Abstract

From the first to the fourth industrial revolutions (4IR) or Industry 4.0 (i4.0), the manufacturing sector has always been at the forefront of innovation and digital technology adoption. However, 4IR or i4.0 comes with diverse and integrated technologies that tend to sweep off all the old orders. This study undertakes a science mapping of research on the role of virtual reality simulation (VRSIM) in manufacturing in the 4IR, which reveals several roles and benefits. The analysis of the conceptual structure of relevant literature highlights the contexts, applications, and relevance of VRSIM in the i4.0 era, including its potent role in predictive modeling and simulation, digital twin and predictive maintenance, additive manufacturing and 3D printing, and virtual manufacturing and immersive virtual digital factory simulation. VRSIM also offers a realistic virtual environment for mapping human–robot collaboration in different manufacturing environments, such as aircraft and automotive assembly lines, evaluating processes, training factory workers on safety, and assessing workers’ ergonomics in digital production and operations. VRSIM in manufacturing offers active research activities, with increasing literature publications and impacts attracting core sources in industrial engineering, manufacturing systems, production and operations, and information technology.

1. Introduction

Digitization of manufacturing operations and processes is not new. From the first industrial revolution to the present Industry 4.0 (i4.0), the manufacturing sector continues to be at the forefront of innovation and digital technology adoption. However, the dimension of the fourth industrial revolution (4IR or i4.0) comes with several integrated technologies that attempt to sweep off the old orders [1]. The advent of the 4IR brought a set of integrated digital technologies capable of transforming traditional manufacturing operations and processes and introducing smart manufacturing [1,2,3]. Among the core digital technologies of the 4IR or i4.0 are virtual reality (VR) and simulation [1,4,5,6,7], which are the focus of this study.

The evolution of i4.0 introduces a set of integrated technologies capable of revolutionizing the manufacturing industry. Some of the allied technologies in 4IR include computer technology, telecommunications, and security architecture, such as the Internet of things (IoT), digital twin (DT), cloud computing, and virtual reality simulation (VRSIM) [1,2,3,4,6,7,8,9,10]. Its key features include the widespread use of the Internet, popularly called the IoT, which connects mobile devices for seamless communication and data exchange, the integration of sensors and intelligent devices into various objects and machines to collect, share, and analyze data to enable automation, pattern recognition, and prediction capabilities [2,3]. Other characteristics of the 4IR include advanced robotics and automation technologies that are transforming industries by enhancing productivity and efficiency and 3D printing technology that enables the creation of complex and customized objects [3,4,6]. Embracing and harnessing its potential while addressing its challenges is essential for ensuring a sustainable and inclusive future. The heightened cybersecurity focus in i4.0 is to ensure robust security measures to protect interconnected systems and sensitive data in smart manufacturing environments [2,3]. Also, cloud computing constitutes a fundamental enabler for i4.0 implementation, mainly by providing limitless, accessible, and scalable virtual storage capacity, enabling industries to store vast amounts of data generated by sensors, IoT devices, and manufacturing processes. Users can access their secure data from anywhere, facilitating real-time monitoring and analysis regardless of geographical location [2,3,4].

While the hype about i4.0 continues, significant improvements are proposed toward advancing the 4IR, leading to the recent conception of Industry 5.0 (i5.0). The emerging i5.0 concept aims to redefine integrated technology to promote human and machine collaboration within the manufacturing landscape (e.g., robots) [3,4]. While i4.0 focuses on integrating advanced technologies and automation, i5.0 emphasizes the cooperation and synergy between humans and machines [3].

VR and simulation existed several decades before i4.0 and traveled separate routes before forming a symbiotic relationship that came to be known as virtual reality simulation (VRSIM), a term coined by Akpan [7] in the early 2000s. Since then, several VRSIM applications have been implemented in healthcare and industrial organizations, e.g., [5,6]. However, other terms, such as “VR Simulation”, “Immersive VR Simulation”, “desktop VR”, and “3D simulation/visualization”, are terms also used by experts to denote the VRSIM concept [7,8,9]. In other instances, VR and simulation can be implemented in collaboration with other related visualization techniques, including augmented reality (AR) as mixed reality [10]. The proliferation of three-dimensional (3D) animation and the increased use of animated graphics on the Internet meant that 3D visualization had become commonplace, causing simulation practitioners to look closer at the benefits of adopting 3D displays in discrete-event simulation (DES) [8,9,10].

In the mid-2000s, Akpan and Brooks [11,12] implemented a VRSIM perspective model of an auto assembly simulation system and evaluated the costs and benefits of VRSIM applications in DES [13]. The clear benefits of VRSIM include advanced visualization capabilities, better clarity, and insight into simulated manufacturing systems, especially for non-technical stakeholders, top management buy-in, and increased acceptance of simulation project outcomes [8,11,12]. These benefits outweighed any associated implementation costs, meaning that it was a matter of time before all simulation practitioners and users accepted this reality [8,9]. A decade later, Turner et al. [13], while examining the trends in manufacturing simulation, assert that the initial limitations of 3D/VR due to the long learning curve and increased model development time identified by Akpan and Brooks [11,12] have been overtaken by improved technology and advanced DES modeling tools with simple drag-and-drop functionalities [13,14]. VRSIM helped in solving a long-standing problem in simulation projects where top management doubted the authenticity of simulation results because it was difficult to relate to the mysterious simulation black box, churning out results that managers did not understand or could not relate to [15,16].

As the global manufacturing landscape continues to experience profound transformation in the 4IR, VRSIM plays significant roles in virtual product design, digital twin and predictive maintenance, and efficient and adaptive manufacturing ecosystem [1,5,17,18]. This study examines the role of virtual reality simulation in manufacturing in Industry 4.0 utilizing based on the science mapping/bibliometric analysis methodology. The research objectives are as follows:

- RO1: analyze the bibliometrics performance of research, including the scientific literature production (SCP) on the role of virtual reality simulation in manufacturing in the 4IR or i4.0.

- RO2: evaluate the intellectual structure of manufacturing VRSIM publications.

- RO3: assess the conceptual structure of research on the subject matter.

- RO4: evaluate the social structures of manufacturing VRSIM SCP to identify authors’ and countries’ collaborations (RO4).

The rest of this paper is organized as follows: Section 2 analyzes this study’s theoretical background and analytical literature review. Section 3 presents the materials and method, including the science mapping and bibliometric analysis framework, data collection processes and procedures, and analysis techniques. Section 4 analyzes the results. Section 5 presents a detailed discussion on the role of VRSIM in manufacturing in Industry 4.0 based on the outcomes of the science mapping study. Finally, Section 6 concludes this paper, highlights the implications of the main findings, and identifies areas for future work.

2. Developments in Data Visualization and VRSIM Applications in Manufacturing

Visualization has remained a crucial aspect of DES since its introduction more than four decades ago. As a decision support system, visualizing the interactions among the various components and elements in a computer-animated simulation model can make a remarkable difference in generating insight and understanding of the simulated manufacturing system. The visual display alters the perception of DES as a black box that appears slightly mysterious to the non-technical client or decision maker [12]. Further, animation is one aspect that differentiates DES from other operations research techniques, such as mathematical or linear programming [12,19,20]. Thus, in DES, solutions are typically obtained by experimentation, and it is often difficult to understand or anticipate precisely how changing the different components of the system will affect the overall system performance [12]. Viewing the modeled operation visually at runtime helps significantly in understanding the model’s behavior and processes [8,10,21]. The DES model’s clarity and proper understanding of the system behavior can lead to new insights regarding improving the system during experiments [10,11,22].

Further, a typical simulation study often involves diverse stakeholders, including the model developer, simulation analyst, project manager, decision maker, project owner, or top management. The visualization capabilities of the VRSIM provide a common ground where these different user roles can understand the simulation manufacturing processes and the solutions for decision making [15]. Presently, there is a consensus about the usefulness of VRSIM in enhancing insight and understanding into the simulation processes, activities, and tasks and improving the overall success of DES projects [15,21].

The literature identifies four types of visual displays in DES, including 2D, 2.5D, 3D, and VR, offering different levels of realism, visualization capability, and systems’ complexities [7,8,9,12]. That is, the higher the dimension of the visual display, the more the clarity and ease of understanding of the information conveyed [8,12]. The 2D display uses icons and visualization techniques that confine its scope to a primarily flat 2D surface [7]. All the display types offer some common characteristics, including some levels of animated graphics, interactivity, and realism. Also, in DES, all the display types can utilize numbers, charts, and texts to show some key statistics on the interface to complement the graphics [7,8,13].

The 2D display possesses lower capabilities than 3D visualization and VR [14,15,16,21]. The 3D visualization contains real binocular stereographic depth effects [9,12,21,22]. Next to the 2D display is the quasi-3D perspective visualization (also called 2.5D), which offers a higher level of realism than the 2D but lower than the complete 3D visualization representation [8]. Thus, most users can relate more easily to the 3D compared to the 2.5D and 2D versions in that order [9,12]. Strictly speaking, the difference between 3D display and VR is that VR often refers to visualization and equipment providing a sense of immersion (e.g., using a head-mounted display to interact with the virtual environment) [13,23,24,25,26]. However, the 3D display and VR are sometimes used interchangeably in DES, especially by simulation software agents and model users [8,27,28]. Although most simulation and modeling software currently provides 3D visualization rather than immersive VR, full VR implementation is becoming popular in DES in the 4IR, especially as VR hardware becomes more affordable [4,5,13]. Thus, the latest form of visual display in DES is the immersive VRSIM, which entails creating highly realistic and interactive virtual environments where users can interact with the virtual world, often with the head-mounted display and similar hardware devices [24,25]. Usually, it helps users to have a sense of real-life presence in a real-life scenario, although it is indeed a computer-generated environment. The immersive VRSIM scenario leverages advanced VR technologies to provide a deeply immersive experience [29,30].

In manufacturing, VRSIM involves creating virtual environments that replicate and simulate manufacturing scenarios, systems, and processes [24,31,32]. The DES-based VRSIM scenarios often include factory layout and planning, digital assembly modeling and simulation, and developing and testing virtual product prototypes [8,31,32,33,34]. Further, the VR-based simulation technique is a potent tool for verifying the design of manufacturing systems [13,35]. It allows the designer to examine the system design in detail, including movements of material handlers, relative positions of machine tools, setups of an individual machine tool, and machining operations on a machine tool. When integrated with design, VR visualization can significantly improve the system’s efficiency and enhance operations and process optimization [4,34]. Finally, VRSIM is a crucial technology in the predictive digital twin for operations maintenance in the 4IR or i4.0 era [24,25,36,37].

3. Methodology

3.1. Data Collection

This study surveyed the Web of Science (WoS) bibliographic database to retrieve the scientific publications records focusing on the role of VRSIM in manufacturing operations activities and processes since the evolution of 4IR, starting from 2010 according to the research, e.g., [2]. The initial data retrieval occurred in March 2023, with the final database survey in October 2023. The rationale for basing our literature survey on the WoS database is that it indexes high-quality scientific literature compared to others, such as SCOPUS and other bibliographic databases [38]. The WoS platform offers the option to retrieve the data as text (.txt), comma-separated values (.csv), and other file formats. This study extracted complete records from 823 published documents as metadata in the text (.txt) format, which were exported into Excel for data cleaning. The cleaned data were subjected to further screening and selection processes, during which non-peer-reviewed documents such as meeting abstracts and editorials were removed. Irrelevant records that did not address virtual reality simulation applications in manufacturing in the context of 4IR/i4.0 were also discarded, leaving 776 relevant publications of interest. Table 1 presents the search terms and the query strings for data collection and the screening process based on standard procedures [39].

Table 1.

Data collection process includes search and retrieval, filtering, screening, and selection criteria of the published documents.

3.2. Data Analysis Techniques and Tools

3.2.1. Bibliometrics Analysis and Science Mapping of Research

Bibliometric analysis is a literature evaluation technique used to study scientific publications based on a topic or research field [40]. It involves using quantitative and descriptive methods to analyze bibliographic data to uncover patterns, trends, relationships, and other valuable insights on a topic of interest. While the quantitative analysis produces empirical results, the descriptive component offers a qualitative assessment of the contents [39,40,41]. This study evaluates the literature on manufacturing VRSIM in the 4IR era.

The science mapping of the literature involves the analyses of the conceptual, intellectual, and social structures of research [39]. The co-occurrence of words identifies the themes and research streams, which form the conceptual design of publications using author keywords as the unit of analysis [41,42]. The co-citation identifies the intellectual structure, while co-authorship evaluates the relationships and social interactions among publications, authors, affiliations, and countries [41].

Bibliometric performance analysis and science mapping methods provide a deep and comprehensive analysis of the research trends and impacts and reveal the research landscape of a field. It also highlights the priorities in a field of study and identifies the areas requiring future studies.

3.2.2. The Choice of Bibliometric Software

This study employed two complementary bibliometrics analysis open-source software (R-Bibliometrix and VOSviewer (version 1.6.20)) for data analysis [40,42]. The final screened metadata in text (.txt) file format was exported to the two applications. Both applications can handle big bibliographic data, analyze the results, and produce visualization. We also employed Microsoft Excel 2021, productivity software in the Microsoft Office 2021 suite, to create charts and graphs.

4. Results and Analysis

4.1. Sample Description and Preliminary Results

Table 2 highlights the summary of results and sample description produced from the R-Bibliometrix software embedded in the R-Studio environment. The results summary shows 58% (450), 41.36% (321), and less than 1% (5) of the total 776 publications on manufacturing VRSIM, being journal articles, conference proceedings, and book chapters, respectively. The results also highlight 17.5% international cooperation among co-authors across several world regions, indicating that the topic is attracting a growing global interest. Also, the published documents appeared in 572 sources authored/co-authored by 2953 researchers, with 17.53% collaborating from several countries (Table 2). The analysis of results in Section 4.2, Section 4.3, Section 4.4 and Section 4.5 helps address the research objectives in Section 1.

Table 2.

Descriptive statistics of the sample and preliminary results.

4.2. Bibliometrics Performance Analyses of Research on VRSIM Application in Manufacturing in the 4IR Era

This section evaluates the bibliometrics performance of publications, including SCP trend on manufacturing VRSIM in i4.0, active usage analysis, and citation impact, which help to address the first research objective (RO1).

4.2.1. Scientific Literature Production Trend

It is important to note that VRSIM in manufacturing existed before the advent of the 4IR. However, its roles in predictive analytics and its functionality as a decision support system [12] play critical parts in 4IR and have become adapted as a part of the integrated technologies in the i4.0, alongside IoT, digital twin, among others [24,25,43]. Figure 1 shows the publication trend on the role of VRSIM in manufacturing since the start of 4IR, which occurred around 2010 [2].

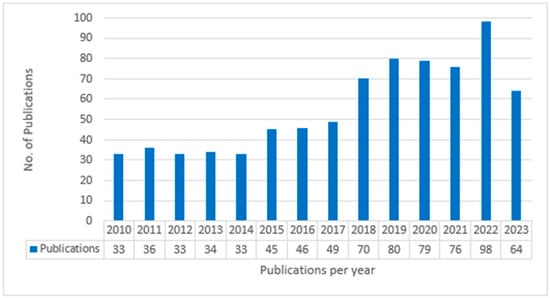

Figure 1.

Publications on VRSIM in manufacturing in the era of Industry 4.0. (The 2023 data are as of 31 October 2023).

The results show a strong research productivity of manufacturing VRSIM, although the first five years (2010 to 2014) remained flat, with SCP per year ranging between 33 and 36, an average of 34 per year). As the popularity of 4IR gained momentum, the SCP recorded further increases from 49 in 2017 to 70 in 2018 and peaked in 2022 at 98, an increase which in part can be attributed to increased research productivity, especially in the period of COVID-19 [18,44]. Figure 1 shows that the SCP produced in the four years of the COVID-19 outbreak (2020–2023) makes up over 40% (316 out of 776) of the total SCP. This trend has been observed in several studies across many disciplines, confirming increased SCP and adoption of digital technologies, including virtual reality and simulation platforms [3,18,34]. The results also show that, as the COVID-19 pandemic ceded, the SCP started to decline (e.g., 2023: Figure 1), indicating the possible impact of COVID-19 on increased adoption of VRSIM technology in manufacturing.

4.2.2. Citation Analysis of Publications

The results summary (Table 2) shows an average of 13.26 citations per document (with a total of 10,291) for the period (2010–2023), which covers the 4IR era [2]. The result was generated using the R-based Bibliometrix (explained in the earlier section). Further analysis identifies VRSIM in manufacturing as a highly cited research field, with 74% of the SCP earning at least one or more citations. The citation impact analysis structure shows that about 42.9% of publications earned between 1 and 9 citations; 21% received more than 10 but less than 30 (10 ≥ TC ≤ 30), while 10% earned 30 or more citations. Further, over 70% of the documents published in 2022 received at least one and up to thirty citations within one year. Also, 33% of publications in 2023 (less than one citable year: CY < 1) received between one and ten citations, indicating a highly cited and active research field. Table 3 presents the complete citation structure of the publications. However, a few documents (15 or 1.80%) earned one hundred citations or more (Table 3).

Table 3.

Citation structure of publications on VRSIM in manufacturing in the 4IR era.

The number of citations reported above is based on WoS bibliographic data. The Google Scholar (scholar.google.com) citation count can be more than the records on WoS. For example, Chandrasegaran et al. [35] earned 394 citations based on WoS data, but over 801 on Google Scholar (accessed on 31 December 2023).

4.2.3. Most-Cited Documents

Table 4 presents the top ten most-cited publications and research themes based on the global citation per the WoS bibliographic data. The results show the total, average (ACY), and normalized (NC) citations per year. All the top ten cited publications had long citable years (nine years or more), except one article [36] that made the list but had shorter citable years (less than four). The most-cited research themes include “Simulation, visualization, and results validation in manufacturing”, “manufacturing simulation applications”, and “VR systems and modeling to simulate scenarios in manufacturing and assembly”. Table 4 presents the complete list of titles and themes and the citations earned. As expected, the most highly cited topics also had the most extended citable years. For example, the three most-cited articles were published in the last 7–10 years.

Table 4.

Ten most-cited documents on the use of VR simulation in Industry 4.0.

4.2.4. Usage Analysis of Publications

Usage information on VRSIM in manufacturing SCP helps establish whether the research field is active. The WoS classifies the literature usage into two categories, namely U1 and U2. U1: the frequency of SCP uses within the past 180 days (last six months: April to October 2023); U2: the same information that occurred within the past ten years (2013–2023). The results in Figure 2 indicate high usage of the publications. The results do not show the purpose of use, although the potential users can include researchers, industry practitioners, and others.

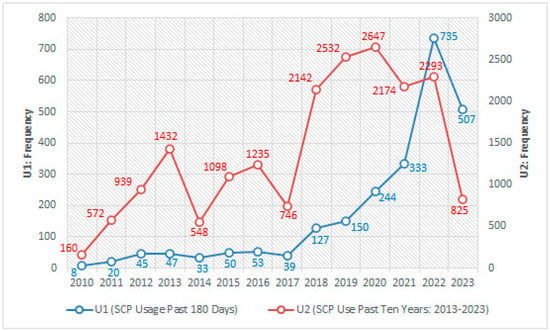

Figure 2.

Usage frequency of SCP on VRSIM in manufacturing in the last six months (U1) and last ten years (U2) based on WoS bibliographic data (2010 to 31 October 2023).

Overall, there was high and frequent use of SCPs on VRSIM in manufacturing, indicating an active research area. The 766 publications were used frequently (U1 = 2391 times; U2 = 19,343 times, respectively). The trend analysis for U1 shows a consistent increase in SCP use across all years, with recent publications used more often, meaning that recently published articles received higher usage counts than the older ones. For example, the 33 articles published in 2010 have been used just 8 times in the last six months and 160 times in the previous ten years (2013 to 2023). Comparatively, the publications in 2021 recorded an access count of 333 times, while the SCP in 2022 recorded a usage count of 735 times for U1, more than twice the number accessed in 2021. U2 also followed a similar trend (Figure 2), although the trend for U2 highlights more variation in use yearly, with more up/down movement, the most yearly variation occurring between 2013 and 2017.

Furthermore, the increased SCP in recent years (2017 to 2022) also mirrors the usage trends, indicating VRSIM in manufacturing as an active research discipline (Figure 1 and Figure 2). The data for 2023 is less than the full year (collected as of 31 October 2023). Therefore, the complete year’s trend is unknown at the time of this analysis.

Generally, 58.2% and 94.1% of the 776 SCPs recorded at least one usage count in the past six months (U1) and ten years (U2), respectively, indicating VRSIM in manufacturing as an active research field. However, the impact of COVID-19, which had ignited digital technology adoption across different sectors [44,48], potentially contributed to the increase in those years (2020–2022), especially for U1.

4.3. Co-Citation Analysis

Co-citation analysis measures the frequency with which pairs of published documents (e.g., articles, authors, or sources) are cited in a particular field of study. The analysis tracks the instances where the pairs (a and b) are co-cited [49]. The implication is that the co-cited papers/articles, authors, or journals share some common research theme. As co-citations occur frequently, research clusters form, and the co-cited document or journal becomes more relevant and influential in a research field network [49,50].

The co-citation analysis also reveals the intellectual structure of research and can be based on articles, authors, or sources. In this study, we employ the sources co-citation analysis as the unit of analysis [39]. The result addresses the second research objective (RO2), which examines the intellectual structure of VRSIM in manufacturing in the 4IR or i4.0, as stated earlier in Section 1.

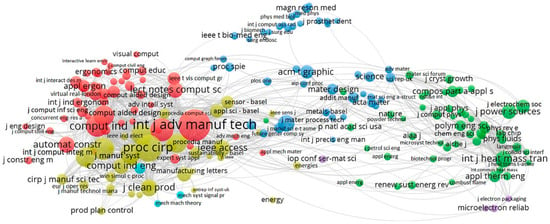

Table 2 shows that out of the 776 publications published in 572 sources, 450 were journal articles (58%), 321 (41.36%) conference proceedings, and 5 (0.64%) as book chapters. Utilizing the VOSviewer bibliographic analysis and visualization software [40], the results identify the eminent co-cited sources classified into five (5) color-coded clusters (red, yellow, blue, light blue, purple, and green) on a co-citation network (Figure 3). Figure 4 presents the sources’ co-citation network analysis, highlighting relationships and connections. The result shows the interconnectedness among 195 that earned at least 20 citations during the period covered in this study.

Figure 3.

Sources co-citation analysis of publications on VRSIM in manufacturing in Industry 4.0.

Figure 4.

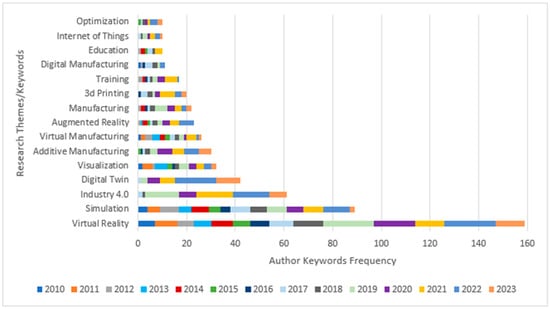

Eminent themes with word frequency greater than ten.

The result shows that the publications on manufacturing VRSIM appeared in sources across multidisciplinary but related disciplines, including manufacturing, operations and production, industrial engineering, operations research, computer science, and information systems, corroborating the nature of manufacturing problems and the integrated technologies in the 4IR [18].

Table 5 presents the top ten prominent sources from each of the six clusters classified as explained above. The table also shows citations earned and the corresponding network strengths of journal articles and proceedings papers on manufacturing VRSIM based on the clusters.

Table 5.

The prominent sources identified in co-citation network analysis classified into six clusters.

4.4. The Conceptual Structure of Publications on VRSIM in Manufacturing

This section evaluates the conceptual structure of publications on VRSIM in manufacturing, which addresses the third research objective (RO3). This study utilizes R-Bibliometrix and VOSviewer to identify the research areas, topics, and themes based on author keywords as the unit of analysis.

4.4.1. Keywords and Themes Analytics

Several studies show that author keywords are pointers to the article’s focus and can help map the conceptual or thematic structure and research themes/streams for any field of study [51,52]. Also, keyword analytics is one of the most popular methods in bibliometric mapping and analysis of the thematic structure of a research field [39,51,53].

The text mining using R-Bibliometrix identified 2437 unstemmed author keywords from the 776 publications (Table 2) with a total word frequency (f) of 3547. The word frequency explains the number of times each keyword re-occurs in the dataset. The sample is stratified into two categories to ensure an in-depth analysis based on the keyword frequency or co-word analysis as follows:

- Prominent keywords: The words are unique and unstemmed, occurring ten times or more (f ≥ 10) in the dataset. In this study, nineteen (19) keywords fall in this category with total word frequency (f) = 553. It implies that less than a percentage point (0.8%) of the keywords re-occurred 15.6% of the time.

- Emerging terms: The remainder of the unique and unstemmed keywords (2418 or 99.2%) were less prominent. We define the emerging terms as the ones with a frequency of occurrence less than ten (f < 10). Most of the terms fall in this category (2994 emerging terms compared to 553 prominent keywords), constituting 84.4% of the total word frequency).

4.4.2. Analysis of Prominent and Eminent Research Themes

The prominent themes classification can be defined as the ones with frequency (f) of occurrences equal to or greater than 10 (f ≥ 10). The eminent themes depict the frequently researched topics on VRSIM in manufacturing in 4IR (or i4.0). The text mining generated using the R-Bibliometrix identifies 15 stemmed unique terms in this category (f ≥ 10), re-occurring 553 times (15.6%) of the total 3547 frequencies. Some of the relevant, prominent themes manufacturing VRSIM other than VR and simulation include “virtual manufacturing”, “additive manufacturing”, and “digital manufacturing”. Other VRSIM in manufacturing research themes relate to “digital twin” and “industry 4.0”, with a word frequency of 42 and 61 times and making 1.2% and 1.7% of the total word frequency, respectively. Figure 4 presents a complete list of eminent research themes and their frequencies.

The benefits of mapping the relevant themes to scientific studies highlight the contexts, applications, and relevance of VRSIM in manufacturing in the i4.0 era. For example, it reveals its potent roles in simulating digital factories [12,13,54,55], product design and smart manufacturing [56], digital twin modeling [25,43], and predictive maintenance [57,58]. Also, VRSIM helps to design, map, and evaluate robot workspace and human-robot co-existence in the manufacturing environment, such as aircraft and automotive assembly lines, evaluate processes, and train factory workers on safety and ergonomics in digital production and operations [17,59,60,61,62,63].

Other areas where manufacturing VRSIM plays essential roles include innovative and efficient product design that shortens the time to market [35,64,65]. Other studies examine VRSIM in virtual manufacturing systems, process engineering, and optimization of operations activities to enhance efficiency and improve manufacturing decisions [18,66,67]. Section 4.4 offers further analysis and identifies such keywords.

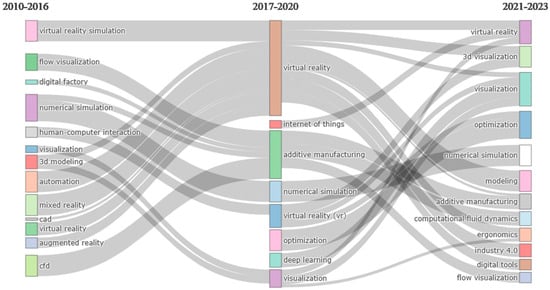

4.4.3. Thematic Evolution of VRSIM Application in Manufacturing

This section analyzes the evolution of the research themes on VRSIM in manufacturing in the 4IR era. The purpose is to identify the transformation in the research focus during the period. Undertaking text analytics of author keywords and science mapping using the R-Bibliometrix application highlights the trending themes. The results based on the default output strategies divide the period into three segments, namely 2010–2016, 2017–2020, and 2021–2023, covering the 4IR era (Figure 5). The focus is to evaluate the conceptual structure of the publications, which addresses the third research objective (RO3).

Figure 5.

Thematic evolution of VRSIM manufacturing in the 4IR era.

The first segment (2010–2016) showed most VRSIM in manufacturing research addressing largely pre-4IR technologies relating to manufacturing (Figure 5), such as “digital factory”, “flow visualization”, “computer aided design”, “visualization”, and “human-computer interaction” [8,10,11,12,54], among others. The second and third segments (2017–2020 and 2021–2023) capture a broader spectrum of research themes, including both the ones in the first segment. The new themes that appear in the second and third segments are “internet of things”, “deep learning”, and “industry 4.0”. The similarity of the research themes across the three segments and the addition of 4IR terminologies confirms that VRSIM in manufacturing had existed prior to the i4.0 era but was integrated among the i4.0 technologies.

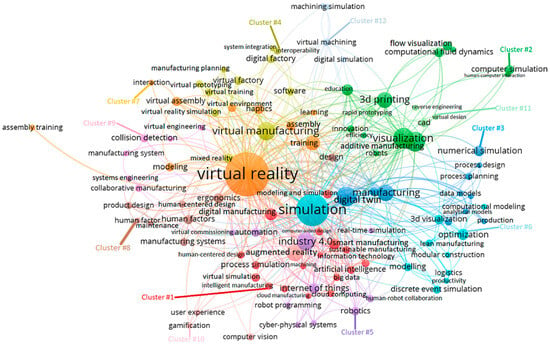

4.4.4. Co-Occurrence of Words Analysis

Co-occurrence of words analysis is a bibliometric evaluation technique that measures relationships between pairs of words in a body of literature. It examines the relationship and interconnectedness among research themes presented in a network map comprising nodes and edges [41,52]. The keywords or themes represent the nodes interconnected by edges (lines) and nodes. The nodes and labels’ sizes depend on the word frequency (the number of occurrences of specific keywords). Thus, the bigger the node, the more frequently the word occurs [41]. The edges serve as the lines that connect two or more nodes; the more connected a node is, the greater the network link strength of that node [41].

The metadata analyzed in this study contains 2437 author keywords (Table 2). Text analytics and visualization results utilizing the VOSViewer application show a co-word network map. For reproducibility, we set the co-word frequency (f) at 3: (f ≥ 3) produced 138 terms less 29 nugatory terminology or words that do not convey contextual meanings, such as country names and similar terms. Also, removing one disconnected theme leaves 108 co-occurrence terms. The text mining algorithm stratifies the themes into twelve (12) color-coded clusters. When using VOSViewer, the cluster categorization contains some random elements, and the group in which the terms appear should be interpreted loosely. Removing one or more keywords can lead to cluster reclassification in the network map. Therefore, the keywords and the network link strength are more crucial than the cluster in which the words appear. The network visualization (Figure 6) highlights the twelve (12) clusters with the prominent themes in each classification listed below.

Figure 6.

Visualization of the co-occurrence network of terms and thematic structure of VRSIM in manufacturing based on author keywords.

The associated values in each theme in the network map represent the word frequency and network link strength, respectively, as follows:

Cluster #1: (digital manufacturing: 11, 24; smart manufacturing: 9, 14; modeling and simulation: 6, 8; artificial intelligence: 5, 13; sustainable manufacturing: 4, 7; intelligent manufacturing: 4, 3, and more).

Cluster #2: (visualization: 32, 40; additive manufacturing: 30, 35; 3D printing: 20, 30; flow visualization: 7, 5; computer simulation: 7, 4, and others).

Cluster #3: (digital twin: 31, 56; manufacturing: 22, 47; numerical simulation: 9, 3; process planning: 4, 9; process design: 3, 6, and more).

Cluster #4 (virtual manufacturing: 26, 57; virtual factory: 6, 10; digital factory: 5, 5; virtual prototyping: 4, 11; virtual reality simulation: 5, 4, and others).

Cluster #5 (industry 4.0: 24, 41; Internet of things: 9, 18; automation: 6, 13; robotics: 6, 13; human–robot collaboration: 4, 12; cyber–physical systems: 3, 4, and others).

Cluster #6 (simulation: 80, 140; optimization: 10, 18; 3D visualization: 7, 9; discrete event simulation: 5, 6; lean manufacturing: 4, 5; logistics: 3, 8, and more).

Cluster #7 (virtual reality: 149, 227; training: 17, 33; virtual assembly: 7, 15; haptics: 7, 13; virtual environment: 5, 11).

Cluster #8 (ergonomics: 8, 19; human factors: 7, 12; manufacturing systems: 5,5; product design: 4, 10; maintenance: 3, 7).

Cluster #9 (collision detection: 5, 5; collaborative manufacturing: 4, 4; virtual engineering: 3, 7; systems engineering: 3, 6).

Cluster #10 (Computer vision: 4, 4; user experience: 3, 9; gamification: 3, 7).

Cluster #11 (rapid prototyping: 8, 20; reverse engineering: 3, 5; virtual design: 3, 2).

Cluster #12 (virtual machining: 4, 12; machining simulation: 3, 3; digital simulation: 3, 4).

4.5. Social Structure

The social structure of a research field analyzes the collaborations among authors, institutions, and countries that contribute to the SCPs. The results address the fourth research objective (RO4), including co-authorship collaboration and countries of affiliation as the units of analysis.

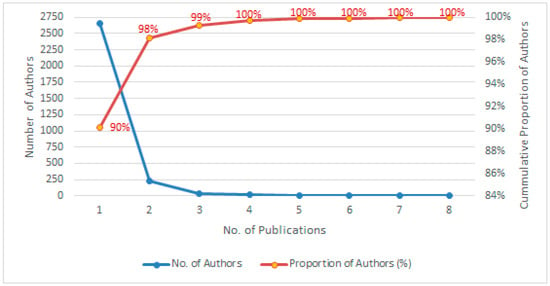

4.5.1. Authors’ Productivity Index Using Lotka’s Law

Lotka’s law in bibliometric analysis is an empirical framework that provides insight into the frequency distribution of scientific literature productivity among authors in an area of study or discipline [18,42]. It shows the dynamics of scholarly research output in different fields and reveals eminent authors who contribute repeatedly on a specific topic versus occasional contributors in a research field [39,40,41,42]. Generally, few prolific authors tend to contribute a disproportionately large amount of the SCP in a discipline, while a vast number (occasional contributors) contribute few articles.

The preliminary results (Table 2) identified 2953 authors/co-authors or contributors of the 776 publications surveyed in this study. We also produce authors’ productivity distribution using the R-Bibliometrix application (described earlier). The results (Figure 7) show the number of authors on the y-axis, the number of publications (x-axis), and the corresponding cumulative proportion (percentage). A high proportion of the authors (90%: 2661/2953) published just one article each, while 8% (236/2953) published two each. Cumulatively, 90% of the authors contributed only one article each, 98% contributed one or two publications, and so on (Figure 7). Also, a negligible proportion (2% or 59/2953) contributed three or more documents. No author contributed nine or more publications.

Figure 7.

Authors’ productivity index of research on the role of VRSIM in manufacturing in Industry 4.0.

In summary, only 10% of the authors published two or more articles on the subject, which matches Lotka’s law expectations (as explained above). Also, this trend can be expected considering the relatively short period of VRSIM application in manufacturing in i4.0, which covers 2010–2023 [2].

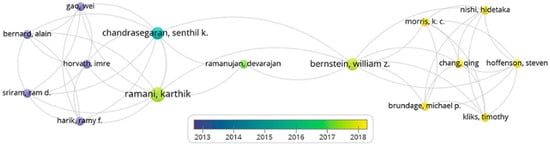

4.5.2. Co-Author Analysis

This section analyzes the co-authorship network to identify patterns of scientific collaborations among those who have contributed to the publications on VRSIM in manufacturing problems. In co-author analysis, two authors are in a collaborative relationship if co-authoring any published document in a particular domain or multiple research domains, interdisciplinary research areas, whether locally or internationally [39,52].

In this study, we employ the VOSViewer application to produce the co-authorship social network map, showing co-authors’ collaboration. The result shows low but increasing partnerships among co-authors. The analysis set the minimum criteria to at least one co-authored publication that received ten (10) citations during the period. Figure 8 shows the connected co-authorships in the i4.0 years of VRSIM roles in manufacturing, addressing many scenarios, such as enhancing decision making to shorten the time to market Chandrasegaran et al. [35]. However, more collaborations tend to occur in recent years (2017–2023). For example, Ref. [55] examined environmental sustainability in the manufacturing industry as a product of collaboration among Brundage, Bernstein, Chang, Klinks, Nishi, and Morris (Figure 8).

Figure 8.

Co-authorship network map of publications on VRSIM in manufacturing in the era of Industry 4.0.

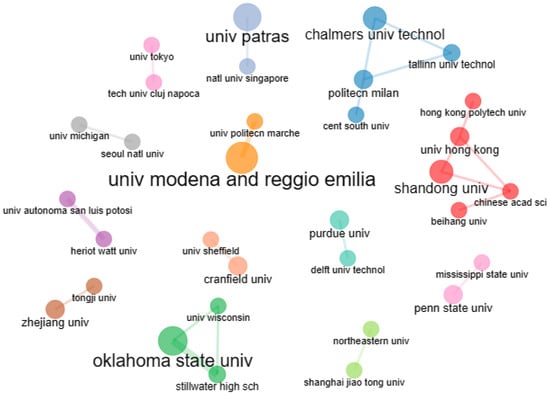

4.5.3. Institutions and Countries Collaboration and Impact

The analysis of the social structure of a research field also applies to collaborations among research institutions and countries of authors [41,42]. The bibliographic data analyzed in this study contains 1012 institutions from 63 countries where authors/co-authors and institutions are domiciled. The results summary (Table 2) shows an international collaboration index of 17.53%, indicating low international collaborations among institutions. Figure 9 also shows low connections among these institutions. However, there appears to be a stronger connection among institutions within countries and regions, e.g., “Oklahoma State University” has a stronger tie with the “University of Wisconsin” in the USA. Similarly, there is good collaboration between “Tongji University” and “Zhejiang University” in China. Figure 9 shows the complete details of the collaborations among the research institutions.

Figure 9.

Collaboration network of authors’ institutions.

Further analysis of the authors’ countries’ collaborations using R-Bibliometrix identifies China, the USA, Germany, the UK, and Italy as the 5 most dominant countries in literature publications on VRSIM in manufacturing in the 4IR, while collaboration indices among the remaining 14 other nations (e.g., frequency of research/article’s collaboration is negligible (Table 6). The analysis also highlights the countries with the most publications on the subject and where the corresponding authors are domiciled (MCP), including China, USA, and Germany, as being the top three. Table 6 shows a complete list of the top twenty (20) countries.

Table 6.

Countries’ international collaborations in publications in two categories, SCP and MCP, and impact.

5. Discussion: The Role of VRSIM in Manufacturing in Industry 4.0

The science mapping and analysis of the conceptual structure of the literature on VRSIM in manufacturing (Section 4.4.4) highlights several roles that this transformative technology plays in Industry 4.0. Although VR and computer simulation existed before the advent of i4.0, VRSIM has been adopted among the core integrated physical and digital technologies towards enhancing automation, connectivity, and intelligent and data-driven decision making in manufacturing. Below are the critical roles of VRSIM in manufacturing in the 4IR based on the results of the conceptual structure analysis of the literature.

The first cluster identifies terms including “smart manufacturing”, “intelligent manufacturing”, and “artificial intelligence”. These terms point to intelligent systems and smart manufacturing in i4.0, a key component of Industry 4.0, which involves using intelligent systems, data-driven decision making, and the Internet of things (IoT) in manufacturing [59,68,69]. VRSIM offers an opportunity to simulate and optimize production processes, monitor equipment in real-time, and improve the overall efficiency of production processes [70].

Another important aspect where VRSIM plays a key role is the digital twin (DT) and predictive maintenance. DT technology in i4.0 enables the creation of virtual replicas of physical systems and processes. VRSIM plays a significant role in simulating and analyzing the behavior of real-world scenarios, allowing for better design, monitoring, and predictive maintenance [25,57,58]. Integrating VRSIM in the digital twin of manufacturing systems provides an in-depth interactive experience, enabling users to visualize, interact, and explore with the digital twin in a highly realistic and intuitive manner, which generates better insights into the manufacturing systems and processes [25,43,71].

Modeling and simulation are critical in predictive maintenance. As one of the integrated technologies in i4.0, VRSIM facilitates a deeper understanding of the functioning and behavior of manufacturing equipment and machines and optimizes maintenance strategies [36]. In the 4IR, predictive maintenance becomes even more crucial with the integration of digital technologies, including the Internet of things (IoT), digital twins, and data-driven processes [24,25]. VRSIM helps to create and simulate a digital replica or digital twin of the manufacturing equipment and other physical assets based on real-time data, capturing the actual equipment’s behavior (e.g., machines) based on real-time data and operational characteristics [24,25,36]. The strategy allows for continuous monitoring and analysis without disrupting physical operations, thus minimizing or eradicating manufacturing downtime [57,58]. The potential machine failure scenarios are modeled and simulated based on what-if conditions and stress factors using historical data and real-time information. The predictive simulation strategy can help to identify the potential impact on equipment performance or machine failure points before any actual occurrence manifests [16,24].

Additive manufacturing and 3D printing are other aspects identified in the conceptual structure (cluster #2) where VRSIM plays a crucial role. Additive manufacturing technologies, e.g., 3D printing, are often part of intelligent manufacturing [72,73,74]. It involves the layer-by-layer construction of objects based on digital 3D models [75]. These technologies enable more flexible and customizable production processes. VRSIM offers several benefits in the additive manufacturing processes by allowing designers and engineers to visualize 3D models realistically, which is valuable in assessing the design of complex structures and prototypes before production [73]. Thus, VRSIM enables virtual prototyping, testing, and simulating the printing process, making it possible to identify potential issues before printing [59]. It also offers the opportunity to optimize parameters such as layer thickness and infill patterns for better performance [76]. VRSIM also offers realistic printing monitoring where virtual printing simulation enables practical evaluation of the additive manufacturing process. VRSIM allows virtual observation of the printing process in real-time to assess potential issues such as layer adhesion, warping, or defects [59,76].

Human–robot collaboration is another area where VRSIM plays a significant role, as pointed out by the conceptual analysis results in the fifth cluster (automation, robotics, human–robot collaboration, and more). VRSIM contributes to testing and optimizing human–robot collaboration and interactions within the manufacturing environment, including assessing how operators interact with machinery and robotic systems and ensuring ergonomic designs, efficient processes, and workflows [17,59,60,61,62,63].

The themes mentioned in the fourth cluster of the conceptual structure analysis identify themes such as “virtual manufacturing”, “virtual factory”, “digital factory”, and “digital prototyping”, which relate to virtual manufacturing (VM) technology, where VRSIM also plays a significant role. VM uses computer-based models and simulations to design, simulate, and optimize the entire manufacturing system, often in a digital or virtual environment [18,77]. It entails the creation of digital models, including product design, production planning, scheduling, and optimization of manufacturing processes [78].

6. Conclusions

This study examined the role of VRSIM in manufacturing in the Industry 4.0 era. The results of the science mapping conducted in this study reveal that VRSIM plays a crucial role in the 4IR in multidimensional pathways. Although VR and computer simulation existed before the advent of i4.0, this transformative technology has been adopted among integrated physical and digital technologies to enhance significant advancements in automation, connectivity, and data-driven decision making in manufacturing.

The first research objective (RO1) examines the performance analysis aspect of bibliometric evaluation, including publication trends, citation analysis of publications, most-cited documents, and usage analysis (U1 and U2), representing the usage of the publications in the last six months and last ten years, respectively. The results identify VRSIM in manufacturing in 4IR as a significantly active and growing research field.

The second research objective (RO2) examines the intellectual structure of the publications on the subject based on source co-citation analysis. The results highlight prominent manufacturing, operations, industrial engineering, and information systems journals that publish articles on the subject. There is also high co-citation among the sources, as shown in Figure 3.

The third research objective (RO3) examines the conceptual structure of SCPs in this study. The analyses cut across keywords analytics, identifying and evaluating the prominent themes that reveal a broad range of research areas about the roles of VRSIM in manufacturing in 4IR. This includes its potent role in predictive modeling and simulation, digital twin and predictive maintenance, additive manufacturing and 3D printing, and virtual manufacturing and immersive virtual digital factory simulation. VRSIM also offers a realistic virtual environment for mapping human–robot collaboration in manufacturing, such as aircraft and automotive assembly lines, evaluating processes, training factory workers on safety, and assessing workers’ ergonomics in digital production and operations. The significance of text analytics based on author keywords highlights the prominent vs. new/emerging themes. The prominent themes highlight the research areas on VRSIM applications in manufacturing in i4.0, where significant scientific studies have been conducted. On the other hand, the less popular keywords represent new and emerging research areas that attract less scientific inquiry and require future studies. In some circumstances, the less prominent terms can also represent a field of study that researchers have abandoned due to lack of interest or importance. However, considering the recent hype surrounding i4.0, VR, and computer simulation, and the short period of 4IR since its inception, the less prominent themes represent new fields of study that require more studies, such as simulation of “virtual commissioning”, “intelligent manufacturing”, and “cloud manufacturing”.

Finally, the fourth research objective (RO4) addressed the social structure of the published documents on VRSIM in manufacturing in i4.0. The results of co-author analysis, institutions, and countries’ collaboration indicate an emerging and developing collaboration network, which points to an evolving research field that can benefit from more network formation among authors, institutions, and countries. Increased partnerships can help explore further research areas on VRSIM in manufacturing towards accomplishing the automation and intelligence manufacturing goals in the 4IR. Further, the results (e.g., Figure 9) indicate that the network relationship among institutions within countries is stronger than collaborations between countries. Future work can form stronger research partnerships among authors, not only within but also across countries.

Author Contributions

Conceptualization: I.J.A.; methodology, I.J.A. and O.F.O.; software, I.J.A.; validation, I.J.A. and O.F.O.; formal analysis, I.J.A.; investigation, I.J.A.; resources, I.J.A. and O.F.O.; data curation, I.J.A.; writing—original draft preparation, I.J.A.; writing—review and editing, I.J.A. and O.F.O.; visualization, I.J.A.; supervision, I.J.A. and O.F.O.; project administration, I.J.A. and O.F.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All relevant data are summarized and included in this article. The authors do not have permission to share any proprietary data.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Barton, M.; Budjac, R.; Tanuska, P.; Gaspar, G.; Schreiber, P. Identification overview of Industry 4.0 essential attributes and resource-limited embedded artificial-intelligence-of-things devices for small and medium-sized enterprises. Appl. Sci. 2022, 12, 5672. [Google Scholar] [CrossRef]

- Datta, P.M. The Road to 4IR (4th Industrial Revolution). In Global Technology Management 4.0; Palgrave Macmillan: Cham, Switzerland, 2022. [Google Scholar]

- Maddikunta, P.K.R.; Pham, Q.V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Liagkou, V.; Salmas, D.; Stylios, C. Realizing virtual reality learning environment for industry 4.0. Procedia CIRP 2019, 79, 712–717. [Google Scholar] [CrossRef]

- Seymour, N.E. VR to OR: A review of the evidence that virtual reality simulation improves operating room performance. World J. Surg. 2018, 32, 182–188. [Google Scholar] [CrossRef] [PubMed]

- Salah, B.; Abidi, M.H.; Mian, S.H.; Krid, M.; Alkhalefah, H.; Abdo, A. Virtual reality-based engineering education to enhance manufacturing sustainability in industry 4.0. Sustainability 2019, 11, 1477. [Google Scholar] [CrossRef]

- Akpan, I.J. An Empirical Study of the Impacts of Virtual Reality on Discrete-Event Simulation. Ph.D. Thesis, University of Lancaster, Lancaster, UK, 2006. Available online: https://ethos.bl.uk/OrderDetails.do?uin=uk.bl.ethos.440409 (accessed on 1 September 2023).

- Waller, A.P.; Ladbrook, J. Virtual worlds: Experiencing virtual factories of the future. In Proceedings of the 34th Winter Simulation Conference: Exploring New Frontiers, San Diego, CA, USA, 8–11 December 2002; ACM: New York, NY, USA, 2002; pp. 513–517. [Google Scholar]

- Barnes, M. Virtual reality & simulation. In Proceedings of the 1996 Winter Simulation Conference, Coronado, CA, USA, 8–11 December 1996; Charnes, J.M., Morrice, D.J., Brunner, D.T., Swain, J.J., Eds.; Association for Computing Machinery: New York, NY, USA, 1996; pp. 101–110. [Google Scholar]

- Lungu, A.J.; Swinkels, W.; Claesen, L.; Tu, P.; Egger, J.; Chen, X. A review on the applications of virtual reality, augmented reality and mixed reality in surgical simulation: An extension to different kinds of surgery. Expert Rev. Med. Devices 2021, 18, 47–62. [Google Scholar] [CrossRef]

- Akpan, J.I.; Brooks, R.J. Practitioners’ perception of the impacts of virtual reality on discrete-event simulation. In Proceedings of the Winter 2005 Simulation Conference, Orlando, FL, USA, 4–7 December 2005; IEEE: Piscataway, NJ, USA, 2005; p. 9. [Google Scholar]

- Akpan, I.J.; Brooks, R.J. Experimental evaluation of user performance on two-dimensional and three-dimensional perspective displays in discrete-event simulation. Decis. Support Syst. 2014, 64, 14–30. [Google Scholar] [CrossRef][Green Version]

- Turner, C.J.; Hutabarat, W.; Oyekan, J.; Tiwari, A. Discrete event simulation and virtual reality use in industry: New opportunities and future trends. IEEE Trans. Hum.-Mach. Syst. 2016, 46, 882–894. [Google Scholar] [CrossRef]

- van der Zee, D.J. Model simplification in manufacturing simulation–Review and framework. Comput. Ind. Eng. 2019, 127, 1056–1067. [Google Scholar] [CrossRef]

- Akpan, I.J.; Shanker, M.; Razavi, R. Improving the success of simulation projects using 3D visualization and virtual reality. J. Oper. Res. Soc. 2020, 71, 1900–1926. [Google Scholar] [CrossRef]

- Akpan, I.J.; Shanker, M. A comparative evaluation of the effectiveness of virtual reality, 3D visualization and 2D visual interactive simulation: An exploratory meta-analysis. Simulation 2019, 95, 145–170. [Google Scholar] [CrossRef]

- Kuts, V.; Modoni, G.E.; Terkaj, W.; Tähemaa, T.; Sacco, M.; Otto, T. Exploiting Factory Telemetry to Support Virtual Reality Simulation in Robotics Cell. In Augmented Reality, Virtual Reality, and Computer Graphics; AVR 2017, Lecture Notes in Computer Science; De Paolis, L., Bourdot, P., Mongelli, A., Eds.; Springer: Cham, Switzerland, 2017; Volume 10324. [Google Scholar] [CrossRef]

- Kobara, Y.M.; Akpan, I.J. Bibliometric Performance and Future Relevance of Virtual Manufacturing Technology in the Fourth Industrial Revolution. Systems 2023, 11, 524. [Google Scholar] [CrossRef]

- Sinuany-Stern, Z. Foundations of operations research: From linear programming to data envelopment analysis. Eur. J. Oper. Res. 2023, 306, 1069–1080. [Google Scholar] [CrossRef]

- Van Wassenhove, L.N.; Pedraza-Martinez, A. Using OR to adapt supply chain management best practices to humanitarian logistics. Int. Transport. Oper. Res. 2012, 19, 307–322. [Google Scholar] [CrossRef]

- Akpan, I.J.; Shanker, M. The confirmed realities and myths about the benefits and costs of 3D visualization and virtual reality in discrete event modeling and simulation: A descriptive meta-analysis of evidence from research and practice. Comput. Ind. Eng. 2017, 112, 197–211. [Google Scholar] [CrossRef]

- van Manen, M.; olde Scholtenhuis, L.; Voordijk, H. Empirically validating five propositions regarding 3D visualizations for subsurface utility projects. Eng. Constr. Archit. Manag. 2022, 29, 2535–2553. [Google Scholar] [CrossRef]

- Wu, B.; Yu, X.; Gu, X. Effectiveness of immersive virtual reality using head-mounted displays on learning performance: A meta-analysis. Br. J. Educ. Technol. 2020, 51, 1991–2005. [Google Scholar] [CrossRef]

- Goodwin, T.; Xu, J.; Celik, N.; Chen, C.H. Real-time digital twin-based optimization with predictive simulation learning. J. Simul. 2022, 1–18. [Google Scholar] [CrossRef]

- Havard, V.; Jeanne, B.; Lacomblez, M.; Baudry, D. Digital twin and virtual reality: A co-simulation environment for design and assessment of industrial workstations. Prod. Manuf. Res. 2019, 7, 472–489. [Google Scholar] [CrossRef]

- Pastel, S.; Chen, C.H.; Petri, K.; Witte, K. Effects of body visualization on performance in head-mounted display virtual reality. PLoS ONE 2020, 15, e0239226. [Google Scholar] [CrossRef]

- Robinson, S.; Lee, E.P.; Edwards, J.S. Simulation based knowledge elicitation: Effect of visual representation and model parameters. Expert Syst. Appl. 2012, 39, 8479–8489. [Google Scholar] [CrossRef]

- Akpan, I.J.; Brooks, R.J. Users’ perceptions of the relative costs and benefits of 2D and 3D visual displays in discrete-event simulation. Simulation 2012, 88, 464–480. [Google Scholar] [CrossRef]

- Qiao, J.; Xu, J.; Li, L.; Ouyang, Y.Q. The integration of immersive virtual reality simulation in interprofessional education: A scoping review. Nurse Educ. Today 2021, 98, 104773. [Google Scholar] [CrossRef] [PubMed]

- Frederiksen, J.G.; Sorensen, S.M.D.; Konge, L.; Svendsen, M.B.S.; Nobel-Jorgensen, M.; Bjerrum, F.; Andersen, S.A.W. Cognitive load and performance in immersive virtual reality versus conventional virtual reality simulation training of laparoscopic surgery: A randomized trial. Surg. Endosc. 2020, 34, 1244–1252. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M.; Bernidaki, D. Simulation in manufacturing: Review and challenges. Procedia CIRP 2014, 25, 213–229. [Google Scholar] [CrossRef]

- Abidi, M.A.; Lyonnet, B.; Chevaillier, P.; Toscano, R.; Baert, P. Simulation of manufacturing processes via virtual reality. In Robotics, Automation, and Control in Industrial and Service Settings; IGI Global: Shenzhen, China, 2015; pp. 142–178. [Google Scholar]

- Choi, S.; Jung, K.; Noh, S.D. Virtual reality applications in manufacturing industries: Past research, present findings, and future directions. Concurr. Eng. 2015, 23, 40–63. [Google Scholar] [CrossRef]

- Lawson, G.; Salanitri, D.; Waterfield, B. Future directions for the development of virtual reality within an automotive manufacturer. Appl. Ergon. 2016, 53, 323–330. [Google Scholar] [CrossRef]

- Chandrasegaran, S.K.; Ramani, K.; Sriram, R.D.; Horváth, I.; Bernard, A.; Harik, R.F.; Gao, W. The evolution, challenges, and future of knowledge representation in product design systems. Comput.-Aided Des. 2013, 45, 204–228. [Google Scholar] [CrossRef]

- Mourtzis, D. Simulation in the design and operation of manufacturing systems: State of the art and new trends. Int. J. Prod. Res. 2020, 58, 1927–1949. [Google Scholar] [CrossRef]

- Da Xu, L.; Wang, C.; Bi, Z.; Yu, J. AutoAssem: An automated assembly planning system for complex products. IEEE Trans. Ind. Inform. 2012, 8, 669–678. [Google Scholar]

- Jacso, P. As We May Search—Comparison of Major Features of the Web of Science, Scopus, and Google Scholar Citation-Based and Citation-Enhanced Databases. Curr. Sci. 2005, 89, 1537–1547. [Google Scholar]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software Survey: VOSviewer, a Computer Program for Bibliometric Mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- Kosacka-Olejnik, M.; Kostrzewski, M.; Marczewska, M.; Mrówczyńska, B.; Pawlewski, P. How digital twin concept supports internal transport systems? Literature review. Energies 2021, 14, 4919. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. Bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Zhu, C.; Liu, Z. Framework for manufacturing-tasks semantic modelling and manufacturing-resource recommendation for digital twin shop-floor. J. Manuf. Syst. 2021, 58, 281–292. [Google Scholar] [CrossRef]

- Akpan, I.J.; McEnroe-Petitte, D.M.; Aguolu, O.G.; Kobara, Y.; Ezeume, I.C. Using visualization technique to communicate the conceptual structure of SARS-CoV-2 to multidisciplinary audience and lessons from the pandemic for future preparedness. Int. J. Healthc. Manag. 2023, 1–13. [Google Scholar] [CrossRef]

- Rosenfeld, P.; Cooper-Balis, E.; Jacob, B. DRAMSim2: A cycle accurate memory system simulator. IEEE Comput. Archit. Lett. 2011, 10, 16–19. [Google Scholar] [CrossRef]

- Nee, A.Y.; Ong, S.K.; Chryssolouris, G.; Mourtzis, D. Augmented reality applications in design and manufacturing. CIRP Ann. 2012, 61, 657–679. [Google Scholar] [CrossRef]

- Goulding, J.; Nadim, W.; Petridis, P.; Alshawi, M. Construction industry offsite production: A virtual reality interactive training environment prototype. Adv. Eng. Inform. 2012, 26, 103–116. [Google Scholar] [CrossRef]

- Raynaud, M.; Goutaudier, V.; Louis, K.; Al-Awadhi, S.; Dubourg, Q.; Truchot, A.; Brousse, R.; Saleh, N.; Giarraputo, A.; Debiais, C.; et al. Impact of the COVID-19 pandemic on publication dynamics and non-COVID-19 research production. BMC Med. Res. Methodol. 2021, 21, 1. [Google Scholar] [CrossRef]

- Egghe, L.; Rousseau, R. Co-citation, bibliographic coupling and a characterization of lattice citation networks. Scientometrics 2002, 55, 349–361. [Google Scholar] [CrossRef]

- Boyack, K.W.; Klavans, R. Co-citation analysis, bibliographic coupling, and direct citation: Which citation approach represents the research front most accurately? J. Am. Soc. Inf. Sci. Technol. 2010, 61, 2389–2404. [Google Scholar] [CrossRef]

- Laengle, S.; Merigó, J.M.; Miranda, J.; Słowińsk, R.; Bomze, I.; Borgonovo, E.; Dyson, R.G.; Oliveira, J.F.; Teunter, R. Forty years of the European Journal of Operational Research: A bibliometric overview. Eur. J. Oper. Res. 2017, 262, 803–816. [Google Scholar] [CrossRef]

- Yan, E.; Ding, Y. Scholarly network similarities: How bibliographic coupling networks, citation networks, co-citation networks, topical networks, co-authorship networks, and co-word networks relate to each other. J. Am. Soc. Inf. Sci. Technol. 2012, 63, 1313–1326. [Google Scholar] [CrossRef]

- Akpan, I.J.; Shanker, M.; Offodile, O.F. Discrete-event simulation is still alive and strong: Evidence from bibliometric performance evaluation of research during COVID-19 global health pandemic. Int. Trans. Oper. Res. 2023. Online version of record before inclusion in an issue. [Google Scholar] [CrossRef]

- da Silva, G.C.; Kaminski, P.C. Application of digital factory concepts to optimise and integrate inventories in automotive pre-assembly areas. Int. J. Comput. Integr. Manuf. 2015, 28, 607–615. [Google Scholar] [CrossRef]

- Chandra Sekaran, S.; Yap, H.J.; Musa, S.N.; Liew, K.E.; Tan, C.H.; Aman, A. The implementation of virtual reality in digital factory—A comprehensive review. Int. J. Adv. Manuf. Technol. 2021, 115, 1349–1366. [Google Scholar] [CrossRef]

- Brundage, M.P.; Bernstein, W.Z.; Hoffenson, S.; Chang, Q.; Nishi, H.; Kliks, T.; Morris, K.C. Analyzing environmental sustainability methods for use earlier in the product lifecycle. J. Clean. Prod. 2018, 187, 877–892. [Google Scholar] [CrossRef]

- Guo, Z.; Zhou, D.; Zhou, Q.; Zhang, X.; Geng, J.; Zeng, S.; Hao, A. Applications of virtual reality in maintenance during the industrial product lifecycle: A systematic review. J. Manuf. Syst. 2020, 56, 525–538. [Google Scholar] [CrossRef]

- Hassan, S.; Yoon, J. Virtual maintenance system with a two-staged ant colony optimization algorithm. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 931–936. [Google Scholar]

- Malik, A.A.; Masood, T.; Bilberg, A. Virtual reality in manufacturing: Immersive and collaborative artificial-reality in design of human-robot workspace. Int. J. Comput. Integr. Manuf. 2020, 33, 22–37. [Google Scholar] [CrossRef]

- Ottogalli, K.; Rosquete, D.; Rojo, J.; Amundarain, A.; Maria Rodriguez, J.; Borro, D. Virtual reality simulation of human-robot coexistence for an aircraft final assembly line: Process evaluation and ergonomics assessment. Int. J. Comput. Integr. Manuf. 2021, 34, 975–995. [Google Scholar] [CrossRef]

- Gammieri, L.; Schumann, M.; Pelliccia, L.; Di Gironimo, G.; Klimant, P. Coupling of a redundant manipulator with a virtual reality environment to enhance human-robot cooperation. Procedia CIRP 2017, 62, 618–623. [Google Scholar] [CrossRef]

- Agethen, P.; Sekar, V.S.; Gaisbauer, F.; Pfeiffer, T.; Otto, M.; Rukzio, E. Behavior analysis of human locomotion in the real world and virtual reality for the manufacturing industry. ACM Trans. Appl. Percept. (TAP) 2018, 15, 1–19. [Google Scholar] [CrossRef]

- Alasti, H.; Elahi, B.; Mohammadpour, A. Interactive Virtual Reality-Based Simulation Model Equipped with Collision-Preventive Feature in Automated Robotic Sites. In Simulation for Industry 4.0: Past, Present, and Future; Springer International Publishing: Cham, Switzerland, 2019; pp. 111–128. [Google Scholar]

- Peng, G.; Hou, X.; Gao, J.; Cheng, D. A visualization system for integrating maintainability design and evaluation at product design stage. Int. J. Adv. Manuf. Technol. 2012, 61, 269–284. [Google Scholar] [CrossRef]

- Yap, H.J.; Tan, C.H.; Phoon, S.Y.; Liew, K.E.; Chandra Sekaran, S. Process planning and scheduling for loop layout robotic workcell using virtual reality technology. Adv. Mech. Eng. 2019, 11, 1687814019878326. [Google Scholar] [CrossRef]

- Robert, O.; Iztok, P.; Borut, B. Real-Time manufacturing optimization with a simulation model and virtual reality. Procedia Manuf. 2019, 38, 1103–1110. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, J.; Tang, G.; Moreland, J.; Fu, D.; Wu, B. Integration of advanced simulation and visualization for manufacturing process optimization. JOM 2016, 68, 1363–1369. [Google Scholar] [CrossRef]

- Munirathinam, S. Industry 4.0: Industrial internet of things (IIOT). Adv. Comput. 2020, 117, 129–164. [Google Scholar]

- Cecil, J.; Albuhamood, S.; Gupta, A. A virtual reality-based internet-of-things (iot) framework for micro devices assembly. In Proceedings of the 23rd ACM Symposium on Virtual Reality Software and Technology, Gothenburg, Sweden, 8–10 November 2017; pp. 1–2. [Google Scholar]

- Zhang, Q.; Xiao, R.; Liu, Z.; Duan, J.; Qin, J. Process simulation and optimization of arc welding robot workstation based on digital twin. Machines 2023, 11, 53. [Google Scholar] [CrossRef]

- Wei, X.; Wu, H.; Yang, Z.; Han, C.; Xu, B. Simulation of manufacturing scenarios’ ambidexterity green technological innovation driven by inter-firm social networks: Based on a multi-objective model. Systems 2023, 11, 39. [Google Scholar] [CrossRef]

- Paul, R.; Anand, S.; Gerner, F. Effect of thermal deformation on part errors in metal powder based additive manufacturing processes. J. Manuf. Sci. Eng. 2014, 136, 031009. [Google Scholar] [CrossRef]

- Bun, P.; Gorski, F.; Wichniarek, R.; Kuczko, W.; Zukowska, M. Low-Cost 3D Printing in Innovative VR Training and Prototyping Solutions. In Intelligent Systems in Production Engineering and Maintenance; Springer: Wrocławska, Poland, 2019; pp. 553–562. [Google Scholar]

- Ostrander, J.K.; Ryan, L.; Dhengre, S.; McComb, C.; Simpson, T.W.; Meisel, N.A. A comparative study of virtual reality and computer-aided design to evaluate parts for additive manufacturing. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Anaheim, CA, USA, 18–21 August 2019; American Society of Mechanical Engineers: New York, NY, USA, 2019; Volume 59186, p. V02AT03A029. [Google Scholar]

- Angjellari, M.; Tamburri, E.; Montaina, L.; Natali, M.; Passeri, D.; Rossi, M.; Terranova, M.L. Beyond the concepts of nanocomposite and 3D printing: PVA and nanodiamonds for layer-by-layer additive manufacturing. Mater. Des. 2017, 119, 12–21. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kazancoglu, Y.; Sezer, M.D.; Top, N.; Sahin, I. Optimizing fused deposition modelling parameters based on the design for additive manufacturing to enhance product sustainability. Comput. Ind. 2023, 145, 103833. [Google Scholar] [CrossRef]

- Yuan, Q.K.; Luo, S.M.; Tang, W.Y. A collaborative design frame based on virtual prototypes and virtual manufacturing. In Proceedings of the 11th IEEE International Conference on Computer-Aided Design and Computer Graphics, Huangshan, China, 19–21 August 2009; pp. 568–571. [Google Scholar] [CrossRef]

- Al-Ahmari, A.M.; Abidi, M.H.; Ahmad, A.; Darmoul, S. Development of a virtual manufacturing assembly simulation system. Adv. Mech. Eng. 2016, 8, 1687814016639824. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).