Highlights

What are the main findings?

- A fluorine-free, silicone-based polyurethane (SiPU) can be used as the only raw material for fabricating membranes, addressing environmental and health concerns associated with fluorine-containing materials.

- The membranes are produced via a simple, one-step electrospinning process that overcomes the complexity of the conventional preparation method.

What is the implication of the main finding?

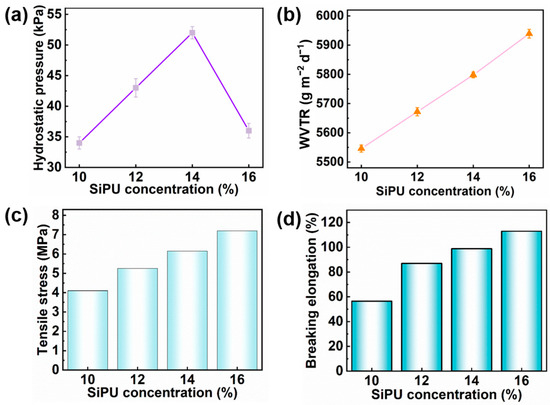

- The optimized SiPU nanofiber membrane demonstrates excellent water repellency (hydrostatic pressure of 52 kPa) and breathability (water vapor transmission rate of 5798 g·m−2·d−1), meeting key performance criteria.

- The optimized SiPU-14 nanofiber membrane exhibits high mechanical strength (tensile strength of 6.15 MPa) and ductility (elongation at break of 98.80%), enhancing durability, comfort, and practical applicability in protective textiles.

Abstract

High-performance waterproof and breathable nanofiber membranes (WBNMs) are in great demand for various advanced applications. However, the fabrication of such membranes often relies on fluorinated materials or involves complex preparation processes, limiting their practical use. In this study, we present an innovative approach by utilizing silicon-containing polyurethane (SiPU) as a single-component, fluorine-free raw material to prepare high-performance WBNMs via a simple one-step electrospinning process. The electrospinning technique enables the formation of SiPU nanofibrous membranes with a small maximum pore size (dmax) and high porosity, while the intrinsic hydrophobicity of SiPU imparts excellent water-repellent characteristics to the membranes. As a result, the single-component SiPU WBNM exhibits superior waterproofness and breathability, with a hydrostatic pressure of 52 kPa and a water vapor transmission rate (WVTR) of 5798 g m−2 d−1. Moreover, the optimized SiPU-14 WBNM demonstrates outstanding mechanical properties, including a tensile strength of 6.15 MPa and an elongation at break of 98.80%. These findings indicate that the single-component SiPU-14 WBNMs not only achieve excellent waterproof and breathable performance but also possess robust mechanical strength, thereby enhancing the comfort and expanding the potential applications of protective textiles, such as outdoor apparel and car seats.

1. Introduction

Waterproof and breathable materials are vital for preventing liquid water from penetrating while allowing water vapor to escape [1,2]. They have a wide range of applications in apparel, healthcare, automotive interiors, water treatment, and the building field [3]. Waterproof and breathable materials can be classified into two main categories: hydrophilic nonporous membranes and hydrophobic microporous membranes [4]. Among these, hydrophobic microporous membranes are more favored due to their superior breathability [5].

Electrospinning technology is a promising technique for manufacturing hydrophobic microporous membranes [6]. The obtained nanofibrous membranes have ultrafine diameters, high specific surface areas, and high porosity [7,8,9,10,11], ensuring that the membranes exhibit excellent waterproofness and breathability [12,13,14]. The preparation of waterproof and breathable nanofiber membranes (WBNMs) based on electrospinning is categorized into two methods: one-step electrospinning and post-treatment [15,16]. The one-step electrospinning approach has attracted significant attention, primarily due to its simplicity and high efficiency.

Pure single polymer electrospinning nanofiber membranes, such as polyurethane (PU) [17,18], poly(vinylidene fluoride) (PVDF) [19], polyethylene terephthalate (PET) [20], polyamide (PA) [21], and polyurethane (PAN) [22], exhibit unsatisfactory waterproofness, with hydrostatic pressure of less than 10 kPa. Zhu et al. [17] reported that single polyurethane (PU) fibrous membrane demonstrated a hydrostatic pressure of 7.2 kPa, which is insufficient to meet practical application requirements. To prepare hydrophobic microporous membranes, some researchers have employed fluorine to reduce the surface energy of the nanofiber membranes [23,24]. Zhao et al. [24] added a fluorinated polyurethane elastomer to the PU electrospinning solution, resulting in a nanofiber membrane that exhibited outstanding waterproofness. However, fluorine-containing materials are harmful to both humans and the environment [25]. Therefore, it is crucial to develop single-polymer, fluorine-free WBNMs through a simple one-step electrospinning process.

Herein, a single-component silicon-containing polyurethane (SiPU) with intrinsically low surface energy was employed as the raw material for the fabrication of fluorine-free WBNMs via a simple one-step electrospinning process. By adjusting the SiPU concentration, key membrane parameters such as maximum pore size (dmax), wettability, and porosity were effectively controlled. The influence of these structural features on the waterproofness, breathability, and mechanical properties of the resulting SiPU WBNMs was systematically investigated. Among the prepared membranes, the SiPU-14 WBNM demonstrated excellent combined waterproof, breathable, and mechanical performance. This research provides a promising strategy for the development of high-performance, single-component WBNMs through a facile one-step electrospinning technique and is expected to inspire further advances in the design of advanced functional membranes.

2. Experimental Section

2.1. Materials

Silicon-containing polyurethane (SiPU) was purchased from Dainichiseika Industries Co., Ltd. (Tokyo, Japan). N, N-Dimethylformamide (AR, ≥99.5%), ethyl acetate (AR, ≥99.5%), and lithium chloride (LiCl) were provided by Aladdin Chemical Reagents Co., Ltd. (Shanghai, China). All the chemicals were used as received without any further purification.

2.2. Preparation of SiPU Nanofiber Membranes

The SiPU solutions were prepared by dissolving SiPU in DMF and ethyl acetate (3:2, volume ratio) with continuous stirring for 8 h at 60 °C. The concentrations of SiPU were 10, 12, 14, and 16%, respectively. The concentration of LiCl of the electrospinning solutions was fixed at 0.01%, corresponding to the total weight of the electrospinning solutions.

The viscosity of the SiPU solutions was measured by a rotary viscosity meter (RVDV-1, Shanghai Yueping Scientific Instrument Co., Ltd., Shanghai, China). Each data point in the viscosity plot is the average value derived from triplicate experiments, and the error bars illustrate the standard deviation of the results.

The above SiPU solutions were pumped through metal needles at a constant feed rate of 0.017 mL/min by using HD-2335 spinning equipment (Beijing Yongkang Leye Technology Development Co., Ltd., Beijing, China). A high voltage of 20 kV was applied to the needle tip. The receiving distance was 20 cm. The temperature and humidity were 25 ± 2 °C and 45 ± 2%, respectively. The thickness of the nanofiber membranes was maintained at approximately 100 μm.

2.3. Structural Characterization of the SiPU WBNMS

The microscopic morphology of the SiPU WBNMs was assessed by using a scanning electron microscope (CFP-1100AI, PMI, Austin, TX, USA). The mean diameter of the SiPU nanofiber membrane was determined by means of statistical analysis, with measurements obtained from 200 nanofibers selected at random from the SEM images. This procedure was conducted utilizing the Nano Measurer software (version 1.2.0.5).

The maximum pore size (dmax) of the PSiPU WBNMs was measured by using a capillary flow porometer (PSM 165, Topas, Fürth, Germany).

The porosity of the SiPU WBNMs was calculated from the following formula:

where ρ1 and ρ2 are the density of polymer material and of the SiPU WBNMs, respectively.

2.4. Performance Characterization of the SiPU WBNMS

The contact angles of the SiPU WBNMs were tested using a contact angle analyzer (OCA20, Dataphysics).

The waterproofness of the SiPU WBNMs was provided by hydrostatic pressure, which was measured via a hydrostatic pressure tester (YG812F, Wenzhou Fangyuan Instrument Co., Ltd., Wenzhou, China) under a pressurization rate of 6 kPa min−1.

The breathability of the SiPU WBNMs was evaluated in terms of the water vapor transmission rate (WVTR), which was measured via a water vapor transmission tester (W3/060, Jinan Languang electromechanical Technology Co., Ltd., Jinan, China).

The mechanical performance of the SiPU WBNMs with a size of 1 cm in width and 5 cm in height was determined using a fiber strength tester (LILY-06ED/PC, Jinan Languang electromechanical Technology Co., Ltd., Jinan, China).

3. Results and Discussion

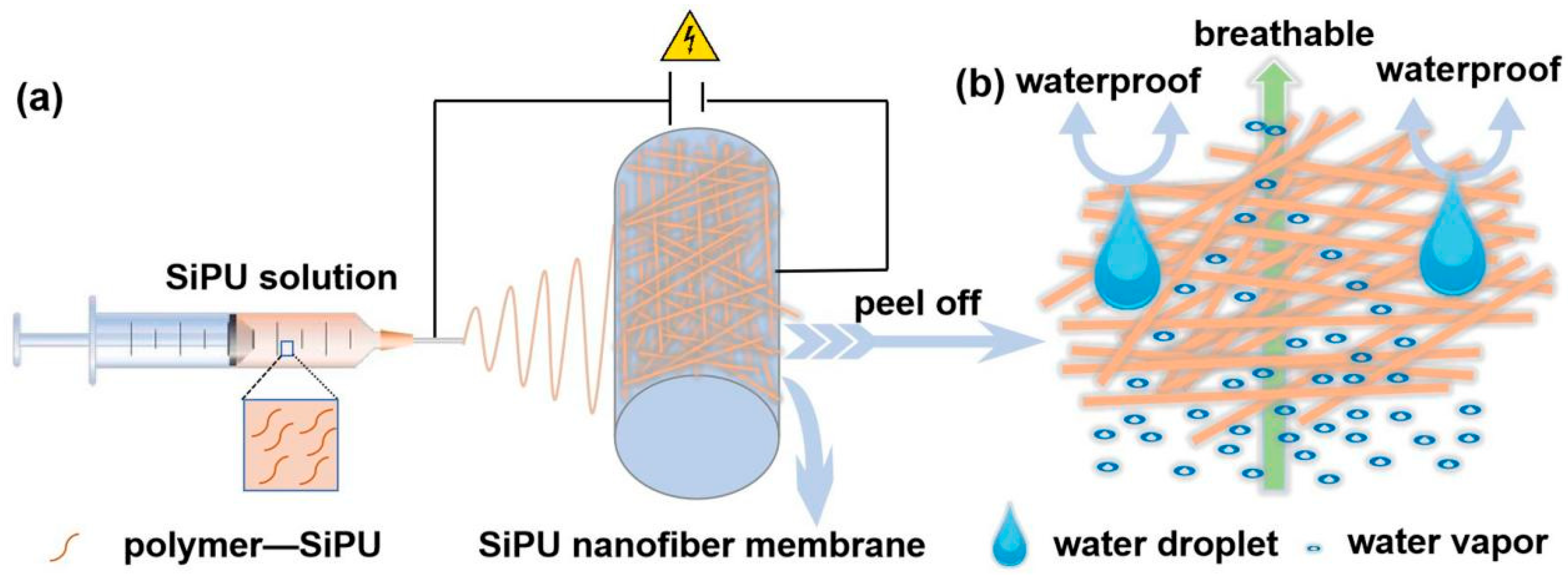

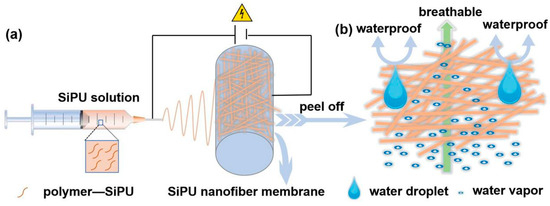

To achieve improved waterproof and mechanical properties, low-surface-energy siliceous polyurethane (SiPU) was selected as a single-component, fluorine-free raw material to prepare highly waterproof and breathable nanofiber membranes (WBNMs) using one-step electrospinning (Figure 1a). The obtained SiPU WBNMs exhibited a randomly disordered three-dimensional porous structure. This interactive porous structure facilitates the transition of water vapor while preventing the penetration of liquid water (Figure 1b).

Figure 1.

Schematic illustration of (a) one-step electrospinning of fluorine-free PU/PMMA WBNMs, and (b) waterproof and breathable mechanism of the PU/PMMA WBNMs.

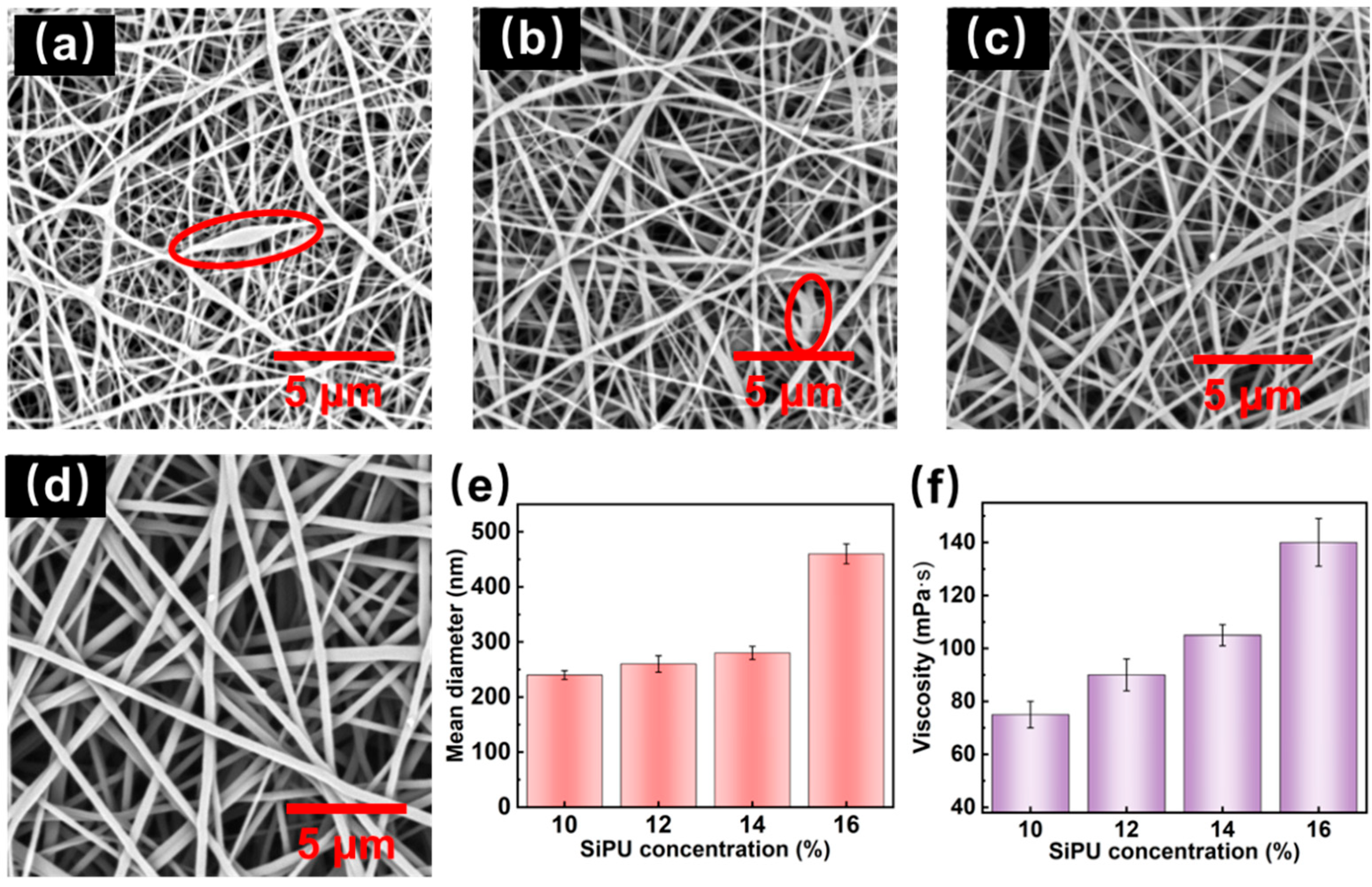

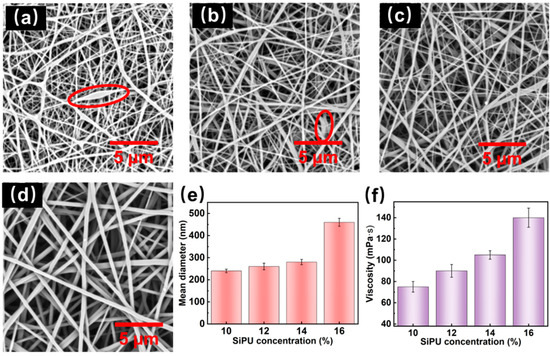

Figure 2a–d present the SEM micrographs of the SiPU WBNMs prepared at different SiPU concentrations. At a SiPU concentration of 10%, the nanofibers exhibit some bead-like structures (Figure 2a). The bead-shaped nanofibers (mean diameter of 240 nm, Figure 2e) were formed due to the relatively low viscosity of the SiPU electrospinning solution (Figure 2f) and the inadequate stretching that occurred during the jet whipping stage in the electrospinning process [22,26]. As the SiPU concentration increased from 10 to 14%, the beads on the nanofibers disappeared (Figure 2b–d), and the mean diameters increased from 260 to 460 nm (Figure 2e). These changes can be attributed to the significant increase in the viscosity of the electrospinning solution (Figure 2f).

Figure 2.

SEM micrographs of SiPU WBNMs at different SiPU concentrations of (a) 10%, (b) 12%, (c) 14%, and (d) 16%. (e) Mean diameter of SiPU WBNMs at different SiPU concentrations. (f) Viscosity of the SiPU electrospinning solution at different SiPU concentrations.

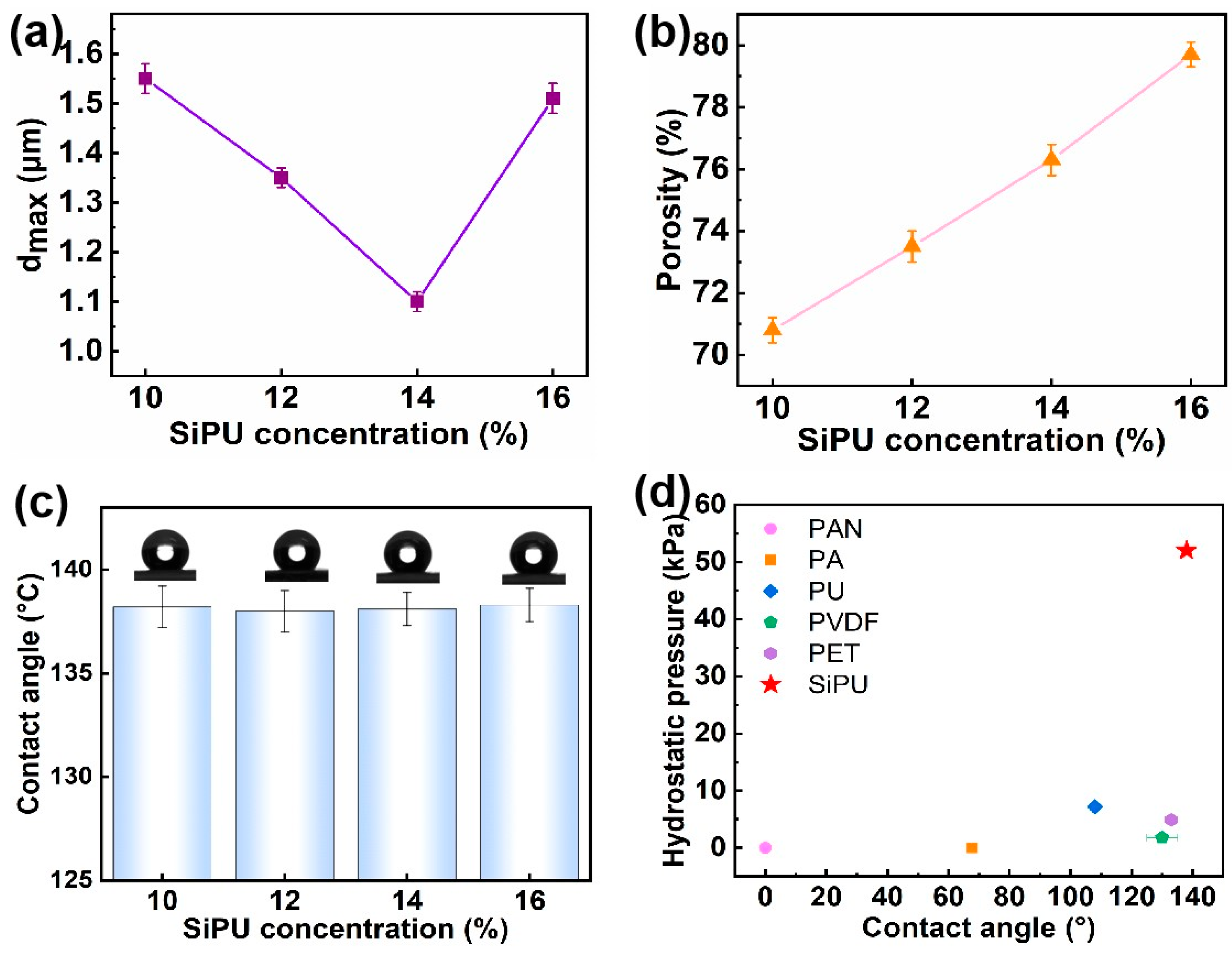

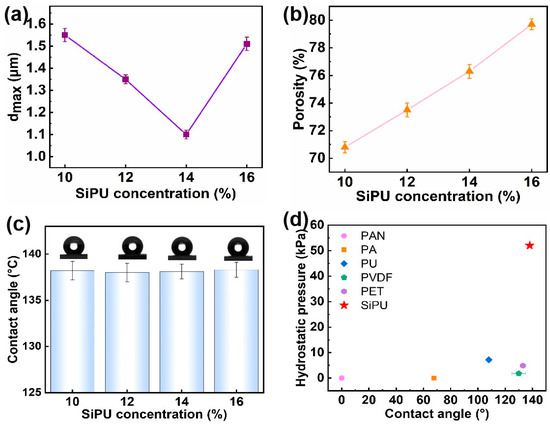

A key criterion for waterproofness is a small pore size that prevents liquid droplets from passing through. Thus, the maximum pore size (dmax) of SiPU WBNMs was investigated. The SiPU nanofiber membrane at a polymer concentration of 10% exhibits a large dmax of 1.55 μm (Figure 3a), which can be attributed to the presence of microsized beads. Similar findings have been reported by Li et al. [27]. As the SiPU concentration increases from 12 to 14%, the bead structure gradually disappears, and the dmax of SiPU WBNMs decreases from 1.35 to 1.10 μm (Figure 3a). However, further increasing the SiPU concentration to 16% leads to a larger dmax of 1.51 μm (Figure 3a). This result may be due to the increased diameter of the nanofibers (Figure 2e), consistent with results reported by Zhao et al. [27]. Concurrently, the porosity of the SiPU WBNMs shows a slight increase from 70.8 to 79.7%, with an increase in polymer concentration from 10 to 16% (Figure 3b). This phenomenon could be attributed to the gradual dissolution of the bead structure.

Figure 3.

dmax (a), porosity (b), and WCA (c) of SiPU WBNMs at different SIPU concentrations. (d) Contrast of waterproofness and contact angle between the SiPU WBNM and other singe component WBNMs.

The waterproof mechanism of nanofiber membrane can be described by the Young–Laplace equation:

where Δp represents the pressure difference across the liquid–gas interface, γ refers to the surface tension of the liquid, and dmax represents the maximum pore size of the nanofiber membranes.

According to the Young–Laplace equation, the hydrostatic pressure was mainly determined by the contact angle and dmax. The SiPU nanofiber membranes exhibited a water contact angle (WCA) of approximately 138° across the concentration range examined (Figure 3c), which can be attributed to the identical material composition and similar surface roughness of the SiPU nanofiber membranes. For SiPU WBNMs, the contact angle kept almost unchanged, so the mainly influenced factor of the hydrostatic pressure is the dmax. The WCA of the SiPU WBNMs was compared with other single-component WBNMs reported in the literature [17,19,20,21,22]. The results demonstrated that the SiPU WBNM possesses the highest WCA and the highest hydrophobicity among the WBNMs reported (Figure 3d and Table S1). Consequently, the SiPU WBNM, composed of a single component, exhibits a low dmax, elevated hydrophobicity, and high porosity, making it a promising candidate for use as an ideal WBNM.

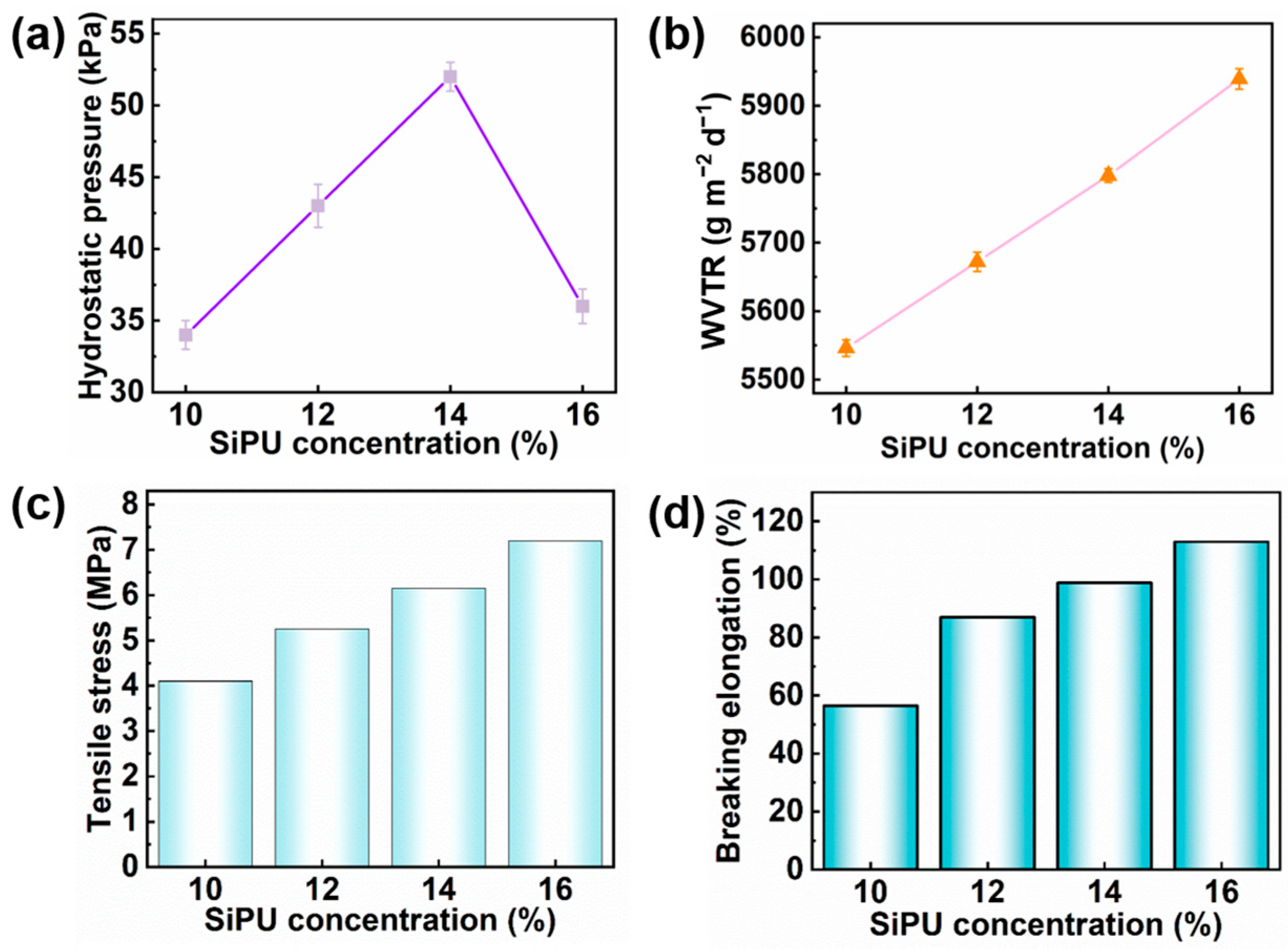

Hydrostatic pressure measurement was employed to assess the waterproofness of SiPU WBNMs with varying SiPU concentrations. The SiPU WBNM prepared with a 10% SiPU concentration exhibited a low hydrostatic pressure of 34 kPa (Figure 4a), which can be attributed to the relatively high dmax value (Figure 3a). As the SiPU concentration increased from 12 to 14%, the hydrostatic pressure of the SiPU nanofiber membranes rose from 43 to 52 kPa (Figure 4a), due to the reduced dmax (Figure 3a). However, further increasing the SiPU concentration to 16% resulted in a decrease in hydrostatic pressure to 36 kPa (Figure 4a), which could be attributed to the increased dmax (Figure 3a). The single-component SiPU WBNM at a SiPU concentration of 14% shows the highest hydrostatic pressure value of 52 kPa. Compared with other single-component polymer WBNMs reported in the literature [17,19,20,21,22], the prepared single-component SiPU WBNM demonstrates the highest waterproof performance (Figure 3d and Table S1).

Figure 4.

Hydrostatic pressure (a), WVTR (b), tensile stress (c), and breaking elongation (d) of SiPU WBNMs at different SiPU concentrations.

The breathability of the nanofiber membrane follows Fick’s law and is primarily affected by porosity. Higher porosity leads to greater breathability [28]. With increasing SiPU concentration from 10 to 16%, the water vapor transmission rate (WVTR) increased slightly from 5546 to 5939 g m−2 d−1 (Figure 4b), which can be attributed to the slightly increased porosity (Figure 3b). The WVTR of the SiPU WBNMs is sufficient for protective material applications, as a WVTR of more than 5 kg m−2 d−1 is considered to indicate a breathable material [29].

During practical implementation, it is essential for WBNMs to possess reliable mechanical properties to withstand deformation [30]. Figure S1 illustrates the typical stress–strain curves of SiPU WBNMs at varying SiPU concentrations. The results indicate that increasing the SiPU concentration from 10 to 14% leads to an enhancement in tensile stress of the SiPU nanofiber membranes from 4.15 to 7.41 MPa, accompanied by an increase in breaking elongation from 56 to 113% (Figure 4c,d). These results can be attributed to the elimination of beads and the increase in nanofiber diameter.

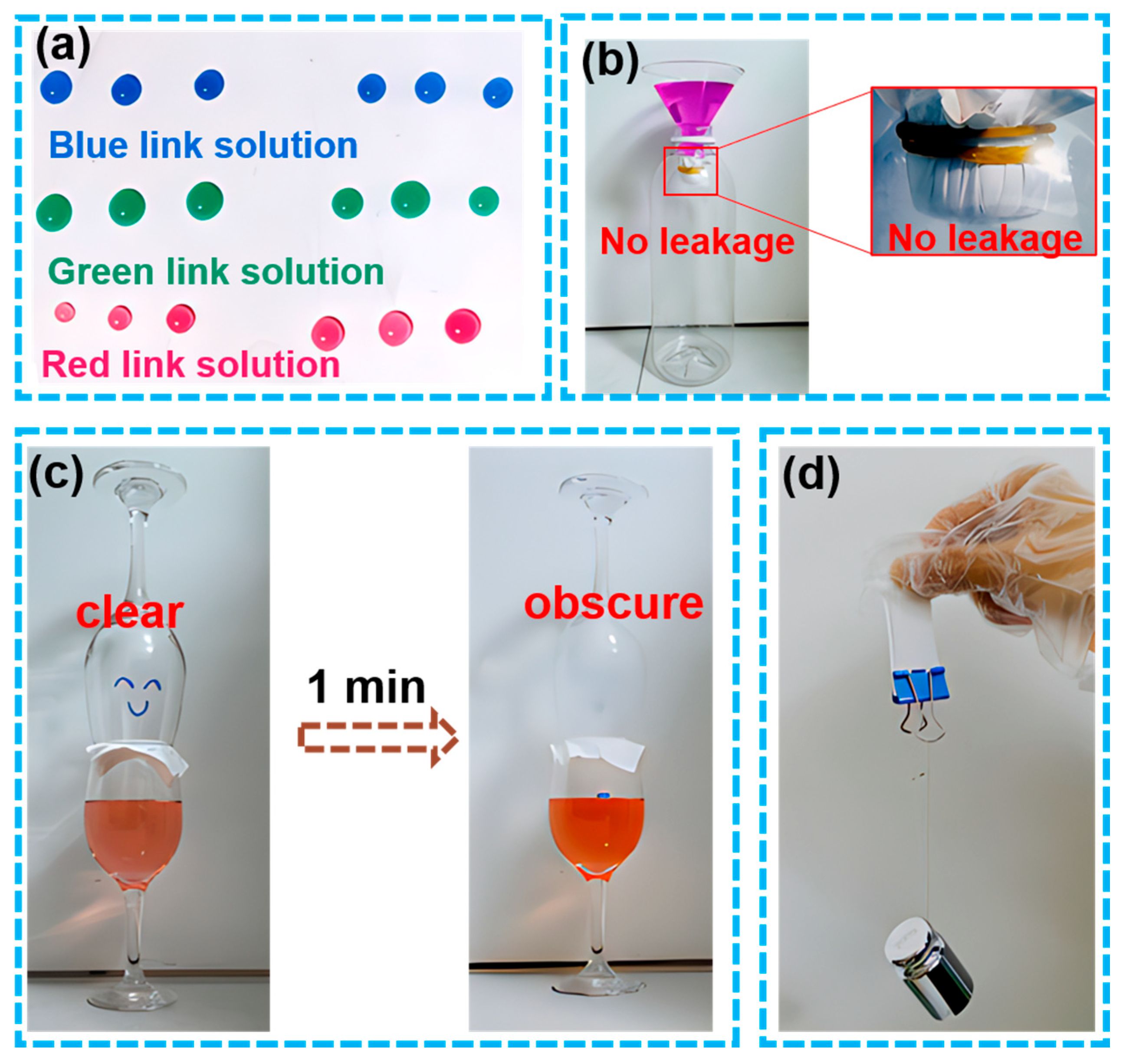

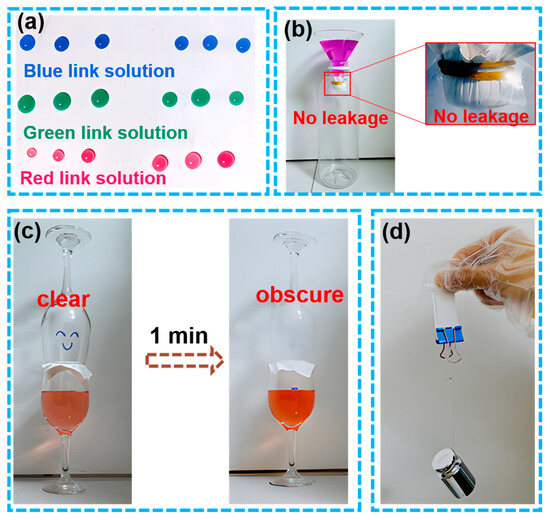

Colored water solutions were dripped onto the SiPU WBNM. Spherical droplets were observed without spreading (Figure 5a), demonstrating the hydrophobic properties of the SiPU WBNM. The high hydrophobicity of the SiPU WBNM provides the necessary conditions for excellent water resistance. The waterproof performance was demonstrated in a subsequent experiment. The SiPU WBNM was used to seal the mouth of a funnel, with 300 mL of water placed above it. It was observed that no water was transferred through the SiPU WBNM (Figure 5b), thereby demonstrating the membrane’s exceptional waterproofness. Another experiment was conducted to verify the breathability of the SiPU WBNM (Figure 5c). The SiPU WBNM was placed in a wine glass filled with boiling water, and another wine glass was inverted on top of the SiPU WBNM (Figure 5c). One minute later, the smiley face logo on the top wine glass became obscure (Figure 5c), indicating that a significant amount of water vapor had passed through the SiPU WBNM from the bottom wine glass to the top wine glass. This experiment demonstrates that the SiPU WBNM possesses excellent breathability. Furthermore, the SiPU WBNM, with a weight of 0.025 g, has been shown to withstand a standard weight of 200 g without breaking (Figure 5d), thus confirming that the SiPU WBNM exhibits outstanding mechanical performance.

Figure 5.

(a) Droplets of colorful water on the surface of the SiPU WBNM. Photographs illustrating the waterproofness (b), breathability (c), and mechanical performance (d) of the SiPU WBNM.

4. Conclusions

In this study, high-performance, fluorine-free, single-component SiPU WBNMs were successfully fabricated via a straightforward electrospinning process. Notably, only one fluorine-free polymer (SiPU) was used as the raw material, eliminating the need for complex post-treatments or environmentally hazardous fluorinated compounds. By systematically optimizing the SiPU concentration, the performance of the SiPU WBNMs was significantly enhanced. The optimized SiPU WBNM with a 14% polymer concentration exhibited outstanding properties, including a high hydrostatic pressure of 52.0 kPa, an impressive WVTR of 5798 g m−2 d−1, and robust tensile strength of 6.2 MPa. These superior waterproof and breathable performances are attributed to the membrane’s small dmax, high hydrophobicity, and excellent porosity. Overall, this work presents a simple, eco-friendly, and scalable strategy for the preparation of advanced functional membranes, offering promising potential for applications in protective clothing and car seats.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/fib13080105/s1: Figure S1: Mechanical strength of SiPU WBNMs at various SiPU concentrations, Table S1: WCA and hydrostatic pressure of various nanofiber membranes prepared by one-step electrospinning.

Author Contributions

D.L.: Conceptualization, Methodology, Formal Analysis, Investigation, Writing—Original Draft, Project Administration, and Funding Acquisition. Y.L.: Software, Validation, and Writing—Review and Editing. Y.C.: Resources and Data Curation. X.W.: Visualization. L.C.: Supervision. S.S.: Writing—Review and Editing. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Key Scientific Research Project of Colleges and Universities in Henan Province (No. 25A460019) and the Research Project of Zhengzhou University of Industrial Technology (2023ZD001).

Data Availability Statement

The original contributions presented in this study are included in the article/Supplementary Material. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yu, Y.; Xu, G.; Zhao, P.; Zhang, J. Biocompatible, robust, waterproof and breathable PDMS-based PU fibrous membranes for potential application in wound dressing. Mater. Today Commun. 2024, 38, 107870. [Google Scholar] [CrossRef]

- Ren, G.; Lu, D.; Zhang, Y.; Cui, Z.; Li, Z.; Yu, H.; He, J. Poly(methyl methacrylate) embedded fluorine-free polyurethane electrospun nanofiber membranes with enhanced waterproof and breathable performance. Compos. Commun. 2023, 43, 101698. [Google Scholar] [CrossRef]

- Chang, Y.; Liu, Y.; Liu, F. Simple fabrication of breathable poly (vinylidene fluoride) fibrous membranes decorated by silica nanoparticles with enhanced waterproof property. Ceram. Int. 2024, 50, 53728–53735. [Google Scholar] [CrossRef]

- Mao, Q.; Ding, M.; Yin, X.; Yu, J.; Zhang, S.; Ding, B. Superelastic and fluorine-free nanofiber membranes prepared by one-step electrospinning for waterproof and breathable applications. Compos. Commun. 2024, 48, 101934. [Google Scholar] [CrossRef]

- Xing, X.; Zhang, X.; Tasin, M.A.S.; Liang, X.; Zhou, H.; Niu, H. Interlaced Amphiphobic Nanofibers for Smart Waterproof and Breathable Membranes with Instant Waterproofness Monitoring Ability. ACS Appl. Polym. Mater. 2024, 6, 7301–7310. [Google Scholar] [CrossRef]

- Wang, H.; Chen, L.; Yi, Y.; Fu, Y.; Xiong, J.; Li, N. Durable polyurethane/SiO2 nanofibrous membranes by electrospinning for waterproof and breathable textiles. ACS Appl. Nano Mater. 2022, 5, 10686–10695. [Google Scholar] [CrossRef]

- Li, L.; Liu, H.; Wang, R.; Li, Q.; Zhang, L.; Liu, Z.; Jiao, T. Preparation and good antibacterial properties of self-assembled P (AA-AM)/CA/GA fiber membrane by electrospinning. Colloids Surf. A Physicochem. Eng. Asp. 2024, 693, 134077. [Google Scholar] [CrossRef]

- Xu, X.; Li, X.; Zhang, L.; Liu, Z.; Gao, L.; Jiao, T. Recent Progress of Applications of Electrospun Nanofibrous Membranes in Environmental Remediation. J. Environ. Chem. Eng. 2024, 12, 114624. [Google Scholar] [CrossRef]

- Liu, Y.; Li, X.; Li, L.; Liu, Z.; Zhao, C.; Jiao, T. Recent progress in gelatin-based electrospun nanofibrous membranes for wound dressings: A Review. J. Mol. Liq. 2024, 415, 126411. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, L.; Zhou, M.; Ma, J.; Wang, K.; Zhang, Y.; Drioli, E.; Cheng, X. Recent progress on functional electrospun polymeric nanofiber membranes. Mater. Today Commun. 2024, 41, 110530. [Google Scholar] [CrossRef]

- Wang, X.; Li, X. Electrospinning to fabricate composite membranes with improved superhydrophobic properties for efficient oil-water separation. Mater. Today Commun. 2024, 38, 107759. [Google Scholar] [CrossRef]

- Zhang, P.; Ren, G.; Tian, L.; Li, B.; Li, Z.; Yu, H.; Wang, R.; He, J. Environmentally Friendly Waterproof and Breathable Nanofiber Membranes with Thermal Regulation Performance by One-Step Electrospinning. Fibers Polym. 2022, 23, 2139–2148. [Google Scholar] [CrossRef]

- Tian, L.; Ren, G.; Zhang, P.; Li, B.; Chang, S.; Yu, H.; Wang, R.; He, J. Preparation of fluorine-free waterproof and breathable electrospun nanofibrous membranes via thiol-ene click reaction. Macromol. Mater. Eng. 2022, 307, 2100757. [Google Scholar] [CrossRef]

- Li, Z.; Ren, G.; Feng, Y.; Zhang, Y.; Cui, Z.; Lu, D.; Zhang, L.; Yu, H.; Li, W.; Liu, P.; et al. Electrospinning of Fluorine-Free Waterproof–Breathable Nanofiber Membranes with Thermal Regulation for Anticounterfeiting. ACS Appl. Nano Mater. 2024, 7, 919–927. [Google Scholar] [CrossRef]

- Gong, X.; Yin, X.; Wang, F.; Liu, X.; Yu, J.; Zhang, S.; Ding, B. Electrospun Nanofibrous Membranes: A Versatile Medium for Waterproof and Breathable Application. Small 2023, 19, 2205067. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Jun, S.C.; Zhang, S.; Wang, F.; Yu, J.; Ding, B. Advancements in electrospun nanofibrous membranes for improved waterproofing and breathability. Macromol. Mater. Eng. 2024, 309, 2300312. [Google Scholar] [CrossRef]

- Zhu, W.; Zhao, J.; Wang, X.; Liu, X.; Yu, J.; Ding, B. Facile fabrication of fluorine-free breathable poly (methylhydrosiloxane)/polyurethane fibrous membranes with enhanced water-resistant capability. J. Colloid Interface Sci. 2019, 556, 541–548. [Google Scholar] [CrossRef]

- Zhang, B.; Li, X.; Lin, Y.; Cheng, N.; Jiao, W.; Wang, X.; Yu, J.; Ding, B. Optimization of Bio-Based Polyurethane Elastic Nanofibrous Membrane via Electrospinning for Waterproof and Breathable Applications. Polymers 2025, 17, 486. [Google Scholar] [CrossRef]

- Zhou, Y.; Yao, L.R.; Gao, Q. Preparation of PVDF Nanofibrous Membrane and its Waterproof and Breathable Property. Adv. Mater. Res. 2013, 796, 327–330. [Google Scholar] [CrossRef]

- You, X.; Wang, H.; He, J.; Qi, K. Fluorine-free and breathable polyethylene terephthalate/polydimethylsiloxane (PET/PDMS) fibrous membranes with robust waterproof property. Compos. Commun. 2023, 40, 101621. [Google Scholar] [CrossRef]

- Zhou, W.; Yu, J.; Zhang, S.; Ding, B. Direct electrospinning of fluorine-free waterproof polyamide/polydimethylsiloxane nanofibrous membranes with highly breathable performance. Compos. Commun. 2022, 35, 101337. [Google Scholar] [CrossRef]

- Sheng, J.; Li, Y.; Wang, X.; Si, Y.; Yu, J.; Ding, B. Thermal inter-fiber adhesion of the polyacrylonitrile/fluorinated polyurethane nanofibrous membranes with enhanced waterproof-breathable performance. Sep. Purif. Technol. 2016, 158, 53–61. [Google Scholar] [CrossRef]

- Wang, J.; Raza, A.; Si, Y.; Cui, L.; Ge, J.; Ding, B.; Yu, J. Synthesis of superamphiphobic breathable membranes utilizing SiO2 nanoparticles decorated fluorinated polyurethane nanofibers. Nanoscale 2012, 4, 7549–7556. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Y.; Sheng, J.; Wang, X.; Liu, L.; Yu, J.; Ding, B. Environmentally friendly and breathable fluorinated polyurethane fibrous membranes exhibiting robust waterproof performance. ACS Appl. Mater. Interfaces 2017, 9, 29302–29310. [Google Scholar] [CrossRef]

- Lin, Y.-F.; Wang, W.-W.; Chang, C.-Y. Environmentally sustainable, fluorine-free and waterproof breathable PDMS/PS nanofibrous membranes for carbon dioxide capture. J. Mater. Chem. A 2018, 6, 9489–9497. [Google Scholar] [CrossRef]

- Wang, N.; Si, Y.; Wang, N.; Sun, G.; El-Newehy, M.; Al-Deyab, S.S.; Ding, B. Multilevel structured polyacrylonitrile/silica nanofibrous membranes for high-performance air filtration. Sep. Purif. Technol. 2014, 126, 44–51. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Si, Y.; Yu, J.; Ding, B. Super-elastic fluorinated polyurethane nanofibrous membranes with simultaneously waterproof and breathable performance. ACS Appl. Polym. Mater. 2022, 4, 5557–5565. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, G.; Nie, G.; Hu, S.; Li, D.; Sun, W.; Li, Z.; Cui, Z.; Lu, D.; Shi, X.; et al. Facile fabrication of fluorine-free waterproof and breathable nanofiber membranes with UV-resistant and acid-alkali resistant performances. Colloids Surf. A Physicochem. Eng. Asp. 2024, 685, 133310. [Google Scholar] [CrossRef]

- Cui, H.; Li, Y.; Zhao, X.; Yin, X.; Yu, J.; Ding, B. Multilevel porous structured polyvinylidene fluoride/polyurethane fibrous membranes for ultrahigh waterproof and breathable application. Compos. Commun. 2017, 6, 63–67. [Google Scholar] [CrossRef]

- Zhang, M.; Sheng, J.; Yin, X.; Yu, J.; Ding, B. Polyvinyl Butyral Modified Polyvinylidene Fluoride Breathable–Waterproof Nanofibrous Membranes with Enhanced Mechanical Performance. Macromol. Mater. Eng. 2017, 302, 1600272. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).