Lignocellulosic Agro-Forest Byproducts as Feedstock for Fused Deposition Modeling 3D Printing Filaments: A Review

Abstract

Highlights

- Agro-industrial byproducts have gained attention as components in filament production for fused deposition modeling 3D printing.

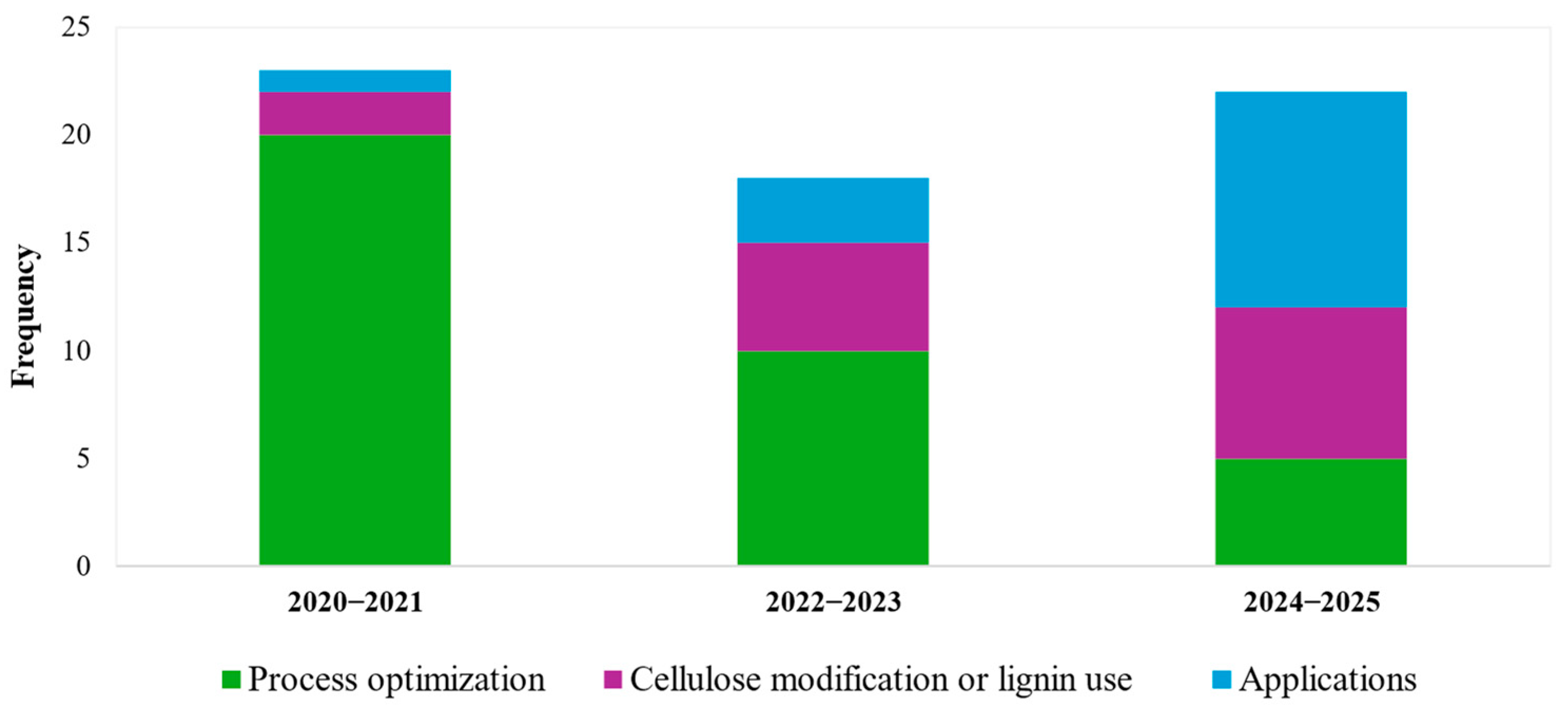

- Most reviewed studies focus on the physical, mechanical, and barrier properties of filaments, and recent research highlights the incorporation of modified cellulose or lignin.

- Despite the novelty of incorporating agro-industrial byproducts, there are still scaling challenges and there are few products on the market.

- There is more focus on analysing the materials and final properties of 3D printing filaments. However, the environmental and regulatory aspects of filament production are less studied.

Abstract

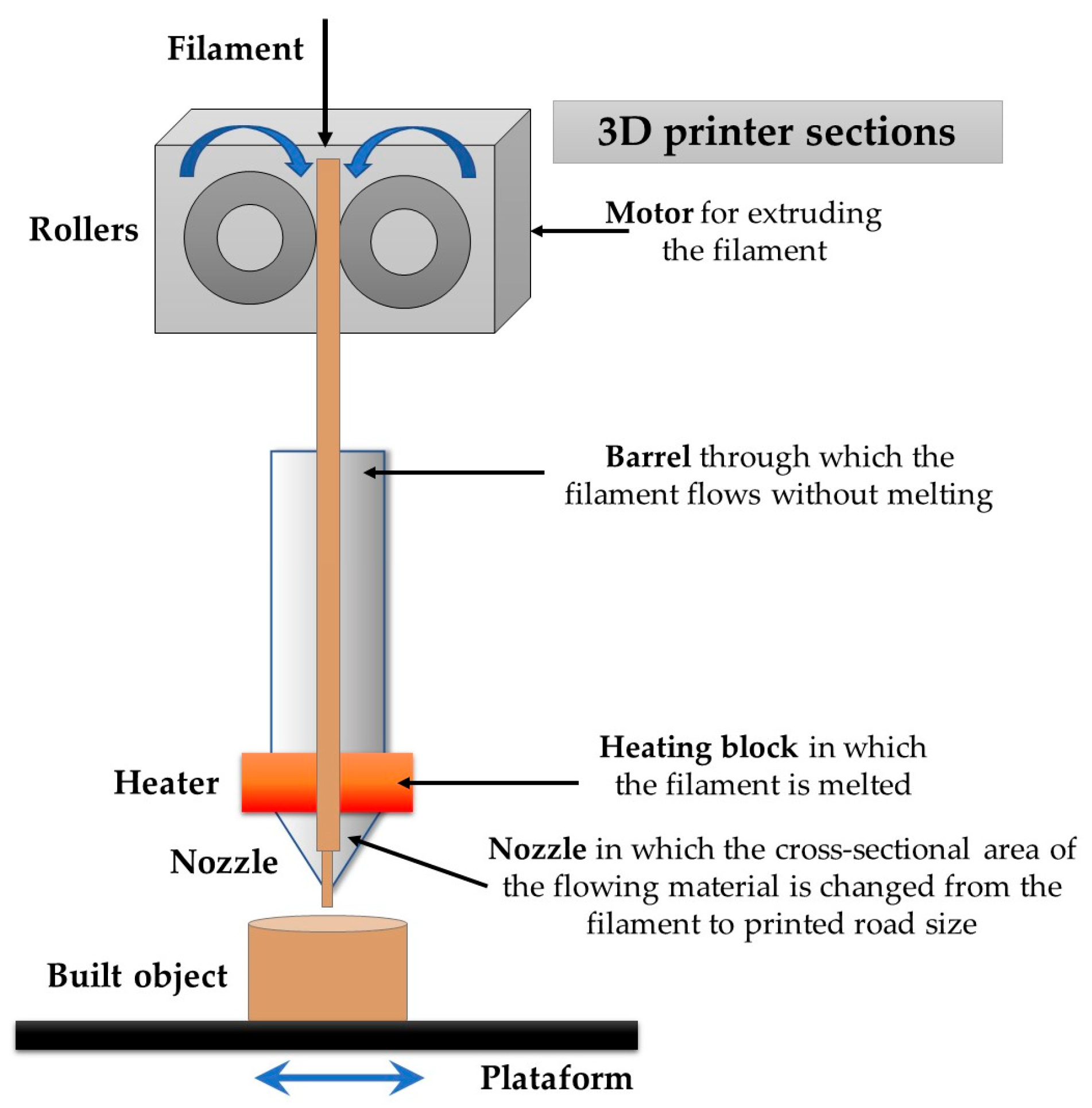

1. Introduction

2. Materials and Methods

- Which lignocellulosic residues are generated, and in what amounts?

- What type of treatment is performed on byproducts to make them suitable for 3D printing?

- What parameters should be considered during the manufacturing of the filament and the 3D structure?

- How do these parameters influence filament production or 3D printing, and what properties are relevant?

- What applications have been studied in recent years?

- What are the technical, environmental, and regulatory considerations for 3D printing based on lignocellulosic waste?

3. Results

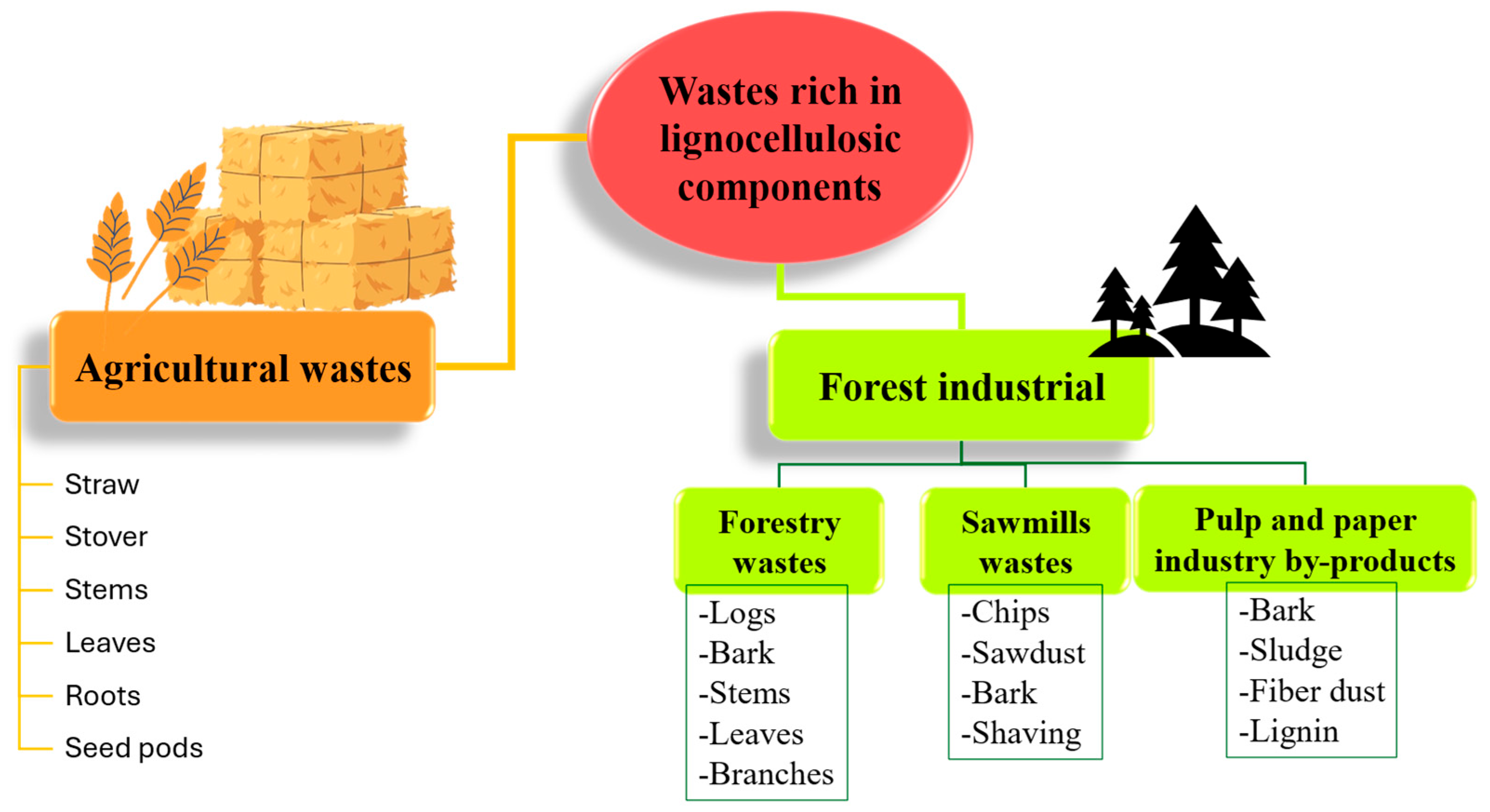

3.1. Agro/Forest Industrial Wastes as a Feedstock

3.1.1. Agricultural Wastes

| Product | Estimated Global Production (Mmt) | Major Producers (%) | Wastes Generated | Ref. | |

|---|---|---|---|---|---|

| Sugarcane | 2000 (2022/2023) | Brazil | 38 | Straw (harvesting). Bagasse, molasses, press mud (sugar elaboration). >279 million tons generated in sugar and ethanol production | [34,35,36] |

| India | 23 | ||||

| China | 5 | ||||

| Thailand | 5 | ||||

| Pakistan | 4 | ||||

| Corn | 1220 (2024) | USA | 31 | Corn stover. 47–50% of the total produced | [42] |

| China | 24 | ||||

| Brazil | 11 | ||||

| EU | 5 | ||||

| Argentina | 4 | ||||

| Wheat | 800 (2024) | China | 18 | Straw. 50% of straw per harvested wheat | |

| EU | 15 | ||||

| India | 14 | ||||

| Russia | 10 | ||||

| USA | 7 | ||||

| Rice | 538 (2024) | India | 27 | Straw (harvesting) and husks. Rice husk is 22% of the total rice produced | [42,43] |

| China | 27 | ||||

| Bangladesh | 7 | ||||

| Indonesia | 6 | ||||

| Vietnam | 5 | ||||

| Soybean | 421 (2024) | Brazil | 40 | Straw and okara. Up to 1.2 kg of okara per kg of soybean processed | [42,44] |

| USA | 28 | ||||

| Argentina | 12 | ||||

| China | 5 | ||||

| India | 3 | ||||

3.1.2. Waste Generated in the Wood Processing, Pulp, and Paper Industry

3.2. Processing Agro/Forest Industrial Waste into Filaments

3.2.1. Raw Material Conditioning

| Filament Components | Lignocellulosic Fiber | Filament Production Conditions | 3D Printing Parameters | Ref. | ||

|---|---|---|---|---|---|---|

| Conditioning or Pretreatment | Particle Size (µm) | Filler Load (wt%) | ||||

| Japanese cedar sapwood + PLA | Milled, sieved, and treated with temperature (180 °C for 2–6 h). Then dried at 105 °C, 24 h | <149 | 0, 20 | Single-screw extruder, 16 rpm, 70–210 °C | RA: 0°, Nozzle T: 210 °C, Bed T: 60 °C, FFS: 30 mm/s, ID: 100%, IP: n.i., LT: 0.30 mm | [65] |

| Black pine (Pinus nigra) timber sawdust + PLA | Sieved, dried at 103 °C | 177–250 | 0–20 | Twin-screw extruder, 100–180 °C, 50 rpm | RA: 45°, Nozzle T: 180 °C, Bed T: 50 °C, FFS: 50 mm/s, ID: 100%, IP: n.i., LT: 0.30 mm | [55] |

| Wood powder + silane + PLA + acrylic ester resin | Acetylation | <48 | 0, 5 | Twin-screw extruder, 170–190 °C | RA: 0°, Nozzle T: 220 °C, Bed T: 55 °C, FFS: 40 mm/s, ID: n.i., IP: n.i., LT: 0.20 mm | [73] |

| Poplar fiber + PLA + silane + tributyl citrate | Milled, coupled, and dried | <117 | 5 | Single-screw extruder 45 rpm, 170 °C | RA: n.i., Nozzle T: 200–240 °C, Bed T: 80 °C, FFS: 20–100 mm/s, ID: 100%, IP: n.i., LT: 0.10–0.50 mm | [74] |

| Recycled woodblock fibers + PLA | Grinding, sieving, dried at 80 °C | <250 | 0–15 | Single-screw extruder, 165 °C | RA: 0°, 90°, Nozzle T: 180–210 °C, Bed T: 45 °C, FFS: 35 mm/s, ID: 100%, IP: Linear, LT: 0.20 mm | [68] |

| Wood ashes + PLA | Dried at 80 °C for 24 h | n.i. | 0–20 | Single-screw extruder, 170–180 °C, 4 rpm | RA: 45°, Nozzle T: 200 °C, Bed T: 60 °C, FFS: 30 mm/s, ID: 100%, IP: n.i., LT: 0.40 mm | [56] |

| Jack pine sawdust + PLA | Milled, sieved, and dried at 80 °C for 24 h | <150 | ||||

| Red Gum sawdust + ABS + maleic anhydride | Milled, sieved, and dried at 105 °C for 24 h | 150–212, 90–150, <90 | 0–20 | n.i. | RA: 45°, Nozzle T: 245–250 °C, Bed T: 100 °C, FFS: 15 mm/s, ID: 100%, IP: n.i., LT: 0.30 mm | [69] |

| Grey Box sawdust + ABS + maleic anhydride | ||||||

| Printed office paper + silane + PLA | Coupled and dried at 103 °C to a constant weight | n.i. | 5–15 | Single-screw extruder, 175–180 °C | Printing parameters n.i. | [75] |

| Organosolv lignin hardwood + PLA | Dried at 60 °C for 72 h | n.i. | 0, 10 | Single-screw extruder, 170–195 °C, 12.2–14.5 rpm | RA: n.i., Nozzle T: 200 °C, Bed T: n.i., FFS: 40 mm/s, ID: 100%, IP: Rectilinear, LT: 0.40 mm | [76] |

| Organosolv lignin hardwood + TPU | Single-screw extruder, 195–200 °C, 9.7–10.4 rpm | RA: n.i., Nozzle T: 210 °C, Bed T: n.i., FFS: 40 mm/s. ID: 100%, IP: Rectilinear, LT: 0.40 mm | ||||

| Organosolv lignin + PLA | Dried at 70 °C overnight | n.i. | 0, 30, 50, 70 | Single-screw extruder, 180 °C | RA: 0°, 90°, Nozzle T: 215 °C, Bed T: 60 °C, FFS: 50 mm/s, ID: 15% inside (100% Top-bottom), IP: n.i., LT: 0.15 mm | [58] |

| Kraft lignin + PLA | ||||||

| Kenaf cellulose fibers + silane + PLA | Alkaline treatment, then coupled, and dried at 110 °C for 24 h | n.i. | 0, 12.5 | Twin-screw extruder, 190–210 °C, 25–29 rpm | RA: n.i., Nozzle T: 210 °C, Bed T: 60 °C, FFS: 60 mm/s, ID: 100%, IP: linear, LT: 0.18–0.27 mm | [77] |

| Kenaf powder + ABS | n.i. | 120 | 0–10 | Twin-screw extruder, 160–260 °C | RA: n.i., Nozzle T: 230 °C, Bed T: 105 °C, FFS: 40–80 mm/s, ID: 100%, IP: linear, LT: 0.18–0.27 mm. | [78] |

| Kenaf cellulose fibers + PLA | Alkaline and bleaching treatment, then coupled, and dried at 50 °C for 24 h | n.i. | 0, 10 | Conical twin-screw microcompounding, 180 °C, 40 rpm | RA: n.i., Nozzle T: 190 °C, Bed T: 60 °C, FFS: 20 mm/s, ID: 300%, IP: n.i., LT: 0.20 mm. | [79] |

| Flour waste (Wheat middling) + PLA | Milled, sieved, and dried at 75 °C for 1 h | n.i. | 0, 10, 20 | Single-screw extruder, 165–175 °C, 5 rpm | RA: n.i., Nozzle T: 230 °C, Bed T: 60 °C, FFS: 20 mm/s. ID: 100%, IP: linear, LT: 0.20 mm. | [80] |

| Rice husks + PLA | ||||||

| Rice straw powder + PLA | Alkaline and ultrasound treatments, dried at 105 °C for 10 h, and milled | <250, <115, <106, <75 | 0, 1 | Twin-screw extruder, 170–190 °C | RA: n.i., Nozzle T: 205 °C, Bed T: 45 °C, FFS: 55 mm/s, ID: 100%, IP: n.i., LT: 0.20 mm | [70] |

| Rice husks + TPC | Acid hydrolysis, methanesulfonic acid, and alkaline treatments, dried at 50 °C for 2 h | <200 | 10 | Single-screw extruder, 160 °C, 0.05 mm/s | RA: n.i., Nozzle T: 210–220–230 °C, Bed T: 80 °C, FFS: 15–20–25 mm/s, ID: 100%, IP: n.i., LT: 0.20–0.30 mm | [71] |

| Rice husks + PLA | Milled, dried, and sieved | n.i. | 0–2 | Single-screw extruder, 177–197 °C, 5–8 rpm | RA: n.i., Nozzle T: 200 °C, Bed T: 60 °C, FFS: 60 mm/s, ID: n.i., IP: n.i., LT: 0.20 mm | [81] |

| Hedysarum coronarium stems + PLA | Milled, sieved, and dried at 40 °C for 72 h | <106 | 0–20 | Single-screw extruder, 160–190 °C, 20 rpm | RA: 45°, Nozzle T: 230 °C, Bed T: 60 °C, FFS: 20 mm/s, ID: 100%, IP: rectilinear, LT: 0.10–0.20 mm | [82] |

| Corn stalk powder + PLA + silanes + additives | Coupled and dried at 105 °C | n.i. | 1–20 | Single-screw extruder, 195–215 °C, 60–80 rpm | RA: n.i., Nozzle T: 195 °C, Bed T: n.i., FFS: 50 mm/s, ID: 100%, IP: n.i., LT: 0.15 mm | [83] |

| Soybean hulls + rHDPE + rPP + maleic anhydride | Pyrolysis, milled, and dried at 85 °C | 0, 20 | Twin-screw extruder, 180 °C, 100 rpm | RA: 0–45–90°, Nozzle T: 200–235 °C, Bed T: 80–100 °C, FFS: 35 mm/s, ID: 100%, IP: n.i., LT: 0.30 mm | [84] | |

| Soybean hulls + PLA/PBAT | Milled, and dried at 80 °C for 3 h | 125 | 0, 5, 10 | Twin-screw extruder, 170–180 °C, 4.3 rpm | RA: 0–45–90°, Nozzle T: 185–215 °C, Bed T: n.i., FFS: n.i., ID: 50–75–100%, IP: n.i., LT: 0.20–0.40 mm | [85] |

| Soybean hulls + TPS | Acid hydrolysis | n.i. | 0, 10 | Single-screw extruder, 165 °C, 0.15 mm/s | RA: 45°, Nozzle T: 220 °C, Bed T: 65 °C, FFS: 30 mm/s, ID: 100%, IP: n.i., LT: 0.20 mm | [86] |

| Oil palm fiber + ABS | Alkaline treatment, mixing, hot press molding, and crushing | n.i. | 0–7 | Single-screw extruder, 160–240 °C, 30 rpm | RA: 0°, Nozzle T: 240 °C, Bed T: 80 °C, FFS: 10 mm/s, ID: 100%, IP: Rectilinear, LT: 0.20 mm | [87] |

| Henequen fibers flour + PLA | Drying and milling (milling in two steps) | 90–250 | 1–5 | Single-screw extruder, 175–185 °C, 15 rpm | RA: 0–45–90°, Nozzle T: 215 °C, Bed T: 60 °C, FFS: 30 mm/s ID: 100%, IP: Lineal, LT: 0.15 mm | [66] |

| Agave tequilana fibers + PLA | Dephited, milled, and sieved | 106–150 | 0–10 | Twin-screw extruder, 160–175 °C, 65 rpm | RA: 0–45–90°, Nozzle T: 190 °C, Bed T: 70 °C, FFS: 50 mm/s. ID: 100%, IP: Crosshatch, LT: n.i. | [88] |

| Pistachio seed husks + PLA | Alkaline treatment, washed, dried at 100 °C for 4 h, and milled | 0.049–0.162 | 0, 5–15 | n.i. | RA: 90°, Nozzle T: 215 °C, Bed T: 60 °C, FFS: 50 mm/s. ID: n.i., IP: n.i., LT: 0.10 mm | [89] |

| Coffee seed husks + PLA | ||||||

| Chestnut seed husks + PLA | ||||||

| Walnut seed husks +PLA | ||||||

| Peanuts shells + PBAT | Milled, sieved, and dried at 60 °C for 24 h | <149 | 0–5 | Single-screw extruder, 150–154 °C, 40 rpm | RA: n.i., Nozzle T: 175 °C, Bed T: n.i., FFS: 30 mm/s, ID:100%, IP: n.i., LT: 0.20 mm | [90] |

| Soybean shells + PBAT | ||||||

| Weed hemp powder + PLA | Dried at 90 °C for 10 h | 150 | 0, 10-15 | Twin-screw extruder, 160–170 °C, 300 rpm | RA: n.i., Nozzle T: 200 °C, Bed T: n.i., FFS: 60 mm/s ID: 50%, IP: n.i., LT: 0.25 mm | [91] |

| Sicilian cherry tomato scraps + PLA | 100 | 0, 15–25 | ||||

| Discarded carob flour + PLA | 130 | 0, 10–20 | ||||

| Orange pruning waste + PLA | 100 | 0, 10–20 | ||||

| Kern hazelnut Shell powder + PLA | Dried at 100 °C for 24 h | 25.8 | 0, 10–30 | Twin-screw extruder, 170–190 °C, 250 rpm | RA: n.i., Nozzle T: 200–220 °C, Bed T: 55 °C, FFS: 25–50 mm/s, ID:100%, IP: Rectilinear, LT: 0.20 mm | [92] |

| Macadamia Nutshells + PLA | Milled, sieved, alkaline treatment, and dried at 85 °C for 48 h | ≈50 | 0, 10 | Single-screw extruder, 160–170 °C, 20–25 rpm | RA: n.i., Nozzle T: 210 °C, Bed T: n.i., FFS: 75 mm/s, ID: 100%, IP: n.i., LT: 0.06 mm | [93] |

3.2.2. Polymer Matrix Selection and Blending

3.2.3. Compatibility of Lignocellulosic Fiber/Filler with Thermoplastics

3.2.4. Compounding Methods (Single-Screw vs. Twin-Screw Extrusion)

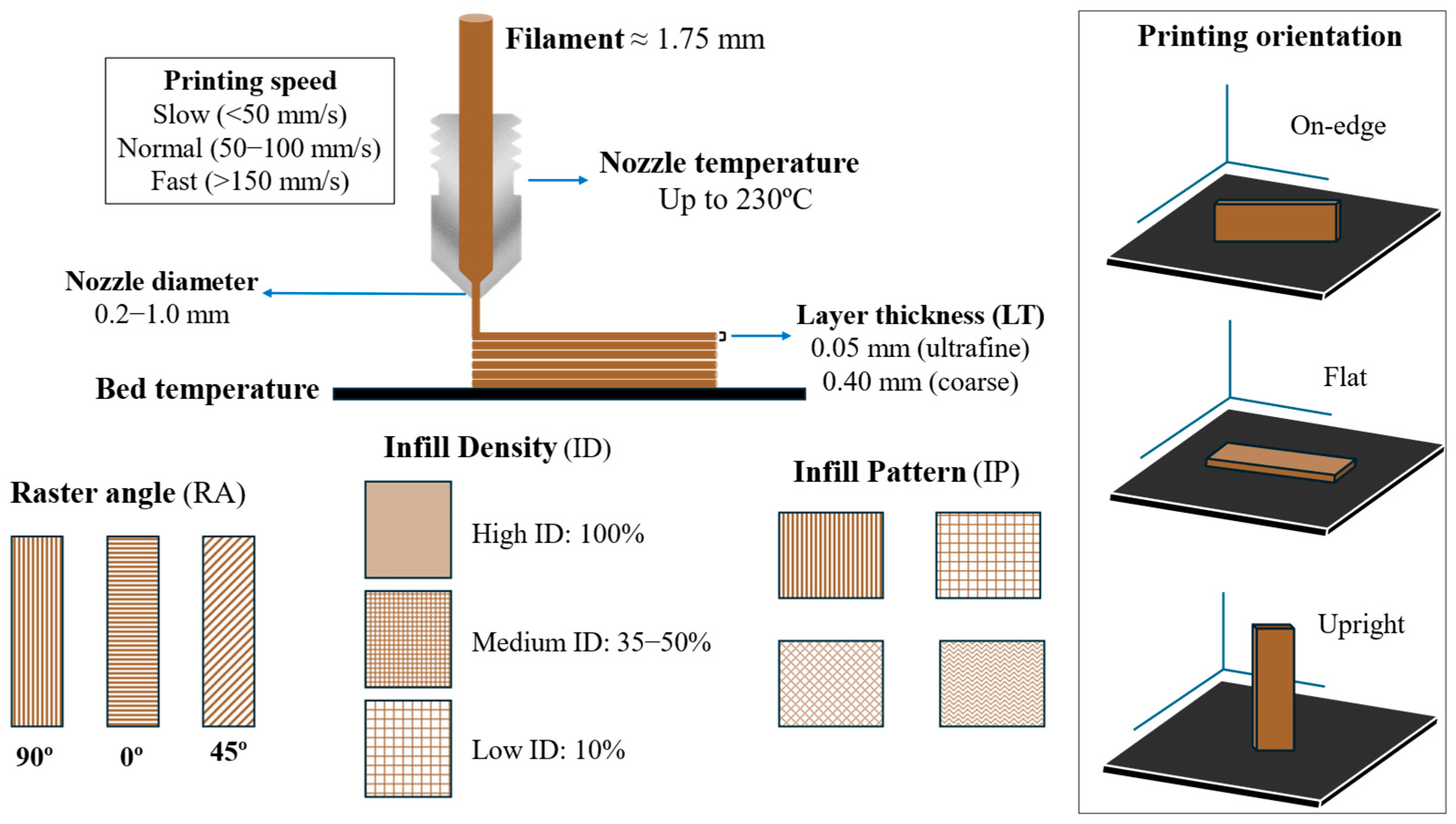

3.2.5. Parameters in 3D Printing

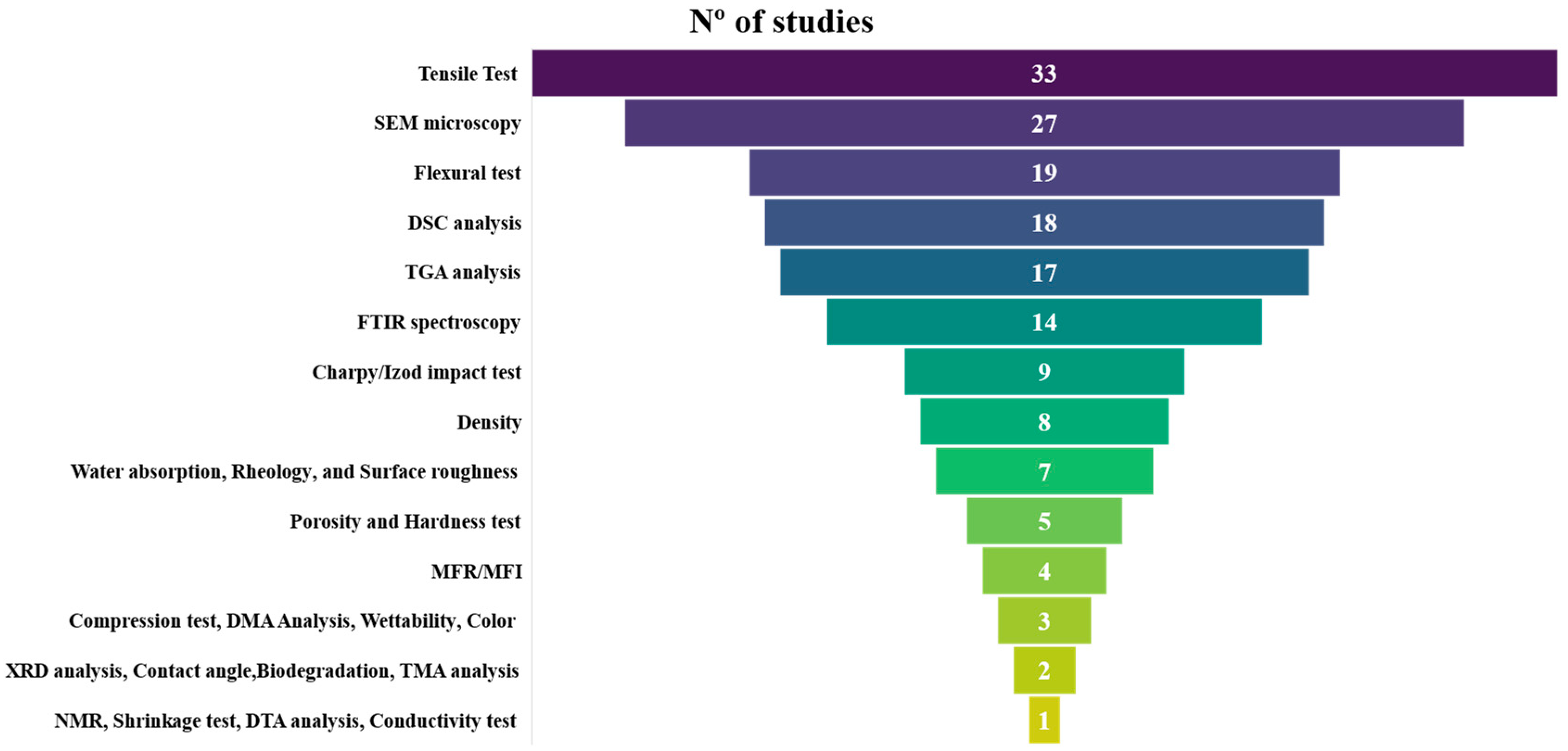

3.2.6. Properties Evaluated in Filaments and 3D Printing

3.3. Recent Studies of Applications

3.4. Scaling-Up

3.5. Environmental and Regulatory Aspects: Life Cycle Assessment and Sustainability Benefits

4. Discussion and Future Perspectives

4.1. Current State

4.2. Future Perspectives

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABS | Acrylonitrile Butadiene Styrene |

| AM | Additive manufacturing |

| DMA | Dynamic mechanical analysis |

| DSC | Differential scanning calorimetry |

| EU | European Union |

| FDM/FFF | Fused deposition modeling |

| FTIR | Fourier Transform Infrared |

| ID | Infill density |

| IP | Infill pattern |

| LCA | Life cycle assessment |

| LT | Layer thickness |

| MFI | Melt flow index |

| MFR | Melt flow rate |

| Mmt | Million metric tons |

| PHA | Polyhydroxyalkanoates |

| PHB | Poly(3-hydroxybutyrate) |

| PBAT | Poly(butylene adipate-co-terephthalate) |

| PLA | Polylactic acid |

| TGA | Thermogravimetric analysis |

| TMA | Thermomechanical analysis |

| TPC | Thermoplastic copolyester |

| TPS | Thermoplastic starch |

| TPU | Thermoplastic polyurethane |

| SEM | Scanning electron microscopy |

| RA | Raster angle |

References

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive Manufacturing: A Comprehensive Review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Zhang, X.; Chen, X.; He, Y.; Cheng, L.; Huo, M.; Yin, J.; Hao, F.; Chen, S.; Wang, P.; et al. Additive Manufacturing of Structural Materials. Mater. Sci. Eng. R Rep. 2021, 145, 100596. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Rab, S. Role of Additive Manufacturing Applications towards Environmental Sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4, 312–322. [Google Scholar] [CrossRef]

- Rasiya, G.; Shukla, A.; Saran, K. Additive Manufacturing—A Review. Mater. Today Proc. 2021, 47, 6896–6901. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2021. Available online: https://www.iso.org/obp/ui/#iso:std:iso-astm:52900:ed-2:v1:en (accessed on 21 May 2025).

- Jiang, Z.; Diggle, B.; Tan, M.L.; Viktorova, J.; Bennett, C.W.; Connal, L.A. Extrusion 3D Printing of Polymeric Materials with Advanced Properties. Adv. Sci. 2020, 7, 2001379. [Google Scholar] [CrossRef]

- Doshi, M.; Mahale, A.; Kumar Singh, S.; Deshmukh, S. Printing Parameters and Materials Affecting Mechanical Properties of FDM-3D Printed Parts: Perspective and Prospects. Mater. Today Proc. 2022, 50, 2269–2275. [Google Scholar] [CrossRef]

- Park, S.; Shou, W.; Makatura, L.; Matusik, W.; Fu, K.K. 3D Printing of Polymer Composites: Materials, Processes, and Applications. Matter 2022, 5, 43–76. [Google Scholar] [CrossRef]

- Jiang, L.; Peng, X.; Walczyk, D. 3D Printing of Biofiber-Reinforced Composites and Their Mechanical Properties: A Review. Rapid Prototyp. J. 2020, 26, 1113–1129. [Google Scholar] [CrossRef]

- Karakurt, I.; Lin, L. 3D Printing Technologies: Techniques, Materials, and Post-Processing. Curr. Opin. Chem. Eng. 2020, 28, 134–143. [Google Scholar] [CrossRef]

- Bodenschatz, U.; Rosenthal, M. 3D Printing of a Wood-Based Furniture Element with Liquid Deposition Modeling. Eur. J. Wood Wood Prod. 2024, 82, 241–244. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Berto, F. 3D Printing of Polymer Composites: A Short Review. Mater. Des. Process. Commun. 2020, 2, e97. [Google Scholar] [CrossRef]

- Mwema, F.M.; Akinlabi, E.T. Basics of Fused Deposition Modelling (FDM). In SpringerBriefs in Applied Sciences and Technology; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1–15. [Google Scholar]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Extrusion-Based Additive Manufacturing Technologies: State of the Art and Future Perspectives. J. Manuf. Process 2022, 83, 607–636. [Google Scholar] [CrossRef]

- Shanmugam, V.; Pavan, M.V.; Babu, K.; Karnan, B. Fused Deposition Modeling Based Polymeric Materials and Their Performance: A Review. Polym. Compos. 2021, 42, 5656–5677. [Google Scholar] [CrossRef]

- Dey, A.; Yodo, N. A Systematic Survey of FDM Process Parameter Optimization and Their Influence on Part Characteristics. J. Manuf. Mater. Process. 2019, 3, 64. [Google Scholar] [CrossRef]

- Algarni, M.; Ghazali, S. Comparative Study of the Sensitivity of PLA, ABS, PEEK, and PETG’s Mechanical Properties to FDM Printing Process Parameters. Crystals 2021, 11, 995. [Google Scholar] [CrossRef]

- Tümer, E.H.; Erbil, H.Y. Extrusion-Based 3D Printing Applications of PLA Composites: A Review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Makki, T.; Vattathurvalappil, S.H.; Theravalappil, R.; Nazir, A.; Alhajeri, A.; Azeem, M.A.; Mahdi, E.; Ummer, A.C.; Ali, U. 3D and 4D Printing: A Review of Virgin Polymers Used in Fused Deposition Modeling. Compos. Part C Open Access 2024, 14, 100472. [Google Scholar] [CrossRef]

- Bouzaglou, O.; Golan, O.; Lachman, N. Process Design and Parameters Interaction in Material Extrusion 3D Printing: A Review. Polymers 2023, 15, 2280. [Google Scholar] [CrossRef]

- Le Guen, M.-J.; Hill, S.; Smith, D.; Theobald, B.; Gaugler, E.; Barakat, A.; Mayer-Laigle, C. Influence of Rice Husk and Wood Biomass Properties on the Manufacture of Filaments for Fused Deposition Modeling. Front. Chem. 2019, 7, 735. [Google Scholar] [CrossRef] [PubMed]

- Chinga-Carrasco, G.; Ehman, N.V.; Filgueira, D.; Johansson, J.; Vallejos, M.E.; Felissia, F.E.; Håkansson, J.; Area, M.C. Bagasse—A Major Agro-Industrial Residue as Potential Resource for Nanocellulose Inks for 3D Printing of Wound Dressing Devices. Addit. Manuf. 2019, 28, 267–274. [Google Scholar] [CrossRef]

- Kangas, H.; Felissia, F.E.; Filgueira, D.; Ehman, N.V.; Vallejos, M.E.; Imlauer, C.M.; Lahtinen, P.; Area, M.C.; Chinga-Carrasco, G. 3D Printing High-Consistency Enzymatic Nanocellulose Obtained from a Soda-Ethanol-O2 Pine Sawdust Pulp. Bioengineering 2019, 6, 60. [Google Scholar] [CrossRef]

- Chinga-Carrasco, G.; Ehman, N.V.; Pettersson, J.; Vallejos, M.E.; Brodin, M.W.; Felissia, F.E.; Håkansson, J.; Area, M.C. Pulping and Pretreatment Affect the Characteristics of Bagasse Inks for Three-Dimensional Printing. ACS Sustain. Chem. Eng. 2018, 6, 4068–4075. [Google Scholar] [CrossRef]

- Ehman, N.; Ponce De León, A.; Felissia, F.; Vallejos, M.; Area, M.C.; Chinga-Carrasco, G. Biocomposites of Polyhydroxyalkanoates and Lignocellulosic Components: A Focus on Biodegradation and 3D Printing. In Bioplastics for Sustainable Development; Springer: Singapore, 2021; pp. 325–345. ISBN 9789811618239. [Google Scholar]

- Hasan, K.M.F.; Rahman, M.M.; Rima, F.K.; Sultana, J.; Taher, M.A.; Horváth, P.G.; Garab, J.; Bejó, L.; Alpár, T. Sustainable Prospects of Lignocellulosic Wood and Natural Fiber-Based Materials in 3D and 4D Printing. Adv. Compos. Hybrid Mater. 2025, 8, 189. [Google Scholar] [CrossRef]

- Ahmed, W.; Alnajjar, F.; Zaneldin, E.; Al-Marzouqi, A.H.; Gochoo, M.; Khalid, S. Implementing FDM 3D Printing Strategies Using Natural Fibers to Produce Biomass Composite. Materials 2020, 13, 4065. [Google Scholar] [CrossRef] [PubMed]

- Ehman, N.V.; Ita-Nagy, D.; Felissia, F.E.; Vallejos, M.E.; Quispe, I.; Area, M.C.; Chinga-Carrasco, G. Biocomposites of Bio-Polyethylene Reinforced with a Hydrothermal-Alkaline Sugarcane Bagasse Pulp and Coupled with a Bio-Based Compatibilizer. Molecules 2020, 25, 2158. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.-T.; Chen, W.-H.; Sarles, P.; Park, Y.-K.; Ok, Y.S. Recover Energy and Materials from Agricultural Waste via Thermochemical Conversion. One Earth 2022, 5, 1200–1204. [Google Scholar] [CrossRef]

- Cho, E.J.; Trinh, L.T.P.; Song, Y.; Lee, Y.G.; Bae, H.-J. Bioconversion of Biomass Waste into High Value Chemicals. Bioresour. Technol. 2020, 298, 122386. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Wang, Y. Recent Progress in the Conversion of Biomass Wastes into Functional Materials for Value-Added Applications. Sci. Technol. Adv. Mater. 2020, 21, 787–804. [Google Scholar] [CrossRef]

- FAO. Technical Platform on the Measurement and Reduction of Food Loss and Waste (TPFLW). Food Loss and Waste Database. Available online: https://www.fao.org/platform-food-loss-waste/flw-data/es (accessed on 20 May 2025).

- Singh, S.; Mishra, N.K.; Yadav, P.K.; Sonkar, S.P. Crop Residues: The Unseen Threat to Environmental Sustainability. Voice Creat. Res. 2025, 7, 12–16. [Google Scholar] [CrossRef]

- Headley, H.; Moonsammy, S.; Davis, H.; Warner, D.; Adams, A.; Timothy Oyedotun, T.D. Modeling Climate Variability and Global Sugarcane Production: Empirical Consideration for Collective Policy Action. Heliyon 2024, 10, e40359. [Google Scholar] [CrossRef]

- FAO. Crops and Livestock Products Database; FAO: Rome, Italy, 2025. [Google Scholar]

- Ungureanu, N.; Vlăduț, V.; Biriș, S.Ș. Sustainable Valorization of Waste and By-Products from Sugarcane Processing. Sustainability 2022, 14, 11089. [Google Scholar] [CrossRef]

- Singh, S.P.; Jawaid, M.; Chandrasekar, M.; Senthilkumar, K.; Yadav, B.; Saba, N.; Siengchin, S. Sugarcane Wastes into Commercial Products: Processing Methods, Production Optimization and Challenges. J. Clean. Prod. 2021, 328, 129453. [Google Scholar] [CrossRef]

- Lee, H.; Jung Sohn, Y.; Jeon, S.; Yang, H.; Son, J.; Jin Kim, Y.; Jae Park, S. Sugarcane Wastes as Microbial Feedstocks: A Review of the Biorefinery Framework from Resource Recovery to Production of Value-Added Products. Bioresour. Technol. 2023, 376, 128879. [Google Scholar] [CrossRef] [PubMed]

- Phiri, R.; Mavinkere Rangappa, S.; Siengchin, S. Agro-Waste for Renewable and Sustainable Green Production: A Review. J. Clean. Prod. 2024, 434, 139989. [Google Scholar] [CrossRef]

- Abd-Rabboh, H.S.M.; Fawy, K.F.; Hamdy, M.S.; Elbehairi, S.I.; Shati, A.A.; Alfaifi, M.Y.; Ibrahium, H.A.; Alamri, S.; Awwad, N.S. Valorization of Rice Husk and Straw Agriculture Wastes of Eastern Saudi Arabia: Production of Bio-Based Silica, Lignocellulose, and Activated Carbon. Materials 2022, 15, 3746. [Google Scholar] [CrossRef]

- Nzereogu, P.U.; Omah, A.D.; Ezema, F.I.; Iwuoha, E.I.; Nwanya, A.C. Silica Extraction from Rice Husk: Comprehensive Review and Applications. Hybrid Adv. 2023, 4, 100111. [Google Scholar] [CrossRef]

- USDA Data and Analysis. Global Production Commodities. Available online: https://www.fas.usda.gov/data/production/commodity/0440000 (accessed on 22 May 2025).

- Silva, L.A.; dos Santos, I.F.S.; Machado, G.d.O.; Tiago Filho, G.L.; Barros, R.M. Rice Husk Energy Production in Brazil: An Economic and Energy Extensive Analysis. J. Clean. Prod. 2021, 290, 125188. [Google Scholar] [CrossRef]

- Canaan, J.M.M.; Brasil, G.S.P.; de Barros, N.R.; Mussagy, C.U.; Guerra, N.B.; Herculano, R.D. Soybean Processing Wastes and Their Potential in the Generation of High Value Added Products. Food Chem. 2022, 373, 131476. [Google Scholar] [CrossRef] [PubMed]

- Tufail, T.; Saeed, F.; Afzaal, M.; Ain, H.B.U.; Gilani, S.A.; Hussain, M.; Anjum, F.M. Wheat Straw: A Natural Remedy against Different Maladies. Food Sci. Nutr. 2021, 9, 2335–2344. [Google Scholar] [CrossRef] [PubMed]

- Thiffault, E.; Gianvenuti, A.; Zuzhang, X.; Walter, S. The Role of Wood Residues in the Transition to Sustainable Bioenergy; FAO: Rome, Italy, 2023; ISBN 978-92-5-137503-7. [Google Scholar]

- Pandey, S. Wood Waste Utilization and Associated Product Development from Under-Utilized Low-Quality Wood and Its Prospects in Nepal. SN Appl. Sci. 2022, 4, 168. [Google Scholar] [CrossRef]

- Halis, R.; Ghazali, A.; Zakarya, I.A. Biofuels from Forest Logging Residues. In Handbook of Biorefinery Research and Technology: Production of Biofuels and Biochemicals; Springer Nature: Singapore, 2024; pp. 593–623. [Google Scholar]

- Silva, M.E.F.; Saetta, R.; Raimondo, R.; Costa, J.M.; Ferreira, J.V.; Brás, I. Forest Waste Composting—Operational Management, Environmental Impacts, and Application. Environ. Sci. Pollut. Res. 2024, 1–17. [Google Scholar] [CrossRef]

- Ramaux, J.; Ziegler-Devin, I.; Besserer, A.; Nouvel, C. 3D Printing of Wood Composites: State of the Art and Opportunities. Polymers 2024, 16, 2827. [Google Scholar] [CrossRef]

- Sikhosana, T.S.; Malebo, N.J.; Mofokeng, T.G.; Motloung, M.P.; Mochane, M.J. Sawdust as a Byproduct of Wood Processing: Properties, Applications and a Reinforcing Filler in Hybrid Polymer Composites. Polymers 2025, 17, 1523. [Google Scholar] [CrossRef]

- Haile, A.; Gelebo, G.G.; Tesfaye, T.; Mengie, W.; Mebrate, M.A.; Abuhay, A.; Limeneh, D.Y. Pulp and Paper Mill Wastes: Utilizations and Prospects for High Value-Added Biomaterials. Bioresour. Bioprocess. 2021, 8, 35. [Google Scholar] [CrossRef]

- Munir, Q.; Afshariantorghabeh, S.; Kärki, T. Industrial Waste Pretreatment Approach for 3D Printing of Sustainable Building Materials. Urban Sci. 2022, 6, 50. [Google Scholar] [CrossRef]

- Turner, T.; Wheeler, R.; Oliver, I.W. Evaluating Land Application of Pulp and Paper Mill Sludge: A Review. J. Environ. Manag. 2022, 317, 115439. [Google Scholar] [CrossRef] [PubMed]

- Narlıoğlu, N.; Salan, T.; Alma, M.H. Properties of 3D-Printed Wood Sawdust-Reinforced PLA Composites. Bioresources 2021, 16, 5467–5480. [Google Scholar] [CrossRef]

- Helaoui, S.; Koubaa, A.; Nouri, H.; Beauregard, M.; Guessasma, S. 3D Printing of Biodegradable Biocomposites Based on Forest Industrial Residues by Fused Deposition Modeling. Ind. Crops Prod. 2024, 222, 119799. [Google Scholar] [CrossRef]

- Argyropoulos, D.D.S.; Crestini, C.; Dahlstrand, C.; Furusjö, E.; Gioia, C.; Jedvert, K.; Henriksson, G.; Hulteberg, C.; Lawoko, M.; Pierrou, C.; et al. Kraft Lignin: A Valuable, Sustainable Resource, Opportunities and Challenges. ChemSusChem 2023, 16, e202300492. [Google Scholar] [CrossRef]

- Frasca, S.; Katsiotis, C.S.; Henrik-Klemens, Å.; Larsson, A.; Strømme, M.; Lindh, J.; Galkin, M.V.; Gising, J. Compatibility of Kraft Lignin and Phenol-Organosolv Lignin with PLA in 3D Printing and Assessment of Mechanical Recycling. ACS Appl. Polym. Mater. 2024, 6, 13574–13584. [Google Scholar] [CrossRef]

- Yang, J.; An, X.; Lu, B.; Cao, H.; Cheng, Z.; Tong, X.; Liu, H.; Ni, Y. Lignin: A Multi-Faceted Role/Function in 3D Printing Inks. Int. J. Biol. Macromol. 2024, 267, 131364. [Google Scholar] [CrossRef] [PubMed]

- Bhayana, M.; Singh, J.; Sharma, A.; Gupta, M. A Review on Optimized FDM 3D Printed Wood/PLA Bio Composite Material Characteristics. Mater. Today Proc. 2023, in press. [CrossRef]

- Ni, Z.; Shi, J.; Li, M.; Lei, W.; Yu, W. FDM 3D Printing and Soil-Burial-Degradation Behaviors of Residue of Astragalus Particles/Thermoplastic Starch/Poly(Lactic Acid) Biocomposites. Polymers 2023, 15, 2382. [Google Scholar] [CrossRef] [PubMed]

- Lendvai, L.; Fekete, I.; Jakab, S.K.; Szarka, G.; Verebélyi, K.; Iván, B. Influence of Environmental Humidity during Filament Storage on the Structural and Mechanical Properties of Material Extrusion 3D-Printed Poly(Lactic Acid) Parts. Results Eng. 2024, 24, 103013. [Google Scholar] [CrossRef]

- Das, A.K.; Agar, D.A.; Rudolfsson, M.; Larsson, S.H. A Review on Wood Powders in 3D Printing: Processes, Properties and Potential Applications. J. Mater. Res. Technol. 2021, 15, 241–255. [Google Scholar] [CrossRef]

- Jasiński, W.; Szymanowski, K.; Nasiłowska, B.; Barlak, M.; Betlej, I.; Prokopiuk, A.; Borysiuk, P. 3D Printing Wood–PLA Composites: The Impact of Wood Particle Size. Polymers 2025, 17, 1165. [Google Scholar] [CrossRef]

- Chien, Y.-C.; Yang, T.-C. Properties of Heat-Treated Wood Fiber–Polylactic Acid Composite Filaments and 3D-Printed Parts Using Fused Filament Fabrication. Polymers 2024, 16, 302. [Google Scholar] [CrossRef] [PubMed]

- Agaliotis, E.M.; Ake-Concha, B.D.; May-Pat, A.; Morales-Arias, J.P.; Bernal, C.; Valadez-Gonzalez, A.; Herrera-Franco, P.J.; Proust, G.; Koh-Dzul, J.F.; Carrillo, J.G.; et al. Tensile Behavior of 3D Printed Polylactic Acid (PLA) Based Composites Reinforced with Natural Fiber. Polymers 2022, 14, 3976. [Google Scholar] [CrossRef]

- Lemos Cosse, R.; van den Berg, T.; Voet, V.; Folkersma, R.; Loos, K. Innovative Approaches for Manufacturing Epoxy-Modified Wood and Cellulose Fiber Composites: A Comparison between Injection Molding and 3D Printing. Chempluschem 2024, 89, e202300714. [Google Scholar] [CrossRef]

- Estakhrianhaghighi, E.; Mirabolghasemi, A.; Zhang, Y.; Lessard, L.; Akbarzadeh, A. 3D-Printed Wood-Fiber Reinforced Architected Cellular Composites. Adv. Eng. Mater. 2020, 22, 2000565. [Google Scholar] [CrossRef]

- Huang, Y.; Löschke, S.; Proust, G. In the Mix: The Effect of Wood Composition on the 3D Printability and Mechanical Performance of Wood-Plastic Composites. Compos. Part C Open Access 2021, 5, 100140. [Google Scholar] [CrossRef]

- Yu, W.; Dong, L.; Lei, W.; Zhou, Y.; Pu, Y.; Zhang, X. Effects of Rice Straw Powder (RSP) Size and Pretreatment on Properties of FDM 3D-Printed RSP/Poly(Lactic Acid) Biocomposites. Molecules 2021, 26, 3234. [Google Scholar] [CrossRef]

- Surendran, A.N.; Malayil, S.; Satyavolu, J.; Kate, K. Influence of Chemical Pretreatment on the Mechanical, Chemical, and Interfacial Properties of 3D-Printed, Rice-Husk-Fiber-Reinforced Composites. J. Compos. Sci. 2023, 7, 357. [Google Scholar] [CrossRef]

- Ponce de León, A.; Ehman, N.; Curi, L.M.; Vallejos, M.E.; Area, M.C. Exploring the Potential of Nanocellulose-Reinforced Polyhydroxyalkanoate Biocomposites for Single-Use Food Packaging. A Review. J. Reinf. Plast. Compos. 2025, in press. [CrossRef]

- Yu, W.; Li, M.; Lei, W.; Pu, Y.; Sun, K.; Ma, Y. Effects of Wood Flour (WF) Pretreatment and the Addition of a Toughening Agent on the Properties of FDM 3D-Printed WF/Poly(Lactic Acid) Biocomposites. Molecules 2022, 27, 2985. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Feng, X.; Xu, M.; Rodrigue, D. Printability and Properties of 3D-Printed Poplar Fiber/Polylactic Acid Biocomposite. Bioresources 2021, 16, 2774–2788. [Google Scholar] [CrossRef]

- Tao, Y.; Liu, M.; Han, W.; Li, P. Waste Office Paper Filled Polylactic Acid Composite Filaments for 3D Printing. Compos. B Eng. 2021, 221, 108998. [Google Scholar] [CrossRef]

- Tokdemir, V.; Altun, S. A Case Study of Wood Thermoplastic Composite Filament for 3D Printing. Bioresources 2021, 17, 21–36. [Google Scholar] [CrossRef]

- Jamadi, A.H.; Razali, N.; Petrů, M.; Taha, M.M.; Muhammad, N.; Ilyas, R.A. Effect of Chemically Treated Kenaf Fibre on Mechanical and Thermal Properties of PLA Composites Prepared through Fused Deposition Modeling (FDM). Polymers 2021, 13, 3299. [Google Scholar] [CrossRef]

- Han, S.N.M.F.; Taha, M.M.; Mansor, M.R.; Rahman, M.A.A. Investigation of Tensile and Flexural Properties of Kenaf Fiber-Reinforced Acrylonitrile Butadiene Styrene Composites Fabricated by Fused Deposition Modeling. J. Eng. Appl. Sci. 2022, 69, 52. [Google Scholar] [CrossRef]

- Aumnate, C.; Soatthiyanon, N.; Makmoon, T.; Potiyaraj, P. Polylactic Acid/Kenaf Cellulose Biocomposite Filaments for Melt Extrusion Based-3D Printing. Cellulose 2021, 28, 8509–8525. [Google Scholar] [CrossRef]

- Giani, N.; Maccaferri, E.; Benelli, T.; Bovo, M.; Torreggiani, D.; Campari, E.G.; Tassinari, P.; Giorgini, L.; Mazzocchetti, L. Valorization of Agro-Wastes as Fillers in PLA-Based Biocomposites for Increasing Sustainability in Fused Deposition Modeling Additive Manufacturing. Materials 2024, 17, 1421. [Google Scholar] [CrossRef]

- Barreto, G.; Restrepo, S.; Vieira, C.M.; Monteiro, S.N.; Colorado, H.A. Rice Husk with PLA: 3D Filament Making and Additive Manufacturing of Samples for Potential Structural Applications. Polymers 2024, 16, 245. [Google Scholar] [CrossRef]

- Scaffaro, R.; Gulino, E.F.; Citarrella, M.C.; Maio, A. Green Composites Based on Hedysarum Coronarium with Outstanding FDM Printability and Mechanical Performance. Polymers 2022, 14, 1198. [Google Scholar] [CrossRef]

- Jiang, J.; Gu, H.; Li, B.; Zhang, J. Preparation and Properties of Straw/PLA Wood Plastic Composites for 3D Printing. IOP Conf. Ser. Earth Environ. Sci. 2021, 692, 032004. [Google Scholar] [CrossRef]

- Maldonado-García, B.; Pal, A.K.; Misra, M.; Gregori, S.; Mohanty, A.K. Sustainable 3D Printed Composites from Recycled Ocean Plastics and Pyrolyzed Soy-Hulls: Optimization of Printing Parameters, Performance Studies and Prototypes Development. Compos. Part C Open Access 2021, 6, 100197. [Google Scholar] [CrossRef]

- Ali, S.; Deiab, I.; Pervaiz, S.; Eltaggaz, A. Development of Sustainable Polymer Composite with Agro-industrial Residue for Biomedical Applications. Polym. Eng. Sci. 2025, 65, 1922–1933. [Google Scholar] [CrossRef]

- Balla, V.K.; Tadimeti, J.G.D.; Kate, K.H.; Satyavolu, J. 3D Printing of Modified Soybean Hull Fiber/Polymer Composites. Mater. Chem. Phys. 2020, 254, 123452. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Ishak, M.R.; Mohammad Taha, M.; Mustapha, F.; Leman, Z. Irianto Mechanical, Thermal and Physical Characteristics of Oil Palm (Elaeis guineensis) Fiber Reinforced Thermoplastic Composites for FDM—Type 3D Printer. Polym. Test. 2023, 120, 107972. [Google Scholar] [CrossRef]

- Figueroa-Velarde, V.; Diaz-Vidal, T.; Cisneros-López, E.O.; Robledo-Ortiz, J.R.; López-Naranjo, E.J.; Ortega-Gudiño, P.; Rosales-Rivera, L.C. Mechanical and Physicochemical Properties of 3D-Printed Agave Fibers/Poly(Lactic) Acid Biocomposites. Materials 2021, 14, 3111. [Google Scholar] [CrossRef]

- Ahmed, S.S.; Abdul-Hamead, A.A.; Flaieh, E.H.; Abdulhameed, S.A. Effect of Seed Husk Waste Powder on the PLA Medical Thread Properties Fabricated via 3D Printer. Curved Layer. Struct. 2024, 11, 20220222. [Google Scholar] [CrossRef]

- Da Silva Fortes, A.G.; De Abreu, I.R.; De Sousa Nascimento Junior, R.; De França, R.A.; Dos Santos Rosa, A.C.F.; De Farias Braz, C.J.; De Carvalho, L.H.; Barbosa, R.; Alves, T.S. Development of Biodegradable Filaments Based on Agro-industrial Waste and Evaluation of Process Parameters in Final Properties. Polym. Compos. 2024, 45, 3683–3699. [Google Scholar] [CrossRef]

- Calì, M.; Pascoletti, G.; Gaeta, M.; Milazzo, G.; Ambu, R. A New Generation of Bio-Composite Thermoplastic Filaments for a More Sustainable Design of Parts Manufactured by FDM. Appl. Sci. 2020, 10, 5852. [Google Scholar] [CrossRef]

- Aliotta, L.; Sergi, C.; Pont, B.D.; Coltelli, M.-B.; Gigante, V.; Lazzeri, A. Sustainable 3D Printed Poly (Lactic Acid) (PLA)/Hazelnut Shell Powder Bio Composites for Design Applications. Mater. Today Sustain. 2024, 26, 100780. [Google Scholar] [CrossRef]

- Song, X.; He, W.; Han, X.; Qin, H. Fused Deposition Modeling of Poly (Lactic Acid)/Nutshells Composite Filaments: Effect of Alkali Treatment. J. Polym. Environ. 2020, 28, 3139–3152. [Google Scholar] [CrossRef]

- Hosseinzadeh, M.H.; Azarniya, A.; Hassanpour, M.; Borhan Panah, M.R.; Hajitabar, A.; Bafetrat, H.A.; Yazdi, M.S. Beyond Standard ABS: Recent Advances in Modified and Composite Filaments Prepared for Fused Deposition Modeling. Heliyon 2025, 11, e43051. [Google Scholar] [CrossRef]

- Väisänen, A.; Alonen, L.; Ylönen, S.; Hyttinen, M. Volatile Organic Compound and Particulate Emissions from the Production and Use of Thermoplastic Biocomposite 3D Printing Filaments. J. Occup. Environ. Hyg. 2022, 19, 381–393. [Google Scholar] [CrossRef] [PubMed]

- Wojnowski, W.; Marć, M.; Kalinowska, K.; Kosmela, P.; Zabiegała, B. Emission Profiles of Volatiles during 3D Printing with ABS, ASA, Nylon, and PETG Polymer Filaments. Molecules 2022, 27, 3814. [Google Scholar] [CrossRef] [PubMed]

- Yousaf, A.; Al Rashid, A.; Polat, R.; Koç, M. Potential and Challenges of Recycled Polymer Plastics and Natural Waste Materials for Additive Manufacturing. Sustain. Mater. Technol. 2024, 41, e01103. [Google Scholar] [CrossRef]

- Gomes, T.E.; Cadete, M.S.; Dias-de-Oliveira, J.; Neto, V. Controlling the Properties of Parts 3D Printed from Recycled Thermoplastics: A Review of Current Practices. Polym. Degrad. Stab. 2022, 196, 109850. [Google Scholar] [CrossRef]

- Ntrivala, M.A.; Pitsavas, A.C.; Lazaridou, K.; Baziakou, Z.; Karavasili, D.; Papadimitriou, M.; Ntagkopoulou, C.; Balla, E.; Bikiaris, D.N. Polycaprolactone (PCL): The Biodegradable Polyester Shaping the Future of Materials—A Review on Synthesis, Properties, Biodegradation, Applications and Future Perspectives. Eur. Polym. J. 2025, 234, 114033. [Google Scholar] [CrossRef]

- Zarna, C.; Opedal, M.T.; Echtermeyer, A.T.; Chinga-Carrasco, G. Reinforcement Ability of Lignocellulosic Components in Biocomposites and Their 3D Printed Applications—A Review. Compos. Part C Open Access 2021, 6, 100171. [Google Scholar] [CrossRef]

- Papanicolaou, G.C.; Portan, D.V.; Kontaxis, L.C. Interrelation between Fiber–Matrix Interphasial Phenomena and Flexural Stress Relaxation Behavior of a Glass Fiber–Polymer Composite. Polymers 2021, 13, 978. [Google Scholar] [CrossRef] [PubMed]

- Allen, K.A.; Kearney, L.T.; Gupta, S.; Ghossein, H.; Keum, J.K.; Damron, J.T.; Humphrey, H.E.; Vaidya, U.; Naskar, A.K. Understanding Interfacial Crystallization Dynamics on Carbon Fiber Reinforced Polypropylene Composite Manufacturing. Compos. B Eng. 2025, 291, 112027. [Google Scholar] [CrossRef]

- Mohammed, M.; Rasidi, M.; Mohammed, A.; Rahman, R.; Osman, A.; Adam, T.; Betar, B.; Dahham, O. Interfacial Bonding Mechanisms of Natural Fibre-Matrix Composites: An Overview. Bioresources 2022, 17, 7031. [Google Scholar] [CrossRef]

- Huang, S.; Fu, Q.; Yan, L.; Kasal, B. Characterization of Interfacial Properties between Fibre and Polymer Matrix in Composite Materials—A Critical Review. J. Mater. Res. Technol. 2021, 13, 1441–1484. [Google Scholar] [CrossRef]

- Hejna, A.; Przybysz-Romatowska, M.; Kosmela, P.; Zedler, Ł.; Korol, J.; Formela, K. Recent Advances in Compatibilization Strategies of Wood-Polymer Composites by Isocyanates. Wood Sci. Technol. 2020, 54, 1091–1119. [Google Scholar] [CrossRef]

- Yang, M.; Su, J.; Zheng, Y.; Fang, C.; Lei, W.; Li, L. Effect of Different Silane Coupling Agents on Properties of Waste Corrugated Paper Fiber/Polylactic Acid Composites. Polymers 2023, 15, 3525. [Google Scholar] [CrossRef]

- Seo, Y.-R.; Kim, B.-J. Fused Filament Fabrication of Poly (Lactic Acid) Reinforced with Silane-Treated Cellulose Fiber for 3D Printing. J. Korean Wood Sci. Technol. 2024, 52, 205–220. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, S.; Zhang, L.; Che, M.; Huang, R.; Cui, M.; Qi, W.; Su, R. Mechanical Properties and Interfacial Adhesion Mechanism of Polyolefin Composites Reinforced with Ethylene Vinyl Alcohol-Coated Cellulose Microfibers. Chem. Eng. J. 2025, 506, 159910. [Google Scholar] [CrossRef]

- da Silveira, P.H.P.M.; dos Santos, M.C.C.; Chaves, Y.S.; Ribeiro, M.P.; Marchi, B.Z.; Monteiro, S.N.; Gomes, A.V.; Tapanes, N.d.L.C.O.; Pereira, P.S.d.C.; Bastos, D.C. Characterization of Thermo-Mechanical and Chemical Properties of Polypropylene/Hemp Fiber Biocomposites: Impact of Maleic Anhydride Compatibilizer and Fiber Content. Polymers 2023, 15, 3271. [Google Scholar] [CrossRef] [PubMed]

- Cakir Yigit, N.; Karagoz, I. A Review of Recent Advances in Bio-Based Polymer Composite Filaments for 3D Printing. Polym. -Plast. Technol. Mater. 2023, 62, 1077–1095. [Google Scholar] [CrossRef]

- Sukmawan, R.; Kusmono; Wildan, M.W. Study of Alkali and Acetylation Treatments on Sisal Fibers Compatibility with Low-Amine/Epoxy Stoichiometric Ratio. Results Eng. 2024, 24, 103127. [Google Scholar] [CrossRef]

- Chanda, S.; Bajwa, D.S.; Holt, G.A.; Stark, N.; Bajwa, S.G.; Quadir, M. Silane Compatibilzation to Improve the Dispersion, Thermal and Mechancial Properties of Cellulose Nanocrystals in Poly (Ethylene Oxide). Nanocomposites 2021, 7, 87–96. [Google Scholar] [CrossRef]

- Mohammed, M.; Rahman, R.; Mohammed, A.M.; Adam, T.; Betar, B.O.; Osman, A.F.; Dahham, O.S. Surface Treatment to Improve Water Repellence and Compatibility of Natural Fiber with Polymer Matrix: Recent Advancement. Polym. Test. 2022, 115, 107707. [Google Scholar] [CrossRef]

- Shaqour, B.; Abuabiah, M.; Abdel-Fattah, S.; Juaidi, A.; Abdallah, R.; Abuzaina, W.; Qarout, M.; Verleije, B.; Cos, P. Gaining a Better Understanding of the Extrusion Process in Fused Filament Fabrication 3D Printing: A Review. Int. J. Adv. Manuf. Technol. 2021, 114, 1279–1291. [Google Scholar] [CrossRef]

- Agrawal, K.; Bhat, A.R. Advances in 3D Printing with Eco-Friendly Materials: A Sustainable Approach to Manufacturing. RSC Sustain. 2025, 3, 2582–2604. [Google Scholar] [CrossRef]

- Dananjaya, S.A.V.; Chevali, V.S.; Dear, J.P.; Potluri, P.; Abeykoon, C. 3D Printing of Biodegradable Polymers and Their Composites—Current State-of-the-Art, Properties, Applications, and Machine Learning for Potential Future Applications. Prog. Mater. Sci. 2024, 146, 101336. [Google Scholar] [CrossRef]

- Justino Netto, J.M.; Sarout, A.I.; Santos, A.L.G.; Lucas, A.d.A.; Chinelatto, M.A.; Alves, J.L.; Gaspar-Cunha, A.; Covas, J.A.; Silveira, Z.d.C. Design and Validation of an Innovative 3D Printer Containing a Co-Rotating Twin Screw Extrusion Unit. Addit. Manuf. 2022, 59, 103192. [Google Scholar] [CrossRef]

- Mogan, J.; Harun, W.S.W.; Kadirgama, K.; Ramasamy, D.; Foudzi, F.M.; Sulong, A.B.; Tarlochan, F.; Ahmad, F. Fused Deposition Modelling of Polymer Composite: A Progress. Polymers 2022, 15, 28. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Janarthanan, G.; Tran, H.N.; Ham, H.J.; Yoon, J.; Noh, I. Bioink Homogeneity Control during 3D Bioprinting of Multicomponent Micro/Nanocomposite Hydrogel for Even Tissue Regeneration Using Novel Twin Screw Extrusion System. Chem. Eng. J. 2021, 415, 128971. [Google Scholar] [CrossRef]

- Ehman, N.; Rodríguez-Fabià, S.; Andreassen, E.; Persson, A.M.R.; Chinga-Carrasco, G. Effect of Thermomechanical Pulp Fibers and Clay on the Characteristics of High- and Low-density Polyethylene Biocomposites. Polym. Compos. 2025, 46, 10460–10473. [Google Scholar] [CrossRef]

- Gašparík, M.; Gaff, M.; Kačík, F.; Sikora, A. Color and Chemical Changes in Teak (Tectona grandis L. f.) and Meranti (Shorea spp.) Wood after Thermal Treatment. Bioresources 2019, 14, 2667–2683. [Google Scholar] [CrossRef]

- Anerao, P.; Kulkarni, A.; Munde, Y. A Review on Exploration of the Mechanical Characteristics of 3D-Printed Biocomposites Fabricated by Fused Deposition Modelling (FDM). Rapid Prototyp. J. 2024, 30, 430–440. [Google Scholar] [CrossRef]

- Yang, T.-C.; Yeh, C.-H. Morphology and Mechanical Properties of 3D Printed Wood Fiber/Polylactic Acid Composite Parts Using Fused Deposition Modeling (FDM): The Effects of Printing Speed. Polymers 2020, 12, 1334. [Google Scholar] [CrossRef] [PubMed]

- Almeida, V.H.M.; Jesus, R.M.; Santana, G.M.; Pereira, T.B. Polylactic Acid Polymer Matrix (Pla) Biocomposites with Plant Fibers for Manufacturing 3D Printing Filaments: A Review. J. Compos. Sci. 2024, 8, 67. [Google Scholar] [CrossRef]

- Ulkir, O.; Akgun, G.; Karadag, A. Mechanical Behavior Prediction of 3D-Printed PLA/Wood Composites Using Artificial Neural Network and Fuzzy Logic. Polym. Adv. Technol. 2025, 36, e70103. [Google Scholar] [CrossRef]

- Algarni, M. The Influence of Raster Angle and Moisture Content on the Mechanical Properties of PLA Parts Produced by Fused Deposition Modeling. Polymers 2021, 13, 237. [Google Scholar] [CrossRef] [PubMed]

- Ramírez-Prieto, J.S.; Martínez-Yáñez, J.S.; González-Hernández, A.G. Effect of Raster Angle on the Tensile and Flexural Strength of 3D Printed PLA+ Parts. AIMS Mater. Sci. 2025, 12, 363–379. [Google Scholar] [CrossRef]

- Yeoh, C.K.; Cheah, C.S.; Pushpanathan, R.; Song, C.C.; Tan, M.A.; Teh, P.L. Effect of Infill Pattern on Mechanical Properties of 3D Printed PLA and CPLA. IOP Conf. Ser. Mater. Sci. Eng. 2020, 957, 012064. [Google Scholar] [CrossRef]

- Nafis, Z.A.S.; Nuzaimah, M.; Kudus, S.I.A.; Yusuf, Y.; Ilyas, R.A.; Knight, V.F.; Norrrahim, M.N.F. Effect of Wood Dust Fibre Treatments Reinforcement on the Properties of Recycled Polypropylene Composite (r-WoPPC) Filament for Fused Deposition Modelling (FDM). Materials 2023, 16, 479. [Google Scholar] [CrossRef]

- Nasir, M.H.M.; Taha, M.M.; Razali, N.; Ilyas, R.A.; Knight, V.F.; Norrrahim, M.N.F. Effect of Chemical Treatment of Sugar Palm Fibre on Rheological and Thermal Properties of the PLA Composites Filament for FDM 3D Printing. Materials 2022, 15, 8082. [Google Scholar] [CrossRef]

- Pereira, D.F.; Branco, A.C.; Cláudio, R.; Marques, A.C.; Figueiredo-Pina, C.G. Development of Composites of PLA Filled with Different Amounts of Rice Husk Fibers for Fused Deposition Modeling. J. Nat. Fibers 2023, 20, 2162183. [Google Scholar] [CrossRef]

- Wang, L.; Yong, L.X.; Loo, S.C.J. Utilizing Food Waste in 3D-Printed PLA Formulations to Achieve Sustainable and Customizable Controlled Delivery Systems. ACS Omega 2024, 9, 34140–34150. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Ji, C.; Sun, L.; Sun, J.; Liu, J. Cellulose Nanofibrils Filled Poly(Lactic Acid) Biocomposite Filament for FDM 3D Printing. Molecules 2020, 25, 2319. [Google Scholar] [CrossRef]

- Zanini, N.; Carneiro, E.; Menezes, L.; Barud, H.; Mulinari, D. Palm Fibers Residues from Agro-Industries as Reinforcement in Biopolymer Filaments for 3D-Printed Scaffolds. Fibers Polym. 2021, 22, 2689–2699. [Google Scholar] [CrossRef]

- Zarna, C.; Chinga-Carrasco, G.; Echtermeyer, A.T. Bending Properties and Numerical Modelling of Cellular Panels Manufactured from Wood Fibre/PLA Biocomposite by 3D Printing. Compos. Part A Appl. Sci. Manuf. 2023, 165, 107368. [Google Scholar] [CrossRef]

- Kennedy, S.M.; Wilson, L.A.; Agu M, J.; D, R.; RB, J.R.; S, B. Natural Fiber Filaments Transforming the Future of Sustainable 3D Printing. MethodsX 2025, 14, 103385. [Google Scholar] [CrossRef] [PubMed]

- Unkarbon. Innovating Natural Fibres for High Performance Composites. 2025. Available online: https://www.unkarbon.earth/materials (accessed on 10 August 2025).

- UPM. UPM Develops a Truly Wood Based Biocomposite Material with up to 100% Renewable Resources—Utilising Residues from Pulp Production, Not Compromising the Food Chain. 2025. Available online: https://www.upm.com/about-us/for-media/releases/2020/03/upm-develops-a-truly-wood-based-biocomposite-material-with-up-to-100--renewable-resources--utilising-residues-from-pulp-production-not-compromising-the-food-chain/ (accessed on 10 August 2025).

- Ali, M.H.; Kurokawa, S.; Shehab, E.; Mukhtarkhanov, M. Development of a Large-Scale Multi-Extrusion FDM Printer, and Its Challenges. Int. J. Lightweight Mater. Manuf. 2023, 6, 198–213. [Google Scholar] [CrossRef]

- Saavedra-Rojas, F.A.; Bhandari, S.; Lopez-Anido, R.A. Environmental Durability of Bio-Based and Synthetic Thermoplastic Composites in Large-Format Additive Manufacturing. Polymers 2024, 16, 787. [Google Scholar] [CrossRef]

- El-Mahdy, D.; Marais, E.; AbdelRahim, M.; Dubor, A.; Cabay, E. Life Cycle Assessment of Earth-Based Residential Unit “TOVA”: A 3D Printed on-Site Load-Bearing Structure. Case Stud. Constr. Mater. 2025, 23, e04925. [Google Scholar] [CrossRef]

- Raza, M.H.; Besklubova, S.; Zhong, R.Y. Economic Analysis of Offsite and Onsite 3D Construction Printing Techniques for Low-Rise Buildings: A Comparative Value Stream Assessment. Addit. Manuf. 2024, 89, 104292. [Google Scholar] [CrossRef]

- Choudhuri, B.; Uddin, M.F.; Sen, R. Review on 3D Printing Technology in Automotive Industry and Electric Vehicle. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2025, in press. [CrossRef]

- Chen, Y. Advantages of 3D Printing for Circular Economy and Its Influence on Designers. Proc. Des. Soc. 2022, 2, 991–1000. [Google Scholar] [CrossRef]

- Rigamonti, L.; Mancini, E. Life Cycle Assessment and Circularity Indicators. Int. J. Life Cycle Assess. 2021, 26, 1937–1942. [Google Scholar] [CrossRef]

- Ulkir, O. Energy-Consumption-Based Life Cycle Assessment of Additive-Manufactured Product with Different Types of Materials. Polymers 2023, 15, 1466. [Google Scholar] [CrossRef] [PubMed]

- Suárez, L.; Domínguez, M. Sustainability and Environmental Impact of Fused Deposition Modelling (FDM) Technologies. Int. J. Adv. Manuf. Technol. 2020, 106, 1267–1279. [Google Scholar] [CrossRef]

- Kumar, R.; Sharma, H.; Saran, C.; Tripathy, T.S.; Sangwan, K.S.; Herrmann, C. A Comparative Study on the Life Cycle Assessment of a 3D Printed Product with PLA, ABS & PETG Materials. Procedia CIRP 2022, 107, 15–20. [Google Scholar] [CrossRef]

- Farhan, M.; Mohammad Taha, M.; Yusuf, Y.; Azwan Sundi, S.; Zakaria, N.H. Environmental Assessment on Fabrication of Bio-Composite Filament Fused Deposition Modeling Through Life Cycle Analysis. Pertanika J. Sci. Technol. 2024, 32, 37–48. [Google Scholar] [CrossRef]

- Hernandez, M.E.; Albajez, J.A.; Lamban, M.P.; Royo, J.; Santolaria, J.; Ng Corrales, L.C. Fused Deposition Modelling Process Environmental Performance through the Carbon Footprint Evaluation. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1193, 012127. [Google Scholar] [CrossRef]

- Napolitano, F.; Cozzolino, E.; Papa, I.; Astarita, A.; Squillace, A. Experimental Integrated Approach for Mechanical Characteristic Optimization of FDM-Printed PLA in an Energy-Saving Perspective. Int. J. Adv. Manuf. Technol. 2022, 121, 3551–3565. [Google Scholar] [CrossRef]

- Marton, A.M.S.; Monticeli, F.M.; Zanini, N.C.; Barbosa, R.F.S.; Medeiros, S.F.; Rosa, D.S.; Mulinari, D.R. Revalorization of Australian Royal Palm (Archontophoenix alexandrae) Waste as Reinforcement in Acrylonitrile Butadiene Styrene (ABS) for Use in 3D Printing Pen. J. Clean. Prod. 2022, 365, 132808. [Google Scholar] [CrossRef]

- Yusuf, Y.; Wong, C.Y.; Mastura, M.T.; Mustafa, N.; Che Daud, Z. NEW WOOD DUST REINFORCED RECYCLED POLYPROPYLENE COMPOSITE FILAMENT AND TRADITIONAL POLYPROPYLENE FILAMENT FOR FDM APPLICATIONS: LIFE CYCLE ASSESSMENT STUDY. J. Sustain. Sci. Manag. 2023, 18, 157–170. [Google Scholar] [CrossRef]

- Ehman, N.; Fabià, S.R.; Catalán, J.; Chinga-Carrasco, G. Emission Risks in Processing and Conversion of Lignocellulose-Based Biocomposites. Compos. Part C Open Access 2025, 17, 100595. [Google Scholar] [CrossRef]

- UN Environmental Programme. From Pollution to Solution: A Global Assessment of Marine Litter and Plastic Pollution; UN Environmental Programme: Nairobi, Kenya, 2022. [Google Scholar]

- Folino, A.; Pangallo, D.; Calabrò, P.S. Assessing Bioplastics Biodegradability by Standard and Research Methods: Current Trends and Open Issues. J. Environ. Chem. Eng. 2023, 11, 109424. [Google Scholar] [CrossRef]

- ASTM D5338-15(2021); Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials Under Controlled Composting Conditions, Incorporating Thermophilic Temperatures. ASTM International: West Conshohocken, PA, USA, 2021; Last Updated: 20 January 2021. Available online: https://store.astm.org/d5338-15r21.html (accessed on 14 August 2025).

- ISO 14855-1:2012; Determination of the Ultimate Aerobic Biodegradability of Plastic Materials Under Controlled Composting Conditions—Method by Analysis of Evolved Dioxide—Part 1: General Method. ISO: Geneva, Switzerland, 2012. Available online: https://www.iso.org/obp/ui#iso:std:iso:14855:-1:ed-2:v1:en (accessed on 14 August 2025).

- ASTM 5988-18(2025); Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials in Soil. ASTM International: West Conshohocken, PA, USA, 2018; Last Updated: 12 February 2025. Available online: https://store.astm.org/d5988-18r25.html (accessed on 14 August 2025).

- ISO 17556:2019; Plastics—Determination of the Ultimate Aerobic Biodegradability of Plastic Materials in Soil by Measuring the Oxygen Demand in a Respirometer or the Amount of Carbon Dioxide Evolved. ISO: Geneva, Switzerland, 2019. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:17556:ed-3:v1:en (accessed on 14 August 2025).

- ASTM D5526-18; Standard Test Method for Determining Anaerobic Biodegradation of Plastic Materials Under Accelerated Landfill Conditions. ASTM International: West Conshohocken, PA, USA, 2018. Available online: https://store.accuristech.com/standards/astm-d5526-18?product_id=2025615 (accessed on 15 August 2025).

- ASTM D5511-18; Standard Test Method for Determining Anaerobic Biodegradation of Plastic Materials Under High-Solids Anaerobic-Digestion Conditions. ASTM International: West Conshohocken, PA, USA, 2018. Available online: https://store.astm.org/d5511-18.html (accessed on 15 August 2025).

- ISO 15985:2014; Plastics—Determination of the Ultimate Anaerobic Biodegradation Under High-Solids Anaerobic-Digestion Conditions—Method by Analysis of Released Biogas. ISO: Geneva, Switzerland, 2014. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:15985:ed-2:v1:en (accessed on 15 August 2025).

- ISO 11734:1995; Water Quality—Evaluation of the "Ultimate" Anaerobic Biodegradability of Organic Compounds in Digested Sludge—Method by Measurement of the Biogas Production. ISO: Geneva, Switzerland, 1995. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:11734:ed-1:v1:en (accessed on 15 August 2025).

- ASTM D6691-24a; Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials in the Marine Environment by a Defined Microbial Consortium or Natural Sea Water Inoculum. ASTM International: West Conshohocken, PA, USA, 2024. Available online: https://store.astm.org/d6691-24a.html (accessed on 15 August 2025).

- ISO 19679:2020; Plastics—Determination of Aerobic Biodegradation of Non-Floating Plastic Materials in A Seawater/Sediment Interface—Method by Analysis of Evolved Carbon Dioxide. ISO: Geneva, Switzerland, 2020. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:19679:ed-2:v1:en (accessed on 15 August 2025).

- ISO 22404:2019; Plastics—Determination of the Aerobic Biodegradation of Non-Floating Materials Exposed to Marine Sediment—Method by Analysis of Evolved Carbon Dioxide. ISO: Geneva, Switzerland, 2019. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:22404:ed-1:v1:en (accessed on 15 August 2025).

- Easton, Z.H.W.; Essink, M.A.J.; Rodriguez Comas, L.; Wurm, F.R.; Gojzewski, H. Acceleration of Biodegradation Using Polymer Blends and Composites. Macromol. Chem. Phys. 2023, 224, 2200421. [Google Scholar] [CrossRef]

- Bhagia, S.; Bornani, K.; Agrawal, R.; Satlewal, A.; Ďurkovič, J.; Lagaňa, R.; Bhagia, M.; Yoo, C.G.; Zhao, X.; Kunc, V.; et al. Critical Review of FDM 3D Printing of PLA Biocomposites Filled with Biomass Resources, Characterization, Biodegradability, Upcycling and Opportunities for Biorefineries. Appl. Mater. Today 2021, 24, 101078. [Google Scholar] [CrossRef]

- Mazur, J.; Sobczak, P.; Panasiewicz, M.; Łusiak, P.; Krajewska, M.; Findura, P.; Obidziński, S.; Żukiewicz-Sobczak, W. Mechanical Properties and Biodegradability of Samples Obtained by 3D Printing Using FDM Technology from PLA Filament with By-Products. Sci. Rep. 2025, 15, 5847. [Google Scholar] [CrossRef] [PubMed]

- Ingle, A.P.; Saxena, S.; Moharil, M.P.; Rivaldi, J.D.; Ramos, L.; Chandel, A.K. Production of Biomaterials and Biochemicals from Lignocellulosic Biomass through Sustainable Approaches: Current Scenario and Future Perspectives. Biotechnol. Sustain. Mater. 2025, 2, 3. [Google Scholar] [CrossRef]

| Characteristics | Non-Biodegradable Matrices | Biodegradable Matrices |

|---|---|---|

| Type | ABS. PETG. Conventional polymers: Nylon, PE, PP, PS, PC, PET. Biobased alternatives: Bio-PE, Bio-PP, Bio-Nylon, Bio-PC | Cellulose, lignin, starch, TPS, chitin, PHAs, PLA, PCL, and PVL. |

| Properties | High mechanical performance (stiffness and tensile and impact strength at low cost) Moisture barrier (non-polar materials improve stability and durability) Poor interfacial adhesion (lignocellulosic fibers need coupling agents or treatments) UV sensitivity (require stabilizers) Thermal stability (melting point below polymer decomposition temperature) | Lower mechanical performance (improved by lignocellulosic fibers, but still below non-biodegradable composites) Reduced density Water absorption lowers durability and promotes fungal growth Thermal constraint (below 200 °C to avoid degradation) |

| Environmental impact | Resistant to microbial degradation: they persist in the environment. Contribute to pollution and long-term waste accumulation. Fossil-based production: Derived from non-renewable sources, increasing greenhouse gas emissions. Difficult to recycle; incineration is possible, but environmentally dependent. | Derived from natural sources (e.g., PLA, PHA, starch thermoplastics) and designed for biodegradability. PBS, PVA, and PCL as fossil-based yet degradable alternatives. Eco-friendly profile: Reduce environmental impact, often categorized as “green materials” or “biocomposites”. They can be sourced from biomass residues, promoting circular resource use. |

| Applications | ABS: Automotive parts, electronics, and toys. PETG: Packaging, medical devices, and household items. PC: 3D printing. Bio-PC is safer for indoor use. Nylon: 3D-printed components such as gears, bearings, and tools. Ideal for aerospace, automotive, healthcare, and consumer products. PE and PP: Widely used in wood–plastic composites due to processing flexibility with lignocellulosic fibers. Recycled thermoplastics can be used in layered structures or blended formulations (with compatibilizers). | PHAs: Packaging, agricultural and biomedical devices, mulch films, hygiene products. PLA: 3D printing, food packaging (cups, trays, containers), and in biomedical fields: tissue engineering, implants, drug carriers. PCL: Medical area, electronics, and packaging industries. PVA: Water-soluble support material for complex 3D-printed geometries. Used in papermaking, textile finishing, printing, adhesives, and emulsifiers |

| Blended Material | Compatibilizer Applied | Change in Properties | Ref. |

|---|---|---|---|

| Henequen fibers and PLA | -- | TS: 60.1 MPa StF: 0.078 mm | [66] |

| Maleic Anhydride | TS: 63.9 MPa StF: 0.091 mm | ||

| Microfibrillated cellulose and PLA | -- | TS: 29.8 MPa IS: 611 J/m2 FS: 54.4 MPa | [107] |

| 3-aminopropyltriethoxysilane | TS: 35.0 MPa IS: 649 J/m2 FS: 58.1 MPa | ||

| Printed office paper and PLA | -- | TS~52 MPa EAB~7.5% | [75] |

| γ-methacryloxypropyl trimethoxysilane | TS~55 MPa EAB~8% | ||

| Kenaf fiber | -- | CA: 63.7° TS~25 MPa EAB~11% | [79] |

| Tetraethyl orthosilicate | CA:71.4° TS~28 MPa EAB~20% | ||

| Tetraethyl orthosilicate + polyethylene glycol | CA: 68.0° TS~30 MPa EAB~17% |

| Stage | Challenges |

|---|---|

| Raw material conditioning |

|

| Filament production |

|

| 3D printing |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ehman, N.; Ponce de León, A.; Quintero Torres, I.N.; Vallejos, M.E.; Area, M.C. Lignocellulosic Agro-Forest Byproducts as Feedstock for Fused Deposition Modeling 3D Printing Filaments: A Review. Fibers 2025, 13, 124. https://doi.org/10.3390/fib13090124

Ehman N, Ponce de León A, Quintero Torres IN, Vallejos ME, Area MC. Lignocellulosic Agro-Forest Byproducts as Feedstock for Fused Deposition Modeling 3D Printing Filaments: A Review. Fibers. 2025; 13(9):124. https://doi.org/10.3390/fib13090124

Chicago/Turabian StyleEhman, Nanci, Agustina Ponce de León, Israel N. Quintero Torres, María E. Vallejos, and M. Cristina Area. 2025. "Lignocellulosic Agro-Forest Byproducts as Feedstock for Fused Deposition Modeling 3D Printing Filaments: A Review" Fibers 13, no. 9: 124. https://doi.org/10.3390/fib13090124

APA StyleEhman, N., Ponce de León, A., Quintero Torres, I. N., Vallejos, M. E., & Area, M. C. (2025). Lignocellulosic Agro-Forest Byproducts as Feedstock for Fused Deposition Modeling 3D Printing Filaments: A Review. Fibers, 13(9), 124. https://doi.org/10.3390/fib13090124