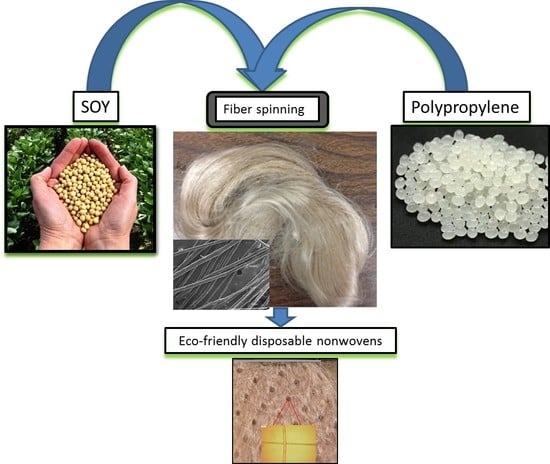

Influence of Spinning Temperature and Filler Content on the Properties of Melt-Spun Soy Flour/Polypropylene Fibers

Abstract

:1. Introduction

2. Experimental

2.1. Materials

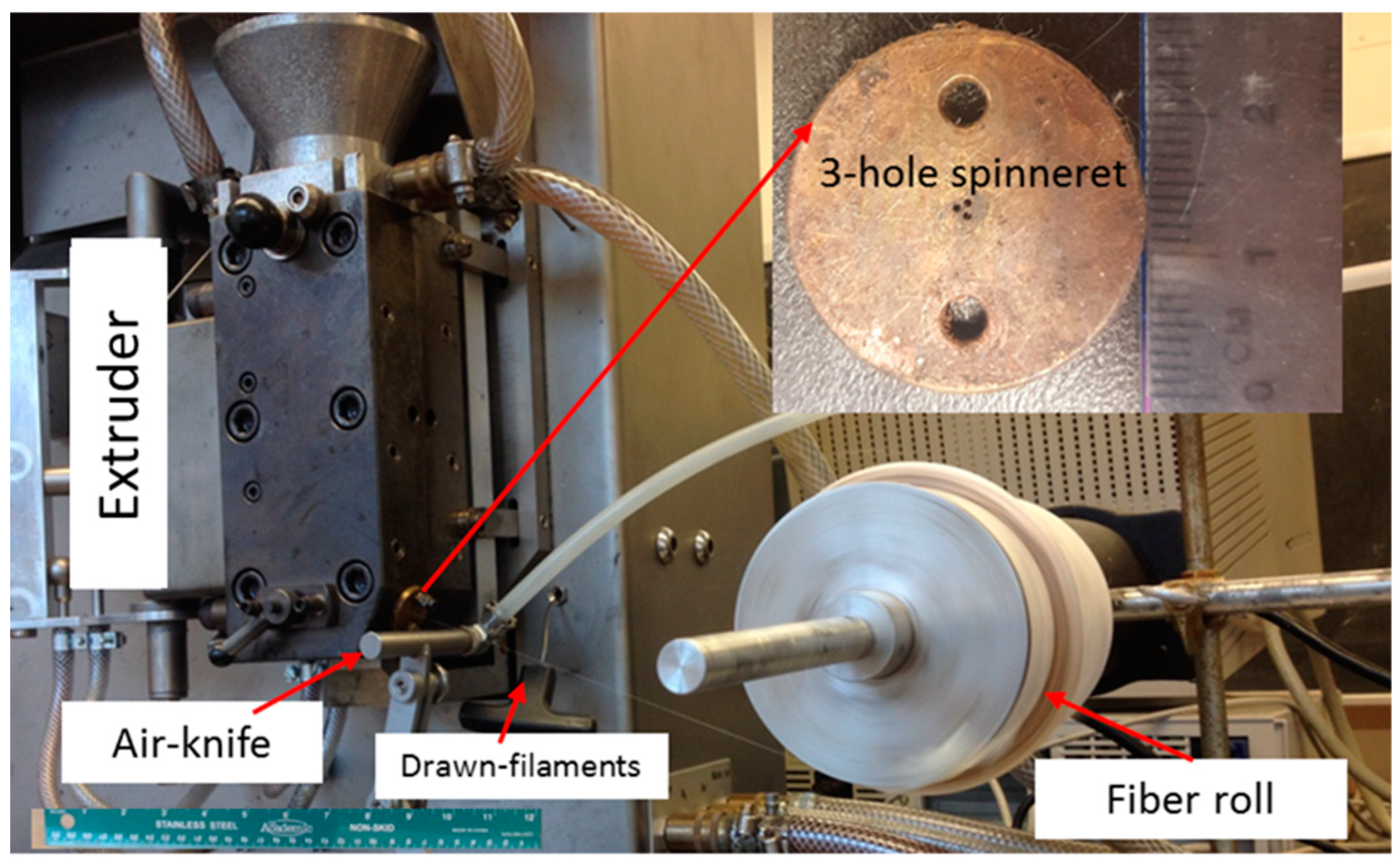

2.2. Spinning

2.3. Characterization

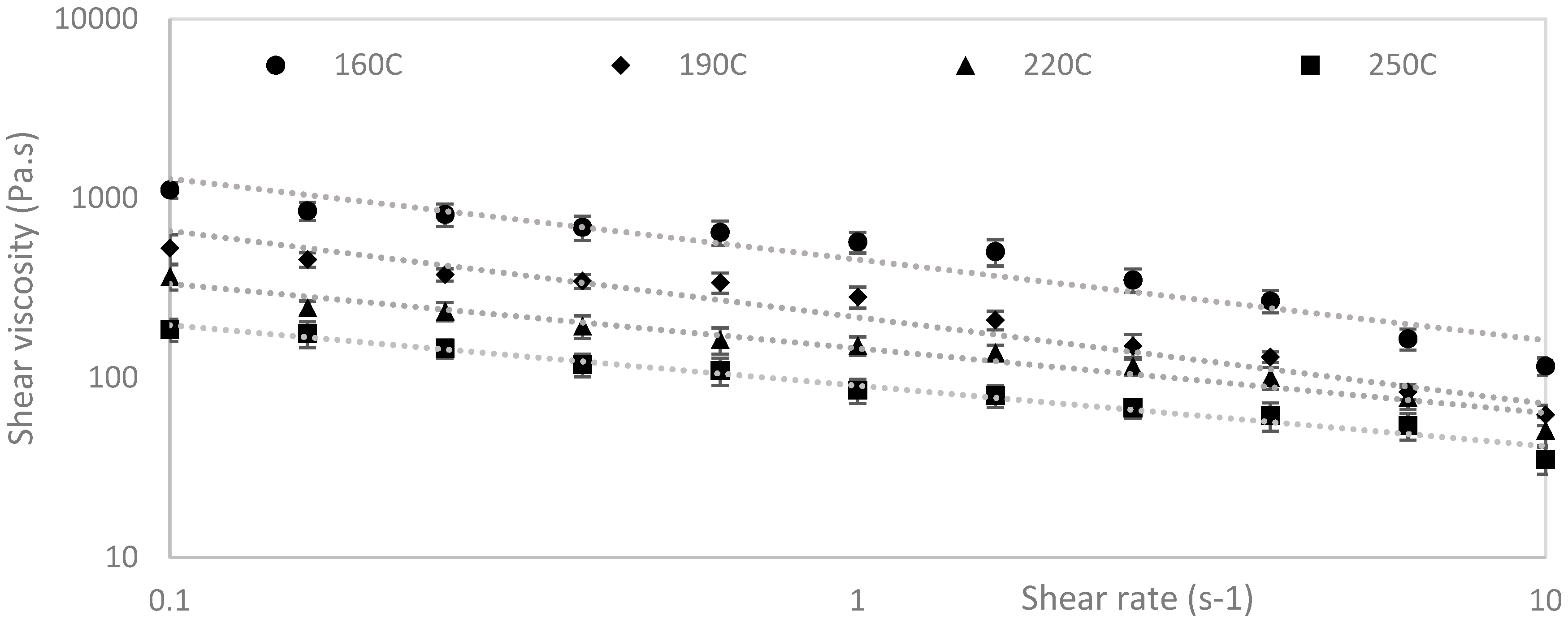

3. Results and Discussion

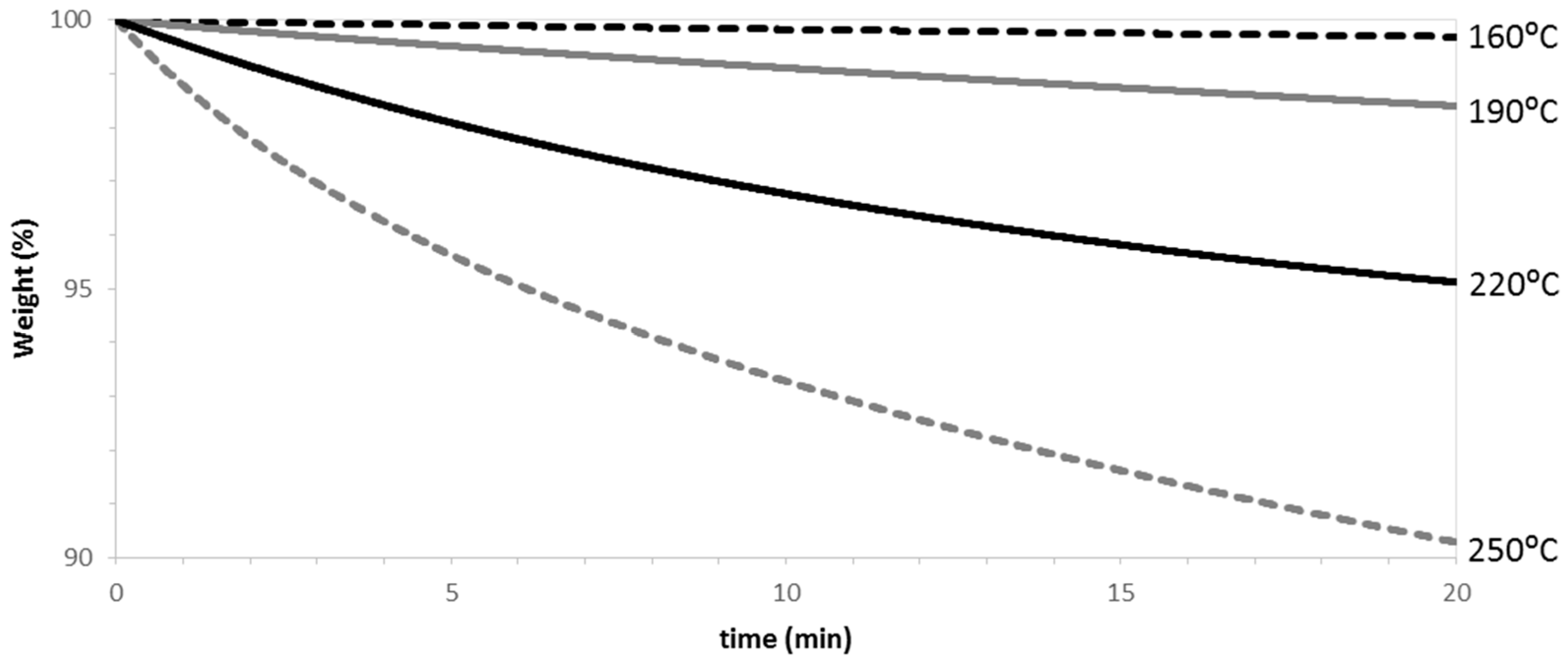

3.1. Thermal Degradation

3.2. Melting Behavior and Crystallinity

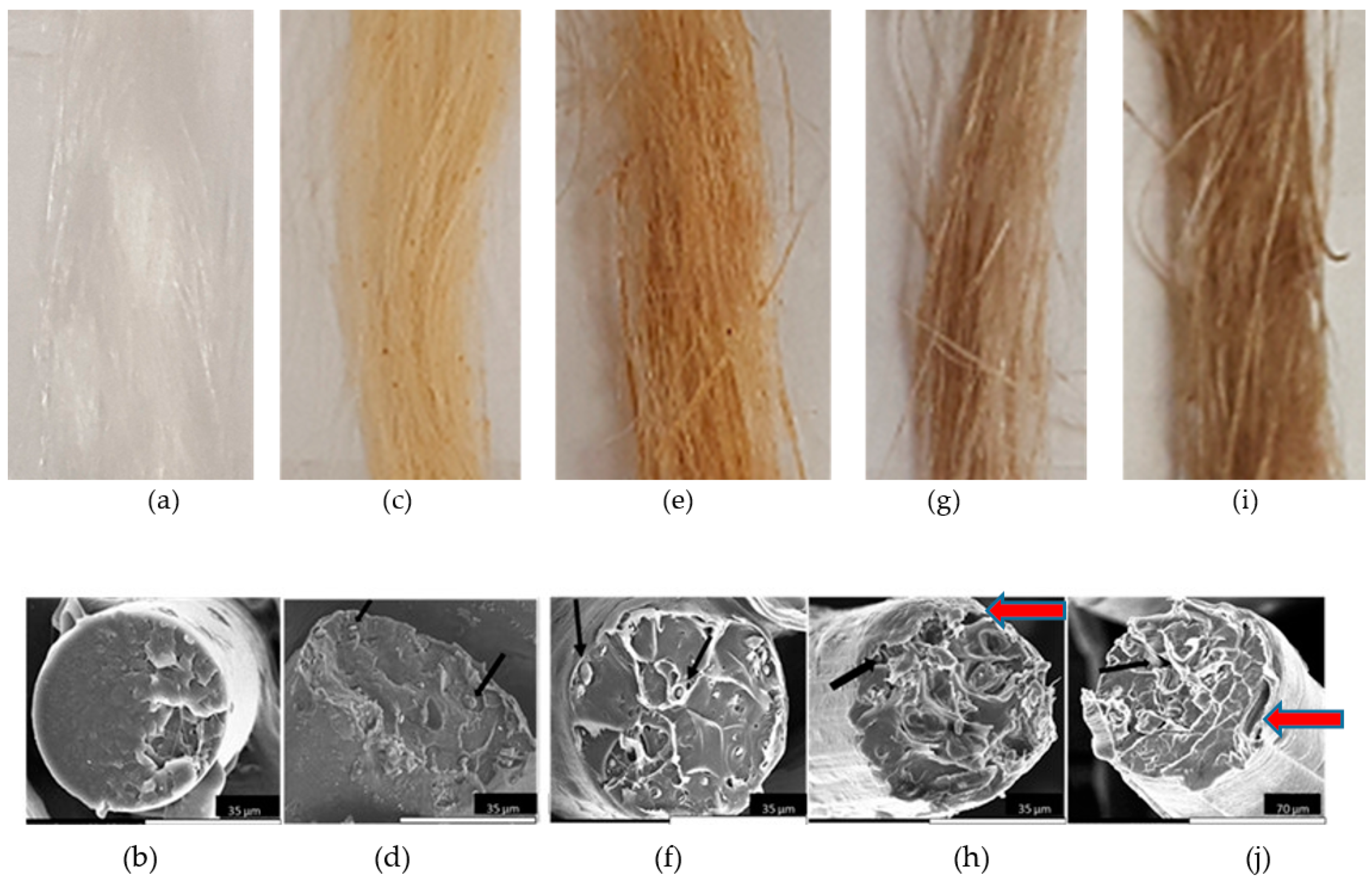

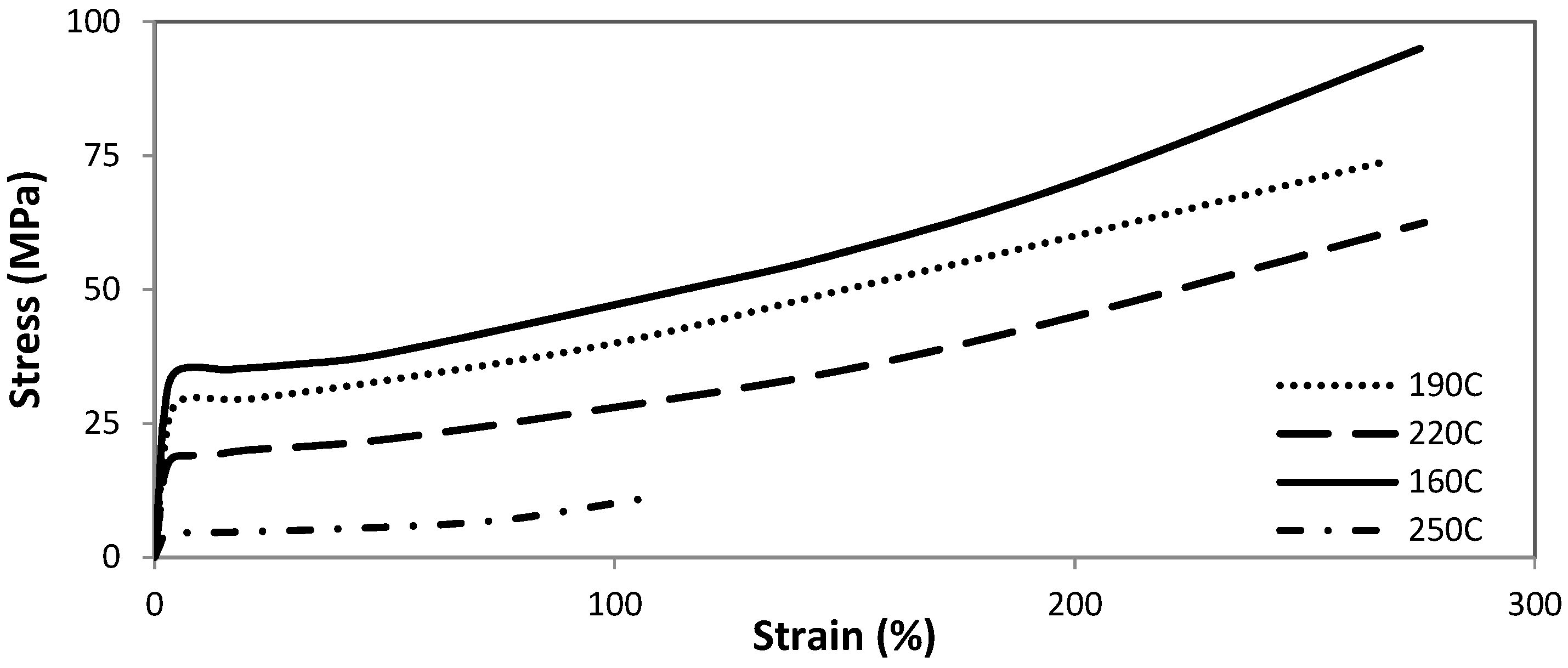

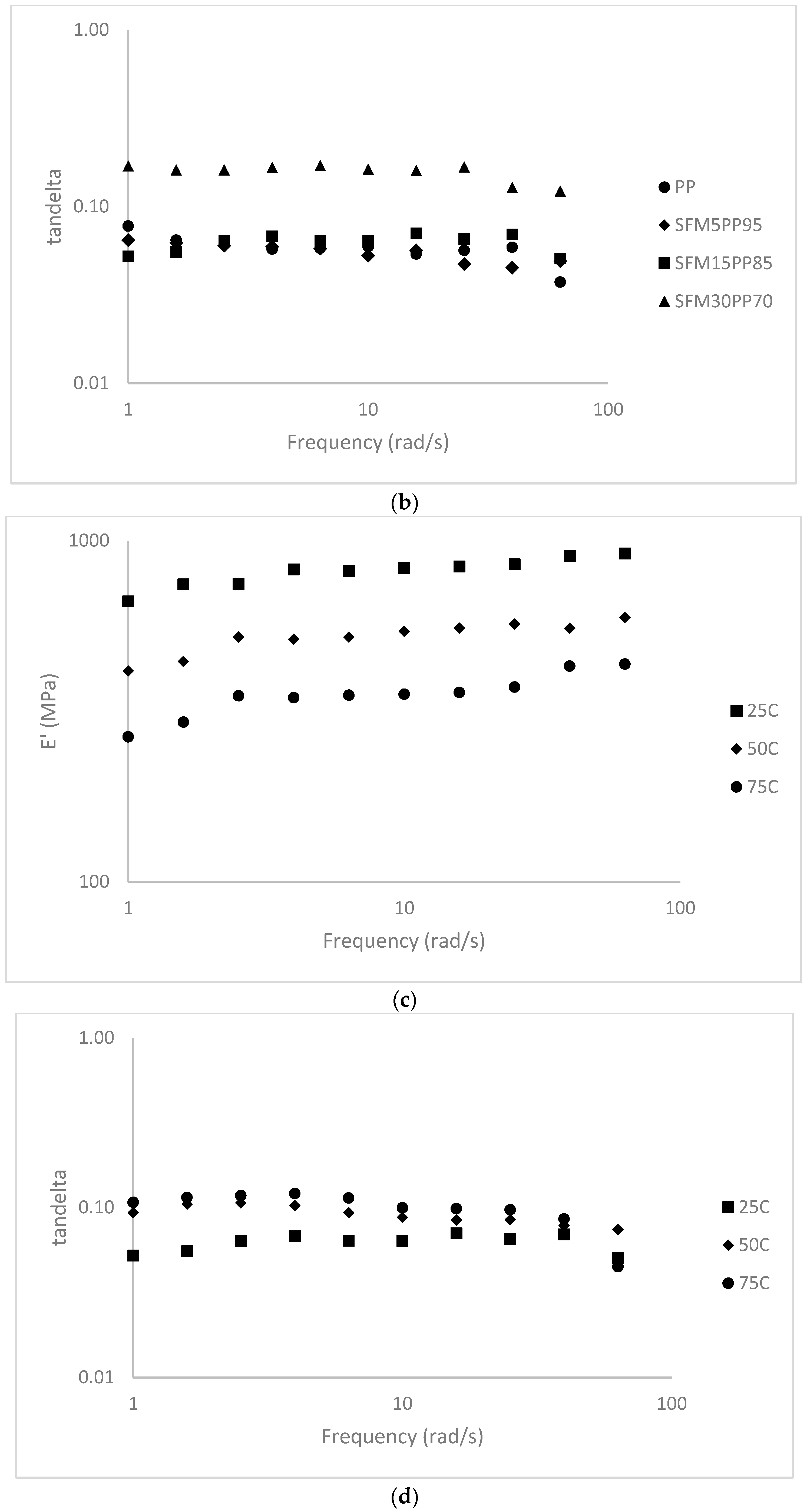

3.3. Effect of Temperature on Fiber Spinnability and Properties

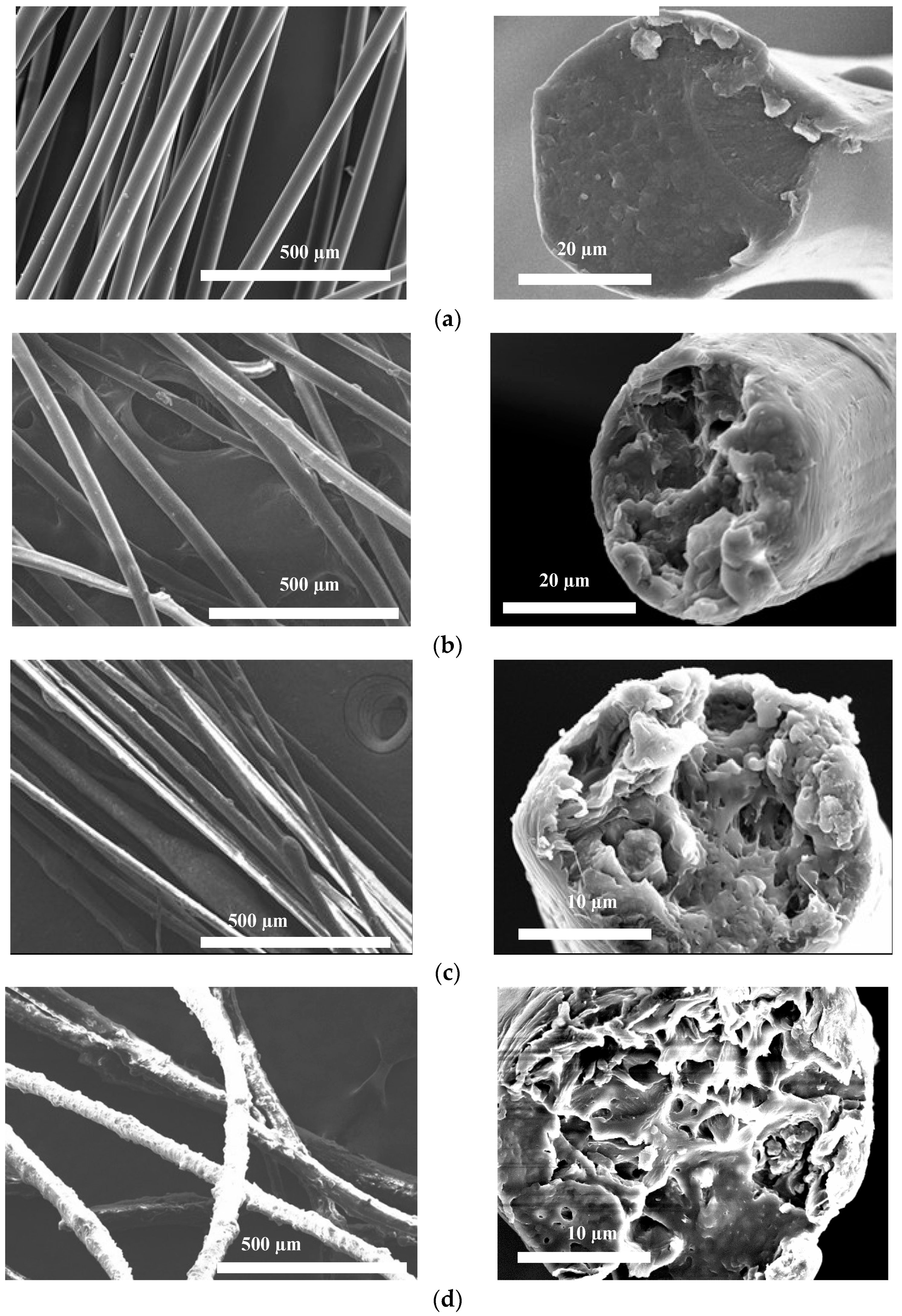

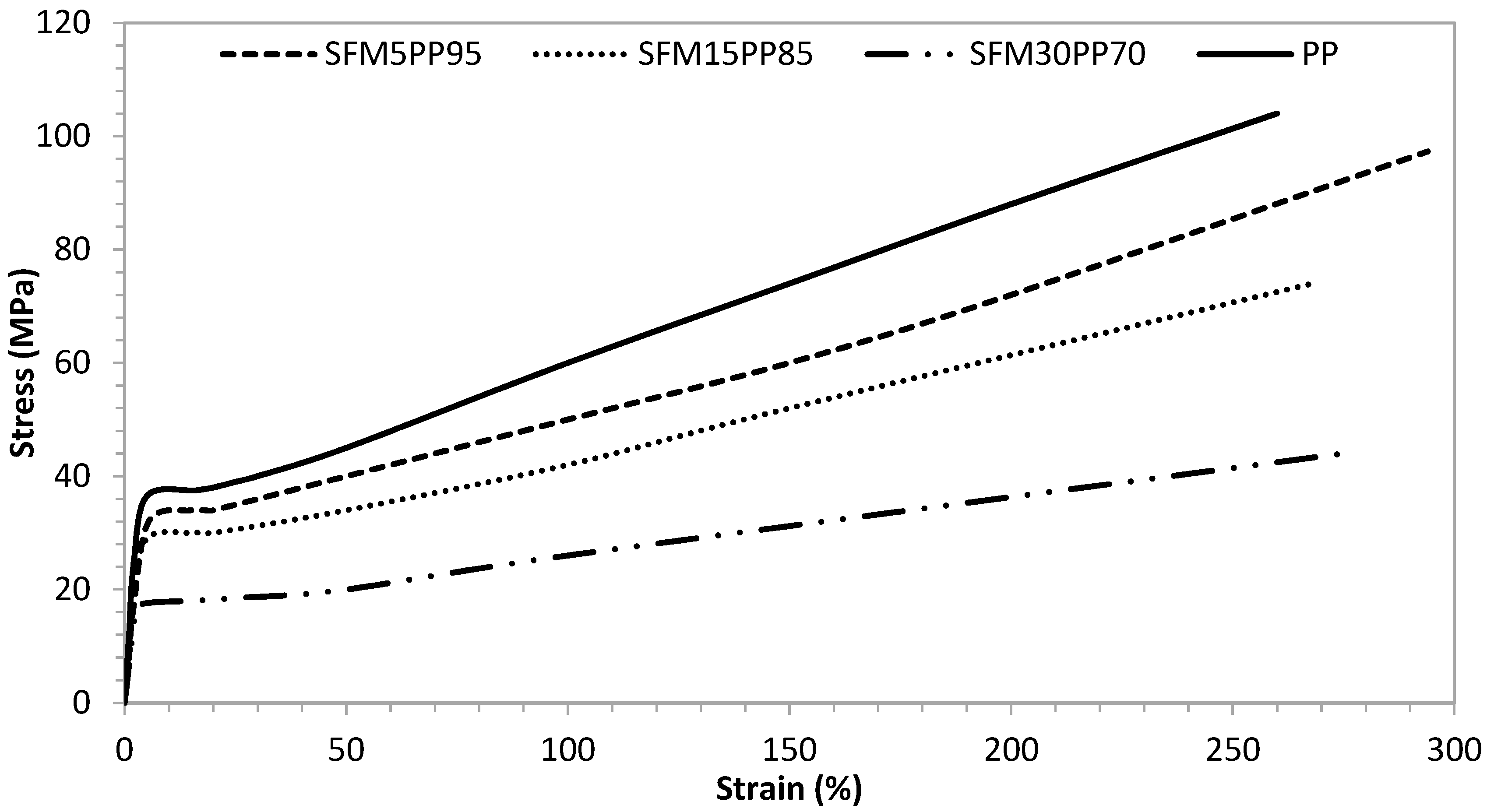

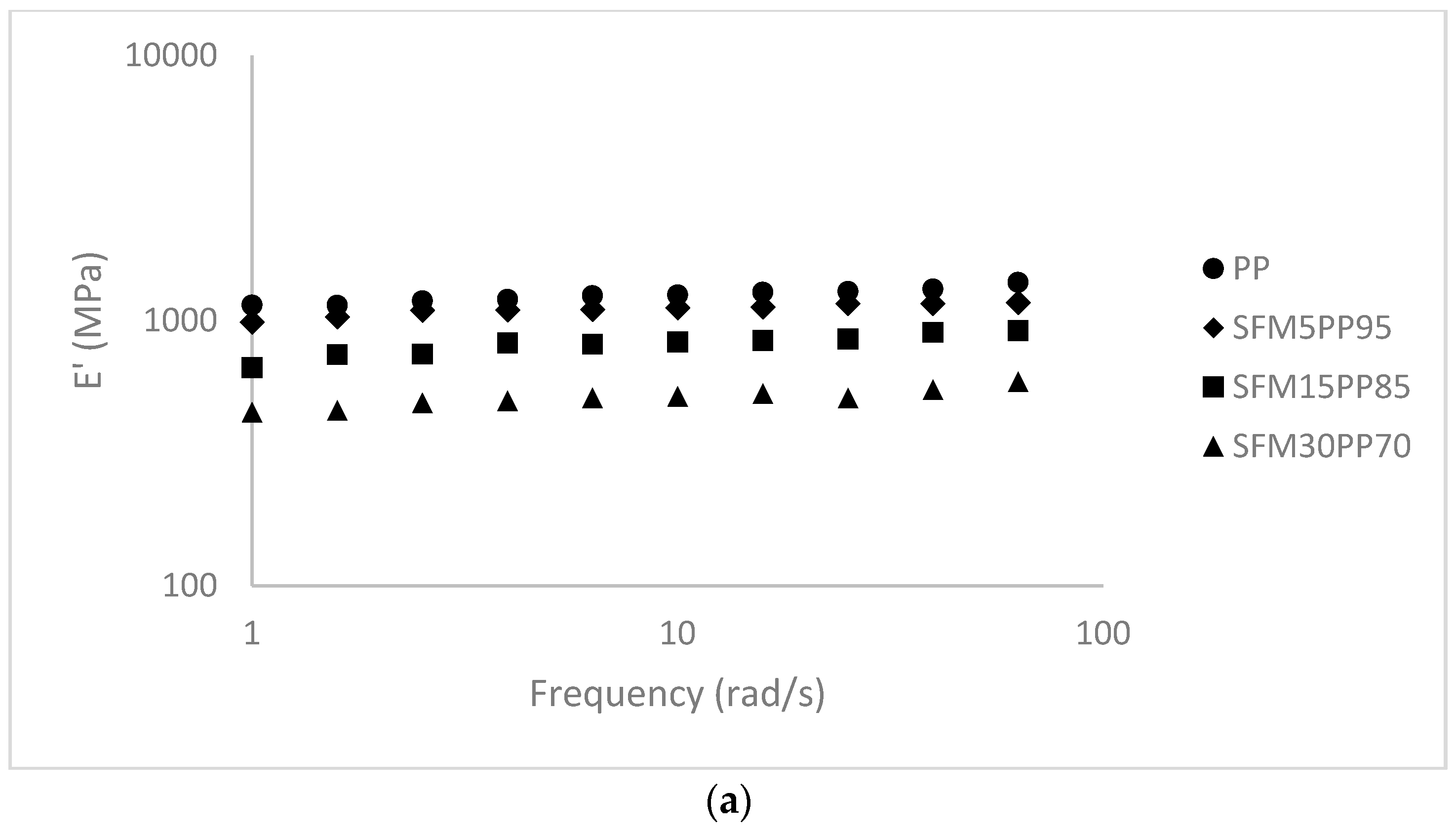

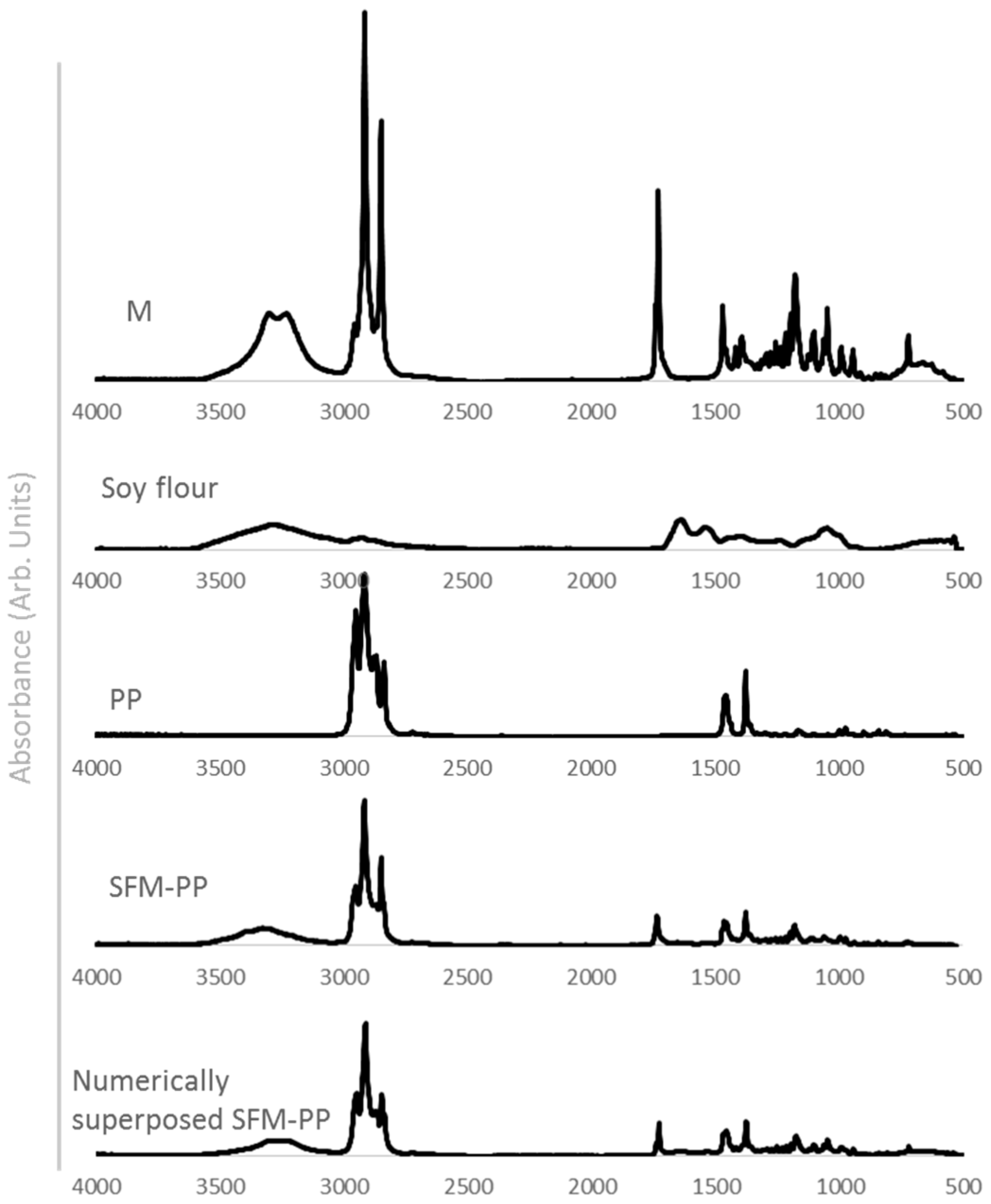

3.4. Effect of Filler Composition on Mechanical Properties

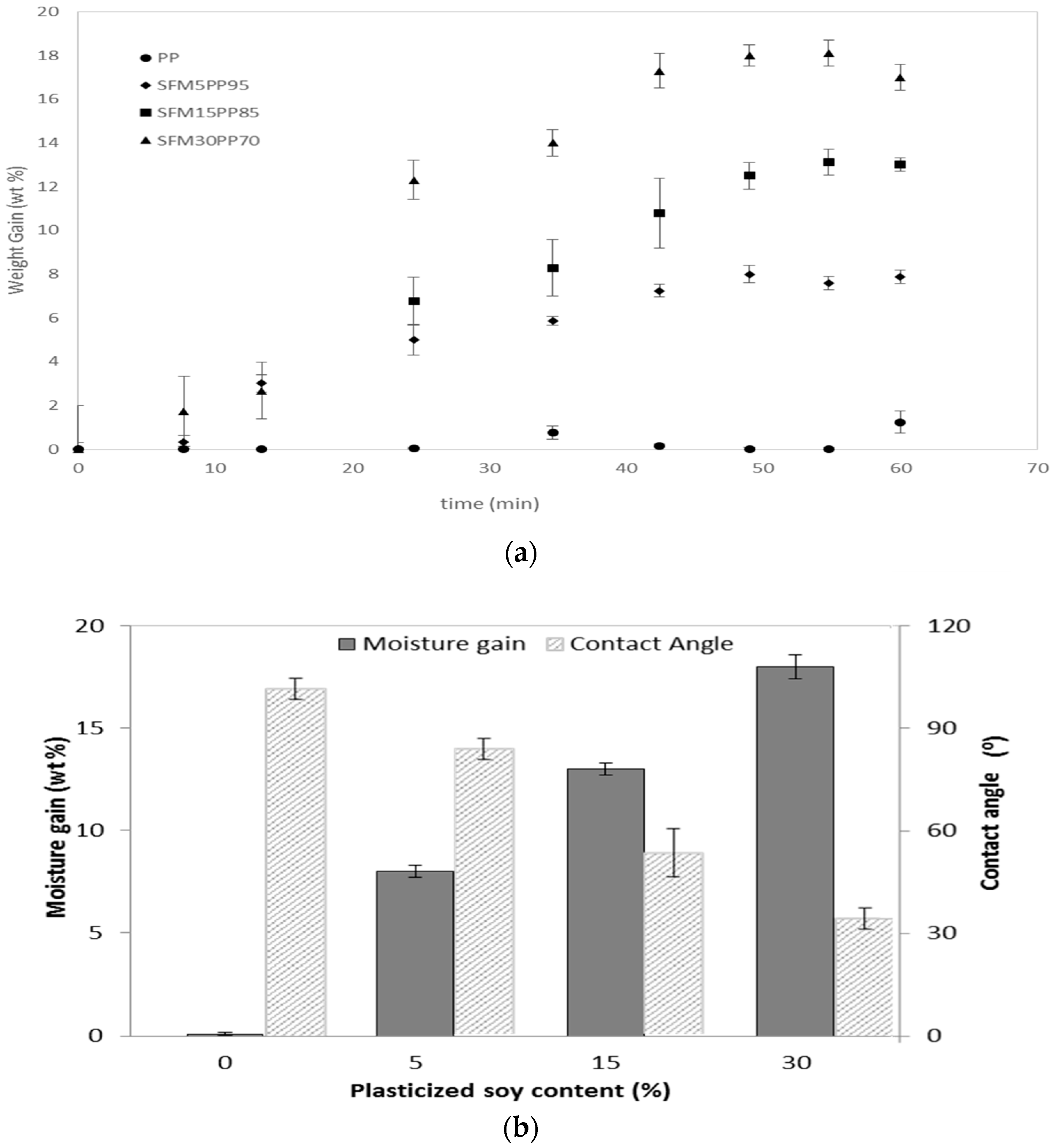

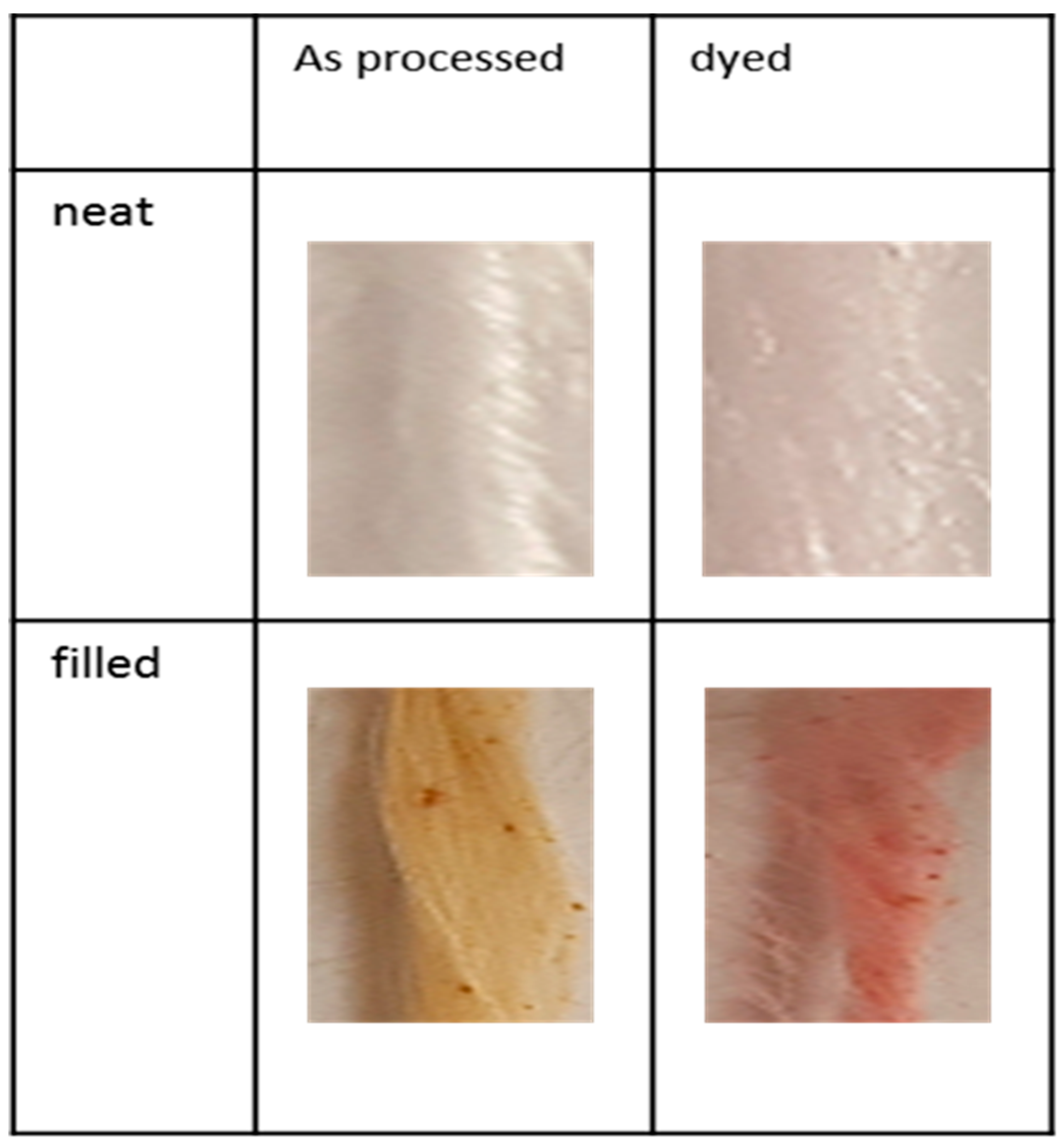

3.5. Hydrophilicity/Coloring

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Six Data Visualizations that Explain the Plastic Problem. Available online: https://www.dw.com/en/six-data-visualizations-that-explain-the-plastic-problem/a-36861883 (accessed on 3 July 2019).

- Total Resin Production in the United States from 2008 to 2017. Available online: https://www.statista.com/statistics/203398/total-us-resin-production-from-2008 (accessed on 3 July 2019).

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Chabba, S.; Matthews, G.F.; Netravali, A.N. ‘Green’composites using cross-linked soy flour and flax yarns. Green Chem. 2005, 7, 576–581. [Google Scholar] [CrossRef]

- Kumar, P.; Sandeep, K.P.; Alavi, S.; Truong, V.D.; Gorga, R.E. Preparation and characterization of bio-nanocomposite films based on soy protein isolate and montmorillonite using melt extrusion. J. Food Eng. 2010, 100, 480–489. [Google Scholar] [CrossRef]

- Guettler, B.E.; Moresoli, C.; Simon, L.C. Contact angle and surface energy analysis of soy materials subjected to potassium permanganate and autoclave treatment. Ind. Crops Prod. 2013, 50, 219–226. [Google Scholar] [CrossRef]

- Salas, C.; Genzer, J.; Lucia, L.A.; Hubbe, M.A.; Rojas, O.J. Water-wettable polypropylene fibers by facile surface treatment based on soy proteins. ACS Appl. Mater. Interfaces 2013, 5, 6541–6548. [Google Scholar] [CrossRef] [PubMed]

- Tummala, P.; Liu, W.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Influence of plasticizers on thermal and mechanical properties and morphology of soy-based bioplastics. Ind. Eng. Chem. Res. 2006, 45, 7491–7496. [Google Scholar] [CrossRef]

- Cunningham, P.; Ogale, A.A.; Dawson, P.L.; Acton, J.C. Tensile properties of soy protein isolate films produced by a thermal compaction technique. J. Food Sci. 2000, 65, 668–671. [Google Scholar] [CrossRef]

- Swain, S.N.; Biswal, S.M.; Nanda, P.K.; Nayak, P.L. Biodegradable soy-based plastics: Opportunities and challenges. J. Polym. Environ. 2004, 12, 35–42. [Google Scholar] [CrossRef]

- Thellen, C.; Hauver, C.; Ratto, J.A. Development of a melt-extrudable biobased soy flour/polyethylene blend for multilayer film applications. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Guettler, B.E.; Moresoli, C.; Simon, L.C. Mechanical properties and crack propagation of soy-polypropylene composites. J. Appl. Polym. Sci. 2013, 130, 175–185. [Google Scholar] [CrossRef]

- Sailaja, R.; Girija, B.G.; Madras, G.; Balasubramanian, N. Effect of compatibilization on mechanical and thermal properties of polypropylene–soy flour composites. J. Mater. Sci. 2008, 43, 64–74. [Google Scholar] [CrossRef]

- Iyer, K.A.; Torkelson, J.M. Dispersion and property enhancements in polyolefin/soy flour biocomposites prepared via melt extrusion followed by Solid-State shear pulverization. Macromol. Mater. Eng. 2015, 300, 772–784. [Google Scholar] [CrossRef]

- Sam, S.T.; Ismail, H.; Ahmad, Z. Linear low-density polyethylene/(soya powder) blends containing polyethylene-g-(maleic anhydride) as a compatibilizer. J. Vinyl Addit. Technol. 2009, 15, 252–259. [Google Scholar] [CrossRef]

- Mazzanti, V.; Mollica, F.; El Kissi, N. Rheological and mechanical characterization of polypropylene-based wood plastic composites. Polym. Compos. 2016, 37, 3460–3473. [Google Scholar] [CrossRef]

- Ting, S.S.; Ismail, H.; Ahmad, Z. Environmental weathering of (linear low-density polyethylene)/(soya powder) blends compatibilized with polyethylene-grafted maleic anhydride. J. Vinyl Addit. Technol. 2012, 18, 57–64. [Google Scholar] [CrossRef]

- Zhu, R.; Liu, H.; Zhang, J. Compatibilizing effects of maleated poly (lactic acid)(PLA) on properties of PLA/soy protein composites. Ind. Eng. Chem. Res. 2012, 51, 7786–7792. [Google Scholar] [CrossRef]

- Liu, B.; Jiang, L.; Liu, H.; Sun, L.; Zhang, J. Different effects of water and glycerol on morphology and properties of poly (lactic acid)/soy protein concentrate blends. Macromol. Mater. Eng. 2010, 295, 123–129. [Google Scholar] [CrossRef]

- Guzdemir, O.; Lukubira, S.; Ogale, A.A. Soy-filled polyethylene fibers for modified surface and hydrophilic characteristics. J. Appl. Polym. Sci. 2018, 135, 46609. [Google Scholar] [CrossRef]

- Mazzanti, V.; Mollica, F. In-line rheometry of polypropylene based wood polymer composites. Polym. Test. 2015, 47, 30–35. [Google Scholar] [CrossRef]

- Mukhopadhyay, S. Natural and synthetic fibres for composite nonwovens. In Composite Non-Woven Materials; Elsevier: Amsterdam, The Netherlands, 2014; pp. 20–29. [Google Scholar]

- Ogale, A.A.; Cunningham, P.; Dawson, P.L.; Acton, J.C. Viscoelastic, thermal, and microstructural characterization of soy protein isolate films. J. Food Sci. 2000, 65, 672–679. [Google Scholar] [CrossRef]

- Cao, K.; Li, Y.; Lu, Z.-Q.; Wu, S.-L.; Chen, Z.-H.; Yao, Z.; Huang, Z.M. Preparation and characterization of high melt strength polypropylene with long chain branched structure by the reactive extrusion process. J. Appl. Polym. Sci. 2011, 121, 3384–3392. [Google Scholar] [CrossRef]

- Lau, H.C.; Bhattacharya, S.N.; Field, G.J. Melt strength of polypropylene: Its relevance to thermoforming. Polym. Eng. Sci. 1998, 38, 1915–1923. [Google Scholar] [CrossRef]

- Bhat, G.S.; Malkan, S.R. Extruded continuous filament nonwovens: Advances in scientific aspects. J. Appl. Polym. Sci. 2002, 83, 572–585. [Google Scholar] [CrossRef]

- Nursten, H.E. Maillard browning reactions in dried foods. In Concentration and Drying of Foods; MacCarthy, D., Ed.; Elsevier Applied Science: London, UK, 1986; pp. 53–58. [Google Scholar]

- Rufián-Henares, J.A.; Delgado-Andrade, C.; Morales, F.J. Assessing the maillard reaction development during the toasting process of common flours employed by the cereal products industry. Food Chem. 2009, 114, 93–99. [Google Scholar] [CrossRef]

- Chen, N.; Zeng, Q.; Lin, Q.; Rao, J. Development of defatted soy flour based bio-adhesives using viscozyme L. Ind. Crops Prod. 2015, 76, 198–203. [Google Scholar] [CrossRef]

- Morales, F.J.; Van Boekel, M. A study on advanced maillard reaction in heated casein/sugar solutions: Colour formation. Int. Dairy J. 1998, 8, 907–915. [Google Scholar] [CrossRef]

- Bosak, D.R.; Ogale, A.A.; Van Dun, J. Bicomponent fibers derived from immiscible polymer blends. Text. Res. J. 2005, 75, 50–56. [Google Scholar] [CrossRef]

- Hasegawa, N.; Okamoto, H.; Kato, M.; Usuki, A. Preparation and mechanical properties of polypropylene–clay hybrids based on modified polypropylene and organophilic clay. J. Appl. Polym. Sci. 2000, 78, 1918–1922. [Google Scholar] [CrossRef]

- Zhao, C.; Qin, H.; Gong, F.; Feng, M.; Zhang, S.; Yang, M. Mechanical, thermal and flammability properties of polyethylene/clay nanocomposites. Polym. Degrad. Stab. 2005, 87, 183–189. [Google Scholar] [CrossRef]

- Villacorta, B.S.; Ogale, A.A.; Hubing, T.H. Effect of heat treatment of carbon nanofibers on the electromagnetic shielding effectiveness of linear low density polyethylene nanocomposites. Polym. Eng. Sci. 2013, 53, 417–423. [Google Scholar] [CrossRef]

- Huang, C.; Lou, C.; Liu, C.; Huang, C.; Song, X.; Lin, J. Polypropylene/graphene and polypropylene/carbon fiber conductive composites: Mechanical, crystallization and electromagnetic properties. Appl. Sci. 2015, 5, 1196–1210. [Google Scholar] [CrossRef]

- Lodha, P.; Netravali, A.N. Thermal and mechanical properties of environment-friendly ‘green’plastics from stearic acid modified-soy protein isolate. Ind. Crops Prod. 2005, 21, 49–64. [Google Scholar] [CrossRef]

- Erbas Kiziltas, E.; Kiziltas, A.; Lee, E.C. Structure and properties of compatibilized recycled polypropylene/recycled polyamide 12 blends with cellulose fibers addition. Polym. Compos. 2018, 39, 3556–3563. [Google Scholar] [CrossRef]

- Schmidt, V.; Giacomelli, C.; Soldi, V. Thermal stability of films formed by soy protein isolate–sodium dodecyl sulfate. Polym. Degrad. Stab. 2005, 87, 25–31. [Google Scholar] [CrossRef]

- Lukubira, S.; Ogale, A.A. Thermal processing and properties of bioplastic sheets derived from meat and bone meal. J. Appl. Polym. Sci. 2013, 130, 256–263. [Google Scholar] [CrossRef]

- Ujhelyiova, A.; Bolhova, E.; Oravkinova, J.; Tiňo, R.; Marcinčin, A. Kinetics of dyeing process of blend polypropylene/polyester fibres with disperse dye. Dyes Pigment. 2007, 72, 212–216. [Google Scholar] [CrossRef]

- Viková, M.; Periyasamy, A.P.; Vik, M.; Ujhelyiová, A. Effect of drawing ratio on difference in optical density and mechanical properties of mass colored photochromic polypropylene filaments. J. Text. Inst. 2017, 108, 1365–1370. [Google Scholar] [CrossRef]

| Fibers | SF+M (wt%) | SFM (wt%) | PP (wt%) | Spinning Temperature (°C) |

|---|---|---|---|---|

| SFM5P95-190 | 4 + 1 | 5 | 95 | 190 |

| SFM15P85-190 | 12 + 3 | 15 | 85 | 190 |

| SFM30P70-190 | 24 + 6 | 30 | 70 | 190 |

| SFM15P85-160 | 12 + 3 | 15 | 85 | 160 |

| SFM15P85-220 | 12 + 3 | 15 | 85 | 220 |

| SFM15P85-250 | 12 + 3 | 15 | 85 | 250 |

| Melting | |||

|---|---|---|---|

| Material | Melting Temperature T (°C) | Enthalpy of Melting ∆Hm (J/g mix) | Degree of Crystallization Xc (%) |

| PP | 150 | 53.3 | 34.0 |

| SFM5PP95 | 151 | 44.2 | 35.2 |

| SFM15PP85 | 147 | 33 | 35.5 |

| SFM30PP70 | 146 | 31 | 38.3 |

| Sample | N | K (Pa·sn) |

|---|---|---|

| SFM15-PP85-160 | 0.55 | 457 |

| SFM15-PP85-190 | 0.52 | 217 |

| SFM15-PP85-220 | 0.64 | 146 |

| SFM15-PP85-250 | 0.67 | 91 |

| Processing Temperature (°C) | Tensile Modulus (MPa) | Yield Stress (MPa) | Yield Strain (%) | Failure Strength (MPa) | Strain-To-Failure (%) | |

|---|---|---|---|---|---|---|

| 1 | 160 | 1313 ± 419 | 35 ± 6 | 4.8 ± 0.4 | 95 ± 30 | 275 ± 42 |

| 2 | 190 | 914 ± 164 | 29 ± 3 | 5.0 ± 1.0 | 74 ± 7 | 268 ± 57 |

| 3 | 220 | 743 ± 217 | 19 ± 4 | 3.8 ± 0.7 | 63 ± 9 | 276 ± 41 |

| 4 | 250 | 207 ± 108 | 4.5 ± 2 | 2.6 ± 0.9 | 11 ± 5 | 106 ± 48 |

| Fibers | Tensile Modulus (MPa) | Yield Strength (MPa) | Yield Strain (%) | Tensile Strength (MPa) | Strain to Failure (%) |

|---|---|---|---|---|---|

| Neat PP | 1224 ± 136 | 37 ± 3 | 5.0 ± 1.3 | 104 ± 10 | 260 ± 35 |

| SFM5PP95-190 | 843 ± 140 | 32 ± 4 | 5.5 ± 0.5 | 97 ± 16 | 294 ± 46 |

| SFM15PP85-190 | 914 ± 164 | 29 ± 3 | 5.0 ± 1.0 | 74 ± 7 | 268 ± 57 |

| SFM30PP70-190 | 674 ± 245 | 18 ± 4 | 6.1 ± 2.6 | 44 ± 11 | 275 ± 42 |

| Fibers | Tensile Modulus (MPa) | Yield Stress (MPa) | Yield Strain (%) | Failure Strength (MPa) | Strain to Failure (%) |

|---|---|---|---|---|---|

| PP | 1210 ± 122 | 36 ± 3 | 5.1 ± 1.1 | 100 ± 12 | 262 ± 31 |

| PP washed | 1214 ± 83 | 43 ± 6 | 7.4 ± 1.0 | 90 ± 25 | 215 ± 47 |

| SFM15PP85-190 | 914 ± 164 | 27 ± 3 | 5.0 ± 1.0 | 74 ± 7 | 268 ± 57 |

| SFM15PP85-190-washed | 780 ± 96 | 28 ± 5 | 5.4 ± 1.2 | 58 ± 9 | 247 ± 61 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guzdemir, O.; Ogale, A.A. Influence of Spinning Temperature and Filler Content on the Properties of Melt-Spun Soy Flour/Polypropylene Fibers. Fibers 2019, 7, 83. https://doi.org/10.3390/fib7100083

Guzdemir O, Ogale AA. Influence of Spinning Temperature and Filler Content on the Properties of Melt-Spun Soy Flour/Polypropylene Fibers. Fibers. 2019; 7(10):83. https://doi.org/10.3390/fib7100083

Chicago/Turabian StyleGuzdemir, Ozgun, and Amod A. Ogale. 2019. "Influence of Spinning Temperature and Filler Content on the Properties of Melt-Spun Soy Flour/Polypropylene Fibers" Fibers 7, no. 10: 83. https://doi.org/10.3390/fib7100083

APA StyleGuzdemir, O., & Ogale, A. A. (2019). Influence of Spinning Temperature and Filler Content on the Properties of Melt-Spun Soy Flour/Polypropylene Fibers. Fibers, 7(10), 83. https://doi.org/10.3390/fib7100083