Analysis of Interfacial Properties in Flax Yarn-Reinforced Epoxy Resin Composites

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Materials

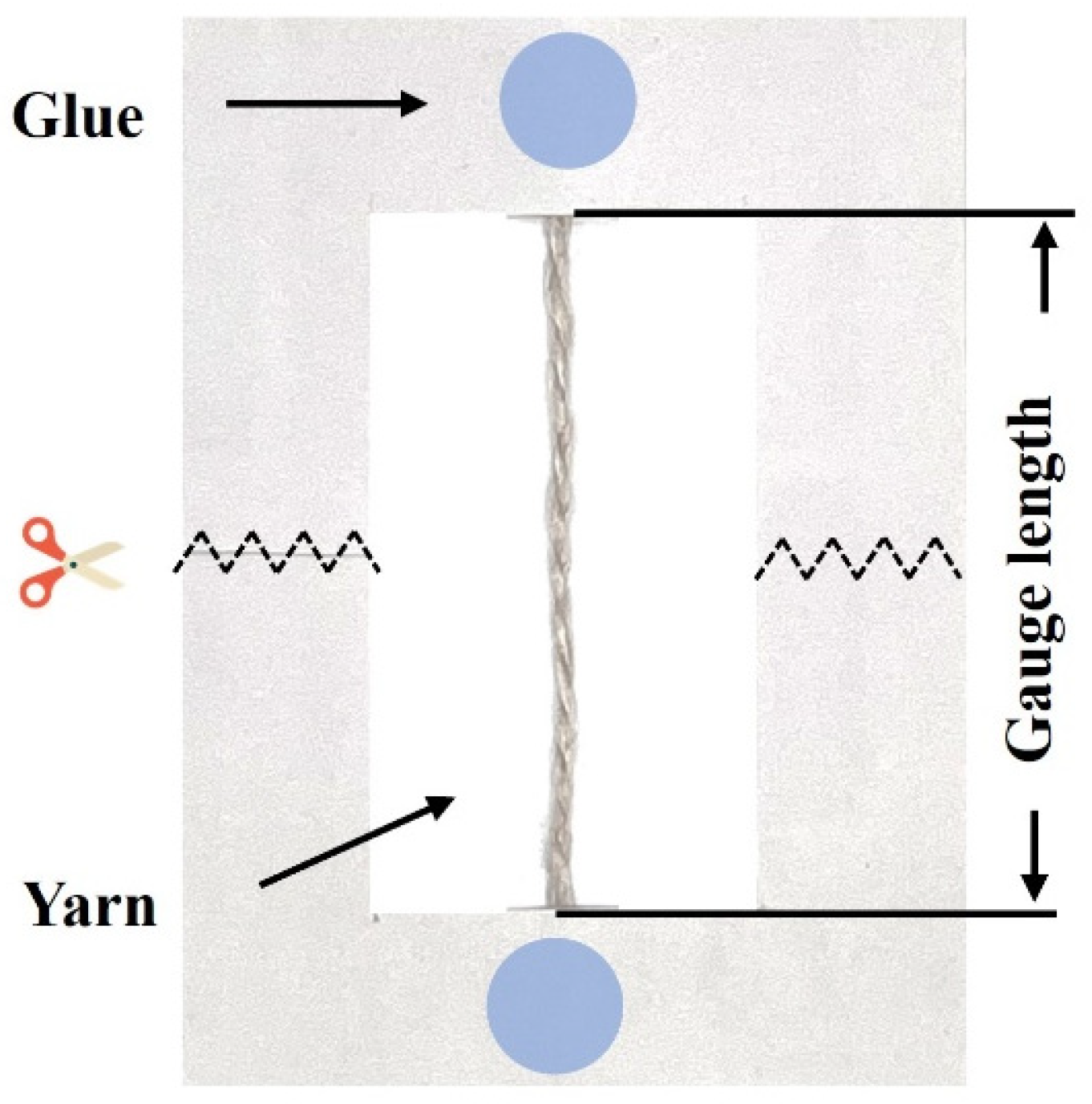

2.2. Yarn Tensile Test

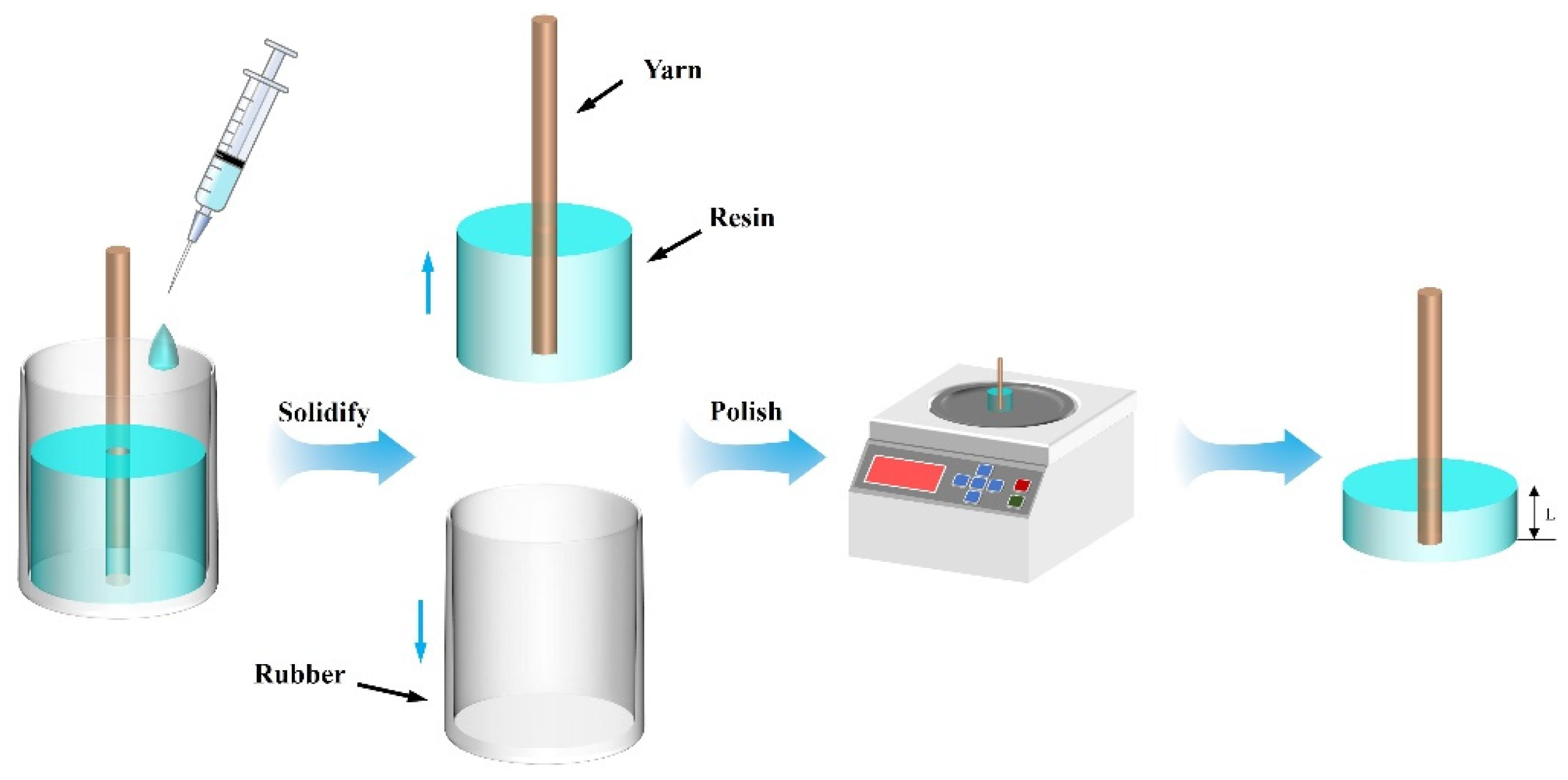

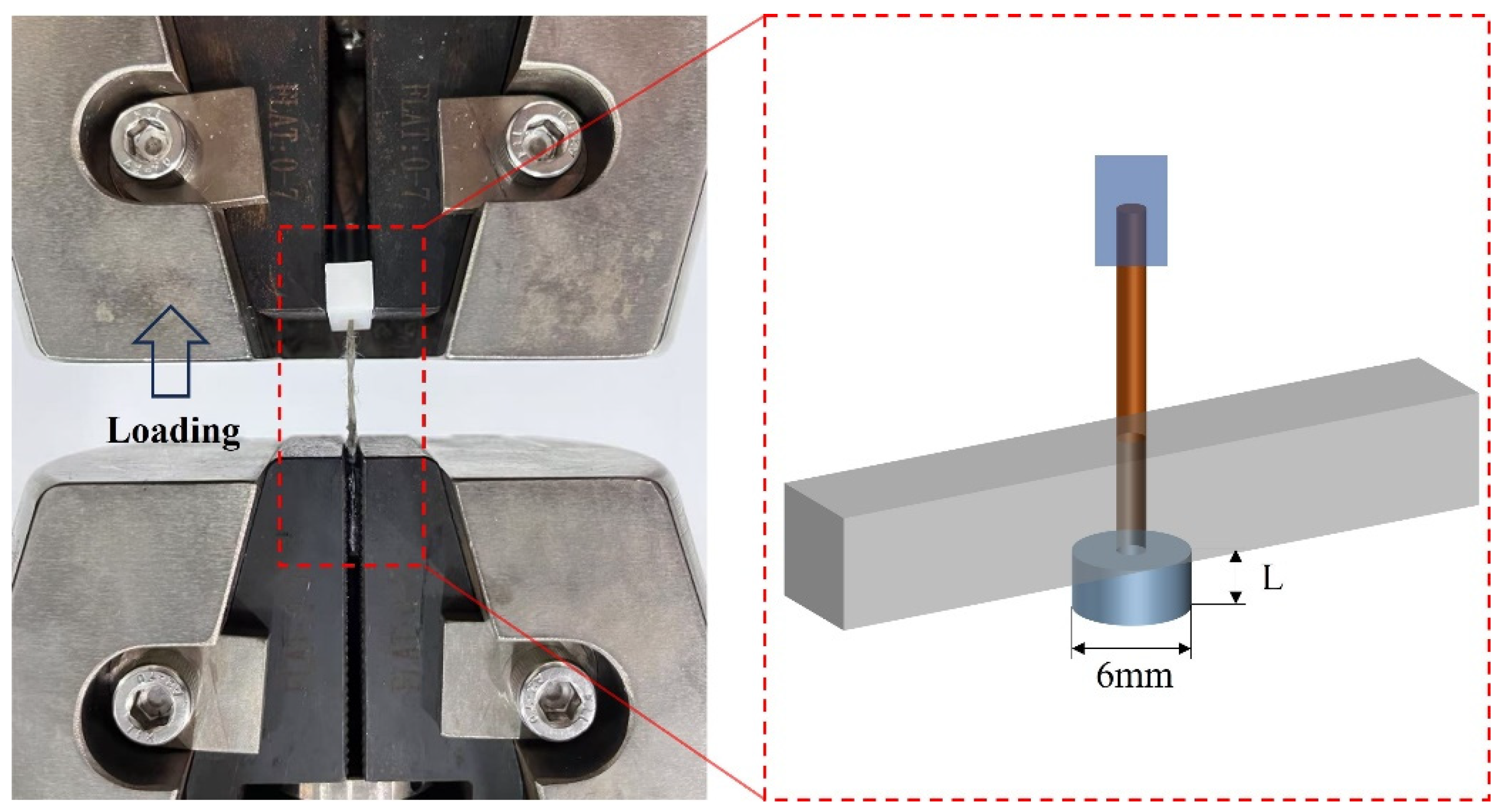

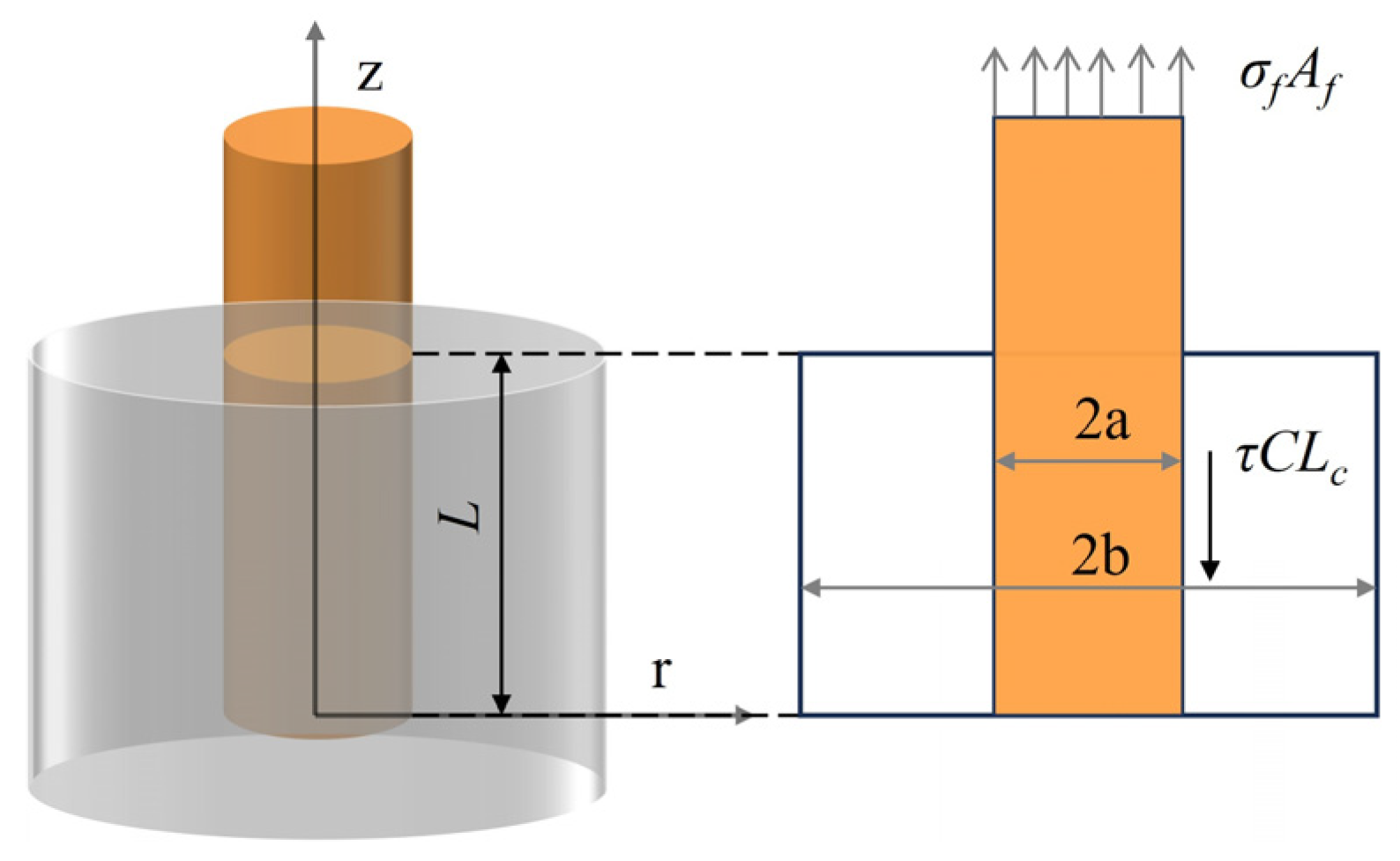

2.3. Yarn Pull-Out Test

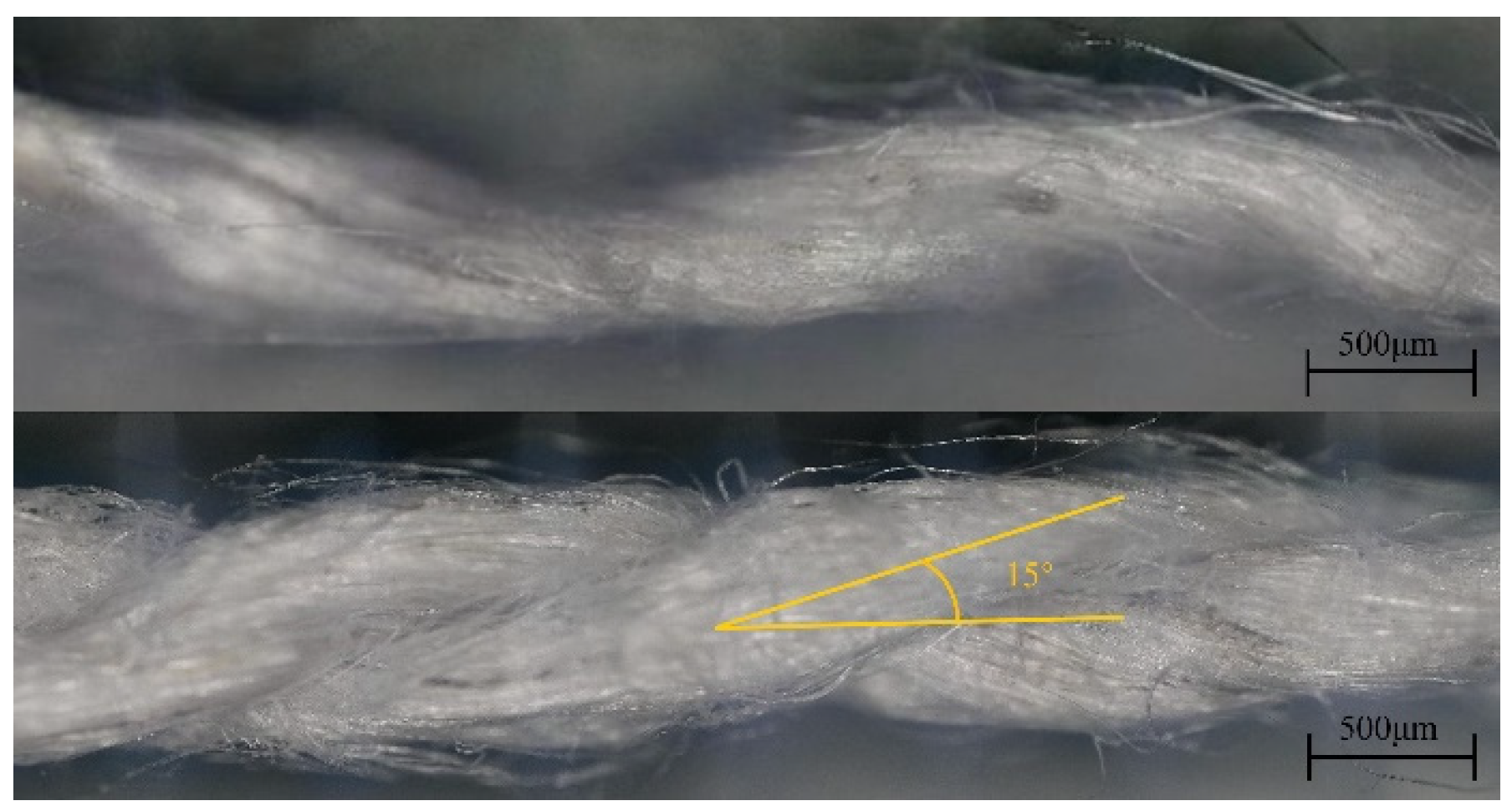

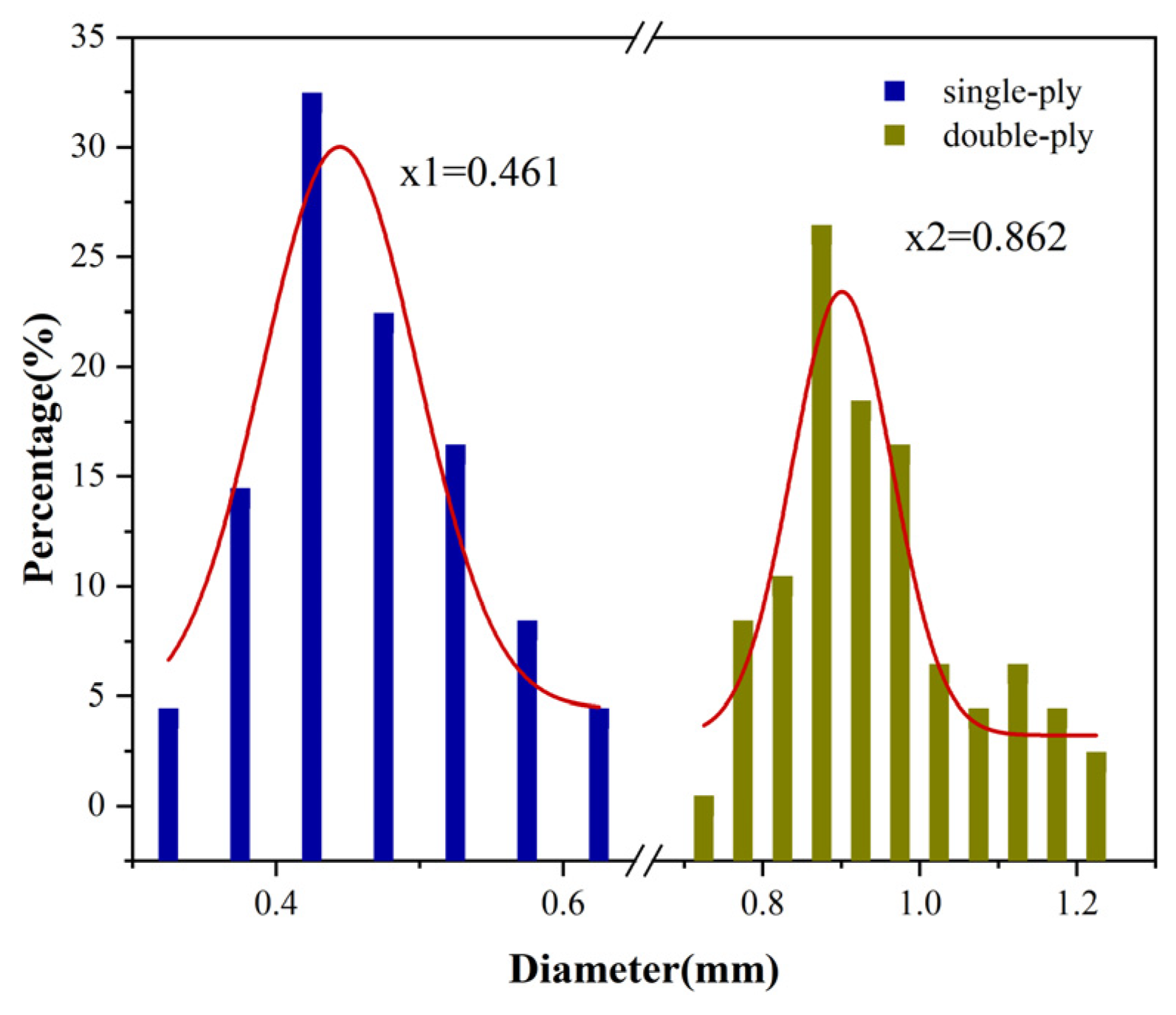

2.4. Yarn Appearance Characterization

2.5. Quasi-Static Nanoindentation Testing

3. Results and Discussion

3.1. Flax Yarn Static Tensile Properties

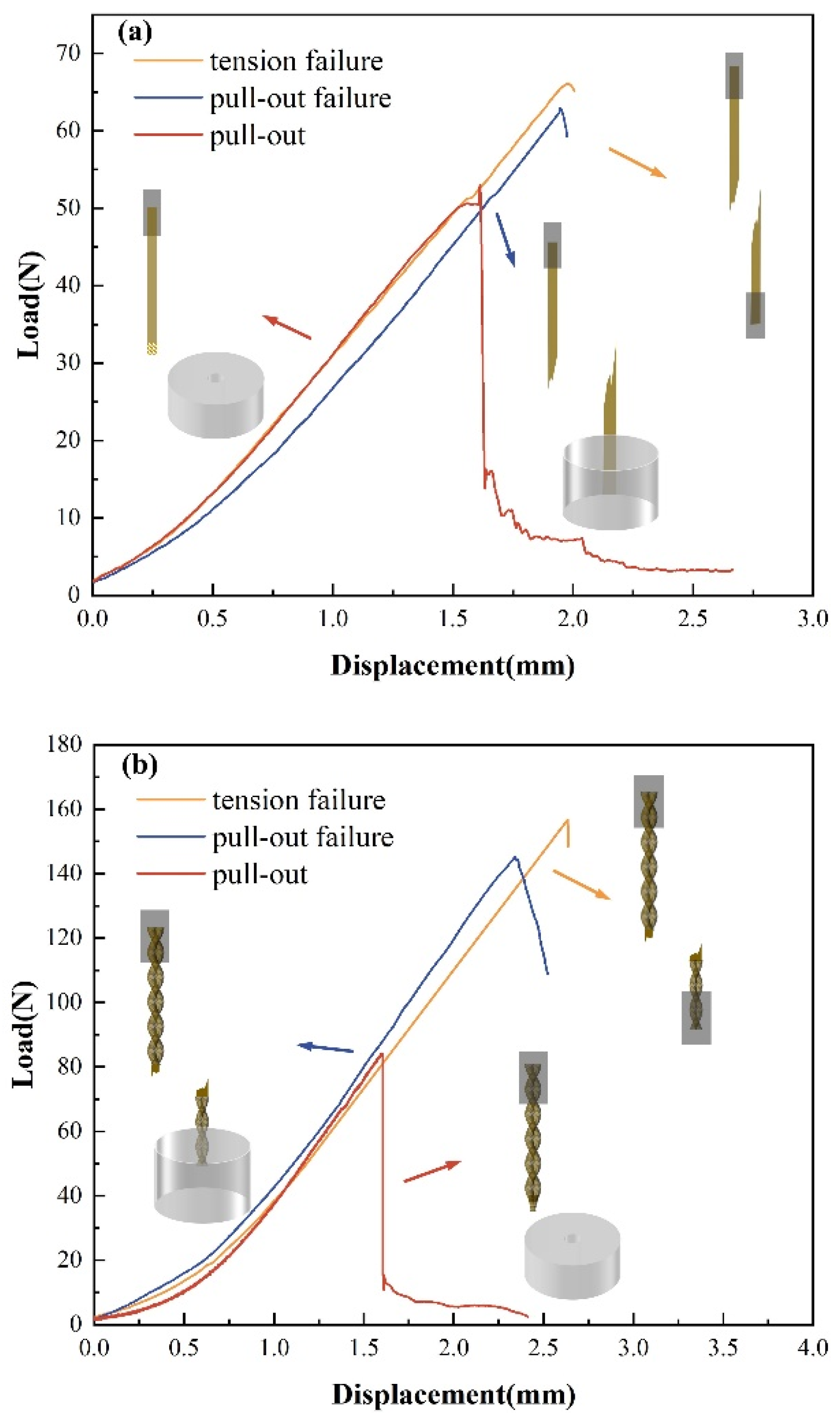

3.2. Effect of Embedding Length on Yarn Pull-Out Behavior

3.3. Critical Embedding Length of Yarn

3.4. Interface Adhesion Properties

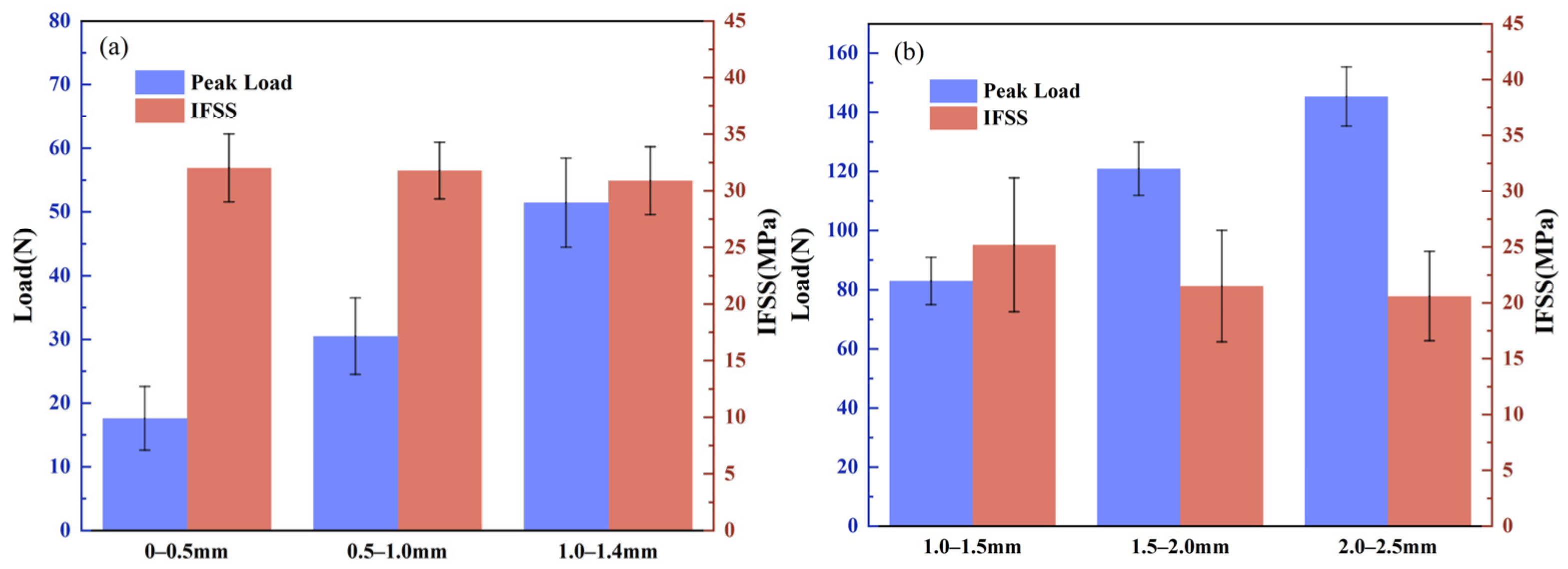

3.4.1. Interfacial Shear Strength

3.4.2. Interfacial Stiffness Modulus and Stiffness

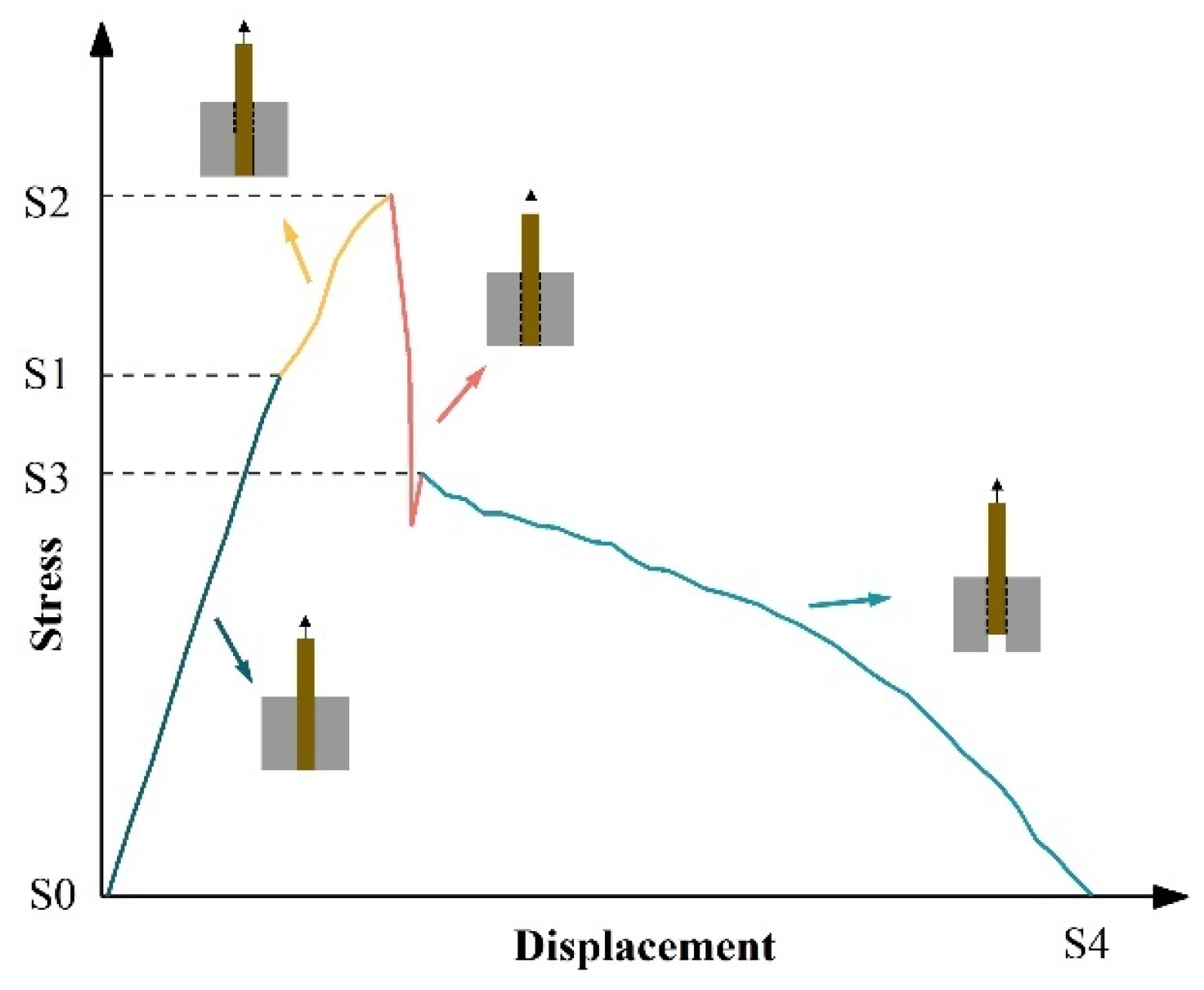

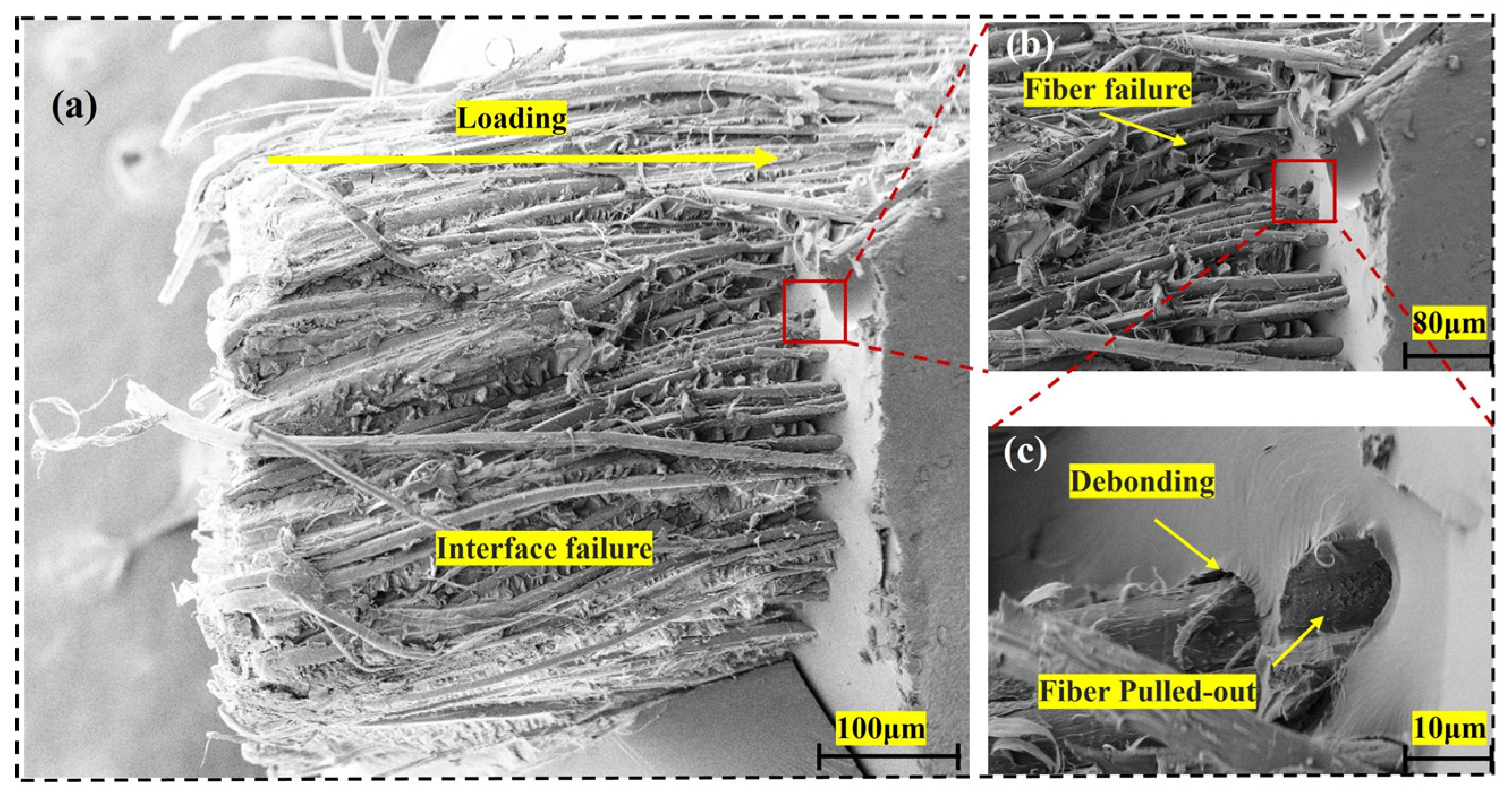

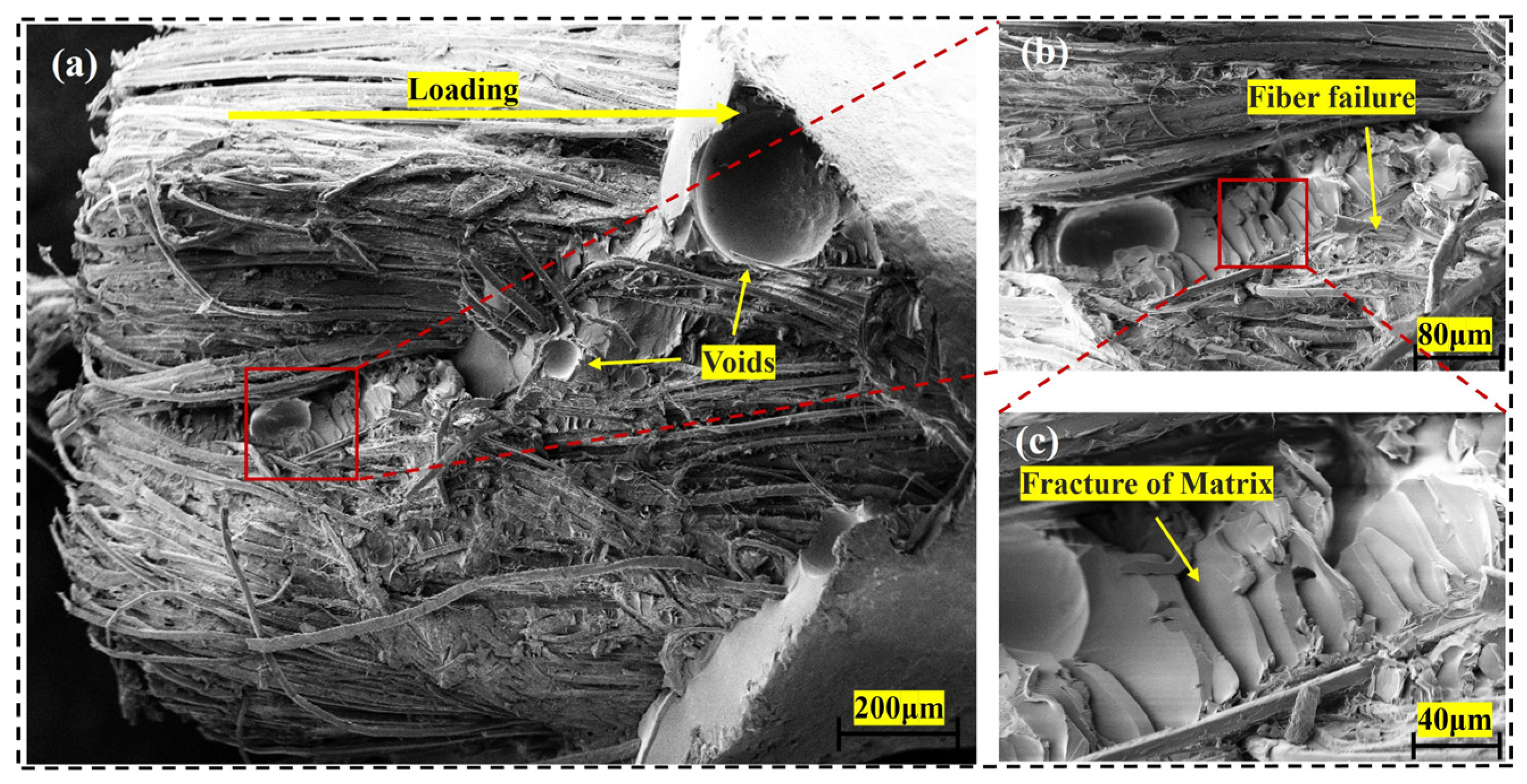

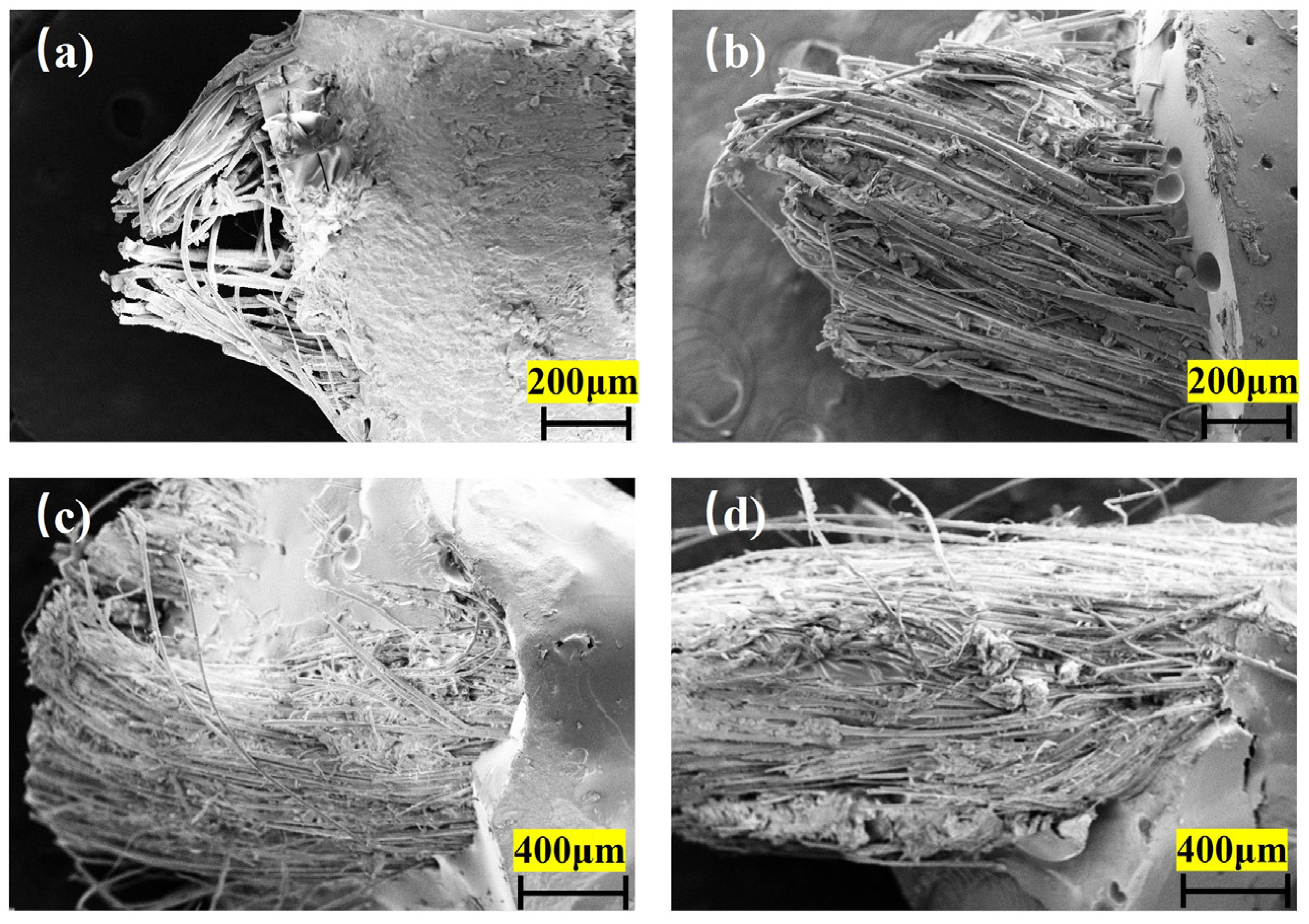

3.4.3. Fracture Characteristics and Interfacial Failure Mechanisms

4. Conclusions

- (1)

- Characteristic strength decreased from 430 MPa (40 mm) to 365 MPa (100 mm) for single-ply, and 288 MPa to 253 MPa for double-ply. Tensile Strength and Elastic Modulus Trends: The tensile strength and elastic modulus of flax yarns decrease with increasing gauge length. Both single- and double-filament yarns exhibit similar trends, which are closely related to the non-uniformity of the internal fiber structure. Under short gauge lengths, the end effects of fibers are reduced, enhancing their synergistic load-bearing capacity and making the tensile performance closer to that of individual fibers. However, extending the gauge length exacerbates defect accumulation and stress distribution unevenness among fibers, leading to overall mechanical property degradation. This phenomenon highlights the critical impact of yarn structure on interfacial stress transfer efficiency.

- (2)

- Interfacial Shear Strength (IFSS) Comparison: Single-ply achieved higher IFSS (30.90–32.03 MPa vs. 20.61–25.21 MPa in double-ply. The tight fiber arrangement and large effective contact area in single-filament yarns result in more pronounced chemical bonding and mechanical interlocking at the interface. In contrast, the twisted structure and inter-filament gaps in double-filament yarns reduce interfacial bonding efficiency, leading to a downward trend in IFSS. Additionally, single-filament yarns primarily fail via interfacial debonding, while double-filament yarns exhibit more complex failure modes, including interfacial separation, internal fiber slippage, and matrix fracture, due to their structural complexity.

- (3)

- Interfacial Failure Mechanisms: The interfacial failure of flax fiber-reinforced composites stems from the inherent hydrophilicity of fibers and the hydrophobicity of resins, as well as stress concentration effects due to the hierarchical yarn structure. Microscopic analysis reveals that interfacial debonding, fiber pull-out, and localized matrix fracture are the dominant failure modes, regulated by the synergistic effects of embedded length and yarn structure. Single-filament yarns tend to fail by interfacial debonding due to their uniform stress transfer paths, whereas double-filament yarns experience more complex failures involving interfacial separation and internal slippage. While the multi-filament synergistic effect of double-filament yarns enhances structural stability, it also weakens local interfacial strength due to stress dispersion. Future research should focus on fiber surface modification, resin wettability optimization, and multi-scale interfacial design to break through the performance bottlenecks of natural fiber composites and promote their widespread application in lightweight and eco-friendly engineering materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Kandasamy, J.; Soundhar, A.; Rajesh, M.; Mallikarjuna Reddy, D.; Kar, V.R. Natural fiber composite for structural applications. In Structural Health Monitoring System for Synthetic, Hybrid and Natural Fiber Composites; Springer: Singapore, 2021; pp. 23–35. [Google Scholar]

- Sudhin, A.; Remanan, M.; Ajeesh, G.; Jayanarayanan, K. Comparison of properties of carbon fiber reinforced thermoplastic and thermosetting composites for aerospace applications. Mater. Today Proc. 2020, 24, 453–462. [Google Scholar] [CrossRef]

- Ferreira, D.P.; Cruz, J.; Fangueiro, R. Surface modification of natural fibers in polymer composites. In Green Composites for Automotive Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 3–41. [Google Scholar]

- Fernández, J.A.; Le Moigne, N.; Caro-Bretelle, A.; El Hage, R.; Le Duc, A.; Lozachmeur, M.; Bono, P.; Bergeret, A. Role of flax cell wall components on the microstructure and transverse mechanical behaviour of flax fabrics reinforced epoxy biocomposites. Ind. Crops Prod. 2016, 85, 93–108. [Google Scholar] [CrossRef]

- Shelly, D.; Singhal, V.; Jaidka, S.; Banea, M.D.; Lee, S.-Y.; Park, S.-J. Mechanical performance of bio-based fiber reinforced polymer composites: A review. Polym. Compos. 2025. early view. [Google Scholar] [CrossRef]

- Behera, S.; Gautam, R.K.; Mohan, S.; Chattopadhyay, A. Hemp fiber surface modification: Its effect on mechanical and tribological properties of hemp fiber reinforced epoxy composites. Polym. Compos. 2021, 42, 5223–5236. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Rajeshkumar, L.; Tamil Selvan, M.; Balaji, D. Influence of fiber surface treatment on the tribological properties of Calotropis gigantea plant fiber reinforced polymer composites. Polym. Compos. 2021, 42, 4308–4317. [Google Scholar] [CrossRef]

- Hendlmeier, A.; Marinovic, L.I.; Al-Assafi, S.; Stojcevski, F.; Henderson, L.C. Sizing effects on the interfacial shear strength of a carbon fibre reinforced two-component thermoplastic polymer. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105622. [Google Scholar] [CrossRef]

- Kim, S.W.; Park, T.; Um, M.K.; Lee, J.; Seong, D.G.; Yi, J.W. Effect of caprolactam modified phenoxy-based sizing material on reactive process of carbon fiber-reinforced thermoplastic polyamide-6. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106104. [Google Scholar] [CrossRef]

- Kumar, D.; Mohanasundaram, S.; Karthikeyan, S.K.; Singh, A.K.; Nagabhooshanam, K.D.V.P.; Balasubramanian, M.; Kumar, N.S.; Sree, S.R. Load bearing properties of sand blasted SS304 wire-mesh and silane-treated pineapple/flax-reinforced Si2N2O modified epoxy resin Composites. J. Polym. Res. 2025, 32, 241–256. [Google Scholar] [CrossRef]

- Shelly, D.; Lee, S.Y.; Park, S.J. Hemp fiber and its bio-composites: A comprehensive review part I—Characteristics and processing. Adv. Compos. Hybrid Mater. 2025, 8, 252. [Google Scholar] [CrossRef]

- Elayaraja, R.; Rajamurugan, G. Utilizing woven flax/hemp yarn on SS304 wiremesh reinforced flax fiber composites for tribological applications. Tribol. Int. 2024, 27, 105909. [Google Scholar] [CrossRef]

- Li, Y.; Chen, C.; Xu, J.; Zhang, Z.; Yuan, B.; Huang, X. Improved mechanical properties of carbon nanotubes-coated flax fiber reinforced composites. J. Mater. Sci. 2015, 50, 1117–1128. [Google Scholar] [CrossRef]

- Goda, K.; Sreekala, M.; Gomes, A.; Kaji, T.; Ohgi, J. Improvement of plant based natural fibers for toughening green composites—Effect of load application during mercerization of ramie fibers. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2213–2220. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Y.; Fu, K.; Li, Q. Determination of interfacial properties of cellulose nanocrystal-modified sisal fibre in epoxy by cyclic single-fibre pull-out. Compos. Sci. Technol. 2020, 193, 108142. [Google Scholar] [CrossRef]

- Majhi, S.; Pradhan, S.; Prakash, V.; Acharya, S.K. Influence of alkali treatment on the interfacial shear strength of Agave lechuguilla fiber and its significance as a reinforcing material in polymer composites for mechanical applications. Polym. Compos. 2023, 44, 3487–3499. [Google Scholar] [CrossRef]

- Wong, S.; Shanks, R.; Hodzic, A. Effect of additives on the interfacial strength of poly (l-lactic acid) and poly (3-hydroxy butyric acid)-flax fibre composites. Compos. Sci. Technol. 2007, 67, 2478–2484. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Toledo Filho, R.D.; de Andrade Silva, F.; Mobasher, B.; Müller, S.; Mechtcherine, V. Interface characteristics of jute fiber systems in a cementitious matrix. Cem. Concr. Res. 2019, 116, 252–265. [Google Scholar] [CrossRef]

- Spārniņš, E.; Nyström, B.; Andersons, J. Interfacial shear strength of flax fibers in thermoset resins evaluated via tensile tests of UD composites. Int. J. Adhes. Adhes. 2012, 36, 39–43. [Google Scholar] [CrossRef]

- Andersons, J.; Joffe, R.; Spārniņš, E. Evaluation of interfacial shear strength by tensile tests of impregnated flax fiber yarns. J. Compos. Mater. 2012, 46, 351–357. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Nicoletti, F.; Vitale, G.; Prestipino, M.; Valenza, A. A new eco-friendly chemical treatment of natural fibres: Effect of sodium bicarbonate on properties of sisal fibre and its epoxy composites. Compos. Part B Eng. 2016, 85, 150–160. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, A.W. Tensile properties of fibre-reinforced metals: Copper/tungsten and copper/molybdenum. J. Mech. Phys. Solids 1965, 13, 329–350. [Google Scholar] [CrossRef]

- Noorvand, H.; Mobasher, B.; Underwood, S.; Kaloush, K. Development of an analytical framework for evaluation of critical fiber length in asphalt concrete with a fiber pullout test. Constr. Build. Mater. 2022, 360, 129561. [Google Scholar] [CrossRef]

- Teklal, F.; Djebbar, A.; Allaoui, S.; Hivet, G.; Joliff, Y.; Kacimi, B. A review of analytical models to describe pull-out behavior–Fiber/matrix adhesion. Compos. Struct. 2018, 201, 791–815. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Andersons, J.; Spārniņš, E.; Joffe, R.; Wallström, L. Strength distribution of elementary flax fibres. Compos. Sci. Technol. 2005, 65, 693–702. [Google Scholar] [CrossRef]

- Placet, V. Characterization of the thermo-mechanical behaviour of Hemp fibres intended for the manufacturing of high performance composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1111–1118. [Google Scholar] [CrossRef]

- Belaadi, A.; Bezazi, A.; Bourchak, M.; Scarpa, F.; Zhu, C. Thermochemical and statistical mechanical properties of natural sisal fibres. Compos. Part B Eng. 2014, 67, 481–489. [Google Scholar] [CrossRef]

- Jihan, S.; Siddiqui, A.; Sweet, M. Fracture strength of E-glass fibre strands using acoustic emission. NDT E Int. 1997, 30, 383–388. [Google Scholar] [CrossRef]

- El Asloun, M.; Donnet, J.; Guilpain, G.; Nardin, M.; Schultz, J. On the estimation of the tensile strength of carbon fibres at short lengths. J. Mater. Sci. 1989, 24, 3504–3510. [Google Scholar] [CrossRef]

- Bos, H.; Van Den Oever, M.; Peters, O. Tensile and compressive properties of flax fibres for natural fibre reinforced composites. J. Mater. Sci. 2002, 37, 1683–1692. [Google Scholar] [CrossRef]

- Romhany, G.; Karger-Kocsis, J.; Czigany, T. Tensile fracture and failure behavior of technical flax fibers. J. Appl. Polym. Sci. 2003, 90, 3638–3645. [Google Scholar] [CrossRef]

- Stamboulis, A.; Baillie, C.; Garkhail, S.; Van Melick, H.; Peijs, T. Environmental durability of flax fibres and their composites based on polypropylene matrix. Appl. Compos. Mater. 2000, 7, 273–294. [Google Scholar] [CrossRef]

- Virk, A.S.; Hall, W.; Summerscales, J. Failure strain as the key design criterion for fracture of natural fibre composites. Compos. Sci. Technol. 2010, 70, 995–999. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Zhou, L.-M.; Mai, Y.-W.; Baillie, C. Interfacial debonding and fibre pull-out stresses: Part VA methodology for evaluation of interfacial properties. J. Mater. Sci. 1994, 29, 5541–5550. [Google Scholar] [CrossRef]

- Bhagat, A.B.; Ghosh, A.K. Performance properties of PP/sisal fibre composites having near critical fibre length and prediction of their properties. Fibers Polym. 2022, 23, 1983–1994. [Google Scholar] [CrossRef]

| Gauge Length (mm) | mσ | σ0 (MPa) | mE | E0 (MPa) |

|---|---|---|---|---|

| Single-ply | ||||

| 40 | 7.999 | 430.486 | 8.097 | 14,893.647 |

| 60 | 7.551 | 399.089 | 6.113 | 14,354.802 |

| 100 | 7.079 | 365.666 | 9.370 | 13,371.246 |

| Double-ply | ||||

| 40 | 9.460 | 288.421 | 7.834 | 6460.084 |

| 60 | 10.455 | 278.764 | 7.999 | 5920.511 |

| 100 | 6.451 | 253.325 | 5.975 | 5341.845 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Li, H.; Camilleri, D.; Surnam, B.Y.R.; Wu, Z.; Cheng, X.; Shi, L.; Lu, W. Analysis of Interfacial Properties in Flax Yarn-Reinforced Epoxy Resin Composites. Fibers 2025, 13, 118. https://doi.org/10.3390/fib13090118

Wang X, Li H, Camilleri D, Surnam BYR, Wu Z, Cheng X, Shi L, Lu W. Analysis of Interfacial Properties in Flax Yarn-Reinforced Epoxy Resin Composites. Fibers. 2025; 13(9):118. https://doi.org/10.3390/fib13090118

Chicago/Turabian StyleWang, Xinlong, Hongjun Li, Duncan Camilleri, B. Y. R. Surnam, Zhenyu Wu, Xiaoying Cheng, Lin Shi, and Wenqi Lu. 2025. "Analysis of Interfacial Properties in Flax Yarn-Reinforced Epoxy Resin Composites" Fibers 13, no. 9: 118. https://doi.org/10.3390/fib13090118

APA StyleWang, X., Li, H., Camilleri, D., Surnam, B. Y. R., Wu, Z., Cheng, X., Shi, L., & Lu, W. (2025). Analysis of Interfacial Properties in Flax Yarn-Reinforced Epoxy Resin Composites. Fibers, 13(9), 118. https://doi.org/10.3390/fib13090118