1. Introduction

A supply chain connects several nodes, including suppliers, distributors, end consumers, and various other participants in a business chain. The core objective of supply chain management is to effectively integrate logistics, fund flow, and information flow so as to reduce costs and improve efficiency. Traditional supply chain management faces problems, such as the lack of data transparency, advanced trust mechanisms, and traceability. Blockchain technology, characterized by decentralization, tamper-resistance, and higher transparency, is well suited to address those existing problems. The World Economic Forum’s “Supply Chain Collaboration through Advanced Manufacturing Technologies” white paper and Deloitte’s “Using blockchain to drive supply chain innovation” report emphasized the transformative impact of blockchaining on supply chains, highlighting its potential to increase transparency, traceability, and trust among participants and help improve collaboration and efficiency. Therefore, integrating blockchain technology into supply chain management will improve operational efficiency and lower the operational risks and costs of supply chains, enabling a new revolution in supply chain management and bolstering industrial chain advancement. Currently, great progress has been made in using blockchain technology to improve the traceability of supply chains, that is, tracking products as they move along the supply chain. Blockchain technology enables the flow of authentic information among manufacturers, retailers, suppliers, and consumers, thus customer trust and confidence can be built. In particular, the pharmaceutical and food safety sectors have especially pressing demands for blockchain technology, as there are over 100,000 deaths due to counterfeit drugs worldwide yearly, costing pharmaceutical companies approximately USD 18 billion a year in lost revenue. Food safety issues also arise globally [

1,

2]. The IBM Food Trust, MediLedger, and other live blockchain applications serve as good examples in this regard. However, aside from the multiple successful commercial applications, we find that there is huge potential for the use of blockchain technology in supply chain collaboration, which has yet to be fully explored. If all participants in a supply chain are considered as nodes and are mapped with blockchain nodes, then the real business network from the perspective of supply chains highly overlaps with the blockchain network. The implementation of blockchain technology for supply-chain collaboration management will enable whole-process value transfer along supply chains and significantly improve efficiency and reduce costs. The inherent advantages of blockchain technology, including decentralized storage, distributed ledgers, data traceability, as well as immutability (which means tamper-resistance), could be brought into full play in facilitating supply chain collaboration.

The present study mainly focuses on the following three research questions:

What are the problems faced by traditional supply-chain collaboration management, and what are their root causes?

What is the impact of blockchain technology on supply chain management, and, specifically, how can it improve collaboration efficiency in the supply chain?

How to build a supply-chain collaboration model based on blockchain technology?

This paper investigates the above research questions by summarizing application cases of blockchain-based supply chains in the existing literature, carrying out a case study of Lenovo, and proposing a conceptual model for blockchain-based information collaboration systems, respectively. The contribution of this paper is twofold. First, by reviewing the related papers, we found that the literature focused on the advantages of blockchain technology in terms of traceability and transparency. However, this paper examines supply-chain collaboration management, which is largely unexplored. Secondly, we conducted semi-structured interviews with Lenovo’s supply chain managers through qualitative research and propose a conceptual model for blockchain-based information collaboration systems which addresses key challenges in traditional supply chain management. It integrates smart contracts, transaction authentication, and real-time data updates in blockchain-based information collaboration systems. It improves supply chain management by enhancing automation, transparency, and efficiency. The model ensures information continuity and authenticity and enables efficient data sharing, resulting in faster supply-chain response and increased effectiveness. The proposal of the model provides theoretical guidance for supply chain management and a significant reference for the strategy of introducing blockchain technology into a supply chain.

The present study includes the following sections.

Section 1 illustrates the background of applying blockchain technology to improve the efficiency of supply chains.

Section 2 reviews the literature and theories related to blockchain technology, supply-chain collaboration management, and blockchain-technology integration cases in supply chain management.

Section 3 analyzes the problems of traditional supply chain management and their causes.

Section 4 introduces the case of Lenovo.

Section 5 proposes a conceptual model for blockchain-based information collaboration systems based on the case study.

Section 6 discusses the potential future applications of the conceptual model for blockchain-based information collaboration systems.

Section 7 summarizes the main findings and conclusions of this study and identifies further research directions and difficulties.

2. Literature Review

The application value and potential use of blockchain technology in supply chain management are key research topics in the academic field and industry. The current theoretical research on supply-chain collaboration management is relatively advanced, yet the emergence of blockchain technology may fundamentally change the form of information sharing and transmission in supply chains and greatly improve the efficiency of supply chain collaboration. This section first outlines the development history of blockchain technology and introduces the basic theories of supply-chain collaboration management before presenting a detailed overview of the current application of blockchain technology in the field of supply chains. In general, the results of existing studies demonstrate that blockchains could reduce costs, enhance sustainability, promote collaboration, and facilitate information sharing in supply chain management. However, only a few studies have focused on the role of information technology in supply chains [

3,

4].

2.1. Blockchain Technology

The rapid development of blockchain technology has attracted worldwide attention. Relevant international organizations and government agencies in various countries have formulated policies on the development and application of blockchain technology accordingly. Top tech companies have also made significant investments in the research and development of blockchain technology. In recent years, the application of blockchains in sectors such as finance, education, healthcare, and the Internet of Things (IoT) has been preliminarily validated.

The blockchain is a technology that was introduced along with the cryptocurrency Bitcoin. It is the original core technology that underpins Bitcoin. According to Nakamoto [

5], a blockchain is a “peer-to-peer distributed timestamp server” that generates “computational proof of the chronological order of transactions” and records all these transactions. It is, in essence, a type of shared database that stores data or information which possesses the characteristics of immutability, traceability, transparency, and collective maintenance. The blockchain is a new application model for various computer technologies, including distributed data storage, peer-to-peer transmission, consensus mechanisms, and cryptographic algorithms. Every transaction in the blockchain needs to be consensually verified by all participants in the blockchain, which ensures the traceability and security of the information. Since all future blocks are connected to previous blocks, it is virtually impossible to modify any data without network consensus.

A distributed ledger is a highly transparent, secure, immutable, and decentralized database. There are three types of blockchain networks, namely, public, private, and consortium blockchains, which are classified according to the extent of access authorization required by the nodes. Luu et al. [

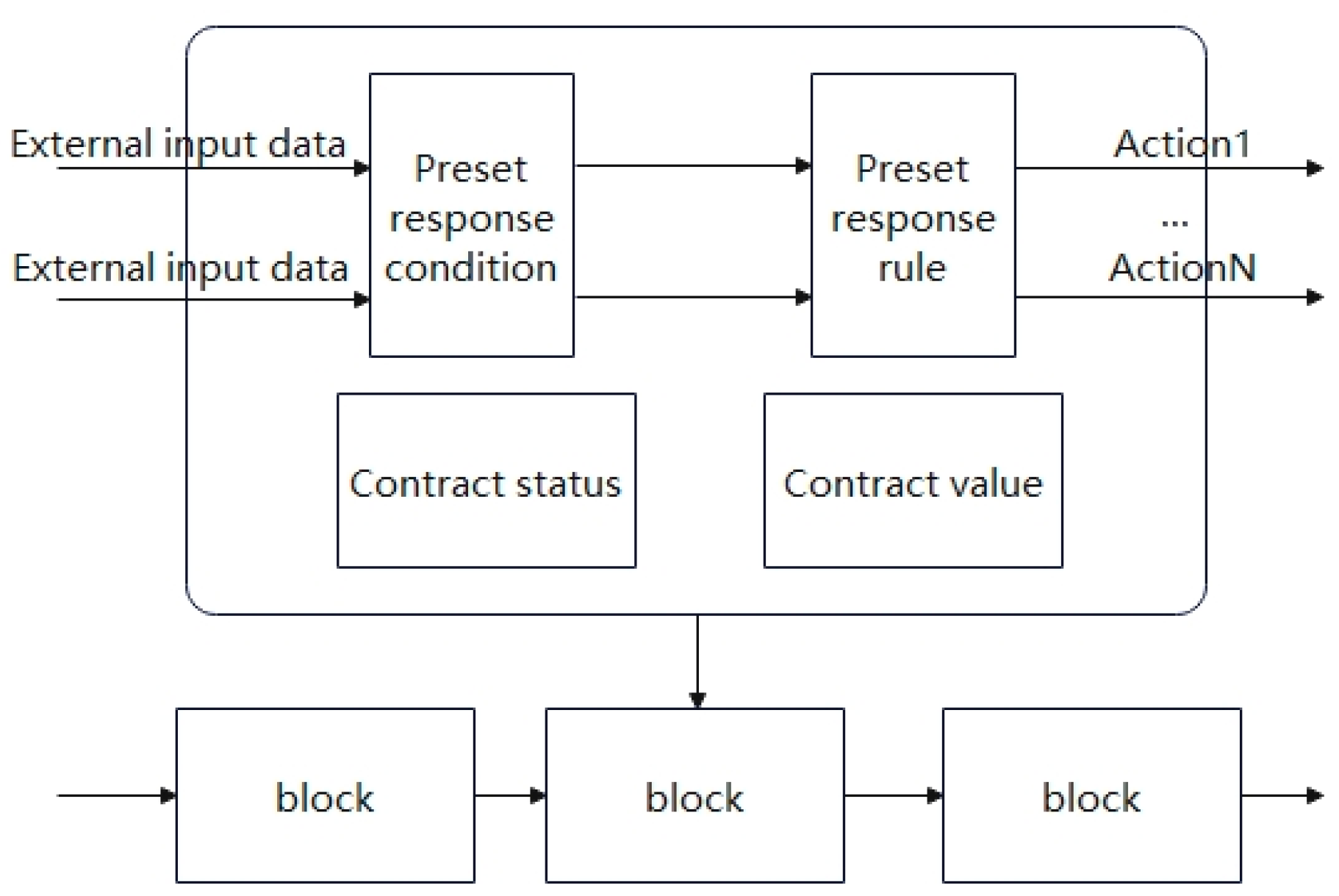

6] proposed the notion of smart contracts, realizing the automation of rule execution using scripting languages. Smart contracts thus serve as an important technological guarantee for blockchain-based technology platforms to achieve autonomy (see

Figure 1). Crosby et al. [

7] defined a blockchain as “essentially a distributed database of records”, wherein each and every transaction is verified by the majority of nodes in the network. Once a transaction is validated in the block and added to the blockchain, the data will be stored permanently.

Based on different types of blockchain technology and their corresponding usage characteristics, Melanie Swan [

8] defined the following stages of prospective blockchain development. Blockchain 1.0 focuses on currency transactions, in particular, realizing peer-to-peer Bitcoin transactions through cryptography. The key features of Blockchain 2.0 are privacy, smart contracts, and blockchain tokens, the most famous platform being Ethereum. Blockchain 3.0 concerns smart contracts that can be applied to more complex real-life scenarios. Meanwhile, the upcoming Blockchain 4.0 will involve artificial intelligence (AI) integration. Currently, blockchain technology is no longer reliant on Bitcoin and other cryptocurrencies. Instead, it is independent, such that it can be used in all areas of life in society. Many industrial sectors, for example, have been actively conducting research on ways to leverage blockchain technology, such as the application of “blockchains + supply chains” [

9].

2.2. Supply Chain Collaboration

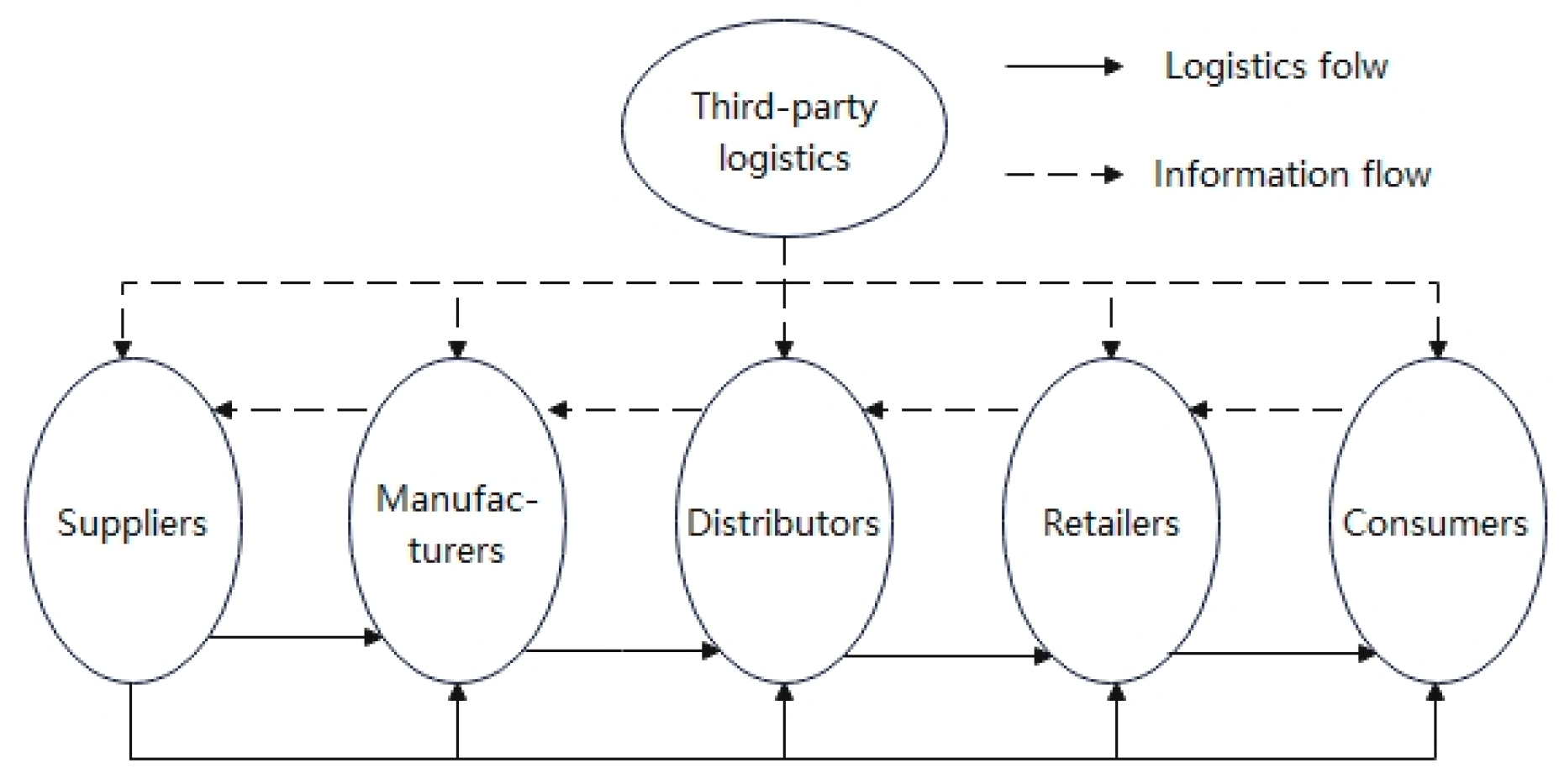

A supply chain is a functional network that connects suppliers, manufacturers, distributors, retailers, consumers, and third-party logistics (see

Figure 2). With the advancement of information technology and network technology, the supply chain management (SCM) model has gradually evolved from the initial human management to computer-information-system-based management. The form of supply chain management has shifted from traditional human management to e-commerce management, which allows for more flexibility, transparency, and accuracy [

10].

Supply chain collaboration refers to the process of mutual/shared participation among participants who have the ambition to establish mutual understanding and a shared vision and share resources to achieve collective goals [

11]. Collaboration in the context of supply chains has been well studied, and any single enterprise involved in the supply chain cannot compete alone. For example, raw-material suppliers should understand the demands of downstream customers in order to adjust the supply and improve the competitiveness of the entire supply chain in a timely fashion [

12]. Supply chain collaboration includes process integration and relationship integration, through which the supply chain participates in the collaborative work of enterprises to “plan and execute supply chain operations to achieve common goals and mutual benefits” [

13]. Supply chain collaboration can realize demand prediction [

14] and risk allocation [

15]. A large number of studies in the literature have demonstrated the importance of supply chain coordination. Chi et al. [

16] discovered that a formal contract has a positive effect on supply chain collaboration through intellectual and operational alignment by using data from a survey of IT and business executives in 209 firms. Sahay [

17] found that collaboration among all participants in a supply chain played a critical role in achieving the efficient operation of the supply chain and proposed a model for customer–supplier collaboration to optimize the operation procedures and facilitate the efficient operation of supply chains. Simatupang et al. [

18] concluded that supply-chain collaboration models should include three critical components, namely, information sharing, decision synchronization, and incentive alignment. According to Holweg et al. [

19], a seamless and synchronized supply chain collaboration leads to increased responsiveness and lower inventory costs for businesses. The study conducted by Wu et al. [

20] found that supply chain collaboration and information sharing have a positive impact on business performance enhancement and identified four key factors, namely, trust, commitment, reciprocity, and power, that influence the effectiveness of information sharing and collaboration in supply chains. Ali et al. [

21] noted that a key approach to reducing uncertainties in supply chains is the obtainment of high-quality information on product requirements. Tage Skjoett-Larsen, Christian Thernøe, and Claus Andresen [

22] examined the benefits and added value from transactions and cooperation among the collaborating parties in a supply chain and concluded that retailers would benefit from the collaboration among the retailers and the suppliers as they could respond quickly to each other’s demands.

2.3. The Use of Blockchain Technology in the Field of Supply Chains

Within a supply chain, there is a complex intermingling of cash, materials/goods, information, and product flows. The coordination mechanism with a single chain leader at the core is no longer able to coordinate all parties involved in a supply chain. As the nodes in supply chains increase in number, their network structures become increasingly complicated, and thus the information delivered may become easily distorted, which reduces the trust between the nodes in the supply chain and affects the efficiency of the supply chain [

23]. The development of blockchain technology provides new solutions to these problems, because it allows for more efficient, secure, and transparent interactions between all parties in a supply chain. Through blockchain technology, all participants in the supply chain can realize data sharing and information exchange while ensuring data privacy and security. Supply chain collaboration based on blockchain technology can improve the efficiency of the supply chain, reduce transaction costs, and enhance the stability and reliability of the supply chain.

With its decentralized nature, blockchain technology can be applied in scenarios of multi-party collaboration, as it addresses problems of insufficiency in the management capability, overall system efficiency, data transparency, and traceability of core enterprises in supply chains. Researchers have actively explored the use of blockchains in supply chains. Tian [

24] attempted to use blockchain technology to realize data storage in supply chains. Leng et al. [

25] built blockchain systems for agricultural supply chain systems based on blockchain technology with a double-chain architecture combining public blockchains and private blockchains, while Malik et al. [

26] proposed a supply chain framework based on consortium blockchains. Abeyratne et al. [

27] made use of blockchain technology in establishing a conceptual model for the management of manufacturing supply chains. Liu et al. [

28] proposed a system verification framework for the smart contracts of port supply chains with probabilistic behaviors and presented an architecture of a consortium blockchain-empowered port supply chain system. Weber et al. [

29] devised smart contracts with built-in translators to facilitate the interaction between nodes by connecting smart contracts through triggers. Chris [

30] argued that the traceability of the blockchain is able to address the problem of supply chain assurance when identifying trustworthy upstream suppliers and trusted tier-II suppliers for an acquirer. Li et al. [

31] analyzed the coupling between supply chain finance and blockchain technology, then proposed a conceptual framework for a block-chain-driven supply-chain finance platform. Kopanaki [

32] explained the relationship between modern IT infrastructure represented by blockchain technology and supply chain resilience.

The research on and the practice of using blockchain technology in the supply chain management of specific industries, such as the pharmaceutical industry, have further demonstrated its role in enhancing transparency and trust. Till et al. [

33] analyzed the value of blockchain technology applied in pharmacy supply chains. Toyoda et al. [

34] proposed a blockchain-based product-ownership management system to satisfy anti-counterfeit demand in the supply chain. Tseng et al. [

35] suggested a management model based on the Gcoin blockchain for drug supply chains to transform drug supply chains from inspection and testing to network-based regulation. Chiacchio et al. [

36] demonstrated the role of blockchain technology in simplifying and enhancing traceability throughout the drug life cycle. Chiacchio et al. [

37] then proposed a decentralized solution based on non-interchangeable tokens (NFTs) that builds on common serialization technology implemented by pharmaceutical manufacturers to improve standard serialization-process tracking capabilities, improve communication among supply chain stakeholders, and increase trust among end consumers.

Essentially, existing research focuses on using blockchain technology to prove the authenticity of the information shared by multiple participants in various business procedures within the supply chains. Choi et al. [

38] considered the impact of applying blockchain technology to acquire all authentic consumer transaction data, based on which consumers are categorized and thus provided with individualized services. Wang et al. [

39] built a blockchain-based framework for supply-chain information management in precast construction and expanded the application of blockchain technology in supply chains of buildings. Sharma et al. [

40] focused on the use of blockchain technology in a hybrid network architecture for smart cities to ensure access to secure data and its sources. Liu et al. [

41] proposed a fine-grained access control (FGAC) framework for supply-chain data sharing based on the blockchain Hyperledger Fabric.

As for the traceability of supply chains, blockchains play an important role in ensuring transparency in supply chains, distributed management of data sources, and incentives to boost the circular economy. Hughes et al. [

42] delved into the advantages of blockchain technology in achieving the Sustainable Development Goals (SDGs) of the United Nations (UN). Kouhizadeh et al. [

43] conducted a comprehensive survey of the supply chain and its internal activities and further evaluated the potential use of blockchain technology to improve sustainability along supply chains. Gopalakrishnan et al. [

44] explored the use of blockchains in solid-waste management. Bumblauskas et al. [

45] examined how businesses use blockchains to achieve higher accuracy and transparency when transporting goods through global supply chains.

In terms of trust mechanisms for supply chains, the use of blockchains allows value exchange between two or more enterprises without a central intermediary, such as a bank or any other third-party platform. Based on multiple case studies, Stefan Tönnissen and Frank Teuteberg [

46] found that the use of blockchain technology not only has an impact on stakeholders in supply chains but also influences business models of operations and supply chains. Zhang et al. [

47] proposed manufacturing service collaboration based on consensus mechanisms of blockchains, which effectively addresses the lack of willingness to collaborate and participate. The blockchain-based solution developed by Perboli et al. [

48] ensures that participating actors in supply chains automatically determine the ownership of goods, confirm shipment, track batches of products, monitor deliveries, and then trigger payments from suppliers. Luthra et al. [

49] noted that the adoption of blockchain technology and smart devices significantly improves the compliance measures of the trading system and effectively avoids fraud. Khaqqi et al. [

50] argued that blockchain technology can be incorporated to address fraud issues in the Emission Trading Scheme and to improve its efficacy with a reputation system. Shala et al. [

51] built a trust evaluation system to evaluate the blockchain-based trust consensus protocol for Machine-to-Machine Communication (M2M) and validated the robustness/resilience of trust consensus protocols and traditional consensus protocols against fake transaction attacks.

Blockchain-based tokens play an important role in the application of supply chains. Patidar et al. [

52] discussed how the tokenization of supply chain management can be achieved using blockchain tokens and analyzed the potential of tokenization to improve supply chain transparency and traceability. Dasaklis et al. [

53] proposed a supply-chain traceability framework based on malleable blockchain tokens to achieve audit tracking in complex supply chain networks. Dos Santos et al. [

54] introduced a food safety traceability system based on blockchain tokens and explored the role of tokens in improving food safety and traceability. It aims to improve the transparency and efficiency of global supply chains and business management. She et al. [

55] analyzed the structure and function of the VeChain ecosystem and discussed its potential in supply chain management.

2.4. Case Studies in the Literature

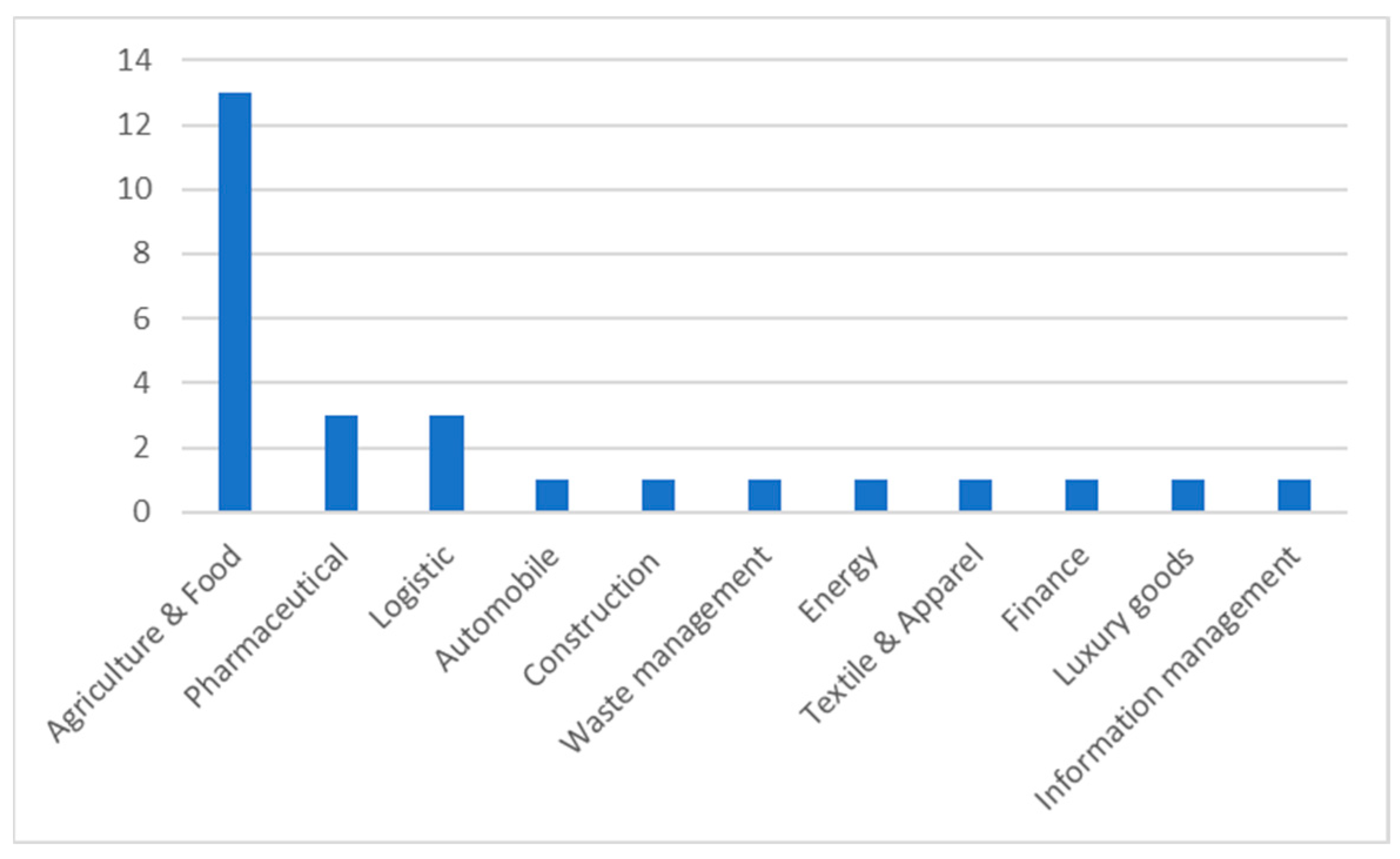

Despite the anticipated benefits and the numerous announcements of pilot cases, we have seen very few successful implementations of blockchain technology solutions in supply chain management. While the literature on blockchain technology supply chains is exceptionally rich, case studies based on real-world business applications are still relatively rare. We conducted a broad review of the previous case studies on blockchain-based supply chains. We collected the most relevant articles by searching for the proper keywords. We first collected the most relevant studies by conducting a keyword search in the Google Scholar database. The final list of primary keywords included “Blockchain”, “Blockchain-based supply chain”, “Case study”, and “Supply chain collaboration”. From Google Scholar, we surveyed peer-reviewed journal articles, academic books, and business-related news articles published from 2018 to 2023. As a result, we refined our selection to a total of 24 references.

Table 1 provides a summary of these 24 references in the literature, and

Table 2 highlights the key research gaps between this study and previous studies.

Overall, case studies regarding blockchain implementation in supply chains are dominated by food supply chains. More than 60% of the total case studies focus on agriculture and food. Pharmaceuticals and logistics are the next most-common areas but still far behind food supply chains (see

Figure 3).

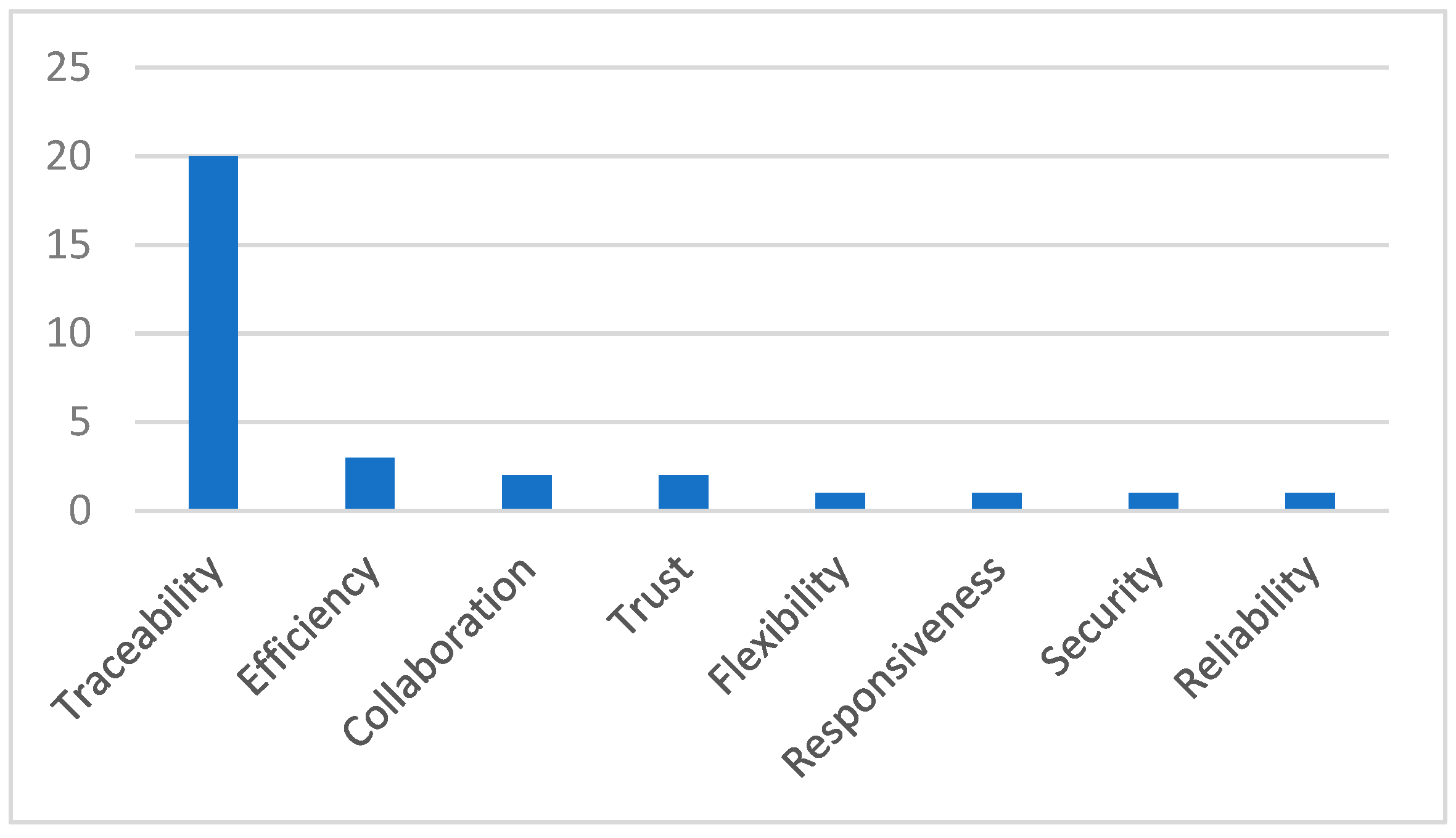

All of the case studies discuss the advantages that blockchain technology brings to the supply chains considered. A common advantage mentioned in the case studies is secure, real-time data handling with monitoring and control of data in a virtual environment. Therefore, the introduction of blockchain technology can bring many benefits to supply chain operations, such as traceability, efficiency, and so on. Improving supply chain traceability is the hottest topic in these case studies (see

Figure 4). However, the application of blockchain technology for supply chain collaboration is rare in the literature.

3. Problems Faced by Traditional Supply Chains

Supply chain collaboration, a concept proposed in the 1990s, aims to reduce internal losses among the nodes/enterprises in supply chains through collaborative management so as to achieve better collaboration and division of labor. The efficient flow of information between upstream and downstream supply chains is critical [

80] to increasing the competitiveness of supply chains. It supports relevant enterprises involved in supply chains, enabling them to better respond to uncertainties arising out of demand fluctuations, thus minimizing the bullwhip effect and reducing business inventories [

81]. In addition, with information sharing, the production costs, environmental costs, and social costs in supply chains are also mitigated [

82]. However, in real-world operations, there are still many problems associated with information collaboration in supply chains.

3.1. Existing Problems in Traditional Supply-Chain Information Collaboration

For traditional business operations, the procurement, manufacturing, logistics, and after-sales service of a supply chain network are usually managed centrally by the core enterprises in the supply chains. As business environments become more complex and business processes more precise, traditional, centralized supply chain management encounters a set of problems, which are listed below.

(1) The control of core enterprises

Core enterprises play an important role in supply chain nodes because unified planning and coordination are required when deploying information technologies in upstream and downstream supply chains, especially inventory management systems and radio-frequency identification (RFID) technology [

63]. However, core enterprises usually have too much power when constraining upstream and downstream supply chains, which easily dampens the enthusiasm of other companies in the supply chain and leads to lower efficiency and higher costs. The concentration of power within core enterprises can result in a dampened enthusiasm among other companies operating within the supply chain. The disproportionate control exercised by these core entities creates an imbalance in decision-making authority, limiting the autonomy and creative input of other supply chain partners. This stifling effect reduces the overall efficiency and agility of the supply chain, resulting in higher costs and suboptimal performance. Furthermore, the excessive control exerted by core enterprises can impede collaboration and hinder the development of synergistic relationships among supply chain partners. Collaboration and information sharing are vital to achieve supply chain objectives, yet the dominant position of core enterprises may discourage open communication and collaboration among the diverse entities within the supply chain network. This lack of collaboration undermines the potential benefits of sharing expertise, resources, and innovative ideas across the supply chain, hindering the overall performance and adaptability of the system.

(2) The mismatch between current capabilities and the requirements for traceability

Another significant challenge in traditional supply chains is the misalignment between current capabilities and the requirements for supply chain traceability [

68,

69]. Supply chains encompass a broad spectrum of interconnected business processes, including product procurement, manufacturing, sales, and consumption, all of which have far-reaching impacts. In this context, ensuring traceability throughout the supply chain becomes paramount in safeguarding product quality and protecting consumers from the risks associated with counterfeit raw materials.

Counterfeit raw materials present a serious threat to the integrity and quality of goods within the supply chain. These substandard materials can compromise product performance, undermine brand reputation, and result in significant financial losses for both manufacturers and consumers. To mitigate this risk, effective supervision and traceability mechanisms are essential.

However, existing traceability capabilities often fall short of meeting the complex requirements of modern supply chains. The supervision carried out by relevant authorities and enterprises, along with third-party anti-counterfeiting platforms, is hindered by a variety of factors, including cost considerations, efficiency limitations, and information challenges. These factors impede the seamless flow of information necessary for robust traceability systems. The supervision of the relevant authorities and enterprises and third-party anti-counterfeiting platforms are inefficient due to the impact of factors such as costs, efficiency, and information.

Cost considerations play a significant role in limiting the effectiveness of traceability measures. Implementing comprehensive traceability solutions requires substantial investments in technology, infrastructure, and workforce training. Many enterprises within the supply chain may find it financially burdensome to adopt and maintain such systems, especially when cost-cutting measures are prioritized to remain competitive.

Furthermore, efficiency issues hinder the seamless execution of traceability processes. The coordination and exchange of information across multiple nodes and partners in the supply chain can be complex and time-consuming. Inefficient information flows, manual data entry, and disparate systems employed by different supply chain entities create bottlenecks and data inconsistencies.

Information challenges further impede effective supply chain traceability. The sheer volume of data generated throughout the supply chain, coupled with variations in data formats and standards, poses significant hurdles. Ensuring accurate and timely information sharing among supply chain partners, relevant authorities, and anti-counterfeiting platforms is a complex task. Incomplete or inaccurate data can compromise the effectiveness of traceability efforts, making it difficult to identify the origins of raw materials or track their movement through the supply chain. As a result, existing traceability capabilities cannot effectively satisfy the requirements for supply chain traceability.

(3) The inadequate development of trust mechanisms

Trust is the foundation of effective supply chain collaboration, as it enables the exchange and sharing of information among related enterprises [

75]. However, given that these enterprises are independent entities operating in their self-interest, each enterprise has its own goals, strategies, and operational constraints. Thus, divergent demands may arise due to varying factors, such as time constraints, cost considerations, service requirements, and other unique circumstances, which can create conflicting objectives and priorities. This misalignment can result in differing demands and expectations among supply chain partners, leading to disagreements, delays, and suboptimal decision making. This lack of effective trust mechanisms and constraints significantly impacts the overall business development of enterprises involved in supply chains.

Moreover, the lack of effective trust mechanisms limits the sharing of sensitive information among supply chain partners. Enterprises may be reluctant to share crucial data, such as production schedules, inventory levels, or customer demand forecasts, due to concerns about information misuse, competitive advantage erosion, or breaches of confidentiality. This information asymmetry restricts the ability to synchronize activities, anticipate demand fluctuations, and respond swiftly to changes in the market environment.

Additionally, the absence of trust mechanisms can lead to opportunistic behavior within the supply chain. Without clear rules, monitoring mechanisms, or consequences of non-compliance, enterprises may engage in opportunistic practices, such as reneging on agreements, manipulating prices, or engaging in unethical behavior. These actions not only erode trust but also disrupt the smooth functioning of the supply chain and impede long-term collaboration. The lack of effective trust mechanisms and constraints affects the business development of enterprises involved in supply chains.

3.2. Analysis of Causes of Problems Faced by Traditional Supply Chains

Drawing on the characteristics of traditional supply chains, this study reveals the root causes behind the challenges encountered by these supply chain systems. Three primary factors contribute to the problems faced by traditional supply chains, namely, immature supply-chain information collaboration, technological and financial discrepancies among enterprises, and insufficient inter-partner trust.

Firstly, the immaturity of supply-chain information collaboration poses a significant obstacle to effective collaboration within traditional supply chains. Information sharing lies at the core of supply chain collaboration, and the level of information shared directly impacts the collaborative outcomes. Unfortunately, many enterprises in supply chains rely on standardized information-sharing mechanisms that impose multiple limitations on effective collaboration. These mechanisms restrict the flow of information among supply chain partners, hindering the exchange of critical data necessary for efficient decision-making. Additionally, partnerships between some enterprises remain relatively unstable, exacerbating the challenges of information collaboration. Furthermore, the lack of compatibility among information technologies utilized by different supply chain participants adds to the barriers, impeding seamless communication and integration of information across the supply chain. Insufficient trust among partners and high maintenance costs further contribute to the overall low level of information collaboration within traditional supply chains.

Secondly, technological and financial discrepancies among enterprises pose challenges to achieving effective supply chain collaboration. To achieve supply chain collaboration, a large amount of money is required to support the unified deployment of information systems. This demands the strong financial strength of enterprises. Additionally, the training of operators and subsequent system maintenance also generate greater costs. Supply chain participants differ in terms of types and levels and represent a wide range of business processes from manufacturing to after-sales service, connecting not only core enterprises with strong financial strength but also small factories for the assembly of parts, as well as many other enterprises of various scales. The economic strengths of such enterprises vary drastically. In traditional supply-chain information collaboration, there are huge differences in investments made by enterprises for information management and information systems, which holds back the development of supply-chain information collaboration.

Thirdly, inter-partner trust within traditional supply chains has not yet reached a sufficient level, impeding effective information collaboration. In the early stages of establishing supply chain relationships, enterprises tend to prioritize short-term profit improvement. However, they often overlook the need to create a multi-tiered, multi-faceted collaboration management approach to secure the benefits of information collaboration. As a result, enterprises are unable to exchange real-time information regarding procurement, manufacturing, transportation, sales, and other business processes. This lack of real-time information exchange limits their ability to respond flexibly to unforeseen circumstances and make high-quality decisions aligned with market demands.

4. Case Study of Lenovo

Blockchain technology allows various participants in a supply chain to store, calculate, and monitor their information in the platform, which enables real-time information transmission and sharing among multiple actors involved in the supply chain. The platform checks and records operations and transactions and achieves intelligent data collection and contracting as well as fulfillment, thus improving the service capability of the supply chain. The present study examines Lenovo’s use of blockchain technology to improve its supply-chain management capability and brings forward a conceptual model for blockchain-based information collaboration systems. We chose Lenovo as the case because it is a globally recognized company with an excellent supply chain. Lenovo has established strong relationships with both upstream and downstream partners, and there is no doubt that its strategies in supply chain management and the implementation of blockchain technology provide leading guidance for various industries.

4.1. Background Information

Lenovo operates in 180 countries and regions and runs 35 factories worldwide. It cooperates with over 1000 suppliers and 2.8 million distributors and third-party agencies. It processes more than 5 million orders and produces more than 150 million units of smart devices on a yearly basis. Lenovo has established a complicated supply chain network. For example, LCFC (Hefei) Electronics Technology Co., Ltd., the company’s largest personal computer (PC) factory in the world, processes 30,000 rolls of electronic materials through the fully automatic warehousing system per day and transfers more than 2000 kinds of raw materials every four hours, meaning that any potential problem in part production may disrupt the supply chain. The LCFC (Hefei) factory actively develops products of the fourth industrial revolution, such as intelligent production scheduling, joint production scheduling, supply chain collaboration based on blockchains, and other innovative applications, greatly improving production efficiency. At the beginning of 2023, the LCFC (Hefei) factory was successfully selected for the “lighthouse factory” list which represents the highest level of global intelligent manufacturing.

Previously, to ensure the stable operation of the entire supply chain, Lenovo, together with its suppliers and OEMs, had to assign a large number of workers to fulfill complicated, time-consuming tasks, including checking the accounts and keeping track of order statuses. Despite this, it failed to achieve efficient collaboration. Since 2017, Lenovo has applied blockchain technology to the supply chain by proposing a model integrating the supply chain and blockchain (hereinafter referred to as the dual-chain integration model). It applies the model to the server business to integrate the flow of information, logistics, and flow of funds in its supply chain, thereby ensuring higher transparency in each manufacturing step. After five years of development, Lenovo has made great progress in the research and application of the combination of blockchains and supply chains (see

Table 3).

4.2. Case Study Deployment

This research employed a qualitative approach and collected data through semi-structured interviews. The interviews were conducted with the head of Lenovo’s blockchain R&D department and two sales managers from the sales department. Each interviewee answered twelve questions, and the process lasted about two hours. Our objective was to examine the business challenges addressed by Lenovo’s blockchain solution in supply chain management, explore its efficiency improvements, and understand the solution’s main contents and framework. Additionally, we aimed to propose a conceptual model of blockchain information collaboration systems based on associative cases. To ensure privacy, the interviews were recorded by handwriting, as requested by the respondents. The main conclusions and interview results are summarized in

Section 4.3 and provided in the

Appendix A.

Following the 5W1H framework, the research method can be described as follows:

Who: The interviewees included the head of the blockchain R&D department at the Lenovo Research Institute and two sales managers from Lenovo’s sales department.

What: The research involved conducting semi-structured interviews to explore Lenovo’s blockchain solution, its impact on supply chain management, and the resolved business difficulties and efficiency improvements.

Where: The interviews took place at Lenovo’s premises or a mutually agreed location.

When: The interviews were conducted within a specific timeframe, with each interview lasting approximately two hours.

Why: The primary purpose was to understand the business challenges addressed by Lenovo’s blockchain solution, assess its efficiency improvements in supply chain management, and propose a conceptual model of blockchain information collaboration systems based on associative cases.

How: The research employed a well-designed interview questionnaire (

Table 4) to guide the interviews and collected data through handwritten notes, as requested by the respondents.

4.3. Results

4.3.1. The Complex Problems and Challenges Confronting Lenovo’s Supply Chain Management

Lenovo uses original equipment manufacturers (OEMs) for production. The raw materials used by the OEMs for production are purchased by Lenovo from certified raw-material suppliers. After the OEMs assemble the finished products, Lenovo conducts a unified quality inspection and stores them in the warehouse. The complex problems and challenges confronting Lenovo’s supply chain management in the process of procurement and sales are listed as follows:

First, ledger records may be inconsistent with the actual inventory. The company deals with a wealth of information regarding plans, procurement, prices, and payments, as well as logistics engaging in multilateral transfer and collaboration with one another. Supposing that mismatches, delays, or human errors occur in the course of exchange and collaboration, problems, such as discrepancies in product inventories, postponed deliveries, extended payment cycles, and unknown order statuses, may arise.

Second, information fragmentation poses a challenge. As the OEMs need to purchase raw materials through Lenovo to produce devices for the company, they cannot find out when the suppliers will accept their orders, and the logistics statuses of shipments will update. This lack of information means they cannot make an accurate production schedule for the next step.

Third, the supply chain cannot respond to information on time. Suppliers, who provide raw materials, have to send the goods directly to the OEMs after receiving orders from Lenovo. So, it is hard for Lenovo to keep track of the accurate times at which the OEMs receive the goods, thus prolonging the entire payment cycle. In the case of defective raw materials, Lenovo, the buyer, is unable to acquire first-hand information, so it cannot respond to the problem promptly and handle it as soon as possible.

4.3.2. The Blockchain-Based Solution of Lenovo and Efficiency Improvement in Its Supply Chain

Under the dual-chain integration model, Lenovo, its suppliers, and OEMs achieve real-time data synchronization. Every piece of information is documented clearly and shared in real time, simplifying the procedures of repeated confirmation among them.

First, in line with the demand schedule, the OEMs upload the purchase orders to the blockchain system through the enterprise resource planning (ERP) system, which in turn simultaneously shares the information with Lenovo and its suppliers. The data shared will automatically trigger the generation of POs, and the suppliers will prepare raw materials in advance, thus effectively shortening the supplier delivery cycle and Lenovo’s payment cycle.

Second, the suppliers upload the information about advanced shipping to the blockchain system after it finishes manufacturing. The OEMs can arrange production schedules following the shipping information shared by the suppliers through the blockchain system without receiving any physical goods.

Lastly, the OEMs need to upload the receipt information of physical goods and the usage information of raw materials to the blockchain system to ensure the consistency of the inventory information of multiple parties and allow them to respond to quality issues, if there are any, promptly.

Dual-chain integration enables Lenovo’s sourcing and sales process to be more cost-effective and faster in a shorter period, making it a key step in quality and efficiency improvement for the enterprise. Through the interview, we learned that the efficiency of its supply chain has been bolstered significantly due to the application of blockchain technology (see

Figure 5). To be more specific, blockchain technology saves more than 15 percent of the cost of human cross-checking in the process of sourcing and sales. Reliable data sharing saves up to 15 percent of the time spent on the procedures of overall estimation and materials preparation. Real-time order tracking allows all parties to gain information about orders seven days earlier than before and increases the delivery accuracy of production schedules by 10 percent. The number of goods in stock becomes more accurate, and the turnover rate rises by over 10 percent. Under the impacts of the COVID-19, Lenovo’s supply chain has demonstrated strong resilience. When faced with unexpected production and work suspension due to pandemic control, decision makers in the supply chain were able to draw up plans to switch production schedules rapidly with the help of blockchain technology in less than two hours, which took at least several days previously, and the success rate of the switch was 80% higher than before.

4.3.3. Technical Solution of Lenovo’s Dual-Chain Integration

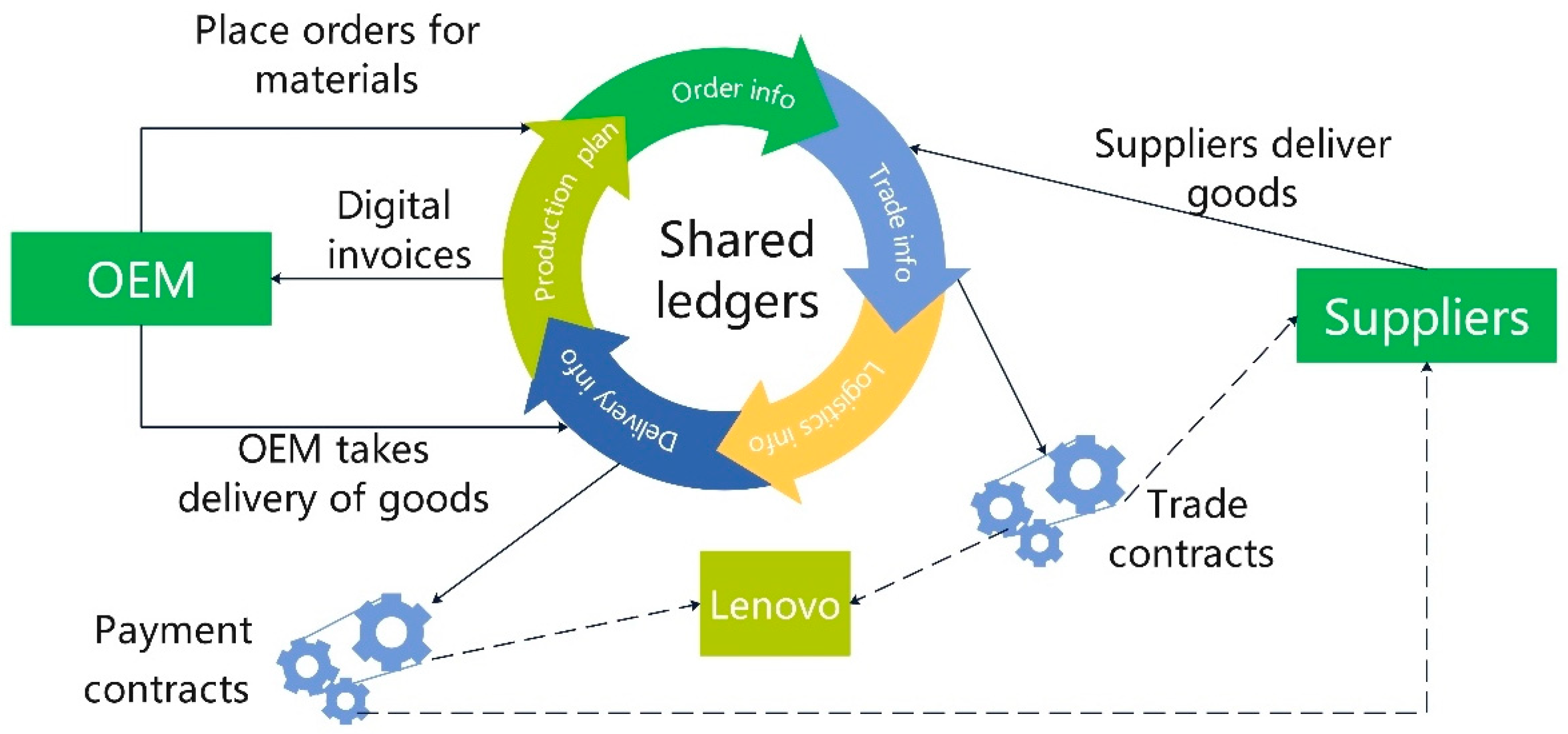

Lenovo has developed a consortium chain network based on Hyperledger Fabric and other mainstream consortium chain technologies and formulated a technical solution to the dual-chain integration (see

Figure 6) to fulfill the following functions: the visualization of the full order delivery cycle of part orders across the enterprises; the achievement of real-time online tracing of manufacturers’ inventories of parts and components; triggering of automated cross-enterprise procedures by the production schedules in the case of understocking; performance of the transfer of property rights of goods according to international trade terms; the affixing of digital signatures and the encryption and decryption of electronic invoices in line with security rules; and the tracking of the shipping and arrival of parts and components.

The business procedure of Lenovo comprises the following steps.

First, an OEM creates a transaction request and uploads the information on the PO to the blockchain-based platform. The enterprise and its suppliers then simultaneously receive the sourcing information shared by the OEM in the supply chain. Based on shared data, the PO generation of the enterprise is triggered automatically, allowing the suppliers to start estimation and materials preparation in advance and shortening the operation time of the entire procedure. The OEM and suppliers will stay informed of the latest statuses of documents in a real-time manner when the enterprise uploads the PO to the blockchain. Next, when the suppliers complete the production of raw materials, they upload the information on advanced shipping to the blockchain network and send the physical goods directly to the OEM. In line with the information shared, such as the shipment and the estimated time of arrival, the OEM revises and improves the production schedule in advance, and the enterprise launches a settlement with the suppliers based on the information shared in the supply chain. Lastly, the OEM needs to upload the receipt information of the physical goods and the production information to the blockchain for the automatic calculation and reconciliation of the inventory information from multiple parties.

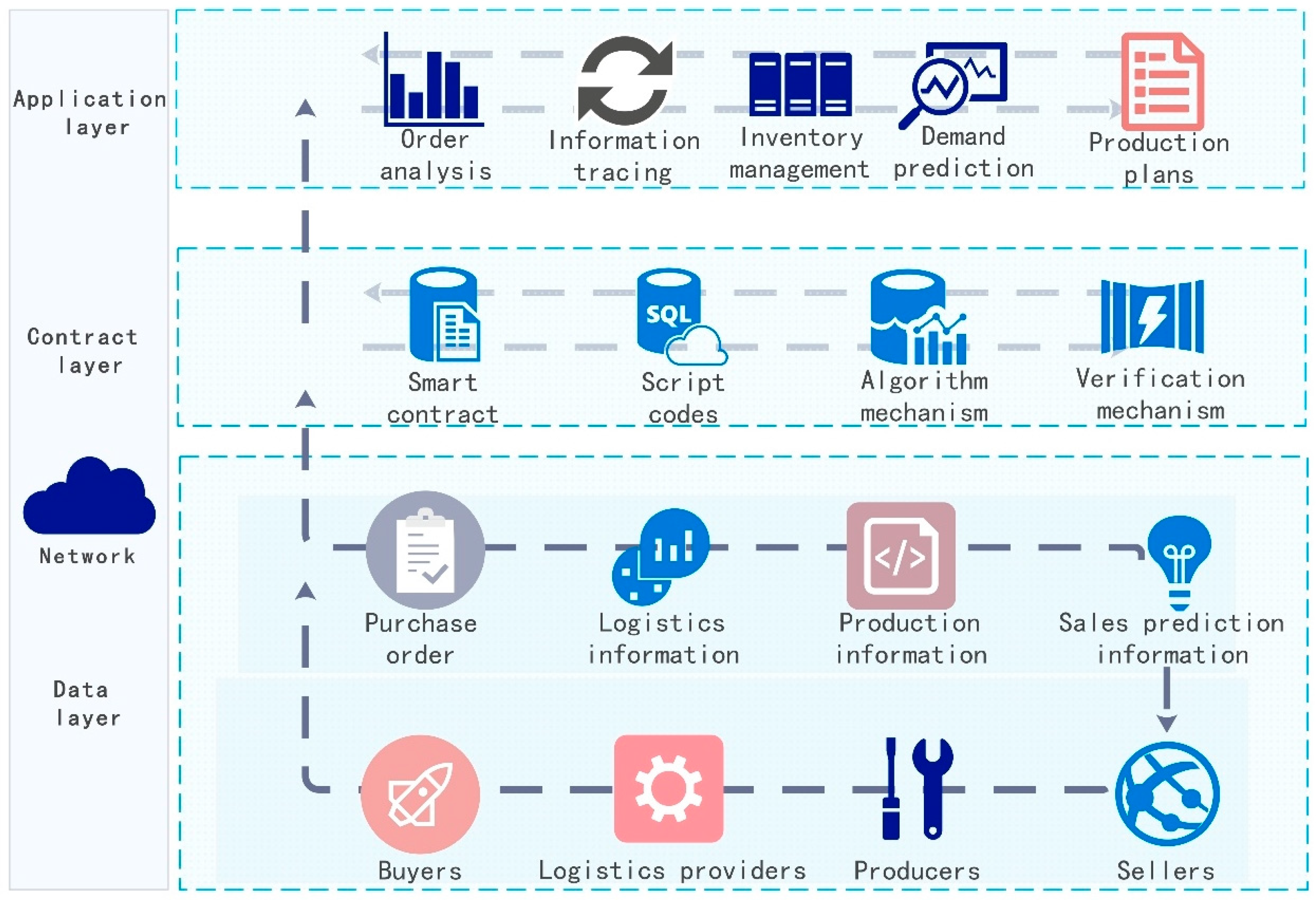

5. Conceptual Model for Blockchain-Based Information Collaboration Systems

Generally speaking, manufacturers such as Lenovo need to designate qualified raw-material suppliers for OEMs in order to control the quality and prices of the finished products they produce. Using such measures, they could reduce the sourcing costs of raw materials by signing bulk purchase agreements with suppliers, thereby reducing the manufacturing costs of the OEMs. Regarding this application scenario, this study brings forward a conceptual model for blockchain-based information collaboration systems. Under the model, the information of the application layer, the contract layer, and the data layer of a supply chain is integrated. Each block in the blockchain contains the information of all previous blocks. Newly added blocks will automatically identify previous contracts and initiate the contracting process. Then, relevant steps will be executed automatically, which enables intelligent information collaboration management at a higher level. The architecture of the model is presented in

Figure 7. The details are as follows:

(1) Data layer

The data layer defines how the data in each node are connected and organized for information verification and data encryption. Starting with the genesis block with no transaction record, new blocks are added continuously. The chain structure thus formed contains hash values, random numbers, the timestamp certifying the transaction, transaction information data, public keys, and private keys. It is the bottom-most underlying data structure of the entire blockchain technology. The integration of the data layer and the Internet of Things (IoT) enables real-time automatic data updates for supply chains and accordingly enhances the quality of information.

(2) Contract layer

The contract layer contains multiple script codes and algorithms that are required for blockchain operations and more complex smart contracts. It plays an essential role in allowing the blockchain system to achieve flexible programming and data manipulation. As a type of self-executing agreement, smart contracts are embedded in the computer code in a blockchain. Under a set of rules contained in the code, all parties to the smart contract agree to interact with each other, and if the pre-defined rules are met, the agreement will be executed automatically. Hence, smart contracts provide a mechanism for the effective management of equity assets with access granted to multiple parties.

With a smart contract, every protocol, procedure, task, and payment comes with a digital record and signature which are identified, verified, stored, and shared. Smart contracts formalize the governance rules—the bylaws, governing statutes, rules of procedure, or articles of association of an organization—and replace day-to-day operations management with self-enforcing codes. Smart contracts often contain one user interface to enable interaction between users and the contracts concluded and ensure that such interaction strictly abides by the logic already set forth. Cryptography and data encryption guarantee the anonymity of the parties to the contracts.

(3) Application layer

The application layer encapsulates the application scenarios of supply chains. It is an intermediary for interactions between participants in supply chains and information platforms as well as a carrier of direct information exchange between users. Supply chain participants keep a record of logistics, information flows, and fund flows via the application layer. Financial institutions facilitate the financial information flow in the supply chain by providing financial services, such as financing, insurance, and auditing, for companies based on the logistics, information, and fund flows. Regulators intelligently monitor the supply chain enterprises and financial institutions involved in regulatory platforms through smart contracts to safeguard the sound development of supply chain networks. Blockchain technology enables efficient and free information flow, financial information flows, and regulatory information flows in supply chains through the application layer.

As an online system, the blockchain system needs to be matched with offline information, such as logistics and people flows, through supporting data processing procedures, namely, physical data acquisition and processing. The details are illustrated as follows:

(1) Data acquisition

The physical layer uses radio-frequency identification (RFID) technology, QR codes, near-field communication (NFC), and sensors to upload information about products, retailers, and logistics to the blockchain system. The data establish the operational basis of the whole supply chain. All participants involved in the supply chain can, based on their characteristics, upload information on product parameters, transactions, logistics statuses, and operation statuses to the blockchain through pre-defined data interfaces. QR codes are most frequently used for data acquisition due to their inexpensive cost. RFID, a sophisticated technology with a moderate cost, requires professional equipment and applies to enterprises and products at a medium price. NFC technology enables higher security and has the highest cost, so it applies to high-value products. Sensors can be used to monitor the operational parameters of products and play a vital role in service-oriented manufacturing. In the actual operations of a supply chain, various data access methods may be adopted according to different needs, as appropriate.

(2) Information storage and management

Blockchain technology ensures the effective integration of information and data between nodes in supply chains. The mesh topology formed among nodes means that the disruption and destruction of certain links will not affect the chain of other nodes, which enhances the stability of supply chain systems. The network facilitates data communications between the application scenarios of the blockchain and secures data transmission via digital signature technology and hash algorithms. To ensure the robust operation of a system, all participants are expected to maintain sound Internet access. In addition, the blockchain system could use keys to authorize different nodes. Authentication via consortium blockchains can be used to individualize authorization for different information operations and protect private information, ensuring the authenticity and availability of the information while improving information security.

(3) Incentive mechanisms for data uploading

Proof-of-stake (PoS) mechanisms are used to measure the workloads of participants, among whom the benefits are distributed accordingly to encourage their contribution. In line with real-time, reliable data acquisition, production and sales schedules are adjusted dynamically, continuously keeping the cost under control and thus driving the overall information quality of supply chains. Incentives act as rewards for nodes that abide by rules and contribute to ledger maintenance, which in turn facilitates the normal operations of blockchains. Regarding information sharing within a supply chain, the incentives for participants in the supply chain who engage in blockchains are economic benefits yielded by information sharing.

To summarize, the conceptual model for blockchain-based information collaboration systems proposed herein has the following characteristics. First, it incorporates smart contracts into supply chain systems to improve the intelligence and automation levels of these systems. Supply chain enterprises struggle with challenges arising out of traditional supply-chain information collaboration management, including poor information continuity, information silos, and inefficient collaboration. The introduction of smart contracts allows the establishment of a highly transparent management system for information collaboration, which, without human interference, enables a more efficient procedure and generates verifiable records and signatures, thereby significantly enhancing the efficiency and effects of information collaboration in supply chains. Second, the establishment of transaction authentication mechanisms in the blockchain ensures the authenticity of information on supply chains and forestalls any attempts to alter the information, thereby enhancing the accuracy of such information. Third, given the compress-store on the blockchain, the model integrates existing databases and leverages integrated data to achieve efficient information sharing and satisfy market demands. Fourth, the blockchain contains real-time data. When the data in the system are updated in a real-time manner, all the data generated by the operations of all links are stored in the system as well, which allows enterprises to exercise systematic management over inventories and other information and propel the response speed of supply chains.

6. Potential Applications of the Conceptual Model for Blockchain-Enhanced Collaboration Systems

At present, the supply-chain enterprise centralized system (such as the ERP system) can only manage the supply chain information within the enterprise and is unable to effectively collect and manage the data generated by the supply chain. The establishment of a unified supply-chain collaboration platform based on blockchaining can distribute and record the complete digital footprints of products in the supply chain process from raw-material procurement to final product sales. All information can be reached immediately by all parties in the supply chain network without the participation of intermediaries, which may affect the quality and transparency of information. It brings higher visibility and controllability to products and supply chain processes, avoids mistransmission of information and unnecessary coordination, and enables supply-chain collaboration partners to discover problems in a timely manner, learn about the operation of the supply chain network, and make better decisions to improve supply-chain collaboration efficiency. At the same time, the integration of supply chain processes based on a transparent and visual shared ledger will further reduce the synergy complexity, optimize the decision-making synchronization process, and truly improve the supply chain synergy performance. To be more specific, it boasts the following advantages:

First, it reduces the costs borne by the enterprises involved in supply chains. As a decentralized, open-source solution, blockchaining lowers the cost of platform deployment and communications and information processing. With a lower participation threshold for enterprises, it encourages supply chain enterprises to make contributions to its development. In addition, blockchain technology could effectively reduce the repetition rate and the storage cost of data and substantially lower inventory levels, thereby achieving cost cuts and efficiency enhancement in supply chains.

Second, it protects businesses’ interests from counterfeit and inferior products. Since the data posted on the blockchain ledger are immutable and traceable, the blockchain could effectively guard against counterfeit and inferior products by pursuing real-time information inquiries in the blockchain-based platforms and taking preventive measures accordingly. When counterfeit and inferior products are identified, the traceability of blockchains ensures that the sources of the counterfeits can be found in a short period of time.

Third, the introduction of blockchain technology improves the efficiency of information dissemination, which, in turn, plays an important role in supporting enterprises, as supply chain nodes lower the cost of information processing. Integrating blockchain technology into supply chains improves information transparency between nodes in supply chains and addresses the information asymmetry between enterprises in upstream and downstream supply chains. The credit of core enterprises is transferred layer by layer through the blockchain to give credit guarantees to small enterprises in the midstream and downstream. Furthermore, blockchain technology ensures the validity of information recorded in the blocks, reduces the credit cost of enterprises as nodes, and bolsters the service quality of supply chains.

Fourth, blockchain technology contributes to the credit enhancement of supply chains. The blockchain-based application scenarios in supply chains provide access to a wealth of data, document the flow of commodities, and effectively fulfill the financial demands of supply chains on the basis of tracing, deposit certificates, mutual trust, and information exchange.

7. Discussion and Conclusion

As a secure, trustworthy, decentralized, and tamper-proof solution with consensus mechanisms, blockchain technology transforms traditional centralized supply chain management. It addresses the challenges confronting traditional supply chain operations, such as inefficiency, lack of data transparency, and poor traceability. As a result, it significantly improves the operational efficiency of the companies involved in the supply chain and provides them with efficient information sharing. Thereby, it offers greater cost-effectiveness, better information quality, fewer moral risks, and the ability to automate the execution of existing contracts using smart contracts. In other words, blockchain technology revolutionizes supply chain management. After a review of the development of blockchain technology and the related literature on the application of blockchain technology in the field of supply chain management, we found that there is a lack of blockchain applications in related fields that focus on improving the collaborative efficiency of supply chains. At the same time, we also found that Lenovo emphasized this aspect in its external publicity, so we carried out a case study with Lenovo as the object. Through interviewing key technical personnel and sales personnel, we investigated the difficulties Lenovo encountered in supply chain management and the business practice of how to apply blockchain technology to solve relevant problems. The benefits of relevant solutions in terms of reducing cost and improving efficiency were summarized. Our research shows that blockchain applications whose main goal is to improve collaboration have certain application prospects and need more attention. In order to help other enterprises in the industry to better learn from Lenovo’s practice, we summarized and abstracted Lenovo’s technical solutions into a data layer, a contract layer, and an application layer, and explained the contents and functions to be realized in each layer, forming a three-layer architectural model of a supply-chain information system based on blockchain technology. The conceptual model proposed in this paper emphasizes the possibility of developing the application of blockchain technology from the perspective of supply chain collaboration and provides the basic direction and content that should be considered, such that it can serve as a reference for other enterprises. It is worthwhile to highlight that our case study primarily examined the collaboration problems within the context of Lenovo’s practice, simply by focusing on the mechanisms of the blockchain instead of the IT industry characteristics. Therefore, the proposed conceptual model is widely applicable and adaptable for various industries and supply chains.

However, blockchain technology still faces some challenges in supply chain collaboration which will be addressed progressively in future research and practices. First of all, the protection of private data should be improved. Many blockchain solutions avoid uploading private data to the chain or simply upload the hash values of data to the chain in order to protect trade secrets. However, the sharing of real business data in supply chains is valued in the field of supply chain collaboration. Therefore, comprehensive use of cryptographic algorithms and even hardware should be ensured to strengthen privacy protection in the blockchain. Second, the application of blockchain-based supply chain collaboration needs to be further promoted. Compared with finance, deposit certificates, pure tracing, and other application scenarios, the blockchain-based application in supply chain collaboration calls for more sophisticated technologies. Still, not many enterprises are ready or willing to adopt the application, so effective promotion is yet to be achieved among enterprises in the upstream and downstream supply chains. Moreover, some “blockchain plus supply chain” projects have yet to achieve systematic business operations management. Third, relevant policies and regulatory systems should be further improved. The smart contract technology of blockchaining could replace intermediaries to a certain extent, thereby steering clear of human interference and rendering equitable and trustworthy transaction information in supply chains. In spite of this, smart contracts are not considered legally binding contracts, meaning that their legal effect remains contestable. Fourth, application standards for relevant technologies should be further specified since the international community now attaches great importance to blockchain standardization. Global and Chinese standardization organizations, such as the International Standardization Organization (ISO), the Institute of Electrical and Electronics Engineers (IEEE), the International Telecommunication Union (ITU), the World Wide Web Consortium (W3C), and the China Communications Standards Association (CCSA), have initiated the standardization of blockchains. However, regarding the application scenario in supply chain collaboration, existing studies on the applicable standards of relevant technologies remain inadequate. Therefore, in the future, typical innovative applications for the large-scale promotion of blockchains could be considered and the logic for the scenarios of blockchain-enabled supply chains could be further clarified.