-site Coordinator instructions to tell drivers to start going to terminal when it re-opens (SC-10) | UCA-21: PoR gives on-site Coordinator instructions to tell drivers to start going to terminal when it will stay closed (SC-0,1,2,4,5) | UCA-22: PoR gives on-site Coordinator instructions too late to tell drivers to start going to terminal when it will re-open (SC-8,9,10) |

| UCA-23: PoR gives on-site Coordinator inadequate instructions on to tell drivers to start going to terminal when it will re-open (SC-0,3,7,8,9,10) | |||

| 3 PoR to Traffic Control Centre: Display “Divert to LZ” | UCA-24: PoR does not instruct Control Centre to display “Divert to LZ” when terminal will close (SC-0,1,2,4,5) | UCA-25: PoR instructs Control Centre to display “Divert to LZ” when terminal will not close (SC-10) | UCA-26: PoR instructs Control Centre too late to display “Divert to LZ” when terminal will close (SC-0,1,2,4,5) |

| UCA-27: PoR does not instruct Control Centre to display “Divert to LZB” when LZA full (SC-1,4) | UCA-28: PoR instructs Control Centre to divert to wrong LZ (SC-7,8,9) | UCA-29: PoR instructs Control Centre too early to display “Divert to LZ” when terminal will close (SC-10) | |

| UCA-30: PoR does not instruct Control Centre to stop display “Divert to LZ” when terminal will open (SC-10) | UCA-31: PoR tells Control Centre to stop display “Divert to LZ” when terminal still closed (SC-0,1,2,4,5) | UCA-32: PoR instructs Control Centre too late to display “Divert to LZB” as LZA full (SC-1,4) | |

| UCA-33: PoR instructs Control Centre too late to stop display “Divert to LZ” when terminal will open (SC-10) | |||

| 4 Traffic Control Centre to VMS: Display “Divert to LZ | UCA-34: Traffic Control Centre does not program VMS to display “Divert to LZ” when terminal will close (SC-0,1,2,4,5) | UCA-35: Traffic Control Centre instructs VMS to display “Divert to LZ” when terminal will not close (SC-10) | UCA-36: Traffic Control Centre instructs VMS too late to display “Divert to LZ” when terminal will close (SC-0,1,2,4,5) |

| UCA-37: Traffic Control Centre does not program VMS to display “Divert to LZB” when LZA full (SC-1,4) | UCA-38: Traffic Control Centre instructs VMS to display divert to wrong LZ (SC-7,8,9) | UCA-39: Traffic Control Centre instructs VMS too late to display “Divert to LZB” as LZA full (SC-1,4) | |

| UCA-40: Traffic Control Centre does not program VMS to stop display “Divert to LZ” when terminal will open (SC-10) | UCA-41: Traffic Control Centre programs VMS to stop display “Divert to LZ” when terminal still closed (SC-0,1,2,4,5) | UCA-42: Traffic Control Centre programs VMS too late to stop display “Divert to LZ” when terminal will open (SC-10) | |

| UCA-43: Traffic Control Centre programs VMS too early to stop display “Divert to LZ” when terminal will re-open (SC-3) | |||

| 5 On-site Coordinator to on-site Traffic Controller: Divert traffic to LZ | UCA-44: On-site Coordinator does not instruct Traffic Controllers to divert trucks to LZ when terminal will close (SC-0,1,2,4,5) | UCA-45: On-site Coordinator instructs Traffic Controllers to divert trucks to LZ when terminal will stay open (SC-10) | UCA-46: On-site Coordinator instructs Traffic Controllers too late to divert traffic to LZ when terminal will close (SC-0,1,2,4,5) |

| UCA-47: On-site Coordinator instructs Traffic Controllers to divert trucks to wrong LZ when terminal will close (SC-7,8,9) | UCA-48: On-site Coordinator instructs Traffic Controllers too early to divert traffic to LZ when terminal will close (SC-10) | ||

| UCA-49: On-site Coordinator instructs Traffic Controllers to divert trucks headed for different terminal to LZ when terminal will close (SC-10) | |||

| 5 On-site Coordinator to on-site Traffic Controllers: Stop divert traffic to LZ | UCA-50: On-site Coordinator does not instruct Traffic Controllers to stop diverting trucks to LZ when terminal will re-open (SC-10) | UCA-51: On-site Coordinator instructs Traffic Controllers to stop divert trucks to LZ when terminal will remain closed (SC-0,1,2,4,5,7,8,9) | UCA-52: On-site Coordinator instructs Traffic Controllers too late to stop divert trucks to LZ when terminal will re-open (SC-10) |

| 6 On-site Traffic Controllers set out re-routing measures | UCA-53: On-site Traffic Controllers do not set out re-routing measures when terminal will close (SC-0,1,2,4,5) | UCA-54: On-site Traffic Controllers set out re-routing measures when terminal will not close (SC-10) | UCA-55: On-site Traffic Controllers set out re-routing measures too late when terminal will close (SC-0,1,2,4,5) |

| UCA-56: On-site Traffic Controllers set out wrong re-routing measures when terminal will close (SC-4, 10) | UCA-57: On-site Traffic Controllers set out re-routing measures too early when terminal will close (SC-10) | ||

| 6 On-site Traffic Controllers remove re-routing measures | UCA-58: On-site Traffic Controllers do not remove re-routing measures when terminal open (SC-10) | UCA-59: On-site Traffic Controllers remove re-routing measures when terminal still closed (SC-0,1,4,5,7,8,9) | UCA-60: On-site Traffic Controllers remove re-routing measures too late when terminal re-open (SC-8,9,10) |

| 7 On-site Traffic Controllers or Parking Attendant to Driver: Drive to terminal | UCA-61: On-site Traffic Controllers or Parking Attendant do not tell x number of first-to-arrive drivers to drive to terminal when re-open (SC-3,7,10) | UCA-62: On-site Traffic Controllers or Parking Attendant tell Driver to drive to terminal when terminal will remain closed (SC-0,1,2,4,5) | UCA-63: On-site Traffic Controllers or Parking Attendant tell Drivers to drive to terminal in fair order too late after terminal open (SC-8,9,10) |

| UCA-64: On-site Traffic Controllers or Parking Attendant tell Driver to drive to terminal in unfair/random order when terminal will open (SC-0,1,2,4,5) | UCA-65: On-site Traffic Controllers or Parking Attendant tell Drivers to drive to terminal too early before terminal open (SC-0,1,3,4,5) | ||

| 8 On-site Inspector to Driver: move truck from road to LZ | UCA-66: On-site Inspector does not tell Driver: move truck from road to LZ (SC-0,4,7,8) | UCA-67: On-site Inspector tells Driver: move truck from road to wrong LZ (SC-7,9,10) | UCA-68: On-site Inspector tells Driver too late: move truck from road to LZ (SC-0,4,7,8) |

| UCA-69: On-site Inspector tells Driver: move truck from road without designating LZ (SC-7,9) | |||

| 9 On-site Police to Driver: move truck from road to LZ | UCA-70: On-site Police does not tell Driver: move truck from road to LZ (SC-0,4,7,8) | UCA-71: On-site Police tells Driver: move truck from road to wrong LZ (SC-7,9) | |

| UCA-72: On-site Police tells Driver: move truck from road from road without designating LZ (SC-4,7) | |||

| 10 Transporter to Driver(s): Delivery instructions | UCA-73: Transporter informs driver to deliver to terminal as fast as possible (SC-1,2,3,4,5) | ||

| 11 PoR to Parking Attendant: send drivers to terminal | UCA-74: PoR does not ask Attendant to send driver to correct terminal once re-open (SC-9, 10) | UCA-75: PoR asks Attendant to send driver to terminal that will not open (SC-0,1,3,4,5) UCA-76: PoR asks Attendant to send driver to terminal in unfair order (SC-7) | |

| 12 Terminal to gate: close | UCA-77: Terminal closes gate too early (SC-0,1,4,5) UCA-78: Terminal closes gate too late (SC-8) | ||

| 12 Terminal to gate: open | UCA-79: Terminal opens gate too early, allowing in trucks who have not waited at LZ (SC-7,8,9) UCA-80: Terminal opens gate too late when trucks are on way from LZ (SC-0,1,4,5) | ||

| 13 Driver: Drives to terminal | UCA:82: Driver does not drive to terminal that is open or about to re-open (SC-10) | UCA-81: Driver drives to terminal that is closed or about to close (SC-0,1,2,4,5) | UCA83: Driver arrives too late at terminal about to close (SC-0,1,2,4,5) |

| UCA-84: Driver drives to wrong terminal (SC-1,4,5) | |||

| 13 Driver: Drives to LZ | UCA-85: Driver routed to LZ on way into port does not drive to designated LZ (SC-0,1,2,4,5) | UCA-86: Driver drives to full LZ | UCA-88: Driver drives to LZ too early–terminal yet to shut (SC-10) |

| 14 Driver: Enters info on social media | UCA-89: Driver tells other drivers to drive to closed terminal (SC-0,1) | UCA-91: Driver tells other drivers too late that terminal about to close (SC-0,1,2,4,5) | |

| UCA-90: Driver tells other drivers terminal about to close (SC-0,1,2,4,5) | |||

| UCA-92: Driver tells other drivers terminal has re-opened (SC-3, 7, 8, 9) | |||

Note

| 1 | Note that the terms “hazard” and “unsafe” as used in STAMP can be misleading as they do not necessarily relate to safety per se. Hazards are system states that can lead to loss of any desirable system outcome – not just safety, but efficiency, punctuality, security, equal treatment and so on. Control actions can be unsafe if they lead to loss of any of these system outcomes. |

References

- Hall, S. Traffic Planning in Port Cities—Discussion Paper; ITF/OECD; ITF Roundtable 169; Simon Fraser University: Buenos Aires, Argentina, 2017. [Google Scholar]

- JICA. Overcoming Congestion Issues. Presentation by Japan International Cooperation Agency. 2018. Available online: https://www.jica.go.jp/ (accessed on 5 June 2024).

- Osadume, R.; Okene, A.; Uzoma, B.; Enaruna, D. An Evaluation of the delay factors in Nigeria’s seaports: A study of the Apapa port complex. J. Transp. Logist. 2023, 8, 191–204. [Google Scholar] [CrossRef]

- Meersman, H.; Van de Voorde, E.; Vanelslander, T. Port congestion and implications to maritime logistics. In Maritime Logistics; Song, D.-W., Panayides, P.M., Eds.; Emerald Group Publishing Limited: Leeds, UK, 2012; pp. 49–68. [Google Scholar] [CrossRef]

- Liu, Z.; Dong, G.; Gui, Y. Data-driven emergency evacuation decision for cruise ports under Covid-19: An improved genetic algorithm and simulation. Phys. A Stat. Mech. Its Appl. 2023, 629, 129094. [Google Scholar]

- Iyoob, M.Z.; van Niekerk, B. CAUDUS: An optimisation model to reducing port traffic congestion. In Proceedings of the 2021 International Conference on Artificial Intelligence, Big Data, Computing and Data Communication Systems (icABCD), Durban, South Africa, 5–6 August 2021; pp. 45–52. [Google Scholar] [CrossRef]

- Lau, Y.K.H.; Lee, M.Y.N. Simulation study of port container terminal quay side traffic. In AsiaSim 2007. Communications in Computer and Information Science; Springer: Berlin/Heidelberg, Germany, 2007; Volume 5. [Google Scholar]

- Vis, I.F.A.; de Koster, R.B.M.; Savelsbergh, M.W.P. Minimum vehicle fleet size under time-window constraints at a container terminal. Transp. Sci. 2005, 39, 249–260. [Google Scholar] [CrossRef]

- Lange, A.-K.; Schwientek, A.; Jahn, C. Reducing truck congestion at ports—Classification and trends. In Digitalization in Maritime and Sustainable Logistics: City Logistics, Port Logistics and Sustainable Supply Chain Management in the Digital Age. Proceedings of the Hamburg International Conference of Logistics (HICL); Jahn, C.K., Wolfgang, R., Christian, M., Eds.; Hamburg University of Technology (TUHH), Institute of Business Logistics and General Management: Hamburg, Germany, 2017; Volume 24, pp. 37–58. [Google Scholar]

- Gracia, M.D.; Mar-Oritz, J.J.; Vargas, M. Truck Appointment Scheduling: A Review of Models and Algorithms. Mathematics 2025, 13, 503. [Google Scholar] [CrossRef]

- Baldouski, D.; Krész, M.; Dávid, B. Scheduling truck arrivals for efficient container flow management in port logistics. Cent. Eur. J. Oper. Res. 2025, 33, 791–818. [Google Scholar] [CrossRef]

- Martin, J.; Thomas, B.J. The container terminal community. Marit. Policy Manag. 2010, 28, 279–292. [Google Scholar] [CrossRef]

- Motono, I.; Furuichi, M. Behavioural approach to normalize land-side traffic of container terminals. In Proceedings of the International Association of Maritime Economists (IAME), Kuala Lumpur, Malaysia, 24–26 August 2015. [Google Scholar]

- Maloni, M.; Jackson, E.C. Stakeholder contributions to container port capacity: A survey of port authorities. Transp. Res. 2007, 46, 23–42. [Google Scholar]

- Estrada, W. More Holistic Approach Needed to Address Backlog at Our Ports. Published online at CalMatters, 18 November 2021. Available online: https://calmatters.org/commentary/2021/11/more-holistic-approach-needed-to-address-backlog-at-our-ports/ (accessed on 2 June 2024).

- Sunitiyoso, Y.; Nuraeni, S.; Pambudi, N.F.; Inayati, T.; Nurdayat, I.F.; Hadiansyah, F.; Tiara, A.R. Port Performance Factors and Their Interactions: A Systems Thinking Approach. Asian J. Shipp. Logist. 2022, 38, 107–123. [Google Scholar] [CrossRef]

- Ha, M.-H.; Yang, Z.; Notteboom, T.; Ng, A.K.Y.; Heo, M.-W. Revisiting Port Performance Measurement: A Hybrid Multi-Stakeholder Framework for the Modelling of Port Performance Indicators. Transp. Res. Part E Logist. Transp. Rev. 2017, 103, 1–16. [Google Scholar]

- Trist, E.L.; Bamforth, K.W. Some social and psychological consequences of the longwall method of coal-getting: An examination of the psychological situation and defences of a work group in relation to the social structure and technological content of the work system. Hum. Relat. 1951, 4, 3–38. [Google Scholar] [CrossRef]

- Fischer, L.; Baskerville, R. Revising the socio-technical perspective for the 21st century: New mechanisms at work. J. Database Manag. 2020, 31, 19. [Google Scholar] [CrossRef]

- Phillips, R.O.; Berg, S.-H. Sociotechnical factors supporting mobile phone use by bus drivers. IISE Trans. Occup. Ergon. Hum. Factors 2023, 11, 1–13. [Google Scholar] [CrossRef]

- Clegg, C. Sociotechnical principles for system design. Appl. Ergon. 2000, 31, 463–477. [Google Scholar] [CrossRef]

- Hughes, H.P.N.; Clegg, C.W.; Bolton, L.E.; Machon, L.C. Systems scenarios: A tool for facilitating the socio-technical design of work systems. Ergonomics 2017, 60, 1319–1335. [Google Scholar] [CrossRef] [PubMed]

- Read, G.J.M.; Beanland, V.; Lenné, M.G.; Stanton, N.A.; Salmon, P.M. Integrating Human Factors Methods and Systems Thinking for Transport Analysis and Design; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Challenger, R.; Clegg, C.W. Crowd disasters: A socio-technical systems perspective. Contemp. Soc. Sci. 2011, 6, 343–360. [Google Scholar] [CrossRef]

- Davis, M.C.; Challenger, R.; Dharshana, N.W.J.; Clegg, C. Advancing sociotechnical systems thinking: A call for bravery. Appl. Ergon. 2014, 45, 171–180. [Google Scholar] [CrossRef]

- Leveson, N. A New accident model for engineering safer systems. Saf. Sci. 2004, 42, 237–270. [Google Scholar] [CrossRef]

- Rad, M.A.; Lefsrud, L.M.; Hendry, M.T. Application of systems thinking accident analysis methods: A review for railways. Saf. Sci. 2023, 160, 106066. [Google Scholar] [CrossRef]

- Delikhoon, M.; Zarei, E.; Banda, O.V.; Faridan, M.; Habibi, E. Systems Thinking Accident Analysis Models: A Systematic Review for Sustainable Safety Management. Sustainability 2022, 14, 5869. [Google Scholar] [CrossRef]

- Leveson, N.; Thomas, J. STPA Handbook; MIT Partnership for Systems Approaches to Safety and Security (PSASS): Cambridge, MA, USA, 2018. [Google Scholar]

- Phillips, R.O.; Rutten, B.; Rezvani, S. Sociotechnical Systems Analysis of Extreme Events and Implications for Infrastructure Management Systems (D4.2); EU H2020 Project “Safeway” Deliverable 4.2; European Commision: Brussels, Belgium, 2021. [Google Scholar]

- Patriarca, R.; Chatzimichailidou, M.; Karanikas, N.; Di Gravio, G. The past and present of System-Theoretic Accident Model And Processes (STAMP) and its associated techniques: A scoping review. Saf. Sci. 2022, 146, 105566. [Google Scholar] [CrossRef]

- Dong, C.; Zhang, Y.; Wang, Z.; Liu, J.; Zhang, J. The hybrid systems method integrating STAMP and HFACS for the causal analysis of the road traffic accident. Ergonomics 2024, 67, 971–994. [Google Scholar] [CrossRef] [PubMed]

- Klein, G.; Ross, K.G.; Moon, B.M.; Klein, D.E.; Hoffman, R.R.; Hollnagel, E. Macrocognition. IEEE Intell. Syst. 2003, 18, 81–85. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).