Abstract

This paper is dedicated to the lifetime prediction of Type I Fiber Bragg gratings (FBG) and to problems that happen when stabilization (also called passivation) conditions or the industrial conditioning procedure depart from ageing ones (e.g., presence of hydrogen during the passivation process). For the first time, a reliable procedure to certify the predicted lifetime based on a “restricted” master curve built on real components (i.e., passivated FBG) is presented. It is worth noting that both procedures (master curve built on non-passivated or on passivated components) are based on the same model (demarcation energy approximation and the existence of a master curve) fed with ageing data (reflectivity decay vs. time and temperature). If the Master Curve (MC) build on passivated components can be derived from the original one, we can certify the lifetime prediction in a reliable manner.

1. Introduction

Over the last two decades, UV-induced Δn profiling in SiO2 glasses was widely used for thw production of in-fibre/waveguide Bragg grating-based (BG) optical devices for the photonics industry. Indeed, photosensitivity allows for the fabrication of an outstanding number of in-Fiber Bragg Grating-based (FBG) optical devices like gain flattening filters (GFF), chromatic dispersion compensator (CDC) and 980 nm pump stabilization. These devices have found numerous applications in optical fiber telecommunication and all fiber laser systems. Most of these applications require long device lifetime (especially submarine optical networks) and the possibility of forecasting possible spontaneous degradation of the photo-induced index change. However, ageing experiments are always performed on a scale too short (<one month) to be extrapolated without a rational methodology. In 1998, Poumellec [1] established a general procedure based on the existence of a demarcation energy and the notion of Master Curve (MC); what he called Variable Reaction Pathways framework or VAREPA framework. This general procedure allows to identify and to check the necessary conditions leading to a reliable prediction of various physical quantities (e.g., laser-induced refractive index changes, photodarkening, radiation induced losses in harsh environment...).

In most cases, the lifetime of a “freshly” written FBG is not large enough to satisfy the operating conditions of submarine optical networks (e.g., less than 1% decrease of the reflectivity during 25 years at 45 °C). However, the distributed nature of activation energies makes it possible to increase the grating stability by erasing thermally the less stable part of the UV-induced refractive index changes. This widespread method is called passivation process and consists in post-annealing the FBG for a time tanneal at a temperature Tanneal > Tuse. Now the question is how to perform a precise and reliable lifetime prediction of such passivated components? The usual procedure is to establish the master curve of simply outgassed components and perform the passivation FBG that have been previously out-gazed at low temperature to avoid any reactions with the remaining H2. The advantage is that this approach remains general since it can be applied to any passivation temperature provided that those are included in the master curve database and can lead to optimization of the passivation specification.

In addition, predictions must be validated. From an industrial point of view, the principle is to compare the prediction established using the MC with accelerated ageing data typically during a few 100 s of hours at a temperature higher than the working temperature, i.e., to build only one isotherm. Such an approach cannot validate the prediction in reliable manner but this is a first step and it allows the detection of potential failures in the lifetime prediction. The only right way is to build a “new” mastercurve with the real components (i.e., passivated gratings) and this is the main objective of this paper.

This approach can also be used to predict in the straight manner the lifetime of passivated components. The major advantage is to use real components (and this includes the “dispersion” of the whole manufacturing process!) resulting in a smaller lifetime prediction uncertainty. In addition, this avoids any potential failure in the predictions if the passivation conditions depart from ageing ones (e.g., presence of hydrogen during the passivation process or passivation temperature higher than the ones used during accelerated ageing).

The main objectives of this paper are thus as follows:

- To quickly recall the master curve approach and related physical hypotheses

- To report for the first time the passivation conditions uncertainty and their impact on the standard type I FBG lifetime prediction

- To report a reliable validation procedure of the lifetime prediction. This procedure is based on building of a “new” MC derivate from real passivated gratings.

- To highlight that building directly the MC on passivated FBG is less general but could be more reliable from an industrial point of view.

Below, we firstly describe FBG writing and the accelerated ageing experiments. Then we quickly recall the theory (i.e., the VAREPA framework) that rationalizes Fiber Bragg Gratings (FBG) lifetime prediction. The main tools in this framework are the concept of demarcation energy and the master curve. Assumptions leading to their pertinence are listed. It is then shown how to obtain the master curve and the associated uncertainty from the experiments and how to determine the passivation parameters according to the lifetime specifications given by the industry. In Section 4 we present the results for FBG dedicated to chromatic dispersion compensation, i.e., MC building, the determination of the passivation conditions and the industrial validation procedure. Finally, Section 5 is devoted to the uncertainty of the passivation process and we describe a reliable lifetime validation procedure.

2. FBG Writing and Accelerated Ageing Experiments

In order predict FBG lifetimes, one usually begins by measuring several quantities related to refractive index changes along the FBG during accelerated ageing experiments. They are usually reflectivity and sometimes Bragg wavelength and Bragg bandwidth. The relation between these quantities and the refractive index changes (noted RIC below) along the grating are explained in Reference [2,3]. Let us recall only the important features. The application of the UV light interference pattern onto the fiber material (I(z)) during a time tw at temperature Tw produces a modulation of the RIC in space Δn(z, tw, Tw) due to some physico-chemical reactions. The important features for the next discussion are 1) the mean index (Δnmean) which is the first component of the Fourier transform of Δn(z, tw, Tw), 2) the refractive index modulation (Δnmod) at the Bragg wavelength which is the second component of the Fourier transform. Due to the linearity of the Fourier transform, the thermal stability of Δnmean, Δnmod, i.e., (the functions Δnmean(t, T)/Δnmean(tw, Tw) and Δnmod(t, T)/Δnmod(tw, Tw)) are a weighted sum of the RIC stability at each point (i.e., of Δn(z, t, T)/Δn(z, tw, Tw). In the simple case (like in slightly Ge-doped H2-loaded fibers), the stability does not depend on the RIC amplitude at the end of the writing process (e.g., Erdogan model of electron trapping [5]). Δnmean and Δnmod will have thus the same stability at any point of the grating and the index contrast will remain the same during the Bragg erasing. Outside of this simple case, the stability of Δnmean and Δnmod will be different.

2.1. Fiber Bragg Gratings (FBG) Writing Method and Pre-Treatments

Two series of 1 mm long uniform Bragg gratings were written in H2-loaded standard telecommunication optical fibers (H2 loading conditions: 140 atm at room temperature for 15 days). To this purpose, the fibers were exposed through a phase mask (Lasiris; pitch = 1057 nm; diffraction power efficiency in the −1, +1 and 0 orders = 34%, 34% and 1% respectively) to a cw laser emitting at 244 nm. All the exposures were carried out at a mean power density ≈35 W/cm2. In this paper we will investigate two series of FBG. The first series was outgassed during 2 days at 50 °C and 2 days at 110 °C to ensure complete out-diffusion of the remaining hydrogen. The second series was first passivated during 10 min at 233 °C and then outgassed during 2 days at 50 °C and then 2 days at 110 °C to ensure complete out-diffusion of the hydrogen.

From a practical point of view, let us remind ourselves that the accelerated ageing process is applied on FBG that have been previously outgassed (i.e., we remove the H2 not consumed during FBG writing) either at room temperature (typically 1 month) or at a temperature low enough to avoid any interaction of the remaining H2 with the glass matrix (typically a 2 days below 110 °C). If the passivation process (FBG stabilization) is achieved under the same conditions than the accelerated ageing process (MC determination), it is possible then to determine its duration for a given temperature to reach a specified lifetime. Thus, to remain general (i.e., any optical fiber chemical composition and any FBG writing conditions) this approach implies to outgass the FBG before to perform the passivation. This is the usual process described in the literature. However, in many cases, industrial manufacturers will passivate FBG before H2 outgazing because it is simpler from the production point of view. In such a case, if there is a significant interaction of H2 with the glass matrix (i.e., formation an H-bearing species or transformation of existing defects that significantly impact the refractive index changes) at the passivation temperature (typically above 220 °C), the lifetime of the passivated grating cannot be deduced from the MC. In such a case it is thus necessary to build a MC direcly with the real (i.e., passivated and outgassed) components.

2.2. Accelerated Ageing Experiments

Three methods exist for carrying out an accelerated test. The true isochronal annealing experiment consists in heating identical gratings at increasing temperatures for a fixed time (a new grating is used for each annealing temperature). The step isochronal annealing is similar to the true isochronal annealing except that the same grating is used for each annealing step. Assuming that each step is independent of the previous ones [4], the step isochronal annealing provides a good approximation of the true isochronal annealing method [4]. It is less time-consuming and thus it is often used. However, the preferred method usually remains to be the isothermal annealing. It consists of holding the temperatures of identical gratings at fixed values above room temperature and periodically recording the grating transmission spectrum [5]. This is the method that we have chosen in this study.

2.3. How to Determine the Refractive Index Decay during the Accelerated Ageing Experiments

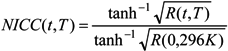

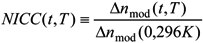

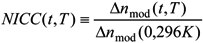

The method consists of measuring the spectral characteristics of a uniform BG during (or after) its annealing in the single mode fiber under study. In this view, the FBG’s first-order spectra were monitored in the course of the writing and annealing experiments by means of a single-frequency tunable laser and an optical power-meter. The accuracy of the reflectivity and λB measurements was estimated to be about 0.2% and 10 pm respectively. Then, to deduce the changes in refractive index from these data, one usually starts by assuming a step-index fiber; a periodicity of the exposure-induced change in refractive index along the fiber axis (  ) and uniformity of this change across the core. The following formulae can then be used to calculate either Δnmod and Δnmean or the Normalized Integrated Coupling Constant (NICC) from the grating reflectivity R at λ = λB [6]. Notice that those formulae are given for a simple grating [6].

) and uniformity of this change across the core. The following formulae can then be used to calculate either Δnmod and Δnmean or the Normalized Integrated Coupling Constant (NICC) from the grating reflectivity R at λ = λB [6]. Notice that those formulae are given for a simple grating [6].

) and uniformity of this change across the core. The following formulae can then be used to calculate either Δnmod and Δnmean or the Normalized Integrated Coupling Constant (NICC) from the grating reflectivity R at λ = λB [6]. Notice that those formulae are given for a simple grating [6].

) and uniformity of this change across the core. The following formulae can then be used to calculate either Δnmod and Δnmean or the Normalized Integrated Coupling Constant (NICC) from the grating reflectivity R at λ = λB [6]. Notice that those formulae are given for a simple grating [6].

In Equation (1), R is the grating reflectivity Rmax at λ = λB, T is the fixed temperature at which the BG has been held for an annealing time t. Notice that provided the FBG is uniform and the integral overlap η (the fraction of the total optical power propagating along the core) does not depend on T and does not change too much during annealing, NICC is the same quantity as the normalized modulation index:  [2], where Δnmod (0,296K) and Δnmod (t, T) are the modulation at the beginning of the annealing and after annealing at T for t respectively. In most experiments, both R and λB are measured at the temperature T of the isothermal ageing. However, this practice can sometimes be an error source if temperature-induced reversible changes in reflectivity are not taken into account. The extent of these changes is known to be significant in some kind of FBG like non-H2-loaded Ge-doped fibers [7]. As these reversible changes can spoil the analysis of the isothermal annealing experiments, it proves necessary to correct the raw data to account for these changes by means of relations similar to those established in [7]. This correction procedure will be applied in the following.

[2], where Δnmod (0,296K) and Δnmod (t, T) are the modulation at the beginning of the annealing and after annealing at T for t respectively. In most experiments, both R and λB are measured at the temperature T of the isothermal ageing. However, this practice can sometimes be an error source if temperature-induced reversible changes in reflectivity are not taken into account. The extent of these changes is known to be significant in some kind of FBG like non-H2-loaded Ge-doped fibers [7]. As these reversible changes can spoil the analysis of the isothermal annealing experiments, it proves necessary to correct the raw data to account for these changes by means of relations similar to those established in [7]. This correction procedure will be applied in the following.

[2], where Δnmod (0,296K) and Δnmod (t, T) are the modulation at the beginning of the annealing and after annealing at T for t respectively. In most experiments, both R and λB are measured at the temperature T of the isothermal ageing. However, this practice can sometimes be an error source if temperature-induced reversible changes in reflectivity are not taken into account. The extent of these changes is known to be significant in some kind of FBG like non-H2-loaded Ge-doped fibers [7]. As these reversible changes can spoil the analysis of the isothermal annealing experiments, it proves necessary to correct the raw data to account for these changes by means of relations similar to those established in [7]. This correction procedure will be applied in the following.

[2], where Δnmod (0,296K) and Δnmod (t, T) are the modulation at the beginning of the annealing and after annealing at T for t respectively. In most experiments, both R and λB are measured at the temperature T of the isothermal ageing. However, this practice can sometimes be an error source if temperature-induced reversible changes in reflectivity are not taken into account. The extent of these changes is known to be significant in some kind of FBG like non-H2-loaded Ge-doped fibers [7]. As these reversible changes can spoil the analysis of the isothermal annealing experiments, it proves necessary to correct the raw data to account for these changes by means of relations similar to those established in [7]. This correction procedure will be applied in the following.3. The Lifetime Prediction Theory: The Master Curve Formalism and the VAREPA Framework

Prediction of grating lifetime from the raw data of the isothermal annealing experiment requires an adequate kinetic model. The model is supposed to be valid beyond the time during which the ageing data have been collected (forecasting). Let us assume that this model exists. It is probably quite complex involving several physical processes [8] and is quite uncomfortable to use. Fortunately, very often the stability can be defined by only one limiting reaction, i.e., the one leading to the formation of the less stable chemical species (the stability of those being largely different from the other species that could contribute to the RIC). In that case, a general approach can be practiced to rationalize the FBG stability; this is the VAREPA framework including the demarcation energy and the master curve formalism. In the following paragraphs, we first describe the assumptions and how they can be validated, a necessary step in order to get confidence in the model. If the main assumptions cannot be validated, corrections can be applied at the expense of a loss of simplicity (demarcation energy approximation is conserved but MC has to be abandoned). Lastly, if no simplifying assumptions can be used, a complete kinetic model should be used.

We have also to remark that beyond the assumption of a limiting reaction, Δn(z, tw, Tw) arises from several physical phenomena directly proportional to each other’s [2,3]: creation of species with a polarizability different from the non-irradiated matter polarizability, some re-organization of the matter (e.g., glass density changes) and stress redistribution. All these phenomena can thus be reduced to only one species that we will call B in such a way that the question of stability of the RIC restricts only to the stability of B.

(A) First group of assumptions (the application field)

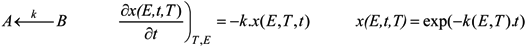

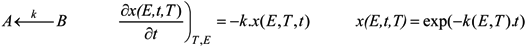

(1) The first assumption we make here is that only one elementary reaction is involved: the limiting reaction of the process that makes B to disappear e.g., A←B. Note that A is not involved in the analysis.

(2) The second assumption is that it is thermally activated (with an activation energy E). The Arrhenius law can be used, the d[B]/dt rate is proportional to a reaction constant k0 like k(E, T) = k0exp(−E/kBT) where kB is the Boltzman constant and [B] is the concentration of the B species.

(3) The third assumption is that activation energy is distributed. As a matter of fact, in glasses, E is not unique. The creation energy of B can vary with its atomic environment. The transition state energy (the bottleneck on the reaction pathway) is also sensitive to the disordered environment in such a way that the activation energy, which is the energy difference between B and the transition state, is distributed. The reaction pathway for erasing B is thus variable (from where the framework has been baptized VAREPA) [1]. Its distribution can be written g(E) and is normalized on the activation energy range, i.e.,

(B) The second group of assumptions (on the reaction towards the computation of time dependence)

For computing the time and temperature dependences of the B content ([B](t, T), we have to make the following assumptions.

(1) Most of the elementary reactions in solids are first order; some are second order when two species associate but these are much less likely. So, this is not so severe and we can write:

x(E, t, T) is the advancement degree of the reaction.

x(E, t, T) is the advancement degree of the reaction.

(2) Concept of demarcation energy, Ed

is a function that varies very fast with E. B0(E) is the initial population produced by the FBG writing.

is a function that varies very fast with E. B0(E) is the initial population produced by the FBG writing.

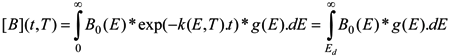

≥ when x(E, t, T) varies faster than g(E), it can be approximated to an Heaviside function at energy Ed and thus we can read:

Ed is properly defined by

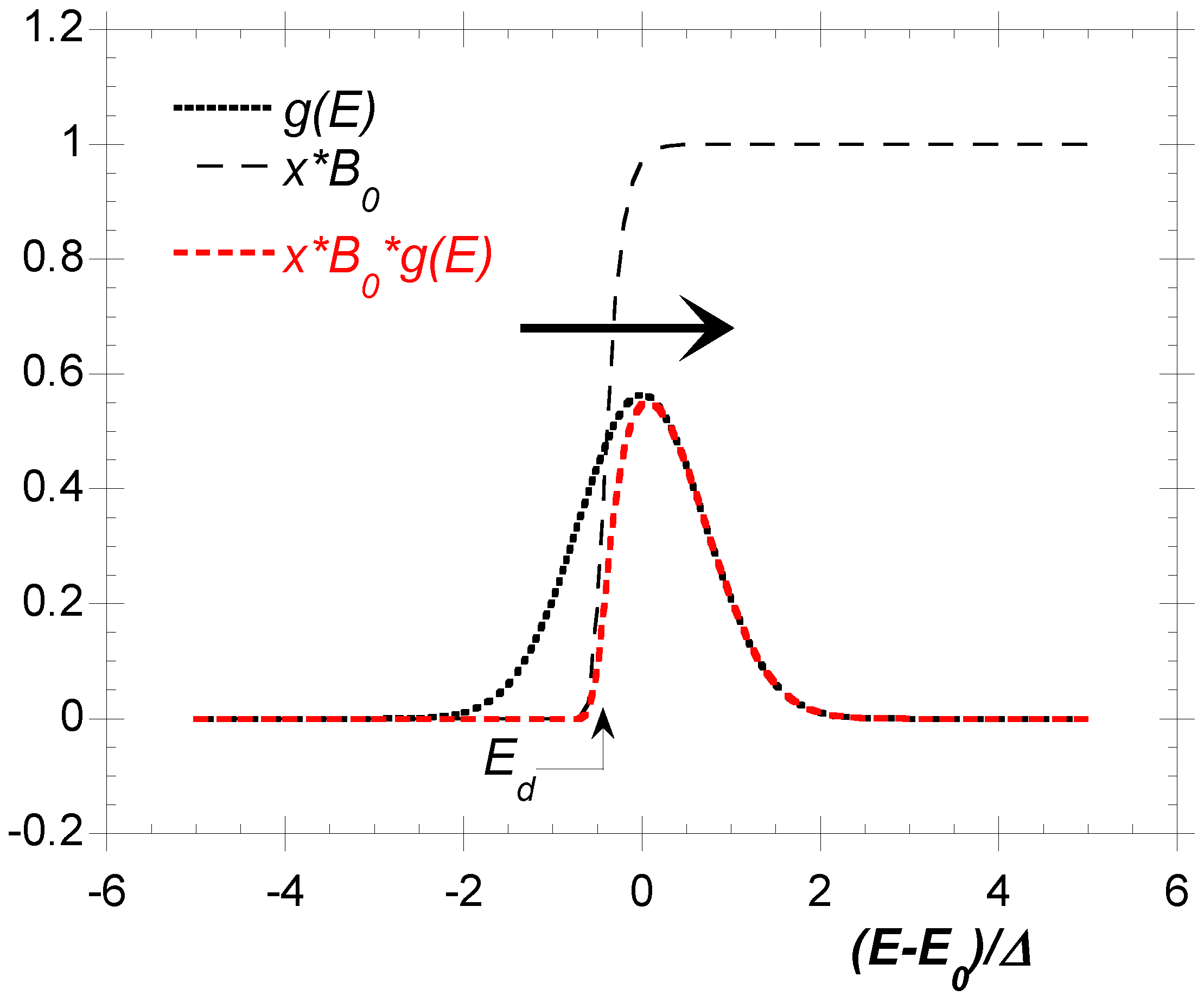

Ed is properly defined by  . For a first order reaction Ed = kB.T.ln(k0t). The reaction properties (i.e., k0) are appearing in Ed only, the disorder (relevant of the glass) appears in g(E). Finally, [B](t, T) is the area under the red dotted curve in Figure 1. The advancement degree x(E, t, T) in progressing erases the B distribution.

. For a first order reaction Ed = kB.T.ln(k0t). The reaction properties (i.e., k0) are appearing in Ed only, the disorder (relevant of the glass) appears in g(E). Finally, [B](t, T) is the area under the red dotted curve in Figure 1. The advancement degree x(E, t, T) in progressing erases the B distribution.

. For a first order reaction Ed = kB.T.ln(k0t). The reaction properties (i.e., k0) are appearing in Ed only, the disorder (relevant of the glass) appears in g(E). Finally, [B](t, T) is the area under the red dotted curve in Figure 1. The advancement degree x(E, t, T) in progressing erases the B distribution.

. For a first order reaction Ed = kB.T.ln(k0t). The reaction properties (i.e., k0) are appearing in Ed only, the disorder (relevant of the glass) appears in g(E). Finally, [B](t, T) is the area under the red dotted curve in Figure 1. The advancement degree x(E, t, T) in progressing erases the B distribution.

Figure 1.

Reaction progresses by erasing B sites, from less stable to the most stable sites.

Figure 1.

Reaction progresses by erasing B sites, from less stable to the most stable sites.

(C) Some consequences:

(1) [B](t, T) can be expressed as a function of the unique variable called demarcation energy (Ed). The curve [B](Ed) is called master curve as it is unique whatever the (t, T) couple may be. We can note that T is equivalent to ln(t) in Ed and thus isochronal ageing data are equivalent to isothermal ageing data for establishing MC. Notice that from practical point of view most people consider that NICC(Ed) is the master curve. This is discussed in Section 4. Now the MC plot allows the user to predict the grating lifetime, providing that the anticipated conditions of BG use Ed = f(tuse, Tuse) correspond to a point on the MC that has been actually sampled during the annealing experiment.

(2) Notice also that the distribution function is included in the MC differentiation as:

4. Results

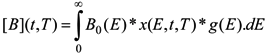

4.1. Step 1: Build the MC with Data Obtained after Accelerated Ageing of Non-Passivated Gratings and Determine the Lifetime in the Conditions of Use

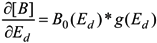

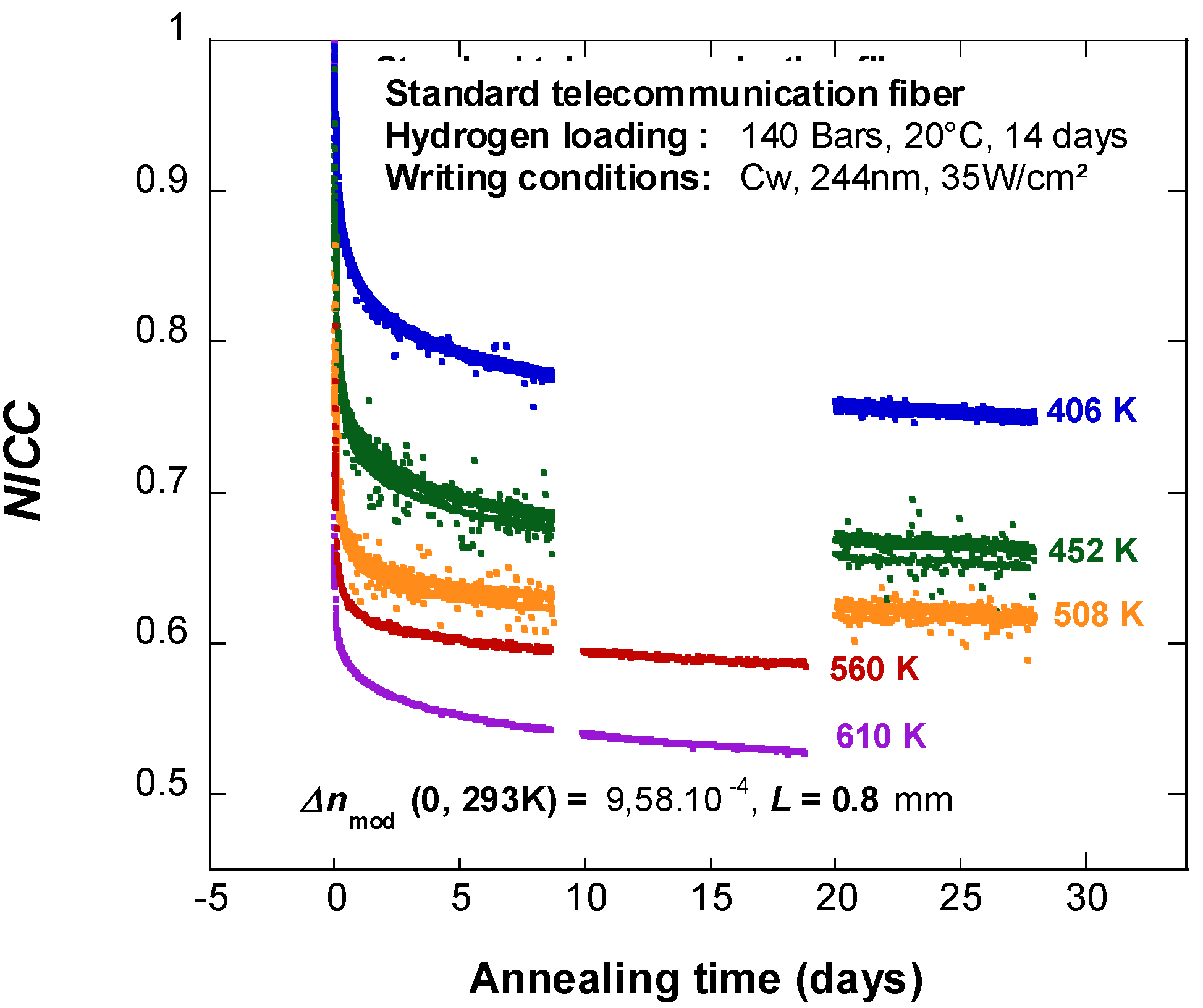

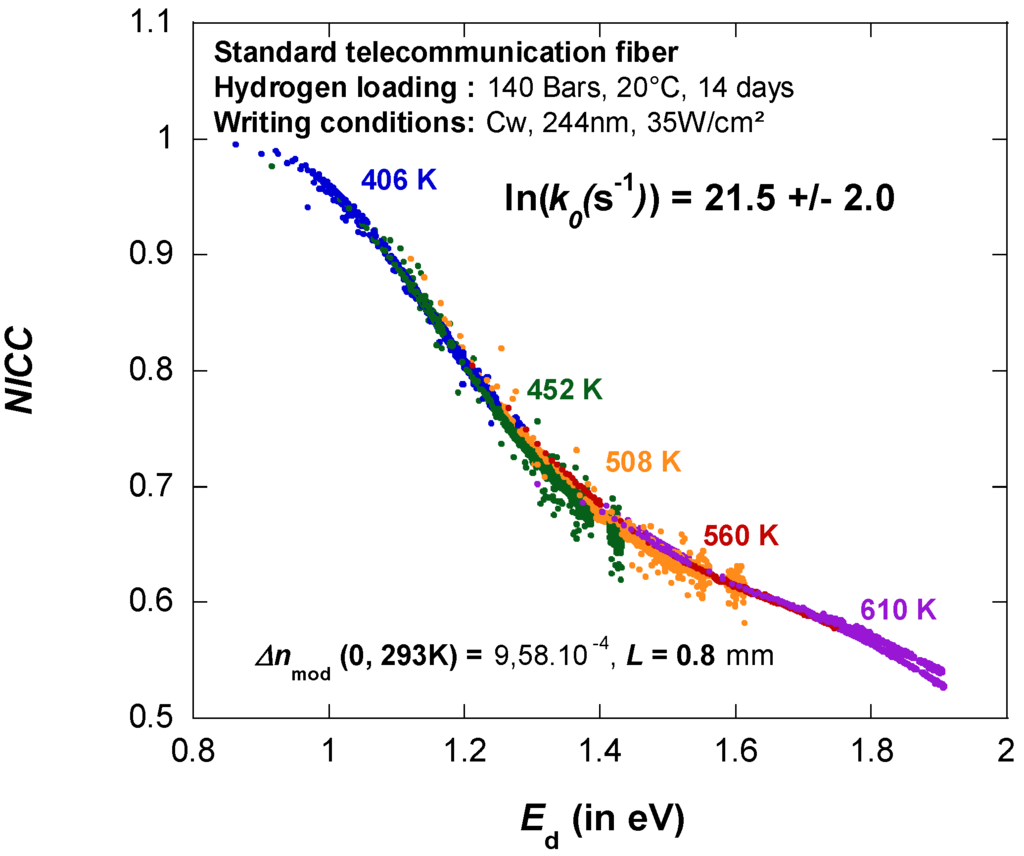

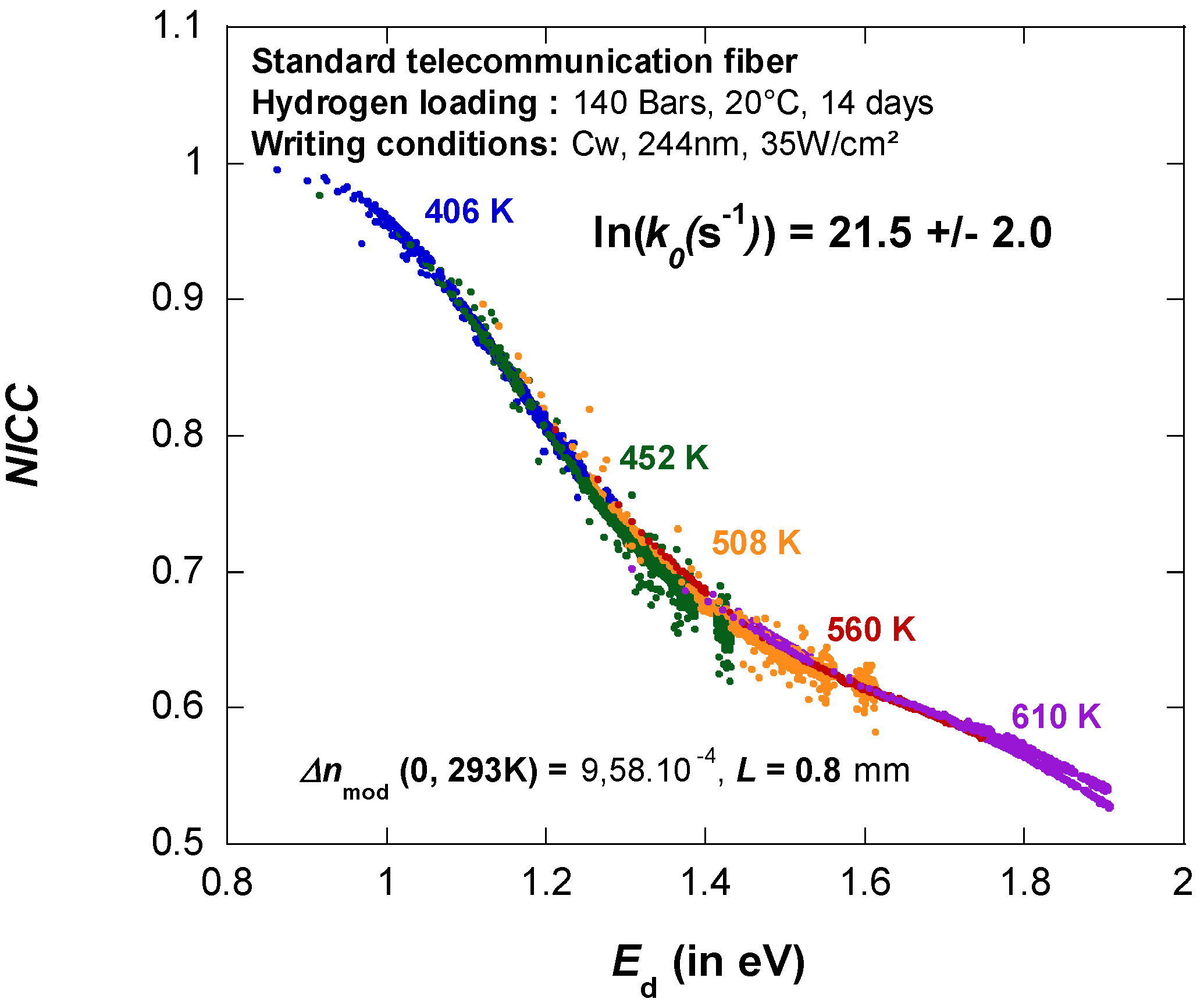

In the following, we have chosen the case of Bragg grating written in standard H2-loaded Ge-doped optical fiber core using a cw244 nm laser. Figure 2 displays the isothermal decays of the Normalized Integrated Coupling Constant NICC(t, T) corresponding to the decays of two or three gratings for each of the five chosen temperatures (406 K, 452 K, 508 K, 560 K and 610 K). The choice of using up to five different temperatures and more than one grating per temperature has been dictated by the necessity to determine and to minimize the error on k0. Figure 3 shows those data series plotted against kB.T.ln(t). Then, as shown in Figure 4, collapsing the data series into a single curve is achieved by adjusting k0 (and its uncertainty) in the demarcation energy expression and gives rise to the master curve (MC) [1,5,9].

Figure 2.

Isothermal decays of identical uniforms Fiber Bragg gratings (FBG) written in an H2-loaded standard telecommunication fiber.

Figure 2.

Isothermal decays of identical uniforms Fiber Bragg gratings (FBG) written in an H2-loaded standard telecommunication fiber.

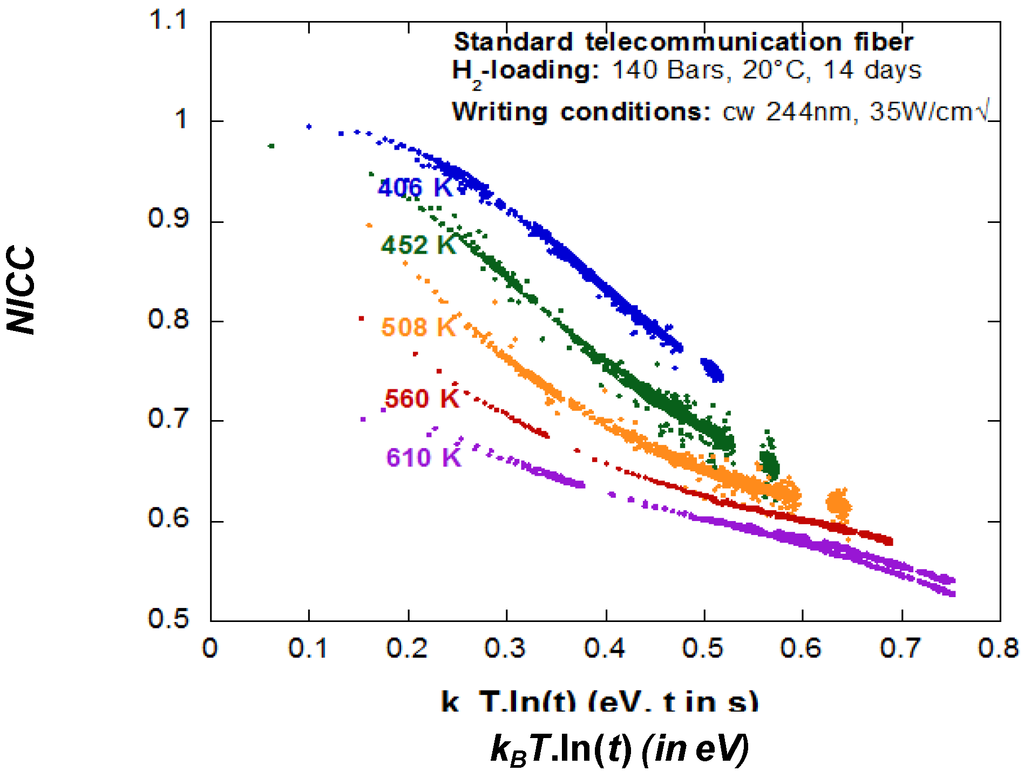

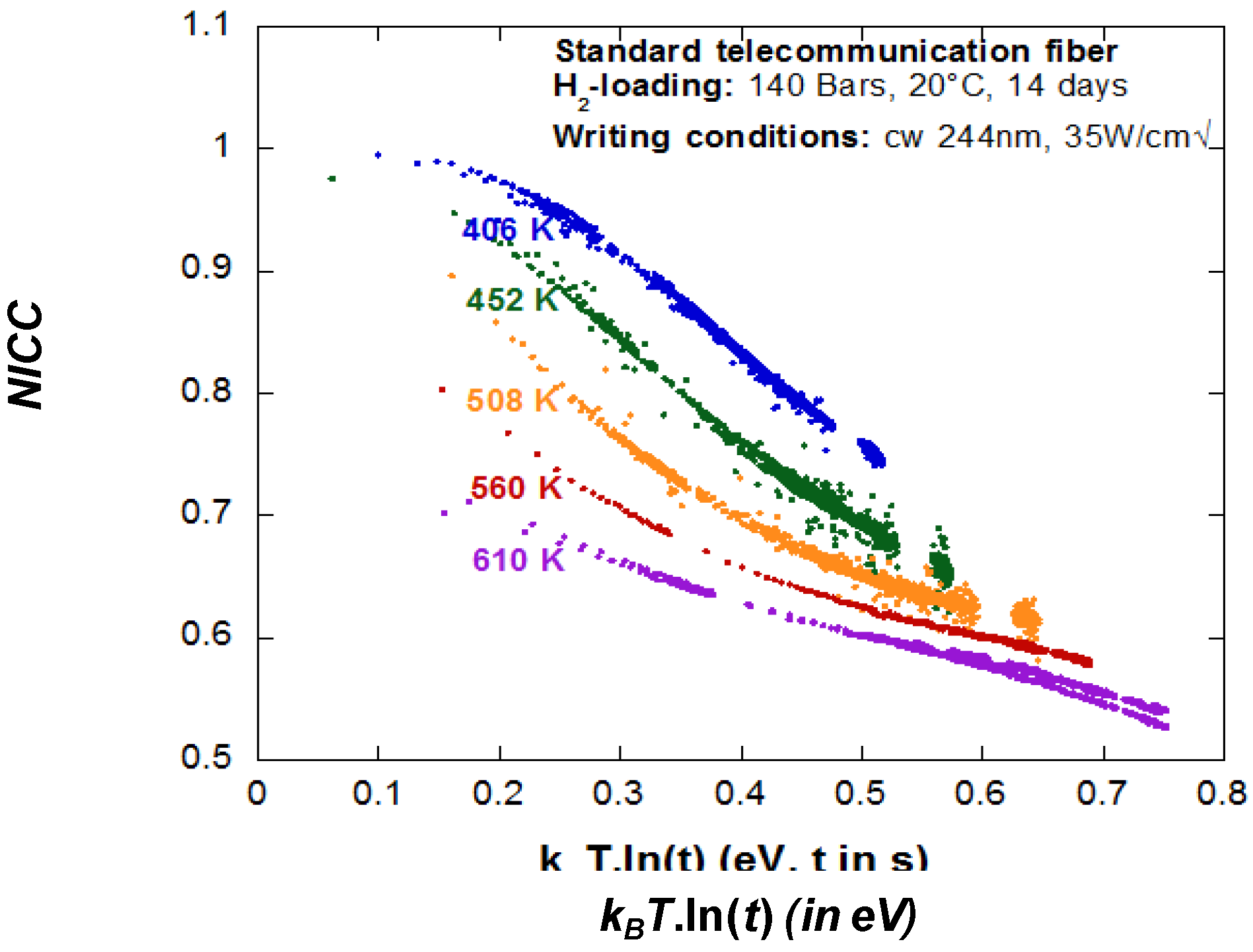

Figure 3.

Normalized Integrated Coupling Constant (NICC) as a function of the intermediate variable kB.T.ln(t).

Figure 3.

Normalized Integrated Coupling Constant (NICC) as a function of the intermediate variable kB.T.ln(t).

Figure 4.

Normalized Integrated Coupling Constant (NICC) as a function of the demarcation energy Ed = kB.T.ln(k0t) (in eV), i.e., the master curve. k0 in s−1.

Figure 4.

Normalized Integrated Coupling Constant (NICC) as a function of the demarcation energy Ed = kB.T.ln(k0t) (in eV), i.e., the master curve. k0 in s−1.

The prediction of FBG passivation conditions is very sensitive to small variations of the master curve fitting parameters [10]. Therefore, it is necessary to estimate the experimental uncertainties to derive confidence intervals for the estimates of the parameters, then as a precaution, we have to choose the worst case. Least square optimization can be used to find the optimum value for k0 and its confidence interval. This has been made in Figure 4 yielding ln(k0 in s−1) = 21.5 ± 2.0. We can here check that it was possible to find a frequency factor (k0) so that the earlier assumptions are reasonable. Indeed it can be shown that if one assumption is not verified in the investigated range of (t, T) and for the expression of Ed that has been previously defined, no collapse is possible. In addition, a key assumption in using these MCs is that the decay in the change of refractive index is just defined by Ed [11]. To check quickly this hypothesis at high temperature, one has to carry out isochronal and isothermal measurements for one quantity (here NICC) and secondly to plot data versus kB.T.ln(Δtisoc) for the first set and kB.Tisot.ln(t) for the second set. If curves are parallel and if they collapse into a MC by k0 optimization, the hypotheses are then fulfilled [4]. In the opposite situation, there may be several parallel or serial limiting reactions with different k0 and different distributions. The analysis is thus more complex for achieving lifetime prediction but it is still possible to perform a VAREPA approach [1,11]. However, no MC exists anymore.

The MC plot allows the FBG manufacturer or the FBG user to predict the grating lifetime, providing that the anticipated conditions of BG use Ed = f(tuse, Tuse) correspond to a point on the MC that has been actually sampled during the annealing experiment. Furthermore, the shape of the distribution of activation energies can be extracted from the slope of the MC by simple differentiation as we mentioned in Section 3C. Since the life function is now available, it is possible to calculate the lifetime for a maximum working temperature. For example for gratings measured in Figure 4, NICC will decrease to 0.82 at 45 °C and 25 years (18% erasure) or 10% erasure over 4.2 years at 45 °C. This lifetime may be not suitable for the most applications and especially for sub-marine networks. However due to the distribution of the activation energies, it is possible to increase the lifetime of our grating by performing a passivation process that suppresses the less stable sites. This is called “the passivation process” and this is the main topic of the following sections.

4.2. The Passivation Process: A Method Used to Enhance the Thermal Stability of BG Written in A Standard Telecommunication Fiber

This widespread method used for increasing the stability of a FBG after its inscription consists in post-annealing the FBG for a time tanneal at a temperature Tanneal > Tuse. A coherent rationale of this method is formulated from the above-mentioned approach [5]: the treatment wipes out the portion of the index change that would normally decay over the lifetime of the device and keeps only the stable portion of the index change [5]. Notice that this method proves to be effective for enhancing the stability of index changes in either non-hydrogenated or H2-loaded Ge-doped fibers.

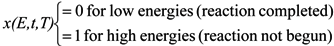

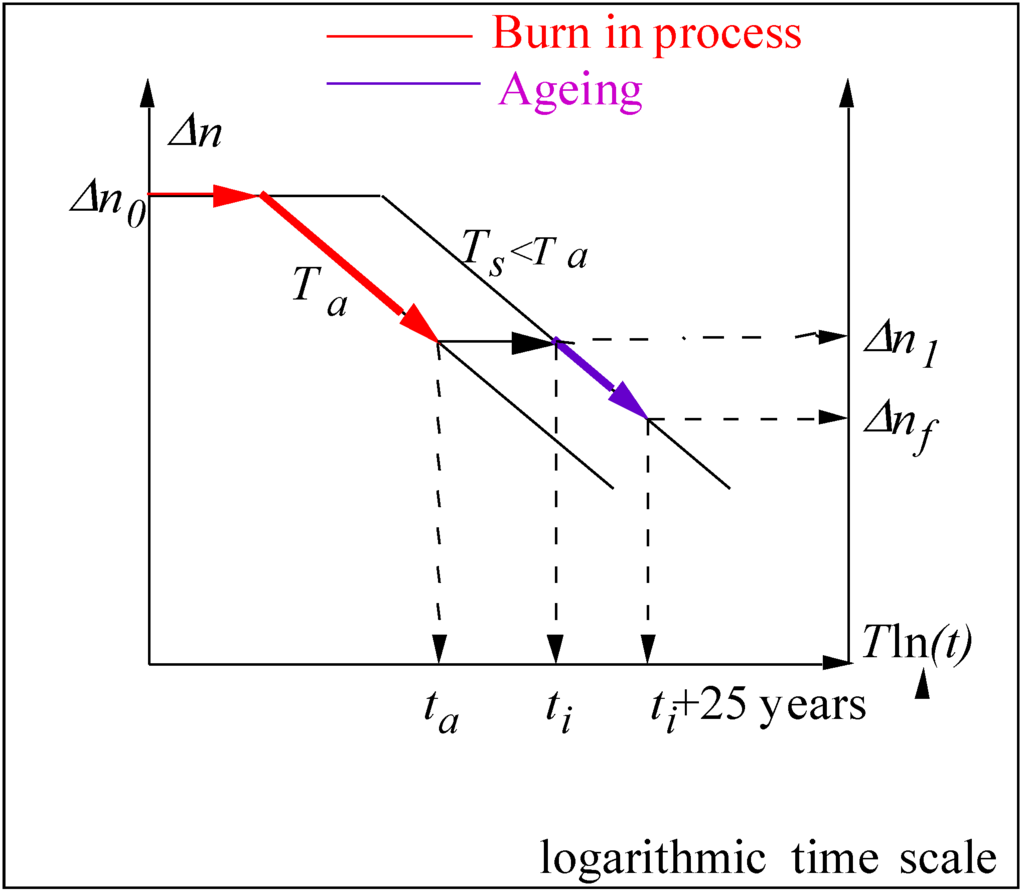

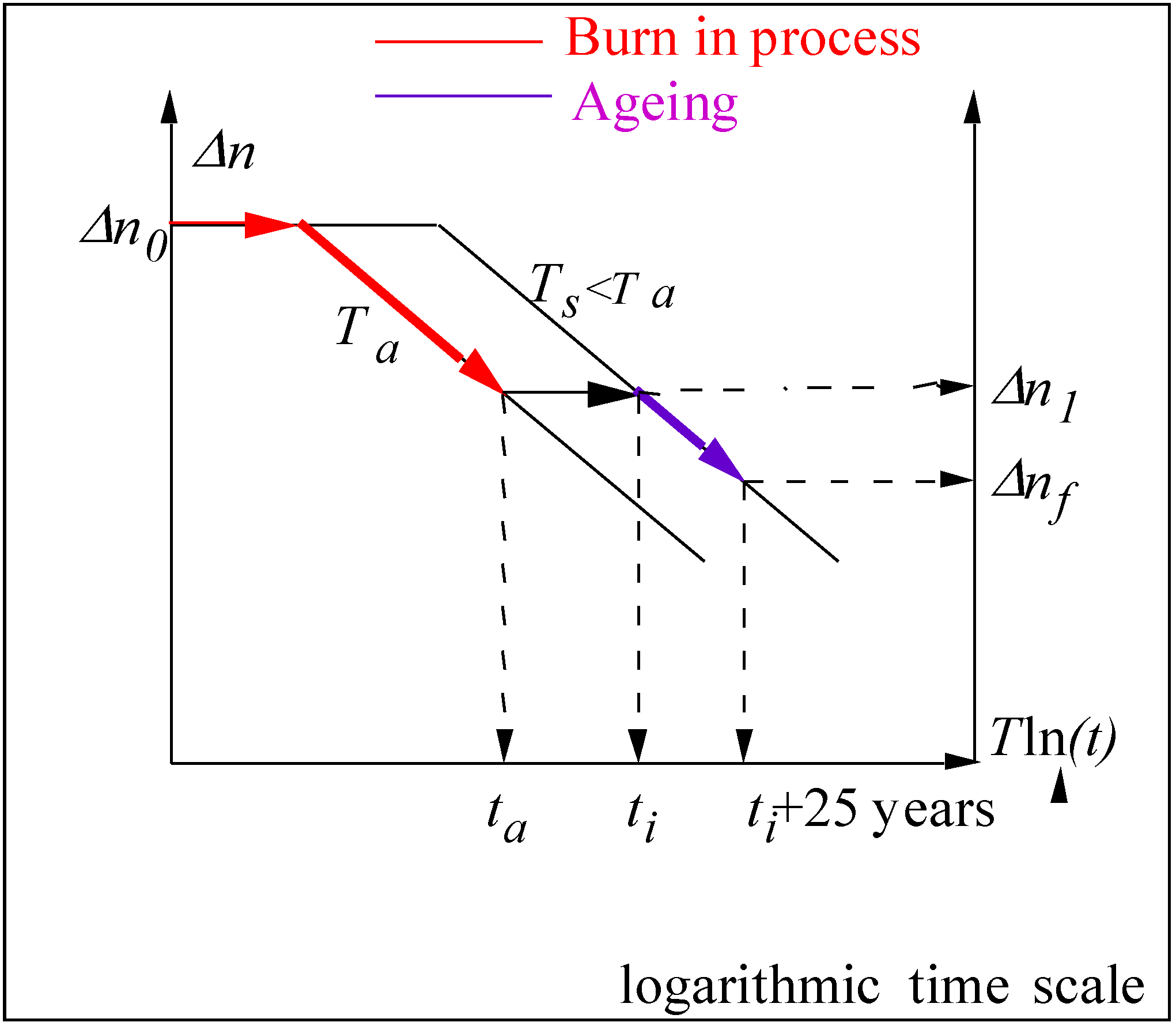

As shown in Figure 5, the stabilization (passivation) induced by an annealing can be computed by renormalizing the final value of the index change Δnf after a time tuse at temperature Tuse by the index change Δn1 after burning in process. If we impose that after a given time at a given temperature (let us say 25 years at 40 °C for instance), the lifetime ratio Δnf/Δn1 has to remain within a given range  with ε < 10% for instance, we obtain the passivation parameters (time ta and temperature Ta). Notice that in general we estimate the uncertainty on k0 based on the data uncertainty, then we chose the worst case value and we added an extra safety margin (typically ε < 1% instead of 10%).

with ε < 10% for instance, we obtain the passivation parameters (time ta and temperature Ta). Notice that in general we estimate the uncertainty on k0 based on the data uncertainty, then we chose the worst case value and we added an extra safety margin (typically ε < 1% instead of 10%).

with ε < 10% for instance, we obtain the passivation parameters (time ta and temperature Ta). Notice that in general we estimate the uncertainty on k0 based on the data uncertainty, then we chose the worst case value and we added an extra safety margin (typically ε < 1% instead of 10%).

with ε < 10% for instance, we obtain the passivation parameters (time ta and temperature Ta). Notice that in general we estimate the uncertainty on k0 based on the data uncertainty, then we chose the worst case value and we added an extra safety margin (typically ε < 1% instead of 10%).

Figure 5.

Scheme of the passivation process (also called burn in process in this figure) [12]. Δn0 is the FBG index modulation (or its reflectivity) before the passivation process at the temperature Ta for a given time ta. Δn1 is the FBG index modulation after the passivation process. Δnf is the final value of the index change after its life for a time tuse at a given temperature Tuse. Δn0/Δn1 is called the passivation (or annealing) ratio. Δnf/Δn1 is called the lifetime ratio.

Figure 5.

Scheme of the passivation process (also called burn in process in this figure) [12]. Δn0 is the FBG index modulation (or its reflectivity) before the passivation process at the temperature Ta for a given time ta. Δn1 is the FBG index modulation after the passivation process. Δnf is the final value of the index change after its life for a time tuse at a given temperature Tuse. Δn0/Δn1 is called the passivation (or annealing) ratio. Δnf/Δn1 is called the lifetime ratio.

From practical point of view and as shown in Figure 5, the stabilisation (passivation) is usually defined by a passivation ratio noted Δn0/Δn1 that is defined by the FBG index modulation Δn1 (or its reflectivity) after a passivation time ta at a given passivation temperature Ta by the FBG index modulation Δn0 (or its reflectivity) before the passivation process. So if the end user imposes that after a given time tuse at a given temperature Tuse (let us say 25 years at 45 °C for instance), the lifetime ratio Δnf/Δn1 has to remain within a given range  with ε < 1% for instance, we determined the related passivation ratio Δn0/Δn1, e.g., 2. This means that the passivated FBG at a chosen passivation temperature Ta (e.g., 220 °C in our study) has to be erased of about a factor 2 to respect the above mentioned lifetime criteria (ε < 1% during 25 years at 45 °C).

with ε < 1% for instance, we determined the related passivation ratio Δn0/Δn1, e.g., 2. This means that the passivated FBG at a chosen passivation temperature Ta (e.g., 220 °C in our study) has to be erased of about a factor 2 to respect the above mentioned lifetime criteria (ε < 1% during 25 years at 45 °C).

with ε < 1% for instance, we determined the related passivation ratio Δn0/Δn1, e.g., 2. This means that the passivated FBG at a chosen passivation temperature Ta (e.g., 220 °C in our study) has to be erased of about a factor 2 to respect the above mentioned lifetime criteria (ε < 1% during 25 years at 45 °C).

with ε < 1% for instance, we determined the related passivation ratio Δn0/Δn1, e.g., 2. This means that the passivated FBG at a chosen passivation temperature Ta (e.g., 220 °C in our study) has to be erased of about a factor 2 to respect the above mentioned lifetime criteria (ε < 1% during 25 years at 45 °C).4.3. Uncertainties in the passivation conditions and impact in the lifetime prediction of passivated FBG:

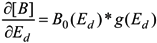

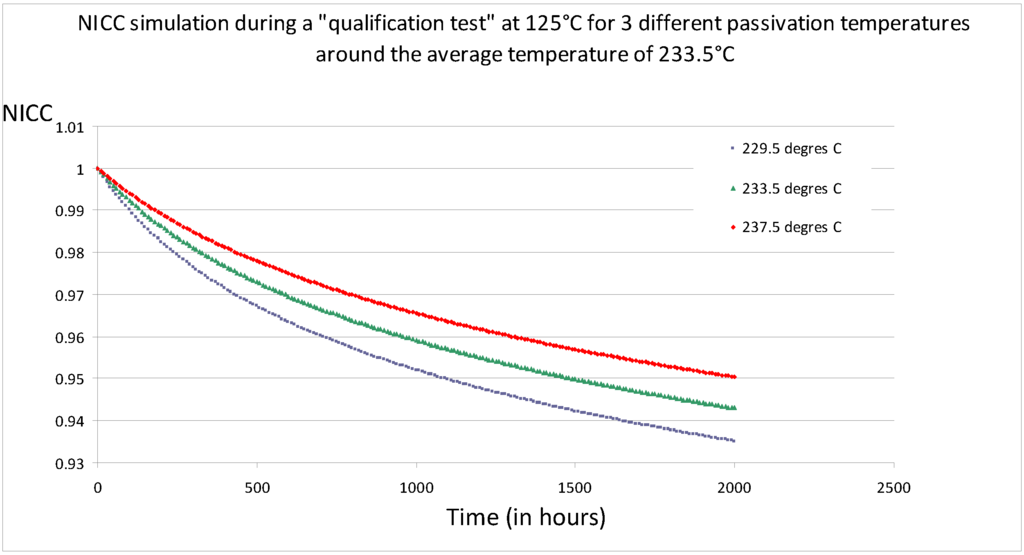

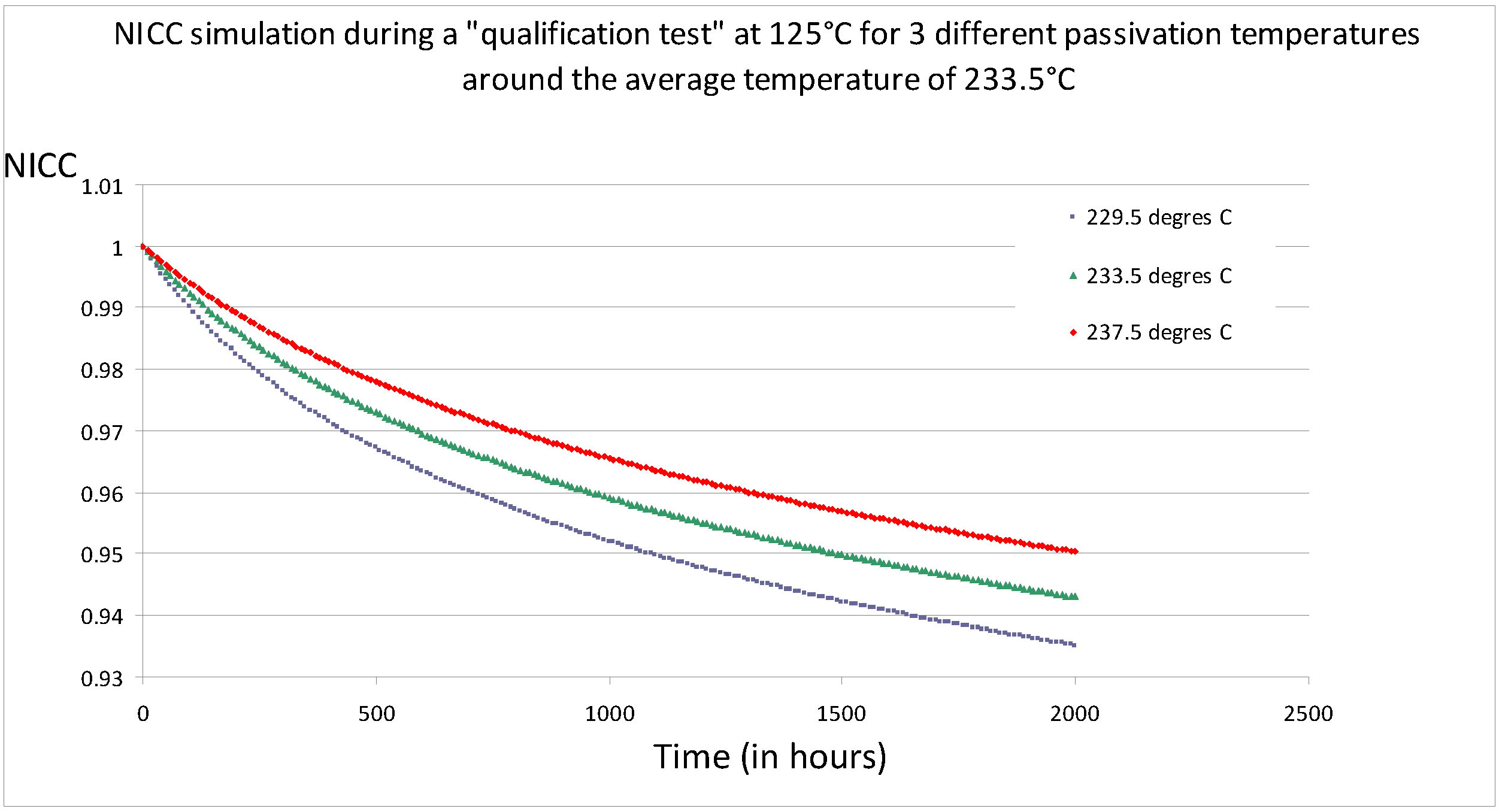

Similarly, the lifetime prediction of passivated FBG is very sensitive to small variations in the parameters of passivation. Therefore, it is necessary to estimate the experimental uncertainties in the passivation conditions to derive confidence intervals for the estimates of the parameters. An illustration of such prediction is shown in Figure 6. It shows the predicted ageing at 125 °C during 2000 h for a FBG passivated during 10 min at three different temperatures, one corresponding to the mean temperature of the passivation process (233.5 °C) and the other two terminals (229.5 °C and 237.5 °C) corresponding to the typical passivation temperature uncertainty that we estimated (±4 °C). Thus the prediction indicates that NICC of the passivated FBG decays about 6% after 2000 h at 125 °C. The uncertainty in passivation temperature leads solely (without taking into account the uncertainty on k0) to an uncertainty of at least 1% of this prediction.

Figure 6.

Simulation of accelerated ageing during 2000 h at 125 °C for a passivated grating during 10 min at different temperatures around 233.5 °C.

Figure 6.

Simulation of accelerated ageing during 2000 h at 125 °C for a passivated grating during 10 min at different temperatures around 233.5 °C.

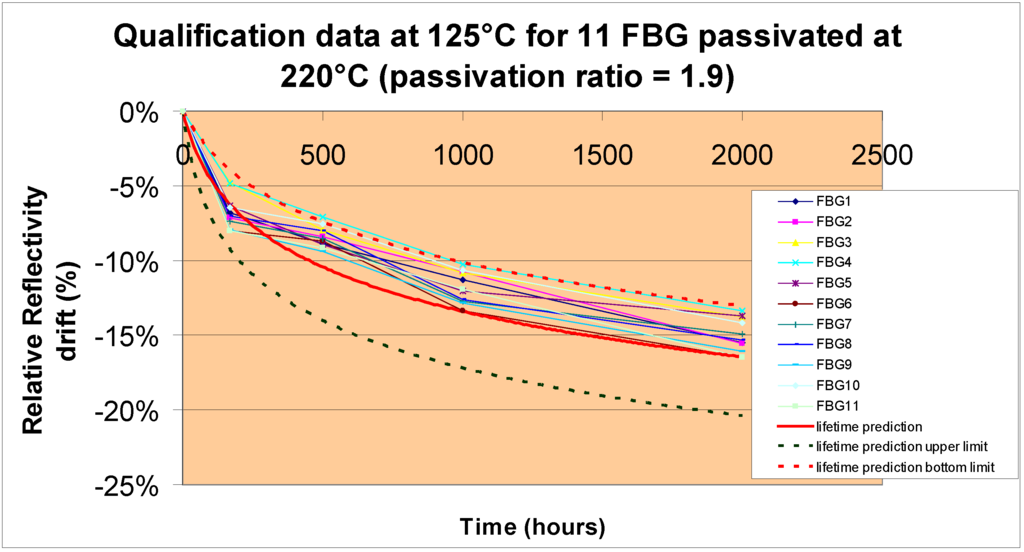

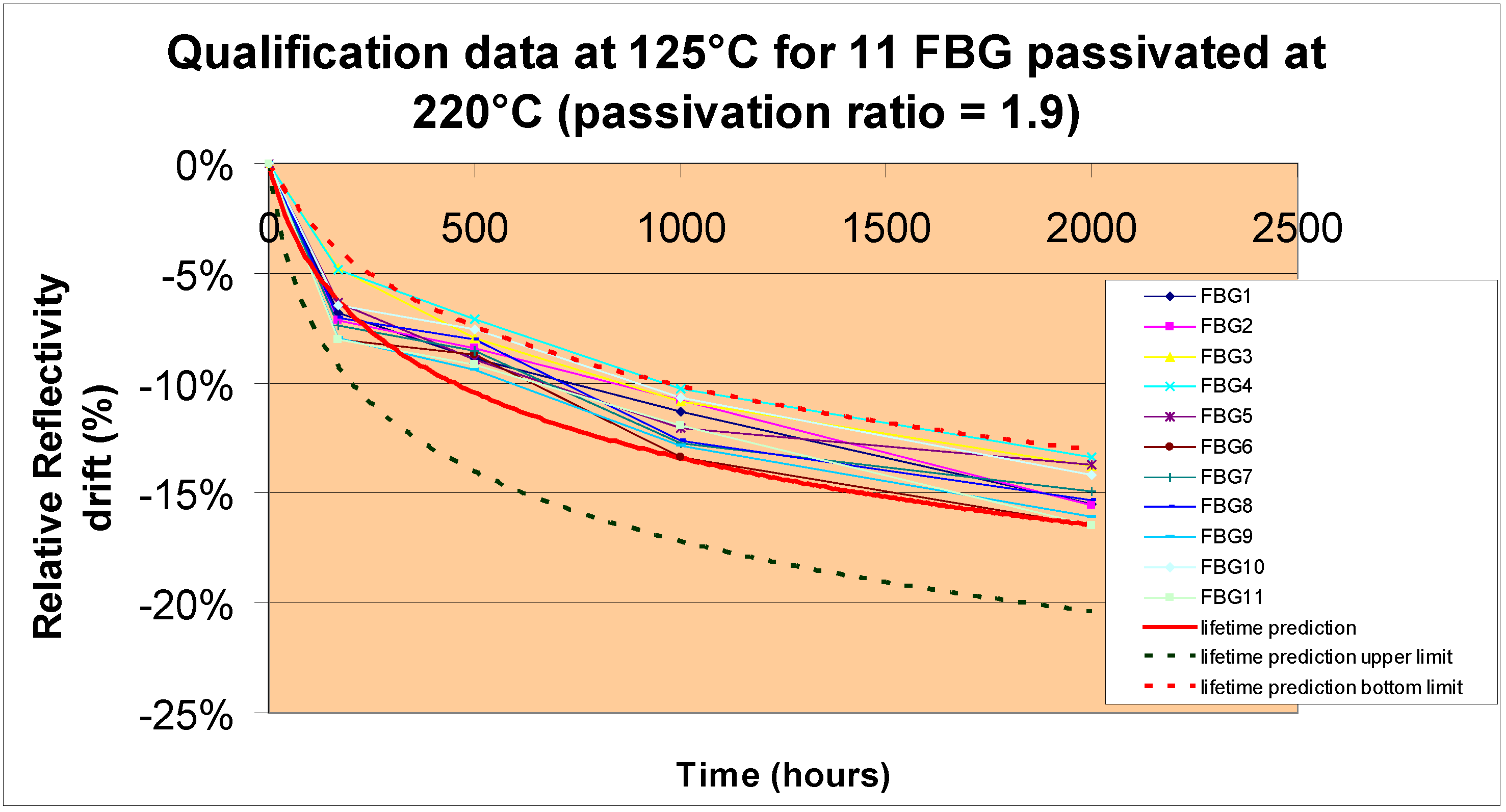

Figure 7.

An example of comparison between qualification data (i.e., accelerated isothermal ageing) at 125 °C and the lifetime prediction for 11 passivated identical FBG using the Master Curve (MC). The passivation ratio Δn0/Δn1 was about 1.9 ± 0.1.

Figure 7.

An example of comparison between qualification data (i.e., accelerated isothermal ageing) at 125 °C and the lifetime prediction for 11 passivated identical FBG using the Master Curve (MC). The passivation ratio Δn0/Δn1 was about 1.9 ± 0.1.

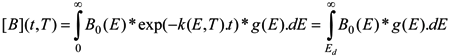

5. A Critical Study of the Passivation Method and How to Perform A Reliable Prediction

5.1. How to Verify the Validity of the FBG Passivation Conditions and Related FBG Lifetime Prediction from Industrial Point of View

From telecommunication companies point of view, the principle is to compare the prediction established using the MC with accelerated ageing data at only one fixed temperature. For the sake of illustration, we present in Figure 7 the accelerated ageing data of passivated FBG together with the related MC prediction during 2000 h at 125 °C. In order to highlight the reproducibility of the process (both the writing and the passivation), we present the ageing data for 11 gratings that have been written and then passivated in the same conditions. As it can be seen the relative reflectivity decreases about 15% ± 2% after 2000 h at 125 °C. The lifetime predictions are also shown in Figure 7 for three different values of the k0 coefficient, i.e., the optimum value for k0 obtained by least square optimization (here ln(k0) = 21.5) but also the upper and the lower bounds corresponding to its confidence interval (ln(k0) = 19.5 and 23.5) that have been estimated based on ageing data uncertainty. As it can be seen, there is a good agreement between qualification data and the lifetime predictions at 125 °C. Indeed, the worst case of the qualification data remains higher than the prediction’s lower bound. It must be mentioned that this approach based on “only” one isotherm is not reliable from a lifetime prediction point of view, but this is only a first step. It could be useful in such a manner and it has the merit to detect some potential failure in the lifetime predictions.

5.2. Potential Failure in the Prediction of Passivation Effect and Subsequent FBG Lifetime due to H2 Reactions at “high” Temperature

Firstly, it is important to remember that the lifetime prediction of a passivated FBG must be verified if the FBG were aged in the same conditions as the ones used to establish the master curve, i.e., a first outgassing at low temperature (typically below 110 °C) followed by ageing along isotherms in order to build a MC. If the chemical conditions during the passivation procedure are changed (e.g., presence of remaining hydrogen that reacts during the passivation process at high temperature), the prediction is no longer possible and another MC has to be established with the proper conditions.

The difference that could be observed between the prediction and isotherms measured on passivated FBG highlights the fact that the lifetime prediction of passivated FBG at “high temperature” (here typically above 150 °C) in the presence of hydrogen cannot be done in a reliable manner with a master curve established with FBG outgassed at low temperature (typically below 100 °C). This is due to chemical reactions during the passivation at high temperature in the presence of hydrogen. These reactions are not included in the master curve previously established and could lead to invalid predictions. Indeed, it is known that the photo-induced species during UV irradiation (point defects such as GeE’ and hydrogenated species such as GeH, GeH2, T-OH with T = Si or Ge) can be transformed under the effect of a rise in temperature (e.g., passivation at temperatures higher than 150 °C). These chemical reactions affect the index modulation and thus FBG reflectivity; specifically it can lead to an “amplification” of the erasure of photo-induced index changes compared to the erasure predicted using the master curve. To conclude, it is important to remember that the master curve is established for FBG prepared under specific conditions and it does not apply a priori if FBG were conditioned (i.e., H2 out-gazing and passivation conditions) in a different manner.

5.3. How to Predict the Lifetime of a Passivated FBG in a Reliable Manner

For a reliable lifetime prediction of passivated FBG, there are thus two procedures:

- (1)

- Establish the master curve of simply outgassed components and perform the passivation of FBG after H2 outgazing at low temperature (below 100 °C) to avoid any reactions with the remaining H2. The advantage is that this approach remains general since it can be applied to any passivation temperature provided that those are included in the master curve database and can lead to optimization of the passivation specification.

- (2)

- An alternative solution is to simply build a mastercurve on the real components (i.e., the gratings written, outgassed and passivated under fixed conditions) that we will called “restricted” master curve. The major advantage is that the master curve is built on components that went through the whole fabrication process and is therefore necessarily representative of the final product’s behavior.

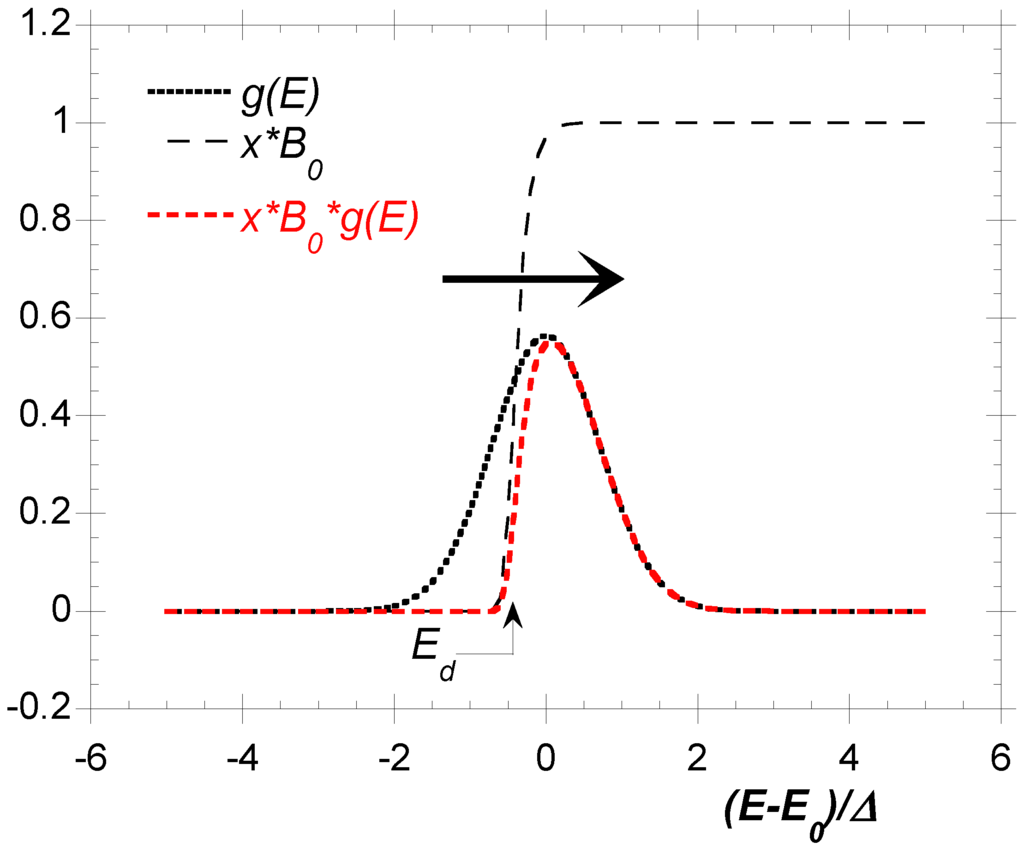

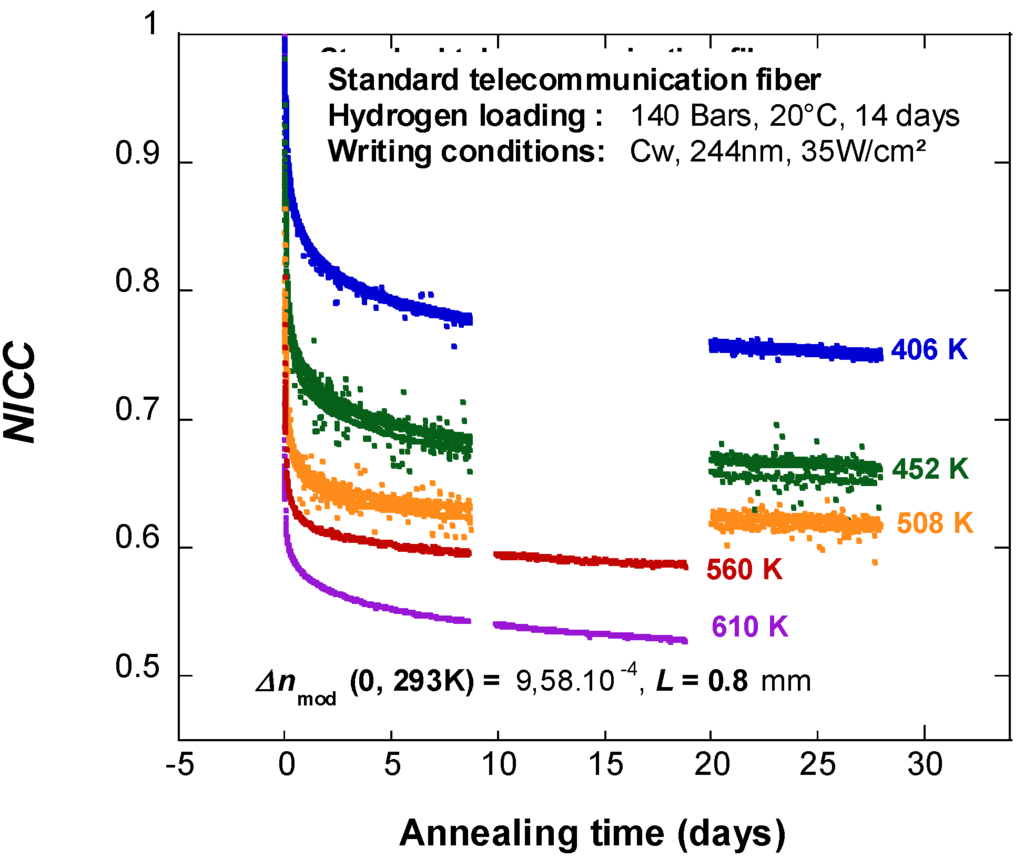

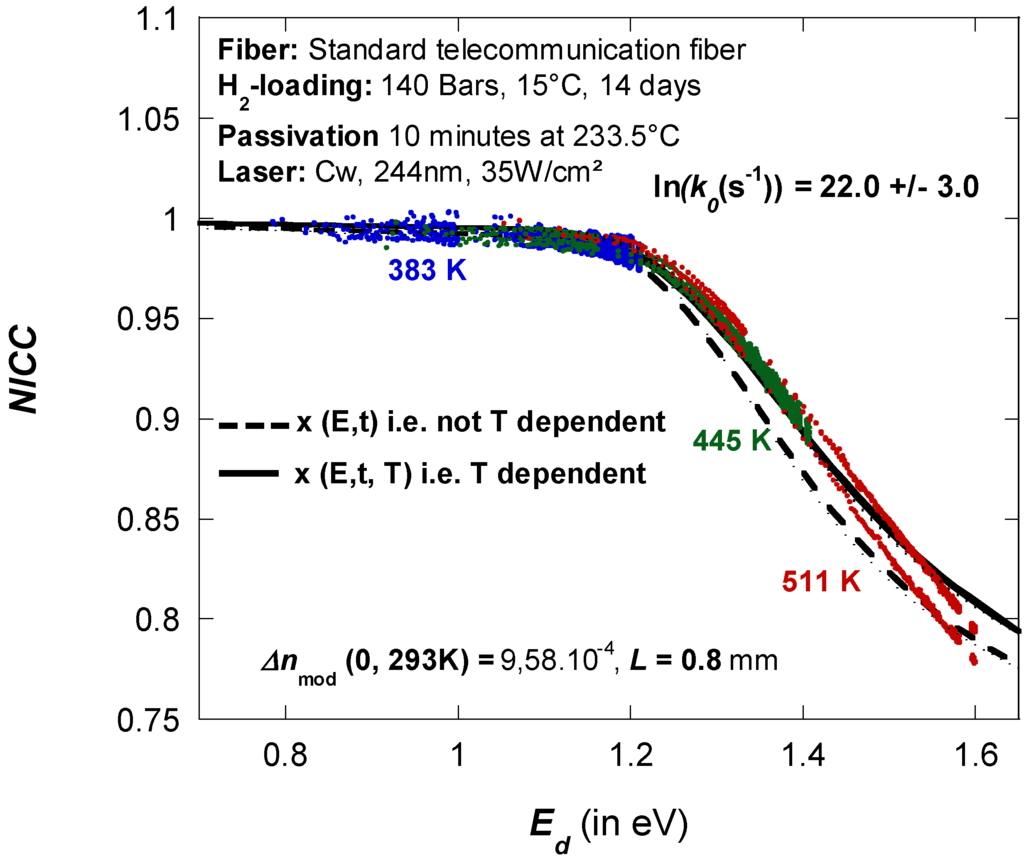

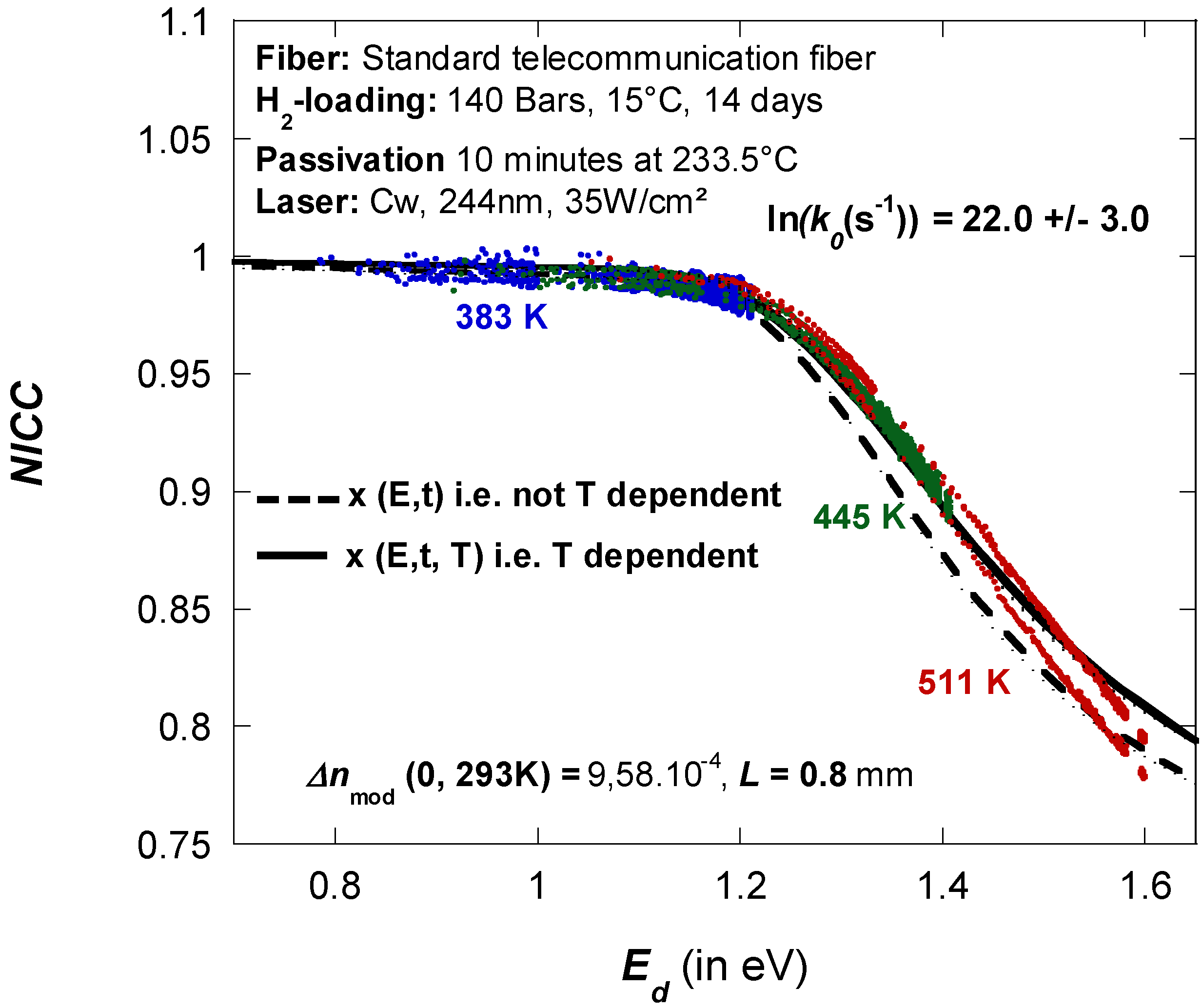

Both approaches are based on the same model fed with ageing data (reflectivity decay vs. time and temperature). The only difference is that one uses gratings that are not annealed while the other uses annealed, i.e., real components. If the main hypotheses are verified (i.e., if the shapes of the NICC curves according to kBTisotln(t) are the same (parallel curves) and if their collapse into a MC is possible by fitting k0), the obtained mastercurve can then be used to predict the behaviour of annealed gratings with time and temperature in a reliable manner. An example of such a “restricted” mastercurve built on passivated gratings is shown in Figure 8 together with its prediction deduced from the initial master curve [12]. The good agreement between those curves allows then the user to validate the FBG lifetime prediction.

Figure 8.

Normalized Integrated Coupling Constant (NICC) as a function of the demarcation energy Ed = kBT.ln(k0t) (in eV), i.e., the master curve for passivated FBG written in H2-loaded germanosilicate core optical fibers. The black lines correspond to the MC prediction based on non-passivated gratings using a non-temperature dependent (black dotted line) and a temperature dependent (black full line) approach.

Figure 8.

Normalized Integrated Coupling Constant (NICC) as a function of the demarcation energy Ed = kBT.ln(k0t) (in eV), i.e., the master curve for passivated FBG written in H2-loaded germanosilicate core optical fibers. The black lines correspond to the MC prediction based on non-passivated gratings using a non-temperature dependent (black dotted line) and a temperature dependent (black full line) approach.

6. Conclusions

In various references [1,11,12], a framework for lifetime and passivation determination of standard type I FBG has been presented. The formalism is based on demarcation energy approximation and the existence of a master curve. This MC can be obtained if a few assumptions are fulfilled (this a necessary and sufficient condition): unicity of the reaction, thermally activated reaction (the Arrehnius law can be considered), distribution of the activation energy (temperature independent) and first order reaction. Departure of one of these constraints leads to non existence of MC. Some extensions can nevertheless be performed (e.g., second order reaction) but most of the cases met in FBG fulfil the assumptions. MC is determined by accelerated ageing under specific conditions that correspond to operating conditions. However, in most cases, the lifetime is not large enough, but due to the distributed nature of activation energies, it is possible to increase the grating stability by erasing thermally the less stable part of the UV induced population created by the UV irradiation. If this passivation process is achieved under the same conditions than the ageing process, it is possible to determine its duration for a given temperature to reach a specified lifetime and optimise the process if necessary. In that case, the MC of the passivated grating can be deduced from the MC before passivation. This is the only way to validate the FBG lifetime prediction in a reliable manner.

However, when the condition of the passivation process is different (hydrogen remaining or even no H2 degassing for instance) determination of the lifetime for a given temperature is no longer possible. In that case, the lifetime can be checked by establishing a “restricted” MC related to the passivated gratings. The major advantage of this approach is that this “restricted” master curve is built on components that went through the whole fabrication process and is therefore necessarily representative of the final product’s behavior. This eliminates hydrogen-related issues mentioned above, for instance. The major drawback is that the master curve and the related predictions are available only for the chosen passivation conditions and cannot be transposed to different passivation conditions. However, this may not be a limitation if a controlled fabrication process is followed.

Acknowledgments

The authors are grateful to 3SP Group, to the “System@tic” Pôle de Compétitivité through CHRONOS project, to Direction générale de la compétitivité, de l'industrie et des services (DGCIS) and to Conseil Général de l’Essonne.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Poumellec, B. Links between writing and erasure (or stability) of Bragg gratings in disordered media. J. Non Cryst. Solids 1998, 239, 108–115. [Google Scholar] [CrossRef]

- Niay, P.; Poumellec, B.; Lancry, M.; Douay, M. Photosensitivity and treatments for enhancing the photosensitivity of silica-based glasses and fibers. Photorefractive Mater. Appl. 2007, 114, 535–569. [Google Scholar]

- Lancry, M.; Poumellec, B. UV laser processing and multiphoton absorption processes in optical telecommunication fibers materials. Physics Reports 2013, 522, 239–261. [Google Scholar] [CrossRef]

- Razafimahatratra, D.; Niay, P.; Douay, M.; Poumellec, B.; Riant, I. Comparison of isochronal and isothermal decays of Bragg gratings written through continuous-wave exposure of an unloaded germanosilicate fiber. Appl. Opt. 2000, 39, 1924–1933. [Google Scholar] [CrossRef]

- Erdogan, T.; Mizrahi, V.; Lemaire, P.J.; Monroe, D. Decay of ultraviolet-induced fiber Bragg gratings. J. Appl. Phys. 1994, 76, 73–80. [Google Scholar] [CrossRef]

- Kashyap, R. Fiber Bragg Gratings. In Optics and Photonics; Kelly, P.L., Kaminov, I., Agrawal, G.P., Eds.; Academic Press: London UK, 1999. [Google Scholar]

- Hidayat, A.; Wang, Q.; Niay, P.; Douay, M.; Poumellec, B.; Kherbouche, F.; Riant, I. Temperature-induced reversible changes in the spectral characteristics of fiber Bragg gratings. Appl. Opt. 2001, 40, 2632–2642. [Google Scholar] [CrossRef]

- Poumellec, B.; Niay, P. About Writing Mechanism of UV Induced Refractive Index Chnage in H2 Loaded Ge Doped SiO2. In Photorefractive Effects, Materials and Devices; OSA: La Colle sur Loup, France, ISBN: 1-55752-755-5; 2003. [Google Scholar]

- Kannan, S.; Guo, J.Z.Y.; Lemaire, P.J. Thermal stability analysis of UV-induced fiber Bragg gratings. J. Lightwave Tech. 1997, 15, 1478–1483. [Google Scholar] [CrossRef]

- Ramecourt, D.; Douay, M. Etude de la Photosensibilité et de la Stabilité de Réseaux D’indice Inscrits dans des Fibres Optiques Germanosilicates Hydrogénées = Photosensitivity and Stability Studies of Grating Based Components Written in H2 Loaded Germanosilicate Optical Fibers. PhD thesis, France, 2001. [Google Scholar]

- Poumellec, B. Kinetics of Thermally Activated Processes in Disordered Media. In Proceedings of POWAG 2000, Giens, France, 2000.

- Poumellec, B.; Riant, I.; Tessier-Lescourret, C. Precise life-time prediction using demarcation energy approximation dor ditributed activation energy reaction. J. Phys. Condens. Matter 2006, 18, 2199. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).