1. Introduction

The remanufacturing of used products has demonstrated significant benefits in reducing resource consumption and carbon emissions [

1,

2]. Remanufacturing requires used products as the production materials, which makes the used-product collection a very essential link to remanufacturing. However, the decentralized nature of modern supply chains presents challenges for efficient used-product collection, as the products are closer to retailers and distant from original manufacturers. As a result, research on improving the efficiency of used-product collection in supply chains has garnered the attention of scholars. Previous studies have primarily focused on optimizing the collection channel within a single supply chain member [

3,

4,

5].

Nevertheless, establishing a mechanism for the collection of used items, incorporating the creation of a reverse logistics channel, promoting the return of products by customers, and overseeing the storage and transportation of these items, demands significant labor and fund investment. Consequently, relying solely on a single channel member within the supply chain to handle the collection of used products can be challenging [

6]. Existing literature indicates that retailer-led collection initiatives might outperform manufacturer or third-party-led efforts in managing reverse logistics [

5]. Yet, when manufacturers depend on retailers to gather used products, the substantial costs involved could temper retailers’ willingness, thus potentially reducing the efficacy of collection efforts. Academic work underscores the vital role of distributing collection duties across the supply chain to optimize outcomes [

7,

8]. In this context, research by Shi et al. has shown that manufacturer collaboration with retailers can significantly improve collection rates within a closed-loop supply chain, offering mutual benefits [

9]. These studies highlight the critical need for cooperative strategies across the supply chain to maximize the success of used-product recovery efforts.

Generally, manufacturers have two modes of supporting retailers in the context of CLSC: fund cooperative and labor cooperative [

10]. The fund cooperative collaboration model involves manufacturers extending monetary support to retailers, serving as an incentive for them to undertake and improve product recovery initiatives. Take, for example, the electronics giant Epson, which could offer fund incentives to its retail partners for the collection of end-of-life products. These incentives can help defray the costs related to gathering, transporting, and processing returned items. Through this model, manufacturers indirectly motivate retailers to boost their collection efforts, thereby lowering the total costs associated with these processes.

Conversely, the labor cooperative collaboration model sees manufacturers actively engaging in recovery efforts by supplying workforce support. In practice, explicit cases of manufacturers directly providing labor or service support to assist retailers in product collection are not yet prevalent, but such forms of collaboration have begun to emerge. For instance, car manufacturers may dispatch technical personnel to help retailers establish or manage collection sites, offering professional guidance on disassembly, sorting, or logistics coordination. BCG (2023) (

https://www.bcg.com/publications/2023/seizing-opportunity-ewaste-recycling?, accessed on 12 November 2025) reports that manufacturers incentivize retailers with product-rebate programs to bolster take-back efforts. Such labor-driven collaboration allows manufacturers to directly influence higher recovery rates, by enhancing logistical and transport efficiencies and advancing recycling methodologies. Additionally, this approach helps to reduce the fund burden of collection on retailers, streamlining the overall recovery process.

These instances illustrate how fund and labor cooperative modes can be applied within the realm of supply chain management to foster more efficient and effective product recovery processes. By engaging in these forms of collaboration, manufacturers and retailers can work together to boost collection rates, diminish costs, and advance the attainment of sustainability objectives within the supply chain [

11,

12]. Both collaborative modes show promise in increasing collection rates, thereby encouraging retailers to more actively participate in the collection of used products.

The existing literature has conducted in-depth research on the recycling mechanism of closed-loop supply chains (CLSCs) under the fund cooperative model. However, research on the labor cooperative model is somewhat inadequate. In particular, there is a lack of research on CLSC recycling that takes both models into account simultaneously. Earlier studies, such as the one by Nie et al. delved into the manufacturer’s role in activity sharing through a static model, which aligns with fund cooperative collaboration but leaves labor cooperative collaboration relatively unexamined [

13]. Our research diverges by utilizing a differential game model to delve into the nuanced roles of manufacturers and retailers in product collection efforts directly. This approach enables an analysis of whether manufacturers should lean towards a fund cooperative mode, which indirectly influences collection rates, or opt for a labor cooperative mode, which has a direct impact, to optimally manage a CLSC that includes retailer involvement in collection efforts.

By adopting a dynamic, game-theoretical framework, our study probes the strategic interplay between manufacturers and retailers, aiming to identify the most effective cooperative mode for elevating collection rates and enhancing CLSC performance. Our goal is to fill the existing research void by shedding light on the labor cooperative collaboration issue and providing a thorough understanding of cooperative collection strategies in CLSCs. This paper seeks to address critical questions, including the following:

- (1)

How should the manufacturer provide subsidies to the retailer under the fund cooperative mode, and how can the optimal collection effort be determined under the labor cooperative mode?

- (2)

Which cooperative mode, fund cooperative or labor cooperative, is preferred for the manufacturer to achieve higher collection efficiency, and what are the impacts on the retailer?

To explore the queries raised, our analysis centers on a remanufacturing closed-loop supply chain (CLSC) that features a partnership between a manufacturer and a retailer. In this arrangement, the retailer serves as the conduit for both the distribution of new items from the manufacturer and the accumulation of used products for recycling. We delve into two distinct cooperative frameworks: the fund cooperative model (Model FC) and the labor cooperative model (Model LC). Our research uncovers that both the manufacturer and the retailer experience had enhanced outcomes through collaborative approaches when juxtaposed with a non-cooperative stance. Notably, the labor support scheme surpasses the fund cooperative scheme in effectiveness, underscoring the paramount importance of a direct labor cooperative approach to the retailer rather than mere monetary aid. Consequently, it is advisable for the manufacturer to engage actively in the collection process beyond merely allocating fund resources. Moreover, our analysis suggests a propensity for the manufacturer to favor the fund cooperative scheme when the cost coefficient associated with collection activities exceeds a specific threshold. We also investigate the concurrent application of both fund and labor cooperative schemes, revealing their capacity to amplify collection efficiency and boost profitability for all parties in the supply chain.

This paper proceeds as follows:

Section 2 provides an overview of the literature pertinent to our study.

Section 3 outlines the theoretical framework of our model.

Section 4 calculates the equilibrium outcomes for varying collaborative approaches.

Section 5 presents a comparative study to evaluate the strategic options available to the manufacturer and their effects on the retailer.

Section 6 broadens the scope of our model to include considerations of the collection cost coefficient and differences in collection capabilities between the manufacturer and retailer. The conclusion of our findings, along with an acknowledgment of the study’s limitations and suggestions for future research avenues, is presented in

Section 7.

Appendix A contains all mathematical proofs related to our analysis.

2. Literature Review

Our research intersects with two critical strands of the literature: the dynamics of non-cooperative and cooperative collection strategies within remanufacturing closed-loop supply chains (CLSCs). For extensive discussions and analyses on remanufacturing CLSCs, please see [

14,

15].

2.1. Non-Cooperative Collection Models

The non-cooperative collection domain primarily delves into the decision-making process regarding the selection of reverse logistics channels. This area has been extensively explored by numerous scholars, including [

4,

5,

16,

17,

18,

19,

20,

21,

22,

23]. Among these contributions, Savaskan et al. conducted a seminal investigation into three predominant reverse channel configurations: manufacturer-led, retailer-led, and third-party-led collections, concluding that retailer-led collection emerges as the optimal choice for enhancing the benefits of both manufacturers and retailers [

5]. Expanding on this, Savaskan and Wassenhove delved into the reverse channel selection quandary amidst retailer competition [

20]. Atasu et al. built upon Savaskan’s research to assess the effects of various collection cost structures, suggesting that under certain scenarios, a manufacturer-led collection strategy could indeed be superior [

16]. Yang et al. focused on the influence of cap-and-trade regulations on manufacturers’ decisions regarding reverse channel options [

22]. Wang and Wu analyzed the challenges associated with collecting used products under similar regulatory conditions [

24]. Jalali et al. proposed a CLSC game theory model simulating the Dell Reconnect supply chain, and studied the competitive recycling behaviors of original equipment manufacturers and social collectors [

25]. Pinakhi et al. designed an efficient multi-channel recycling structure and analyzed the effects of competition, collection efficiency, individual rationality, and information asymmetry on the profitability of enterprises [

26]. Additionally, Li et al. explored the positive impact of consumers’ expectations of corporate social responsibility in demand markets on product recycling and refurbishment by establishing a CLSC network with corporate social responsibility [

27].

The academic community has significantly explored optimal collection strategies within various configurations of supply chains, highlighting contributions by [

3,

28,

29,

30,

31,

32]. Subramanian et al. investigated how extended producer responsibility (EPR) legislation affects product collection strategies, particularly when manufacturers are responsible for collecting used products [

29]. Wang et al. examined a closed-loop supply chain model featuring a single manufacturer and two competing retailers tasked with collecting used products, focusing on the impact of potential collusion among retailers on the dynamics of the supply chain [

30]. Li et al. delved into the intersection of used-product collection and carbon emissions decisions within a CLSC, especially under the lens of fairness concerns by the collecting party [

33]. Sahebi et al. analyzed the scenario in which both the manufacturer and retailer jointly undertake the collection of used products within a CLSC framework, highlighting the collaborative approach to optimize collection decisions [

34]. Furthermore, Yi et al. analyzed the battery recycling supply chain under three recycling modes involving manufacturers, retailers, and recyclers, and found that the adoption of blockchain technology would enhance the recycling rate, pricing, and supply chain profits [

35].

The body of work referenced has significantly advanced the understanding of remanufacturing within closed-loop supply chains. A common thread in most of these studies is their focus on scenarios where only a single supply chain member undertakes the collection task. This approach overlooks the potential for enhancing collection efficiency through collaborative efforts among supply chain participants. Our research builds upon this foundation by expanding the scope to include cooperative problems, aiming to explore how manufacturers can increase the collection rate by strategically choosing between different modes of cooperation. This extension seeks to fill a gap in the literature by examining the dynamics of cooperative collection and its impact on the efficiency and effectiveness of closed-loop supply chain remanufacturing processes.

2.2. Cooperative Collection Models

The second stream of literature focus on the cooperative collection problems among supply chain members. Many papers are devoted to investigating how the supply chain members should cooperate on used-product collection through collection expenditure sharing or cooperative alliance.

Given the significant costs associated with collection activities, a collaborative approach to share these expenses can alleviate the fund load on the entity responsible for collection. Xie et al. posited a scenario in which the manufacturer absorbs a portion of the retailer’s collection costs, delving into how such a cost-sharing agreement influences the profitability of supply chain entities [

36]. In their analysis, the proportion of costs borne by the manufacturer is treated as a given factor rather than a variable subject to optimization. This methodological choice echoes throughout several other research works, including those by [

10,

11,

37,

38], where the fund sharing ratio is similarly regarded as an external parameter.

Contrastingly, a subset of scholars has ventured into optimizing the collection cost-sharing ratio. Studies such as [

9,

13,

39,

40] are prime examples, with Shi et al. specifically focusing on the decision-making process regarding the selection of collection modes in the context of shared cost burdens among supply chain members [

9]. Further extending this line of inquiry, Kong et al. explored the selection of cooperative modes within a three-tier reverse supply chain composed of a producer, a collector, and a recycler, examining how these entities can synergistically engage to optimize the reverse logistics process [

41].

Moreover, supply chain members also form cooperative alliances to achieve higher collection efficiency and profit [

42]. These papers considered several supply chain members as cooperative coalitions which also acted as centralized decision-makers [

43,

44,

45,

46,

47,

48]. To cite a few, Ma et al. explored the cooperative alliance formed by supply chain members, and concluded that cooperative alliances are conducive to increasing the interests of all parties and achieving a win-win situation [

46]. Tian et al. examined the existence of a stable collection alliance between competing manufacturers with different products [

49]. Zheng et al. investigated whether the manufacturer and retailer should cooperate on collection through a recycling alliance or a cost-sharing mode [

50]. Qi et al. explored the equilibrium strategies of stakeholders in a closed-loop supply chain under carbon emission constraints by constructing a closed-loop supply chain model of cooperation between manufacturers and retailers [

51]. Xiao et al. established a closed-loop supply chain composed of battery suppliers, manufacturers, and third-party recyclers and investigated the profits of all parties in the supply chain under the supplier–manufacturer alliance and manufacturer–third-party alliance recycling models [

52]. Tatarczak and Grela proposed a multiple-criteria decision-making method to simplify the decision-making process of alliance formation, providing a more flexible, simple, accurate, effective, and systematic decision support tool for evaluating and selecting partners during the alliance formation process [

53].

Most studies in the cooperative collection field have mainly focused on the above two aspects, and few studies have considered the cooperation with collection activities, i.e., supply chain members participate jointly in the collection activities. Most relevant to our study, Nie et al. explored the selection of activity sharing and fund sharing under the third-party collection. They assumed that the manufacturer shares part of the collection responsibility decided by the third-party collector [

13]. The manufacturer did not involve himself in the collection activities with the static model. Their study can be regarded as another form of fund cooperative approach, i.e., the collector decides the collection rate level, and then the manufacturer decides the sharing ratio, which is the fund provided to the collector.

2.3. Dynamic Collection Models

In recent years, the dynamic aspects of used-product collection processes have garnered attention from scholars, recognizing factors such as increasing consumer awareness about environmental benefits, instructing consumers on participating in collection programs, maintaining recycling facilities, and mastering diverse recycling techniques. These elements play a pivotal role in shaping the long-term dynamics of product collection efforts.

Hussain underscored the importance of elevating customer consciousness regarding the environmental impact of product collection and guiding them on how to contribute effectively [

54]. Huang et al. focused on the operational side, examining the maintenance of recycling facilities [

55], while De Giovanni and Zaccour delved into the learning curve associated with different recycling methods, acknowledging these as critical to the evolving nature of product collection [

56]. Minner and Kiesmüller distinguished between static and dynamic collection policies, advocating for the application of dynamic models to thoroughly analyze used-product collection strategies [

57]. Utilizing differential game theory, De Giovanni and Zaccour investigated dynamic control strategies within closed-loop supply chains (CLSCs) for product collection [

56]. Huang et al. explored the effect of random disturbances on collection efforts, particularly when the manufacturer is responsible for gathering used products [

55]. De Giovanni et al. assessed dynamic incentive strategies among CLSC members to bolster collection rates [

58].

Furthering this research trajectory, Huang probed into dynamic collection strategies within CLSCs, taking into account the fairness concerns among supply chain participants [

59]. Schlosser et al. tackled the joint issues of dynamic pricing and collection efforts, employing general formulations to model demand and cost influences [

60]. Chen et al. also addressed the dynamic nature of collection processes, using system dynamics methodology to investigate the outsourcing of collection activities by manufacturers, highlighting the increasing complexity and strategic importance of dynamic considerations in managing used-product collection in sustainable supply chain operations [

61].

The contributions from these studies have broadened the scope and methodologies applied to the investigation of used-product collection within closed-loop supply chains (CLSCs) by emphasizing the dynamic attributes of the collection process. By employing dynamic models, these works aim to scrutinize long-term strategic issues related to product collection, marking a significant advancement in the field.

2.4. Contribution of This Study

Existing studies on CLSCs have primarily focused on developing optimal dynamic collection strategies within specific operational contexts. These studies have advanced our understanding of customer participation, operational efficiency, and strategic planning through the use of analytical models. However, the cooperative dynamics among CLSC members remain underexplored, particularly regarding how manufacturers and retailers jointly adjust their strategies over time to improve collection performance. Few studies have examined the interactive decision-making processes that drive sustained improvements in recycling efficiency and environmental outcomes. Addressing this gap is essential for deepening our understanding of how collaborative mechanisms can be structured and managed to advance the long-term sustainability of CLSCs.

This study enriches the literature on cooperative product collection in CLSCs through several novel contributions.

(1) We investigate two specific collaborative arrangements—fund cooperative and labor cooperative—and model their dynamic interactions using a differential game framework. Our analysis of labor cooperative collaboration represents a marked departure from prior studies, which have largely confined cooperation to static cost-sharing settings [

13]. By introducing a dynamic perspective, we capture the evolving and active engagement of both manufacturers and retailers in improving collection efficiency.

(2) The findings reveal that manufacturers should go beyond traditional financial support and take a more hands-on role in collection operations through labor-based cooperation. This perspective, rarely addressed in existing research, highlights a shift from passive subsidy models to active participation, enhancing both operational efficiency and strategic flexibility.

(3) We further analyze a hybrid approach that integrates fund and labor cooperative approaches, showing that combining these modes can yield superior performance and mutual profitability for supply chain members. The results also acknowledge real-world constraints—such as financial or operational limitations—that may shape the manufacturer’s optimal choice between the two modes.

Table 1 summarizes the comparison between this study and existing literature. Overall, this research expands the theoretical lens of CLSC cooperation by introducing and formalizing the concept of labor cooperative collaboration in a dynamic setting. It not only fills a critical gap in the literature but also provides actionable guidance for manufacturers seeking to enhance remanufacturing efficiency and promote coordinated, sustainable development across the closed-loop supply chain.

3. Problem Description and Model Assumption

In this closed-loop supply chain model, there is a singular manufacturer and retailer partnership. The manufacturer integrates both raw materials and reclaimed used products into the production of new items, utilizing the latter as a cost-saving and environmentally friendly alternative to raw materials. Consequently, products derived from both sources are considered equivalent in quality and function. The manufacturer distributes these products to consumers via the retailer. In the reverse logistics chain, the manufacturer incentivizes the retailer to collect used products by compensating them a fixed amount per unit collected.

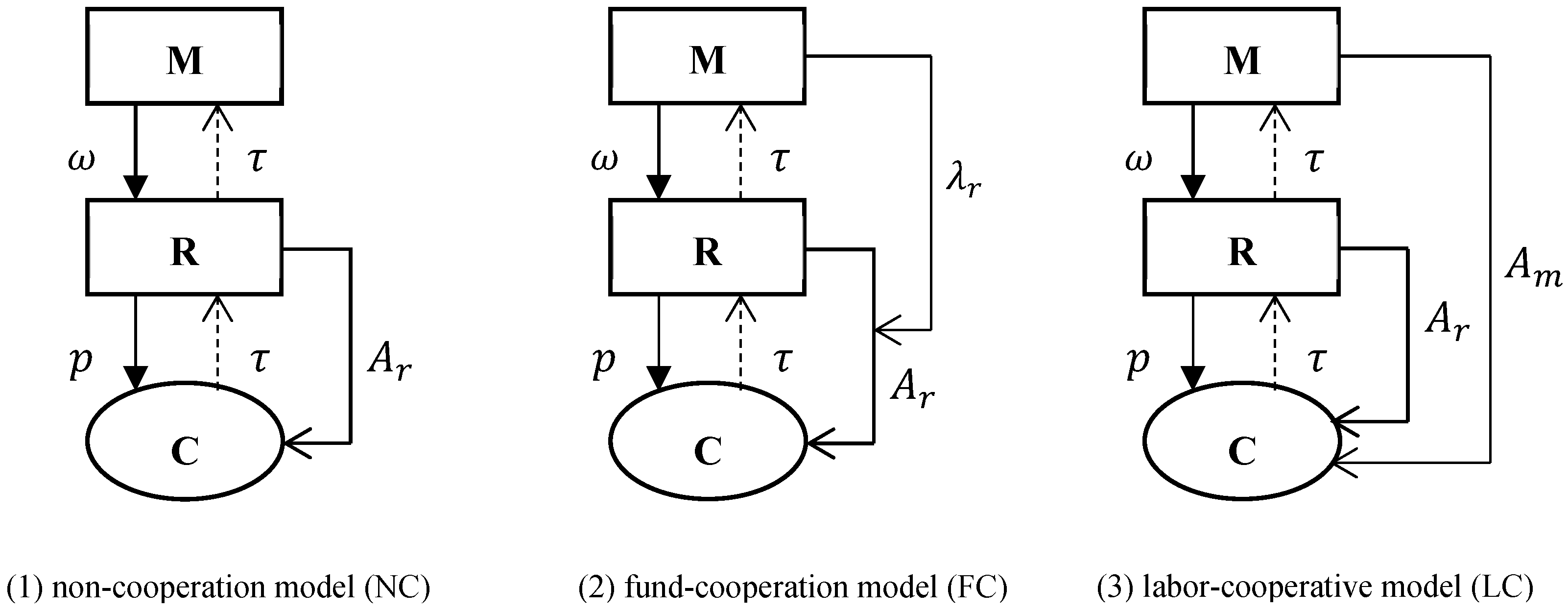

To augment the efficiency of the used-product recovery process, the manufacturer evaluates two cooperative collection strategies with the retailer: (1) a fund cooperative program (FC), where the manufacturer subsidizes the retailer’s collection efforts, and (2) a labor cooperative program (LC), involving the manufacturer directly in collection-related activities, such as reverse logistics operations and promotional efforts for collection. The latter strategy, LC, necessitates the manufacturer’s active participation in the collection process, thereby entailing an investment of labor resources.

Figure 1 illustrates the schematic diagrams of the three cooperation modes.

In this notation, represents the profit of a supply chain member under model . Here, can be either or , indicating the manufacturer and retailer, respectively. Meanwhile, corresponds to one of three different models: NC (non-cooperation model), FC (fund cooperative model), and LC (labor cooperative model).

We follow the dynamic used-product collection model proposed by De Giovanni and Zaccour [

56], and Huang et al. [

55].

denotes the used-product collection effort at time

, including collection advertising, reverse facilities maintenance, reverse logistics, etc.

represents the collection rate at time

, indicating the proportion of used products that are collected at a given time. Thus, the collection rate

is the state variable and the collection effort is the control variable in the dynamic collection system. As only the retailer is involved in the collection activities, the collection dynamics under the model NC and FC are the same, and formulated as follows:

where

quantifies the impact of collection efforts on the collection rate, demonstrating how effectively actions taken by the supply chain members enhance the rate at which used products are gathered.

is the decay rate, indicating how the collection rate diminishes over time without ongoing collection efforts and

denotes the initial collection rate at the beginning of the considered time period, setting the baseline from which collection efforts commence [

59,

62].

As the manufacturer is involved in the collection activities under the LC mode, the collection dynamics is then formulated as follows:

Additionally, the discount rate of the system is denoted by

and the decision period is assumed to be

. For analytical tractability, we assume that the collection effort coefficients of the manufacturer and the retailer are identical in this stage. This simplification allows us to focus on the strategic interaction effects between the two parties without introducing additional parameters that do not alter the qualitative nature of the results. Such an assumption has also been commonly adopted in the closed-loop supply chain literature [

5,

62]. In the Extension section, we further relax this assumption by allowing for different collection cost coefficients between the manufacturer and the retailer. This setting indirectly captures the heterogeneity in their collection capabilities and effort efficiencies, thereby testing the robustness of the model under asymmetric conditions.

Table 2 summarizes all notations used in the paper.

We present the following assumptions which are used in this paper.

Assumption 1. We adopt the linear demand function, which is widely used in existing studies [

55,

58]

, i.e., .

Assumption 2. Let and represent the unit cost of manufacturing a new product with raw materials or used products, respectively. Assume that remanufacturing can effectively reduce the manufacturer’s production cost as remanufacturing saves raw materials, i.e., . This assumption has been widely used in the CLSC literature [

5,

20,

63,

64,

65,

66].

Assumption 3. We also assume , which means the cost incurred by the manufacturer in acquiring used products (through payments to the retailer) does not exceed the cost savings realized from remanufacturing [

5,

34,

55].

Assumption 4. The collection cost incurred by collection activities for supply chain members is , where represents the collection cost coefficient. The quadratic collection cost function captures the characteristic that marginal returns should diminish with collection efforts, which also means it is unrealistic and economical for the collector to achieve a very high collection rate.

4. Model Analysis

In addressing the differential game models under the various cooperative collection models (NC, FC, and LC), this section employs an open-loop control strategy to find the equilibrium solutions.

4.1. Benchmark Model: No Cooperative (Model NC)

In the scenario where the retailer is solely responsible for collecting used products without any cooperative support from the manufacturer, the supply chain dynamics are primarily driven by the retailer’s efforts and the pricing strategies employed by both the manufacturer and retailer. The manufacturer sets the wholesale price,

, while the retailer determines the retail price,

, and the collection effort,

. The objective functions are as follows:

Proposition 1. With NC model, assume , the equilibrium is solved as follows:

The equilibrium collection rate trajectory is calculated as follows:

where

is the adjoint variable and

.

and

denote the steady state of the dynamic system, given by the following:

Proposition 1 outlines the equilibrium control strategies for both members within the framework of the non-cooperation model (NC). As the collection rate should be confined between 0 and 1, we have

and

, i.e.,

. This assumption indicates that the collection cost coefficient cannot be excessively small, as it would lead to an unrealistically high collection rate that exceeds 1. It is well-established that used products are widely dispersed, posing significant challenges in the collection process. Moreover, some consumers opt to retain their old products despite their lack of utility. As a result, the collection rate is far from reaching 1, and the collection cost coefficient is not negligibly small. Similar findings in a static setting were also reported by Savaskan et al. [

5]. This highlights the managerial need for cooperative collection mechanisms that share costs and responsibilities between manufacturers and retailers to overcome dispersion-related inefficiencies. We summarize the profit rate for the manufacturer and retailer at the steady state when they have the same collection cost coefficient

in

Table A1 in

Appendix A.

Corollary 1. With NC model, the optimal used-product transfer price of the manufacturer is .

This strategy suggests that as the unit transfer price escalates, so does the manufacturer’s profitability. Consequently, this approach enables the manufacturer to share the entirety of the unit cost savings derived from remanufacturing processes with the retailer, optimizing economic incentives while maintaining the viability of the remanufacturing effort. This implies that the manufacturer’s profit is not derived from the cost savings but rather from the demand increase effect resulting from lower production costs. The transfer price serves as a motivational factor for the retailer to engage in collection activities, leading to a reduction in production costs and ultimately generating more sales of new products for the manufacturer. This strategic coordination ensures mutual benefit and transforms remanufacturing cost savings into a market-driven gain rather than a unilateral profit source.

4.2. Fund-Cooperative (Model FC)

In this section, we delve into a scenario where the manufacturer contributes funds to offset some of the retailer’s expenses associated with collecting used products. Denote

as the cost-sharing ratio, which is decided by the manufacturer. The collection expenditure incurred by the collection activities is

. The manufacturer will share a

percentage, which is,

. Thus, the retailer’s collection expenditure is

. The supply chain members’ objective functions under the FC model are as follows:

Proposition 2. With FC model, assume , the equilibrium strategies are as follows:

The equilibrium collection rate trajectory is calculated as follows:

where

,

are adjoint variables, and

.

denote the steady state of the dynamic collection system, which is listed as follows:

Proposition 2 operates under assumptions analogous to those in Proposition 1, suggesting that despite the introduction of a fund cooperative program by the manufacturer to support the retailer’s collection efforts, the associated costs of collection will remain substantial. Similarly to Corollary 1, we obtain the following conclusion.

Corollary 2. Under model FC, the optimal transfer price of the manufacturer is .

According to Corollary 2, when the manufacturer adopts a fund cooperative program for the retailer, the optimal strategy remains the same: transferring all unit cost savings to the retailer while benefiting from increased sales. Proposition 3 establishes a condition that determines the circumstances in which implementing a fund cooperative program would be advantageous for the manufacturer.

Proposition 3. There exists a threshold value such that if , it is beneficial for the manufacturer to implement the fund cooperative program, where .

Proposition 3 shows that the manufacturer will benefit from a fund cooperative program only if the collection cost coefficient exceeds a certain threshold. Then, if the retailer has a low collection cost coefficient, the collection cost might be acceptable to the retailer and the fund cooperative would lose its motivational effect. Interestingly, as we have assumed to confine the collection rate to below 1, it is easy to verify that the threshold value is smaller than . This means that under the assumption that , the manufacturer will always be willing to provide a fund cooperative program to raise their profit level.

4.3. Labor-Cooperative (Model LC)

This subsection explores a scenario where the manufacturer engages in a direct collaboration with the retailer by actively participating in the collection process. Denote the manufacturer’s collection effort as

, and the collection cost is then

. Thus, the supply chain members’ objective functions under model LC are as follows:

Proposition 4. With LC model LC, assume that ; the equilibrium is solved as follows:

The equilibrium collection rate trajectory is calculated as follows:

where

and

are adjoint variables, and

.

denote the steady state of the dynamic collection system, which is listed as follows:

Proposition 3, like Propositions 1 and 2, is built on a consistent foundational assumption.

Corollary 3. With the LC model, the optimal transfer price of the manufacturer is .

Corollary 3 elucidates that, across the various cooperative programs implemented by the manufacturer—whether they involve no cooperation, a fund cooperative model, or direct labor support—the optimal strategy for the manufacturer does not waver. In every scenario, the manufacturer opts to pass the entirety of unit cost savings derived from remanufacturing processes onto the retailer. This approach not only incentivizes the retailer’s participation in the collection and remanufacturing efforts but also proves advantageous for the manufacturer.

Proposition 5. There exists a threshold value such that if , it is beneficial for the manufacturer to implement the labor cooperative program, where .

As with the fund cooperative scenario, the manufacturer may find it beneficial to conduct a labor cooperative program only if the collection cost coefficient is high. When combining Propositions 3 and 5, we can infer that when the collection cost coefficient is quite high, which indicates the retailer is losing motivation for collection, it is profitable for the manufacturer to participate in a cooperative collection program to stimulate collection directly or indirectly. Note that we have assumed in Proposition 4, and , which means that the manufacturer will always be able to profit by implement a labor cooperative program.

5. Comparative Analysis

This section conducts a comparative analysis to scrutinize the outcomes in terms of the collection rates, pricing strategies, collection efforts, and profitability of supply chain participants across the three cooperative collection models: non-cooperation (NC), fund cooperative (FC), and labor cooperative (LC). This examination will provide a detailed understanding of how each cooperative approach affects the dynamics of the closed-loop supply chain. As the specific conditions for the three models are not exactly the same, we limit our comparison analysis in to ensure that all three models are realistic. Our comparison is based on the steady state to avoid mathematical triviality.

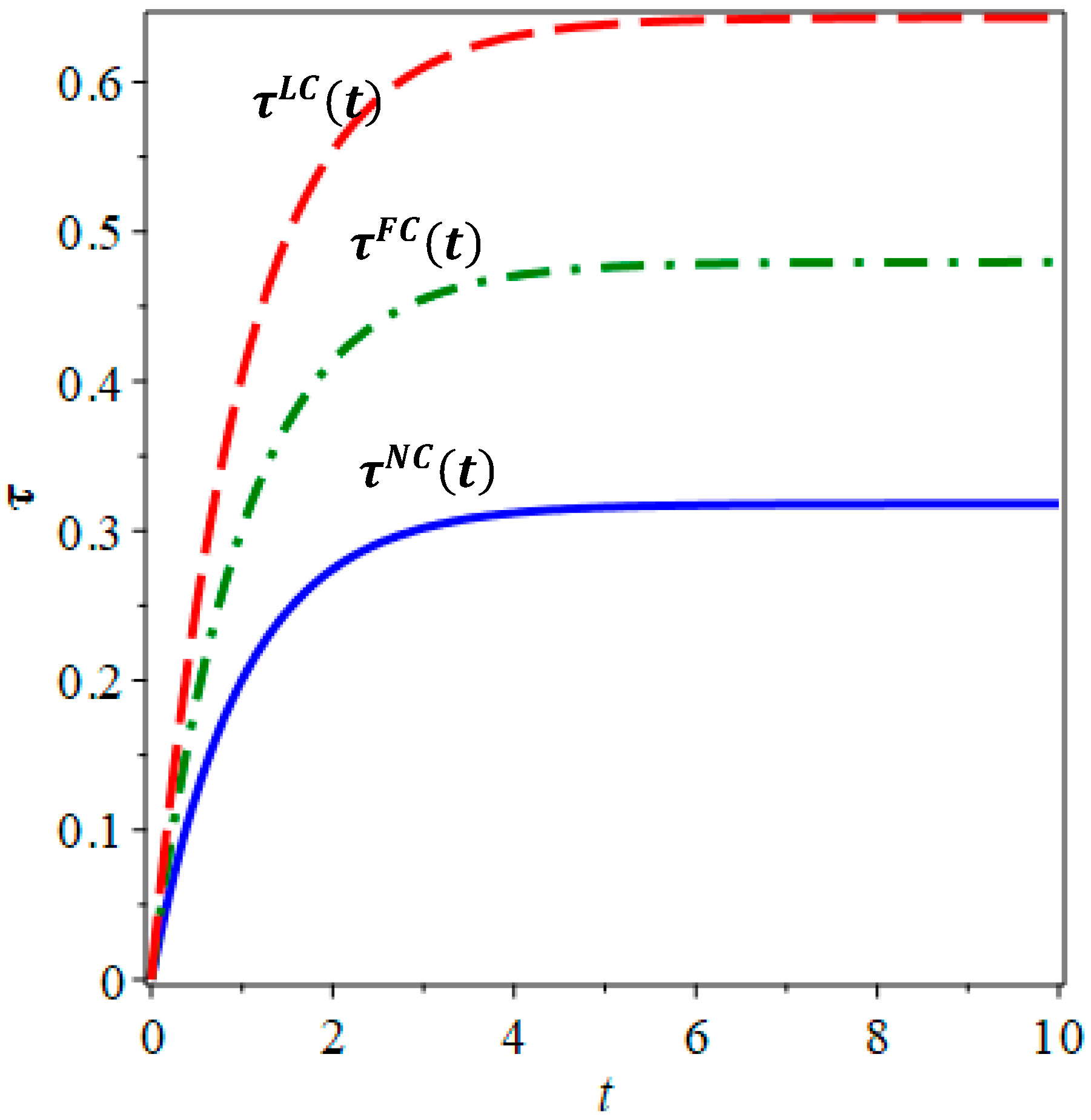

Proposition 6. The collection rates under three collection models satisfy the following: .

Proposition 6 demonstrates that the manufacturer’s adoption of a cooperative collection program consistently enhances the collection rates within the CLSC. Importantly, Proposition 6 highlights that the labor cooperative program is particularly effective in improving the collection rate. This finding deviates from conventional studies that primarily advocate for the adoption of a fund cooperative approach by supply chain members to enhance collection efficiency in a CLSC. Compared with pure fund cooperation, this hands-on involvement facilitates better resource allocation and faster responsiveness, thereby achieving higher collection rates. The underlying reasons for this discrepancy can be inferred from the response functions associated with the three cooperative programs.

When implementing the fund cooperative program, the rise in collection rates can be attributed to the retailer’s involvement in the collection effort. On the other hand, the labor cooperative program exerts a direct influence that affects not only the retailer but also the manufacturer’s enthusiasm towards collection activities. Proposition 6 explicitly states that the manufacturer should actively participate in the collection process instead of solely relying on fund support to the retailer. Although the fund cooperative program is effective in improving collection efficiency, its indirect effect is less potent compared to the direct effect of the labor cooperative program.

And

Figure 2 further illustrates the optimal evolutionary trajectories of the collection rates under three different collection models. According to Huang et al. [

55], the parameters are chosen as follows:

Figure 2 also suggests that the collection rates will approach to a steady state along with the time.

Proposition 7. The wholesale prices and retail prices under three collection models satisfy the following: , .

Corollary 4. The market demands of the product under three collection models satisfy the following: .

Proposition 7 elucidates that engaging in cooperative efforts to collect used products can precipitate a reduction in retail prices, which, according to Corollary 4, fosters an uptick in sales. This outcome aligns with the intuitive expectation that an enhanced collection rate correlates with lower retail pricing, thus boosting sales volumes. Among the examined cooperative models, the labor cooperative program (LC) emerges as the most effective, offering the lowest retail price and the highest sales figures.

Contrary to initial expectations, an increase in the collection rate does not invariably lead to a decrease in the wholesale price; rather, it can lead to an increase. This scenario unfolds as the manufacturer aims to incentivize the retailer’s collection efforts by allocating the entirety of cost savings from remanufacturing to the retailer, which, in turn, elevates the wholesale price. Through this strategy, the manufacturer leverages the cost savings to enhance the wholesale price, aiming to amplify their revenue. Concurrently, while the retailer sees a boost in revenue from the collection of used products, they might witness a reduction in revenue from direct product sales due to the lowered retail price. By transferring remanufacturing benefits to the retailer, the manufacturer raises the wholesale price as a reward for greater collection effort, while the lower retail price stimulates market demand—illustrating how collaboration realigns profits across the supply chain to achieve higher overall efficiency. This dynamic underlines a complex interplay between cooperative collection efforts, pricing strategies, and revenue streams for both the manufacturer and retailer in the closed-loop supply chain.

Proposition 8. The manufacturer’s profits under three collection models satisfy the following: .

Proposition 8 underscores the advantageous position of the manufacturer in the realm of cooperative collection efforts, pinpointing the labor cooperative program (LC) as the pinnacle of profitability among the modes of cooperation. Despite the upfront costs associated with directly engaging in collection activities, the manufacturer stands to gain from reduced production expenses and a surge in product sales, both outcomes of the heightened collection rates brought about by the LC program. Furthermore, the strategic decision by the manufacturer to elevate the wholesale price plays a significant role in bolstering marginal profits. These benefits are not solely confined to cost reduction and sales enhancement; the active participation of the manufacturer in the collection process through the LC mode substantially elevates the overall profitability. This involvement facilitates a more effective collection mechanism, directly translating into higher profit margins for the manufacturer. Therefore, from both operational and fund perspectives, the labor cooperative emerges as the superior mode of cooperative collection for the manufacturer, validating the dual advantages of boosting collection efficiency and amplifying profitability through active engagement in collection efforts.

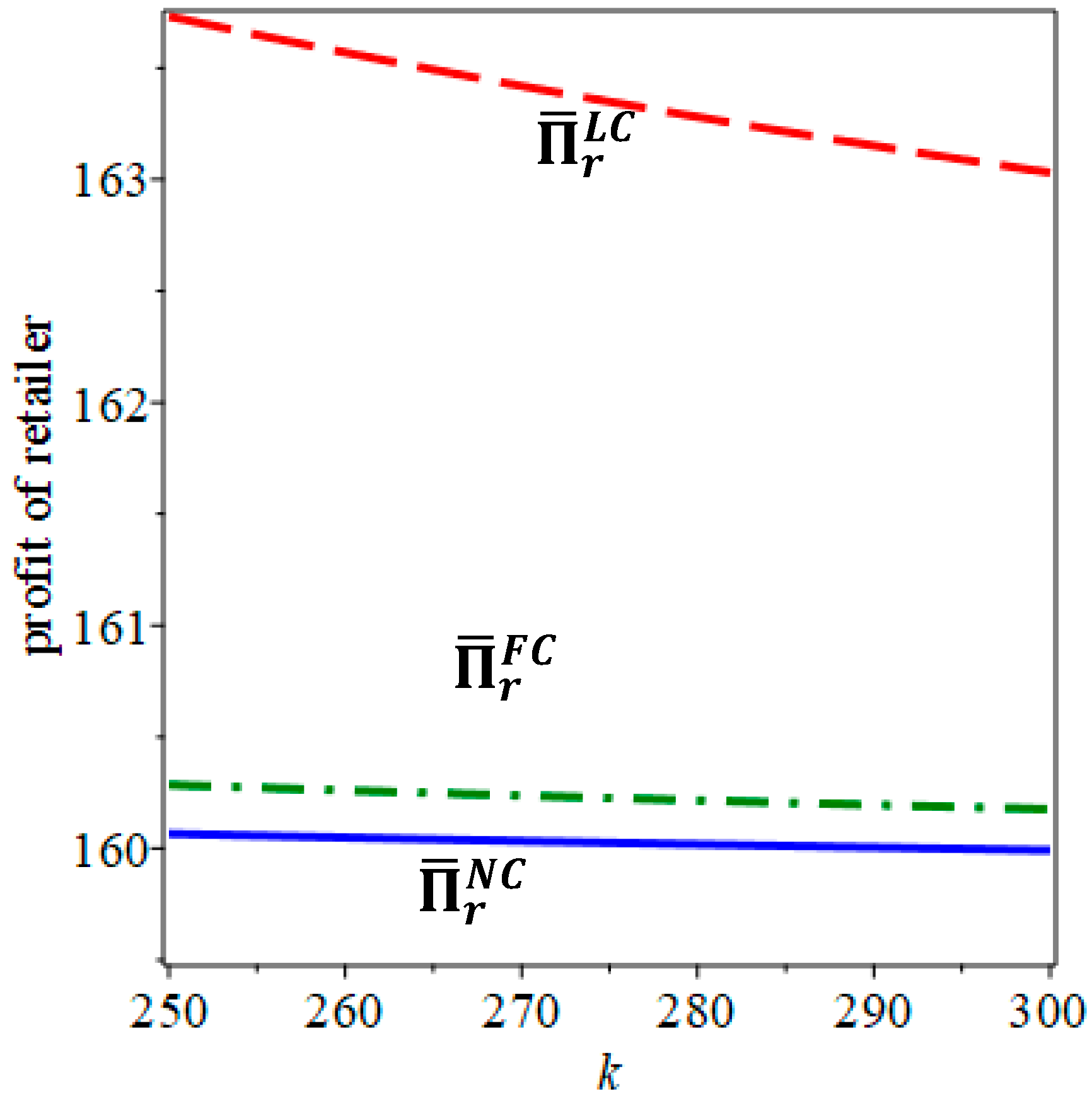

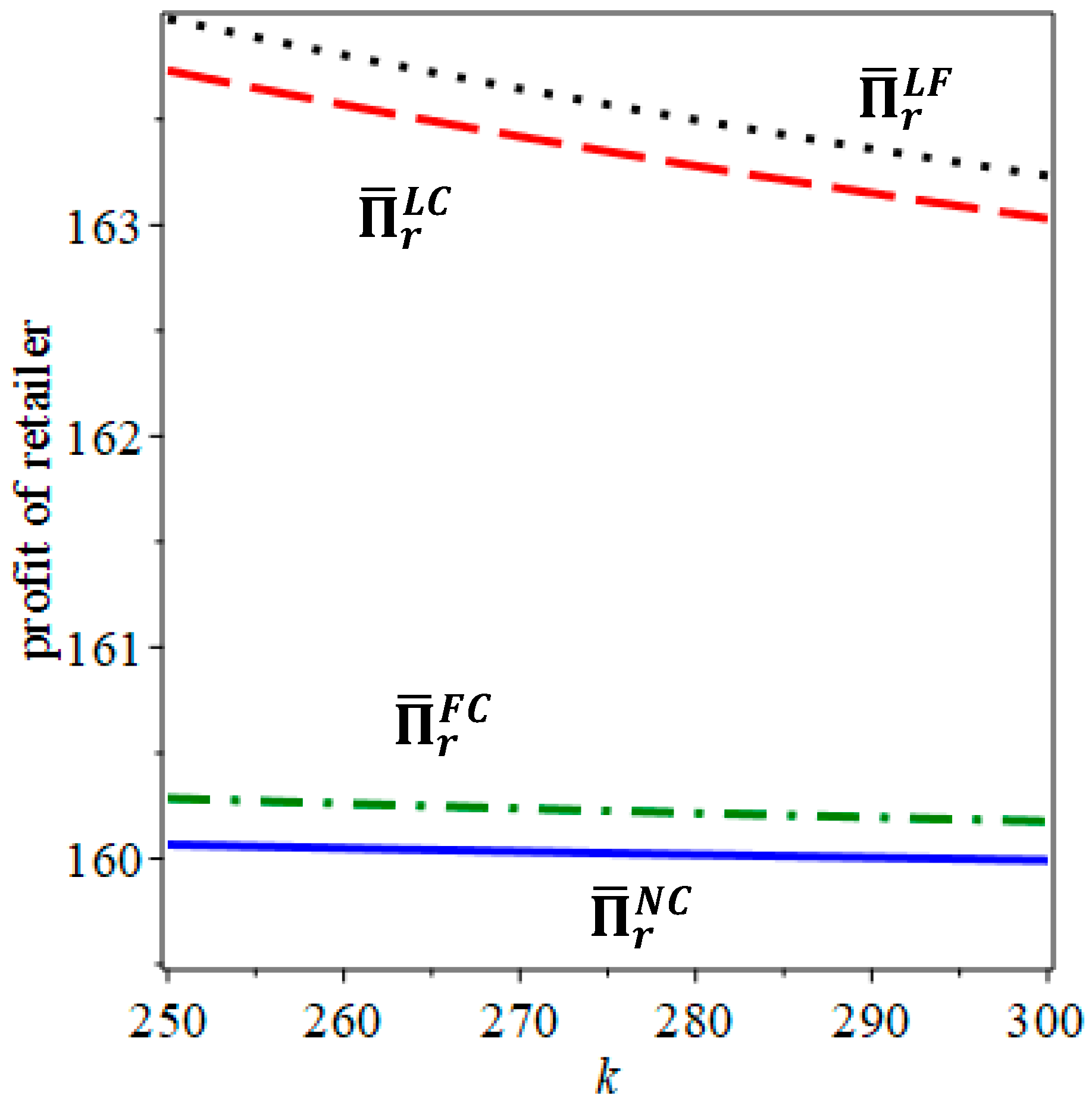

To compare the retailer’s profit across different cooperative collection modes, we turn to numerical methods due to the complexity of deriving analytical results.

Observation 1. The retailer’s profits under three collection models satisfy the following: .

Figure 3 showcases that the retailer’s profits uniformly decline as the collection cost coefficient increases. However, it also highlights that the retailer gains from the manufacturer’s engagement in cooperative collection efforts. Notably, in the labor cooperative model (LC), even though the manufacturer opts to increase the wholesale price—potentially diminishing the retailer’s marginal profit—the overall fund outcome for the retailer is still positive. This beneficial effect stems from two key factors: enhanced product sales driven by the elevated collection rate and additional income from the transfer fee paid by the manufacturer to the retailer for participating in the collection program. Observation 1 further substantiates that the boost in sales and the transfer fee compensation more than compensate for the decrease in marginal profit experienced by the retailer. Thus, both Proposition 8 and Observation 1 converge on the conclusion that the labor cooperative model not only maximizes profitability for the manufacturer but also ensures increased profits for the retailer, culminating in a Pareto improvement within the labor cooperative framework. This finding underscores the effectiveness of the labor cooperative program in enhancing the closed-loop supply chain’s overall profitability and efficiency, benefiting all involved parties.

To sum up, we could conclude that the manufacturer and retailer can always benefit from cooperative collection programs, namely, they can achieve a Pareto improvement through cooperation in used-product collection. The labor cooperative is the most effective method of improving the collection rate of the CLSC and is also the most advantageous to both the manufacturer and retailer. The manufacturer should participate directly in the collection activities and not merely provide funding to the retailer to improve the collection rate indirectly.

6. Extension 1: Impact of Collection Cost

In the baseline model, we have assumed that the manufacturer and the retailer share the same collection cost coefficient for collection activities. In reality, however, differences in collection processes, capabilities, and operational experience may lead to heterogeneity in these cost coefficients. Such cost differences can also be interpreted as reflecting variations in the efficiency with which collection efforts translate into actual recovery performance. Therefore, this section further examines how asymmetric cost coefficients influence the cooperative collection mode preferences of the manufacturer and the retailer. This analysis is also equivalent to exploring the collection decisions of the manufacturer and retailer under the asymmetric effects of collection efforts on recovery performance.

The manufacturer’s collection cost coefficient is denoted by

and the retailer’s collection cost coefficient remains

.

represents the ratio of the manufacturer’s cost coefficient to the retailer’s cost coefficient. It should be noted that

means that the manufacturer’s cost coefficient is higher than the retailer’s cost coefficient, which might result in the manufacturer being less motivated to participate in the collection activities, and therefore less likely to choose the labor cooperative program. On the other hand,

implies that the manufacturer has a lower cost coefficient than the retailer, so the manufacturer will be more motivated to be involved in the collection process. Use the superscript

to represent the scenarios with different collection cost coefficients. Proposition 9 demonstrates how the difference in cost coefficient could affect the collection rate under three cooperative collection programs. And we summarize the profit rate for the manufacturer and retailer at the steady state when they have different collection cost coefficient in

Table A2 in

Appendix A.

Proposition 9. With different collection cost coefficients, the collection rates under three cooperative collection models satisfy the following:

- (i)

If and , then ;

- (ii)

If and , then .

Proposition 9 delineates that, provided the manufacturer’s collection cost coefficient remains below a specific threshold—implying that the cost implications for the manufacturer are relatively moderate—the labor cooperative model (LC) consistently secures the highest collection rate compared with the other cooperative collection models. However, when the cost coefficient surpasses this threshold, implying a relatively high collection cost for the manufacturer, the labor cooperative mode no longer yields the highest collection rate, and instead, the fund cooperative mode becomes more favorable. This finding aligns with intuition, as a substantial collection cost discourages the manufacturer from engaging directly in collection activities. Proposition 9 establishes that the threshold value is approximately 2. Therefore, even if the manufacturer’s cost coefficient is twice that of the retailer’s, the manufacturer can still enhance collection efficiency by directly implementing the labor cooperative program. When the manufacturer’s collection cost is moderate, the efficiency gains from direct participation outweigh the extra expense, making labor cooperation optimal; once the cost exceeds the threshold, the incentive to participate diminishes, and fund cooperation becomes the rational choice for sustaining profitability. It is worth noting that this cost asymmetry can also be interpreted as capturing asymmetric effects of collection efforts on recovery efficiency between the manufacturer and the retailer, further reinforcing the managerial insight that efficiency heterogeneity critically shapes cooperative mode selection.

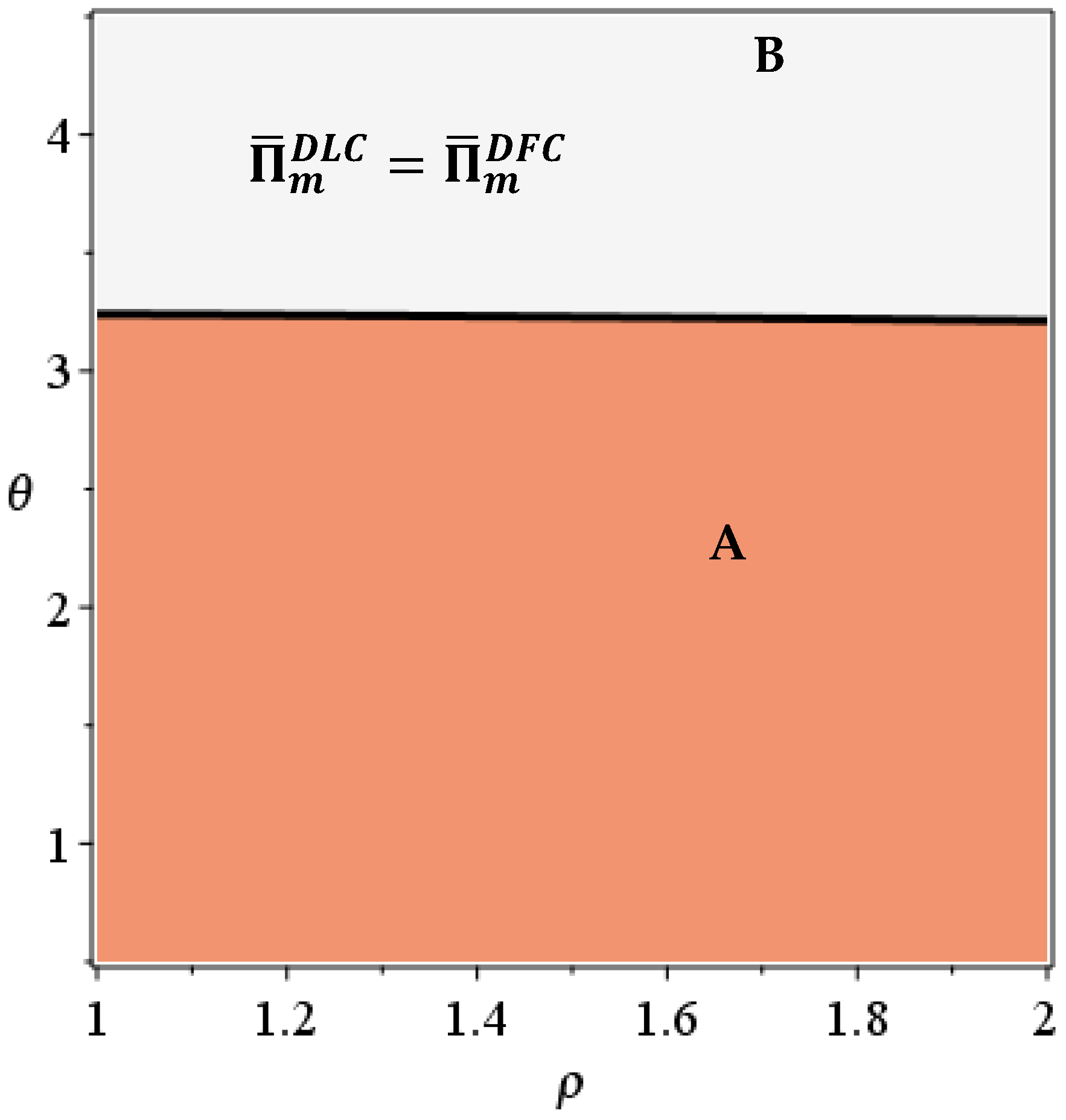

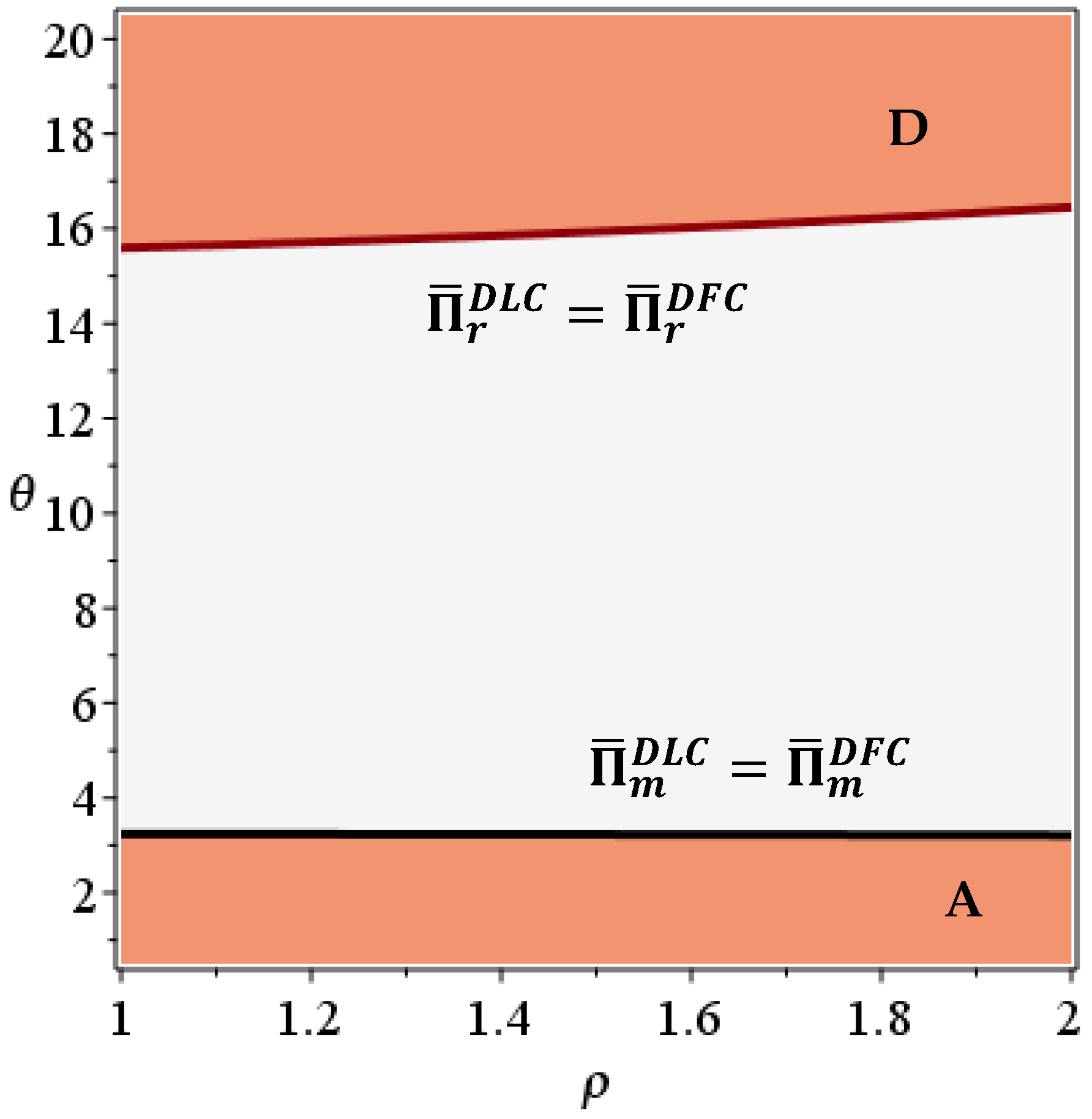

The following

Figure 4 and

Figure 5 compare the profits of the manufacturer and retailer to develop insights into how the difference in collection cost could affect the cooperative mode preferences. The parameter values are chosen to be the same as those in

Section 4. In

Figure 4, area A represents

and area B represents

.

Observation 2. With different collection cost coefficients, there exists threshold such that when , the manufacturer’s profits satisfy the following: ; otherwise, when , .

Observation 2 points out that the choice of cooperative mode by the manufacturer is influenced by the relative magnitude of the collection cost coefficient ratio. When the manufacturer’s cost coefficient is relatively small, indicating manageable collection-related expenses on their part, the labor cooperative program (LC) emerges as the most lucrative option. This preference is attributed to the enhanced collection rates and subsequent profit increases facilitated by the manufacturer’s direct involvement in collection activities. However, the situation shifts when the manufacturer’s cost coefficient significantly exceeds that of the retailer (), highlighting a scenario where the manufacturer’s collection costs are substantially higher. In such cases, the manufacturer finds it more advantageous to opt for the fund cooperative model (FC).

Figure 5 depicts the influence of the cost coefficient ratio

on the retailer’s profits under three cooperative collection models. In

Figure 5, area C represents

and area

D represents

.

Observation 3. With different collection cost coefficients, there exists threshold such that when , the retailer’s profits satisfy the following: ; when , there is .

Observation 3 shows that the retailer’s cooperative preference is also dependent upon the manufacturer’s cost coefficient, which means that the collection difficulty of the manufacturer would influence the retailer’s preference for cooperative collection modes. A rise in the manufacturer’s collection cost would result in a decrease in the manufacturer’s collection efforts, which would lead to a decline in the retailer’s collection earnings. When the manufacturer’s collection costs are high, retailers lean towards preferring a fund cooperative model. However, with the cost difference between the manufacturer and the retailer typically being small, the labor cooperative model often emerges as the most advantageous for the retailer in many scenarios. This approach, favoring direct manufacturer involvement in collection efforts, benefits the supply chain by enhancing collection efficiency and reducing operational burdens on the retailer, making it a preferable strategy, unless the manufacturer’s costs are significantly elevated.

When the collection cost coefficient is identical for both the manufacturer and retailer, they share a preference for the labor cooperative mode as the most beneficial approach. This preference underscores the mutual advantages of direct involvement by the manufacturer in the collection process. However, disparities in the collection cost coefficient can shift their cooperative mode preferences. Specifically, when the manufacturer’s cost coefficient is significantly higher, both parties find the fund cooperative mode more profitable. Conversely, as long as the manufacturer’s cost coefficient remains within a reasonable range—not excessively high—the labor cooperative mode continues to be preferred by both. It is important to note, though, that the exact threshold values dictating these preference shifts differ between the manufacturer and retailer, reflecting the nuanced impact of cost dynamics on their strategic choices. We illustrate the manufacturer and retailer’s preference consensus regarding the cost coefficient ratio in

Figure 6.

Observation 4. When , the manufacturer and retailer can achieve a cooperative mode consensus on labor cooperative; when , they can achieve a cooperative mode consensus on fund cooperative; when , they cannot achieve a consensus on cooperative mode selection.

Cooperative collection efforts between the manufacturer and retailer can invariably lead to a Pareto improvement, optimizing benefits for both parties. When the manufacturer’s collection cost coefficient is relatively low, the labor cooperative program emerges as the most advantageous, leveraging direct involvement in collection activities to enhance efficiency and profitability. Conversely, if the manufacturer’s cost coefficient is high, the fund cooperative program becomes preferable, offsetting the retailer’s collection costs through monetary support and optimizing the supply chain’s overall cost-effectiveness.

However, when the manufacturer’s cost coefficient falls within a moderate range, a divergence in preferences appears: the manufacturer benefits more from the fund cooperative due to its cost-effectiveness, while the retailer sees greater advantages in the labor cooperative, which often results in higher collection rates and sales. This scenario highlights a challenge in reaching a unified decision on the cooperative collection mode, as the differing impacts of the cost coefficient lead to a misalignment in their optimal strategies. The disparity in preferences underscores the complexity of negotiating cooperative agreements, particularly when cost dynamics introduce variability into the strategic calculus of each party.

7. Extension 2: Labor and Fund Cooperative (Model LF)

In the previous section, we have analyzed the collaboration between the manufacturer and retailer, in which the former provides fund support or engages in joint collection efforts with the latter. Therefore, in this section, we will focus on discussing the scenario in which the manufacturer not only provides fund support to the retailer for sharing the cost of collection but also participates in collection activities by investing labor.

denotes the cost-sharing ratio, and

represents the manufacturer’s collection efforts. At this time, the manufacturer’s collection cost is composed of two parts. The first part is the shared cost of the retailer’s collection

, and the second part is the cost of the manufacturer’s personal involvement in the collection

. The retailer’s recycling cost is thus determined as

. And the supply chain members’ objective functions under model LF are as follows:

Proposition 10. Under model LF, assume that , the equilibrium is solved as follows:

The collection rate trajectory is calculated as follows:

where

and

are adjoint variables, and

.

denote the steady state of the dynamic system, which are given as follows:

Corollary 5. Under model LF, the optimal transfer price of the manufacturer is .

Even if the manufacturer provides both fund and labor support, they would still prefer to pay the transfer fee to the retailer to increase their own profit.

Proposition 11. There exists a threshold value such that if , it is beneficial for the manufacturer to implement both the fund cooperative and labor cooperative programs, where .

Similarly to the two cooperative modes mentioned above, the manufacturer can also earn more profits under the fund–labor mode only when the retailer’s cost coefficient is relatively large. Since the assumption in Proposition 10 is that , and this assumption condition is greater than , the manufacturer is always motivated to provide both fund and labor support when the assumption condition is met.

After evaluating separate fund and labor support scenarios and finding the labor cooperative model to be more beneficial for both parties, this section will directly compare all three cooperative models: non-cooperation (NC), fund cooperative (FC), and labor cooperative (LC). This analysis aims to clarify the manufacturer’s optimal collection strategy by assessing each model’s impact on efficiency, profitability, and supply chain sustainability, guiding the manufacturer’s strategic choice for mutual benefit. Since the constraints of the four models are not completely the same, this section will compare and analyze them under the restriction of to ensure that all four models are realistic.

Proposition 12. The collection rates under four collection models satisfy the following: .

Among the three cooperation models, compared to the fund cooperative and labor cooperative programs, the manufacturer’s participation in collection activities while providing funding is most effective in improving the collection rate. This cooperation model provides recycling support to the retailer through both indirect and direct means. Through this dual cooperation, the manufacturer simultaneously alleviates the retailer’s cost pressure and enhances execution efficiency, resulting in the highest overall collection performance.

Proposition 13. The manufacturer’s profits under four collection models satisfy the following: .

Proposition 13 indicates that the manufacturer can still benefit from all three cooperative modes, and they can obtain the highest profit level when they provide funding support and participate in product collection at the same time. By combining financial assistance with direct participation, the manufacturer achieves a complementary synergy between cost sharing and operational involvement. This dual role not only amplifies efficiency and recovery rates but also allows the manufacturer to capture greater value through enhanced coordination and expanded market demand.

Observation 5. The retailer’s profits under four collection models satisfy the following: .

As shown in

Figure 7, it is obvious that for the retailer, they hope that the manufacturer can provide support for their collecting activities while sharing their collection costs.

Observation 5 reveals that a combined labor and fund (LF) cooperative program surpasses both the fund cooperative (FC) and labor cooperative (LC) programs in improving collection rates and boosting profits for supply chain members. Given the prior examination of varying collection cost coefficients between the manufacturer and retailer, this section will delve into how these differences influence their cooperation mode choice among the three strategies. This exploration aims to provide deeper insights into the strategic decisions regarding the most effective cooperative mode, considering the dynamic interplay of cost factors within the supply chain framework.

Proposition 14. With different collection cost coefficients, the collection rates under three cooperative collection models satisfy the following:

- (i)

If and , then ;

- (ii)

If and , then ;

- (iii)

If and , then .

The increase in the cost coefficient for the manufacturer means that their difficulty in participating in collection activities also increases accordingly. Therefore, as increases, providing direct funding gradually becomes more effective than implementing labor cooperation in terms of product collection rate. When the critical value of is around 4, the high collection cost makes it unlikely for the manufacturer to choose the labor and fund cooperative.

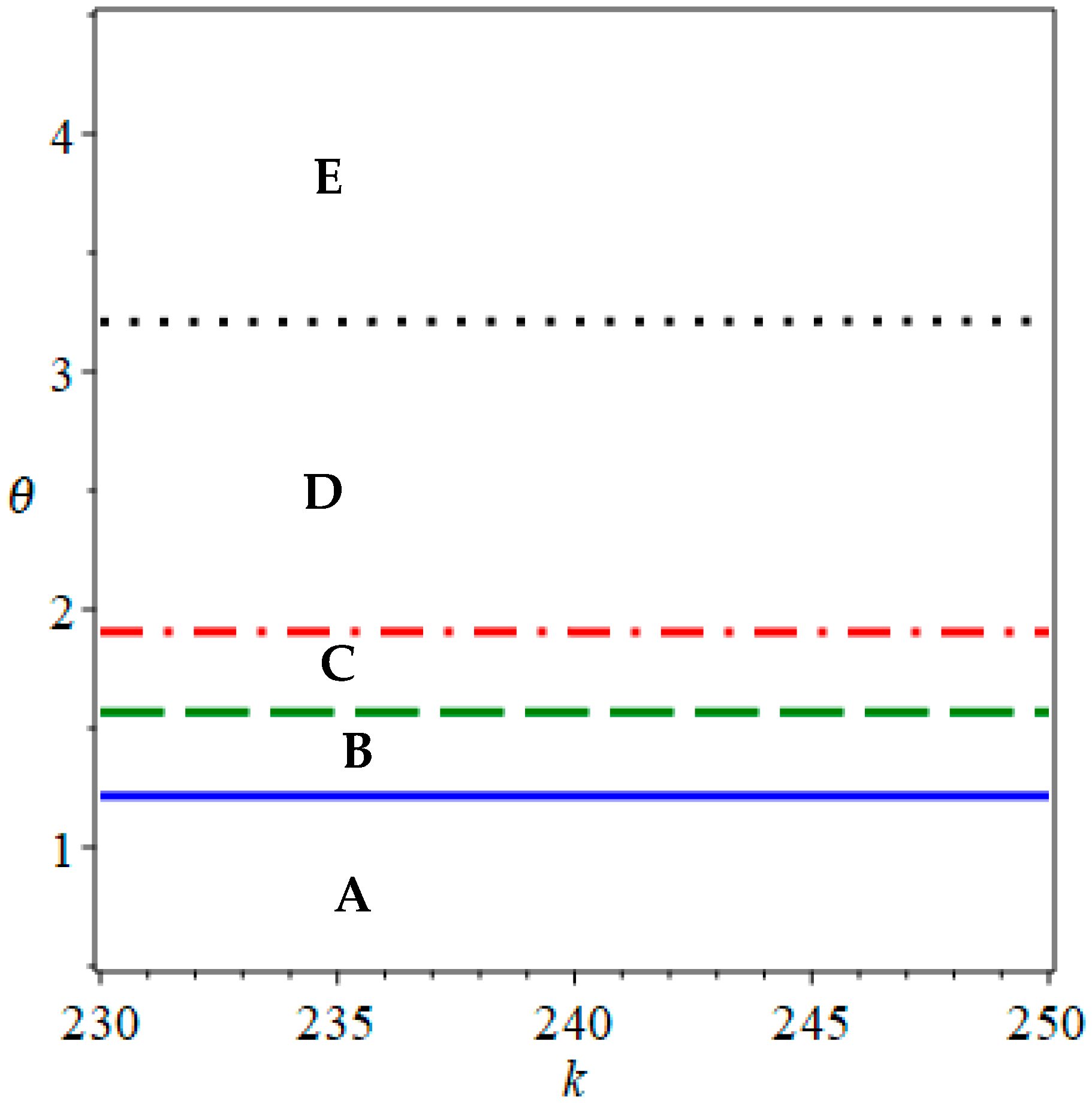

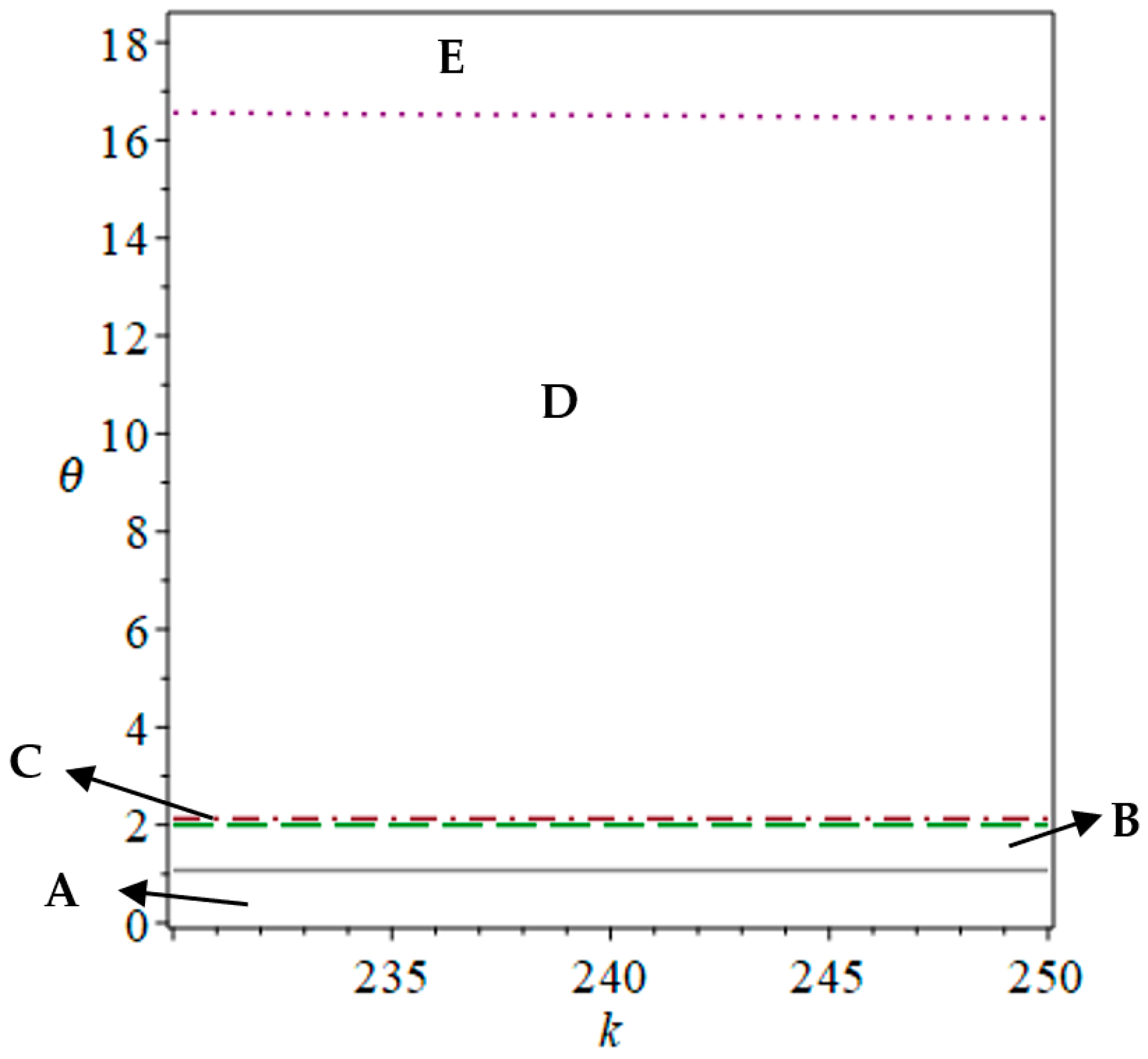

The following

Figure 8 and

Figure 9 compare the profits of the manufacturer and retailer under four collection models, in order to explore in depth how differences in collection costs affect the preference for cooperative modes.

Observation 6. With different collection cost coefficients, there exists four thresholds such that the manufacturer’s profits are related as follows:

when , ;

when , ;

when , ;

when , ;

when , .

Observation 6 indicates that only when the collection cost coefficient of the manufacturer is similar to that of the retailer (area A) will they tend to provide both funding and labor support. As long as the manufacturer’s cost coefficient is not too large, the labor cooperative is the most profitable for them (area B, area C and area D). However, if their cost coefficient is much larger than that of the retailer (area E), the best choice for the manufacturer is to provide funding support. And at this point, the manufacturer will give up providing both funding and labor supports.

Observation 7. With different collection cost coefficients, there exists four thresholds such that the retailer’s profits satisfy the following:

when , ;

when , ;

when , ;

when , ;

when , .

Observation 7 shows that in most cases (area A, area B, area C, and area D), the retailer hopes that the manufacturer can participate in used-product collection to share part of the recycling tasks, and only when the manufacturer’s cost coefficient is very large (area E), do they prefer the fund cooperative program.

Observation 8. The consensus of the cooperative mode for both the manufacturer and retailer is summarized as follows:

when , they can achieve a consensus on the labor and fund cooperative mode (area A);

when , they can achieve a consensus on the labor cooperative mode (area B);

when , they cannot achieve a consensus (area C);

when , they can achieve a consensus on the fund cooperative mode (area D).

When the manufacturer’s collection cost coefficient remains relatively moderate, adopting the combined labor and fund (LF) cooperative program emerges as the optimal strategy, offering substantial benefits to both the manufacturer and retailer. This program leverages the strengths of both labor and fund support, enhancing collection efficiency and profitability for both parties. If the manufacturer’s collection costs are marginally higher than the retailer’s, the fund cooperative (FC) program becomes the most suitable choice under these conditions, optimizing benefits given the slight cost disparity. However, when the manufacturer’s collection costs significantly exceed those of the retailer, the manufacturer tends to favor the FC program for its cost-effectiveness, while the retailer sees greater advantage in the labor cooperative (LC) program due to its potential for higher collection rates and sales benefits. This divergence in preferences indicates a lack of consensus between the manufacturer and retailer, complicating the cooperative strategy decision. In scenarios where the manufacturer’s collection costs are exceptionally high, the FC program is advised for the manufacturer, aligning with the retailer’s preference under these extreme cost conditions. This alignment suggests that, in cases of substantial cost differentials, the FC program offers a common ground, maximizing the achievable benefits despite the high cost burden on the manufacturer.

It is essential to explore the optimal mechanisms for the manufacturer’s involvement in the collection process. In particular, the availability of both fund support and labor support from the manufacturer proves to be pivotal. Notably, if the manufacturer’s collection costs align closely with those of the retailer, the simultaneous provision of both types of support emerges as the most favorable strategy for both parties involved. This observation underscores the insufficiency of relying solely on either fund or labor support within the manufacturer’s collection system. Recognizing this, resource-permitting conditions necessitate that the manufacturer adopts a comprehensive approach by simultaneously offering both support mechanisms in the collection system. Such an approach not only enhances the overall collection efficiency of the system but also bolsters the performance of the manufacturer and retailer.

However, it is important to acknowledge that there may be instances where certain strategy limitations or cost constraints arise, impeding the manufacturer’s ability to deploy both forms of support. In such cases, it is prudent for the manufacturer to prioritize their involvement in the practical aspects of the collection activities within the collection system. Naturally, it is crucial to address the scenario wherein the manufacturer’s collection costs escalate significantly, surpassing those incurred by the retailer. Under such circumstances, it is advisable for the manufacturer to limit their involvement to providing fund support exclusively. By adapting this approach, the manufacturer can still contribute to the collection system without incurring excessive costs.

In conclusion, these findings align fundamentally with the basic model. The main difference is that the simultaneous implementation of both fund and labor cooperation programs by the manufacturer emerges as a crucial factor in achieving these desired outcomes. When manufacturers are limited to choosing only one form of support, both manufacturers and retailers tend to prefer labor support, which is the main result of the basic model. The scenarios depicted in regions C and D of

Figure 10, where the manufacturer’s collection costs are significantly higher than those of the retailer, are deemed unrealistic.

8. Conclusions

In this paper, we examine the collection cooperative mode selection problem in a CLSC considering collection dynamics. The retailer manages the used-product collection in the CLSC. To enhance the collection rate of the CLSC, the manufacturer considers implementing a cooperative collection program for the retailer. The cooperative collection program could be either a fund cooperative or a labor cooperative, that is, by providing funds to the retailer or by participating in the collection activities. Previous studies have focused more on the fund cooperative and have not taken into account labor cooperative collaboration [

51,

52,

58], while this study incorporates both into the CLSC framework simultaneously to fill this research gap. By utilizing a labor cooperative program, the manufacturer becomes actively involved in the collection process and directly contributes to the improvement of the collection rate. In a fund cooperative program, the manufacturer provides funds to the retailer to share their collection expenditure, improving the collection rate indirectly through the retailer [

9,

36]. To develop the cooperative mode selection insights, we employ a differential model that captures the situation where the manufacturer and retailer participate in the collection activities jointly.

The equilibrium strategies across different cooperative collection models share characteristics, particularly when the collection cost coefficient is on the higher end. At these equilibriums, the dynamics of the collection rate tend to stabilize, reaching a steady state. This stability reflects a balance achieved through the cooperation strategies, highlighting the effectiveness of these models in optimizing the collection process [

25]. A key finding is the manufacturer’s strategy to allocate all remanufacturing cost savings to the retailer. This approach is aimed at motivating the retailer to intensify their collection efforts, recognizing the critical role of the retailer in the reverse supply chain [

16,

20]. Furthermore, upon implementing a cooperative collection program, the manufacturer strategically increases the wholesale price. This adjustment not only stimulates higher sales volumes but also enhances the manufacturer’s marginal profits, underscoring a dual focus on maximizing benefits across both the forward and reverse supply chains [

29,

62]. This observation underscores the manufacturer’s strategic emphasis on bolstering the efficiency of the forward chain while simultaneously incentivizing the retailer’s participation in the reverse chain through fund benefits. The practice of passing on cost savings to the retailer serves as a compelling motivator, ensuring active retailer involvement in collection efforts and contributing to the overall sustainability and profitability of the supply chain.

Not surprisingly, the manufacturer could improve the collection efficiency by implementing a cooperative collection program. Although the manufacturer tends to raise the wholesale price under the cooperative modes, the transfer of cost savings contributes to the reduction in the retail price and finally results in the increase in the product sales. The manufacturer and retailer could achieve a Pareto improvement through a cooperative collection program. Regarding the cooperative mode selection, both the manufacturer and retailer would be most advantaged by the labor cooperative program. This indicates that the manufacturer can further enhance collection efficiency by becoming involved in the collection activities that can be more advantageous for the CLSC members.

Additionally, we expand our analysis to include how differences in collection costs influence the cooperative preferences of both the manufacturer and retailer. These cost discrepancies could arise from variations in the collection processes they employ or their respective efficiencies in managing these activities. We find that such cost differences significantly impact the manufacturer’s choice of cooperative program. When the manufacturer’s costs are not excessively high, the labor cooperative model remains the most advantageous, benefiting both the manufacturer and the retailer. However, when the manufacturer faces higher collection costs, they lean towards the fund cooperative mode to mitigate escalating expenses associated with collection activities. In scenarios where the manufacturer’s costs are moderate, a discrepancy in preferences emerges: the manufacturer favors the fund cooperative model, while the retailer leans towards the labor cooperative model, indicating a challenge in reaching agreement on the optimal cooperative collection strategy [

40].

Moreover, we delve into the possibility of the manufacturer concurrently offering both fund and labor cooperative programs, if feasible. Our findings suggest that when the manufacturer’s collection costs are similar to those of the retailer, simultaneously engaging in both programs is advisable to maximize the collection rate and profit for both parties. Conversely, if the manufacturer’s collection costs are noticeably higher than the retailer’s, opting for the labor cooperative program is deemed most effective. It is only when the manufacturer’s collection costs are significantly greater than the retailer’s that shifting towards the fund cooperative program becomes the optimal strategy.

The managerial implications for the supply chain members are quite meaningful. Previous studies have predominantly assumed that CLSC managers adopt a fund cooperative mode for collection [

51,

52], relying heavily on this approach due to its ease of implementation. However, our findings indicate that labor cooperative efforts can lead to higher collection efficiency and prove to be more profitable for both manufacturers and retailers. Therefore, manufacturers should not solely rely on retailers to provide funds but should actively engage in collection efforts themselves.

If the manufacturer’s fund conditions and technique conditions permit it, the optimal choice should involve providing both fund and labor support to retailers within their collection systems. This approach not only maximizes the overall system recovery rate but also enhances the performance levels of manufacturers and retailers individually. However, in practice, this may depend on the manufacturer’s fund constraints or strategic considerations. For instance, if the manufacturer lacks sufficient initial funds to implement both forms of support simultaneously, they may be compelled to choose one over the other. Under such circumstances, active participation in the collection activities is often the more advantageous mechanism for both parties.

Naturally, it is important to recognize that the manufacturer’s involvement in collection may incur higher costs compared to the retailer. Nevertheless, as long as the manufacturer’s costs are not excessively higher, the optimal cooperative mechanism remains unchanged, whether it is the implementation of labor support or the simultaneous adoption of both support mechanisms. However, if the manufacturer’s costs for conducting collection activities are excessively high, then providing fund support becomes their best choice. Hence, manufacturers should thoroughly evaluate their cost coefficients associated with collection. If it is determined that the costs of conducting collection are prohibitively high, enabling retailers to carry out product collection through fund support proves to be a better choice for recovery rates and benefits for both parties involved.

The core management implication of this study lies in that decision-makers in CLSC should transcend the traditional mindset of fund cooperative models and view reverse logistics cooperation as a strategic resource integration issue that requires meticulous management. Specifically, manufacturers should not merely act as fund backers but proactively engage in and empower retailers’ reverse logistics activities through providing technical support, optimizing the reverse logistics process, sharing data, and conducting joint marketing, as this usually leads to higher reverse logistics efficiency and profits. To make the best choice, manufacturers need to establish a scientific cost assessment and decision-making framework in order to quantitatively compare their own reverse logistics costs. When the cost of manufacturers’ reverse logistics activities is not high, a mixed model of providing both fund and labor can achieve system optimization; when the cost of manufacturers’ reverse logistics activities is too high, prioritizing a fund cooperative model becomes their best choice. In summary, managers should abandon the “one-size-fits-all” subsidy model and, based on a deep understanding of their own and partners’ cost structures, select the most appropriate depth and mode of cooperation, and through ingenious contract design, transform reverse logistics activities from a cost center into a value creation center that enhances the competitiveness and sustainability of the entire supply chain.

From a managerial perspective, adopting an infinite-horizon framework allows the model to reveal the long-term strategic differences between the fund cooperative and labor cooperative modes without being constrained by terminal effects. In practice, however, cooperation in closed-loop supply chains usually occurs within finite contractual or operational periods. Under such finite horizons, managers may observe time-dependent behaviors—such as stronger short-term incentives for fund-based cooperation or delayed engagement in labor-based cooperation—before reaching equilibrium. Therefore, the infinite-horizon setup should be viewed as an abstraction of ongoing collaboration, providing insights into the steady-state tendencies of each mode, while finite-horizon extensions could further help managers understand how cooperation strategies evolve over specific time frames.

There are several limitations to this study. We ignore other collection channels, such as manufacturer and third-party collections, and focus only on retailer collection. Savaskan et al. [

5] and Atasu et al. [

16] have shown that the retailer collection is more likely to be the most efficient channel among other reverse channels. Thus, we examine the cooperative program selection problem under the retailer collection channel. Future studies can also investigate the cooperative collection problem under other reverse channels. Moreover, we conduct our study in a simple supply chain frame. Future studies could incorporate competing factors such as manufacturer or retailer competing factors to further consider the cooperative collection selection problem and investigate how competing factors might affect the results.