Abstract

Fibers of various origins are of great importance for the manufacture of new generation cement composites. The use of modified composite binders allows these highly efficient building materials to be used for 3D-printing of structures for various functional purposes. In this article, changes in building codes are proposed, in particular, the concept of the rheological technological index (RTI) mixtures is introduced, the hardware and method for determining which will reproduce the key features of real processes. An instrument was developed to determine a RTI value. The mixes based on composite binders and combined steel and polypropylene fibers were created. The optimally designed composition made it possible to obtain composites with a compressive strength of 93 MPa and a tensile strength of 11 MPa. At the same time, improved durability characteristics were achieved, such as water absorption of 2.5% and the F300 frost resistance grade. The obtained fine-grained fiber-reinforced concrete composite is characterized by high adhesion strength of the fiber with the cement paste. The microstructure of the developed composite, and especially the interfacial transition zone, has a denser structure compared to traditional concrete. The obtained materials, due to their high strength characteristics due to the use of a composite binder and combined fiber, can be recommended for use in high-rise construction.

1. Introduction

It is known that the performances of concrete products are significantly increased when they have dispersed reinforcement [1,2]. Using fibers of various compositions together with a composite polymineral binder, it is possible to produce cement composites of a new generation [3,4]. A careful approach to the calculation and selection of the composition of the grain mixture allowed for the transition to a more efficient technology for the manufacture of composite materials [5,6]. One of the modern effective concreting technologies, 3D printing, is not only in the efficient distribution of the concrete mixture according to the construction object scheme, but also in ensuring high adhesion strength of the structural layers of the mixture, as well as the complete filling of the formwork volumes with high-density concrete [7,8].

These technological parameters can be ensured by efficient work methods and the use of high quality materials. The requirements of 3D building technologies are met by high-strength fine-grained concrete, which includes an aggregate containing fractions calculated taking into account the closest packing factor. This composite has high strength and high durability [9,10]. Obtaining a high-strength material consists in the initial molding of a strong macrostructural matrix with filling larger pores with a plastic mixture and combining them into a single composite monolith. The main difficulty here is the operation of efficient filling of all pores with a plastic mixture [11,12].

The development of 3D-printing is constrained, among other things, by the weak availability of regulations. For the development of building technologies, it is necessary to create new effective materials with the required controllable properties: fast setting, high strength and uniformity [13,14]. The most important aspect of ensuring the constructive reliability and technical safety of additively formed objects is the value of interlayer adhesion. Insufficient bond strength of the layers leads to poor structural stability of the side layers [15,16].

Interlayer adhesion is one of the specific requirements for materials for construction printing. This property is usually not taken into account in traditional technologies and at the same time depends on a number of factors. Portland cement, traditionally used for the production of fine-grained concrete, including for additive construction, is the weak point of this system [17,18]. The totality of its indicators is not favorable for the formation of a set of necessary properties of mixtures for 3D printing. The standard fineness of grinding of ordinary cements, satisfactory for traditional concretes, the main task in the production of which is to achieve the required strength with a minimum consumption of binder, is far from optimal in the case of obtaining compositions for construction printing in terms of water-holding capacity and rate of strength gain. In addition, modern cements for the most part are of high quality, which, with relatively low strength requirements for additive-obtained composites, leads to their overruns due to the need to provide a sufficient amount of cement glue in the mixture, participating in the formation of special properties [19,20].

Creation of composite materials for special purposes requires an individual approach [21,22]. Composites for additive technologies in most cases are multicomponent, containing both mineral and organic components, as a result of complex interaction processes that ensure the formation of a special set of technological properties and performances [23,24,25,26,27,28,29,30].

Fiber is intended to improve the quality characteristics of concrete after it gains its design strength [31,32,33,34]. At the same time, the most common type of fiber is steel [31,32,33,34,35,36,37]. The efficiency of using steel fiber reinforced concrete in structures is achieved by reducing labor costs for reinforcement work, as well as reducing the consumption of mortar and steel [38,39,40,41]. Technological operations can be combined, and as a result, the concrete mass is reinforced, which leads to a decrease in labor intensity by 27% and savings in building materials per 1 m3 of the finished product. Compared to steel fiber, polypropylene is a lighter material, which is important for the construction of high-rise buildings using 3D printing. In addition, polypropylene fiber is resistant to alkalis and the absolute majority of chemicals; therefore, it does not lose its properties when all known additives are added to concrete.

Thus, to create a stable technological process of layer-by-layer synthesis, an integrated approach is required in solving a complex problem such as the creation, on a scientific basis, of formulations of high-quality concrete mixtures and special-purpose composites with the required adjustable properties (fast setting, sufficiently high strength, homogeneity and adhesion strength between different layers), creating a comfortable living environment.

The aim of the work is to develop 3D printing mortars with combined steel and polypropylene fibers. To achieve this aim, it is necessary to solve the following tasks:

- −

- Formulate and propose a new concept of rheotechnological index (RTI) of mixtures, as well as to develop a device for measuring RTI;

- −

- Prepare proposals for the regulatory code framework of 3D printed fiber mortars;

- −

- Develop and research fiber-reinforced concrete based on polymineral binders.

2. Materials and Methods

2.1. Materials

The following materials were used in experimental studies:

- −

- Portland cement CEM I 42.5 N (Belgorodsky cement, Belgorod, Russia) with factory grinding fineness of 300 m2/kg;

- −

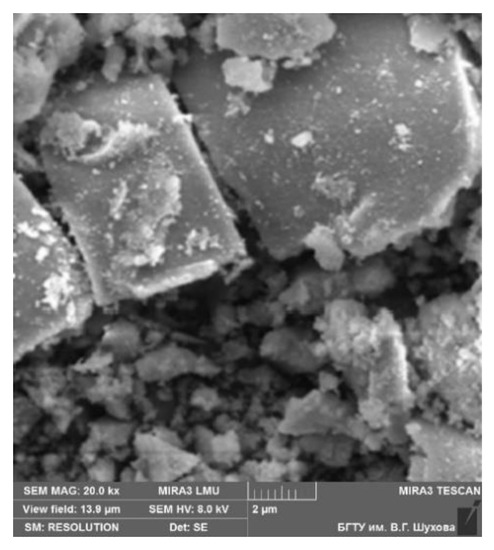

- Mineral modifier (MM) obtained by joint grinding to a specific surface area of 500 m2/kg of sand, clayey rocks and chalk in a ratio of 2:2:1 (Figure 1).

Figure 1. Microstructure of the mineral modifier.

Figure 1. Microstructure of the mineral modifier.

Screening of crushing quartzite sandstone (SCQS) with a fraction of 2.5–5 mm was used as a fine aggregate. Its interaction with the surface of the modifier particles and Portland cement clinker ensures the creation of a high homogeneity of the structure, a decrease in stresses in the interfacial transition zone (ITZ), and an increase in adhesion to the cement paste;

- −

- To improve the physical and mechanical properties, quartz sand (QS) with a fraction of 1.5–2.5 mm was introduced into the composition;

- −

- Polycarboxylate superplasticizer (SP) Melflux 5581 (BASF, Ludwigshafen, Germany) contributing to a significant increase in the water-reducing ability of the molding mix;

- −

Figure 2. Appearance of the fibers: (a) polypropylene; and (b) steel.

Figure 2. Appearance of the fibers: (a) polypropylene; and (b) steel. Table 1. Mix proportions.

Table 1. Mix proportions.

2.2. Mix Design

Table 2 presents the developed specimens. It has been suggested that the strength of fine-grained fiber-reinforced concrete can be increased by introducing a combined fiber and a composite binder in comparison with traditional concrete. For uniform distribution of fiber throughout the volume of the mixture without the formation of clots and “hedgehogs”, the introduction of the components of the mixture must be carried out strictly in the following sequence: first, the fine aggregate is mixed with the fiber, and then the binder and water with the superplasticizer are introduced. In any case, it is necessary to control the presence of “hedgehogs” in the mixture and, if they appear, the fiber feed rate should be reduced.

Table 2.

Mix proportions, kg/m3.

2.3. Methods

The characteristics of the microstructure of the components were determined using an ASAP-2010 N porometer (Micromeritics, Norcross, GA, USA).

The printability metric cannot be determined by any one property and will always be complex. Its components are the rheological characteristics of the mixtures (yield stress and viscosity) and some technological characteristics—the degree of thixotropy, homogeneity at a certain scale level (aggregate size) and the dynamics of changes in properties over time. In this regard, for a numerical assessment of the degree of “printability”, it is proposed to introduce the concept of the rheological technological index of mixtures, the hardware and method for determining which will reproduce the key features of real processes. To determine a RTI value, a device was developed (Figure 3a), which consists of a conical body 1, into which a piston of a certain mass 2 freely enters. Before testing, the body of the device is turned over and filled with the test mixture with a slight excess. The piston has a limiting protrusion that prevents it from leaving the housing during filling with the mixture. After filling (Figure 3b), a special table is installed on the inverted body with holes for the mixture to exit during test 3, through which its excess is also squeezed out, thereby ensuring complete filling. The body and the stage are turned over and connected with each other by spring clips 4. The device prepared for testing is installed on a standard shaking table provided for by the Russian standard GOST 310.4-81. The value of RTI of the mixture corresponds to the immersion depth of the piston after a cycle of 30 shakes at a frequency of 1 Hz.

Figure 3.

Developed device for determining the rheotechnological index (a) and the sequence for determining the RTI (b).

The extrudability of the mixture, characterized by RTI, is determined by the formula:

where; 80 is the distance of the maximum possible immersion of the working body of the viscometer, mm; h—immersion value, mm; 11—idle speed, mm.

RTI = 80 − h + 11

The indicator of the bearing capacity of the freshly formed layer (plastic strength) is determined by the formula:

where; P is the pressure exerted on the mixture at which the mixture begins to be squeezed out of the mold, kg; S is the area of the stamp used for compression, m2.

The fixation time of the structure is determined for dispersed mortar mixtures for construction printing in minutes from the moment of mixing until the mortar is able to withstand a specific load corresponding to 10 times the average density, determined using a Vik device with special nozzles, with no more than 10% deformation in height. The average density of the mortar is determined for dispersed mortar mixtures for construction printing by the mass of the mixture in a measuring cell of a known volume. The appearance of the system for determining these indicators is shown in Figure 4.

Figure 4.

A set of equipment and devices for determining the bearing capacity of a newly formed layer.

After the end of the printing process, the surplus of the mixture is cut off from the surface of the array using a spatula so that its height is 40 ± 1 mm. Using a ruler, a square and a spatula, the mass is cut into six beams (Figure 5).

Figure 5.

Newly formed specimens.

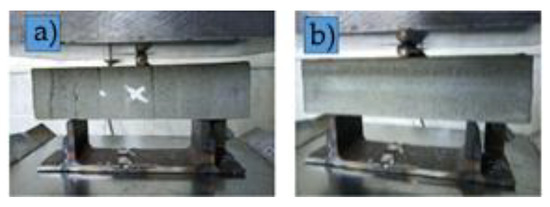

The flexural strength was determined in accordance with the Russian standard GOST 30744 as an average value between tests along horizontal layers and perpendicular to these layers (Figure 6).

Figure 6.

Determination of the flexural strength of printed specimens with loading: (a) along horizontal layers; and (b) perpendicular to horizontal layers.

The halves of the beams obtained after flexural tests were immediately tested for compression (Figure 7). Due to the fact that concretes for high-rise structures have been developed, the frost resistance study was carried out according to the second basic method F2 in accordance with the Russian standard GOST 10060-2012 on samples of 100 × 100 × 100 mm. The samples were immersed in water, first at 1/3 of the height for a day, then at 2/3 of the height for a day, and then completely immersed in water for two days. Then, the samples were placed in a Polair CV-105S freezer at a temperature of −18 °C. Each freezing cycle lasted 2.5 h, the thawing cycle at a temperature of 20 °C—2 h. The frost resistance grade was evaluated by the value of the ultimate strength in compression after a certain number of freeze–thaw cycles, according to the Russian standard GOST 10060-2012, taking into account the number of cycles at which the weight loss does not exceed 2% and there are no cracks, chips, and flaking of the ribs on the samples.

Figure 7.

Determination of the compressive strength of printed halves specimens with loading: (a) along horizontal layers; and (b) perpendicular to horizontal layers.

The water absorption of the samples was determined according to the Russian standard GOST 12730. The samples were placed in a container filled with water so that the water level in the container was about 50 mm higher than the upper level of the laid samples. The samples were placed on spacers so that the height of the sample was minimal (the prisms and cylinders were placed on their side). The water temperature in the container should be (20 ± 2) °C. The samples were weighed every 24 h of water absorption on a balance with an error of no more than 0.1%. Samples taken out of water were preliminarily wiped with a wrung out damp cloth. The weight of the water flowed out of the pores of the sample onto the weighing pan was included in the weight of the saturated sample. The test was carried out until the results of two successive weighing differed by no more than 0.1%.

3. Results and Discussion

3.1. Proposals for the Regulatory Code Framework of 3D-Printed Fiber Mortars

The functional purpose of ready-made concrete mixes determines the selection and requirements for raw materials, as well as the patterns of its use for each specific composite material. To create a stable technological process, it is necessary to develop a special composite binder and select aggregates that provide the necessary technological, physical, mechanical properties and performances of the hardened composite. The developed laid mixtures must have such properties as:

- −

- Pumpability,

- −

- Ability to extrusion and ease of production,

- −

- Setting time and temperature change dynamics,

- −

- Compressive and flexural strength in parallel and perpendicular directions relative to the plane of the contact zone.

Rocks of layer-by-layer formation and layered structure can be considered as natural prototypes of additively obtained structures. In most cases, these rocks have an order of magnitude higher interlayer adhesion index than those of artificially obtained analogs. When analyzing the reasons for this phenomenon, it was revealed that the natural cementing substance in its composition has a significant content of dispersed fragments of the base rock (rock-forming mineral). This leads to the convergence of the compositions and properties of the layers of the base rock and the interlayers that unite them, contributes to the formation of a seam that does not have significant differences at the micro- and macroscopic levels and, as a consequence of the high adhesion strength. According to the main provisions of the law of affinity of structures [26], this phenomenon can and should be artificially recreated in the design and creation of binding compositions originally intended for additively obtained materials.

Another important aspect that requires attention when complementing the development of additive technologies is the control of the technological process and the quality of the resulting products. Taking into account the specifics of the methods of layer-by-layer synthesis, as a rule, giving a time interval between the formation of adjacent layers, there are risks of the occurrence of fields of mechanical stresses in structures, which, with an unfavorable confluence of factors, can lead to the occurrence of significant deformations or even defects.

For the rational use and implementation of 3D printing technology, it is important to conduct a scientific analysis of the potential applications of products obtained using 3D technology. This is determined by the nature of the needs of buildings and structures, as well as by the materials science analysis of the use of various building materials in the construction of buildings.

3.2. Rheological Characteristics of Mortars

For the conditions of 3D technologies, the time indicator of the strength development and hardening of the molding mixture is important. This has a positive effect, as it helps to eliminate cracking during hydration. The results show that the starts of setting for mixes 2, 3 and 4 are 1 h 53 min, 1 h 56 min, and 1 h 59 min, and the ends of setting are 2 h 41 min, 2 h 45 min and 2 h 49 min, respectively.

As you can see from Table 2, the use of the superplasticizer in an amount of 0.5 wt.% by the cement made it possible to reduce water demand by more than 20% and increase the workability of the mixture. In addition to 3D printing, these compositions can be used for the reconstruction and repair of buildings and structures. This corresponds to the indicators of workability of the mixture (Table 3).

Table 3.

Rheological characteristics of mortars.

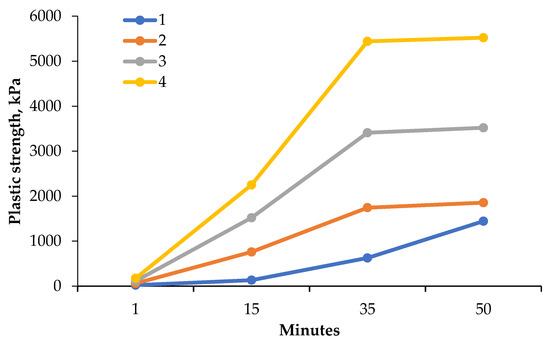

Having made up based on the results presented in Table 2 curve of the development of plastic strength over time, it clearly gets the advantages of the developed mortars (Figure 8).

Figure 8.

Development of plastic strength over time.

Due to the introduction of the mineral modifier into the composition, the necessary workability of the mixture was achieved with a low water-cement ratio; therefore, it can be considered that this modifier fully meets the requirements for mixtures for 3D printing technologies. The reduction in mixing water consumption due to the use of MM is up to 25%, which reduces the porosity and increases the density of the material and, ultimately, increases the service life of the product or structure.

3.3. Physical and Mechanical Properties

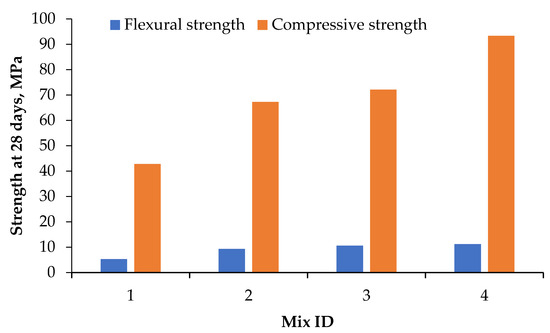

A significant increase in strength indicators was achieved with the use of the developed composite binder, which is clearly demonstrated by the diagram in Figure 9.

Figure 9.

Compressive and flexural strength of developed fiber mortars.

As follows from the data obtained, the strength of the prototypes of the developed concrete composition increased: in compression—by 36.5%, in flexion—by 43.4% compared to unreinforced material, which is consistent with previous studies by other authors [4,5]

3.4. Durability

Frost resistance and water absorption of monolithic fiber-reinforced mortar used in 3D additive technologies affect the durability properties. The results of the study of these indicators of the developed fine-grained fiber-reinforced mortar show that this material is characterized by low water absorption and high frost resistance (Table 4).

Table 4.

Frost resistance and water absorption of the mortars.

The frost resistance of fiber-reinforced mortar in comparison with ordinary reinforced concrete is increased by almost seven times [3]. The water absorption of fiber-reinforced mortar is also related to the percentage of reinforcement, and is directly proportional to the content of fiber in the composition of the material. This property of the developed concrete is almost two times higher than that of traditional concrete [1,2]. An increase in the ultimate strength (which was revealed in the previous subsection) and durability of the material reduces the risks of cracking and shrinkage, as well as creep during the operation of the structure.

Of great importance from the point of view of durability are the characteristics of the binder, which creates a reinforcing skeleton in a concrete paste and binds aggregate particles into a single conglomerate. The products of hydration of cement clinker represent the solid phase of cement paste with the mineral modifier and modifier components, a liquid phase that fills non-hydrated pores and capillaries, and a gaseous phase dissolved in water. With dispersed reinforcement, the risk of cracking of the concrete structure during operation is significantly reduced, and, consequently, the possibility of water penetration is reduced. These results are consistent with studies by other authors in recent years [27,28,29].

3.5. Binder Adhesion to Fiber

The indicators of adhesion of fibers to a composite binder with a mineral modifier have also been optimized. The obtained fine-grained fiber-reinforced concrete is characterized by high adhesion strength of the fiber to the hardening cement paste. The interfacial transition zone and the entire structure have a dense structure, compared to conventional fiber-reinforced concrete. The nature of the porosity also differs from the traditional fiber-reinforced concrete. Due to the presence of MM in the composition (with specific area 500 m2/kg, average particle diameter of 12.0 μm and density of 2400 kg/m3), the percentage of total porosity has decreased, the pores are smaller, and more filled with hydrated new growths.

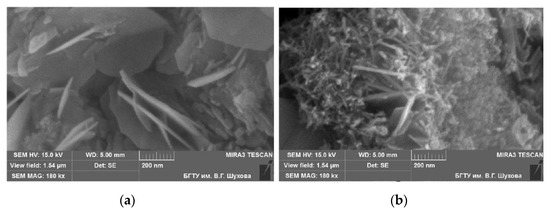

The increase in the strength indicators of the obtained fiber-reinforced concrete is explained by the formation of low-basic calcium silicate hydrates as a result of hydration reactions, which is associated with the optimization of the composition and the ratio of the components of the mineral modifier. By microphotographic studies of the structure of the developed composite, it was found that the structure-forming elements are located more evenly throughout the volume (crystals up to 5 µm in size, Figure 10a). The structure of no additive cement paste is characterized by the predominance of highly basic calcium silicate hydrates and portlandite, in this case, areas of uneven filling of space and crystals of unequal size are noted (Figure 10b).

Figure 10.

SEM images: (a) Mix ID 4, and (b) Mix ID 1.

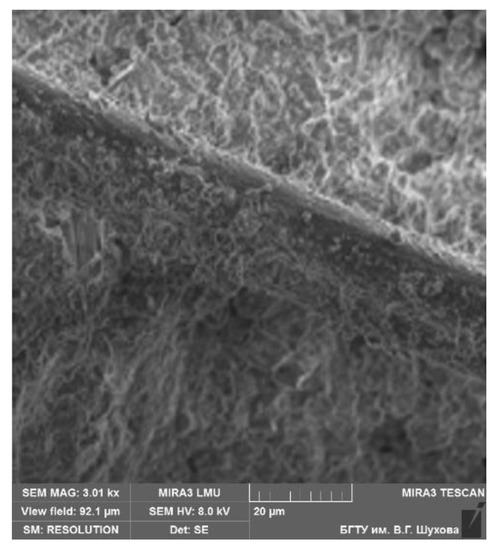

This is due to the lower energy consumption of the processes of interaction of cement clinker minerals with MM components in the presence of a superplasticizer, which reduces the rate of their formation and the type of products formed. Unreacted modifier particles play the role of microfiller and reduce shrinkage during material hardening. Microcracking is practically reduced to zero due to the use of a mineral modifier. In addition to silicate hydrates, the modifier components form ettringite-like phases as a result of hydration reaction with the gypsum of Portland cement. These processes contribute to the acceleration of hardening and the growth of strength, as well as the uniformity of distribution of new growths throughout the entire volume. New microparticles adhere tightly to the cement clinker grains and fill all the pores and voids. At the same time, the permeability of the composite decreases (Figure 11).

Figure 11.

Fiber mortar interfacial transition zone (specimen 4).

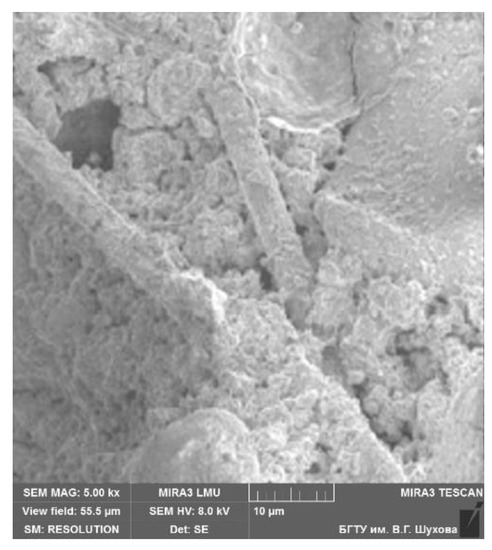

The interfacial transition zone in the obtained fiber-reinforced concrete looks like an adhesive monolith without the presence of any pores and voids, cracks and cavities. It is characterized by strong adhesion of the fibers to the cement matrix, compacted by hydrated new growths. Thus, the mineral modifier significantly increases the adhesion of the hardening binder to the fibers. When the fiber mortar is destroyed, the remains of the composite binder are fixed on the fibers, which indicate a high degree of adhesion of the components of the ITZ (Figure 12).

Figure 12.

The nature of the adhesion of the fiber to the binding matrix.

4. Conclusions

It was established that the physical and mechanical characteristics of fiber-reinforced mortar based on the composite binder are 15–20% higher than those of conventional fine-grained concrete (mortar). The optimal content of components in the composition of high-strength fiber-reinforced mortar provides the required properties in comparison with similar compositions without a mineral modifier. It was found that fiber-reinforced mortar with the addition of a modifier and the densest packing of the aggregate exceeds the strength of ordinary fine-grained concrete by almost 1.5 times. This is due to the effective selection of the composition with a dense spatial packing of particles, as well as the peculiarities of structure formation. When added to the composition of the combined fiber (steel and polypropylene, 1.6% and 0.24%, respectively), there is a significant increase in the indicators of material properties: strength, modulus of elasticity, water absorption and frost resistance.

The use of composite binders with the addition of MM makes it possible to obtain a composite with high construction and technical properties. The achievement of this result is due to the calculation of the amount of combined fiber and the closest packing ratio of fine aggregate, with a different composition of particle fractions. The use of this material in construction will increase the efficiency of construction production, expand the raw material base of the construction industry, and help improve the environmental situation.

Changes to building codes are proposed, in particular, the concept of rheological technological index of RTI mixtures is introduced, the hardware and method for determining that will reproduce the key features of real processes. An instrument was developed to determine the RTI value. The resulting composite, which has a compressive strength of over 90 MPa, and a bending strength of over 10 MPa, and high deformation rates will make it possible to produce effective building structures for difficult operating conditions.

Fiber reinforcement of a mortar structure significantly increases the durability of the structure. Therefore, the frost resistance of fiber-reinforced concrete in comparison with ordinary reinforced concrete is increased by almost seven times. The water absorption of fiber-reinforced concrete is also related to the percentage of reinforcement, and is directly proportional to the content of fiber in the composition of the material. This property of the developed fiber-reinforced concrete is almost two times higher than that of traditional concrete.

Of great importance from the point of view of the resistance of concrete to aggressive environmental influences are the characteristics of a binder that creates a reinforcing skeleton in a mortar matrix and binds aggregate particles into a single conglomerate. The products of hydration of cement clinker represent the solid phase of cement paste with a mineral modifier and modifier components, a liquid phase that fills non-hydrated pores and capillaries, and a gaseous phase dissolved in water.

With dispersed reinforcement, the risk of cracking of the concrete structure during operation is significantly reduced, and, consequently, the possibility of penetration of aggressive substances is reduced. Thus, the resulting fiber-reinforced mortar with a mineral modifier has a higher durability than conventional reinforced concrete. Combined fiber constituting 1.6 wt.% mortars, allows you to create an effective material for monolithic construction.

The characteristics of a fiber-reinforced mortar depend on the complex influence of the properties of the cement matrix and the fiber used (size, shape, material of manufacture, etc.). In this case, in any case, the strength properties of fiber-reinforced concrete will be significantly higher than traditional reinforced concrete reinforced in the usual way (metal meshes, frames, rods), as well as the possibility of cracking, which is more than 80% lower than that of reinforced concrete. The high durability of this material is due to the nature of the porosity. It is minimal due to the presence of fiber, which acts as a mechanical internal vibrator during molding.

The structure of fiber-reinforced mortar on a composite binder with a mineral modifier is characterized by a high degree of adhesion of the cement stone to the fiber. In the process of hydration of a composite binder with a superplasticizer and a mineral modifier, the distribution of new growths throughout the volume is uniform. Based on the main findings of this study, it can be concluded that the resulting fiber-reinforced concrete is recommended for the use in the construction of high-rise buildings using 3D printing technologies.

Author Contributions

Conceptualization, V.L. and M.A.; methodology, M.A., R.F. and A.A.; software, A.A., G.M., R.F.; validation, M.E., M.A. and A.V.; formal analysis, M.A. and R.F.; investigation, V.L. and M.A.; resources, A.V. and G.M.; data curation, M.E. and R.F.; writing—original draft preparation, M.A., A.A., V.U. and A.V.; writing—review and editing, M.A., R.F., V.U. and A.A.; visualization, A.A. and M.A.; supervision, G.M., M.E. and V.L.; project administration, V.L., M.A. and R.F.; funding acquisition, R.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research work was carried out within the framework of the RFBR grant No. 18-29-24113 as well as with financial support from the Ministry of Science and Higher Education of the Russian Federation within the framework of the Priority 2030 program and the use of equipment from the Center for High Technologies of BSTU n.a. V.G. Shukhov.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing not applicable.

Acknowledgments

The authors also gratefully acknowledge the financial support by the Department of Civil Engineering, College of Engineering, Prince Sattam Bin Abdulaziz University, Saudi Arabia.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Klyuyev, S.V.; Guryanov, Y.V. External reinforcing of fiber concrete constructions by carbon fiber tapes. Mag. Civ. Eng. 2013, 1, 21–26. [Google Scholar] [CrossRef]

- Zharikov, I.S.; Laketich, A.; Laketich, N. Impact of concrete quality works on concrete strength of monolithic constructions. Constr. Mater. Prod. 2018, 1, 51–58. [Google Scholar] [CrossRef]

- Ali, M.; Abbas, S.; Salah, B.; Akhter, J.; Saleem, W.; Haruna, S.; Room, S.; Abdulkadir, I. Investigating Optimal Confinement Behaviour of Low-Strength Concrete through Quantitative and Analytical Approaches. Materials 2021, 14, 4675. [Google Scholar] [CrossRef]

- Ramakrishnan, K.; Depak, S.; Hariharan, K.; Abid, S.R.; Murali, G.; Cecchin, D.; Fediuk, R.; Amran, Y.M.; Abdelgader, H.S.; Khatib, J.M. Standard and modified falling mass impact tests on preplaced aggregate fibrous concrete and slurry infiltrated fibrous concrete. Constr. Build. Mater. 2021, 298, 123857. [Google Scholar] [CrossRef]

- Usanova, K.; Barabanshchikov, Y.G. Cold-bonded fly ash aggregate concrete. Mag. Civ. Eng. 2020, 95, 104–118. [Google Scholar] [CrossRef]

- Fediuk, R.S.; Ibragimov, R.A.; Lesovik, V.S.; Pak, A.A.; Krylov, V.V.; Poleschuk, M.M.; Stoyushko, N.Y.; Gladkova, N.A. Processing equipment for grinding of building powders. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327, 042029. [Google Scholar] [CrossRef]

- Chernysheva, N.; Lesovik, V.; Fediuk, R.; Vatin, N. Improvement of Performances of the Gypsum-Cement Fiber Reinforced Composite (GCFRC). Materials 2020, 13, 3847. [Google Scholar] [CrossRef]

- Lukuttsova, N.P.; Karpikov, E.G.; Luginina, I.G.; Pykin, A.A.; Ustinov, A.G.; Pinchukova, I.N. High-performance fine concrete modified with nano-dispersion additive. Int. J. Appl. Eng. Res. 2014, 9, 16725–16731. [Google Scholar]

- Stroganov, V.; Sagadeev, E.; Ibragimov, R.; Potapova, L. Mechanical activation effect on the biostability of modified cement compositions. Constr. Build. Mater. 2020, 246, 118506. [Google Scholar] [CrossRef]

- Bataev, D.K.-S.; Murtazayev, S.-A.Y.; Salamanova, M.S.; Viskhanov, S.S. Utilization of Cement Kiln Dust in Production of Alkali-Activated Clinker-Free Binders. In Proceedings of the International Symposium “Engineering and Earth Sciences: Applied and Fundamental Research” Dedicated to the 85th Anniversary of H.I. Ibragimov (ISEES 2019), Grozny, Russia, 1 April 2019; Atlantis Highlights in Material Sciences and Technology (AHMST). Atlantis Press: Dordrecht, The Netherlands, 2019; Volume 1, pp. 457–460. Available online: https://www.atlantis-press.com/proceedings/isees-19/125914222 (accessed on 25 November 2021).

- Murali, G.; Fediuk, R.A. Taguchi approach for study on impact response of ultra-high-performance polypropylene fibrous cementitious composite. J. Build. Eng. 2020, 30, 101301. [Google Scholar] [CrossRef]

- Semenov, P.; Uzunian, A.; Davidenko, A.; Derevschikov, A.; Goncharenko, Y.; Kachanov, V.; Khodyrev, V.; Meschanin, A.; Minaev, N.; Mochalov, V.; et al. First study of radiation hardness of lead tungstate crystals at low temperatures. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2007, 582, 575–580. [Google Scholar] [CrossRef] [Green Version]

- Fediuk, R.S.; Yevdokimova, Y.G.; Smoliakov, A.K.; Stoyushko, N.Y.; Lesovik, V.S. Use of geonics scientific positions for designing of building composites for protective (fortification) structures. IOP Conf. Series: Mater. Sci. Eng. 2017, 221, 012011. [Google Scholar] [CrossRef]

- Fediuk, R.; Mosaberpanah, M.A.; Lesovik, V. Development of fiber reinforced self-compacting concrete (FRSCC): Towards an efficient utilization of quaternary composite binders and fibers. Adv. Concr. Constr. 2020, 9, 387–395. [Google Scholar]

- Elistratkin, M.Y.; Lesovik, V.S.; Zagorodnjuk, L.H. New point of view on materials development. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327, 032020. [Google Scholar] [CrossRef] [Green Version]

- Volodchenko, A.A.; Lesovik, V.S.; A Cherepanova, I.; Zagorodnjuk, L.H.; Elistratkin, M.Y.; Volodchenko, A.N. Peculiarities of non-autoclaved lime wall materials production using clays. In International Conference on Mechanical Engineering, Automation and Control Systems 2017: Proceedings of the IOP Conference Series: Materials Science and Engineering, Tomsk, Russia, 4–6 December 2017; IOP Publishing: Bristol, UK, 2018; Volume 327, p. 022021. [Google Scholar]

- Klyuyev, S.V.; Klyuyev, A.V.; Sopin, D.M.; Netrebenko, A.V.; Kazlitin, S.A. Heavy loaded floors based on fine-grained fiber concrete. Mag. Civ. Eng. 2013, 3, 7–14. [Google Scholar] [CrossRef]

- Begich, Y.E.; Klyuev, S.V.; Jos, V.A.; Cherkashin, A.V. Fine-grained concrete with various types of fibers. Mag. Civ. Eng. 2020, 97, 9702. [Google Scholar] [CrossRef]

- Anikanova, T.V.; Pogoromsky, A.S. The use of semi-aquatic calcium sulfate to intensify the processes of hardening of structural heat-insulating foamed concrete. Constr. Mater. Prod. 2018, 1, 25–32. [Google Scholar]

- Khan, M.I.; Sutanto, M.H.; Bin Napiah, M.; Zoorob, S.E.; Al-Sabaeei, A.M.; Rafiq, W.; Ali, M.; Memon, A.M. Investigating the mechanical properties and fuel spillage resistance of semi-flexible pavement surfacing containing irradiated waste PET based grouts. Constr. Build. Mater. 2021, 304, 124641. [Google Scholar] [CrossRef]

- Szeląg, M. Properties of cracking patterns of multi-walled carbon nanotube-reinforced cement matrix. Materials 2019, 12, 2942. [Google Scholar] [CrossRef] [Green Version]

- Korsun, V.; Vatin, N.; Korsun, A.; Nemova, D. Physical-mechanical properties of the modified fine-grained concrete subjected to thermal effects up to 200 °C. Appl. Mech. Mater. 2014, 633, 1013–1017. [Google Scholar] [CrossRef]

- Lukuttsova, N.; Pashayan, A.; Khomyakova, E.; Suleymanova, L.; Kleymenicheva, Y. The use of additives based on industrial wastes for concrete. Int. J. Appl. Eng. Res. 2016, 11, 7566–7570. [Google Scholar]

- Murtazayev, S.-A.Y.; Salamanova, M.S.; Alaskhanov, A.K.; Ismailova, Z.K. Development of Multicomponent Binders Using Fine Powders. In Proceedings of the International Symposium: “Engineering and Earth Sciences: Applied and Fundamental Research” Dedicated to the 85th Anniversary of H.I. Ibragimov (ISEES 2019), Grozny, Russia, 1 April 2019; Atlantis Highlights in Material Sciences and Technology (AHMST). Atlantis Press: Dordrecht, The Netherlands, 2019; Volume 1, pp. 500–503. [Google Scholar]

- Izotov, V.S.; Ibragimov, R.A. Hydration Products of Portland Cement Modified with a Complex Admixture. Inorg. Mater. 2015, 51, 187–190. [Google Scholar] [CrossRef]

- Tolstoy, A.; Lesovik, V.; Fediuk, R.; Amran, M.; Gunasekaran, M.; Vatin, N.; Vasilev, Y. Production of Greener High-Strength Concrete Using Russian Quartz Sandstone Mine Waste Aggregates. Materials 2020, 13, 5575. [Google Scholar] [CrossRef]

- Tian, W.; Qi, B.; Liu, Y.; Liu, K.; Wang, W. Early frost resistance and permeability properties of carbon fiber/cement-based composite cured by ohmic heating under ultra-low temperature. Constr. Build. Mater. 2021, 282, 122729. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M. Combined Effect of Multi-Walled Carbon Nanotubes, Steel Fibre and Glass Fibre Mesh on Novel Two-Stage Expanded Clay Aggregate Concrete against Impact Loading. Crystals 2021, 11, 720. [Google Scholar] [CrossRef]

- Wang, J. Frost durability and stress-strain relationship of lining shotcrete in cold environment. Constr. Build. Mater. 2018, 198, 58–69. [Google Scholar] [CrossRef]

- Amran, Y.H. Influence of structural parameters on the properties of fibred-foamed concrete. Innov. Infrastruct. Solut. 2020, 5, 1–18. [Google Scholar] [CrossRef]

- Tan, K.; Nichols, J.M. Frost Resistance of Concrete with Different Strength Grades and Mineral Admixtures. Mod. Civil Struct. Eng. 2018, 2, 1–8. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Alyousef, R.; Alabduljabbar, H.; Khudhair, M.H.R.; Hejazi, F.; Alaskar, A.; Alrshoudi, F.; Siddik, A. Performance properties of structural fibred-foamed concrete. Results Eng. 2020, 5, 100092. [Google Scholar] [CrossRef]

- Murali, G.; Sallal, R.; Abid, K.; Karthikeyan, M.K.; Haridharan, M.A.; Siva, A. Low-velocity impact response of novel prepacked expanded clay aggregate fibrous concrete produced with carbon nano tube, glass fiber mesh and steel fiber. Constr. Build. Mater. 2021, 284, 122749. [Google Scholar] [CrossRef]

- Al-Nini, A.; Nikbakht, E.; Syamsir, A.; Shafiq, N.; Mohammed, B.S.; Al-Fakih, A.; Al-Nini, W.; Amran, Y.H.M. Flexural Behavior of Double-Skin Steel Tube Beams Filled with Fiber-Reinforced Cementitious Composite and Strengthened with CFRP Sheets. Materials 2020, 13, 3064. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Abdelgader, H.S.; Amran, Y.H.M.; Shekarchi, M.; Wilde, K. Repeated Projectile Impact Tests on Multi-Layered Fibrous Cementitious Composites. Int. J. Civ. Eng. 2021, 19, 635–651. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Amran, Y.M.; Abdelgader, H.S.; Fediuk, R.; Susrutha, A.; Poonguzhali, K. Impact performance of novel multi-layered prepacked aggregate fibrous composites under compression and bending. Structures 2020, 28, 1502–1515. [Google Scholar] [CrossRef]

- Fediuk, R.; Amran, M.; Klyuev, S.; Klyuev, A. Increasing the Performance of a Fiber-Reinforced Concrete for Protective Facilities. Fibers 2021, 9, 64. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Vatin, N.; Lee, Y.H.; Murali, G.; Ozbakkaloglu, T.; Klyuev, S.; Alabduljabber, H. Fibre-Reinforced Foamed Concretes: A Review. Mater. 2020, 13, 4323. [Google Scholar] [CrossRef]

- Abid, S.R.; Murali, G.; Amran, M.; Vatin, N.; Fediuk, R.; Karelina, M. Evaluation of Mode II Fracture Toughness of Hybrid Fibrous Geopolymer Composites. Materials 2021, 14, 349. [Google Scholar] [CrossRef]

- Jaishankar, P.; Murali, G.; Salaimanimagudam, M.P.; Amran, Y.H.M.; Fediuk, R.; Karthikeyan, K. Study of Topology Optimized Hammerhead Pier Beam Made with Novel Preplaced Aggregate Fibrous Concrete. Period. Polytech. Civ. Eng. 2020, 65, 287–298. [Google Scholar] [CrossRef]

- Bosnjak, J.; Sharma, A.; Grauf, K. Mechanical Properties of Concrete with Steel and Polypropylene Fibres at Elevated Temperatures. Fibers 2019, 7, 9. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).