Strength and Micro-Mechanism of Guar Gum–Palm Fiber Composite for Improvement of Expansive Soil

Abstract

1. Introduction

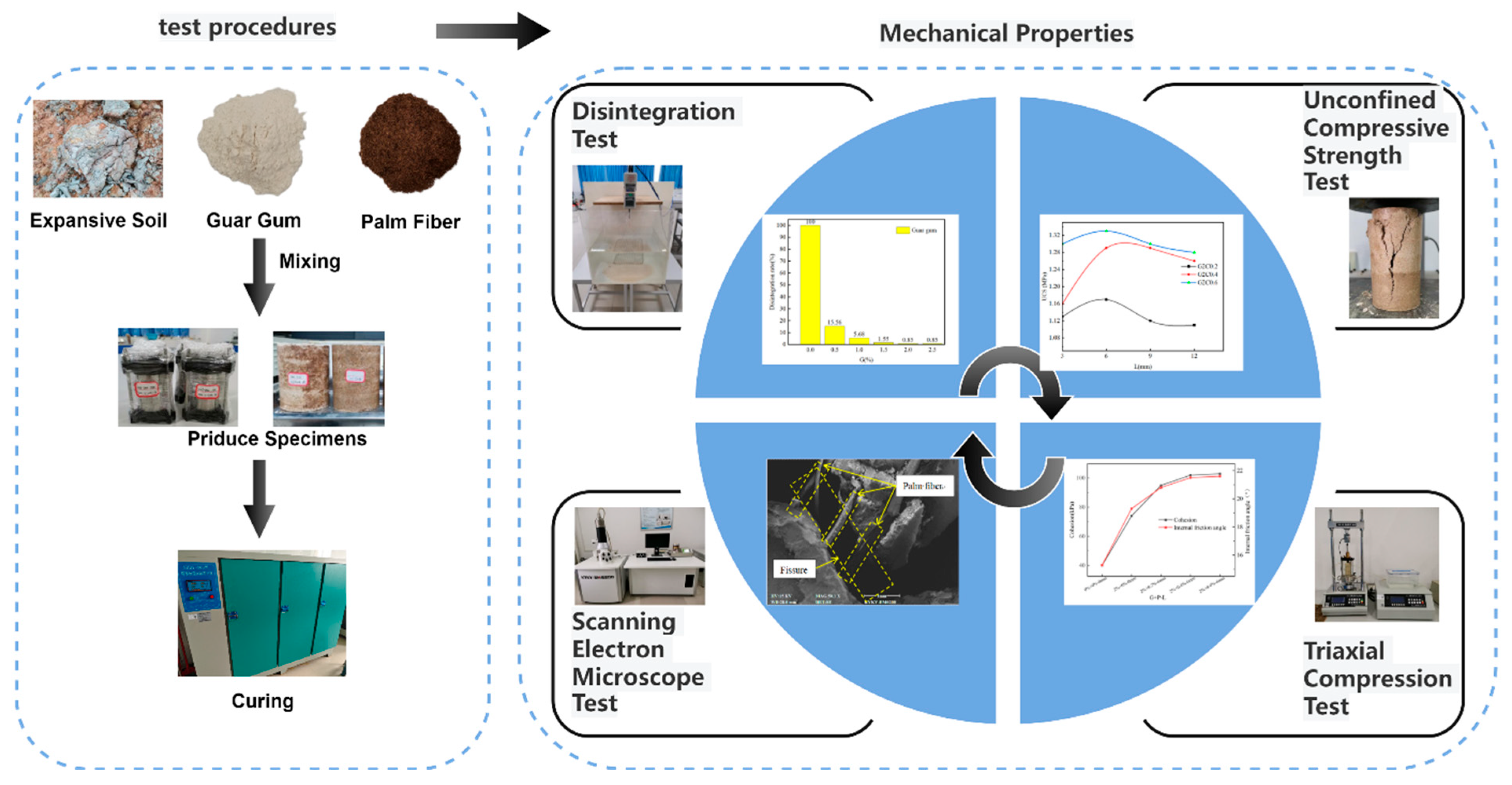

2. Materials and Methods

2.1. Expansive Soil

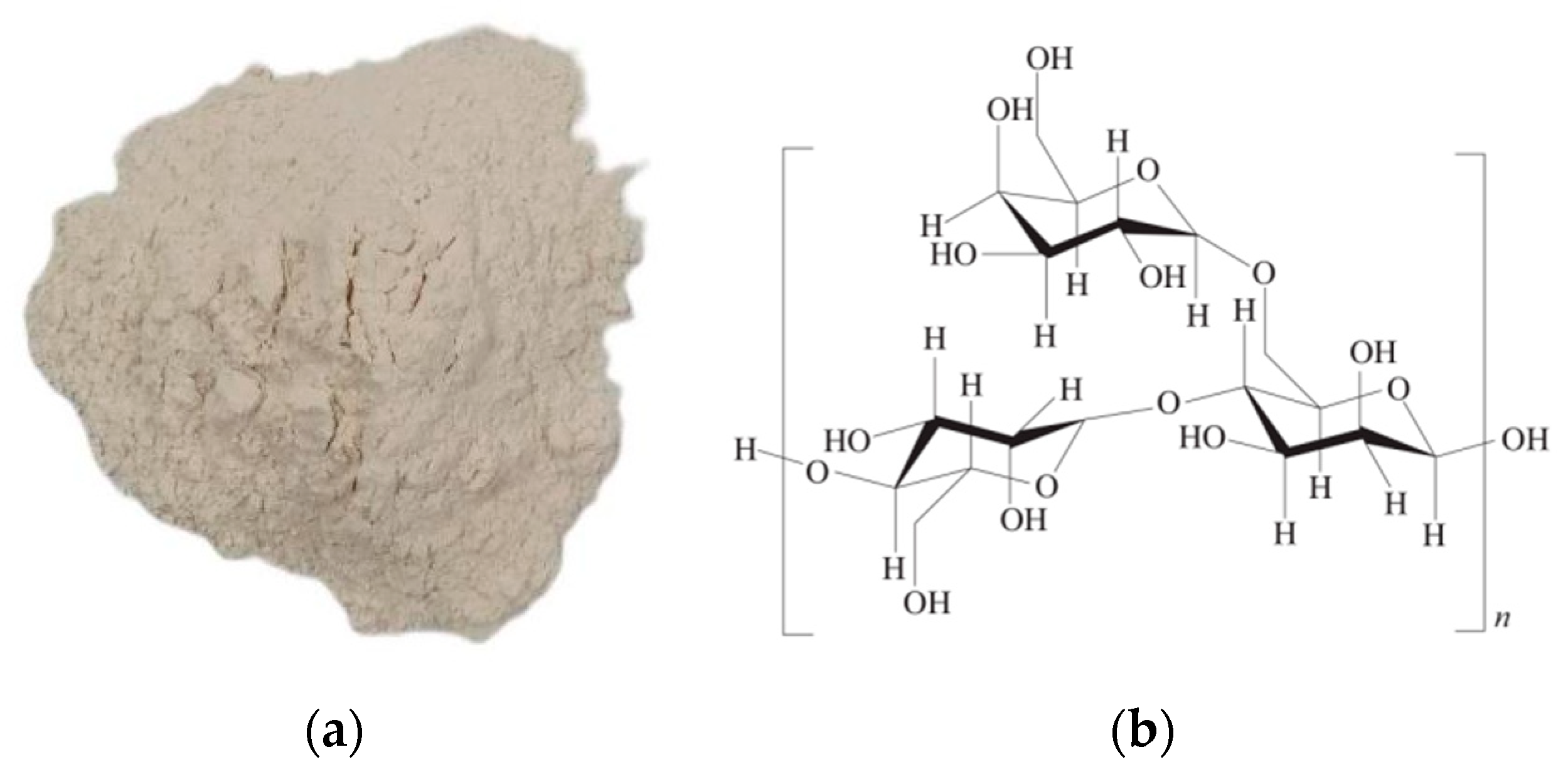

2.2. Guar Gum

2.3. Palm Fiber

2.4. Experimental Design

Sample Preparation

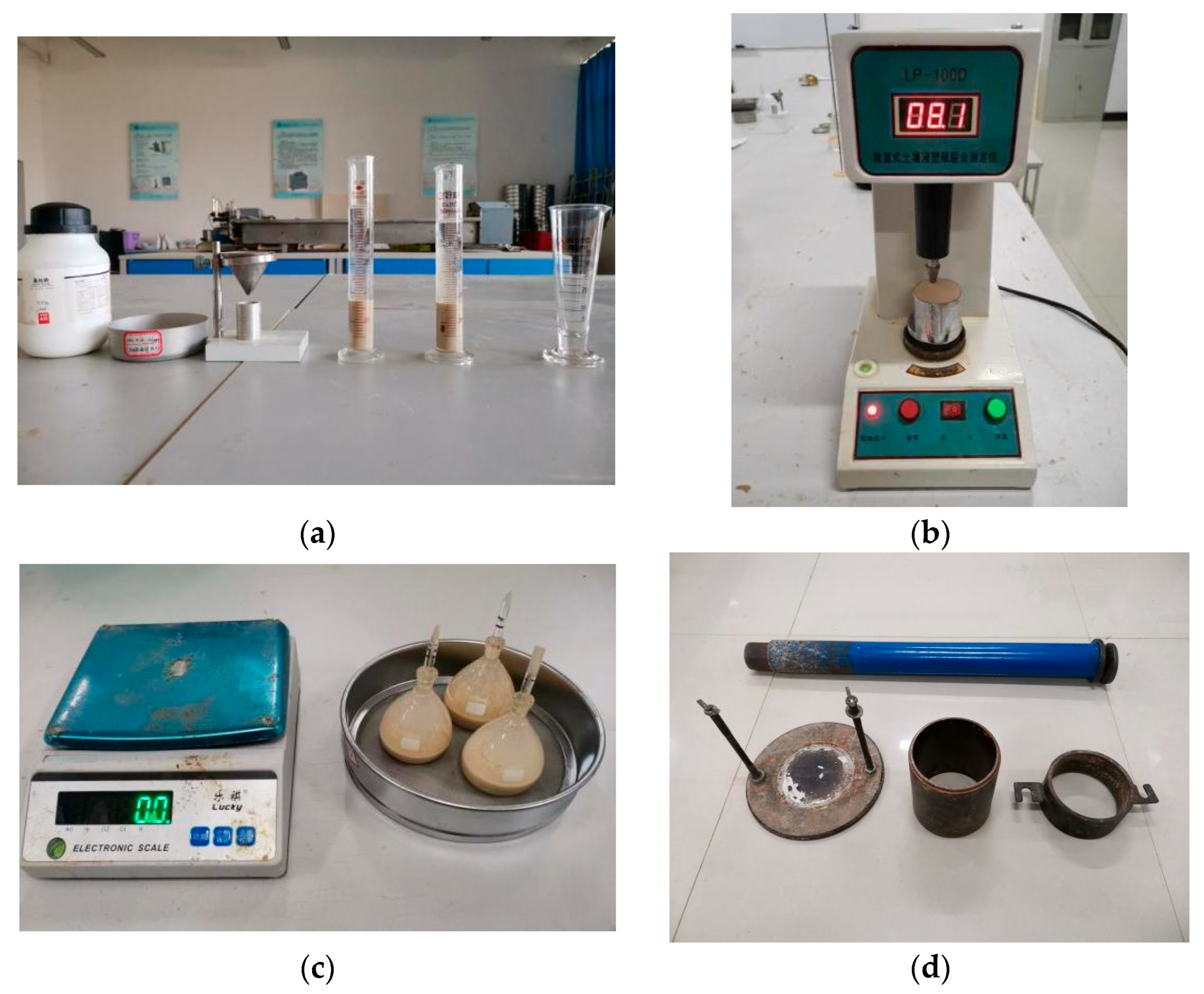

2.5. Experimental Methods

- Free expansion rate test

- Plastic limit and liquid limit test

- The specific gravity test

- The compaction test

- Disintegration rate test

- Unconfined compressive strength test

- Triaxial compression strength test

- Scanning electron microscopy (SEM) test

3. Result Analysis

3.1. Analysis of Basic Physical Test Results of Expansive Soil

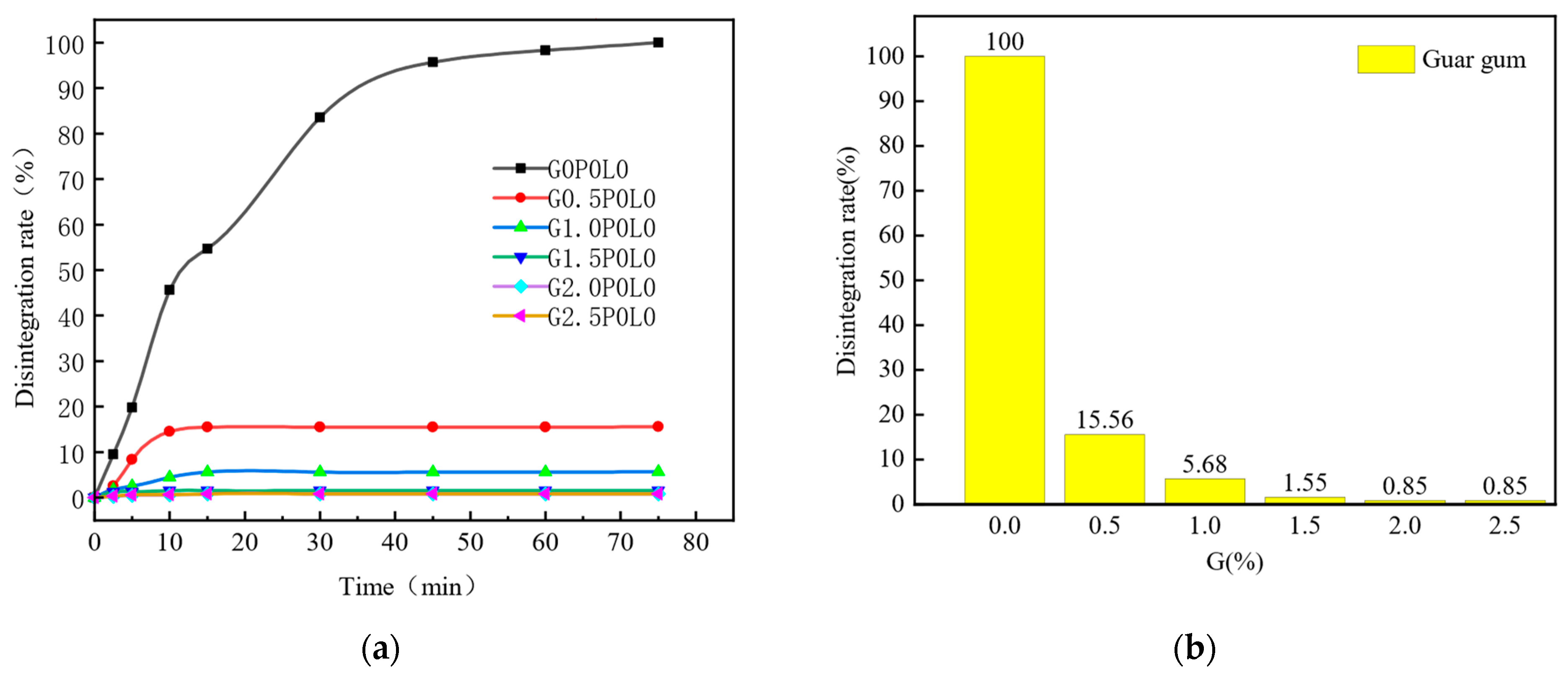

3.2. Effect of Guar Gum Content on Disintegration Characteristics of Expansive Soil

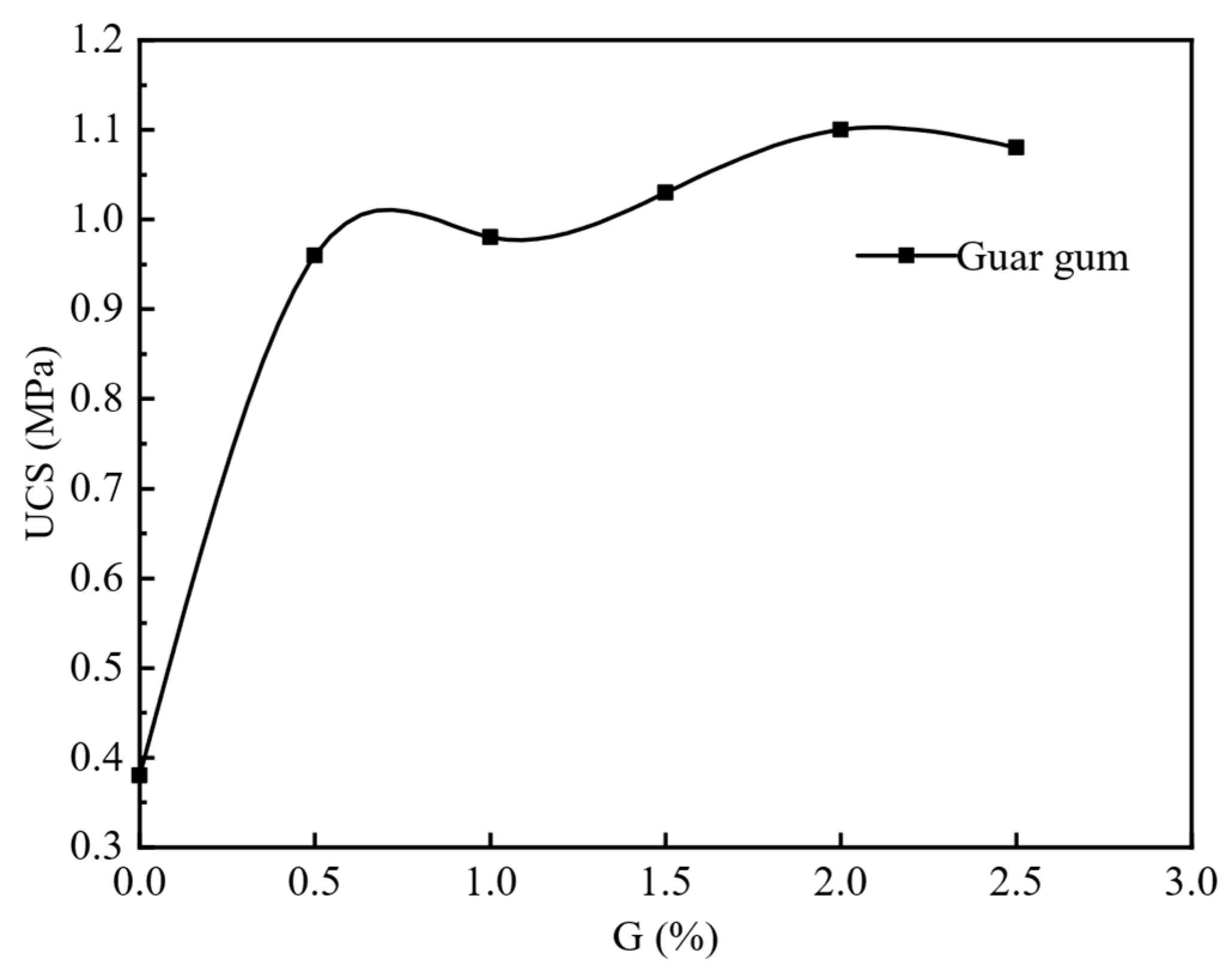

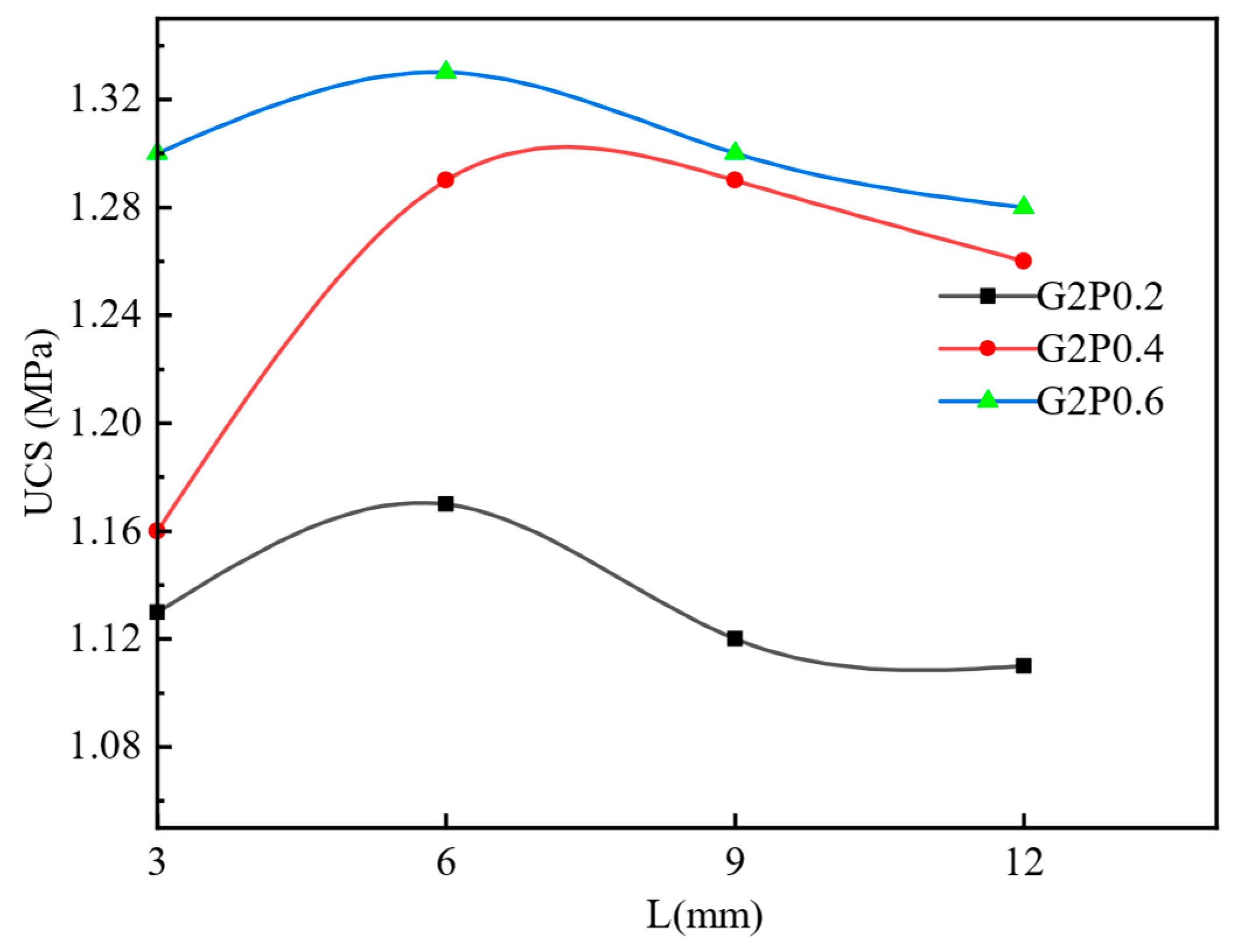

3.3. The Effect of Palm Fiber Content and Length on UCS

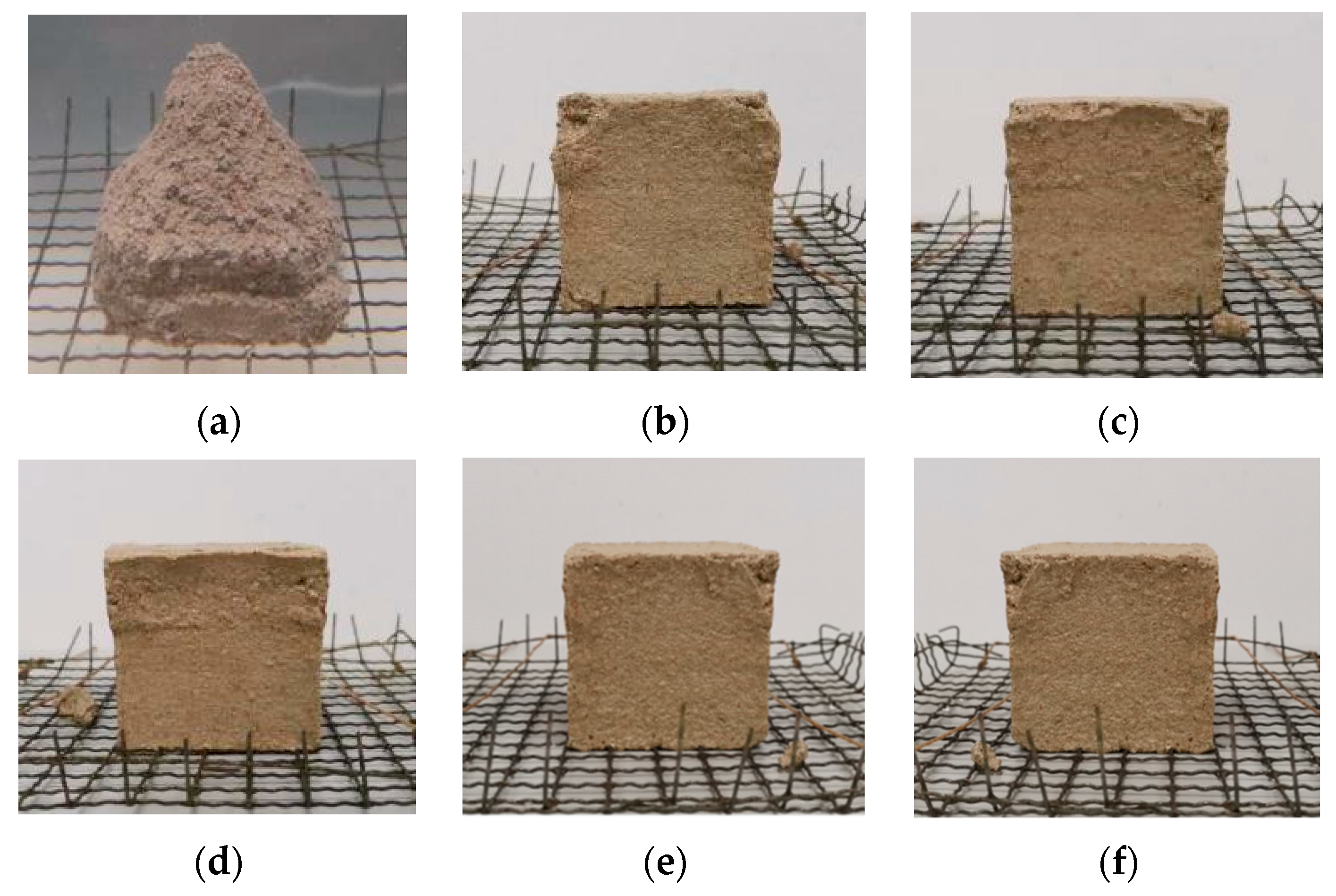

Failure Modes of Improved Expansive Soil Samples

3.4. Triaxial Compression Strength Test

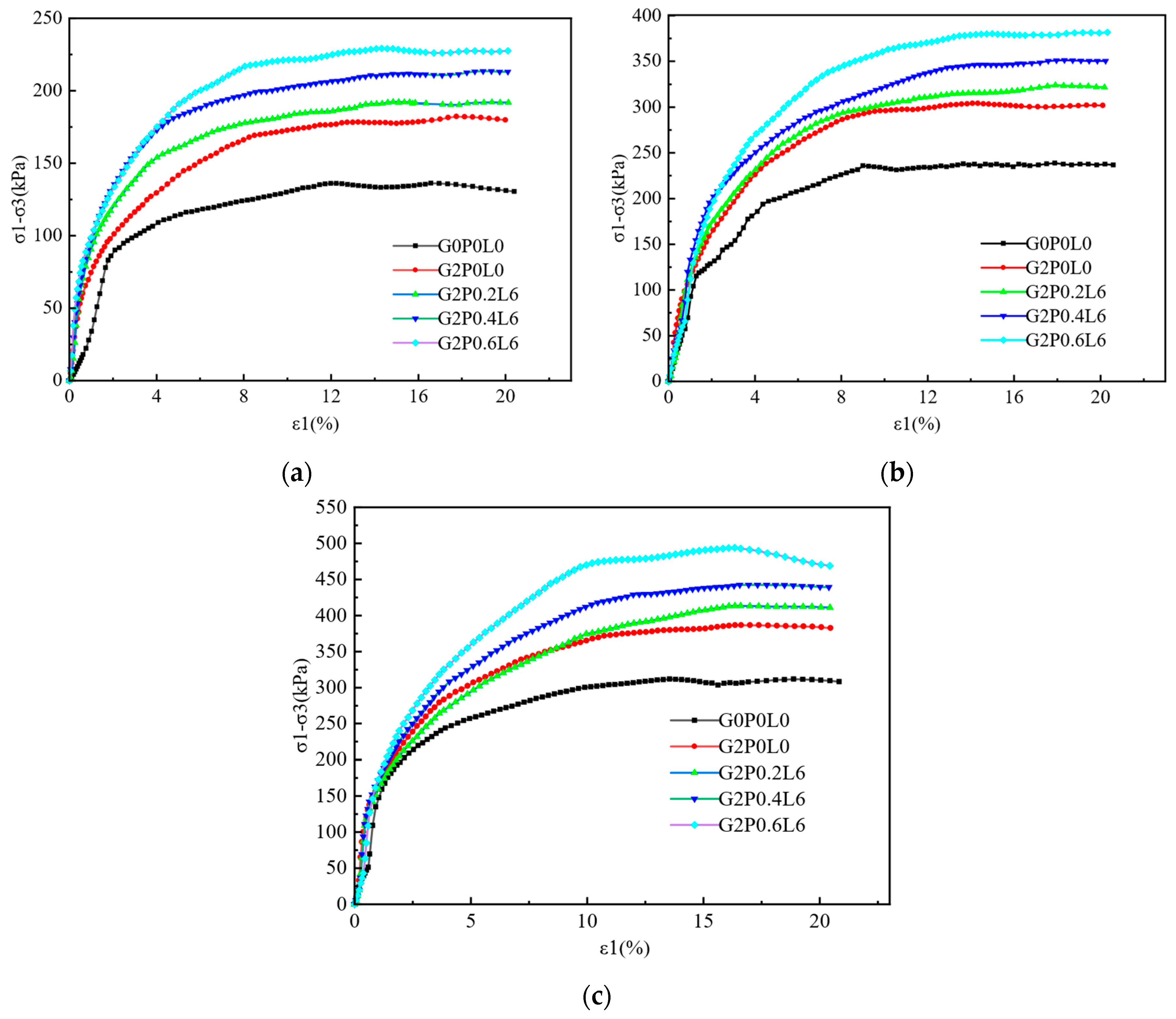

3.4.1. Stress–Strain Relationship Curve of Improved Expansive Soil

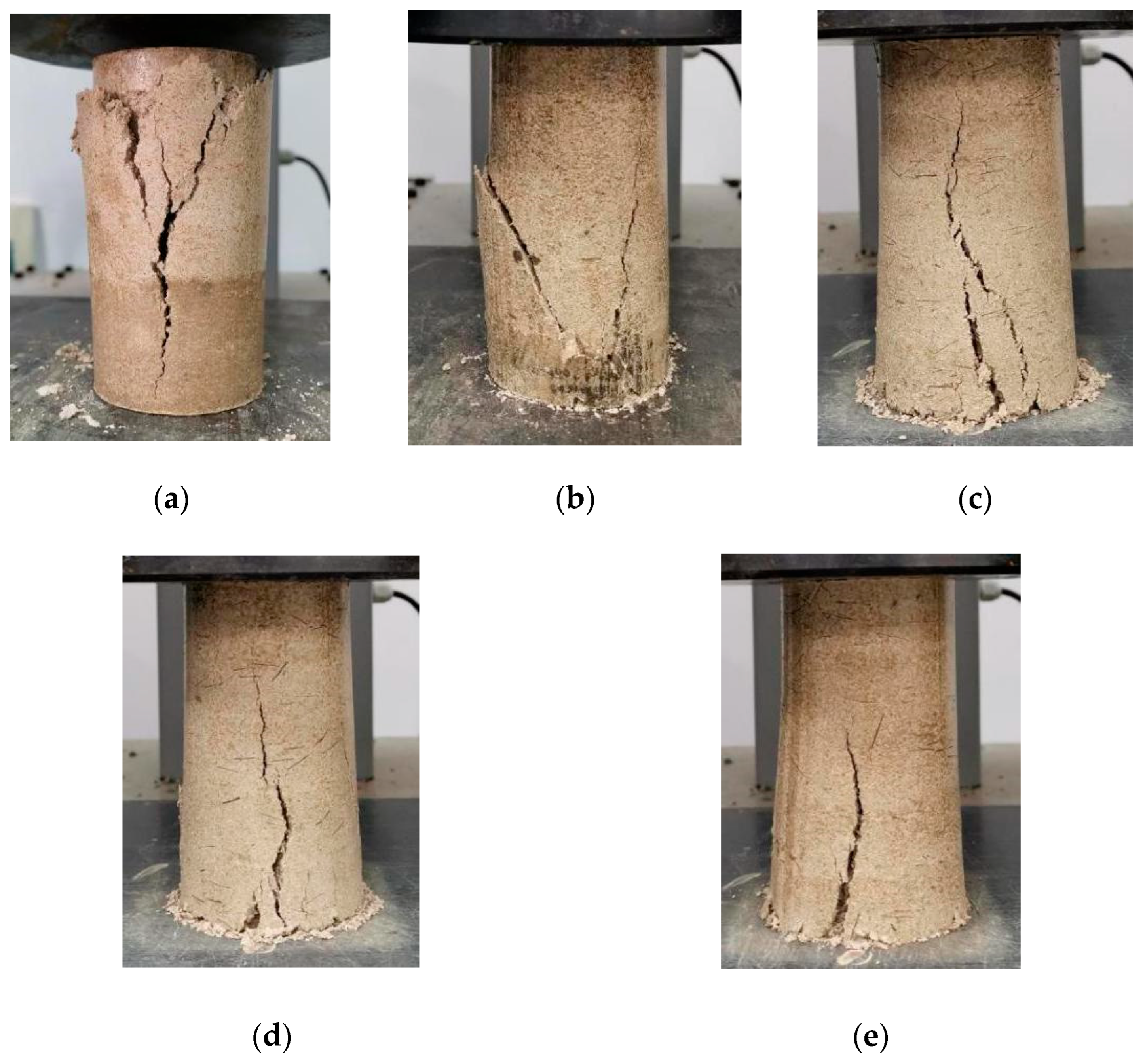

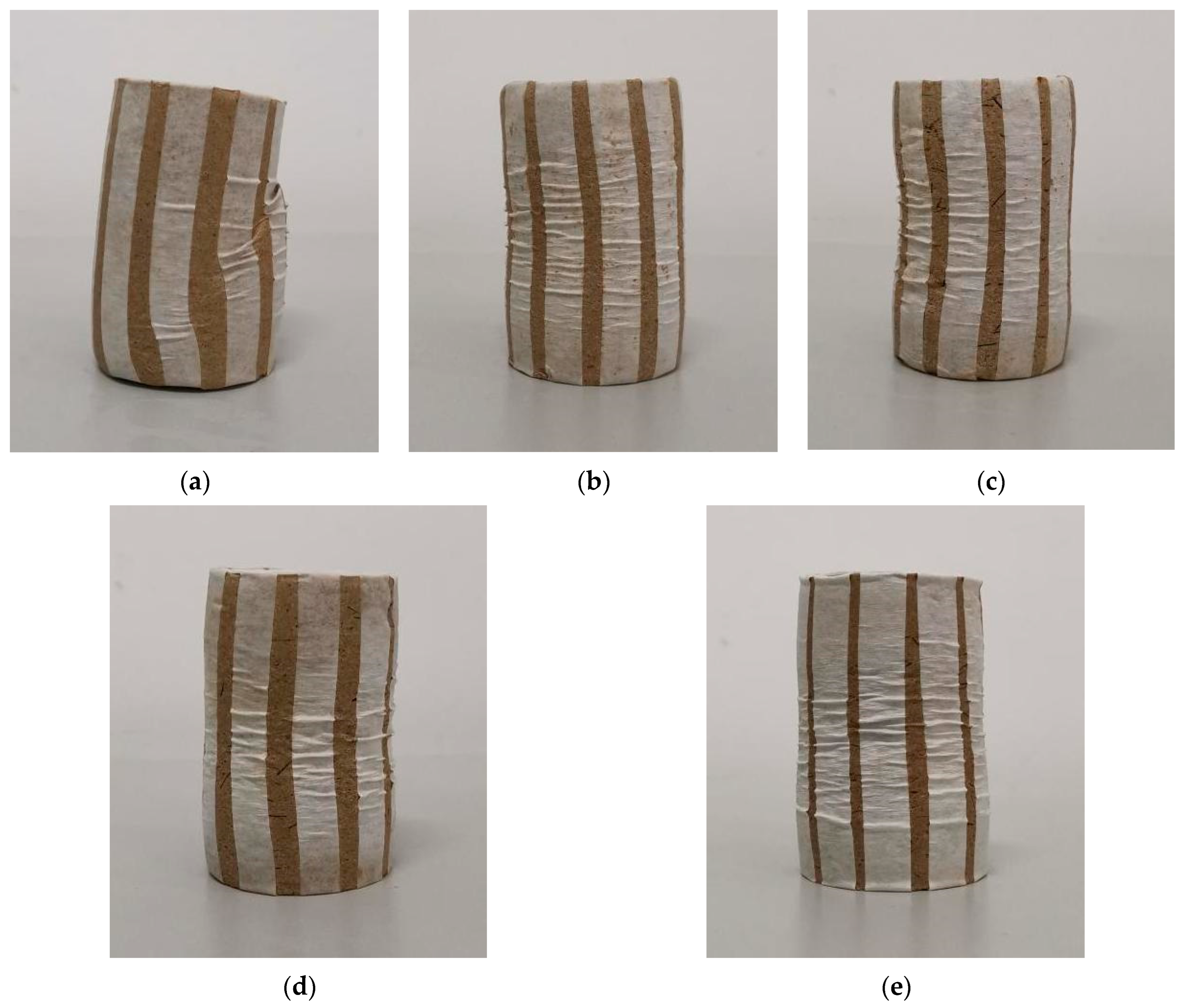

3.4.2. Shear Failure Modes of Improved Expansive Soil Samples in Triaxial Compression Test

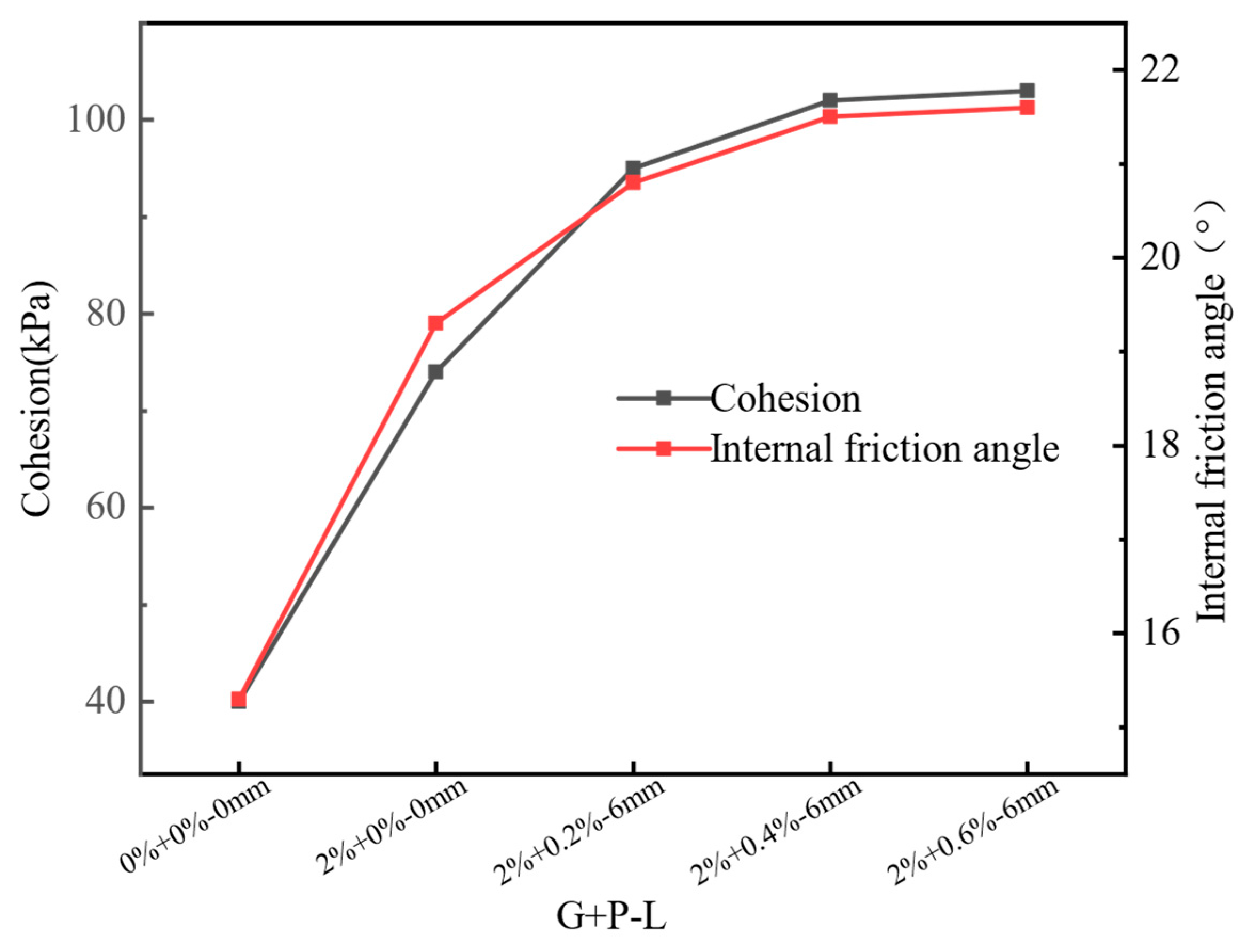

3.4.3. The Effect of Guar Gum and Palm Fiber Content on the Shear Strength Parameters of Modified Expansive Soil

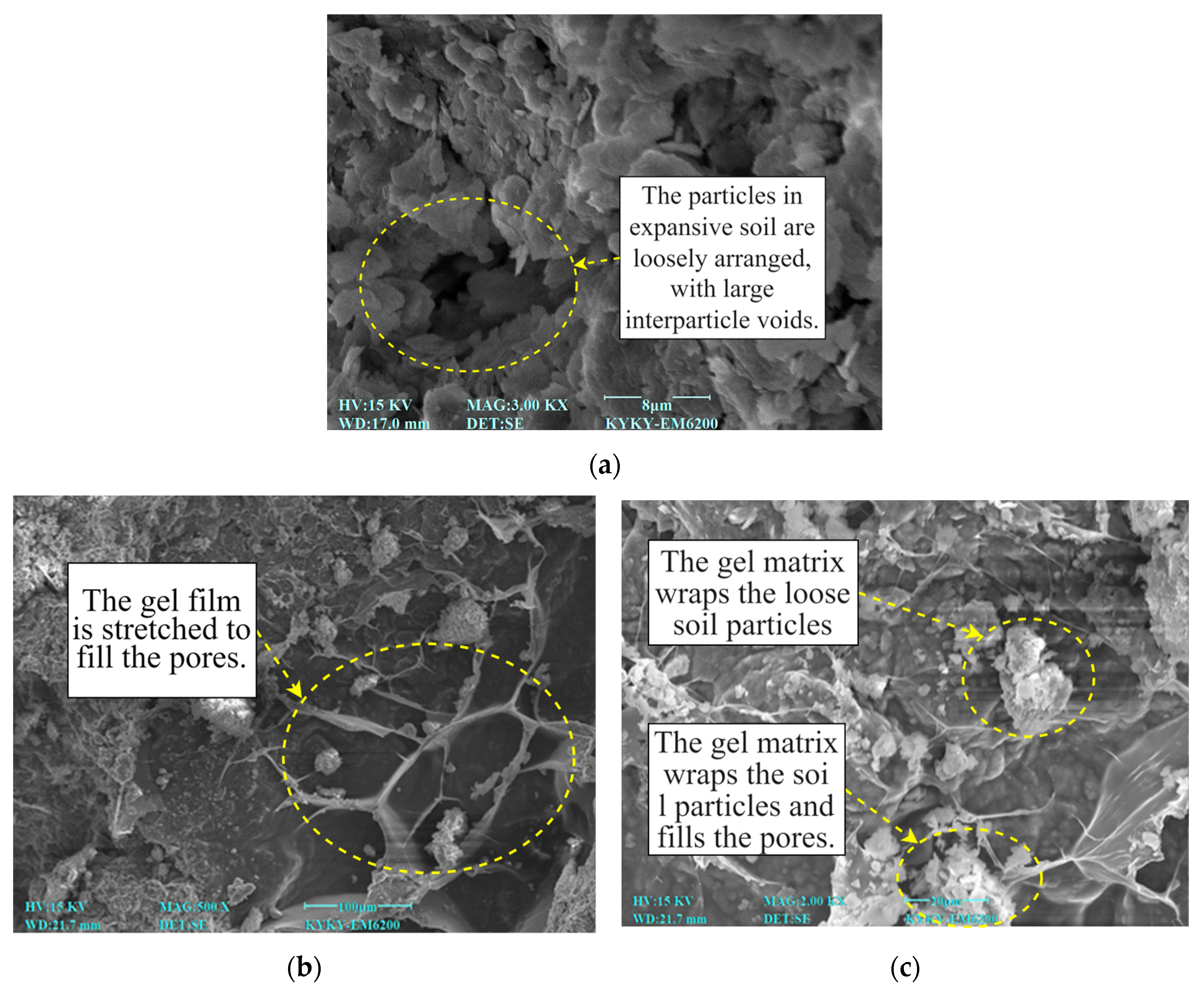

3.5. Mechanism Analysis of Guar Gum-Improved Soil

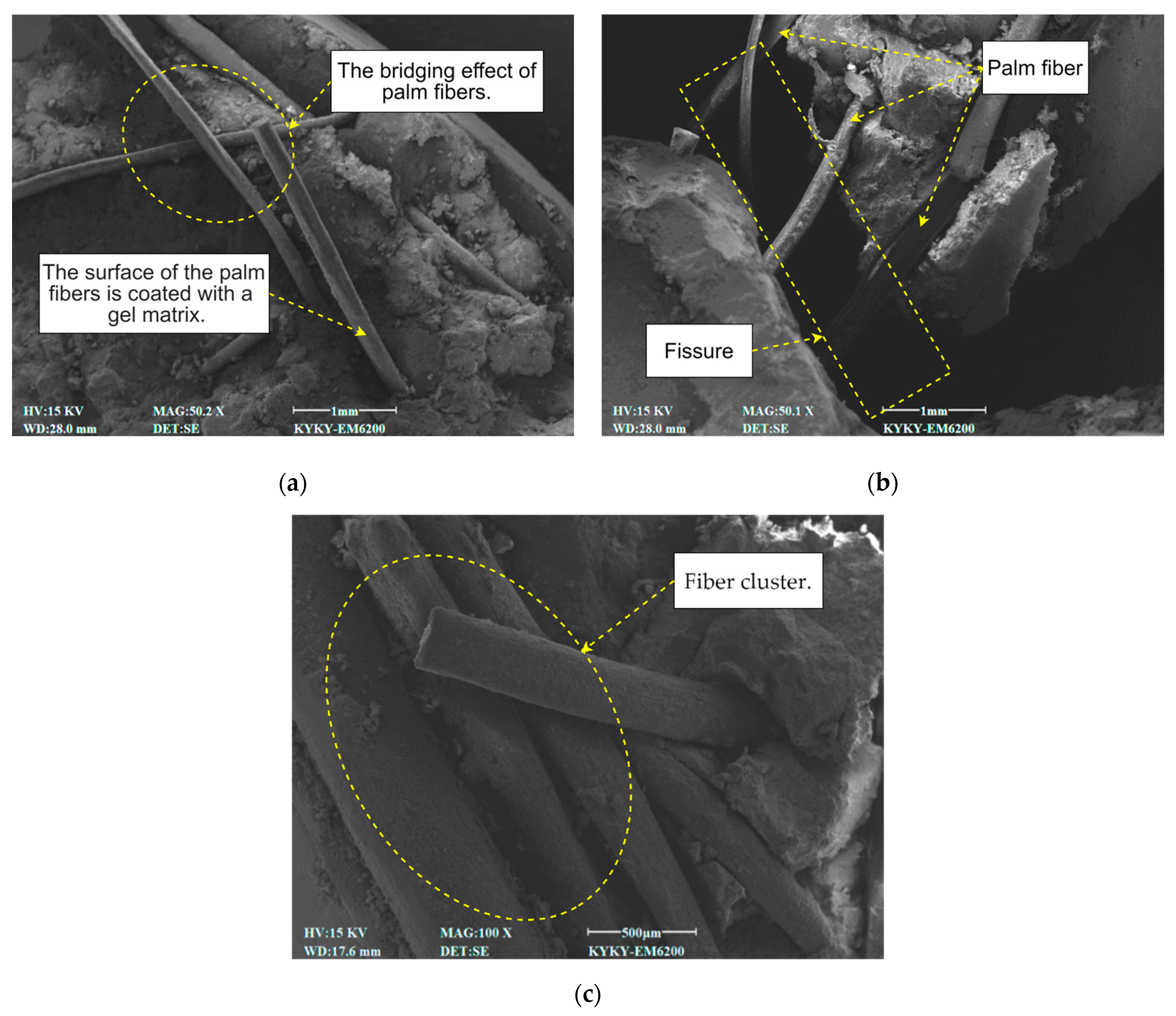

3.6. Mechanism of Guar Gum–Palm Fiber Composite Improvement of Expansive Soil

4. Discussion

- Guar gum can effectively improve the water stability of expansive soil. With the increase in guar gum content, the disintegration resistance of the samples significantly improves. When the guar gum content reaches 2%, the disintegration rate of the sample reaches the threshold of 0.85% and virtually no further disintegration occurs. Therefore, it is recommended that the guar gum content in practical applications be 2%.

- Both guar gum and guar gum–palm fiber composite materials can enhance the unconfined compressive strength of expansive soil, with the guar gum–palm fiber composite material showing the best improvement. Under the condition of a fixed palm fiber content, the compressive strength of the soil initially increases and then decreases as the palm fiber length increases. When the palm fiber content is 0.6% and the length is 6 mm, the unconfined compressive strength of the composite-improved soil increases the most, with a 20.9% higher compressive strength compared to expansive soil improved with 2% guar gum.

- The addition of palm fiber can improve the shear strength of guar gum-treated soil. As the palm fiber content increases, the stress–strain curve of the composite-improved soil gradually rises. The two shear strength indicators, cohesion and internal friction angle, both increase as the palm fiber content rises. When the ratio is 2% guar gum and 0.6%-6 mm palm fiber, the increase in the two shear strength indicators levels off, with increases of 52.1% and 12.4%, respectively, compared to pure guar gum-treated soil. However, further increasing the palm fiber content is detrimental to the improvement of the soil’s shear strength.

- Guar gum and palm fiber have a significant impact on the failure modes of the expansive soil samples. Under axial pressure, the guar gum-improved soil exhibits a “V”-shaped failure, with cracks not penetrating the sample, while the composite-improved soil shows irregular vertical cracks, and as the content increases, the cracks gradually shorten. Under shear failure, both guar gum-improved soil and guar gum–palm fiber composite-improved soil show bulging failure, and the deformation gradually decreases with the increase in palm fiber content.

- Scanning electron microscope analysis of the micro-improvement mechanism of guar gum–palm fiber-improved soil reveals that the gel matrix generated by the hydration reaction of guar gum can enhance the bonding strength of soil particles through stretching, wrapping, and filling, thus improving the water stability and mechanical properties of expansive soil. The reinforcement effect of palm fiber further enhances the mechanical properties of the improved soil.

- This composite improvement method can not only effectively increase the bearing capacity and deformation ability of expansive soil but also is environmentally friendly and has broad potential for promotion. However, this study is limited to expansive soil in Nanning, Guangxi, China, and the results are applicable only under conventional conditions. Therefore, the identified optimal ratio has certain limitations, and further research and verification are needed for specific situations.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Derbyshire, E. Geological hazards in loess terrain, with particular reference to the loess regions of China. Earth-Sci. Rev. 2001, 54, 231–260. [Google Scholar] [CrossRef]

- Jiang, M.; Zhang, F.; Hu, H.; Cui, Y.; Peng, J. Structural characterization of natural loess and remolded loess under triaxial tests. Eng. Geol. 2014, 181, 249–260. [Google Scholar] [CrossRef]

- Tiwari, N.; Satyam, N.; Puppala, A.J. Strength and durability assessment of expansive soil stabilized with recycled ash and natural fibers. Transp. Geotech. 2021, 29, 100556. [Google Scholar] [CrossRef]

- Rabab’ah, S.; Al Hattamleh, O.; Aldeeky, H.; Alfoul, B.A. Effect of glass fiber on the properties of expansive soil and its utilization as subgrade reinforcement in pavement applications. Case Stud. Constr. Mater. 2021, 14, e00485. [Google Scholar] [CrossRef]

- Blayi, R.A.; Sherwani, A.F.H.; Ibrahim, H.H.; Faraj, R.H.; Daraei, A. Strength improvement of expansive soil by utilizing waste glass powder. Case Stud. Constr. Mater. 2020, 13, e00427. [Google Scholar] [CrossRef]

- Jain, A.K.; Jha, A.K. Geotechnical behaviour and micro-analyses of expansive soil amended with marble dust. Soils Found. 2020, 60, 737–751. [Google Scholar] [CrossRef]

- Narani, S.; Abbaspour, M.; Hosseini, S.M.M.; Aflaki, E.; Nejad, F.M. Sustainable reuse of Waste Tire Textile Fibers (WTTFs) as reinforcement materials for expansive soils: With a special focus on landfill liners/covers. J. Clean. Prod. 2020, 247, 119151. [Google Scholar] [CrossRef]

- Cai, Y.; Xu, L.; Liu, W.; Shang, Y.; Su, N.; Feng, D. Field Test Study on the dynamic response of the cement-improved expansive soil subgrade of a heavy-haul railway. Soil Dyn. Earthq. Eng. 2020, 128, 105878. [Google Scholar] [CrossRef]

- Dang, L.C.; Khabbaz, H.; Ni, B.-J. Improving engineering characteristics of expansive soils using industry waste as a sustainable application for reuse of bagasse ash. Transp. Geotech. 2021, 31, 100637. [Google Scholar] [CrossRef]

- Ma, B.; Cai, K.; Zeng, X.; Li, Z.; Hu, Z.; Chen, Q.; He, C.; Chen, B.; Huang, X. Experimental study on physical-mechanical properties of expansive soil improved by multiple admixtures. Adv. Civ. Eng. 2021, 2021, 5567753. [Google Scholar] [CrossRef]

- Xie, W.-l.; Li, P.; Zhang, M.-s.; Cheng, T.-e.; Wang, Y. Collapse behavior and microstructural evolution of loess soils from the Loess Plateau of China. J. Mt. Sci. 2018, 15, 1642–1657. [Google Scholar] [CrossRef]

- Barman, D.; Dash, S.K. Stabilization of expansive soils using chemical additives: A review. J. Rock Mech. Geotech. Eng. 2022, 14, 1319–1342. [Google Scholar] [CrossRef]

- Ayeldeen, M.; Negm, A.; El-Sawwaf, M.; Kitazume, M. Enhancing mechanical behaviors of collapsible soil using two biopolymers. J. Rock Mech. Geotech. Eng. 2017, 9, 329–339. [Google Scholar] [CrossRef]

- Hamza, M.; Nie, Z.; Aziz, M.; Ijaz, N.; Fang, C.; Ghani, M.U.; Ijaz, Z.; Noshin, S.; Salman, M. Geotechnical properties of problematic expansive subgrade stabilized with guar gum biopolymer. Clean Technol. Environ. Policy 2023, 25, 1699–1719. [Google Scholar] [CrossRef]

- Fatehi, H.; Abtahi, S.M.; Hashemolhosseini, H.; Hejazi, S.M. A novel study on using protein based biopolymers in soil strengthening. Constr. Build. Mater. 2018, 167, 813–821. [Google Scholar] [CrossRef]

- Xu, X.; Chu, H.; Wang, Q.; Li, J.; Yuan, X.; Niu, C.; Lei, H.; Yu, Z. Dispersion, mechanical, hydrophysical properties and mechanistic analysis of improved dispersive soil using guar gum. Bull. Eng. Geol. Environ. 2025, 84, 56. [Google Scholar] [CrossRef]

- Anandha Kumar, S.; Sujatha, E.R.; Pugazhendi, A.; Jamal, M.T. Guar gum-stabilized soil: A clean, sustainable and economic alternative liner material for landfills. Clean Technol. Environ. Policy 2023, 25, 323–341. [Google Scholar] [CrossRef]

- Bouazza, A.; Gates, W.P.; Ranjith, P.G. Hydraulic conductivity of biopolymer-treated silty sand. Géotechnique 2009, 59, 71–72. [Google Scholar] [CrossRef]

- Widianti, A.; Diana, W.; Alghifari, M. Shear strength and elastic modulus behavior of coconut fiber-reinforced expansive soil. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Batu Pahat, Malaysia, 1–2 December 2020; p. 012043. [Google Scholar]

- Medina-Martinez, C.; Sandoval-Herazo, L.; Castro, S.; Vivar-Ocampo, R.; González, D. Natural fibers: An alternative for the reinforcement of expansive soils. Sustainability 2022, 14, 9275. [Google Scholar] [CrossRef]

- Verma, D.; Gope, P.; Shandilya, A.; Gupta, A.; Maheshwari, M. Coir fibre reinforcement and application in polymer composites. J. Mater. Environ. Sci 2013, 4, 263–276. [Google Scholar]

- Keshav, N.; Prabhu, A.; Kattimani, A.; Dharwad, A.; Kallatti, C.; Mahalank, S. Enhancing the properties of expansive soil using biopolymers—Xanthan gum and guar gum. In Proceedings of the Indian Geotechnical Conference 2019: IGC-2019, Surat, India, 19–21 December 2019; Volume IV, pp. 129–135. [Google Scholar]

- Vydehi, K.V.; Moghal, A.A.B. Effect of biopolymeric stabilization on the strength and compressibility characteristics of cohesive soil. J. Mater. Civ. Eng. 2022, 34, 04021428. [Google Scholar] [CrossRef]

- Vydehi, K.V.; Moghal, A.A.B. Compressibility characteristics of Guar gum-treated expansive soil. In Proceedings of the Ground Improvement and Reinforced Soil Structures: Proceedings of Indian Geotechnical Conference; Springer: Berlin/Heidelberg, Germany, 2020; Volume 2, pp. 339–345. [Google Scholar]

- Inoue, A.; Watanabe, T.; Kohyama, N.; Brusewitz, A.M. Characterization of illitization of smectite in bentonite beds at Kinnekulle, Sweden. Clays Clay Miner. 1990, 38, 241–249. [Google Scholar] [CrossRef]

- JTG 3430-2020; Test Methods of Soils for Highway Engineering. Transportation Ministry of the People’s Republic of China: Beijing, China, 2020.

- JTGE51-2009; Test Methods for Inorganic Binder Stabilized Materials in Highway Engineering. Chinese Standard: Beijing, China, 2009.

- Nelson, J.; Miller, D.J. Expansive Soils: Problems and Practice in Foundation and Pavement Engineering; John Wiley & Sons: Hoboken, NJ, USA, 1997. [Google Scholar]

- Khattak, M.J.; Alrashidi, M. Durability and mechanistic characteristics of fiber reinforced soil–cement mixtures. Int. J. Pavement Eng. 2006, 7, 53–62. [Google Scholar] [CrossRef]

- Adabi, M.; Darvishan, E.; Eyvazi, G.; Jahanbaksh Motlagh, H. Geoenvironmental application of novel persian gum biopolymer in sandy soil stabilization. Arab. J. Sci. Eng. 2022, 47, 12915–12929. [Google Scholar] [CrossRef]

- Yixian, W.; Panpan, G.; Shengbiao, S.; Haiping, Y.; Binxiang, Y. Study on strength influence mechanism of fiber-reinforced expansive soil using jute. Geotech. Geol. Eng. 2016, 34, 1079–1088. [Google Scholar] [CrossRef]

- Acharya, R.; Pedarla, A.; Bheemasetti, T.V.; Puppala, A.J. Assessment of guar gum biopolymer treatment toward mitigation of desiccation cracking on slopes built with expansive soils. Transp. Res. Rec. 2017, 2657, 78–88. [Google Scholar] [CrossRef]

- Consoli, N.C.; Casagrande, M.D.; Prietto, P.D.; Thomé, A.n. Plate load test on fiber-reinforced soil. J. Geotech. Geoenvironmental Eng. 2003, 129, 951–955. [Google Scholar] [CrossRef]

- Hu, Q.; Song, W.; Hu, J. Study of the mechanical properties and water stability of microbially cured, coir-fiber-reinforced clay soil. Sustainability 2023, 15, 13261. [Google Scholar] [CrossRef]

- Chen, J.; Mu, J.; Chen, A.; Long, Y.; Zhang, Y.; Zou, J. Experimental Study on the Properties of Basalt Fiber–Cement-Stabilized Expansive Soil. Sustainability 2024, 16, 7579. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Z.; Chen, H.; Shao, L.; Zhou, X.; Wang, S. Triaxial shear behavior of basalt fiber-reinforced loess based on digital image technology. KSCE J. Civ. Eng. 2021, 25, 3714–3726. [Google Scholar] [CrossRef]

- Festugato, L.; Menger, E.; Benezra, F.; Kipper, E.A.; Consoli, N.C. Fibre-reinforced cemented soils compressive and tensile strength assessment as a function of filament length. Geotext. Geomembr. 2017, 45, 77–82. [Google Scholar] [CrossRef]

- Hamza, M.; Nie, Z.; Aziz, M.; Ijaz, N.; Ameer, M.F.; Ijaz, Z. Geotechnical properties of problematic expansive subgrade stabilized with xanthan gum biopolymer. Road Mater. Pavement Des. 2023, 24, 1869–1883. [Google Scholar] [CrossRef]

- Wan, J.; Ouyang, F.; Xiao, H.; Wang, L.; Tao, G. Experimental study on the physical and mechanical properties of modified clay using xanthan gum and guar gum composite materials. Sustainability 2024, 16, 5432. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Saisree, S. Geotechnical behaviour of guar gum-treated soil. Soils Found. 2019, 59, 2155–2166. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, J.; Wang, Y.; Qi, C.; Ma, X.; Che, W.; Ma, K. Wetting–drying effects on the mechanical performance of xanthan gum biopolymer-stabilized soil. Environ. Earth Sci. 2024, 83, 197. [Google Scholar] [CrossRef]

- Fu, H.; Zha, H.; Zeng, L.; Chen, C.; Jia, C.; Bian, H. Research progress on ecological protection technology of highway slope: Status and challenges. Transp. Saf. Environ. 2020, 2, 3–17. [Google Scholar] [CrossRef]

- Karimi, A.; Rahmatabadi, D.; Baghani, M. Various FDM mechanisms used in the fabrication of continuous-fiber reinforced composites: A review. Polymers 2024, 16, 831. [Google Scholar] [CrossRef]

| Density (g·cm3) | Mean Diameter (mm) | Young’s Modulus (GPa) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|

| 1.37 | 0.3 | 0.8 | 135.2 | 18.75 |

| Specimen Number | Test Type | Sample Type | Dosage of Guar Gum (G/%) | Dosage of Palm Fiber (P/%) | Length of Palm Fiber (L/mm) |

|---|---|---|---|---|---|

| 1 | Disintegration test | Expansive soil | 0 | 0 | 0 |

| 2~6 | Expansive soil + Guar gum | 0.5, 1, 1.5, 2, 2.5 | 0 | 0 | |

| 7 | Unconfined compressive strength test | Expansive soil | 0 | 0 | 0 |

| 8~11 | Expansive soil + Guar gum | 0.5, 1, 1.5, 2 | 0 | 0 | |

| 12~15 | Expansive soil + Guar gum + Palm fiber | 2 (Optimal) | 0.2 | 3, 6, 9, 12 | |

| 16~19 | 0.4 | 3, 6, 9, 12 | |||

| 20~23 | 0.6 | 3, 6, 9, 12 | |||

| 24 | Triaxial compression test | Expansive soil | 0 | 0 | 0 |

| 25 | Expansive soil + Guar gum | 2 (Optimal) | 0 | 0 | |

| 26 | Expansive soil + Guar gum + Palm fiber | 2 (Optimal) | 0.2 | 6 (Optimal) | |

| 27 | 0.4 | ||||

| 28 | 0.6 |

| Liquid Limit (%) | Plastic Limit (%) | Plasticity Index (%) | Free Swelling Ratio (%) | Specific Gravity | Maximum Dry Density (g/cm3) | Optimum Moisture Content (%) |

|---|---|---|---|---|---|---|

| 59.3 | 20.9 | 38.4 | 75 | 2.68 | 1.78 | 14.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Huang, Y.; Chen, A.; Ji, X.; Liao, X.; Li, S.; Xiao, Y. Strength and Micro-Mechanism of Guar Gum–Palm Fiber Composite for Improvement of Expansive Soil. Fibers 2025, 13, 104. https://doi.org/10.3390/fib13080104

Chen J, Huang Y, Chen A, Ji X, Liao X, Li S, Xiao Y. Strength and Micro-Mechanism of Guar Gum–Palm Fiber Composite for Improvement of Expansive Soil. Fibers. 2025; 13(8):104. https://doi.org/10.3390/fib13080104

Chicago/Turabian StyleChen, Junhua, Yuejian Huang, Aijun Chen, Xinping Ji, Xiao Liao, Shouqian Li, and Ying Xiao. 2025. "Strength and Micro-Mechanism of Guar Gum–Palm Fiber Composite for Improvement of Expansive Soil" Fibers 13, no. 8: 104. https://doi.org/10.3390/fib13080104

APA StyleChen, J., Huang, Y., Chen, A., Ji, X., Liao, X., Li, S., & Xiao, Y. (2025). Strength and Micro-Mechanism of Guar Gum–Palm Fiber Composite for Improvement of Expansive Soil. Fibers, 13(8), 104. https://doi.org/10.3390/fib13080104