Quality of Plywood Bonded with Nanolignin-Enriched Cardanol-Formaldehyde Adhesive

Abstract

1. Introduction

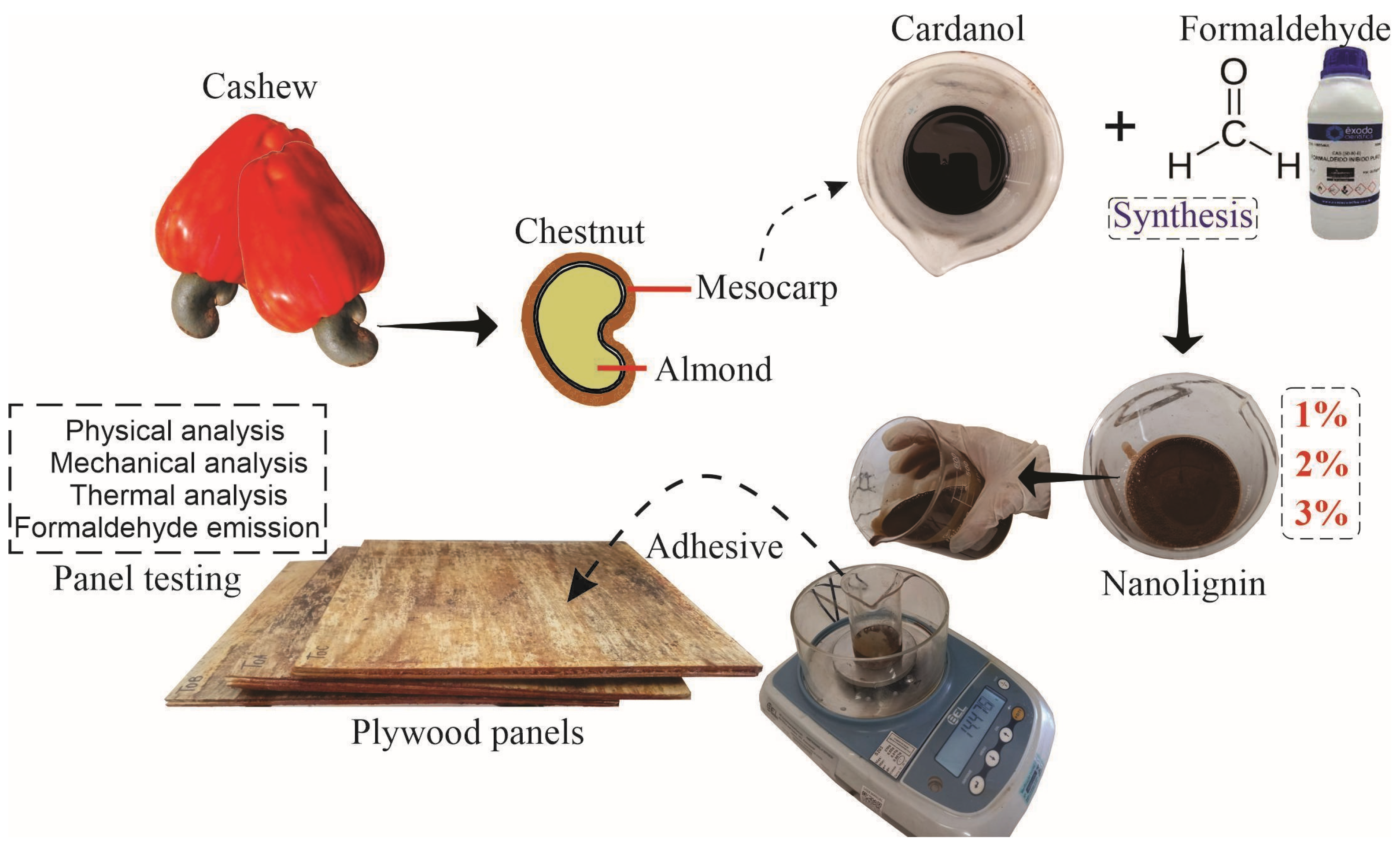

2. Materials and Methods

2.1. Preparation of Materials

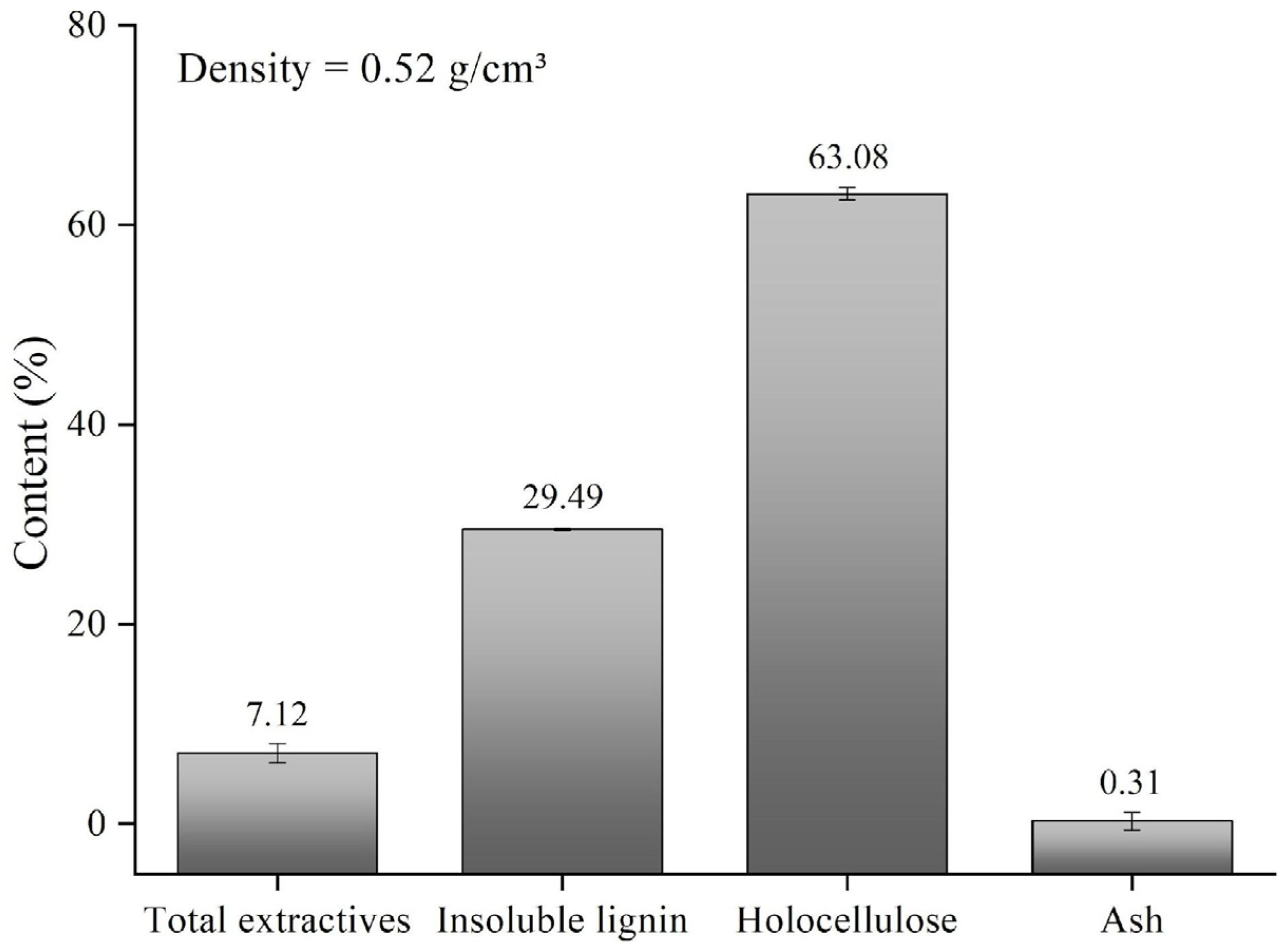

2.2. Characterization of the Wood

2.3. Adhesive Formulation and Characterization

2.4. Adhesion Performance

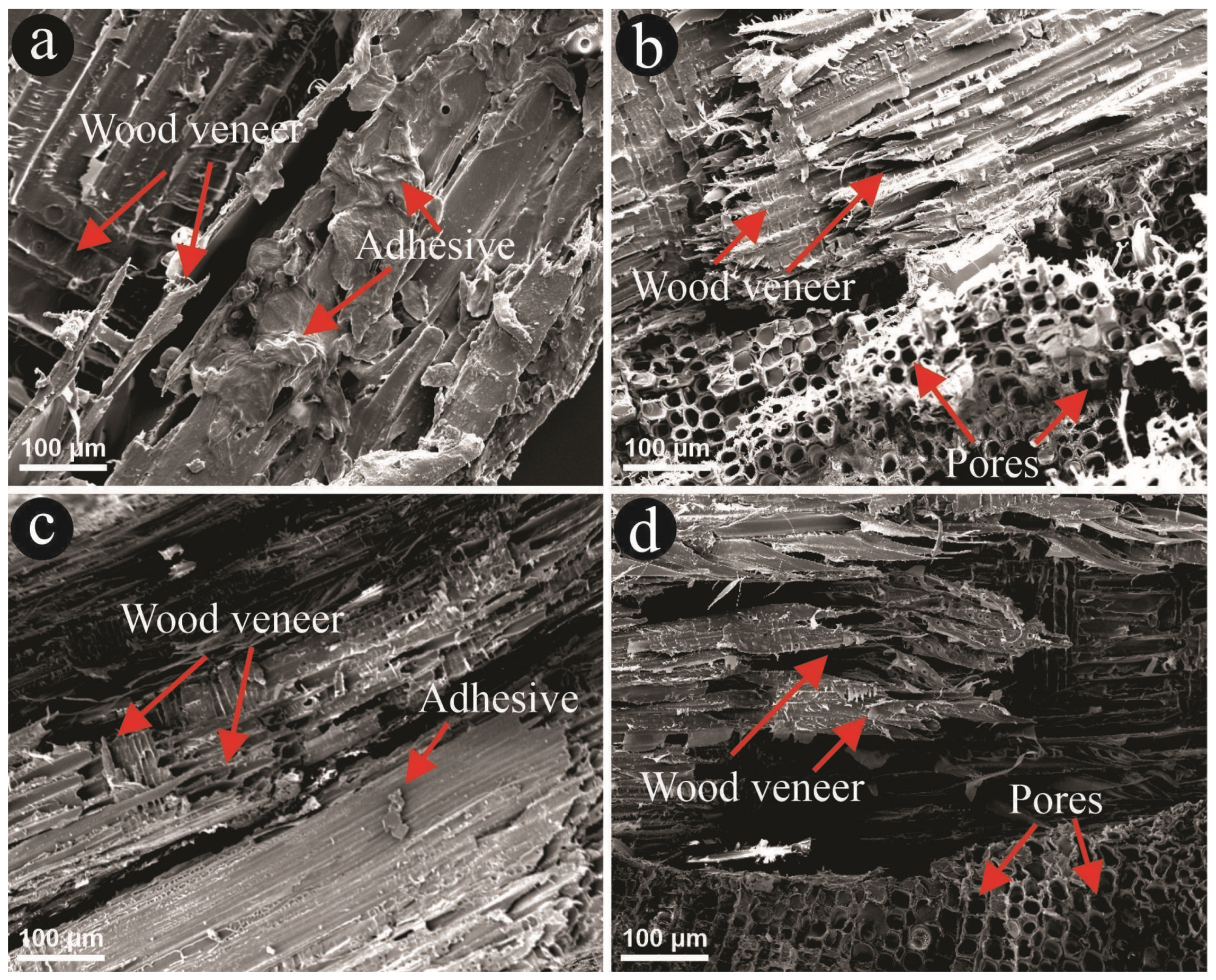

2.5. Microstructural Analysis

2.6. Formaldehyde Emission

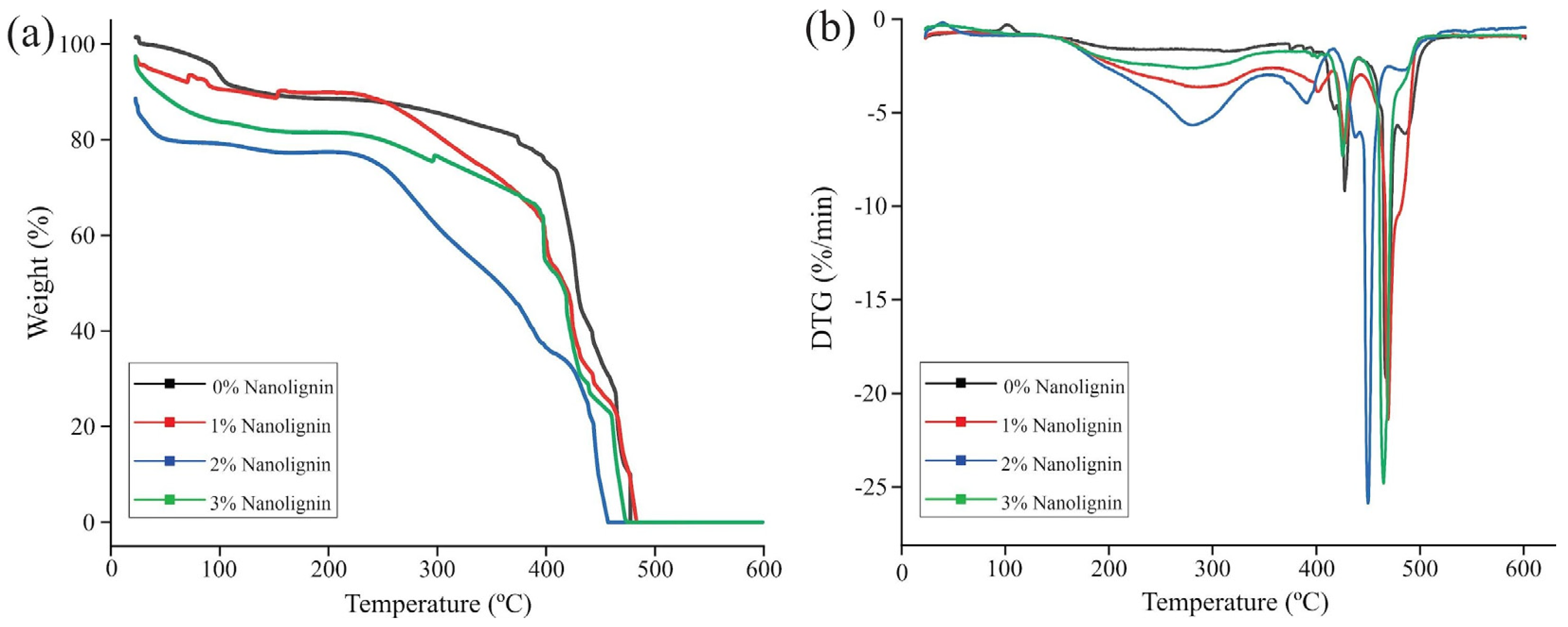

2.7. Thermal Evaluation of Plywood

2.8. Experimental Design and Data Statistical Analysis

3. Results and Discussion

3.1. Characterization of Materials

3.2. Adhesive Characterization

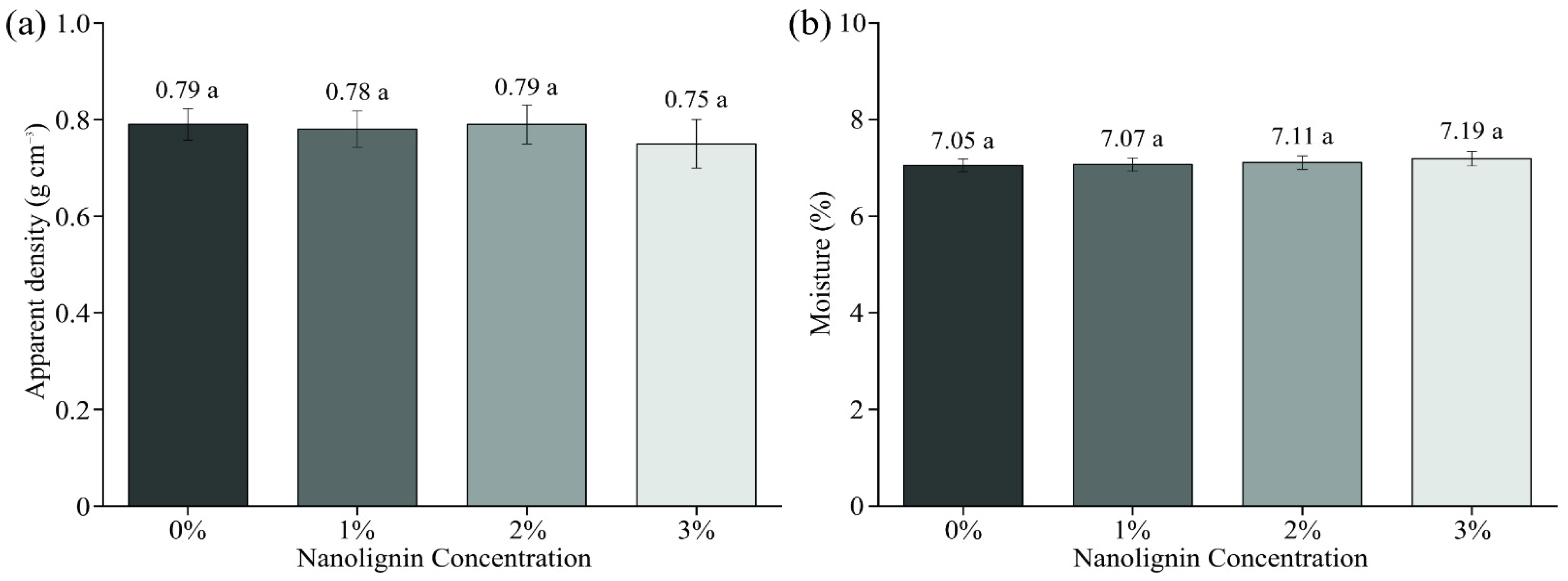

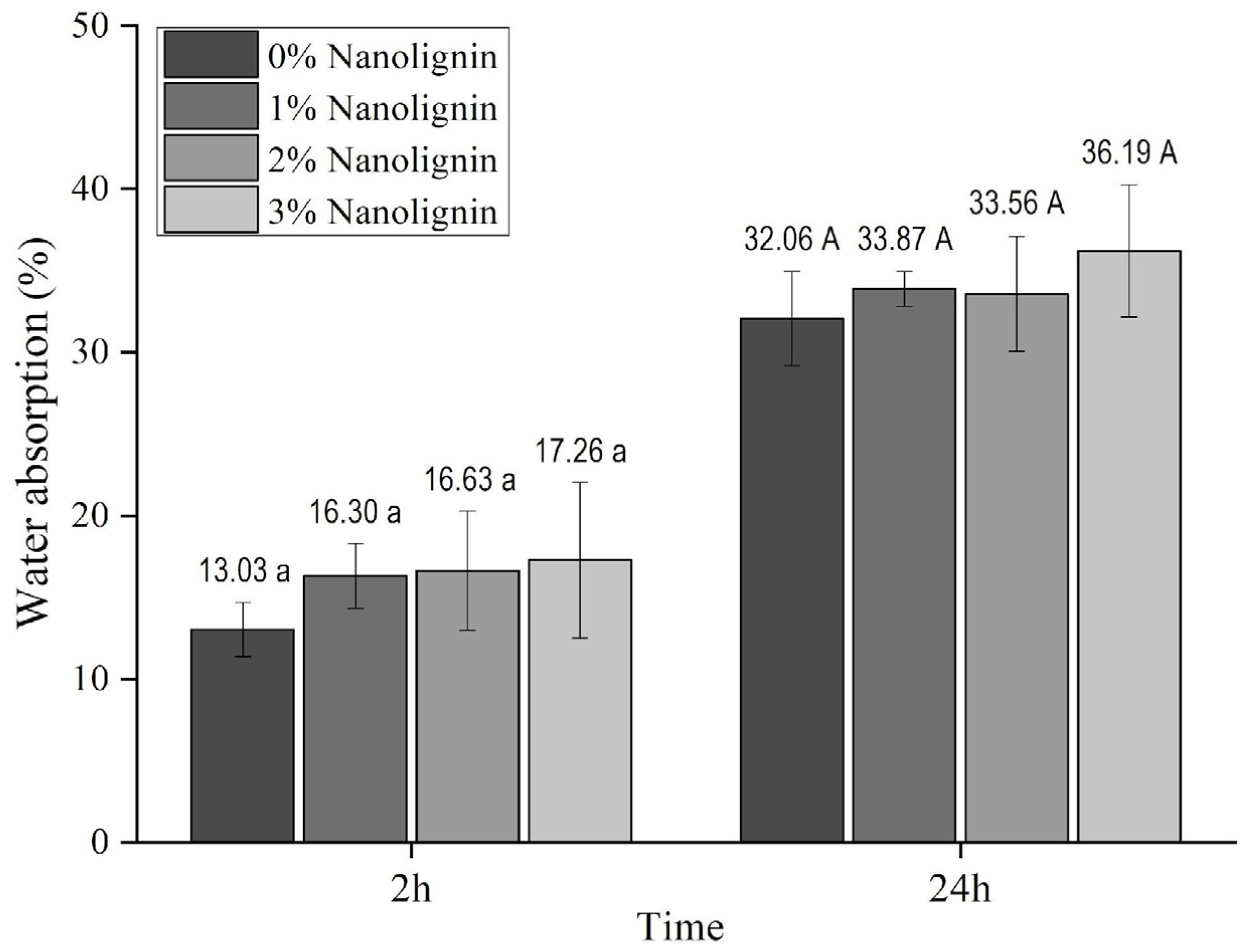

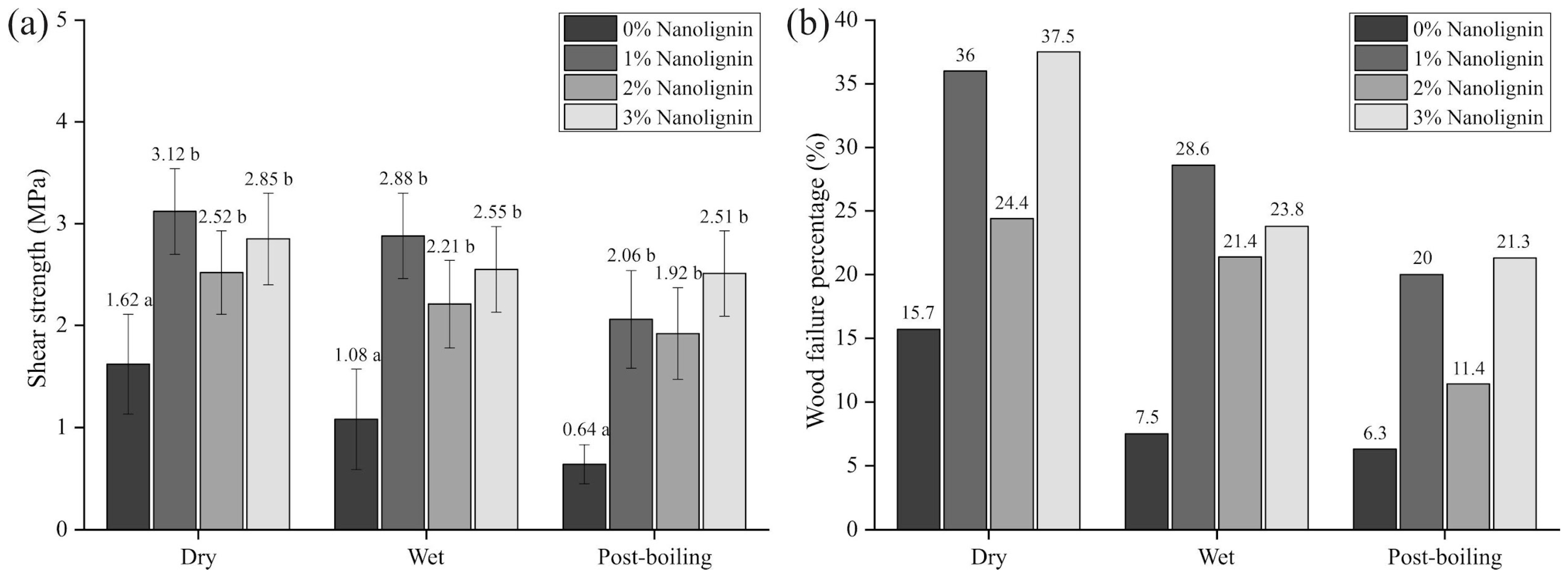

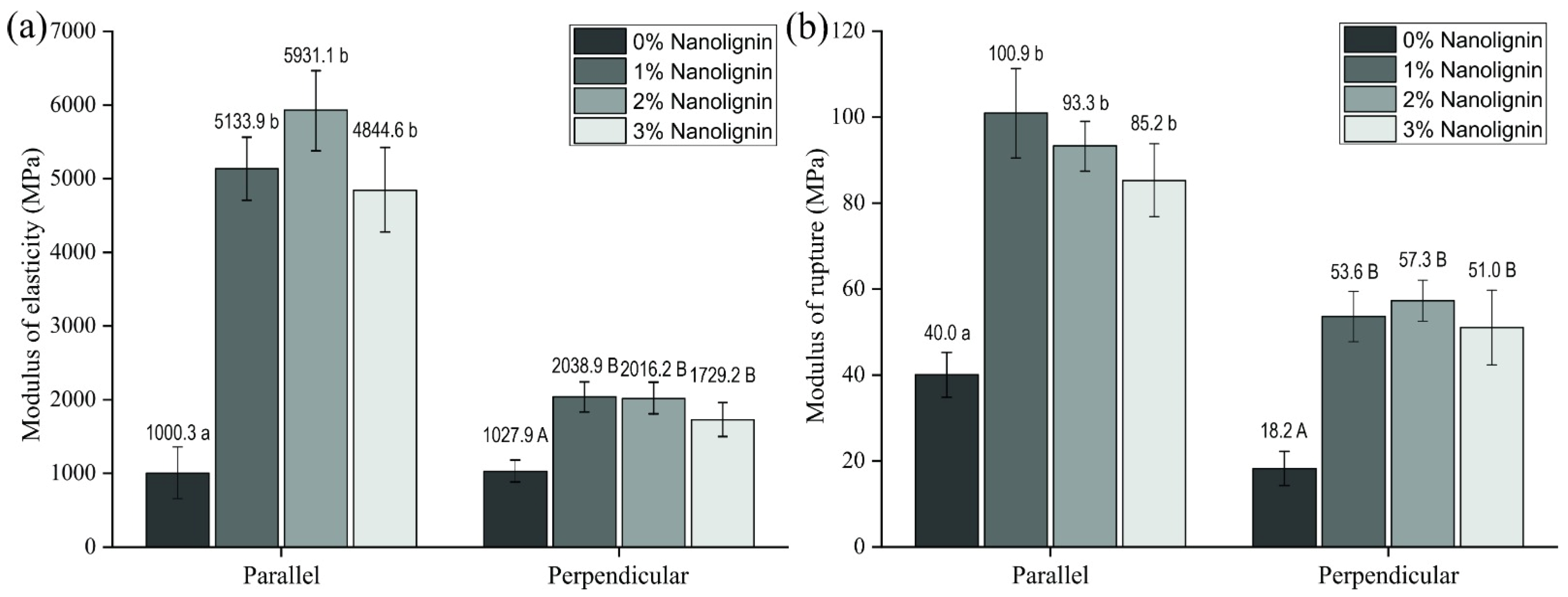

3.3. Physical–Mechanical and Microstructural Properties of Plywood

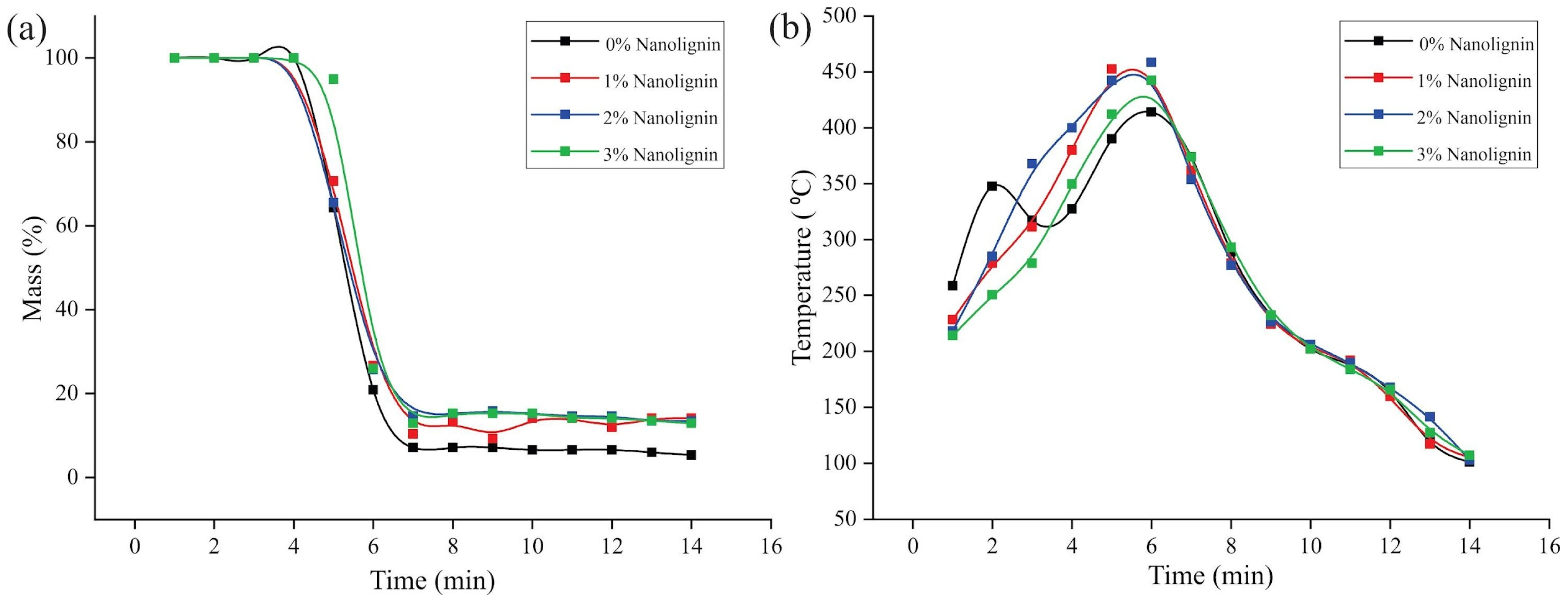

3.4. Thermal Properties of Plywood

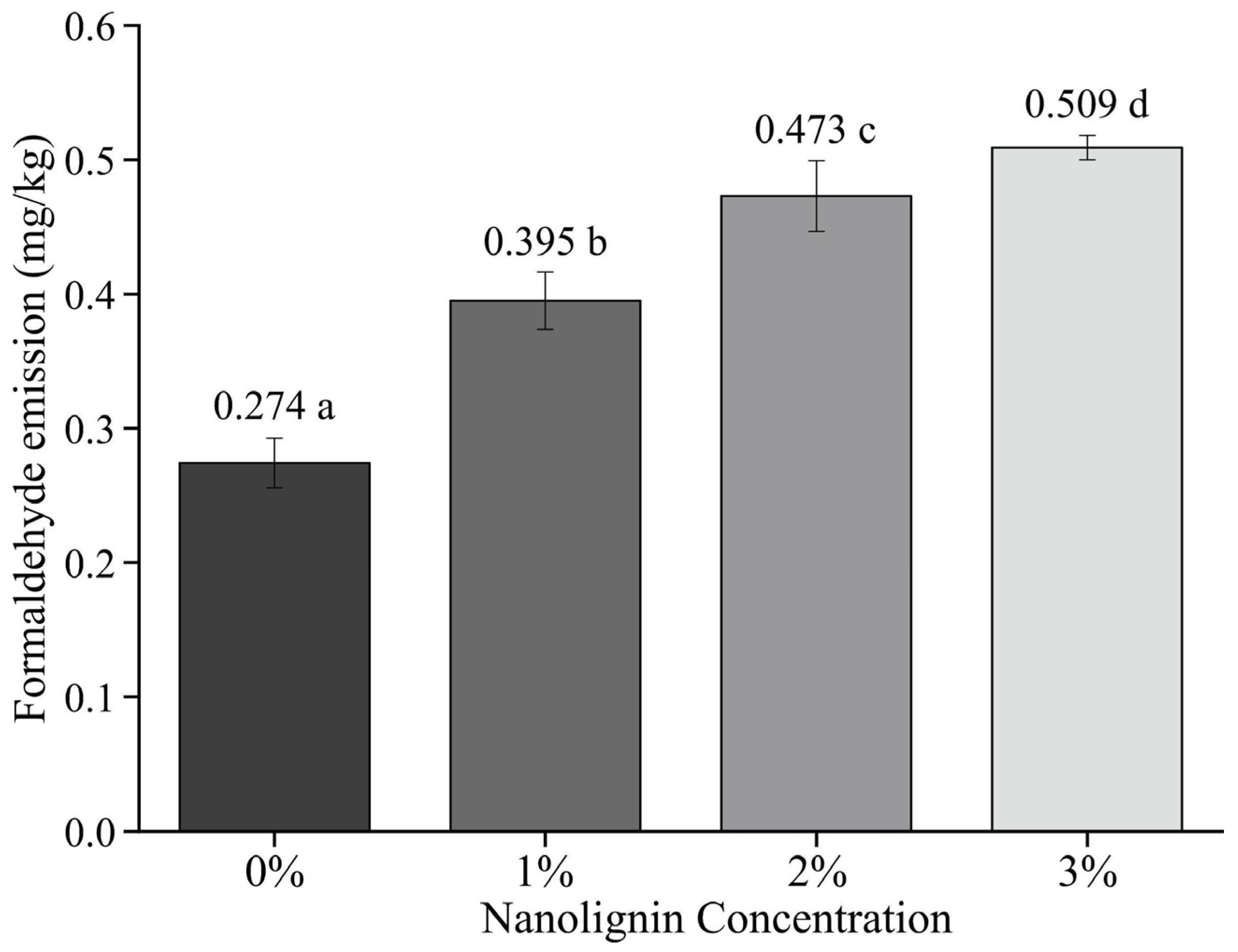

3.5. Formaldehyde Emission

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zeng, G.; Zhou, Y.; Liang, Y.; Zhang, F.; Luo, J.; Li, J.; Fang, Z. A hair fiber inspired bio-based adhesive with high bonding strength and mildew tolerance. Chem. Eng. J. 2022, 434, 134632. [Google Scholar] [CrossRef]

- Mili, M.; Hashmi, S.A.R.; Ather, M.; Hada, V.; Markandeya, N.; Kamble, S.; Mohapatra, M.; Rathore, S.K.S.; Srivastava, A.K.; Verma, S. Novel lignin as natural-biodegradable binder for various sectors—A review. J. Appl. Polym. Sci. 2022, 139, 51951. [Google Scholar] [CrossRef]

- Oktay, S.; Kızılcan, N.; Bengü, B. Environment-friendly cornstarch and tannin-based wood adhesives for interior particleboard production as an alternative to formaldehyde-based wood adhesives. Pigment Resin Technol. 2024, 53, 173–182. [Google Scholar] [CrossRef]

- Selakjani, P.P.; Dorieh, A.; Pizzi, A.; Shahavi, M.H.; Hasankhah, A.; Shekarsaraee, S.; Ashouri, M.; Movahed, S.G.; Abatari, M.N. Reducing free formaldehyde emission, improvement of thickness swelling and increasing storage stability of novel medium density fiberboard by urea-formaldehyde adhesive modified by phenol derivatives. Int. J. Adhes. Adhes. 2021, 111, 102962. [Google Scholar] [CrossRef]

- Khanjanzadeh, H.; Behrooz, R.; Bahramifar, N.; Pinkl, S.; Gindl-Altmutter, W. Application of surface chemical functionalized cellulose nanocrystals to improve the performance of UF adhesives used in wood-based composites-MDF type. Carbohydr. Polym. 2019, 206, 11–20. [Google Scholar] [CrossRef]

- Raydan, N.D.V.; Leroyer, L.; Charrier, B.; Robles, E. Recent advances on the development of protein-based adhesives for wood composite materials—A review. Molecules 2021, 26, 7617. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Gong, X.; Yang, G.; Li, Q.; Zhou, N. Preparation and characterization of a nanolignin phenol formaldehyde resin by replacing phenol partially with lignin nanoparticles. RSC Adv. 2019, 9, 29255–29262. [Google Scholar] [CrossRef]

- Wang, P.; Liu, J.; Chi, C.; Zhang, Y.; Chen, D.; Chen, Q. Solvent-free synthesis, plasticization and compatibilization of cardanol grafted onto liquid isoprene rubber. Compos. Sci. Technol. 2021, 215, 109027. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, C.; Zeng, W.; Zhou, Q. Making alkyd greener: Modified cardanol as bio-based reactive diluents for alkyd coating. Prog. Org. Coat. 2019, 135, 281–290. [Google Scholar] [CrossRef]

- Bo, C.; Shi, Z.; Hu, L.; Pan, Z.; Hu, Y.; Yang, X.; Zhang, M.; Zhou, Y. Cardanol derived P, Si and N based precursors to develop flame retardant phenolic foam. Sci. Rep. 2020, 10, 12082. [Google Scholar] [CrossRef]

- Jadhav, N.L.; Sastry, S.K.C.; Pinjari, D.V. Energy efficient room temperature synthesis of cardanol-based novolac resin using acoustic cavitation. Ultrason. Sonochem. 2018, 42, 532–540. [Google Scholar] [CrossRef] [PubMed]

- Moita Neto, J.M.; Lopes, J.A.D.; Lima, S.G.; Macedo, A.O.A.; Citó, A.M.G.L. Resina tipo resol do líquido da casca da castanha de caju. An. ABQ 1997, 46, 220–223. [Google Scholar]

- França, F.C.; Coelho, E.D.L.; Uchôa, A.F.; Rodrigues, F.H.; Ribeiro, M.E.; Soares, S.D.A.; Ricardo, N.M. Synthesis and characterization of alkylphenyl polyglycosidic surfactants from amylose and alkyl phenols extracted from natural CNSL. Química Nova 2016, 39, 771–781. [Google Scholar] [CrossRef]

- Faria, D.L.; Scatolino, M.V.; Oliveira, J.E.; Gonçalves, F.G.; Soriano, J.; Paula Protásio, T.; Junior, J.B.G. Cardanol-based adhesive with reduced formaldehyde emission to produce particleboards with waste from bean crops. Environ. Sci. Pollut. Res. 2023, 30, 48270–48287. [Google Scholar] [CrossRef] [PubMed]

- Santos, R.S.; Souza, A.A.; Paoli, M.; Souza, C.M.L. Cardanol–formaldehyde thermoset composites reinforced with buriti fibers: Preparation and characterization. Compos Part A Appl. Sci. 2010, 41, 1123–1129. [Google Scholar] [CrossRef]

- Balaji, A.; Karthikeyan, B.; Swaminathan, J.; Raj, C.S. Mechanical behavior of short bagasse fiber reinforced cardanol-formaldehyde composites. Fibers Polym. 2017, 18, 1193–1199. [Google Scholar] [CrossRef]

- Balaji, A.; Karthikeyan, B.; Swaminathan, J.; Raj, C.S. Effect of filler content of chemically treated short bagasse fiber-reinforced cardanol polymer composites. J. Nat. Fibers 2019, 16, 613–627. [Google Scholar] [CrossRef]

- Shislov, O.F.; Troshin, D.P.; Baulina, N.S.; Glukhikh, V.V.; Stoyanov, O.V. Synthesis and properties of glues for densified laminated wood based on alcohol-soluble phenol–cardanol–formaldehyde resolic resins. Polym Sci. 2015, 8, 37–41. [Google Scholar] [CrossRef]

- Caillol, S. Cardanol: A promising building block for biobased polymers and additives. Curr. Opin. Green Sustain. Chem. 2018, 14, 26–32. [Google Scholar] [CrossRef]

- Furtini, A.C.C.; Brito, F.M.S.; Junior, M.G.; Furtini, J.A.O.; Pinto, L.M.A.; Protásio, T.P.; Mendes, L.M.; Guimarães, J.B., Jr. Substitution of urea–formaldehyde by renewable phenolic compound for environmentally appropriate production of particleboards. Environ. Sci. Pollut. Res. 2022, 29, 66562–66577. [Google Scholar] [CrossRef]

- Torres, L.A.Z.; Woiciechowski, A.L.; Andrade Tanobe, V.O.; Karp, S.G.; Lorenci, L.C.G.; Faulds, C.; Soccol, C.R. Lignin as a potential source of high-added value compounds: A review. J. Clean. Prod. 2020, 263, 121499. [Google Scholar] [CrossRef]

- Gendron, J.; Stambouli, I.; Bruel, C.; Boumghar, Y.; Montplaisir, D. Characterization of different types of lignin and their potential use in green adhesives. Ind. Crops Prod. 2022, 182, 114893. [Google Scholar] [CrossRef]

- Kalami, S.; Chen, N.; Borazjani, H.; Nejad, M. Comparative analysis of different lignins as phenol replacement in phenolic adhesive formulations. Ind. Crops Prod. 2018, 125, 520–528. [Google Scholar] [CrossRef]

- Collins, M.N.; Nechifor, M.; Tanasă, F.; Zănoagă, M.; McLoughlin, A.; Stróżyk, M.A.; Culebras, M.C.-A. Teacă Valorization of lignin in polymer and composite systems for advanced engineering applications—A Review. Int. J. Biol. Macromol. 2019, 131, 828–849. [Google Scholar] [CrossRef]

- Li, W.; Sun, H.; Wang, G.; Sui, W.; Dai, l.; Si, C. Lignin as a green and multifunctional alternative to phenol for resin synthesis. Green Chem. 2023, 25, 2241–2261. [Google Scholar] [CrossRef]

- Gao, Z.; Lang, X.; Chen, S.; Zhao, C. Mini-review on the synthesis of lignin-based phenolic resin. Energy Fuels 2021, 35, 18385–18395. [Google Scholar] [CrossRef]

- Bansode, A.; Barde, M.; Asafu-Adjaye, O.; Patil, V.; Hinkle, J.; Via, B.K.; Adhikari, S.; Adamczyk, A.J.; Farag, R.T. Elder Synthesis of biobased novolac phenol-formaldehyde wood adhesives from biorefinery-derived lignocellu-losic biomass. ACS Sustain. Chem. Eng. 2021, 9, 10990–11002. [Google Scholar] [CrossRef]

- Zhou, J.; Hu, L.; Zhou, Y.; Jia, P.B. Liang Liquefaction and characterization of enzymatic hydrolysis lignin with phosphotungstic acid. Cellul. Chem. Technol. 2018, 52, 387–391. [Google Scholar]

- Ren, X.; Lin, W.; Wang, Z.; Shi, Z.; Zheng, C. Liu Preparation of high molecular weight thermoplastic bio-based phenolic resin and fiber based on lignin liquefaction Mater. Res. Express 2021, 8, 015308. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, Y.; Gong, Z.; Chang, Z.; Meng, Y.; Qu, W.; Zhu, C. Prepara-tion and characterization of lignin copolymerized phenolic resins with superior stiff-ening effect for natural rubber composites. Polymer 2024, 308, 127366. [Google Scholar] [CrossRef]

- Luckman, S.S.; Cunha, A.B.; Rios, P.D.; Zanatta, P. Influência da incorporação de lignina Kraft à resina ureia-formaldeído nas propriedades tecnológicas de painéis aglomerados convencionais. Sci. For. 2021, 49, e3527. [Google Scholar] [CrossRef]

- Nair, S.S.; Sharma, S.; Pu, Y.; Sun, Q.; Pan, S.; Zhu, J.Y.; Deng, Y.; Ragauskas, A.J. High shear homogenization of lignin to nanolignin and thermal stability of Nanolignin-Polyvinyl alcohol blends. ChemSusChem 2014, 7, 3513–3520. [Google Scholar] [CrossRef] [PubMed]

- Xue, Z.; Sun, H.; Wang, G.; Sui, W.; Jia, H.; Si, C. Fabrication modulation of lignin-derived carbon nanosphere supported Pd nanoparticle via lignin fraction-ation for improved catalytic performance in vanillin hydrodeoxygenation. Int. J. Biol. Macromol. 2024, 258, 128963. [Google Scholar] [CrossRef]

- Gong, X.; Meng, Y.; Lu, J.; Tao, Y.; Cheng, Y.; Wang, H. A review on lignin-based phenolic resin adhesive. Macromol. Chem. Phys. 2022, 223, 2100434. [Google Scholar] [CrossRef]

- Younesi-Kordkheili, H.; Pizzi, A.; Erfani, S.; Amiri, M. The synthesis of maleated nanolignin–polyvinyl alcohol–hexamine resin as a cold-setting wood adhesive. Eur. J. Wood Wood Prod. 2024, 82, 159–166. [Google Scholar] [CrossRef]

- Zhu, Y.; Bian, R.; Yu, Y.; Li, J.; Li, C.; Lyu, Y.; Li, J. Aminated alkali lignin nanoparticles enabled formaldehyde-free biomass wood adhesive with high strength, toughness, and mildew resistance. Chem. Eng. J. 2024, 494, 152914. [Google Scholar] [CrossRef]

- Lopes, T.A.; Lopes, N.F.; Portilho, G.R.; Andrade, F.A.; Silva, L.B.J.; Castro, R.V.O.; Tonoli, G.H.D.; Carneiro, A.D.C.O. Nano-Partículas de Lignina e Seus Efeitos nas Propriedades do Adesivo Ureia-Formaldeído para Colagem de Madeira. In Engenharia Industrial Madeireira: Tecnologia, Pesquisa e Tendências, 1st ed.; Gonçalves, F.G., Ed.; Editora Científica Digital: São Paulo, Brazil, 2020; pp. 219–242. [Google Scholar]

- NBR 11941; Wood: Basic Density Efficiency. ABNT: Rio de Janeiro, Brazil, 2003.

- T 204 om-97; Solvent Extractives of Wood and Pulp. TAPPI: Atlanta, GA, USA, 1997.

- T 222 om-02; Acid-Insoluble Lignin in Wood Pulp. TAPPI: Atlanta, GA, USA, 2002.

- 211 om-02; Ash in Wood, Pulp, Paper and Paperboard: Combustion at 525 °C. TAPPI: Atlanta, GA, USA, 2002.

- Browning, B.L. The Chemistry of Wood; J. Wiley: New York, NY, USA, 1963; p. 689. [Google Scholar]

- D 1490-01; Standard Test Method for Nonvolatile Content of Urea-Formaldehyde Resin Solutions. ASTM International: West Conshohocken, PA, USA, 2013.

- D 1200-10; Standard Test Method for Viscosity by Ford Viscosity Cup. ASTM International: West Conshohocken, PA, USA, 2010.

- ABNT NBR 9485; Compensado: Determinação da Massa Específica Aparente. ABNT. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2011.

- ABNT NBR 9484; Compensado: Determinação do Teor de Umidade. ABNT. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2011.

- ABNT NBR 9586; Compensado—Determinação da Absorção de Água. ABNT. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2011.

- ABNT NBR ISO 12466-1; Madeira Compensada: Qualidade de Colagem: Parte 1: Métodos de Ensaio. ABNT: Rio de Janeiro, Brazil, 2012.

- ABNT NBR 9533; Compensado: Determinação da Resistência à Flexão estática. ABNT. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2012.

- EN 717-3; Wood-Based Panels—Determination of Formaldehyde Release, Part 3: Formaldehyde Release by the Flask Method. 1996. Available online: https://www.en-standard.eu/bs-en-717-3-1996-wood-based-panels-determination-of-formaldehyde-release-formaldehyde-release-by-the-flask-method/?gclid=Cj0KCQiA1ZGcBhCoARIsAGQ0kkrFkuQ2YIEtzBkQ3TJxzZtTuRQQXrQNP3xumprDfnqr03LyoARtY_saAl2zEALw_wcB (accessed on 31 January 2025).

- Setter, C.; Borges, F.A.; Cardoso, C.R.; Mendes, R.F.; Oliveira, T.J.P. Energy quality of pellets produced from coffee residue: Characterization of the products obtained via slow pyrolysis. Ind. Crops Prod. 2020, 154, 112731. [Google Scholar] [CrossRef]

- Faria, D.L.; Gonçalves, F.G.; Maffioletti, F.D.; Scatolino, M.V.; Soriano, J.; Paula Protásio, T.; Lopez, Y.M.; Paes, J.B.; Mendes, L.M.; Guimarães Junior, J.B.; et al. Particleboards based on agricultural and agroforestry wastes glued with vegetal polyurethane adhesive: An efficient and eco-friendly alternative. Ind. Crops Prod. 2024, 214, 118540. [Google Scholar] [CrossRef]

- Matos, A.C.; Guimarães Junior, J.B.; Borges, C.C.; Matos, L.C.; Ferreira, J.C.; Mendes, L.M. Influência de diferentes composições estruturais de Schizolobium parahyba var. amazonicum (Huber ex Ducke) Barneby e Pinus oocarpa var. oocarpa (Schiede ex Schltdl) para a produção de compensados multilaminados. Sci. For. 2019, 124, 799–810. [Google Scholar]

- Brito, F.M.S.; Mendes, L.M.; Silva, P.X.S.; Júnior, J.B.G.; Palumbo, S.K.C. Technological characterization of particleboards constituted with pistachio shell (Pistacia vera) and Pinus oocarpa wood. Rev. Bras. Ciências Agrárias 2021, 16, e8902. [Google Scholar] [CrossRef]

- Iwakiri, S.; Trianoski, R. Painéis de Madeira Reconstituída; Scientia Forestalis: Curitiba, Brazil, 2020; pp. 7–8. [Google Scholar]

- Lourenço, Y.B.C.; Santos, C.A.D.; Furtini, A.C.C.; Mendes, L.M.; Guimarães Junior, J.B. Utilization of nanotalc modified adhesives in plywood panels. Maderas. Cienc. Tecnol. 2024, 26. [Google Scholar] [CrossRef]

- Furtini, A.C.C.; Santos, C.A.D.; Garcia, H.V.S.; Brito, F.M.S.; Santos, T.P.D.; Mendes, L.M.; Guimarães Júnior, J.B. Performance of cross laminated timber panels made of Pinus oocarpa and Coffea arabica waste. Coffee Sci. 2021, 16, e161854. [Google Scholar] [CrossRef]

- Santiago, S.B.; Gonçalves, F.G.; Lelis, R.C.C.; Segundinho, P.G.A.; Paes, J.B.; Arantes, M.D.C. Colagem de madeira de eucalipto com adesivos naturais. Rev. Matéria 2018, 23, e12151. [Google Scholar] [CrossRef]

- Villarruel, D.C.V.; Novais Miranda, E.H.; Gomes, D.A.C.; Furtini, A.C.C.; Santos, C.A.; Mendes, L.M.; Guimarães Júnior, J.B. Evaluation of the addition of wheat residues in the production of Pinus oocarpa agglomerated panels. Clean Technol. Environ. Policy 2023, 25, 1753–1760. [Google Scholar] [CrossRef]

- Sun, B.; Wang, Z.; Liu, J. Changes of chemical properties and the water vapour sorption of Eucalyptus pellita wood thermally modified in vacuum. J. Wood Sci. 2017, 63, 133–139. [Google Scholar] [CrossRef]

- Neitzel, N.; Hosseinpourpia, R.; Walther, T.; Adamopoulos, S. Alternative materials from agro-industry for wood panel manufacturing—A review. Materials 2022, 15, 4542. [Google Scholar] [CrossRef]

- Osterberg, M.; Sipponen, M.H.; Mattos, B.D.; Rojas, O.J. Spherical lignin particles: A review on their sustainability and applications. Green Chem. 2020, 22, 2712–2733. [Google Scholar] [CrossRef]

- Mestry, S.U.; Khuntia, S.P.; Mhaske, S.T. Development of waterborne polyurethane dispersions (WPUDs) from novel cardanol-based reactive dispersing agent. Polym. Bull. 2021, 78, 6819–6834. [Google Scholar] [CrossRef]

- Galdino, D.S.; Kondo, M.Y.; Araujo, V.A.; Ferrufino, G.L.A.A.; Faustino, E.; Santos, H.F.D.; Christoforo, A.L.; Luna, C.M.R.; Campos, C.I.D. Thermal and gluing properties of phenol-based resin with lignin for potential application in structural composites. Polymers 2023, 15, 357. [Google Scholar] [CrossRef]

- Parameswaran, P.S.; Abraham, B.T.; Thachil, E.T. Cardanol-based resol phenolics—A comparative study. Progress Rubber Plast. Recycl. Technol. 2010, 26, 31–50. [Google Scholar] [CrossRef]

- Solt, P.; Rößiger, B.; Konnerth, J.; Van Herwijnen, H.W. Lignin phenol formaldehyde resoles using base-catalysed depolymerized kraft lignin. Polymers 2018, 10, 1162. [Google Scholar] [CrossRef]

- Papadopoulou, E.; Wild, P.J.; Kountouras, S.; Chrissafis, K. Evaluation of torrefaction condensates as phenol substitutes in the synthesis of phenol-formaldehyde adhesives suitable for plywood. Thermochimica Acta 2018, 663, 27–33. [Google Scholar] [CrossRef]

- Pappa, C.P.; Cailotto, S.; Gigli, M.; Crestini, C.; Triantafyllidis, K.S. Kraft (Nano) Lignin as reactive additive in epoxy polymer bio-composites. Polymers 2024, 16, 553. [Google Scholar] [CrossRef] [PubMed]

- Pipíška, T.; Bekhta, P.; Král, P.; Paschová, Z. Effects of different pressures and veneer moisture content in adjacent layers on properties of PUF bonded plywood. J. Adhesion Sci. Technol. 2024, 38, 1043–1052. [Google Scholar] [CrossRef]

- Caillol, S. The future of cardanol as small giant for biobased aromatic polymers and additives. Eur. Polym. J. 2023, 193, 112096. [Google Scholar] [CrossRef]

- Setter, C.; Zidanes, U.L.; Novais Miranda, E.H.; Brito, F.M.S.; Mendes, L.M.; Junior, J.B.G. Influence of wood species and adhesive type on the performance of multilaminated plywood. Environ. Sci. Pollut. Res. 2021, 28, 50835–50846. [Google Scholar] [CrossRef]

- Younesi-Kordkheili, H.; Pizzi, A. Improving the properties of phenol-lignin-glyoxal as a wood adhesive by lignin nanoparticles. Eur. J. Wood Wood Prod. 2023, 81, 507–512. [Google Scholar] [CrossRef]

- Kordkheili, H.Y.; Pizzi, A. Improving properties of phenol-lignin-glyoxal resin as a wood adhesive by an epoxy resin. Eur. J. Wood Wood Prod. 2021, 79, 199–205. [Google Scholar] [CrossRef]

- Kordkheili, H.Y.; Pizzi, A. Properties of plywood panels bonded with ionic liquid-modified lignin–phenol–formaldehyde resin. J. Adhesion 2018, 94, 143–154. [Google Scholar] [CrossRef]

- Lengowski, E.C.; Bonfatti Júnior, E.A.; Dallo, R.; Nisgoski, S.; Mattos, J.L.M.D.; Prata, J.G. Nanocellulose-reinforced phenol-formaldehyde resin for plywood panel production. Maderas Cienc. Tecnol. 2021, 23. [Google Scholar] [CrossRef]

- Feng, S.; Shui, T.; Wang, H.; Ai, X.; Kuboki, T.; Xu, C.C. Properties of phenolic adhesives formulated with activated organosolv lignin derived from cornstalk. Ind. Crops Prod. 2021, 161, 113225. [Google Scholar] [CrossRef]

- EN 310; Wood based panels – Determination of modulus of elasticity and modulus of rupture in static bending. EN—European Committee for Standardization: Brussels, Belgium, 1993.

- NBR 9531; Plywood Sheets: Classification. ABNT: Rio de Janeiro, Brazil, 1986.

- Reis, A.H.S.; Silva, D.W.; Vilela, A.P.; Mendes, R.F.; Mendes, L.M. Physical-mechanical properties of plywood produced with Acrocarpus fraxinifolius and Pinus oocarpa. Floresta Ambiente 2019, 26, e20170157. [Google Scholar] [CrossRef]

- Bilik, A.C.B.; Trianoski, R. Evaluation of the physico-mechanical properties of plywood panels and laminated veneer lumber of Pinus glabra Walt. Floresta 2022, 52, 323–331. [Google Scholar] [CrossRef]

- Magalhães, M.A.; Vital, B.R.; Carneiro, A.C.O.; Silva, C.M.D.; Fialho, L.F.; Figueiro, C.G.; Ferreira, J.C. Adição de lignina Kraft à resina fenólica para a fabricação de compensados. Ciência Madeira 2019, 10, 142–149. [Google Scholar] [CrossRef]

- Sardar, N.M.; Rasim, Y.K. Fire retardant and fungi protection materials for wood constructions. J. Pharm. Negat. Results 2023, 1023–1026. [Google Scholar] [CrossRef]

- Sharma, R.K.; Wooten, J.B.; Baliga, V.L.; Lin, X.; Chan, W.G.; Hajaligol, M.R. Characterization of chars from pyrolysis of lignin. Fuel 2004, 83, 1469–1482. [Google Scholar] [CrossRef]

- Bianchi, O.; Dal Castel, C.; Oliveira, R.V.B.; Bertuoli, P.T.; Hillig, E. Nonisothermal degradation of wood using thermogravimetric measurements. Polímeros 2010, 20, 395–400. [Google Scholar] [CrossRef]

- Floch, A.; Jourdes, M.; Teissedre, P. Polysaccharides and lignin from oak wood used in cooperage: Composition, interest, assays: A review. Carbohydr. Res. 2015, 417, 94–102. [Google Scholar] [CrossRef]

- Martínez, M.G.; Couce, A.A.; Dupont, C.; Silva Perez, D.; Thiéry, S.; Meyer, X.M.; Gourdon, C. Torrefaction of cellulose, hemicelluloses and lignin extracted from woody and agricultural biomass in TGA-GC/MS: Linking production profiles of volatile species to biomass type and macromolecular composition. Ind. Crops Prod. 2022, 176, 114350. [Google Scholar] [CrossRef]

- Dorieh, A.; Pahlavan, F.; Hájková, K.; Hýsek, Š.; Farajollah Pour, M.; Fini, H. Advancing Sustainable Building Materials: Reducing Formaldehyde Emissions in Medium Density Fiber Boards with Lignin Nanoparticles. Adv. Sustain. Syst. 2024, 8, 2400102. [Google Scholar] [CrossRef]

- Núñez-Decap, M.; Friz-Sánchez, C.; Opazo-Carlsson, C.; Moya-Rojas, B.; Vidal-Vega, M. A Potential Replacement to Phenol–Formaldehyde-Based Adhesives: A Study of Plywood Panels Manufactured with Bio-Based Wood Protein and Nanolignin Adhesives. Forests 2024, 15, 1345. [Google Scholar] [CrossRef]

- Younesi-Kordkheili, H. Reduction of formaldehyde emission from urea-formaldehyde resin by maleated nanolignin. Int. J. Adhes. Adhes. 2024, 132, 103677. [Google Scholar] [CrossRef]

- BS EN 13986:2004+A1:2015; Wood-Based Panels for Use in Construction. Characteristics, Evaluation of Conformity and Marking. BSI: London, UK, 2015. Available online: https://www.en-standard.eu/bs-en-13986-2004-a1-2015-wood-based-panels-for-use-in-construction-characteristics-evaluation-of-conformity-and-marking/?gclid=Cj0KCQiA1ZGcBhCoARIsAGQ0kkojpktyTiMbjpzkCuN-cqBxxnO06mf87HBrZ885l27F45WSQrOnbnAaAhTwEALw_wcB (accessed on 24 January 2025).

- Taghiyari, H.R.; Hosseini, S.B.; Ghahri, S.; Ghofrani, M.; Papadopoulos, A.N. Formaldehyde emission in micron-sized wollastonite-treated plywood bonded with soy flour and urea-formaldehyde resin. Appl. Sci. 2020, 10, 6709. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Dziurka, D.; Mirski, R.; Szentner, K. Properties of plywood produced with urea-formaldehyde adhesive modified with nanocellulose and microcellulose. Drv. Ind. 2020, 71, 61–67. [Google Scholar] [CrossRef]

| Property | Total Samples | Dimensions (cm) | Standard |

|---|---|---|---|

| Apparent density (g/cm3) | 6 | 8 × 2.5 | NBR 9485 [45] |

| Moisture (dry basis) (%) | 6 | 8 × 2.5 | NBR 9484 [46] |

| Total water absorption (%) | 6 | 8 × 2.5 | NBR 9486 [47] |

| Shear strength (dry, wet and post-boil) (MPa) | 9 | 10 × 2.5 | NBR 12466-1 [48] |

| Static bending with evaluation of modulus of elasticity (MOE) and modulus of rupture (MOR) (MPa) | 9 | 25 × 5 | NBR 9533 [49] |

| Treatment (Nanolignin Content %) | Viscosity (Pa⋅s) | Solids Content (%) | pH |

|---|---|---|---|

| 0 | 2.32 ± 0.50 * c | 95.82 ± 0.64 d | 9.73 ± 0.07 c |

| 1 | 1.49 ± 0.10 b | 81.30 ± 0.69 c | 9.57 ± 0.05 b |

| 2 | 1.11 ± 0.10 a | 75.23 ± 2.40 b | 9.51 ± 0.10 b |

| 3 | 0.74 ± 0.45 a | 71.05 ± 0.18 a | 9.39 ± 0.08 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magalhães, M.R.R.; Batista, F.G.; Furtini, A.C.C.; Scatolino, M.V.; Brito, F.M.S.; Mendes, L.M.; de Paula Protásio, T.; Junior, J.B.G. Quality of Plywood Bonded with Nanolignin-Enriched Cardanol-Formaldehyde Adhesive. Fibers 2025, 13, 95. https://doi.org/10.3390/fib13070095

Magalhães MRR, Batista FG, Furtini ACC, Scatolino MV, Brito FMS, Mendes LM, de Paula Protásio T, Junior JBG. Quality of Plywood Bonded with Nanolignin-Enriched Cardanol-Formaldehyde Adhesive. Fibers. 2025; 13(7):95. https://doi.org/10.3390/fib13070095

Chicago/Turabian StyleMagalhães, Maria Rita Ramos, Felipe Gomes Batista, Ana Carolina Corrêa Furtini, Mário Vanoli Scatolino, Flávia Maria Silva Brito, Lourival Marin Mendes, Thiago de Paula Protásio, and José Benedito Guimarães Junior. 2025. "Quality of Plywood Bonded with Nanolignin-Enriched Cardanol-Formaldehyde Adhesive" Fibers 13, no. 7: 95. https://doi.org/10.3390/fib13070095

APA StyleMagalhães, M. R. R., Batista, F. G., Furtini, A. C. C., Scatolino, M. V., Brito, F. M. S., Mendes, L. M., de Paula Protásio, T., & Junior, J. B. G. (2025). Quality of Plywood Bonded with Nanolignin-Enriched Cardanol-Formaldehyde Adhesive. Fibers, 13(7), 95. https://doi.org/10.3390/fib13070095