1. Introduction

During pandemics like the COVID-19 outbreak, airports and other transportation hubs can act as significant transmission points for disease. In addition to airborne transmission, viruses and bacteria can spread through contact with contaminated surfaces, including luggage. Although the risk of transmission through luggage is relatively low compared to other modes, it remains important to disinfect luggage to prevent disease spread [

1].

In 2020, European airports had a loss of 1.32 billion passengers and EUR 33.6 billion in passenger revenue, in terms of people and money, respectively [

2]. Airports and airlines have not yet returned to their pre-pandemic levels because of a variety of factors, including a decline in passenger demand, quarantine restrictions, and a drop in the number of domestic and international flights [

3]. To address regulatory guidelines and customer concerns over potential transmission during travel, the majority of airlines incorporated in-flight social distancing measures together with supplementary sanitary and hygiene precautions [

4]. In order to eradicate any remaining virus particles, airports and airlines are now required to use hospital-grade disinfectants as a result of the COVID-19 pandemic [

5].

Research has indicated that SARS-CoV-2, the virus responsible for COVID-19, can remain viable on surfaces like cardboard, plastic, and stainless steel for up to 72 h [

6]. This means any contaminated surface, including luggage, could potentially be infectious for several days after exposure. Additionally, the virus can be transmitted via fomites, which are objects or materials likely to carry infection, such as doorknobs, light switches, and luggage handles [

7]. Therefore, it is crucial to thoroughly disinfect all surfaces that are frequently touched, including luggage, to prevent virus spread.

Apart from viruses, bacteria such as

Staphylococcus aureus,

Escherichia coli, and Salmonella can also be present on luggage surfaces, causing a range of illnesses, from skin infections to food poisoning [

8].

The pandemic issue has had a significant impact on the aviation sector. The implementation of travel prohibitions by governments globally, which resulted in a decrease in the number of passengers at airports and airlines, also compelled airports and airlines to undergo significant internal reform in terms of operability and efficiency [

9].

Estimating the exact number of people who could become infected through luggage interaction is challenging, but the risk is significant enough to warrant attention. A study on COVID-19 transmission in a Chinese hotel found the virus on surfaces such as door handles, light switches, and trash cans, indicating that contaminated surfaces can facilitate transmission [

10]. Although the authors of the study did not specifically investigate luggage, contaminated luggage is likely to contribute to the spread of disease in similar settings.

To mitigate the risk of transmission through luggage, it is important to disinfect luggage and other surfaces that passengers may encounter [

11]. The following sections will describe the disinfection process for luggage during check-in and the procedures for disinfecting luggage when a person arrives from a high-incidence country. We will also discuss the potential for new technologies to enhance luggage disinfection effectiveness in the future.

In this article, we propose and test two different models of baggage disinfection: selective and indiscriminate disinfection. Selective disinfection involves checking baggage for viruses or bacteria and then disinfecting only the positive baggage. Indiscriminate disinfection involves disinfecting all baggage, regardless of whether it has been checked. These two models were conceptualized and simulated in the Technomatix Plant Simulation virtual environment.

The primary research question was to understand the options for automatic baggage disinfection at airports, given the potential for future pandemics and the limited number of articles in this research direction.

Few authors address baggage disinfection in their articles. For example, one article [

12] focuses on designing the baggage disinfection tunnel at railway stations, bus stations, and airports. Another article [

13] addresses a similar issue, but it focuses more on the system for informing passengers about baggage sterilization at the airport. We did not find any relevant articles addressing the design of disinfection tunnels and comparing selective and non-selective methods.

For our work, it is also important to review the literature on methods for testing baggage for viruses. At the moment, there are several new methods that have the potential to be widely used in the future. Two articles [

14,

15] discuss various testing methods that provide a time from several seconds to hours, depending on the method. The results of the articles show that the testing time can be in the range of 30 s to 15 min. Most of these rapid testing methods are still in the research phase and may not be stable.

A further article [

16] also highlights an innovative testing method using biosensors. The biosensing platform is created by the 3D nanoprinting of three-dimensional electrodes and can identify the virus in up to 30 s. Another study [

17] also reported the use of a cobalt-functionalized TiO2 nanotube (Co-TNT)-based electrochemical sensor for the rapid detection of SARS-CoV-2 S-RBD protein in approximately 30 s.

Although this method has certain drawbacks, we will take its testing time as a basis, as our main goal is to create a logistics system for baggage disinfection, which is only possible with the help of rapid testing technology. Testing with these sensors is carried out only for the presence of the SARS-CoV-2 virus.

In addition to proposing new models, this article also provides a framework for their application, taking into account various aspects, such as the risk of disease transmission, implementation costs, and legal constraints. The research highlights how crucial system resilience is to stop the spread of infectious diseases. The overall reliability and resilience of the system to operational failures increases if a non-selective model is designed, as fewer critical points of failure are present.

This research offers a thorough understanding by comparatively examining the operational implications of the two models, facilitating stakeholders to make informed decisions about costs, risks and effectiveness. Operational challenges faced by airport authorities are addressed while maintaining high standards of hygiene through a balance between efficiency and thoroughness.

This research also supports the creation of greener airport operations by the minimizing the unnecessary use of chemicals and focusing on targeted disinfection. In addition, adherence to good cleaning practices improves public health safety, which is consistent with international initiatives to control and prevent infectious diseases.

We plan to extend our research in the future and implement its results at Košice International Airport to test and improve our luggage disinfection concept.

2. Literature Review

The COVID-19 pandemic has prompted airports and airlines to take steps to ensure that luggage is thoroughly disinfected to prevent the spread of disease. To accomplish this, several disinfection techniques are being employed, including the use of UV-C light, aerosol sprays, and other cleaning agents [

18].

One of the most commonly used disinfection methods is UV-C light. UV-C light is effective against a wide range of viruses and bacteria, including virus SARS-CoV-2. In UV-C disinfection, luggage is passed through a UV-C chamber, where it is exposed to high-intensity UV-C light for a predetermined amount of time. The UV-C light destroys the DNA or RNA of the viruses and bacteria, rendering them unable to infect humans [

19]. This method is highly effective and is currently being used in several airports and airlines around the world.

Another disinfection technique used in some airports and airlines is the use of aerosol sprays. These sprays contain disinfectant chemicals that are sprayed onto the luggage to kill any viruses or bacteria present on the surface. While this method is effective in killing viruses and bacteria, it can also create a risk of respiratory irritation for individuals who may inhale the chemicals. The aerosol disinfection is the delivery mechanism for the chemical agents, although aerosol disinfection methods usually have special formulations to improve their properties. Additionally, aerosol sprays can damage certain types of luggage coating, which can cause distress to passengers. As a result, many airports and airlines are moving away from this method and towards UV-C light disinfection [

20].

In addition to UV-C light and aerosol sprays, other cleaning agents, such as quaternary ammonium compounds (quats) and hydrogen peroxide, are being used to disinfect luggage. Quats are highly effective against a wide range of viruses and bacteria and are often used in hospital settings. Hydrogen peroxide is also effective against viruses and bacteria and is commonly used as a disinfectant in healthcare settings.

The disinfection process for luggage typically involves the following steps [

21]:

Luggage is placed on a conveyor belt and passed through a disinfection chamber.

The luggage is exposed to high-intensity UV-C light for a predetermined amount of time. If using aerosol sprays or other cleaning agents, the disinfectant is sprayed onto the luggage [

22].

After disinfection, the luggage is taken to the baggage handling system for transport to the plane.

To ensure that luggage is thoroughly disinfected, airports and airlines are employing several measures, including increasing the frequency of disinfection, using multiple disinfection methods, and using high-quality disinfectants. Additionally, some airports are using automated systems to track the movement of luggage through the disinfection process to ensure that all luggage is properly disinfected [

23].

Despite the various methods and measures put in place to disinfect luggage during check-in, there are still some challenges and limitations. For example, some types of luggage, such as leather or fabrics, may be more difficult to disinfect than hard-shell suitcases. Additionally, the disinfection process may not be 100% effective in all cases, and there is still a small risk of viruses being transmitted through luggage [

12,

24].

Furthermore, some airports and airlines are also implementing measures to reduce the amount of physical contact that passengers have with their luggage during the check-in and boarding process. For example, some airports have implemented contactless check-in and baggage drop-off systems, where passengers can check in and drop off their luggage without meeting airport staff or other passengers. Additionally, some airlines have implemented measures, such as limiting the number of carry-on bags allowed on board and prohibiting the use of overhead bins, to reduce the amount of physical contact between passengers and their luggage [

25].

While reducing the amount of carry-on luggage can indirectly minimize contact be-tween passengers and their belongings—thereby reducing the potential risks of infection transmission—its primary purpose is to simplify the boarding process.

When it comes to luggage disinfection upon arrival from high-risk countries, airports have implemented additional measures to prevent the spread of disease. These measures include identifying high-risk passengers and screening their luggage upon arrival.

One way that airports identify high-risk passengers is by using a combination of passenger health declarations and thermal scanners. Health declarations are forms that passengers are required to fill out prior to boarding their flight, which provide information about their recent travel history and any symptoms they may be experiencing. Thermal scanners are used to detect passengers with a fever, which can be a sign of infection. Once high-risk passengers are identified, their luggage is screened for potential contaminants [

26].

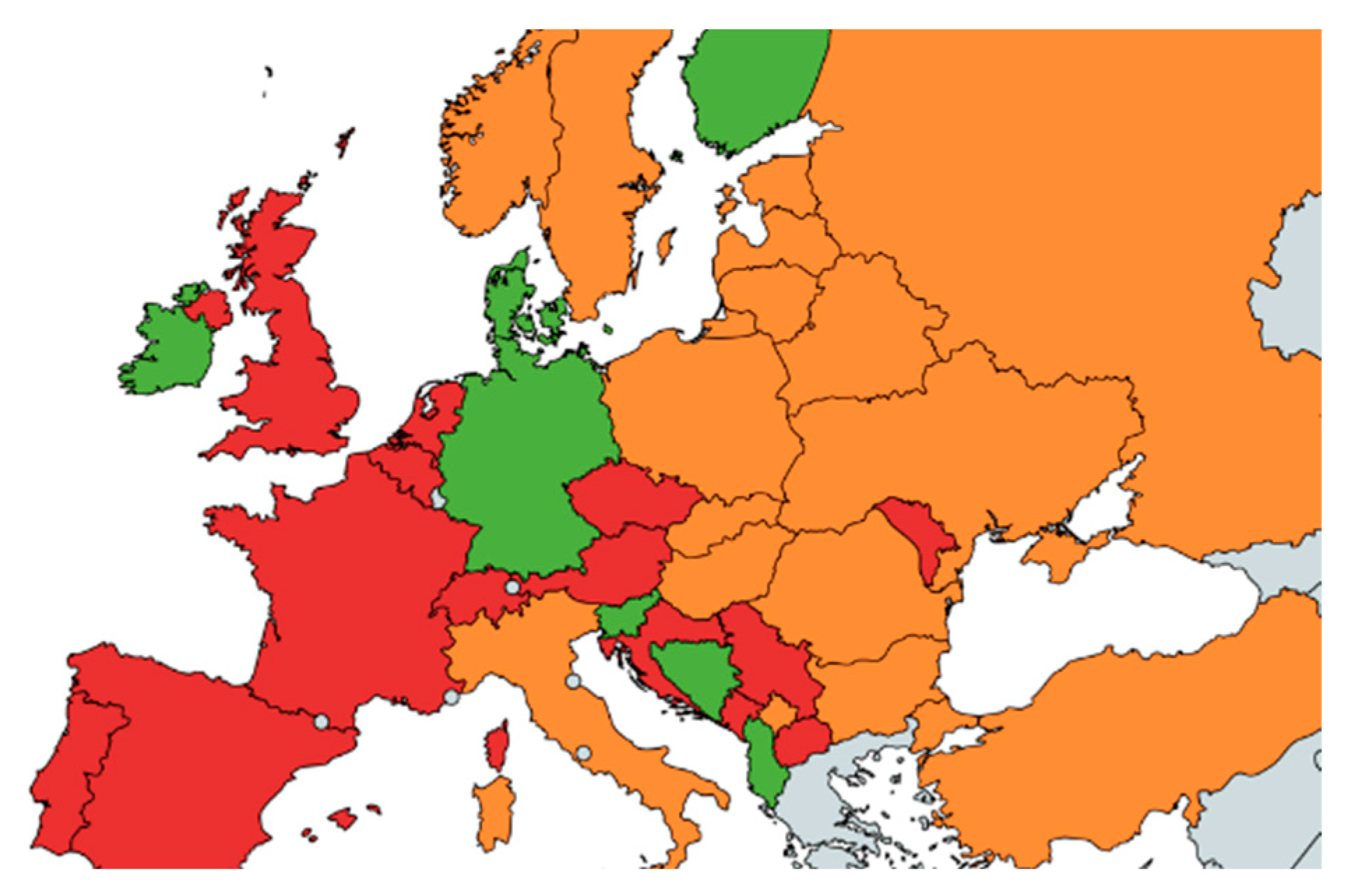

Based on international health data, airports should also create a map to understand which country poses a greater risk of contracting the virus. Airport authorities use maps of regions and countries with a different risk of morbidity to avoid the spread of viruses and bacteria, as well as to prevent the spread of pandemics [

27]. These maps are based on the data from the World Health Organization and other sources, and they classify the areas into three categories: green, yellow, and red zones. Depending on the zone, different measures are applied to the luggage of the passengers arriving at the airport [

28].

When a plane arrives at an airport from a red zone, which indicates a high level of infection, each piece of luggage is disinfected using an automatic disinfection system that consists of a tunnel with UV-C light and a spray system with non-foaming soap solution. This system is designed to kill the viral particles on the surface of the luggage and reduce the transmission of the disease through fomites [

29,

30].

If a plane arrives from a green zone, which indicates a low level of infection, passengers’ luggage does not need to be disinfected. However, passengers are still advised to wash their hands frequently and avoid touching their face after handling their luggage.

If an aircraft arrives from a yellow zone, which indicates a moderate level of infection, the decision to use disinfection also depends on other indicators, such as the general state of the outbreaks of a pandemic in the country, intensity, seasonality, and more. In some cases, passengers may be asked to consent to have their luggage disinfected or to undertake this themselves, using disinfectant wipes or sprays provided by airport staff [

31].

An example of such a map is shown in

Figure 1. This is designed to illustrate the principle by which the system works to recognize more and less risky countries.

The additional measures taken to disinfect luggage upon arrival from high-risk countries are essential in preventing the spread of disease. By identifying high-risk passengers and thoroughly screening their luggage, airports can help to reduce the risk of transmission and ensure the safety of staff and passengers.

3. Methodology

Modelling was performed in the Technomatix Plant Simulation 16.1. (TPS) environment. This software was chosen for modelling because of its flexibility in use and its focus on manufacturing processes [

32].

Technomatix Plant Simulation is a versatile 2D and 3D modelling software that is used by engineers and manufacturers to simulate, optimize, and evaluate complex manufacturing and logistics systems. It is widely used in various industries, including in automotive, electronics, aerospace, and consumer products. TPS facilitates the creation of virtual prototypes of manufacturing systems and their subsequent analysis, allowing for the optimization of production processes, improved efficiency, and cost reduction. The software provides a complete set of tools and functions that can be used to evaluate and optimize production system performance [

33].

The software uses an object-oriented approach to modeling, which means that the system is represented by a set of objects, each of which has its own properties, methods, and behavior. The software uses a proprietary modeling language called “SimTalk” to define the behavior and interaction of these objects in the simulation [

34].

The use of TPS in this study enabled us to conduct virtual simulations of selective and non-selective luggage disinfection systems and compare their performance. This allowed us to accurately model the various stages of the disinfection processes, including baggage check-in, disinfection, and baggage handling. The simulations provided valuable insights into the effectiveness and efficiency of the two systems.

Baggage Handling Chain

The baggage handling chain can be divided into several stages, each of which is crucial to the overall efficiency of airport operations.

The first stage is baggage check-in, where passengers bring their luggage to the check-in desk. Here, airline employees check the bags, print luggage tags, and ensure that the luggage is directed to the correct flight. This process typically takes around 1–5 min per bag, depending on factors such as the number of passengers in line, the efficiency of the check-in staff, and any required security screening procedures [

35].

Next is the baggage sorting and screening stage. The baggage handling system reads the tags and sorts the luggage according to flight and destination. Security staff then inspect the baggage to ensure it does not contain prohibited items. This stage usually takes 0.5–2 min per bag, depending on the system’s efficiency and the volume of bags being processed.

After clearing security, the baggage is transported to the aircraft via conveyor belts, carts, and other transportation methods. The duration of this process can vary based on the distance between the check-in area and the aircraft, the efficiency of the system, and any unforeseen delays, typically taking around 5–10 min per bag.

Once the baggage arrives at the plane, ground service agents load it into the aircraft’s cargo hold. This loading process generally takes 2–3 min per bag, and it is influenced by factors such as the size of the aircraft, the number of bags, and the efficiency of the ground staff.

Upon reaching the destination, the baggage is unloaded from the cargo hold. This process takes approximately 3 min per bag, although it can be affected by the aircraft size, the number of bags, and potential delays.

Following unloading, the baggage is sorted according to its final destination and then sent to the baggage claim area. This sorting process typically takes around 5 min per bag, depending on the system’s efficiency and the volume of bags.

Finally, passengers retrieve their bags at the baggage claim area. This process usually takes around 5–10 min per bag, depending on the number of passengers waiting and the efficiency of the claim area [

36].

Our simulation divides these processes into two main parts: from check-in to baggage loading onto the plane, and from the plane’s arrival to baggage unloading and delivery to passengers. We introduced a new element in each part: the disinfection of the luggage. By testing this new system in a computer simulation environment, we compared it with the existing system to draw conclusions about its time and efficiency. Baggage check-in: Passengers take their luggage to the check-in desk, where airline employees check bags, print out luggage tags, and distribute them to the flights.

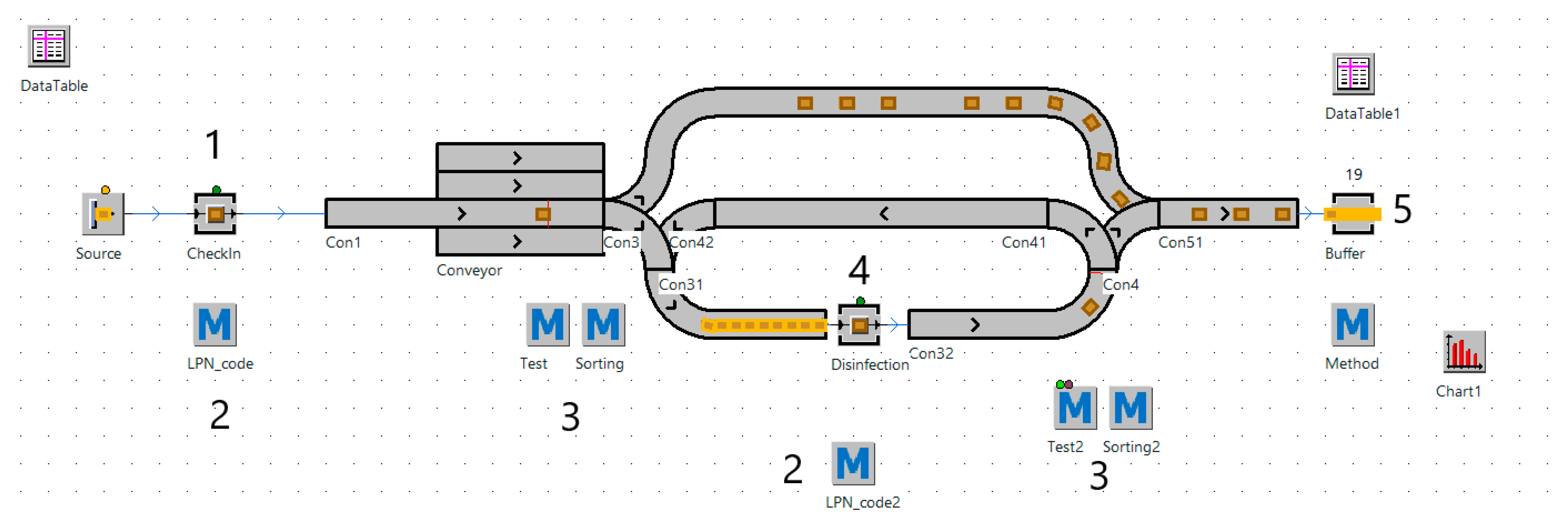

The chain of processes is shown in

Figure 2.

In our simulation, we tried to divide these processes into 2 parts, namely, from check-in to baggage loading on board the plane and from arrival of the plane and baggage unloading until the passenger receives their baggage. In each of these parts, we introduced a new element, namely, the disinfection of the luggage. Having tested the new system in a computer simulation environment, we will try to compare it with the existing system and draw conclusions about its time and efficiency.

4. Experimental Part: Selective Luggage Disinfection System during Check-In

As described in the previous parts, luggage that has been in close contact with an infected person or with an infected surface is likely to be a carrier of viruses or bacteria.

As viruses can survive for up to 72 h on the surface of luggage, depending on the material, and as bacteria can multiply under favorable conditions and sufficient humidity, the idea of testing and disinfecting checked luggage looks very promising.

The aim of the research part of this paper was to simulate an alternative system for checking in and diverting airport passengers’ luggage with automatic testing for viruses and its subsequent disinfection. The simulation is presented in

Figure 3 and represents a set of material, operational, and transport elements of the TPS together with a function assignment element. The simulation was focused on an average of 140 pieces of luggage.

At point 1 in

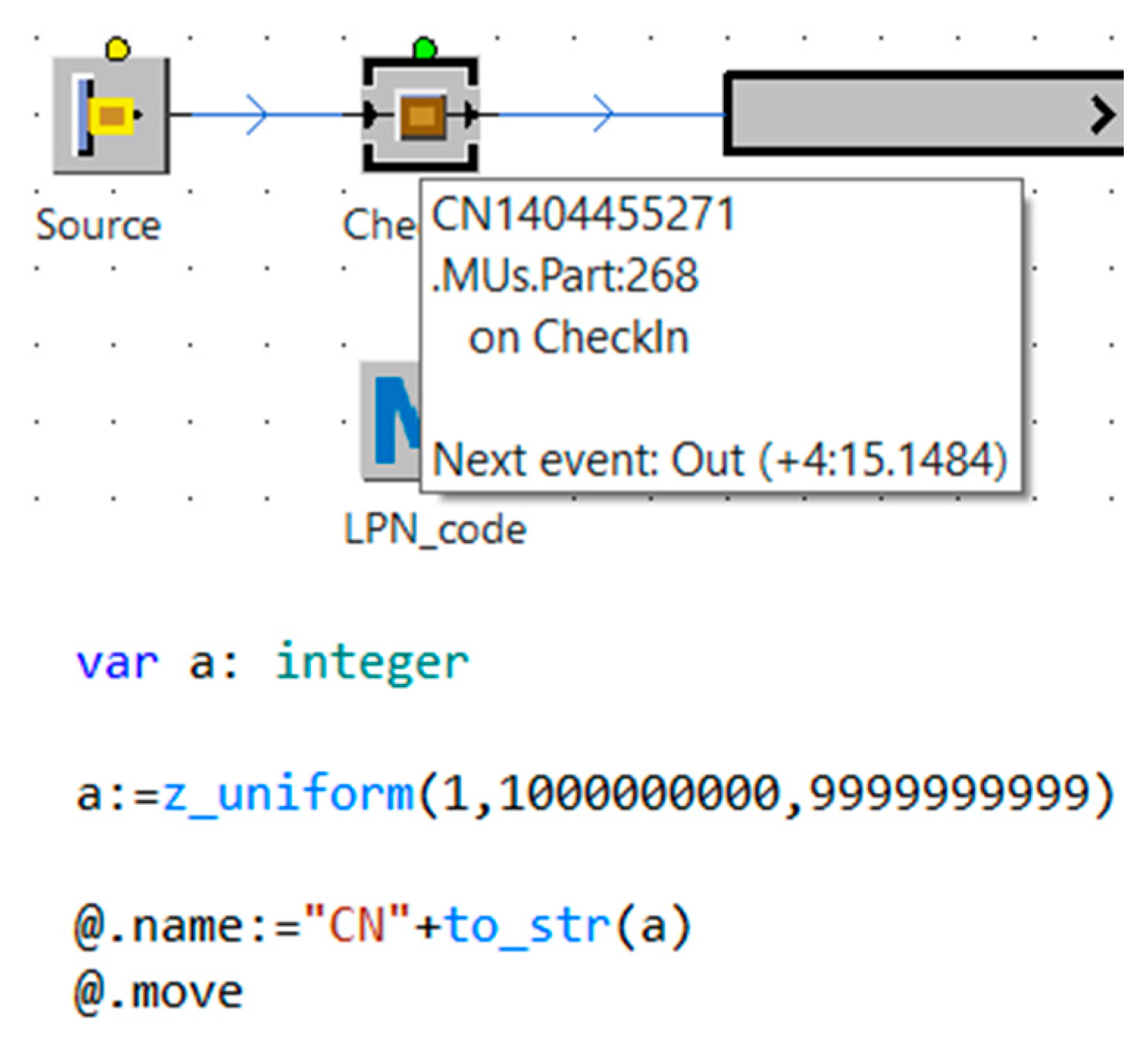

Figure 3, the passenger hands over his/her luggage at the check-in point and the luggage is checked in. At check-in, each bag is given a unique LPN number [

37].

The license plate number (LPN) is a unique 10-digit number. Frist digit corresponds to the prefix, which indicates the general classification of the plate; the three following digits indicate the ticket number, and the last six digits indicate the serial number. The LPN is generated by the baggage reclaim system at check-in and allows the identification of the item being carried. The LPN is printed and affixed to the baggage and a detailed history of the baggage’s journey and the processes it has undergone is recorded using a laser as it is transferred to other stations or conveyors, or handled by staff. As can be seen in

Figure 4, the model automatically generates an LPN code for each piece of luggage separately [

38].

Next, the luggage moves to the place where it is tested (number 3 in

Figure 3) for possible viruses or bacteria. The development of rapid surface detection technologies for COVID-19 has greatly enhanced the ability to quickly and accurately determine the presence of the virus on various surfaces, including baggage. Testing technologies typically use molecular techniques, such as real-time reverse transcription–polymerase chain reaction (RT-PCR) or new biosensors that can detect viral RNA or specific proteins within seconds or minutes. The rapid detection process allows for immediate action, ensuring that infected baggage is identified and decontaminated before further processing. This innovation not only improves the efficiency of the disinfection models in question, but also provides a higher level of security by preventing the spread of the virus at airports.

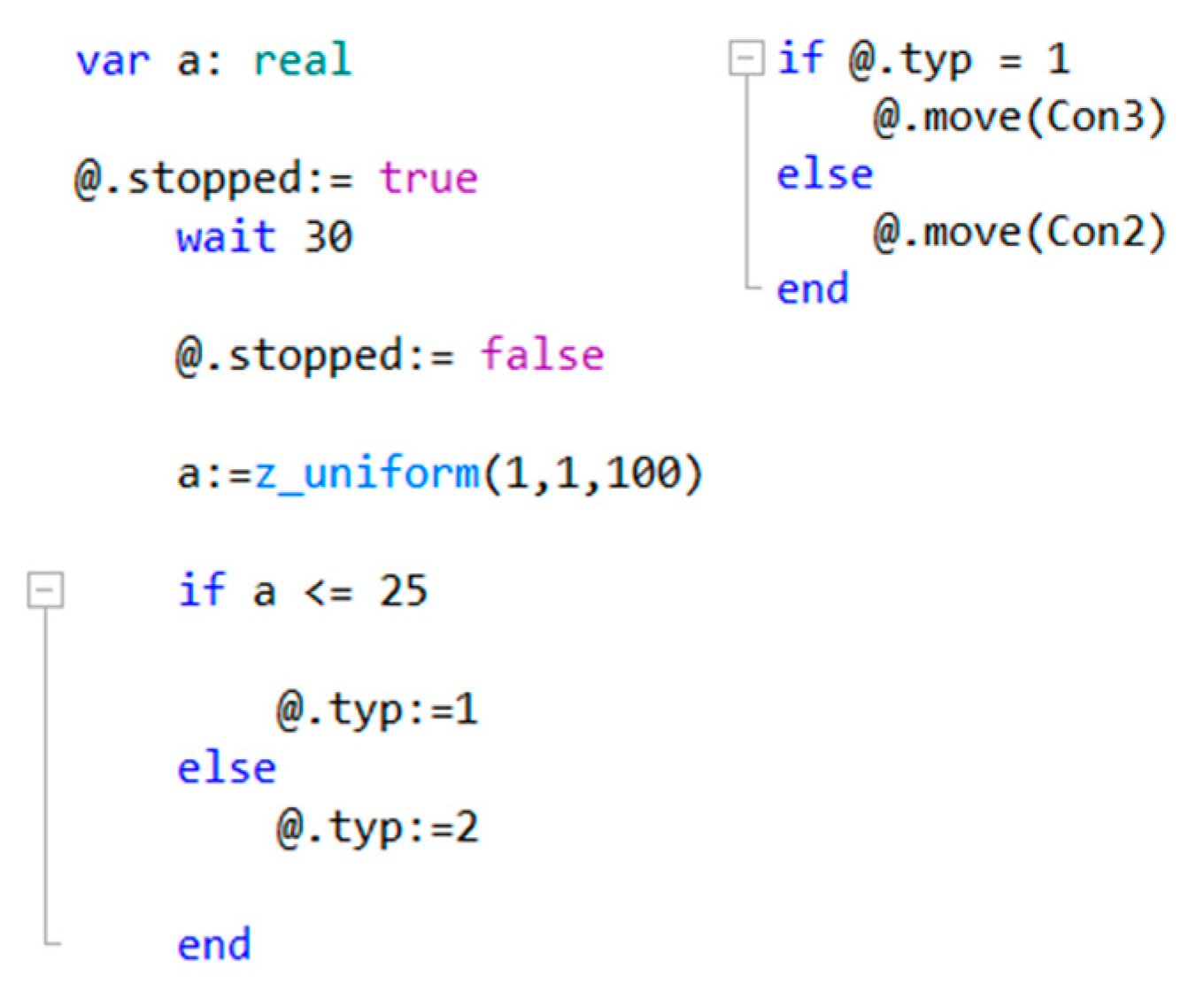

Figure 5 shows the testing and sorting method code. Virus testing methods using new technologies can last from 2 to 10 min on average. In our simulation, we selected 3.5 min as the average time. In order to speed up the baggage check-in process, four testing stations were added at point 2 (

Figure 3). Testing in this case was carried out generally for the presence of the SARS-CoV-2 virus.

According to the test results, the luggage is sorted. Luggage with a negative test result move through the upper way and proceed directly to the warehouse. If the test result is positive, the luggage moves down the lower way and proceeds to the disinfection station (number 4 in

Figure 3).

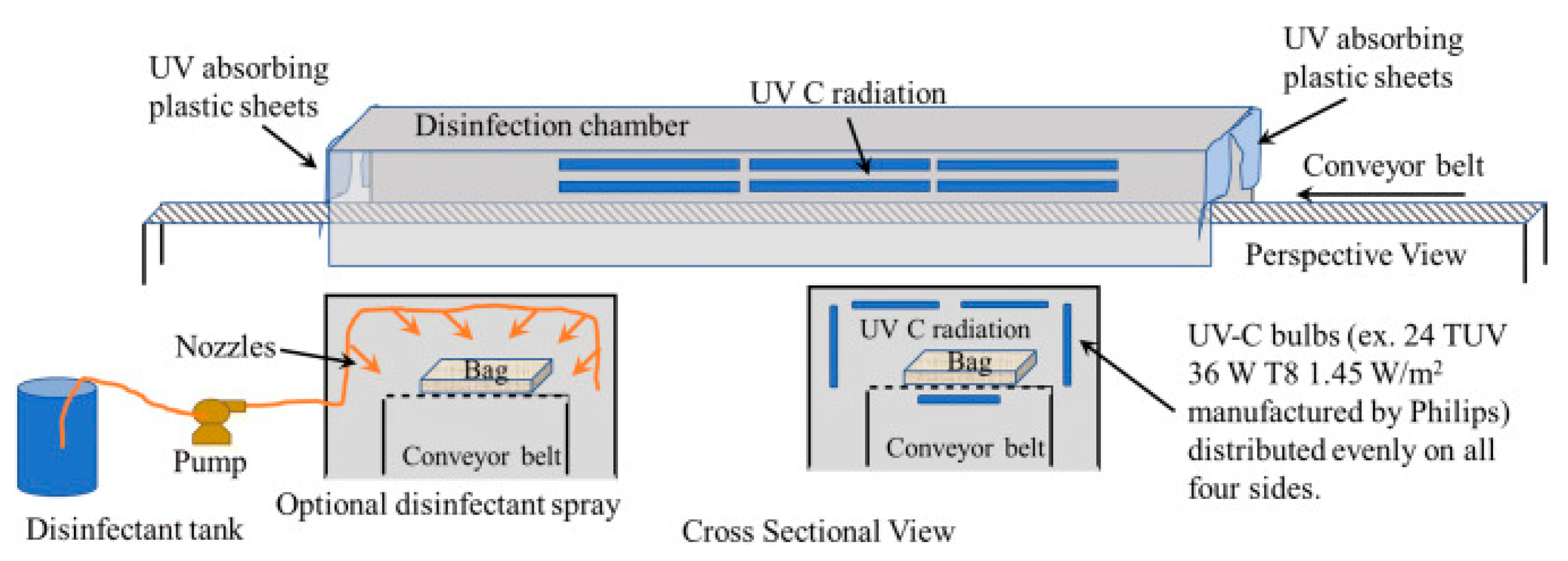

A tunnel system like the X-ray machines used for passenger luggage in airports has been developed for disinfecting fomites. The system consists of eight 36-watt T8 TUV lamps that illuminate every square meter on the conveyor belt for 10 s. For standard airline baggage sizes, 24 of these lamps are evenly distributed on all four sides of the tunnel. The entry and exit points on the conveyor belt are protected from UV-C light leakage by installing thin plastic (e.g., acrylic) curtains. An optional non-foaming soap solution spray system can be used as an additional disinfection step, since it is very effective against viruses and bacteria. No sodium hypochlorite solutions are used in this design. In this system, the lower part of the luggage will receive a lower dose of UV radiation due to the shielding by the conveyor system. A schematic of the disinfection unit design is shown in

Figure 6.

UV-C-based disinfection works by damaging the DNA/RNA of bacteria and viruses and preventing their replication. The disinfection time depends on the size of the luggage and whether a non-foaming soap solution spray phase is used. The average disinfection time is exactly 40 s [

39].

After successful completion of the disinfection process, the information about the end of the disinfection is entered in the LPN code of the luggage, and the material is sent to the second point of testing and sorting. Here, as in the previous case, in case of a negative test result, the luggage is sent to a warehouse, and in case of a positive result, it is sent back to the disinfection station in a special direction. If the luggage fails to pass the disinfection test for the third time, the airport staff are notified to examine the situation in detail.

The disinfection time depends on the size of the luggage and whether a non-foaming soap solution spray phase is used.

After successful completion of the disinfection process, information about the end of the disinfection is entered into the luggage LPN code and the material is sent to the second point of testing and sorting. Here, as in the previous case, in case of a negative test result, the luggage is sent to the warehouse, and in case of a positive result, it is sent back to the disinfection station by a special route. If the luggage fails disinfection a second time, the airport staff are notified to investigate the situation in more detail.

At the end of the transportation, all the material is moved to the warehouse, from where the luggage is transported to the aircraft, and then it is loaded onto the aircraft deck.

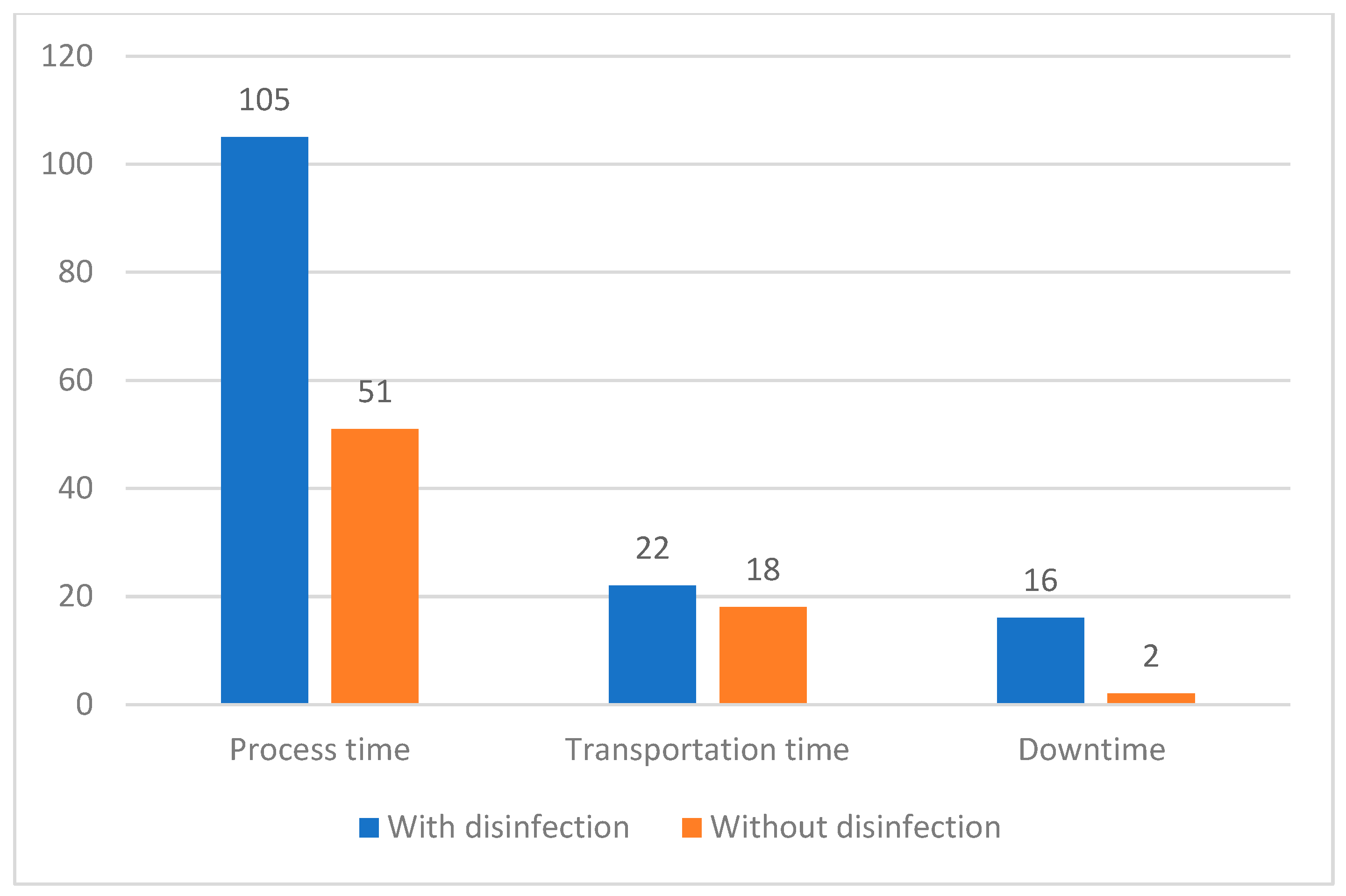

Figure 7 illustrates the change in the distribution of time between the different processes after the introduction of the disinfection. The increase in the process time and downtime is a direct result of the additional disinfection and testing steps, while the transportation time remains relatively unchanged. This detailed analysis emphasizes the moderate but manageable impact of disinfection on the baggage handling process.

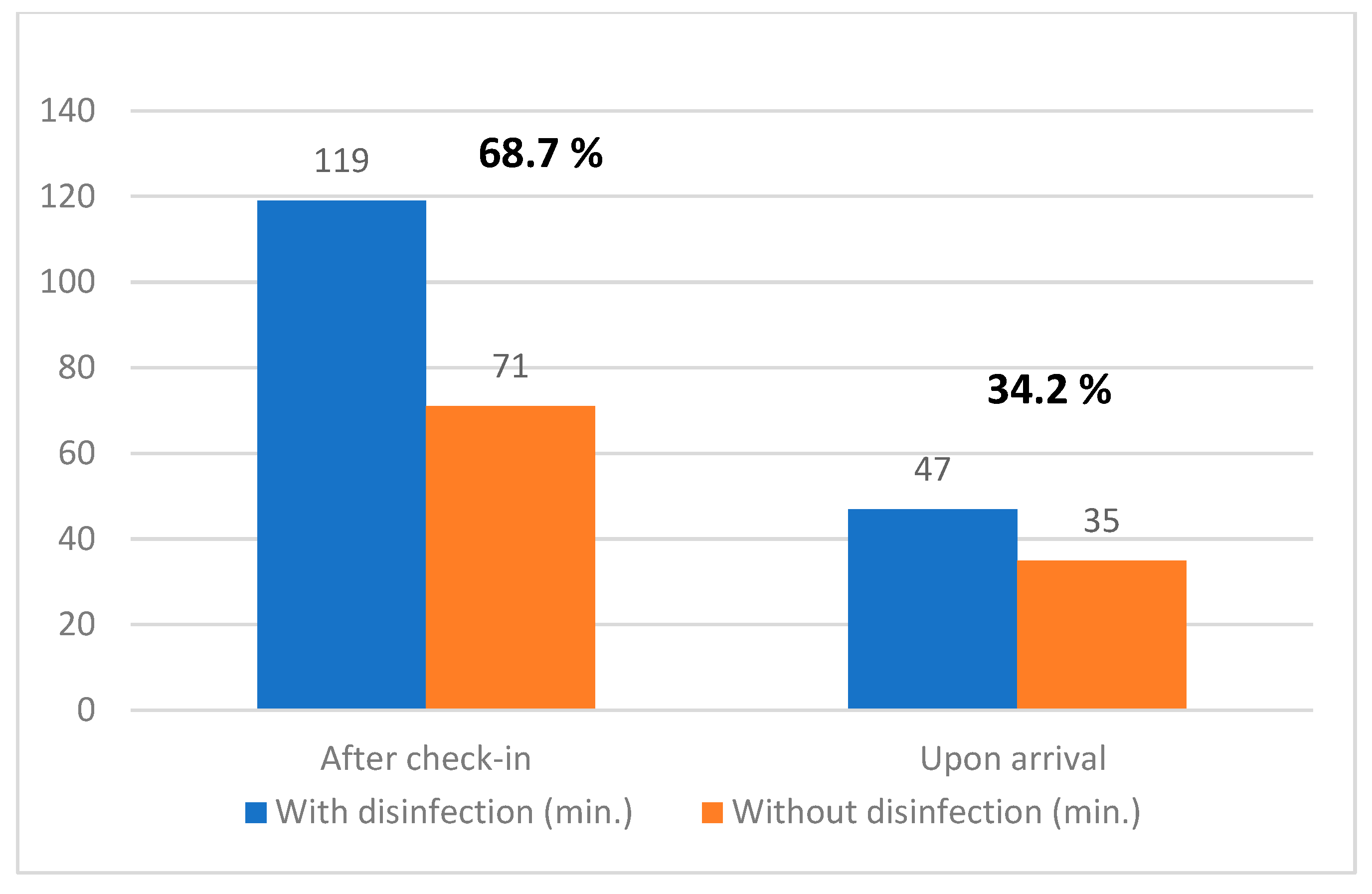

The difference between the time taken which the luggage to pass through the systems with and without disinfection was 22.2%. The total simulation time increased by 68.7%, given that the testing was set up for positive rates of 25% for the total luggage count. In addition, 3% of all the luggage had to be disinfected twice.

The processing time with disinfection includes the standard processing steps, as well as an additional 20 s for the disinfection process. For a typical drawstring bag, the total processing time is approximately 105 min of the total processing time. In the scenario without disinfection, the processing time is slightly shorter and accounts for 51 min of the total processing time.

The transportation time remains relatively constant, as disinfection has little direct impact. On average, transportation accounts for 22 min. Additional handling associated with the disinfection process can cause minor delays, but these are not significant. The transportation time without disinfection takes about 18 min. The absence of disinfection ensures the smoother and, potentially, faster movement of baggage between different points.

The downtime, which includes the waiting time and any necessary rechecks, increases to 16 min. This reflects the additional time that baggage can spend waiting at various checkpoints during the disinfection and testing phases. Without disinfection, the downtime is less—2 min. A more optimized process without the need for disinfection or retesting results in less downtime for baggage. The simulation was run 20 times, and each time, the results remained within the statistical error of a few percent. In general, the number of runs does not affect the repeated result, as the simulation was set up to show the percentage probability of infected baggage.

5. Experimental Part: Non-Selective Luggage Disinfection System upon Arrival from High-Risk Countries

The main difference in the second model is the movement of the disinfection process from the first stage (before the departure of the plane) to the second stage (upon the arrival of the plane). This system allows a more flexible response to the emerging risks of diseases and pandemics, as well as a more responsible approach to the disinfection process, because the country where the passenger plane arrives will not count on the quality of the disinfection services provided in the sending country.

Shifting the disinfection process from the baggage loading phase to the aircraft unloading phase will avoid the risk of flight departure delays, as the increase in time for baggage collection is not as critical as the increase in time for flight departure.

The second example used the same principles of the Tecnomatix Plant Simulation as the first example. The same times were used for the luggage check-in processes, disinfection, and transportation. The same LPN process control system was also used. The second model is shown in

Figure 8.

The main difference is that there is no process for scanning luggage for viruses. Instead, attention is paid to which country the plane is arriving from and whether that country is in a black zone, in which case, all pieces of luggage are disinfected upon arrival. In cases in which a plane arrives from a green-zone country, all luggage moves directly to the place of its delivery to the passengers.

To understand the impact of this approach on non-selective disinfection, a simulation was run, and the resulting process times were analyzed.

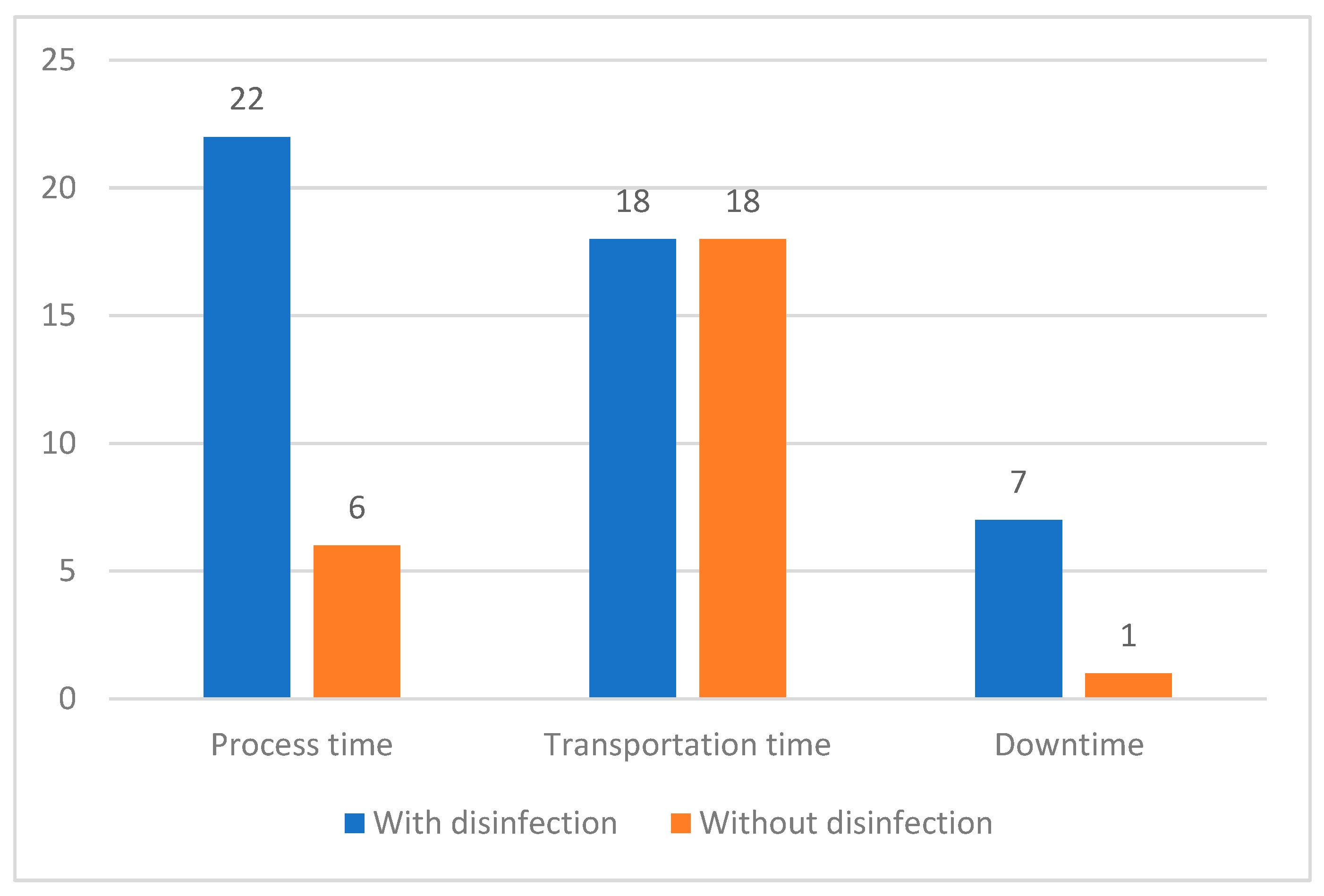

Figure 9 illustrates the change in the distribution of time between the different processes after the introduction of disinfection.

The difference between the passage time of a unit of luggage with and without disinfection was 12 min. The peculiarity of the second simulation is that it is adaptive and adjusts to the incidence rates in the country from which the plane arrives. This means that the amount of disinfected luggage will be 100% or 0%. In the case of full disinfection, the total simulation time increases by 34.2%.

The transportation time takes up a significant portion of the processing time. The transportation time remains virtually unchanged regardless of whether disinfection is applied. This is due to the continuous flow of baggage to the delivery point without additional processing.

The downtime, which includes any waiting periods during disinfection or other processes, is 7 min in the case of disinfection, and it is virtually nonexistent in the case of no disinfection. This reflects the time spent ensuring that disinfection procedures are performed properly. The reduction in downtime corresponds to the smoother operation of the baggage handling system without an additional disinfection step.

6. Results

The first model of selective disinfection showed a more adaptive approach to the disinfection process. Because of the selective disinfection process, the time increase was 20 min (68.7%). On the other hand, this system needs more conveyors and contains a testing process. The baggage testing process could represent a weak point in this system, as test results can sometimes arrive too late and, currently, the technology does not allow for the quick and universal detection of a wide spectrum of viruses and bacteria simultaneously.

Furthermore, a problem may arise if disinfection is performed with soap or any other solution in addition to UV light. This makes retesting impossible, and should therefore be excluded from the system.

The second model of non-selective luggage disinfection allows a more flexible response to emerging disease and pandemic risks, as well as a more responsible disinfection process, since the country where the passenger aircraft arrives will not rely on the quality of disinfection services provided in the sending country.

Shifting the disinfection process from the baggage loading stage to the aircraft unloading stage will avoid the risk of flight departure delays, as the increase in time for baggage collection is not as critical as the increase in time for flight departure.

The main difference is that there is no process for scanning luggage for viruses and bacteria. Instead, attention is paid to the country from which the plane is arriving, and whether that country is in a red zone, in which case, all luggage will be disinfected upon arrival. In the case of an aircraft arriving from a country in a green zone, all luggage is sent directly to the delivery point for passengers.

However, the main disadvantage of this system is that there is no process for scanning baggage for viruses and bacteria. This could potentially lead to contaminated luggage being brought into a country.

Both simulations showed a slight increase in the overall disinfection chain time. In the first simulation, the difference between the system with and without disinfection was 20 min (68.7%), while in the second simulation, the difference was 12 min (34.2%) (

Figure 10).

On the other hand, it can be said that the second system is easier and more flexible to use, requires less capital expenditure, and is less exposed to risks due to the smaller number of links.

Table 1 presents a comparative analysis of the selective and non-selective luggage disinfection models across four key parameters: processing time increase, equipment and process requirements, cost implications, and pathogen detection efficacy. Each parameter is evaluated to provide a comprehensive understanding of the operational impacts and effectiveness of each disinfection approach.

By eliminating the need for human cleaning and disinfection, automated disinfection systems can increase the efficiency of airport operations. This may result in less traffic jams, quicker luggage processing, and increased airport productivity. Additionally, automation can guarantee a constant level of disinfection, which is challenging to accomplish with human procedures.

The development and implementation of advanced disinfection systems requires significant upfront investment. This includes research and development costs, the purchase of new equipment, and the training of personnel for operation and maintenance. Compatibility issues, the need for extensive testing, and potential system failures are risks that must be carefully managed. In addition, maintaining and updating these systems over time can be complex and costly.

While automation can increase efficiency, it also introduces the risk of disruption in the event of a system failure. For example, if an automated disinfection system fails, this can lead to delays or require manual intervention, which can negate part of the efficiency gains.

7. Discussion

In this study, we examined the implementation of automated baggage disinfection systems at airports, but several limitations should be recognized. First, the simulation environment used in this study, while sophisticated, cannot fully replicate the complexities of a real-world airport environment. Factors such as different passenger behaviors, unexpected delays, and the nuances of human interactions with luggage were not comprehensively modeled. Therefore, the results may not fully reflect how these disinfection systems will function in real-world airport environments.

The range of pathogens considered in this study was primarily focused on SARS-CoV-2 and a few selected bacteria. This focus may limit the generalizability of the results to other pathogens that may behave differently in the context of baggage transfer and disinfection. The efficacy of disinfection systems against a wider range of viruses and bacteria, especially those with different survival characteristics on surfaces, remains to be tested.

Another limitation is the assumption that disinfection systems will work in the same way for different types of baggage. In this study, we did not consider the variability in the materials used to make the luggage, which can affect the effectiveness of UV and other disinfection methods. For example, porous or textured surfaces may hold pathogens more persistently than smooth surfaces, potentially reducing the effectiveness of the disinfection process.

In addition, the selective disinfection model is heavily dependent on the accuracy of the initial testing phase, which, in this study, was considered to be near-perfect. In reality, diagnostic tests can give false negatives, allowing contaminated baggage to bypass the disinfection process. This possibility could undermine the effectiveness of the selective disinfection approach and pose a risk to public health.

These limitations emphasize the need for further research and testing in real-world environments to validate the findings and address the gaps identified in this study.

To increase the reliability and applicability of this study, several research improvements could be made in future research. One significant improvement would be to incorporate real-world data into the simulation models. By integrating data from real airport operations, including passenger traffic, baggage types, and disinfection system performance, future studies could provide more accurate and generalizable results. In addition, testing the proposed disinfection systems in real-world airport environments would be invaluable to validate the simulation results and identify practical issues that may not be apparent in a virtual environment.

Further research could also examine the long-term impact of repeated disinfection on baggage materials, as this could affect both baggage durability and passenger satisfaction. The interaction of disinfection systems with testing methods should also be highlighted. The further development of these methods would definitely improve the effectiveness of our disinfection system.

These improvements would not only enhance current research, but also contribute to the broader goal of ensuring that airports operate more safely and efficiently in the face of current and future public health challenges.

8. Conclusions

In the interest of stopping the spread of infectious diseases, this study offers two approaches to disinfecting luggage. The first type is a selective disinfection system, in which only luggage that fail the test in which they are scanned for microbes and viruses are disinfected. The second model, in which all luggage is disinfected upon arrival from high-risk countries, is a non-selective disinfection system.

The simulation results show that the selective disinfection system demonstrates an efficient process, with a minimal increase in processing time. The selective disinfection model showed a more adaptive approach to the disinfection process, with a time increase of 20 min (68.7%). The non-selective disinfection model allows for a more flexible response to emerging disease and pandemic risks, and it is less exposed to risks due to the smaller number of links. However, this system does not involve scanning luggage for viruses and bacteria, which could potentially lead to contaminated luggage being brought into the country.

Ultimately, the best system for a particular airport will depend on several factors, including the level of risk of disease transmission, the cost of the system, and the impact on passengers, as well as the specific needs and regulations of the country or region. Further research and consultation are therefore required before a final decision can be made. These practical innovative models, which were tested in a simulation environment, are valuable for airport authorities and policymakers in tailoring disinfection systems to their unique contexts.

In this research, we point out that the first model of selective disinfection offers an adaptive approach with only a moderate increase in processing time (20 min). However, it requires additional equipment and its testing process can be delayed, especially when certain disinfectants are used, making retesting impossible.

In contrast, the second non-selective model eliminates the need for pathogen scanning by disinfecting all luggage from high-risk countries upon arrival. Its advantages include greater flexibility in responding to emerging diseases, the avoidance of flight departure delays, and a more reliable disinfection process, as it does not rely on the quality of services from the departure country.

This research advances the field of airport hygiene by introducing new, effective, and flexible models of disinfection. These models not only improve operational efficiency and environmental sustainability, but also provide reliable solutions to manage the risks associated with the transmission of infectious diseases via air transport.

From the results of this study, we recommend that airports consider implementing a non-selective disinfection system on arrival from high-risk countries. This system is more flexible and cheaper than a selective disinfection system and is less exposed to risks.

We also recommend that airports continue to monitor the situation and adjust their disinfection protocols as necessary. Airports should consider setting up a system to scan baggage for viruses and bacteria if the risk of disease transmission increases.

We hope this study will help airports to make informed decisions about baggage disinfection and protect the health of their passengers and staff.