Flexural Performance of a New Hybrid Basalt-Polypropylene Fiber-Reinforced Concrete Oriented to Concrete Pipelines

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Material

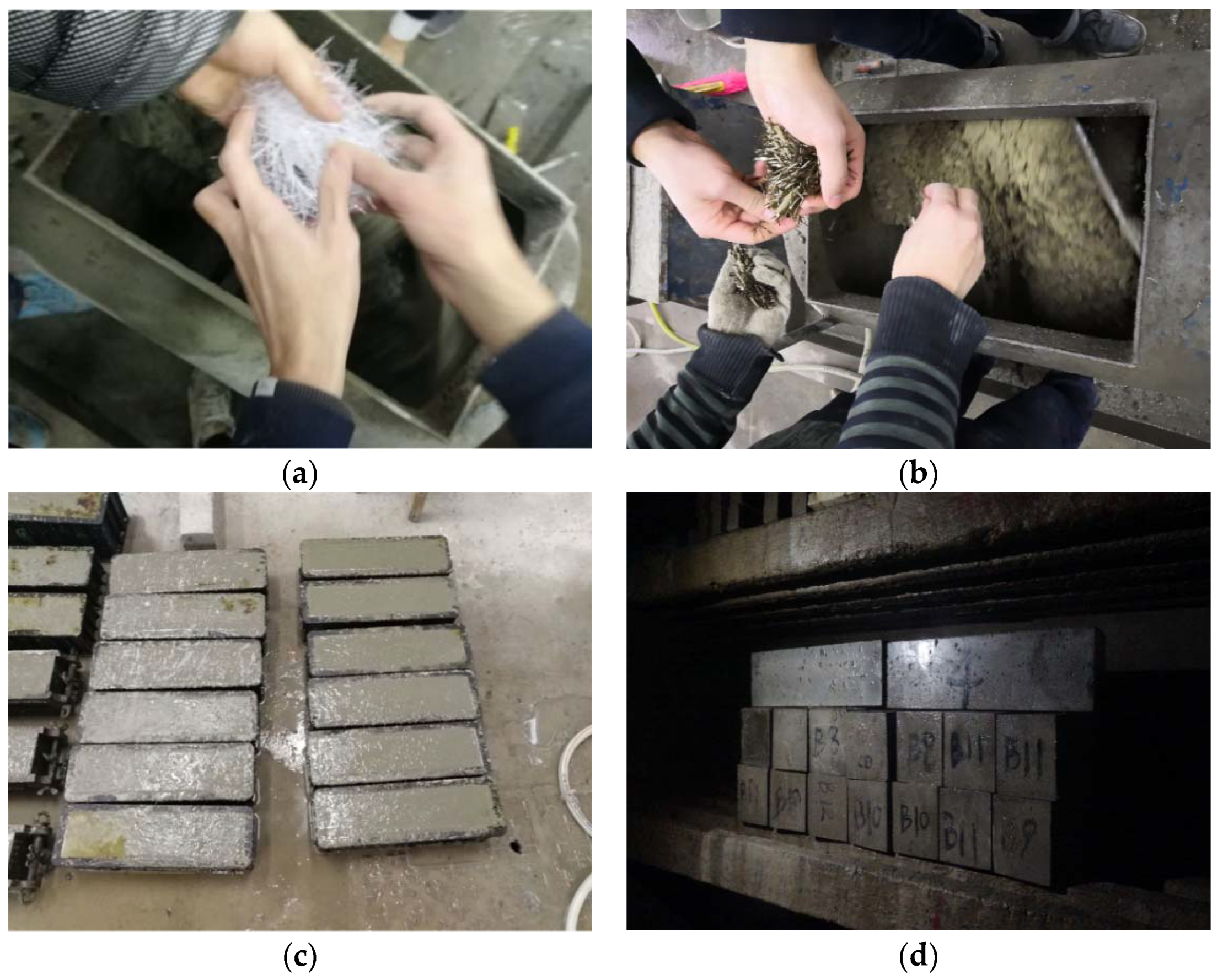

2.2. Test Material Preparation

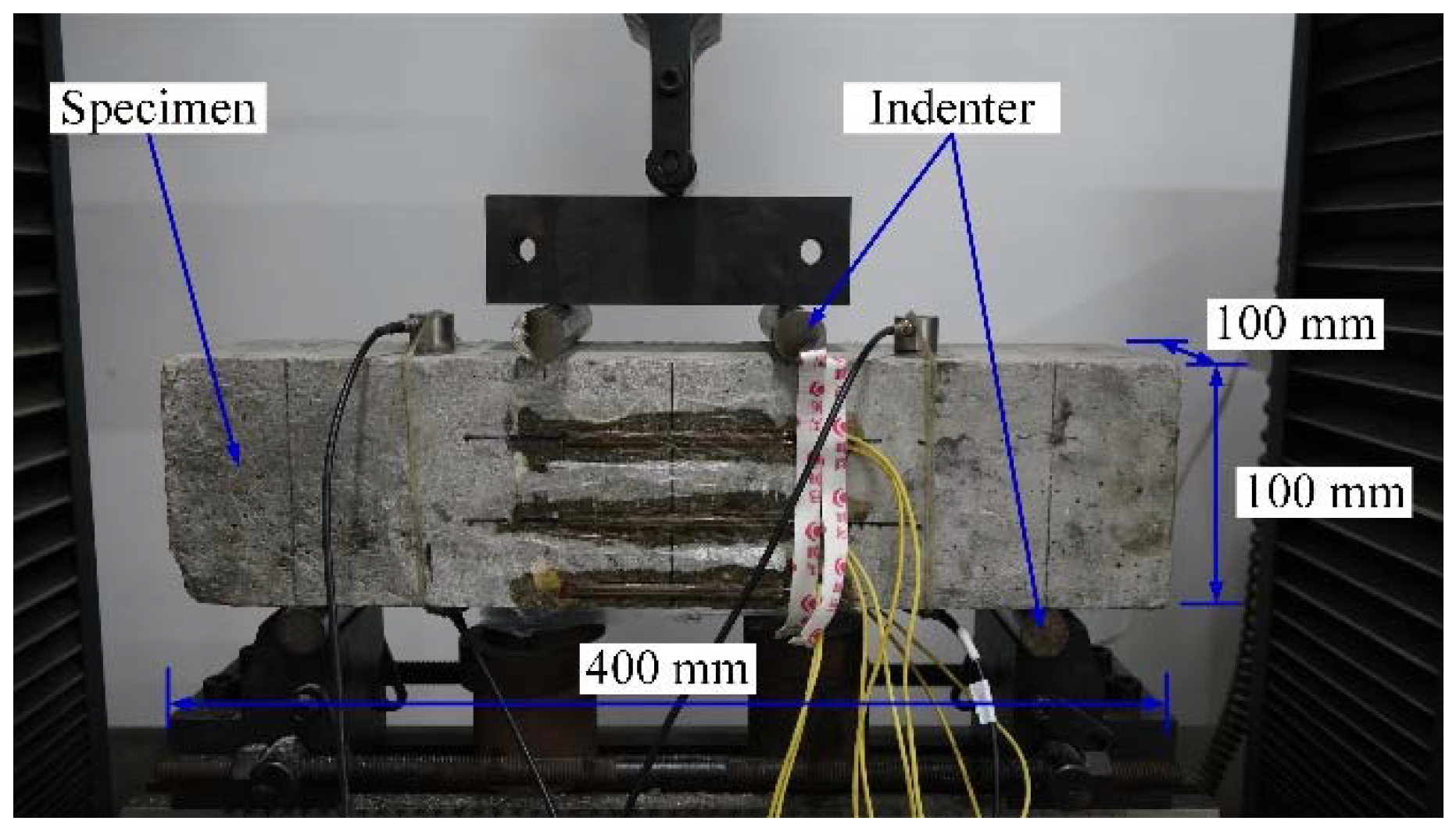

2.3. Experimental Test Method

3. Test Results

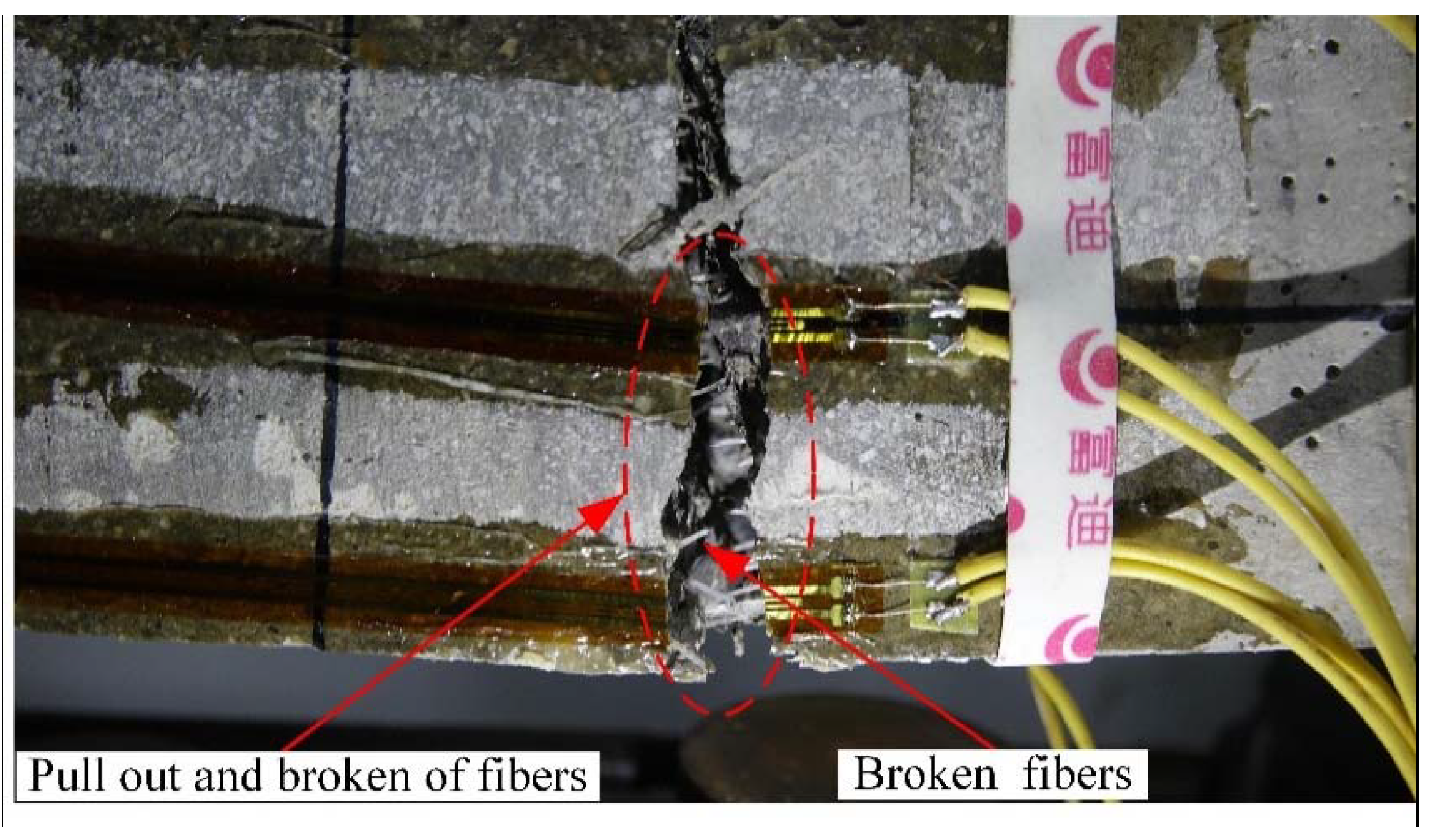

3.1. Failure Modes

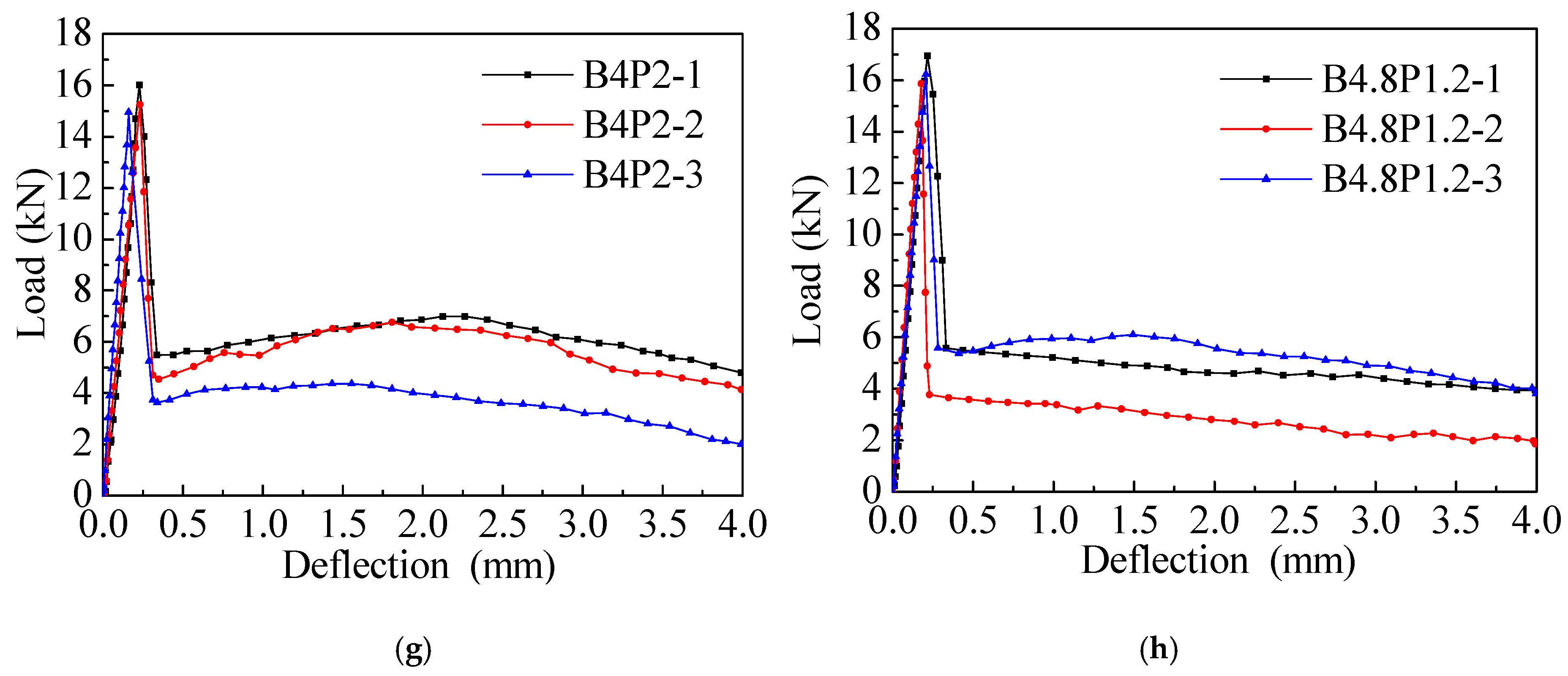

3.2. Load-Deflection Curve

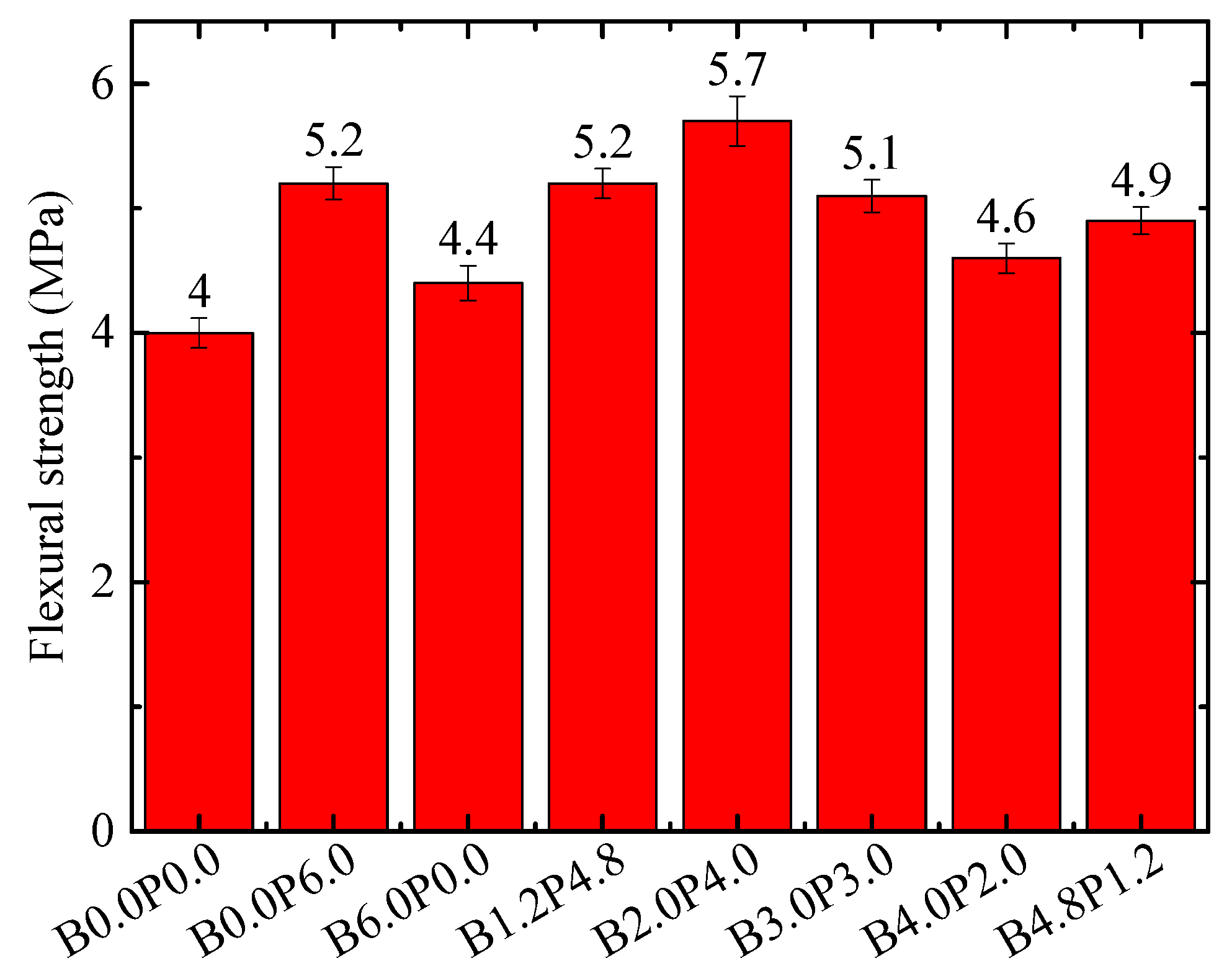

3.3. Flexural Strength

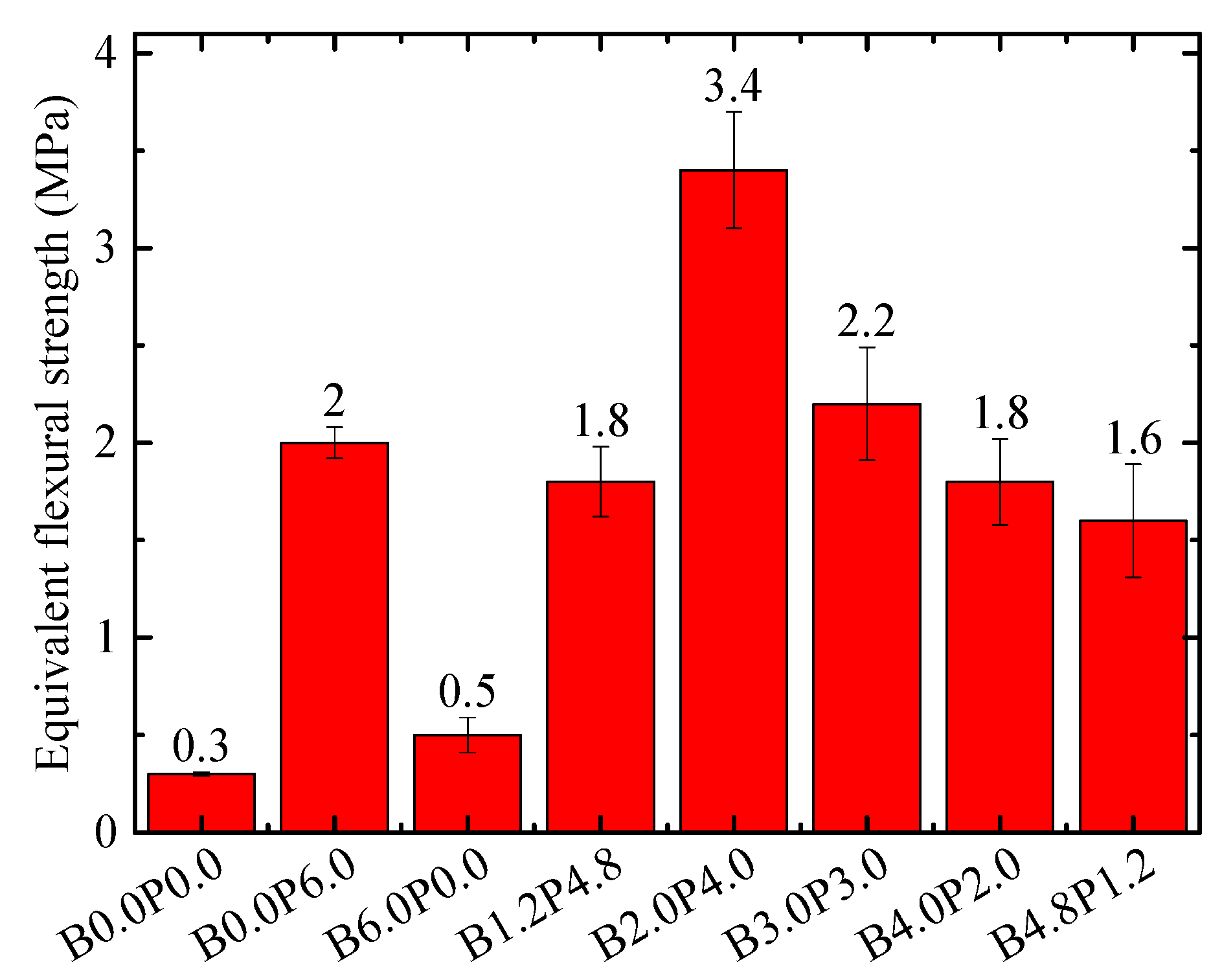

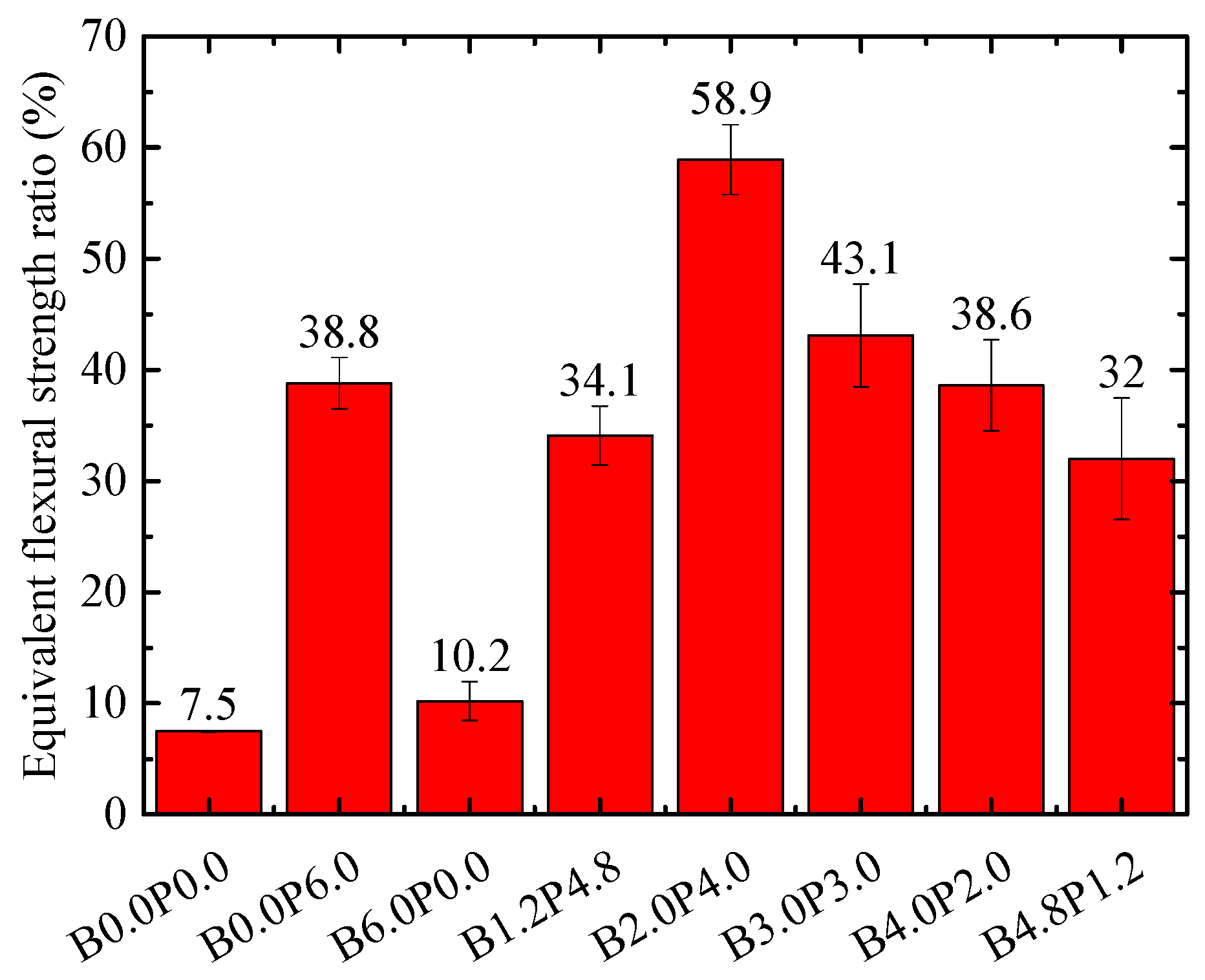

3.4. Flexural Toughness

4. Discussion

4.1. Analysis of the Mechanism of Hybrid Fibers

4.2. Technology and Economic Analysis

5. Conclusions

- (1)

- The addition of mono-BF proved not to enhance the concrete ductility, while the macro PPF significantly improve the brittleness of concrete and makes the failure modes of PPFRC and HBPFRCs change from the sudden brittle failure of plain concrete to ductile failure.

- (2)

- The addition of hybrid BF and PPF can effectively improve the flexural strength of concrete. Further, the addition of macro PPF proved to increase the post-cracking flexural toughness of concrete. Compared with the control group, when the mass ratio of BF to PPF is 1:2, the flexural toughness and equivalent flexural strength of the HBPFRC specimen were increased by 10.2 times, and the percentage of equivalent flexural strength of it was increased by 7.1 times.

- (3)

- BF mainly improves the flexural performance of concrete before the occurrence of macro-cracks, while the macro PPF plays the bridging role and improves the flexural performance of concrete in the process of crack evolution from micro-crack to the macro-crack.

- (4)

- B2P4 specimen significantly improves the energy dissipation capacity of concrete material with just a small increase in cost. From the perspective of both technology and economy, when the mass ratio of BF to PPF is 1:2, the bending performance and economic benefits of FRC reach the optimal level, and this mix ratio is the optimal fiber mixing ratio in this test.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guerini, V.; Conforti, A.; Plizzari, G.; Kawashima, S. Influence of Steel and Macro-Synthetic Fibers on Concrete Properties. Fibers 2018, 6, 47. [Google Scholar] [CrossRef] [Green Version]

- Das, C.S.; Dey, T.; Dandapat, R.; Mukharjee, B.B.; Kumar, J. Performance evaluation of polypropylene fibre reinforced recycled aggregate concrete. Constr. Build. Mater. 2018, 189, 649–659. [Google Scholar] [CrossRef]

- Okeola, A.A.; Abuodha, S.O.; Mwero, J. Experimental Investigation of the Physical and Mechanical Properties of Sisal Fiber-Reinforced Concrete. Fibers 2018, 6, 53. [Google Scholar] [CrossRef] [Green Version]

- Kytinou, V.K.; Chalioris, C.E.; Karayannis, C.G. Analysis of Residual Flexural Stiffness of Steel Fiber-Reinforced Concrete Beams with Steel Reinforcement. Materials 2020, 13, 2698. [Google Scholar] [CrossRef] [PubMed]

- Chalioris, C.; Panagiotopoulos, T.A. Flexural analysis of steel fibre-reinforced concrete members. Comput. Concr. 2018, 22, 11–25. [Google Scholar] [CrossRef]

- Choi, S.-W.; Choi, J.; Lee, S.-C. Probabilistic Analysis for Strain-Hardening Behavior of High-Performance Fiber-Reinforced Concrete. Materials 2019, 12, 2399. [Google Scholar] [CrossRef] [Green Version]

- Jain, K.; Singh, B. Deformed steel fibres as minimum shear reinforcement—An investigation. Structures 2016, 7, 126–137. [Google Scholar] [CrossRef]

- JSCE-SF4. Standard for Flexural Strength and Flexural Toughness, Method of Tests for Steel Fiber Reinforced Concrete; Concrete Library of JSCE, Japan Concrete Institute (JCI): Tokyo, Japan, 1984; pp. 58–66. [Google Scholar]

- ASTM C1018-97. Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar] [CrossRef]

- CECS 13:2009. Standard Test Methods for Fiber Reinforced Concrete; Chinese Association Standards of Engineering Construction Standardization: Beijing, China, 2009. [Google Scholar]

- Buratti, N.; Mazzotti, C.; Savoia, M. Post-cracking behaviour of steel and macro-synthetic fibre-reinforced concretes. Constr. Build. Mater. 2011, 25, 2713–2722. [Google Scholar] [CrossRef]

- Nicolaides, D.; Markou, G. Modelling the flexural behaviour of fibre reinforced concrete beams with FEM. Eng. Struct. 2015, 99, 653–665. [Google Scholar] [CrossRef]

- Pujadas, P.; Blanco, A.; Cavalaro, S.H.P.; De La Fuente, A.; Aguado, A. Flexural Post-cracking Creep Behaviour of Macro-synthetic and Steel Fiber Reinforced Concrete. In Creep Behaviour in Cracked Sections of Fibre Reinforced Concrete; Serna, P., Llano-Tore, A., Cavalaro, S.H.P., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 77–87. [Google Scholar]

- Enfedaque, A.; Alberti, M.G.; Galvez, J.; Beltrán, M. Constitutive relationship of polyolefin fibre-reinforced concrete: Experimental and numerical approaches to tensile and flexural behaviour. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 358–373. [Google Scholar] [CrossRef]

- Li, B.; Chi, Y.; Xu, L.; Shi, Y.; Li, C. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Constr. Build. Mater. 2018, 191, 80–94. [Google Scholar] [CrossRef]

- Mínguez, J.; González, D.C.; Vicente, M.A. Fiber geometrical parameters of fiber-reinforced high strength concrete and their influence on the residual post-peak flexural tensile strength. Constr. Build. Mater. 2018, 168, 906–922. [Google Scholar] [CrossRef]

- Liu, F.; Ding, W.; Qiao, Y. Experimental investigation on the flexural behavior of hybrid steel-PVA fiber reinforced concrete containing fly ash and slag powder. Constr. Build. Mater. 2019, 228, 116706. [Google Scholar] [CrossRef]

- Carrillo, J.; Torres, D.; Guerrero, H. Correlation between results obtained from four-point bending tests (4PBT) and double punch tests (DPT) in concrete reinforced with hooked-end steel fibers. Eng. Struct. 2021, 239, 112353. [Google Scholar] [CrossRef]

- Ferdosian, I.; Camões, A. Mechanical performance and post-cracking behavior of self-compacting steel-fiber reinforced eco-efficient ultra-high performance concrete. Cem. Concr. Compos. 2021, 121, 104050. [Google Scholar] [CrossRef]

- Guo, H.; Jiang, L.; Tao, J.; Chen, Y.; Zheng, Z.; Jia, B. Influence of a hybrid combination of steel and polypropylene fibers on concrete toughness. Constr. Build. Mater. 2021, 275, 122132. [Google Scholar] [CrossRef]

- Meng, G.; Wu, B.; Xu, S.; Huang, J. Modelling and experimental validation of flexural tensile properties of steel fiber reinforced concrete. Constr. Build. Mater. 2021, 273, 121974. [Google Scholar] [CrossRef]

- Abadel, A.; Abbas, H.; Almusallam, T.; Al-Salloum, Y.; Siddiqui, N. Mechanical properties of hybrid fibre-reinforced concrete—analytical modelling and experimental behaviour. Mag. Concr. Res. 2016, 68, 1–21. [Google Scholar] [CrossRef]

- Yang, X.; Liang, N.; Liu, X.; Zhong, Z. A study of test and statistical damage constitutive model of multi-size polypropylene fiber concrete under impact load. Int. J. Damage Mech. 2018, 28, 973–989. [Google Scholar] [CrossRef]

- Koniki, S.; Prasad, D.R. Influence of hybrid fibres on strength and stress-strain behaviour of concrete under uniaxial stresses. Constr. Build. Mater. 2019, 207, 238–248. [Google Scholar] [CrossRef]

- Bošnjak, J.; Sharma, A.; Grauf, K. Mechanical Properties of Concrete with Steel and Polypropylene Fibres at Elevated Temperatures. Fibers 2019, 7, 9. [Google Scholar] [CrossRef] [Green Version]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Nataraja, M.; Dhang, N.; Gupta, A. Stress–strain curves for steel-fiber reinforced concrete under compression. Cem. Concr. Compos. 1999, 21, 383–390. [Google Scholar] [CrossRef]

- Betterman, L.; Ouyang, C.; Shah, S. Fiber-matrix interaction in microfiber-reinforced mortar. Adv. Cem. Based Mater. 1995, 2, 53–61. [Google Scholar] [CrossRef]

- Banthia, N.; Majdzadeh, F.; Wu, J.; Bindiganavile, V. Fiber synergy in Hybrid Fiber Reinforced Concrete (HyFRC) in flexure and direct shear. Cem. Concr. Compos. 2014, 48, 91–97. [Google Scholar] [CrossRef]

- Kasagani, H.; Rao, C. Effect of graded fibers on stress strain behaviour of Glass Fiber Reinforced Concrete in tension. Constr. Build. Mater. 2018, 183, 592–604. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Soe, K.T.; Zhang, Y.; Zhang, L. Material properties of a new hybrid fibre-reinforced engineered cementitious composite. Constr. Build. Mater. 2013, 43, 399–407. [Google Scholar] [CrossRef]

- Zhang, C.; Han, S.; Hua, Y. Flexural performance of reinforced self-consolidating concrete beams containing hybrid fibers. Constr. Build. Mater. 2018, 174, 11–23. [Google Scholar] [CrossRef]

- Caetano, H.; Rodrigues, J.P.C.; Pimienta, P. Flexural strength at high temperatures of a high strength steel and polypropylene fibre concrete. Constr. Build. Mater. 2019, 227, 116721. [Google Scholar] [CrossRef]

- Bhogone, M.V.; Subramaniam, K.V.L. Early-age tensile constitutive relationships for steel and polypropylene fiber reinforced concrete. Eng. Fract. Mech. 2021, 244, 107556. [Google Scholar] [CrossRef]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- Branston, J.; Das, S.; Kenno, S.Y.; Taylor, C. Mechanical behaviour of basalt fibre reinforced concrete. Constr. Build. Mater. 2016, 124, 878–886. [Google Scholar] [CrossRef]

- Borhan, T.M. Properties of glass concrete reinforced with short basalt fibre. Mater. Des. 2012, 42, 265–271. [Google Scholar] [CrossRef]

- Sim, J.; Park, C.; Moon, D.Y. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part. B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Kizilkanat, A.B.; Kabay, N.; Akyüncü, V.; Chowdhury, S.; Akça, A.H. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Fu, Q.; Niu, D.; Li, D.; Wang, Y.; Zhang, J.; Huang, D. Impact characterization and modelling of basalt‒polypropylene fibre-reinforced concrete containing mineral admixtures. Cem. Concr. Compos. 2018, 93, 246–259. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Bai, L.; Addae, M.; Neupane, A. Research on the impact response and model of hybrid basalt-macro synthetic polypropylene fiber reinforced concrete. Constr. Build. Mater. 2019, 204, 303–316. [Google Scholar] [CrossRef]

- Fu, Q.; Niu, D.; Zhang, J.; Huang, D.; Hong, M. Impact response of concrete reinforced with hybrid basalt-polypropylene fibers. Powder Technol. 2018, 326, 411–424. [Google Scholar] [CrossRef]

- Smarzewski, P. Flexural Toughness of High-Performance Concrete with Basalt and Polypropylene Short Fibres. Adv. Civ. Eng. 2018, 2018, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Smarzewski, P. Influence of basalt-polypropylene fibres on fracture properties of high performance concrete. Compos. Struct. 2019, 209, 23–33. [Google Scholar] [CrossRef]

- Liang, N.; Zhong, Y.; Liu, X. Experimental study of flexural toughness for multi-scale polypropylene fiber reinforced concrete. J. Cent. South Univ. 2017, 48, 2783–2789. (In Chinese) [Google Scholar]

- Deng, Z.; Liu, X.; Yang, X.; Liang, N.; Yan, R.; Chen, P.; Miao, Q.; Xu, Y. A study of tensile and compressive properties of hybrid basalt-polypropylene fiber-reinforced concrete under uniaxial loads. Struct. Concr. 2021, 22, 396–409. [Google Scholar] [CrossRef]

- Pujadas, P.; Blanco, A.; Cavalaro, S.; Aguado, A. Plastic fibres as the only reinforcement for flat suspended slabs: Experimental investigation and numerical simulation. Constr. Build. Mater. 2014, 57, 92–104. [Google Scholar] [CrossRef]

- Pujadas, P.; Blanco, A.; Cavalaro, S.H.P.; De La Fuente, A.; Aguado, A. The need to consider flexural post-cracking creep behavior of macro-synthetic fiber reinforced concrete. Constr. Build. Mater. 2017, 149, 790–800. [Google Scholar] [CrossRef]

- De la Fuente, A.; Escariz, R.C.; Figueiredo, A.; Aguado, A. Design of macro-synthetic fibre reinforced concrete pipes. Constr. Build. Mater. 2013, 43, 523–532. [Google Scholar] [CrossRef]

- De la Fuente, A.; Escariz, R.C.; Figueiredo, A.; Molins, C.; Aguado, A. A new design method for steel fibre reinforced concrete pipes. Constr. Build. Mater. 2012, 30, 547–555. [Google Scholar] [CrossRef]

- De La Fuente, A.; De Figueiredo, A.D.; Aguado, A.; Molins, C.; Neto, P.J.C.; Figueiredo, A. Experimentación y simulación numérica de tubos de hormigón con fibras. Mater. Constr. 2010, 61, 275–288. [Google Scholar] [CrossRef] [Green Version]

- Deng, Z.; Liu, X.; Chen, P.; de la Fuente, A.; Zhou, X.; Liang, N.; Han, Y.; Du, L. Basalt-polypropylene fiber reinforced concrete for durable and sustainable pipe production. Part 1: Experimental program. Struct. Concr. 2021. [Google Scholar] [CrossRef]

- Deng, Z.; Liu, X.; Chen, P.; de la Fuente, A.; Zhao, Y.; Liang, N.; Zhou, X.; Du, L.; Han, Y. Basalt-polypropylene fiber reinforced concrete for durable and sustainable pipe production. Part 2: Numerical and parametric analysis. Struct. Concr. 2021. [Google Scholar] [CrossRef]

- Soutsos, M.; Le, T.; Lampropoulos, A. Flexural performance of fibre reinforced concrete made with steel and synthetic fibres. Constr. Build. Mater. 2012, 36, 704–710. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E.; Patel, M.K. Open-loop recycling: A LCA case study of PET bottle-to-fibre recycling. Resour. Conserv. Recycl. 2010, 55, 34–52. [Google Scholar] [CrossRef]

- Strezov, L.; Herbertson, J. A Life Cycle Perspective on Steel Building Materials; Principals of the Crucible Group Pty Ltd.: Newcastle, Australian, 2006. [Google Scholar]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibres in concrete: A review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Y.; Zhang, X.; Wang, S. Cost performance analysis of fiber-constrained concrete prisms. China Concr. Cem. Prod. 2009, 36, 46–47. (In Chinese) [Google Scholar] [CrossRef]

| Type of Fibers | Φf/λf | Volume of Fibers (%) | fc (MPa) | Height × Width × Length (mm3) | Author |

|---|---|---|---|---|---|

| SF; MSF | SF: 50; MSF: 48–158 | 0.22–0.74 | 40.9–50.2 | 150 × 150 × 550 | Buratti et al. [11] |

| SF | 37.5–81.3 | 8 | 200 | 100 × 100 × 500 | Nicolaides and Markou [12] |

| SF; PFF | SF: 83; MSF: / | SF: 0.51; PFF: 0.51 | 52.2 | 150 × 150 × 600 | Pujadas et al. [13] |

| PFF | 64.5 | 0.33, 0.49, 1.10 | 28–31 | 100 × 100 × 430 | Enfedaque et al. [14] |

| SF; PPF | SF: 40, 60, 80; PPF: 280 | SF: 0.5, 1.0, 1.5, 2.0; PFF: 0.1, 0.15, 0.2 | 47.5–58.1 | 100 × 100 × 400 | Li et al. [15] |

| SF | 37.5 | 1.78 | 82.1 | 100 × 100 × 350 | Mínguez et al. [16] |

| SF; PVAF | SF: 56; PVAF: 308 | SF: 0.5, 1.0, 1.5; PFF: 0.5, 1.0, 1.5 | / | 100 × 100 × 400 | Liu et al. [17] |

| SF | 65 | 0.26, 0.52, 0.77 | 21.3–28.1 | 150 × 150 × 600 | Carrillo et al. [18] |

| SF | 65 | 1, 2, 2.5, 7 | 152.1 | 40 × 40 × 160 | Ferdosian and Camões [19] |

| SF; PPF | SF: 40; PPF: 200 | SF: 2.0, 2.5, 3.0; PFF: 0.12, 0.17, 0.22 | 60.1–66.1 | 100 × 100 × 400 | Guo et al. [20] |

| SF | 80 | 0.075; 0.1 | / | 150 × 150 × 550 | Meng et al. [21] |

| Materials | Mass (kg/m3) |

|---|---|

| Cement | 375 |

| Coarse aggregate 10~20 mm | 545 |

| Coarse aggregate 5~10 mm | 545 |

| Sand | 850 |

| Water | 135 |

| Water reducer | 3.75 |

| Fiber Type | BF | PPF |

|---|---|---|

| Diameter (mm) | 0.013 | 0.8 |

| Length (mm) | 19 | 50 |

| Tensile strength (MPa) | 3300–4500 | 706 |

| Aspect ratio | 1460 | 63 |

| Density (g/cm3) | 2.75 | 0.95 |

| Elongation (%) | 2.4–3.0 | 10 |

| Elastic modulus (GPa) | 95–115 | 7.4 |

| Shape | straight | corrugated |

| Specimen | The Fiber Content in kg/m3 (% in Volume) | |

|---|---|---|

| BF | PPF | |

| B0.0P0.0 | 0.0 (0%) | 0.0 (0%) |

| B0.0P6.0 | 0.0 (0%) | 6.0 (0.63%) |

| B6.0P0.0 | 6.0 (0.22%) | 0.0 (0%) |

| B1.2P4.8 | 1.2 (0.04%) | 4.8 (0.51%) |

| B2P4 | 2.0 (0.07%) | 4.0 (0.42%) |

| B3.0P3.0 | 3.0 (0.11%) | 3.0 (0.32%) |

| B4.0P2.0 | 4.0 (0.15%) | 2.0 (0.21%) |

| B4.8P1.2 | 4.8 (0.17%) | 1.2 (0.13%) |

| Specimen | Total Price (CNY) | Flexural Strength (MPa) | Flexural Toughness (J) | Cost-Effectiveness | |

|---|---|---|---|---|---|

| Flexural Strength (kPa/CNY) | Flexural Toughness (10−3 J/CNY) | ||||

| B0.0P0.0 | 0 | 4 | 2 | / | / |

| B0.0P6.0 | 210 | 5.2 | 13.3 | 5.7 | 53.8 |

| B6.0P0.0 | 150 | 4.4 | 3 | 2.7 | 6.7 |

| B1.2P4.8 | 198 | 5.2 | 11.9 | 6.1 | 50.0 |

| B2P4 | 190 | 5.7 | 22.4 | 8.9 | 107.4 |

| B3.0P3.0 | 180 | 5.1 | 14.6 | 6.1 | 70.0 |

| B4.0P2.0 | 170 | 4.6 | 11.9 | 3.5 | 58.2 |

| B4.8P1.2 | 162 | 4.9 | 10.5 | 5.6 | 52.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Z.; Liu, X.; Liang, N.; de la Fuente, A.; Peng, H. Flexural Performance of a New Hybrid Basalt-Polypropylene Fiber-Reinforced Concrete Oriented to Concrete Pipelines. Fibers 2021, 9, 43. https://doi.org/10.3390/fib9070043

Deng Z, Liu X, Liang N, de la Fuente A, Peng H. Flexural Performance of a New Hybrid Basalt-Polypropylene Fiber-Reinforced Concrete Oriented to Concrete Pipelines. Fibers. 2021; 9(7):43. https://doi.org/10.3390/fib9070043

Chicago/Turabian StyleDeng, Zhiyun, Xinrong Liu, Ninghui Liang, Albert de la Fuente, and Haoyang Peng. 2021. "Flexural Performance of a New Hybrid Basalt-Polypropylene Fiber-Reinforced Concrete Oriented to Concrete Pipelines" Fibers 9, no. 7: 43. https://doi.org/10.3390/fib9070043

APA StyleDeng, Z., Liu, X., Liang, N., de la Fuente, A., & Peng, H. (2021). Flexural Performance of a New Hybrid Basalt-Polypropylene Fiber-Reinforced Concrete Oriented to Concrete Pipelines. Fibers, 9(7), 43. https://doi.org/10.3390/fib9070043