1. Introduction

Manufacturing systems have changed over the last decades due to user demands. The changes were due to rapid technological advances, more complex systems, and changing customer needs. Hence, manufacturing systems must be flexible, reliable, and focused on the user’s customization. These changes brought new opportunities for businesses, but there is uncertainty about the implementation and use of modern technologies. One of these technologies is the digital twin (DT) method, which transforms physical spaces into virtual spaces. However, this digital transformation could bring more problems and affect a manufacturing system’s lifecycle [

1].

A digital twin (DT) is a virtual representation of a physical asset that is virtually indistinguishable from its physical counterpart. It includes design and engineering details that describe the asset’s geometry, materials, components, and behavior or performance. In other words, it is the digital counterpart of a physical entity. DT is a model that shows the virtual and physical space of a system. The system uses sensors, actuators, controllers, and interaction models to integrate the physical and virtual space into one single system. The model’s process connects the flow of data and information between the physical and virtual spaces. DT uses conceptualization, comparison, and collaboration tools to solve problems and to innovate. It can simulate and optimize three areas of a manufacturing system: production planning and control, maintenance, and layout planning [

2].

The digital twin method is relevant for factories in staying at the forefront of the next industrial revolution, Industry 4.0. It is a duplicate, backup copy of a system of interest. It provides digital solutions for manufacturing companies. These solutions will add business value to their processes and products. These companies will be able to simulate current and future processes and make better decisions. DT digitalizes the system, its process, and products. The DT advantages are operational improvement, quick development of products, fewer defects, easy access to data, and the creation of new businesses [

3].

The implementation of DT adds several values for businesses, in terms of quality, warranty, costs and services, operational costs, record retention and serialization, new product introduction costs and lead times, and revenue growth opportunities. Moreover, DT presents diverse models based on a system’s maturity and complexity, such as digital visualization, digital development, digital twin enterprise, digital twin ecosystem, and digital twin orchestration. These models go from low-level maturity to high-level-maturity. Digital twin intends to provide real time images of objects, processes, and information. These images can add important value in improving business performance. The development of digital twin uses knowledge of information technology and operations technology to model business processes and fulfill business functions.

Nevertheless, there are many challenges in implementing DT in a manufacturing system. One challenge is the connection and integration of all Internet of Things (IoT) devices, machines, and objects. These connections allow data-sharing among physical and virtual spaces. It is also important to consider that DT works with real-time data, without requiring human-o-human interaction. Moreover, DT operations must be autonomous. Overcoming these challenges establish big milestones in the creation of digital twins. Moreover, costs and time are always challenging for new and big projects. The time and resources needed to carry out this work could be enormous. It is difficult to estimate the cost of implementing DT, due to its variety. Complex systems require a huge investment for developing and operating DT technology [

4].

1.1. Specific Contribution

This article focuses on studying the ambiguity of some problems with the DT concept and its implementation. There are problems related to the DT definition and/or the development of DT models in a manufacturing domain [

5]. It is necessary to define, characterize, and describe the DT concept for manufacturing systems.

Previous articles have considered the use of systems theory or science to define digital twin technology. All of them supported DT and presented the benefits of implementing DT in manufacturing domains. Nevertheless, they presented different purposes and scopes of study. Mandi et al. [

6] studied the integration of DT into model-based systems engineering (MBSE). They characterized different DT levels based on model sophistication. Bianconi et al. [

7] used systems thinking principles to study the DT definitions in the literature. They presented a methodological reference that could help researchers propose a new DT definition. Dietz and Pernul [

8] used a system-of-systems approach to describe DT technology. They presented future applications of DT in different fields, DT capabilities, and challenges from a business perspective.

This article analyzes the digital twin concept and its implementation in manufacturing systems through the application of systems thinking methods and tools. System thinking allows the DT implementation problem refinement, and the discovery of potential solutions. This is possible through the development of conceptual models that help to define and refine a problem space. Moreover, system thinking provides tools to discover and explore a solution space. These tools include the conceptagon, the systemigram, and the theory of inventive problem solving (the TRIZ method, according to its Russian acronym) to study the DT implementation problem and its potential solutions. Systems thinking also uses the CATWOE analysis to define the DT problem from the stakeholder’s perspective. The “CATWOE” mnemonic stands for Customer, Actor, Transformation, Worldview, Owner, and Environment. The CATWOE analysis uses the 9 windows tool to study the DT implementation problem, based on time and space. Finally, it uses the ideal final result (IFR) tool to propose the best practical solution for creating an exact digital twin of a manufacturing system. Each of these methods analyzes the implementation of a digital twin manufacturing using a systems approach.

1.2. Limitations

This study was somewhat limited in terms of scope and methodology. First, it used only a few systems thinking methods to study the idea of developing DT models for the manufacturing sector. Using more systems thinking tools would enrich the problem space and the solution space. Second, this work focused on all manufacturing systems. It used a holistic approach, considering and generalizing all types of manufacturing. Third, it studied the problem and solution spaces associated with DT implementation in manufacturing systems. It structured and analyzed these problems and proposed some potential solutions. It did not proceed further to solve these problems. This study did not present a particular case study or solution.

Finally, this paper studied the research problem from the managers’ perspectives. It did not consider other points of view. Overall, this article is a good initial step in working on DT models for manufacturing domains. This study suggests further research to develop a framework for DT implementation in manufacturing systems. Also, it requires further researchto study DT behavior and integration into a real system.

This article follows the following structure.

Section 2 presents a literature review, including the most relevant topics for the development of this article.

Section 3 sets out the systems thinking methods for analyzing the implementation of a digital twin model in a manufacturing domain.

Section 4 presents a discussion of the results from the analysis performed with respect to the digital twin model.

Section 5 presents the conclusions and proposes future research of digital twin technology in manufacturing systems.

3. Methodology

This section describes the methodology used to analyze the problem of implementing a DT in a manufacturing system. This article uses non-traditional methods to analyze this research problem. It uses system thinking methods and tools to perform the analysis. It uses the conceptagon method to define a digital twin in a manufacturing system. Then, it uses the systemigram approach to examine a DT’s relationship with other systems. Finally, it uses the TRIZ method to study the problem and solution spaces in implementing DT models in a manufacturing system.

3.1. Conceptagon

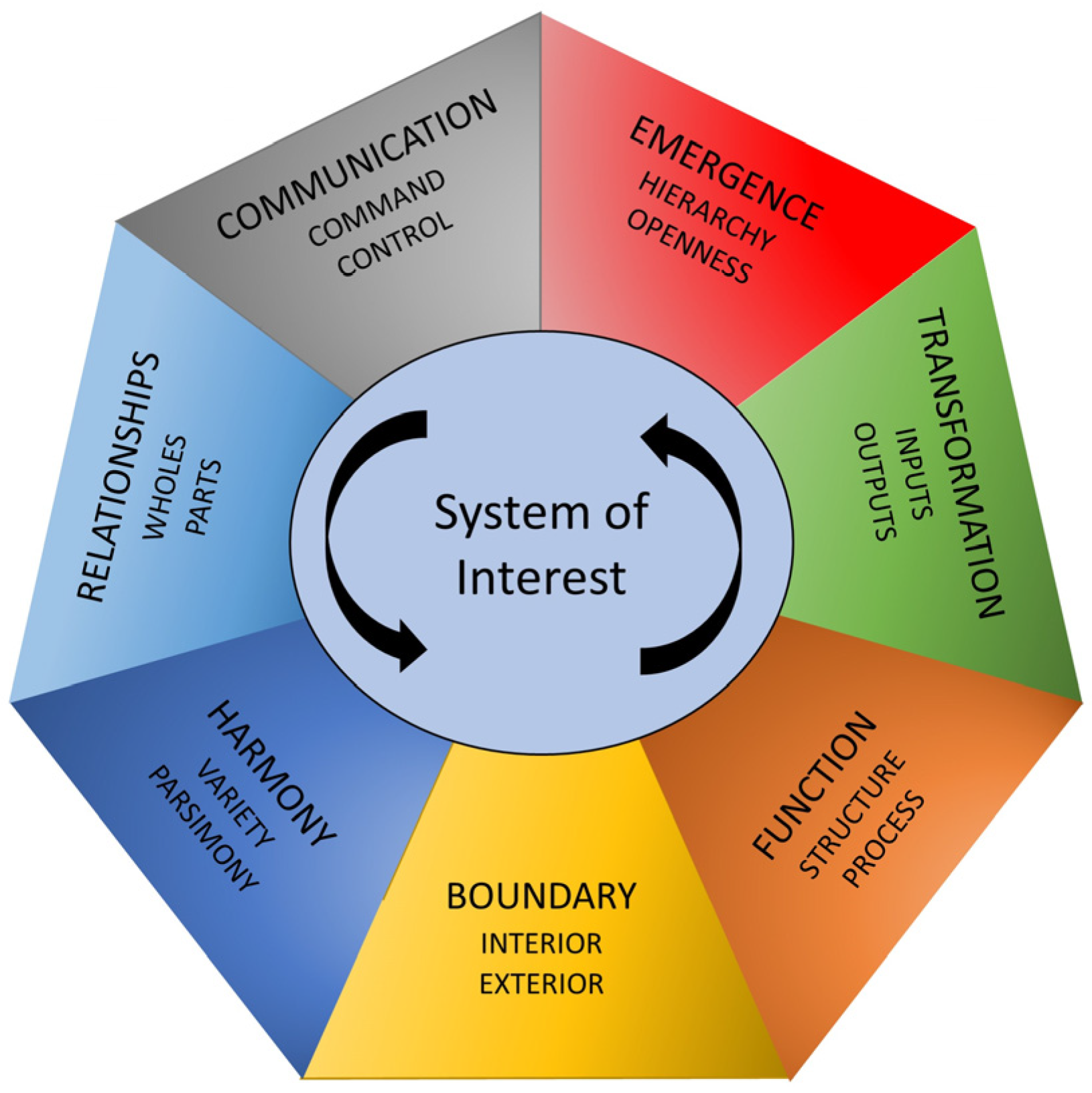

This article explores the DT manufacturing system model through the conceptagon framework, as shown in

Figure 2. This framework that provides system architectures with a holistic understanding of a system and the systemic process. It is an analytic and powerful tool for defining the problem space and the solution space. It has 21 attributes divided into 7 triads. The conceptagon framework’s purpose is to establish a broader understanding of the system of interest, its components, its relationships, and its processes. Conceptagon also establishes an intelligent discussion and collaboration between the domain or system researchers [

21].

This article uses the conceptagon framework to analyze DT development in a manufacturing system. It is important to clarify that there is not an official method for using the conceptagon framework. The authors applied the conceptagon in this way so that researchers could have the freedom to study the sets of triads as they wished. They will discover the linkages across the triads, which will guide them to new analyses for their system of interest.

3.1.1. Boundaries, Interiors, and Exteriors

This triad discusses the design of a digital twin model for manufacturing systems. It explores the interior, exterior, and boundaries of a system. The definition of a system’s boundary comes from the definition of the system’s interior and exterior. A system’s interior encompasses all the objects or components that are in the system. It shows the relationship between them. The system’s exterior is the environment to which the system belongs. Here, the system interacts with other systems. Hence, the system’s boundaries are what makes the system different than others. It delimits the interior and exterior of a system. It distinguishes a system from other systems and makes it unique. Also, it shows that the system has no control or authority beyond its boundaries.

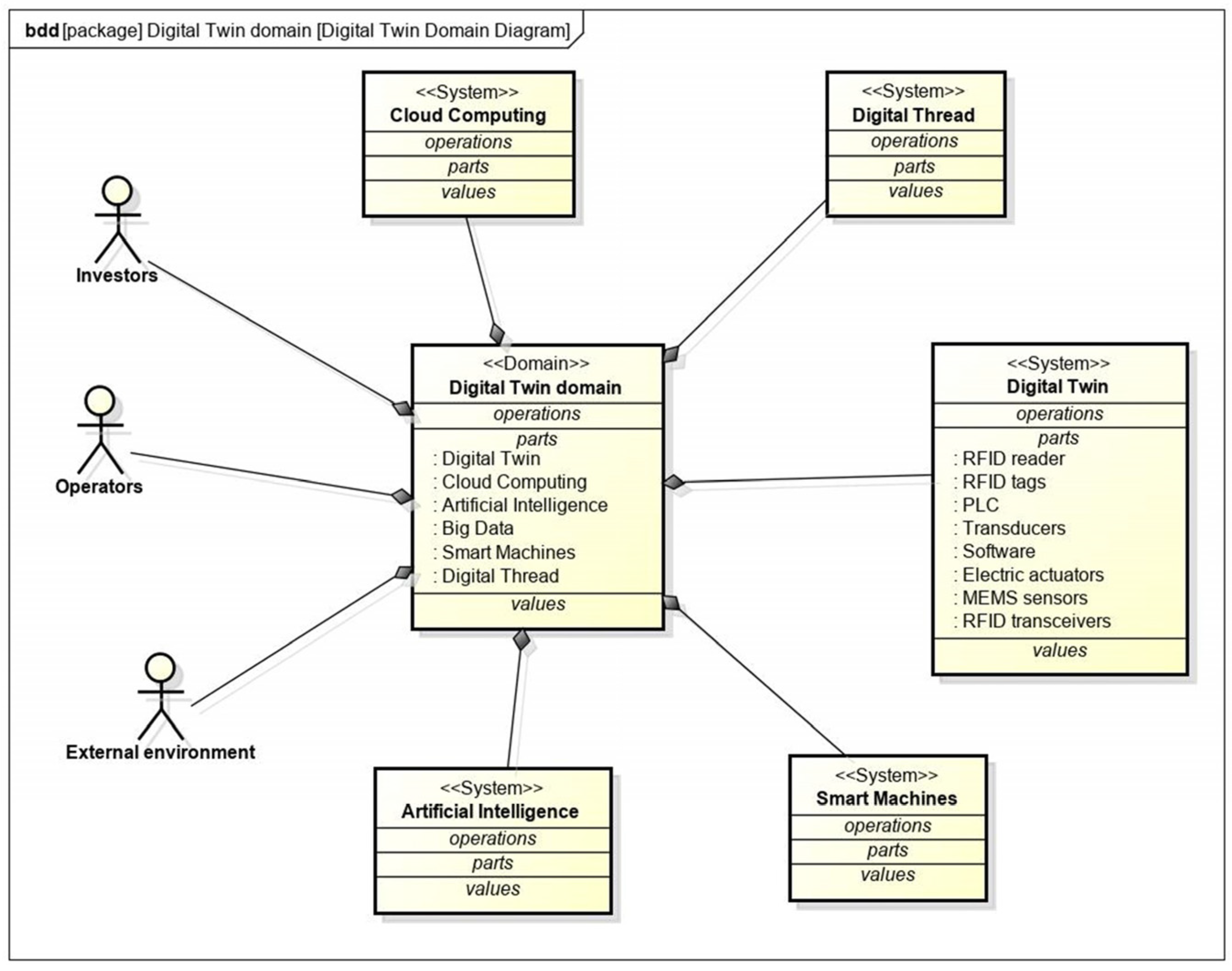

The interior of a manufacturing DT system presents many components.

Figure 3 shows the DT components. These are RFID readers, RFID tags, PLC, transducers, software, electric actuators, switches, MEMS sensors, and RFID transceivers. The exterior of the DT system model is the manufacturing system. This is a bigger domain or system holding the DT domain that becomes a subsystem of the manufacturing system. This domain incorporates stakeholders and other components, such as artificial intelligence, digital thread, cloud computing, and smart machines. The DT manufacturing system boundary is the DT physical counterpart that provides specific characteristics that limit the model [

22].

This article used systems modelling language (SysML) to model the DT subsystem of a manufacturing system. It uses the “composition to association” arrows to connect objects as blocks and actors on the diagram. It connects stakeholders (investors and operators), the external environment, cloud computing, digital threads, artificial intelligence, and smart machines to the DT domain. This domain includes the DT model that controls other “systems” or components in performing the diagnostic and prognostic DT functions. These other “systems” are components from the manufacturing system’s viewpoint.

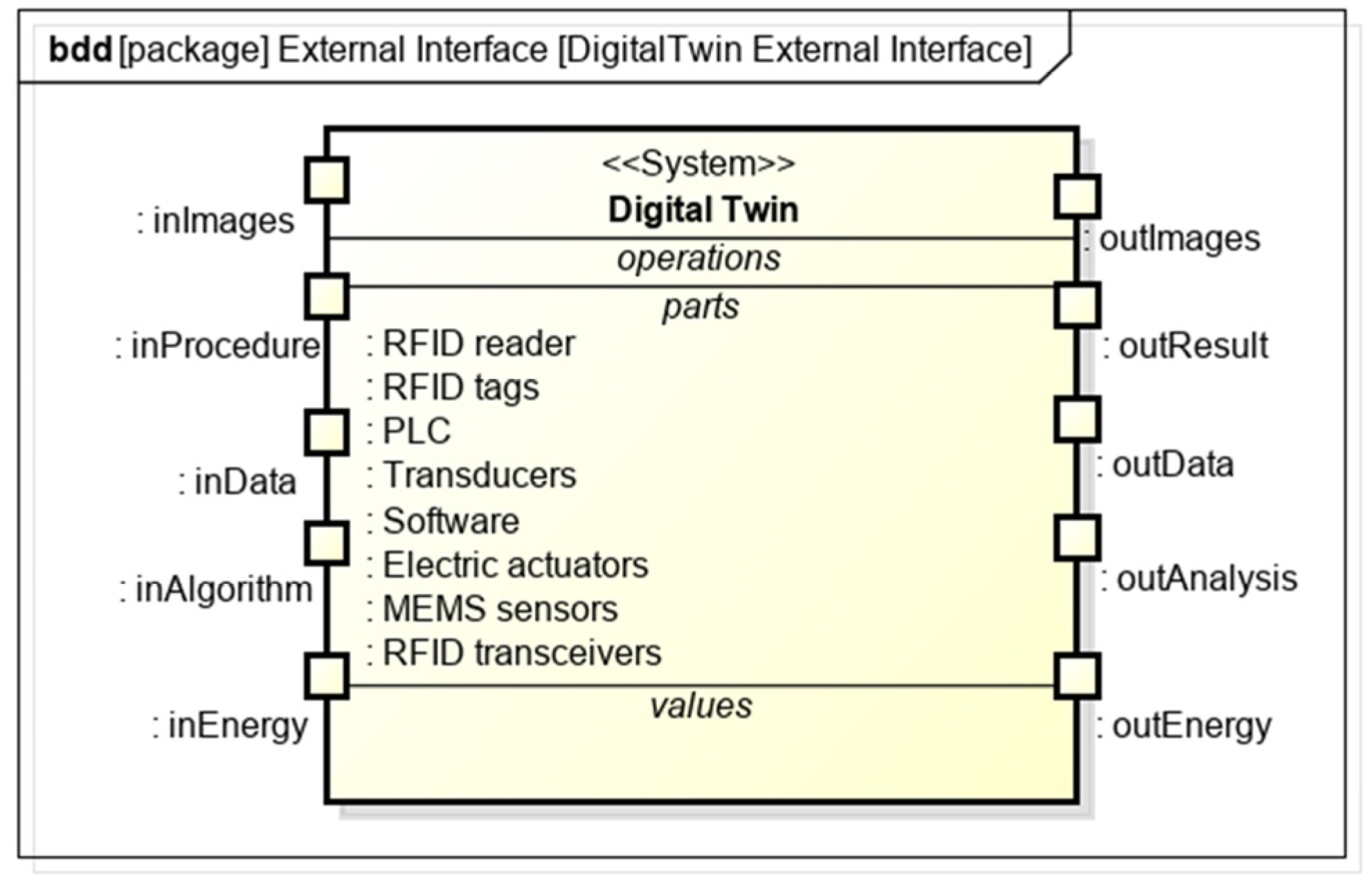

3.1.2. Input, Output, and Transformation

In this triad, the DT model shows a high-level description of its behavior and purpose. The DT processes transform inputs into outputs. Inputs are elements that enter a system to undergo a transformation. The DT inputs are images, procedures, data, algorithms, and energy. The transformation is the system process or processes that transform inputs into outputs. DT processes are the diagnostic, prognostic, and simulation of objects, data, and processes. The outputs are images, results, data, analysis, and energy. The DT goal is to provide information and data relevant to the operations of the manufacturing system to which it belongs.

Figure 4 shows the DT components, inputs, and outputs.

This article used SysML to model the inputs and outputs of the DT subsystem. SysML is an external interface that displays the DT parts in the block and shows ports as inputs and outputs, similar to a process model. The SysML model shows the DT technology that receives images, data, algorithms, energy, and procedures to use and transform them into outputs. These outputs go to the end user in the form of images, analysis, data, and results. These outputs help users to make informed decisions.

3.1.3. Relationships, Wholes, and Parts

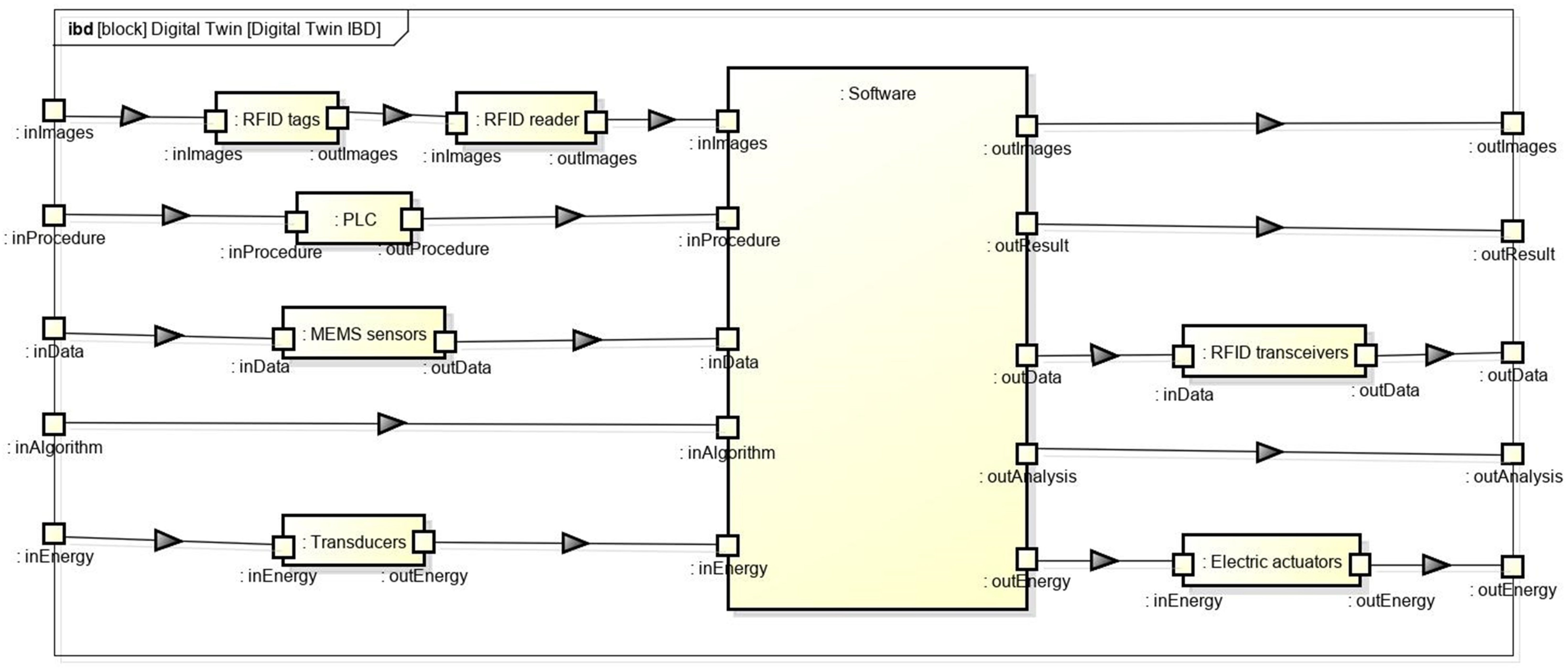

This triad studies the relationship of the system’s parts and the system as one single entity. In this case, the DT is an entire system that cannot exist without the parts. However, the DT is more than its parts in the sense that the single elements cannot perform the DT functions on their own. It is the collective behavior that arises from the part’s relationships that enables DT functions. All parts of the DT work together as one entity to fulfill their collective functions. There are many relationships between the parts in the system’s interior. These relationships affect the system as a whole and its environment. Hence, it is not possible to improve the parts without considering the entire system. However, sometimes degrading a system’s parts may improve the performance of the system.

Figure 5 shows the DT internal interface.

The interior of a DT shows the relationship of the system’s components and how they transform the inputs into outputs. For instance, the object’s data is an input to the DT. MEMS sensors collect data from the physical object. Then, the DT software performs the data analysis or operation. The user can see the results and use the RFID transceivers to send commands to the object.

The article used SysML to diagram the DT internal interface. SysML provides a block diagram that comes from the digital twin domain diagram. The digital twin subsystem allows the addition of an internal block diagram that shows inputs, outputs, and DT components. It uses “item flow” arrows and ports to diagram the relationship between components, which are blocks on the diagram.

3.1.4. Emergence, Hierarchy, and Openness

This triad underlines the presence of emergence behavior on systems, due to openness creating hierarchy levels in the system domain. The system experiences evolution due to its characteristic of openness that allows it to add components and make relationships with other systems. This happens due to the external relationships of the system with its environment. This exposure generates unexpected changes in the system, called emergent behaviors. The emergence attribute makes systems evolve, adopting new features and functions. It is here that the concept of hierarchy becomes relevant in the understanding of systems. The different hierarchy levels create new dynamics with specific structures [

6].

As for the digital twin, being part of a bigger system makes it susceptible to changes. Adding new components to the manufacturing system will affect the digital twin’s operations. It will expand the DT’s resources and functions. These changes will create emergent behaviors in the DT that require organization, so that they do not disrupt the system within which the DT belongs or the other systems around it. The DT itself is an open system that will incorporate modern technologies, such as IoT devices and software. This openness causes an evolution in the DT model. As the literature review explains, a system could start developing a DT of components. Then, it could integrate these DT components into subsystems. Later, it could integrate different subsystems into a single system. The DT model evolution creates emergent behaviors, new structures, and new dynamics.

3.1.5. Structure, Process, and Function

Systems present structures and processes to perform their function. The structure allows a system to perform all of its functions. This functional architecture includes requirements, resources, rules, people, materials, etc. These internal components are interrelated with each other, creating processes. The system processes are the series of activities that produce an outcome. This outcome is the main function of the system. Structures and processes are responsible for the system’s constraints. Therefore, the system’s design creates a robust model structure, with defined processes [

23].

The DT does not have a physical structure, but as an operational tool it has a digital structure. However, the technology that enables the digital twin is comprised of physical components. As this article mentions above, the digital twin model is the virtual representation of a physical object. However, the entire digital twin technology is more than the software that displays a virtual copy of the physical object. It has several components that work together to enable the DT functions.

Figure 3 shows the DT components. The main function of a DT is to improve a system’s processes for performing diagnostics and prognostics. Moreover, a DT has several processes working together to perform its functions. Some of these functions are collecting and analyzing data in real time. It recognizes and inspects objects with RFID technology. It uses software to create a CAD model of the system of interest, its process, and/or its products. It runs simulations to provide prognostic information about the system’s status.

3.1.6. Communication, Command, and Control

This triad studies the governance of a system. It focuses on the system’s communication received from other systems and, in an ideal case, the system’s answers. This triad discusses a system’s means of communication, both internal and external. Communication is a key step in starting a system’s processes, transforming inputs into outputs, and performing the system’s functions. Systems that keep good internal and external communications acknowledge them through feedback and control. The system’s structure provides the system with command-and-control functions. The system commands its internal elements to perform their functions. Moreover, subsystems are part of the manufacturing system’s control of other subsystems, to enable them to work together for the main system’s goals. These are system’s characteristics, where one system gives and the other obeys [

6].

The DT components maintains constant communication between the internal elements to enable them to use their relationships to perform their functions. It controls the system’s internal components to fulfill its goal. It communicates with other systems to receive inputs and transform them into outputs. The means of communication are RFID technology, transducers, and PLCs. These components communicate internally with the software that performs the DT functions. Then, the DT sends the results, information, data, etc., to other systems that are part of the overall manufacturing system. Moreover, the external communications of the DT with other systems, such as IoT devices, are crucial in meeting the system’s goals. The DT also receives commands from other systems, such as smart machines, cloud computing, etc., to perform activities that satisfy the other system’s needs. Feedback from the internal components and the external systems enables the DT to control their parts effectively. Finally, this triad helps the digital twin to be dynamic, adapt to different environments, and evolve.

3.1.7. Harmony, Variety, and Parsimony

This triad discusses the best arrangements between a system’s components. There is harmony when a system has the best arrangement or the ideal structure. However, harmony is not easy to achieve, due to the variety of components and the parsimony in systems. Systems have several parts with a variety of elements, features, types, etc. Parsimony is a system’s constraint that keeps the system as simple as possible [

23].

The DT and its components work together in perfect harmony to meet the major system’s goals. The DT fulfills its function, although it has different components in quality, characteristics, and type. Moreover, the parsimony in a DT model prevents it from becoming complex and adding more components. It is normal to think that this restriction limits the DT’s evolution. However, the DT could evolve and be more intelligent and autonomous with the actual components, or with the reduction of them. This accords with the statement of Madni et al. [

6] regarding distinct types of DT: predigital twins, digital twins, adaptive digital twins, and intelligent digital twins. These DT types were not required to incorporate additional components or technology to upgrade a DT model. Furthermore, since parsimony is a constraint, the DT limits itself to develop new features, abilities, and functions.

3.2. Systemigram

This article presents a systemigram for understanding the relationship between a DT model and a manufacturing system, for the implementation of a DT. This DT model considers as essential the use of concepts such as the system readiness level, systems engineering, and digital transformation for the DT implementation.

The systemigram describes and structures the problem of implementing digital twin models in manufacturing systems. Furthermore, it shows the relationship between the DT concept and systems engineering. The latter could help in DT modeling and developing in manufacturing domains.

Figure 6 shows a systemigram for the conceptual analysis of DT manufacturing systems.

Manufacturing systems encompass different components, such as production processes, machines, computers, people, etc. These elements and data undergo a transformation to the digital world. Digital transformation involves both digitization and the digitalization of objects, processes, and data to achieve the goal of transforming organizational systems into the digital world. Digitization is the transformation of non-digital objects into digital objects. Digitalization is a method of restructuring organizations from a system level perspective.

Digital transformation is the last phase in implementing IT technology in businesses [

24], changing the business model with a new logic for doing business and creating value. It promotes data sharing with other systems to make impactful changes in the business world. The process of digital transformation is disruptive. Digital changes are disruptive because they have a significant impact on business operations. They can change an entire business model and create a revolution. Digital transformation creates a virtual space for analyzing data. It also allows the identification of requirements and threads that set the limits of the digital twin [

1].

In addition to digital transformation, manufacturing systems must consider the system readiness level (SRL). The SRL is an index that evaluates the maturity of a system in performing certain operations. Further, this index could determine the implementation of a digital twin. An SRL has five levels: concept refinement, technology development, system development and demonstration, production and development, and operations and support. Once the system is ready to implement a digital twin, it is time to consider the components of the system’s twin. The components of a digital twin are materials, digital models, geometry, performance, and dynamics [

25].

Finally, the DT provides relevant information to the manufacturing system to improve production processes and create better products according to customer needs. It also enhances the use of systems engineering for the development of manufacturing systems. Systems architectures could use model-based systems engineering (MBSE), system thinking methods, or the V-model to create or improve systems. This last action closes a system’s cycle of relationships.

3.3. TRIZ Method

The theory of inventive problem solving (TRIZ according to its Russian acronym) is a system thinking method for analyzing and forecasting problems. It is part of systems thinking, because it uses a systemic approach to solve problems. It assumes that solutions to problems lie in the patterns of invention. It encompasses two main concepts: generalization of problems and solutions, and elimination of contradictions. According to this method, problems are contradictions that cannot exist together. TRIZ presents 40 principles of innovative thinking, 39 characteristics of technical parameters, and nine laws of systems evolution [

26].

There are three steps in using the TRIZ method. First, TRIZ defines the problem and the contradiction in a few words. Second, it studies the problems as if they were systems. Hence, it considers stakeholders, components, and system’s interactions. The best tool for the second step is 9 windows. Finally, it decides on the principles of innovative thinking to solve the contradiction.

To define the problem, it is necessary to apply a technique before using the TRIZ method. This technique is the CATWOE analysis developed by Smyth and Checkland [

27]. They studied several historical definitions and created this technique to formulate a root definition for a proposed system. The CATWOE analysis considers the following elements: customers, actors, transformation, worldview, owner, and the environment. This article carried out a CATWOE analysis to support a holistic perspective of the research problem. This article decided to study the DT implementation problem in manufacturing from the managers’ viewpoints. The CATWOE analysis for a potential DT manufacturing system is the following:

Customers: The managers;

Actors: The employees, investors, government, suppliers, and users;

Transformation: The availability of a virtual system that interacts with the physical manufacturing system and other systems to help manage and keep track of manufacturing processes. Cloud storages save factory data and allow access from every point in the world with internet connection;

Worldview: The digital twin system is a future investment. Managers expect to make profit in the long term. The manufacturing industry is evolving into the next stage, Industry 4.0;

Owner: The CEO and shareholders of manufacturing systems that decide to implement a digital system corresponding to the business’s actual physical manufacturing system;

Environment: The constraints of every engineering project are the costs, the time, and the performance related to the implementation of the digital system.

After performing the CATWOE analysis, the root definition of a DT manufacturing system is the following: A manager-operated and -owned digital twin simplifies the interaction between the virtual space, the physical space, and surrounding systems that are part of supply chain management. It helps to manage different work processes. It works with cloud storage to save data and allow access from every point in the world, due to internet connectivity. This digital twin is a future investment from which managers expect to make profit in the long term. The constraints of every engineering project are the costs, the time, and the performance related to digital twin implementation.

Based on the system’s root definition, this article defined the problem and the contradiction. The problem is how to develop accurate digital twin models of a manufacturing system. In other words, the problem is how to determine if a system has developed an accurate DT model or if the DT resembles its physical object. Hence, it is a problem of model fidelity and accuracy. The research problem’s contradiction, based on the TRIZ technical parameters, is improving the digital twin’s adaptability or versability without decreasing its automation extension. Therefore, the problem could be in the design phase of the digital twin model. The TRIZ innovative solutions for this problem are identifying inexpensive short-living objects, discarding and recovering, and changing parameters [

28]. The digital twin model of the manufacturing system must be accurate in resembling the physical system’s characteristics and attributes, to avoid problems such as system disruption.

After studying the problem from a high-level perspective, the problem was studied in detail. The 9 windows tool reduces the complexity of a problem [

29]. It gives a system new perspectives on the problem, based on time and space. It assists in identifying the real problem to solve. It uses a 3 × 3 matrix that creates nine segments of “the world.” The row labels are past, present, and future. The column labels are the super-system, the system, and the subsystem. The system’s problem is placed in the center of the matrix. The subsystem presents the system’s components that can solve the system’s problem from the past, present, and future perspectives. The super-system is the environment where the system belongs, and it proposes solutions based on time.

Table 1 shows the matrix that illustrates the use of the 9 windows tool for analyzing a DT implementation problem.

The problem is that there is not a clear definition of digital twins in manufacturing systems. Factories are developing inaccurate digital twin models. All of these could be detrimental to the regular operations of a manufacturing system. The subsystem solution is to design an integration model for digital twin components and other devices in the system. The super-system solution is to create a digital thread that connects data and systems throughout the supply chain. The system solution is developing a framework or method to create digital twin models of a manufacturing system. This framework must support autonomous operations and the assessment of accurate digital twin models of manufacturing systems.

Finally, the TRIZ step considers the development of the ideal final result (IFR). The IFR is one of the most powerful tools of the TRIZ method. This tool looks for the ideal condition or solution of a system, irrespective of the problem’s constraints. The TRIZ method describes ideal systems as systems that do not exist until they perform all their functions [

30]. This is a contradiction, in that this work found the problem lines above using the TRIZ technical parameters. Then, the TRIZ method applies a system thinking tool to transform the problem and find some solutions. To conclude, the TRIZ method selects the solution that presents a functional ideal model to solve the research problem and to achieve the IFR.

This work already defined the problem lines, above. In this case, the research problem is the lack of a clear definition and an accurate digital twin model of a manufacturing system. The problem’s contradiction is improving the digital twin’s adaptability or versability without decreasing its extent of automation. Then, this work used the 9 windows tool to transform the problem and present some potential solutions. Finally, this work selected the ideal solution to implement DT models in a manufacturing domain. The IFR technique creates digital twin models that expand the automation in the manufacturing system internally, and externally to other systems in the supply chain. The ideal digital twin model must show adaptability to new systems, subsystems, components, and environments to improve continuously over time.

4. Results and Discussion

The analysis of digital twin implementation for manufacturing systems presented several results. The article showed how important it is to use a systems approach, to achieve a higher perspective for consideration of the problem or system of interest. Implementing a DT is not easy. Some companies still have doubts about the benefits of DT, due to its novelty. Organizations are still testing and measuring the impact of a DT in their daily activities. Other companies have not heard of DT or know very little about it. There are also companies that do not have the infrastructure or the means to implement a DT [

31].

There is no common definition of a DT. This prevents an understanding of the DT concept. Hence, some factories do not realize its value, to the point of degrading it [

5,

32]. Moreover, the integration of data is a challenge for DT development. This integration gives users access to all data in a system’s lifecycle from various locations. This is difficult, due to different data sources, formats, interfaces, and security protocols [

33,

34].

A DT also needs a standardized information model that integrates the different system components, to allow the DT to work across different components, subsystems, and systems. Standard technology, models, information, and APIs keep data flowing smoothly throughout a system. It is recommended that system designers try to standardize system components as much as possible [

35]. Finally, a DT must resemble the physical system accurately and in real time. This involves the integration of several components that must work together to fulfill the DT’s diagnostic and prognostic functions [

36].

Through the application of the conceptagon method, it is noticeable that a digital twin is a complex system [

15,

37,

38]. It has distinct parts that are related to each other to fulfill their collective mission. Since the software is enabled by many components, the digital twin boundary could be unclear [

39]. This happens due to the extension of the digital twin in the manufacturing system [

40]. Hence, it is important to consider the digital twin as a system, and to consider the relationships between its parts.

In addition, the digital twin processes are crucial in transforming inputs into outputs. The outputs are based on the digital twin’s structure and arranged functions [

41]. ADT has several processes in performing its functions. The main DT function is to perform diagnostics and prognostics for a system’s regular operations [

2]. The DT tool has a virtual structure, but the technology that enables the digital twin is comprised of physical components [

42].

Moreover, it is important that a DT manufacturing system be open to other systems and environments, to enable upgrading and to remain important over time [

8]. However, this openness creates emergent behaviors in the system. A digital twin experiences new behaviors that arise from the constant relationship between the digital twin’s components, and the digital twin itself, with other systems in the supply chain. A DT incorporates new components, creates new processes, and creates new relationships. This forces a digital twin to establish order and determine the hierarchy within the system [

43].

An open digital twin communicates with other systems to receive inputs and transform them into outputs [

15]. This creates two main functions in the digital twin: being in command and being in control of other systems in the supply chain.

Finally, the digital twin components must be harmonious with themselves and with other systems to work normally [

44]. However, a DT presents many constraints. The system’s limitation attributes are parsimony and variety, which are contradictory. A DT has several components that differ in quality, characteristics, and type [

5]. Each components perform the necessary work and obtains the resources to do it. However, a DT should find a balance and remain as simple as possible. In summary, a DT must be dynamic, adapt to different environments, and evolve [

6].

The systemigram illustrated the relationship of a DT with other concepts and systems. It presented a picture of DT implementation. It showed the relationships between the manufacturing system and the DT. The manufacturing system needs to transform its components into the digital world. The transformation will make possible the implementation of a digital twin. The system needs to add cloud computing, a digital thread, artificial intelligence, and other requirements to satisfy the digital twin’s needs [

22]. Nevertheless, a manufacturing system should evaluate its system readiness level, before implementing modern technology such as a DT [

45].

Based on the systemigram, it is possible to identify two benefits of implementing a DT. First, it will improve the manufacturing system’s operations and create new business opportunities [

34]; second, it will increase the knowledge and use of systems’ engineering in the academy and in industry [

6].

The TRIZ method helped to refine the problem and the contradiction to find the best ideal solution to DT implementation. The problem is the lack of a single definition [

5,

32], methodology [

35], and the indicators for developing accurate digital twin models of a manufacturing system [

36]. The research problem’s contradiction is improving the digital twin’s adaptability or versability without decreasing the DT’s extension of automation. The TRIZ innovative solutions for this problem are identifying inexpensive short-living objects, discarding and recovering, and changing parameters. The digital twin model of the manufacturing system should be accurate in resembling the physical system’s operations and avoid problems such as system disruption. Then, the 9 windows tool showed some potential solutions to solve the DT implementation problem. The literature also studied these problems and solutions. These solutions are:

Creating business models that include digital transformation [

1,

24,

46];

Connecting different manufacturing systems to prevent the supply chain disruption [

47,

48];

Creating a digital thread that connects data and systems throughout the supply chain [

49,

50];

Implementing technology such as IoT devices that support autonomous operations [

51,

52];

Designing an integration model for multiple and diverse components in the system [

53,

54];

Developing a framework or method to create accurate digital twin models of a manufacturing system [

55,

56,

57].

Finally, the IFR technique shows that the ideal DT model is one that expands its automation to all manufacturing system operations. It also expands its automation to the other systems in the supply chain. For instance, a digital twin should be capable of ordering supplies when there are not enough materials in stock [

49]. The ideal DT model adapts to new system, subsystems, components, and environments, without losing its functionality [

6].

5. Conclusions

Systems thinking tools are useful in understanding the problem and finding potential solutions for DT implementation in a manufacturing domain. The methods and tools used in this article were the conceptagon, the systemigram, CATWOE analysis, 9 windows, the ideal final result technique, and the TRIZ method. All of these tools analyzed the problem of implementing digital twin models in manufacturing systems. Systems thinking allows researchers to learn more about the problem space and to find potential solutions. Moreover, systems thinking studies all the attributes of a digital twin model from a systems perspective. Finally, it presents potential solutions from different perspectives.

The analysis showed that a DT model is a complex system comprised of many components that are interrelated with each other in performing diagnostic and prognostic functions. The ideal DT model for manufacturing domains must be an open system that improves continuously and adapts to different circumstances. DT implementation must consider the following attributes: communication, emergence, transformation, function, boundary, harmony, and relationships. These attributes could help to model the DT manufacturing system architecture.

The results and discussion section highlighted some challenges in the implementation of DT in manufacturing systems. Some organizations believe there are many uncertainties about DT, such as the definition, the benefits, the impact on daily activities, etc. Moreover, the development of DT presents challenges in the integration of components and data that are heterogeneous. The biggest challenge is to create DT models that resemble physical objects accurately. The implementation of a digital twin is challenging because of its complexity, novelty, and cost. It involves the integration of several components and systems, such as IoT devices.

After giving a description of a digital twin model and defining the problem of implementing a DT in a manufacturing system, a main conclusion was reached. It is necessary to develop a framework to create accurate DT models of a manufacturing system. This new DT system is a complex system that requires a holistic approach for its implementation to benefit the final products, the processes, and the entire system.

This article considered, as future research, the development of a framework or method to develop DT models for a manufacturing system. Such future research would help manufacturers evaluate the possibilities of implementing DT models in their factories Moreover, it will provide them with a broad perspective for analyzing the current digital transformation of their factories. They could measure how far along their factories are in implementing modern technologies, such as DT models. For example, factories could measure their adaptability and flexibility to technological changes.