A Patent Mining Approach to Accurately Identifying Innovative Industrial Clusters Based on the Multivariate DBSCAN Algorithm

Abstract

1. Introduction

2. Literature Review

2.1. The Definition of IIC

2.2. Data Source of Industrial Clusters Research

2.3. Identification Algorithms

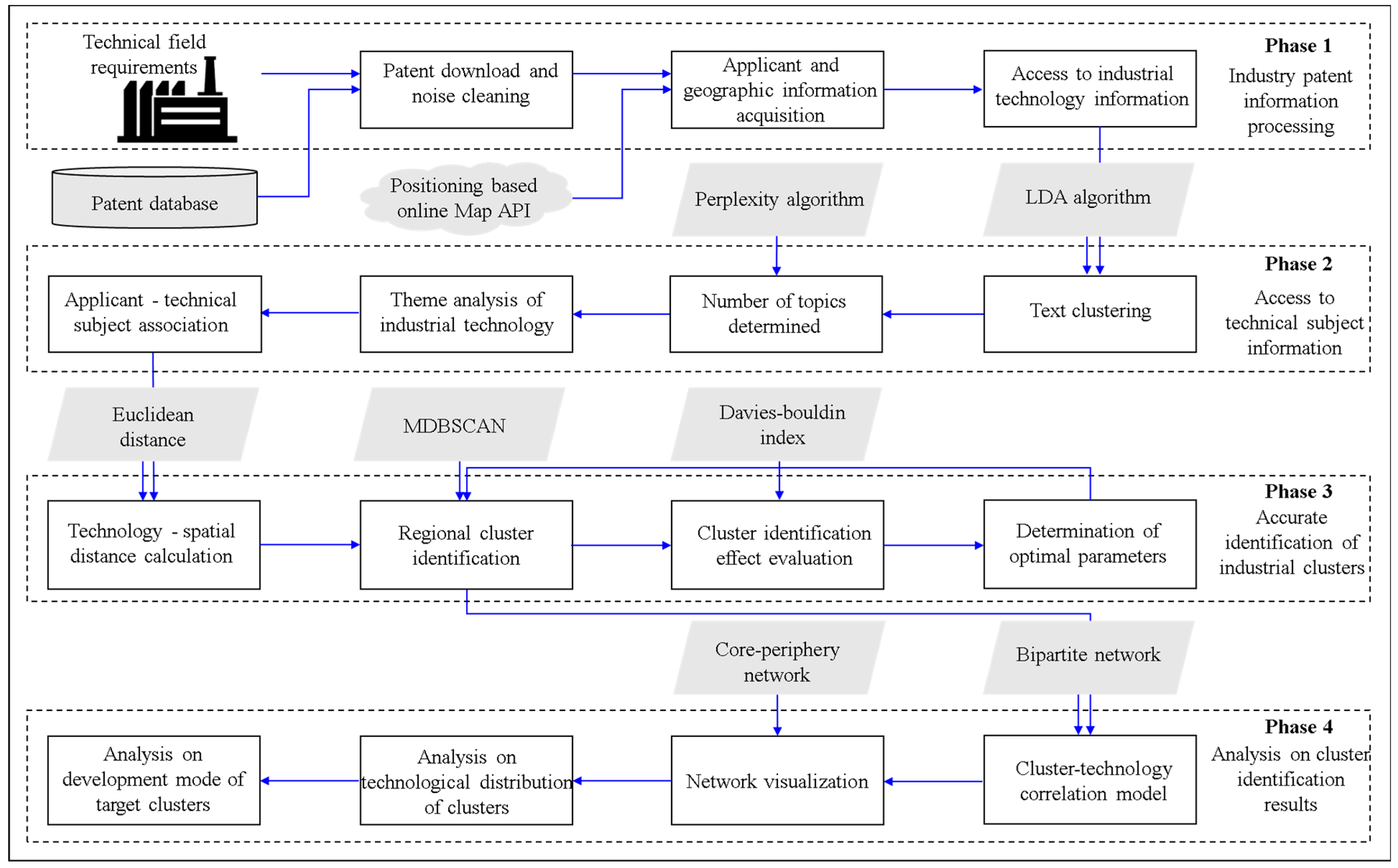

3. Research Framework and Methodology

3.1. Patent Geographic Information Mining Based on Applicants and API Map

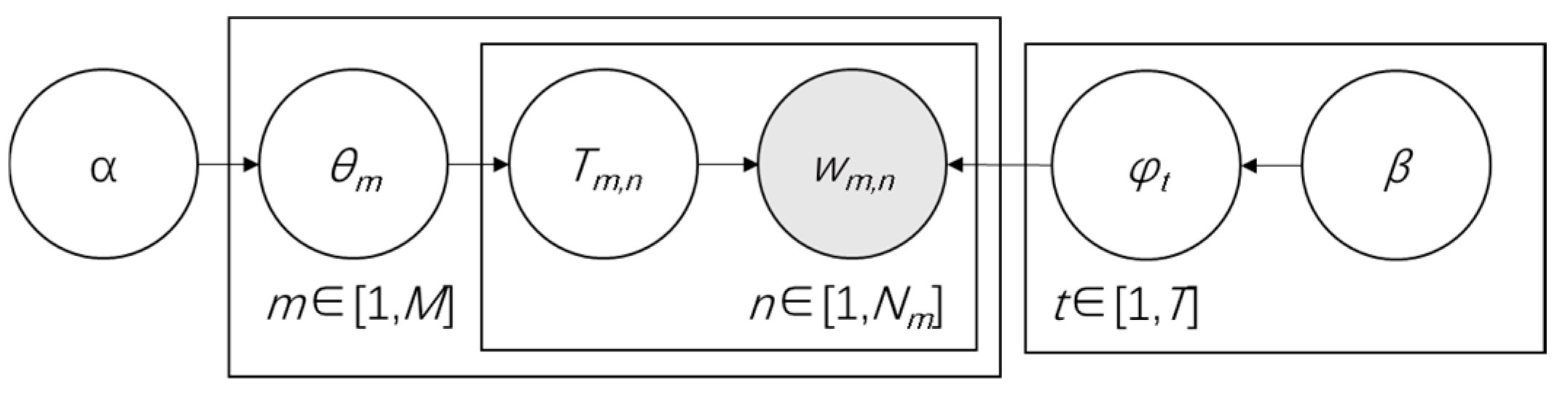

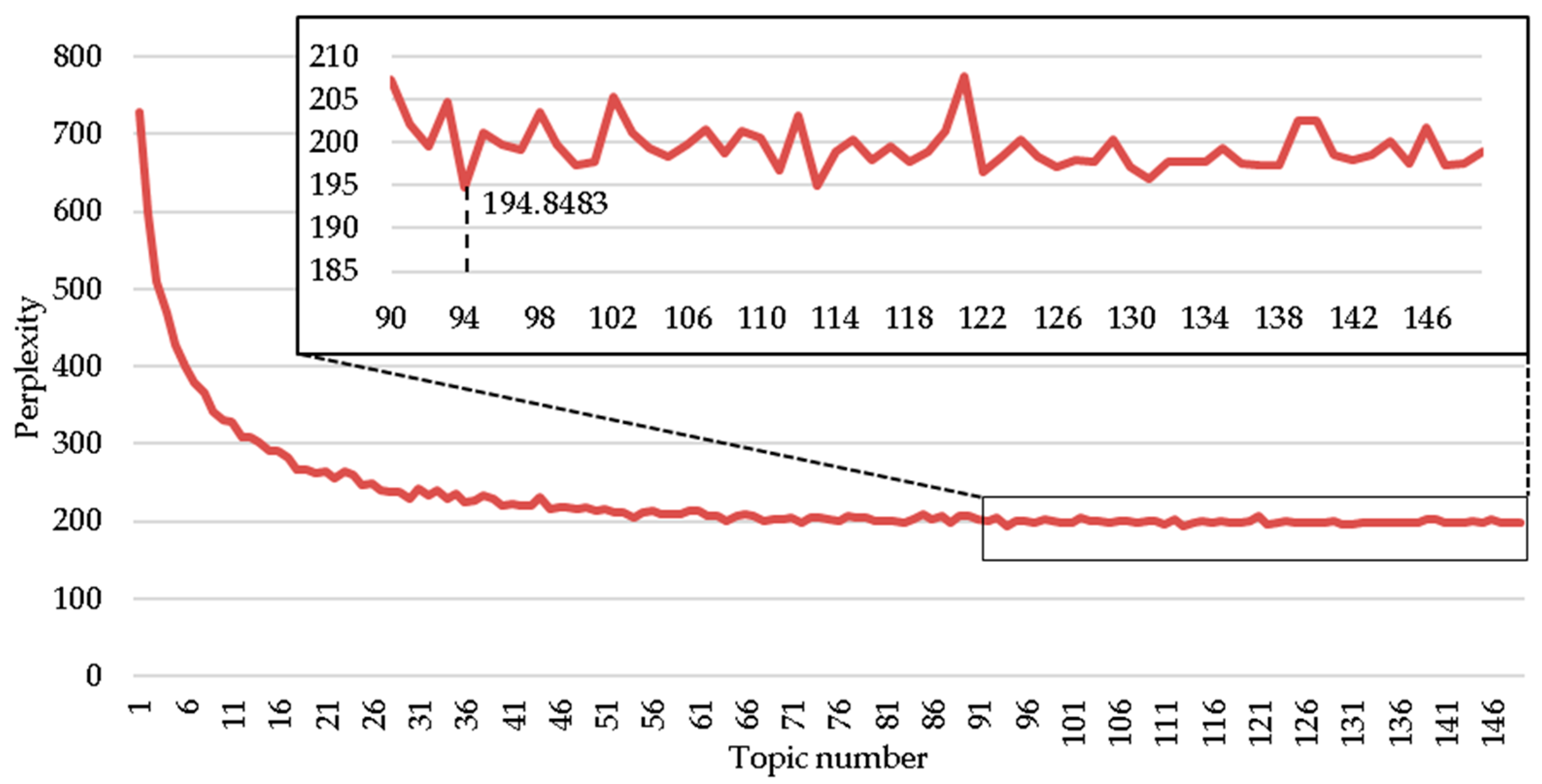

3.2. Patent Technological Subject Acquisition Based on the LDA Model

3.3. Accurate Identification of Industrial Clusters Based on MDBSCAN

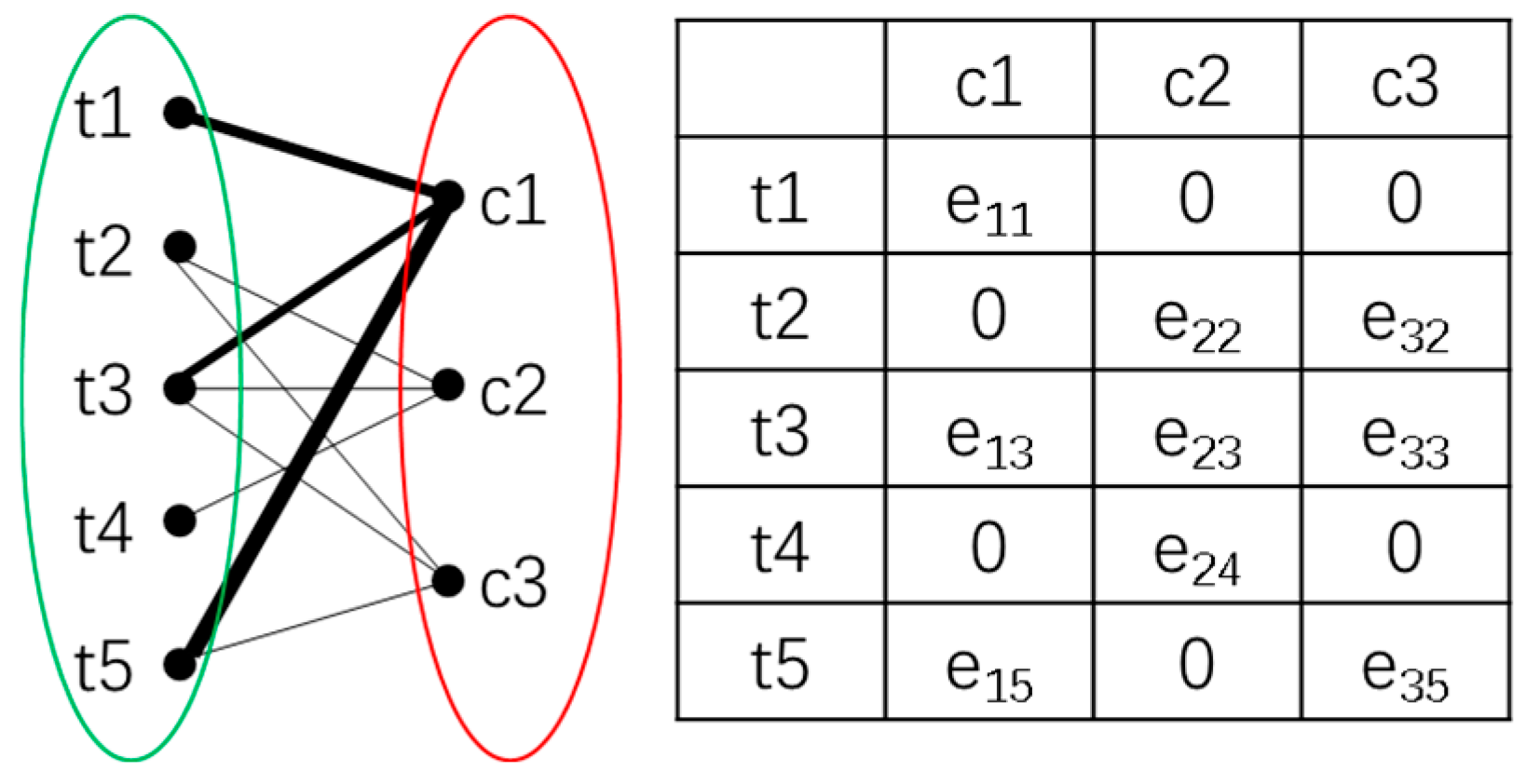

3.4. Analysis of Cluster Identification Results with Bipartite Network

4. Empirical Research

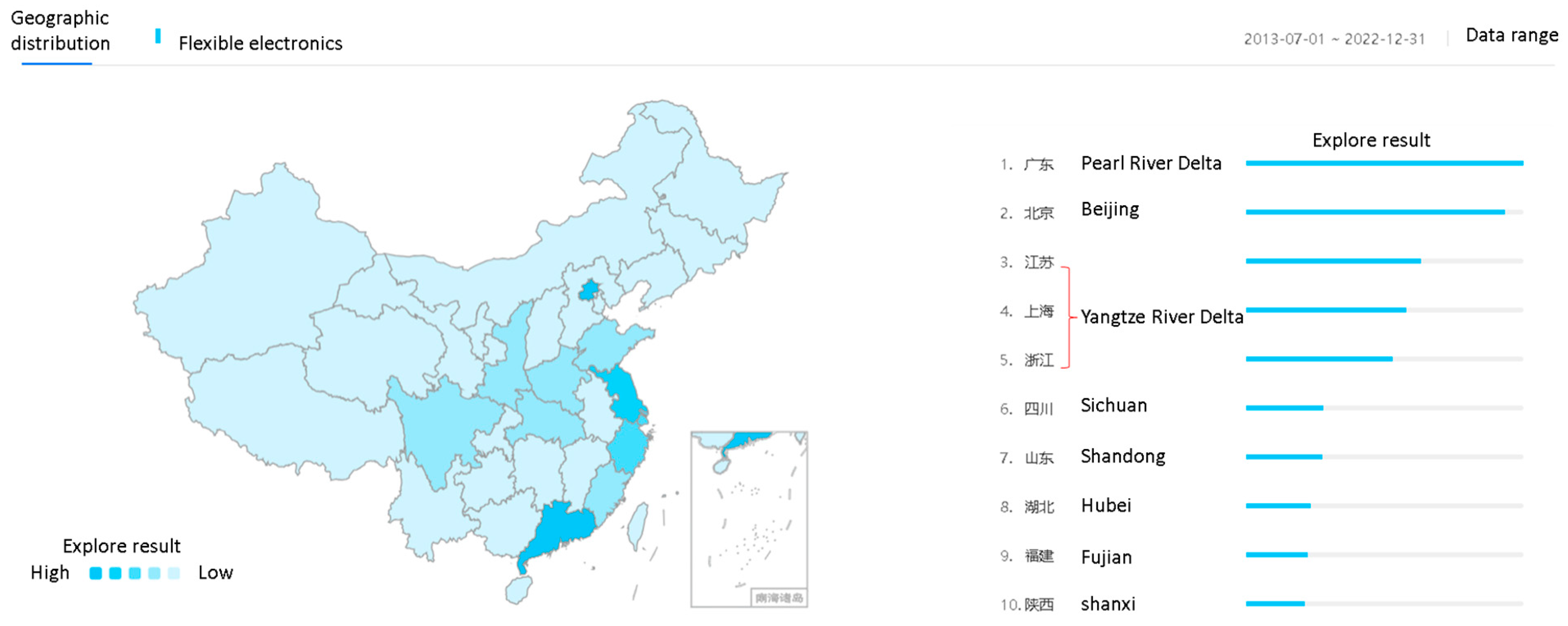

4.1. Data Collection

4.2. Obtaining Technology Topic and Keywords

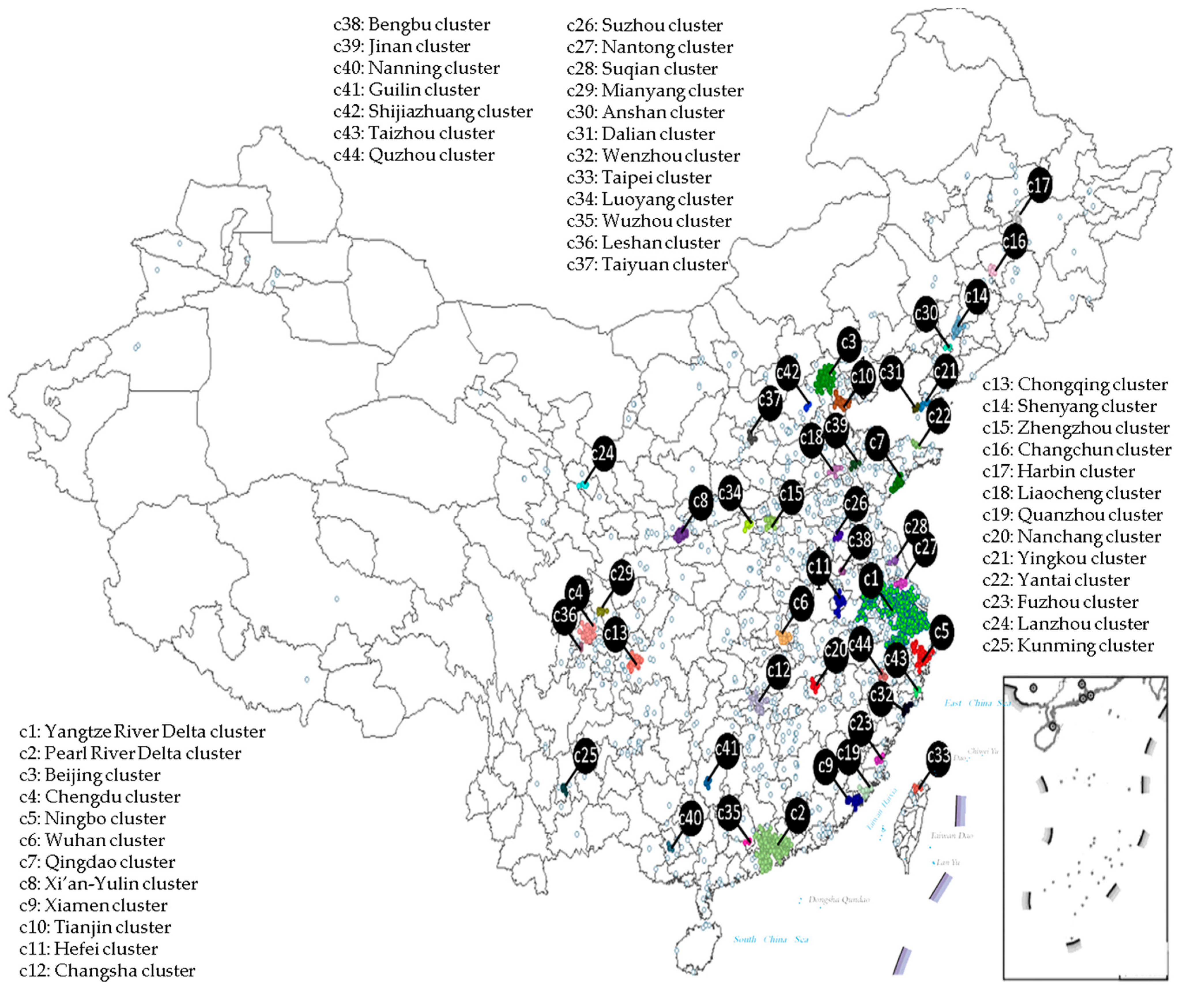

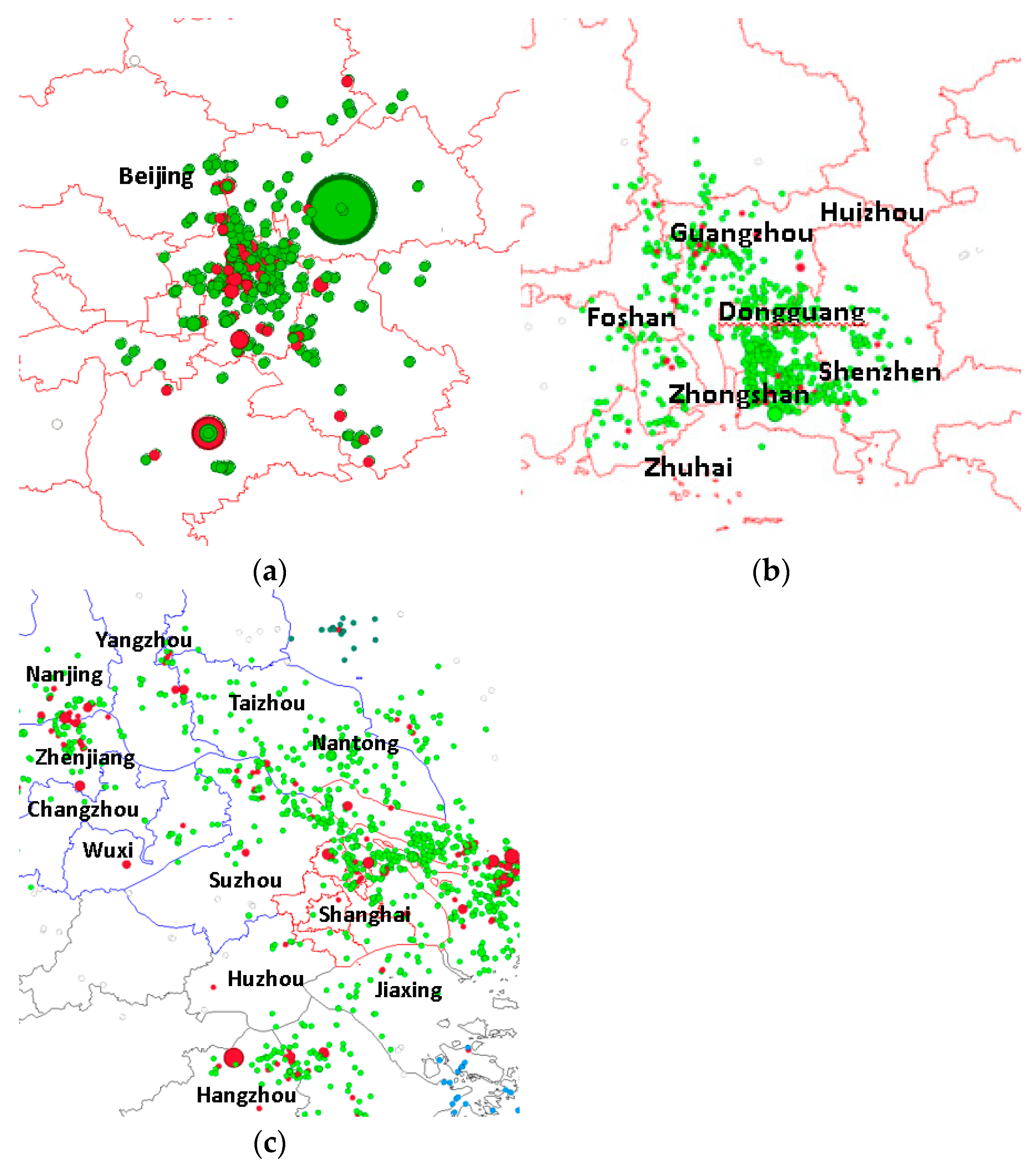

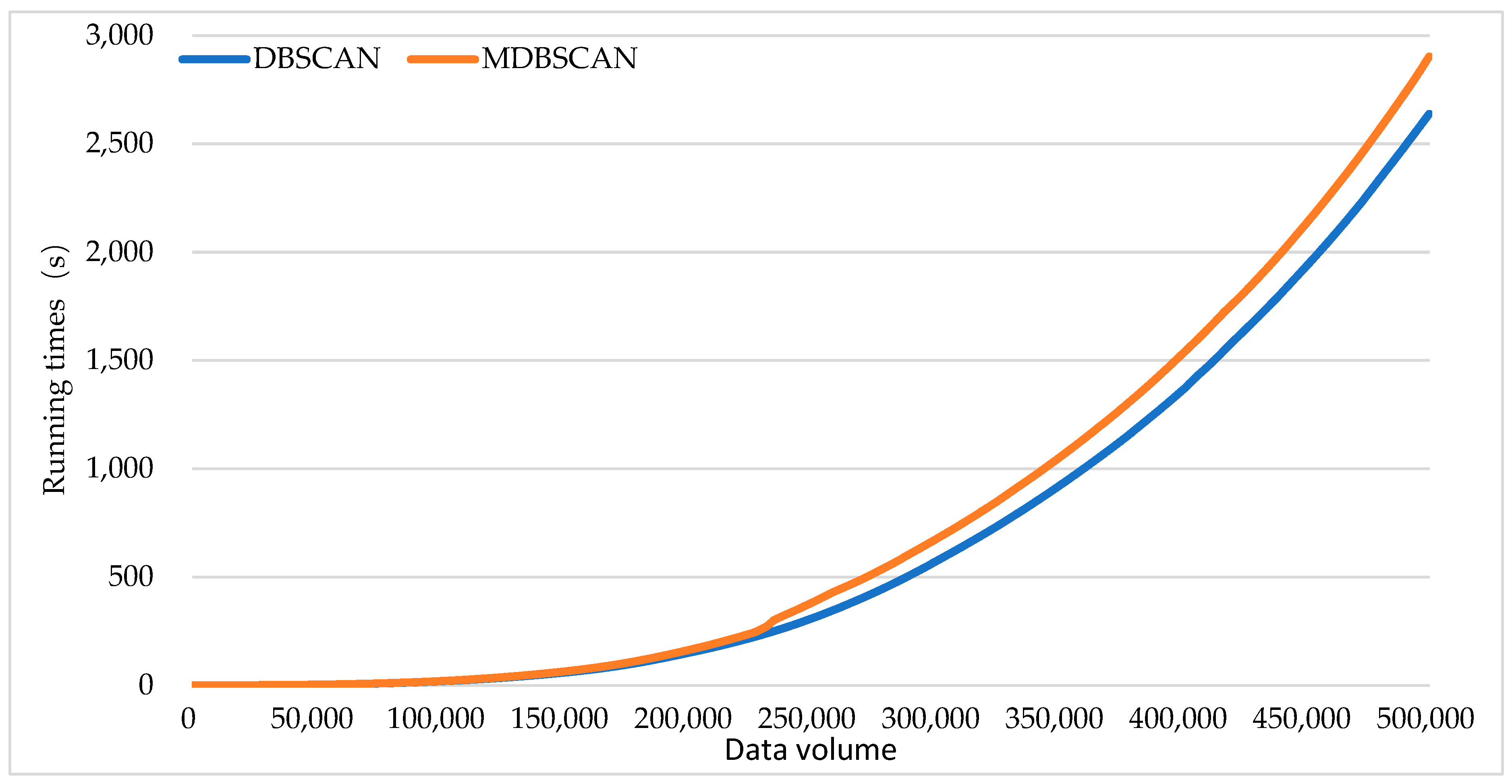

4.3. FEI Clusters

4.4. Clusters Identification Results Analysis

5. Discussion

5.1. Comparison with the Previous Approaches

5.2. Impact on Industry Cluster Research

6. Conclusions and Limitations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. The Pseudo Code for MDBSCAN Preprocessing

| Algorithm A1: MDBSCAN |

| 1. Input: Patent data DB 2. Output: A set of clusters. 3. /*Step 1: Extraction of space data and technological data*/ 4. Data_space = data[‘space’] 5. Data_technological = data[‘lda_topic’] 6. /*Step 2: Calculation of space distance and technological distance*/ 7. Import Euclidean_Distance algoritham 8. sd = Euclidean_Distance(Data_space) 9. td = Euclidean_Distance(Data_technological) 10. /* Step 3: Run MDBSCAN algorithm*/ 11. for sdmin in range(sd): 12. for tdmin in range(td): 13. for xmin in range(x): 14. if((sd ≤ sdmin)&(td ≤ tdmin)): 15. C = 0; 16. for each point P in database DB: 17. if label(P) != undefined 18. continue 19. Neighbors N = RangeQuery(DB, p, sdmin, tdmin) 20. if |N| < xmin: /* if number of neighbors less than xmin, P is set as noise*/ 21. label(P) = Noise 22. continue 23. C = C + 1 24. label(P) = C /*Initiation of clusters label*/ 25. Seed set S = N \{P} 26. for each point Q in S{ 27. if label(Q) = Noise: 28. label(Q) = C 29. if label(Q) != undefined: 30. continue 31. label(Q) = C 32. Neighbors N = RangeQuery(DB, p, sdmin, tdmin) 33. if N ≥ xmin: 34. S = S.append(N) /* neighbors set N are append in seed set S */ 35. end 36. end 37. end 38. end 39. end 40. end |

Appendix B. LDA Topic Classification Results

| No. | Topic | Keywords |

| T1 | Polyacrylate | Tubular furnace, bottom plate layer, coating layer, polyacrylate, RNN |

| T2 | Metal nanotubes | Driving electrode, dielectric layer, gold nanorod, cladding layer, cathode body |

| T3 | Hydrogel | Preparation, conductivity, sintered product, support matrix, polyacrylamide |

| T4 | Conductive polymer | Polymer materials, conductivity, polymeric materials, polymers |

| T5 | polyurethane | Polyurethane, adhesive, insulation pad, curing adhesive, PU |

| T6 | Polyethylene terephthalate | Polyethylene terephthalate, fiber layer, PET, device |

| T7 | Organic materials | Thiophene polymer, protein film, fiber bundle, nano carbon coating, naphthalene tetramethylene diamine |

| T8 | Conductive adhesive | Bonding, conductive adhesive, epoxy resin, corrosion resistance, flexibility |

| T9 | Carbon based materials | Carbon nano, tube-based, foam layer, graphene, polydimethylsiloxane |

| T10 | Carbon nanomaterials | Film remover, carbon nanofiber membrane, carbon nanotube, organic transistor, hydrogen film |

| T11 | Inorganic materials | Inorganic materials, silk fibroin, indium antimonide, perovskite, inorganic nanometer |

| T12 | Metal foil | Foil, copper foil, emitter, flexible circuit, embedded |

| T13 | Copper indium gallium selenium | Silicon-based substrate, copper indium gallium sulfide selenium sensitized layer, copper indium gallium sulfide selenium sensitized semiconductor, hydrogen ion, solar cell |

| T14 | III-V family | III-V family, gallium arsenide, indium phosphide, gallium nitride, coated surface |

| T15 | Metal nanowires | Conductive film, preparation, silver paste circuit layer, platinum-based bimetallic, platinum-based bimetallic nanowires |

| T16 | Dimethyl siloxane | Dimethyl siloxane, thermal permeation method, wet chemical method, dipole moment, isolation layer |

| T17 | biodegradable | Green, fiber bundle, natural, biological, protein film |

| T18 | liquid metal | Microflow pipeline, melting point, temperature, solidification, robustness |

| T19 | Structured conductive polymer | Structural type, conductivity, conductivity, polyacetylene, carbon nanomaterials |

| T20 | Magnetron sputtering | Compensation meter, mask diagram, touch panel, Magnetron sputtering metal-plated electrode, hardening film |

| T21 | Stretchable | Dense circuit, stretch type, bow tie type, aluminum silver alloy, non-device area |

| T22 | Graphene | Graphene conductive electrode, high membrane-based bonding strength, data cable, amorphous silicon film, output terminal |

| T23 | Cu2SnS3 | Single membrane, Cu2SnS3, hydrophilicity, fuel cell, silicon-coated carbon particles |

| T24 | Flexible | Digital signals, protective devices, plasma elements, organic material layers, bending resistance properties |

| T25 | Co-polyester | Micro nano particles, fiber optic communication, Z-resin, transparency, Co-polyester |

| T26 | developable | Circuit layer, flexibility, folding, electrolyte, size |

| T27 | Nanoparticles | Polymer, conductivity, Magnetron sputtering coater, metal, UV laser |

| T28 | Semiconductor type carbon nanotubes | Generation tube, charge, titanium nitride film layer, carbon nanotube optoelectronic device, enrichment method |

| T29 | Flexible polymer | Elasticity, structural layer, dimethyl carbonate, substrate, printed circuit board |

| T30 | Memory attribute | Photosensitive sensors, gold nanoparticles, nanoimprinting technology, memory alloys, Bragg gratings |

| T31 | Polyimide PI | Tin-based nanocrystals, gallium-based indium tin, silver paste circuit layer, etching solution, polyimide-based |

| T32 | Resistive type | Signal processing circuit, flow meter, pressure, piezoresistive stress sensor, corresponding stress |

| T33 | Lift off process | Graphene glass carbon sheet, ultrasonic induction layer, linear movement, deposited thin film material, organic adhesive film |

| T34 | Photon welding | Zinc oxide nanotubes, nano photons, resin-like vacuum deposition, peripheral circuit, UV curing |

| T35 | Low-temperature soldering | Non-contact circuit, high temperature resistance, solder paste, welding, polymer material fiber mesh |

| T36 | Evaporative deposition | Plasma chemical vapor deposition machine, thin film resistor, tin sol, deposition machine, induction board |

| T37 | Soft etching | Single-material film, fuel cell, corrosion resistance, crystal drying, photolithography and etching, prefabricated film |

| T38 | reactive sputtering | Pre sputtering chamber, buried resistance material layer, impedance tester, flap valve, Magnetron sputtering deposition chamber |

| T39 | Sputter deposition | Magnetron magnetic plating, Magnetron sputtering coating source, deposition particles, roll-to-roll vacuum deposition machine, deposition coating |

| T40 | Atmospheric chemical vapor deposition | Ion chemical vapor deposition, optoelectronics, atmospheric pressure chemical vapor deposition devices, micro/nano optics, conductive sheets |

| T41 | Arc evaporation | Super hydrophobicity, zinc oxide nanowires, arc ion plating, arc ion plating, DC arc spraying method |

| T42 | Plasma enhanced chemical deposition | Silicon oxide micro ring core cavity, chemical vapor deposition cavity, deposition insulation layer, pulse power supply, chemical vapor deposition reaction chamber |

| T43 | screen printing | Substrate film, ink, pattern, semiconductor tube, scraper |

| T44 | Additive manufacturing | 3D printing, gel electrolyte, main arc power supply, UV curing, lamination |

| T45 | Electron beam evaporation | Zinc oxide nanocrystals, polymer-based composites, passivation alloys, near-infrared reflectance, electron beam current, |

| T46 | RF sputtering | Vacuum conditions, thin films, direct current, power, temperature |

| T47 | Laser pulse evaporation | Dielectric layer, nano plating, laser pen, pulsed light, alkaline solution |

| T48 | Piezoelectric method | Ultrasonic motor, integrated module, piezoelectric coefficient, electromechanical resonator, consistency |

| T49 | Inkjet printing | Hydrogen film, substrate, carbon ink, organic liquid source, polymethyl methacrylate, |

| T50 | Transfer Integration | Integrated variable torque sensor, seal, substrate, heating element, circuit board heat transfer printing |

| T51 | Nanoimprinting | Electron beam, template, transparent strip, flexible circuit strip, nano imprinted substrate |

| T52 | Dry preparation | Surface nanostructure, photoresist, semiconductor device, dry etching, roughness |

| T53 | Wet preparation | Electromagnetic shielding film, wet etching machine, drilling, high-frequency mixed pressure, electroplating |

| T54 | Low pressure chemical vapor deposition | Plasma chemical vapor deposition machine, atomic flow, thin film, temperature, pressure |

| T55 | Photolithography | Corrosion resistance, laser, photolithography, concentric ring, grating |

| T56 | Capacitive type | Sensors, capacitors, nanowires, pressure, conductivity |

| T57 | Hot bubble method | Heat dissipation, metal nano ink, high-temperature sintering, particle-free copper ink, thermoplastic ink powder |

| T58 | Roll to roll preparation | Thermal conductive layer, deposited particles, roll-to-roll vacuum deposition machine, array, carbon nanotubes |

| T59 | DC sputtering | Nanoimprint adhesive, deposition layer, metal frame, DC sputtering, current |

| T60 | Resistive evaporation | Passive resistance film, coating machine, thin film, hole lithography, inflatable pump |

| T61 | Chemical vapor deposition | Chemical vapor deposition, photonic crystal period, cathode to ground, source plate, preparation method |

| T61 | Porous deposition | Porous, thin film, deposition system, agglomeration device, ion beam |

| T63 | Sol gel method | Bare electrode, sol gel method, synthetic rubber, magnetic absorber, silicon substrate |

| T64 | Inorganic display | Inorganic electroluminescence, substrate, luminescent material, display screen, coating |

| T65 | Blood oxygen | Blood oxygen signal, sensor, health, parameters, measuring instrument |

| T66 | Mechanical energy generation | Power generation film, generator, motor, energy, mechanism |

| T67 | Electroencephalogram | Sensitivity, recognition, intention, EEG signals, head-mounted |

| T68 | Piezoelectric type | Thermoelectric materials, pressure sensors, arrays, touch, sensitivity |

| T69 | temperature | Integrated sensing, ambient temperature, variable shape, sensor, thermal interface |

| T70 | Organic semiconductor | Micro lens, electrode block, organic insulation layer, electroplated nickel, crystalline silicon solar energy |

| T71 | pressure | Adhesive, artificial intelligence, pressure sensing, direct current method, die-casting mold |

| T72 | display | Organic field-effect transistor, large amplitude, bipolar plate, display screen, curved screen |

| T73 | chronic disease | Chronic diseases, physiological monitoring sensors, deposition rate, powder cavity, nanoliposomes |

| T74 | Silicon thin film battery | Silicon film, nanoribbons, solar energy, insulation board, sic |

| T75 | humidity | Flow generation, conductive mesh, temperature and humidity, water treatment, dampers |

| T76 | Dye sensitized battery | Photosensitive materials, solar cells, gate metal electrodes, sensitivity, transformers |

| T77 | Communication device NFC | Magnetron sputtering metal plating electrode fixture, real-time communication, auxiliary substrate, isolator, digital signal transmission |

| T78 | Perovskite battery | Solar cells, transparent electrodes, formamidine perovskite, nano copper aerosols, zirconium targets |

| T79 | Optoelectronics | Copper wire layer, insulation layer, light trough, photodetector, conductive silicone adhesive layer |

| T80 | Organic display | Registers, organic luminescent material films, prepackaging, prepackaging layers, wire racks |

| T81 | Thin film solar cells | Electrode block, organic insulating layer, electroplated nickel, crystalline silicon solar energy, flexible circuit board |

| T82 | ultra-thin glass | Float glass, high vitrification, chemical vapor deposition chamber, deposition insulation layer, pulse power supply |

| T83 | strain | Regulator, strain gauge, torsion wheel, torque sensor, display end |

| T84 | Inorganic semiconductor | Silicon dioxide layer, titanium dioxide photocatalytic network, target base, Raman spectroscopy, semiconductor materials |

| T85 | clothing | Medical clothing, work clothes, flexible sensors, intelligence, functionality |

| T86 | automobile | Film-forming agent, humanized automotive parts, electrode part, flexible roll |

| T87 | Energy storage | Flexible lithium-ion batteries, flexible electrolytes, carbon nanotubes, porous carbon nanofiber films, electrolytes |

| T88 | fingerprint | Sensors, sensing circuits, signals, fingerprint modules, bonding effects |

| T89 | packing | RFID, high mechanical strength, accommodating parts, labels, circuits |

| T90 | Energy collection | Battery, energy, electrode, preparation method, positive electrode |

| T91 | Industry 4.0 | Industry 4.0, intelligent online, wireless, sensor, portable |

| T92 | fault diagnosis | Pressure, capacitive, sensor, load, equipment failure |

| T93 | Wearable | Intelligent device, flexible display screen, bracelet, touch signal, cover glass |

| T94 | medical care | Flexible paddles, polypropylene, substrate holder, healthcare, water absorption |

References

- Zhuang, Z.; Fu, S.; Lan, S.; Yu, H.; Yang, C.; Huang, G.Q. Research on economic benefits of multi-city logistics development based on data-driven analysis. Adv. Eng. Inform. 2021, 49, 101322. [Google Scholar] [CrossRef]

- Marshall, A. Principles of Economics; Macmillan and Co.: London, UK; New York, NY, USA, 1890. [Google Scholar]

- Porter, M.E. The Competitive Advantage of Nations; Free Press: New York, NY, USA, 1990; 855p. [Google Scholar]

- Zhuang, T.; Zhao, S.L. Collaborative innovation relationship in Yangtze River Delta of China: Subjects collaboration and spatial correlation. Technol. Soc. 2022, 69, 101974. [Google Scholar]

- Huang, Q. Reconstruction of the global industrial chain under the epidemic—Develop an industrial chain cluster combining horizontal division of labor and vertical integration. China Econ. Wkly. 2020, 780, 24–29. [Google Scholar]

- Nishimura, J.; Okamuro, H. R&D productivity and the organization of cluster policy: An empirical evaluation of the Industrial Cluster Project in Japan. J. Technol. Transf. 2011, 36, 117–144. [Google Scholar]

- Guzman, J.; Stern, S. Where is Silicon Valley? Science 2015, 347, 606–609. [Google Scholar] [CrossRef]

- Best, M.H. Greater Boston׳s industrial ecosystem: A manufactory of sectors. Technovation 2015, 39, 4–13. [Google Scholar] [CrossRef]

- Filatotchev, I.; Liu, X.; Lu, J.; Wright, M. Knowledge spillovers through human mobility across national borders: Evidence from Zhongguancun Science Park in China. Res. Policy 2011, 40, 453–462. [Google Scholar] [CrossRef]

- Yongsheng, X.; Xiaole, Z.; Wei, W. Coupling or lock-in? Co-evolution of cultural embedders and cluster innovation-exploratory case study of Shaoxing textile cluster. Technol. Soc. 2021, 67, 101765. [Google Scholar] [CrossRef]

- China Ministry of Science and Technology, Measures for Pilot Certification of Innovative Industrial Clusters. Available online: https://www.most.gov.cn/xxgk/xinxifenlei/fdzdgknr/qtwj/qtwj2013/201307/t20130702_106869.html (accessed on 20 March 2024).

- China Ministry of Industry and Information Technology. Guiding Opinions of the Ministry of Industry and Information Technology on Further Promoting the Development of Industrial Clusters. Available online: https://www.gov.cn/gongbao/content/2015/content_2975894.htm (accessed on 20 March 2024).

- China Ministry of Industry and Information Technology. Measures for Promoting the Development of Characteristic Industrial Clusters of Small and Medium Enterprises. Available online: https://www.gov.cn/zhengce/zhengceku/2022-09/14/content_5709725.htm (accessed on 20 March 2024).

- Karreman, B.; Burger, M.J.; van Eenennaam, F. Revealed competition between cluster organizations: An exploratory analysis of the European life sciences sector. Environ. Plan. A 2018, 51, 705–723. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Ma, C. A research on the cluster competitiveness evaluation of the Chinese automobile industry based on cuckoo-AHP. Chin. Manag. Stud. 2016, 10, 746–769. [Google Scholar] [CrossRef]

- Geum, Y.; Kim, M.; Lee, S. How industrial convergence happens: A taxonomical approach based on empirical evidences. Technol. Forecast. Soc. Chang. 2016, 107, 112–120. [Google Scholar] [CrossRef]

- Sun, C.C.; Lin, G.T.R.; Tzeng, G.H. The evaluation of cluster policy by fuzzy MCDM: Empirical evidence from HsinChu Science Park. Expert. Syst. Appl. 2009, 36, 11895–11906. [Google Scholar] [CrossRef]

- Dimos, C.; Fai, F.M.; Tomlinson, P.R. The attractiveness of university and corporate anchor tenants in the conception of a new cluster. Reg. Stud. 2021, 55, 1473–1486. [Google Scholar] [CrossRef]

- Xiao, R.B. Four development stages of collective intelligence. Front. Inf. Technol. Electron. Eng. 2024, 25, 903–916. [Google Scholar] [CrossRef]

- Anselin, L. Local Indicators of Spatial Association-LISA. Geogr. Anal. 2010, 27, 93–115. [Google Scholar] [CrossRef]

- Voyer, R. Knowledge-Based Industrial Clustering: International Comparisons. In Local and Regional Systems of Innovation; Springer: Boston, MA, USA, 1998; pp. 81–110. [Google Scholar]

- Simmie, J.; Sennett, J. Innovative clusters: Global or local linkages? Natl. Inst. Econ. Rev. 1999, 170, 87–98. [Google Scholar] [CrossRef]

- Xiong, W.; Li, J. The Knowledge Spillover Effect of Multi-Scale Urban Innovation Networks on Industrial Development: Evidence from the Automobile Manufacturing Industry in China. Systems 2024, 12, 5. [Google Scholar] [CrossRef]

- Guo, B.; Guo, J. Patterns of technological learning within the knowledge systems of industrial clusters in emerging economies: Evidence from China. Technovation 2011, 31, 87–104. [Google Scholar] [CrossRef]

- Engel, J.S.; Del-Palacio, I. Global networks of clusters of innovation: Accelerating the innovation process. Bus. Horiz. 2009, 52, 493–503. [Google Scholar] [CrossRef]

- Molina-Morales, F.X.; Martinez-Fernandez, M.T. Social Networks: Effects of Social Capital on Firm Innovation. J. Small Bus. Manag. 2010, 48, 258–279. [Google Scholar] [CrossRef]

- Nie, L.; Wang, Y. Spatial Effects of Service Industry’s Heterogeneous Agglomeration on Industrial Structure Optimization: Evidence from China. Systems 2024, 12, 85. [Google Scholar] [CrossRef]

- Shi, J.; Lai, W. Fuzzy AHP approach to evaluate incentive factors of high-tech talent agglomeration. Expert. Syst. Appl. 2023, 212, 118652. [Google Scholar] [CrossRef]

- McLoughlin, F.; Duffy, A.; Conlon, M. A clustering approach to domestic electricity load profile characterisation using smart metering data. Appl. Energy 2015, 141, 190–199. [Google Scholar] [CrossRef]

- Xu, Y.; Li, X.; Tao, C.; Zhou, X. Connected knowledge spillovers, technological cluster innovation and efficient industrial structure. J. Innov. Knowl. 2022, 7, 100195. [Google Scholar] [CrossRef]

- National Research Council; Policy and Global Affairs. Growing Innovation Clusters for American Prosperity: Summary of a Symposium; National Academies Press: Washington, WA, USA, 2011. [Google Scholar]

- Corrocher, N.; Lamperti, F.; Mavilia, R. Do science parks sustain or trigger innovation? Empirical evidence from Italy. Technol. Forecast. Soc. Chang. 2019, 147, 140–151. [Google Scholar] [CrossRef]

- Delgado, M.; Porter, M.E.; Stern, S. Defining clusters of related industries. J. Econ. Geogr. 2016, 16, 1–38. [Google Scholar] [CrossRef]

- Yang, T.; He, M. Study on the Features of Textile Industry Cluster in Guangzhong. Int. J. Bus. Manag. 2010, 6, 243. [Google Scholar]

- Lan, S.; Yang, C.; Huang, G.Q. Data analysis for metropolitan economic and logistics development. Adv. Eng. Inform. 2017, 32, 66–76. [Google Scholar] [CrossRef]

- Zhao, W.; Watanabe, C.; Griffy-Brown, C. Competitive advantage in an industry cluster: The case of Dalian Software Park in China. Technol. Soc. 2009, 31, 139–149. [Google Scholar] [CrossRef]

- Liu, C. The effects of innovation alliance on network structure and density of cluster. Expert. Syst. Appl. 2011, 38, 299–305. [Google Scholar] [CrossRef]

- Catini, R.; Karamshuk, D.; Penner, O.; Riccaboni, M. Identifying geographic clusters: A network analytic approach. Res. Policy 2015, 44, 1749–1762. [Google Scholar] [CrossRef]

- Lin, W.; Yu, W.; Xiao, R. Measuring Patent Similarity Based on Text Mining and Image Recognition. Systems 2023, 11, 294. [Google Scholar] [CrossRef]

- Liu, C.Y.; Yang, J.C. Decoding Patent Information Using Patent Maps. Data Sci. J. 2008, 7, 14–22. [Google Scholar] [CrossRef]

- Li, X.; Fan, M.; Zhou, Y.; Fu, J.; Yuan, F.; Huang, L. Monitoring and forecasting the development trends of nanogenerator technology using citation analysis and text mining. Nano Energy 2020, 71, 104636. [Google Scholar] [CrossRef]

- Tiefelsdorf, M.; Boots, B. A Note on the Extremities of Local Moran’s I is and Their Impact on Global Moran’s I. Geogr. Anal. 1997, 29, 248–257. [Google Scholar] [CrossRef]

- Trappey, A.J.C.; Pa, R.J.S.; Chen, N.K.T.; Huang, A.Z.C.; Li, K.; Hung, L.P. Digital transformation of technological IP portfolio analysis for complex domain of satellite communication innovations. Adv. Eng. Inform. 2023, 55, 101879. [Google Scholar] [CrossRef]

- Kagawa, S.; Suh, S.; Kondo, Y.; Nansai, K. Identifying environmentally important supply chain clusters in the automobile industry. Econ. Syst. Res. 2013, 25, 265–286. [Google Scholar] [CrossRef]

- Argüelles, M.; Benavides, C.; Fernández, I. A new approach to the identification of regional clusters: Hierarchical clustering on principal components. Appl. Econ. 2014, 46, 2511–2519. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhao, Z.; Zhang, P. A new method for identifying industrial clustering using the standard deviational ellipse. Sci. Rep. 2023, 13, 578. [Google Scholar] [CrossRef]

- Souris, M.; Bichaud, L. Statistical methods for bivariate spatial analysis in marked points. Examples in spatial epidemiology. Spat. Spatiotemporal Epidemiol. 2011, 2, 227–234. [Google Scholar] [CrossRef]

- Anselin, L.; Li, X. Tobler’s Law in a Multivariate World. Geogr. Anal. 2020, 52, 494–510. [Google Scholar] [CrossRef]

- Guo, J.; Lao, X.; Shen, T. Location-Based Method to Identify Industrial Clusters in Beijing-Tianjin-Hebei Area in China. J. Urban. Plan. Dev. 2019, 145, 04019001. [Google Scholar] [CrossRef]

- Billings, S.B.; Johnson, E.B. The location quotient as an estimator of industrial concentration. Reg. Sci. Urban. Econ. 2012, 42, 642–647. [Google Scholar] [CrossRef]

- Lai, Y.L.; Hsu, M.S.; Lin, F.J.; Chen, Y.; Lin, Y. The effects of industry cluster knowledge management on innovation performance. J. Bus. Res. 2014, 67, 734–739. [Google Scholar] [CrossRef]

- Li, C.Z.; Xu, Z.B.; Qiao, C.; Luo, T. Hierarchical clustering driven by cognitive features. Sci. China-Inf. Sci. 2014, 57, 1–14. [Google Scholar] [CrossRef][Green Version]

- Murtagh, F.; Contreras, P. Algorithms for hierarchical clustering: An overview. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2012, 2, 86–97. [Google Scholar] [CrossRef]

- Pavlis, M.; Dolega, L.; Singleton, A. A Modified DBSCAN Clustering Method to Estimate Retail Center Extent. Geogr. Anal. 2018, 50, 141–161. [Google Scholar] [CrossRef]

- Neto, A.C.A.; Sander, J.; Campello, R.J.G.B.; Nascimento, M.A. Efficient Computation and Visualization of Multiple Density-Based Clustering Hierarchies. IEEE Trans. Knowl. Data Eng. 2021, 33, 3075–3089. [Google Scholar] [CrossRef]

- Blei, D.M.; Ng, A.; Jordan, M.I. Latent Dirichlet Allocation. J. Mach. Learn. Res. 2003, 3, 993–1022. [Google Scholar]

- Park, H.; Park, T.; Lee, Y. Partially collapsed Gibbs sampling for latent Dirichlet allocation. Expert. Syst. Appl. 2019, 131, 208–218. [Google Scholar] [CrossRef]

- Yi, K.; Zhou, Z.; Wu, Y.; Zhang, Q.; Li, X. Empathic connectivity of exhibition technology and users in the digital Transformation: An integrated method of social network analysis and LDA model. Adv. Eng. Inform. 2023, 56, 102019. [Google Scholar] [CrossRef]

- Newman, D.; Asuncion, A.; Smyth, P.; Welling, M. Distributed Algorithms for Topic Models. J. Mach. Learn. Res. 2009, 10, 1801–1828. [Google Scholar]

- Andewelt, R.B. Analysis of patent pools under the antitrust laws. Antitrust Law. J. 1984, 53, 611–639. [Google Scholar]

- Liu, Z.; Chen, X.; Xu, W.; Chen, Y.; Li, X. Detecting industry clusters from the bottom up based on co-location patterns mining: A case study in Dongguan, China. Env. Plan. B-Urban. Anal. City Sci. 2021, 48, 2827–2841. [Google Scholar] [CrossRef]

- Malmberg, A.; Maskell, P. The Elusive Concept of Localization Economies: Towards a Knowledge-Based Theory of Spatial Clustering. Environ. Plan. A 2016, 34, 429–449. [Google Scholar] [CrossRef]

- Flores-Sintas, A.; Cadenas, J.M.; Martin, F. Detecting homogeneous groups in clustering using the Euclidean distance. Fuzzy Sets Syst. 2001, 120, 213–225. [Google Scholar] [CrossRef]

- Monticone, L.C.; Snow, R.E.; Box, F. Minimizing Great-Circle Distance Ratios of Undesired and Desired Signal Paths on a Spherical Earth. IEEE Trans. Veh. Technol. 2009, 58, 4868–4877. [Google Scholar] [CrossRef]

- Shang, S.; Zheng, K.; Jensen, C.S.; Yang, B.; Kalnis, P.; Li, G.; Wen, J. Discovery of Path Nearby Clusters in Spatial Networks. IEEE Trans. Knowl. Data Eng. 2015, 27, 1505–1518. [Google Scholar] [CrossRef]

- Fouedjio, F. A hierarchical clustering method for multivariate geostatistical data. Spat. Stat. 2016, 18, 333–351. [Google Scholar] [CrossRef]

- Fouedjio, F. A spectral clustering approach for multivariate geostatistical data. Int. J. Data Sci. Anal. 2017, 4, 301–312. [Google Scholar] [CrossRef]

- García, J.; Crawford, B.; Soto, R.; Castro, C.; Paredes, F. A k-means binarization framework applied to multidimensional knapsack problem. Appl. Intell. 2018, 48, 357–380. [Google Scholar] [CrossRef]

- Aliguliyev, R.M. Performance evaluation of density-based clustering methods. Inf. Sci. 2009, 179, 3583–3602. [Google Scholar] [CrossRef]

- Song, W.; Wang, Y.; Pan, Z. A novel cell partition method by introducing Silhouette Coefficient for fast approximate nearest neighbor search. Inf. Sci. 2023, 642, 119216. [Google Scholar] [CrossRef]

- Ertunç, E.; Karkınlı, A.E.; Bozdağ, A. A clustering-based approach to land valuation in land consolidation projects. Land Use Policy 2021, 111, 105739. [Google Scholar] [CrossRef]

- Xiao, J.; Lu, J.; Li, X. Davies Bouldin Index based hierarchical initialization K-means. Intell. Data Anal. 2017, 21, 1327–1338. [Google Scholar] [CrossRef]

- Katarya, R.; Saini, R. Enhancing the wine tasting experience using greedy clustering wine recommender system. Multimed Tools Appl. 2022, 81, 807–840. [Google Scholar] [CrossRef]

- Zhou, T.; Ren, J.; Medo, M.; Zhang, Y. Bipartite network projection and personal recommendation. Phys. Review. E Stat. Nonlinear Soft Matter Phys. 2007, 76, 46115. [Google Scholar] [CrossRef]

- Hu, Y. Efficient, high-quality force-directed graph drawing. Math. J. 2005, 10, 37–71. [Google Scholar]

- Markusen, A. Sticky Places in Slippery Space: A Typology of Industrial Districts. Econ. Geogr. 1996, 72, 293–313. [Google Scholar] [CrossRef]

- Bagheri, A.; Saraee, M.; de Jong, F. ADM-LDA: An aspect detection model based on topic modelling using the structure of review sentences. J. Inf. Sci. 2014, 40, 621–636. [Google Scholar] [CrossRef]

- Liu, J.; Wei, J.; Liu, Y.; Jin, D. How to channel knowledge coproduction behavior in an online community: Combining machine learning and narrative analysis. Technol. Forecast. Soc. Chang. 2022, 183, 121887. [Google Scholar] [CrossRef]

- Kukalis, S. Agglomeration Economies and Firm Performance: The Case of Industry Clusters. J. Manag. 2010, 36, 453–481. [Google Scholar] [CrossRef]

- Haque, N. Mapping prospects and challenges of managing sludge from effluent treatment in Bangladesh. J. Clean Prod. 2020, 259, 120898. [Google Scholar] [CrossRef]

- Someda, H.; Akagi, T.; Kajikawa, Y. An analysis of the spillover effects based on patents and inter-industrial transactions for an emerging blockchain technology. Scientometrics 2022, 127, 4299–4314. [Google Scholar] [CrossRef]

- Lee, J.; Ko, N.; Yoon, J.; Son, C. An approach for discovering firm-specific technology opportunities: Application of link prediction to F-term networks. Technol. Forecast. Soc. Chang. 2021, 168, 120746. [Google Scholar] [CrossRef]

- Ma, T.; Zhou, X.; Liu, J.; Lou, Z.; Hua, Z.; Wang, R. Combining topic modeling and SAO semantic analysis to identify technological opportunities of emerging technologies. Technol. Forecast. Soc Chang. 2021, 173, 121159. [Google Scholar] [CrossRef]

| Application No. | Patent Title | Applicant | Applicant Address | Longitude and Latitude |

|---|---|---|---|---|

| CN202011550473.0 | A method of making a conductive circuit board | Shenzhen Bairou New Material Technology Co. | No.8 Baoqing Road, Baolong Community, Baolong Street, Longgang District, Shenzhen, Guangdong | 118.09644, 24.48541 |

| CN202010943557.4 | The production method of circuit board with embedded conductive lines | Pengding Holdings (Shenzhen) Co. | Building A1 to Building A3, Peng Ding Park, Song Luo Road, Yan Luo Community, Yan Luo Street, Baoan District, Shenzhen City, Guangdong | 113.86367, 22.79640 |

| CN202010195388.0 | A circuit board and its manufacturing method | Yancheng Wixin Co. | No.999, Yandu Road, Yandu District, Yancheng City, Jiangsu | 120.18987, 33.34369 |

| … | … | … | … | |

| CN201410149990.5 | Preparation of copper-zinc-tin-sulfur films on flexible substrates using magnetron sputtering | Guangdong University of Technology | No.100 Waihuan West Road, Guangzhou University City, Panyu District, Guangzhou City, Guangdong | 113.39960, 23.04570 |

| Rank | sdmin | tdmin | xmin | Number of IIC | DBI |

|---|---|---|---|---|---|

| 1 | 225 | 100 | 5 | 13 | 0.442539712 |

| 2 | 225 | 300 | 5 | 7 | 0.435385726 |

| 3 | 225 | 50 | 5 | 23 | 0.42753337 |

| 4 | 200 | 50 | 5 | 25 | 0.412094281 |

| 5 | 25 | 350 | 10 | 44 | 0.40390312 |

| 6 | 25 | 400 | 10 | 44 | 0.40390312 |

| 7 | 25 | 450 | 10 | 44 | 0.40390312 |

| 8 | 25 | 500 | 10 | 44 | 0.40390312 |

| 9 | 25 | 550 | 10 | 44 | 0.40390312 |

| 10 | 25 | 600 | 10 | 44 | 0.40390312 |

| 11 | 25 | 650 | 10 | 44 | 0.40390312 |

| 12 | 25 | 700 | 10 | 44 | 0.40390312 |

| 13 | 25 | 750 | 10 | 44 | 0.40390312 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, S.; Wang, T.; Lin, W.; Chen, Z.; Xiao, R. A Patent Mining Approach to Accurately Identifying Innovative Industrial Clusters Based on the Multivariate DBSCAN Algorithm. Systems 2024, 12, 321. https://doi.org/10.3390/systems12090321

Zeng S, Wang T, Lin W, Chen Z, Xiao R. A Patent Mining Approach to Accurately Identifying Innovative Industrial Clusters Based on the Multivariate DBSCAN Algorithm. Systems. 2024; 12(9):321. https://doi.org/10.3390/systems12090321

Chicago/Turabian StyleZeng, Siping, Ting Wang, Wenguang Lin, Zhizhen Chen, and Renbin Xiao. 2024. "A Patent Mining Approach to Accurately Identifying Innovative Industrial Clusters Based on the Multivariate DBSCAN Algorithm" Systems 12, no. 9: 321. https://doi.org/10.3390/systems12090321

APA StyleZeng, S., Wang, T., Lin, W., Chen, Z., & Xiao, R. (2024). A Patent Mining Approach to Accurately Identifying Innovative Industrial Clusters Based on the Multivariate DBSCAN Algorithm. Systems, 12(9), 321. https://doi.org/10.3390/systems12090321