Hierarchical Modeling of Archaeological and Modern Flax Fiber: From Micro- to Macroscale

Abstract

Highlights

- What are the main findings?

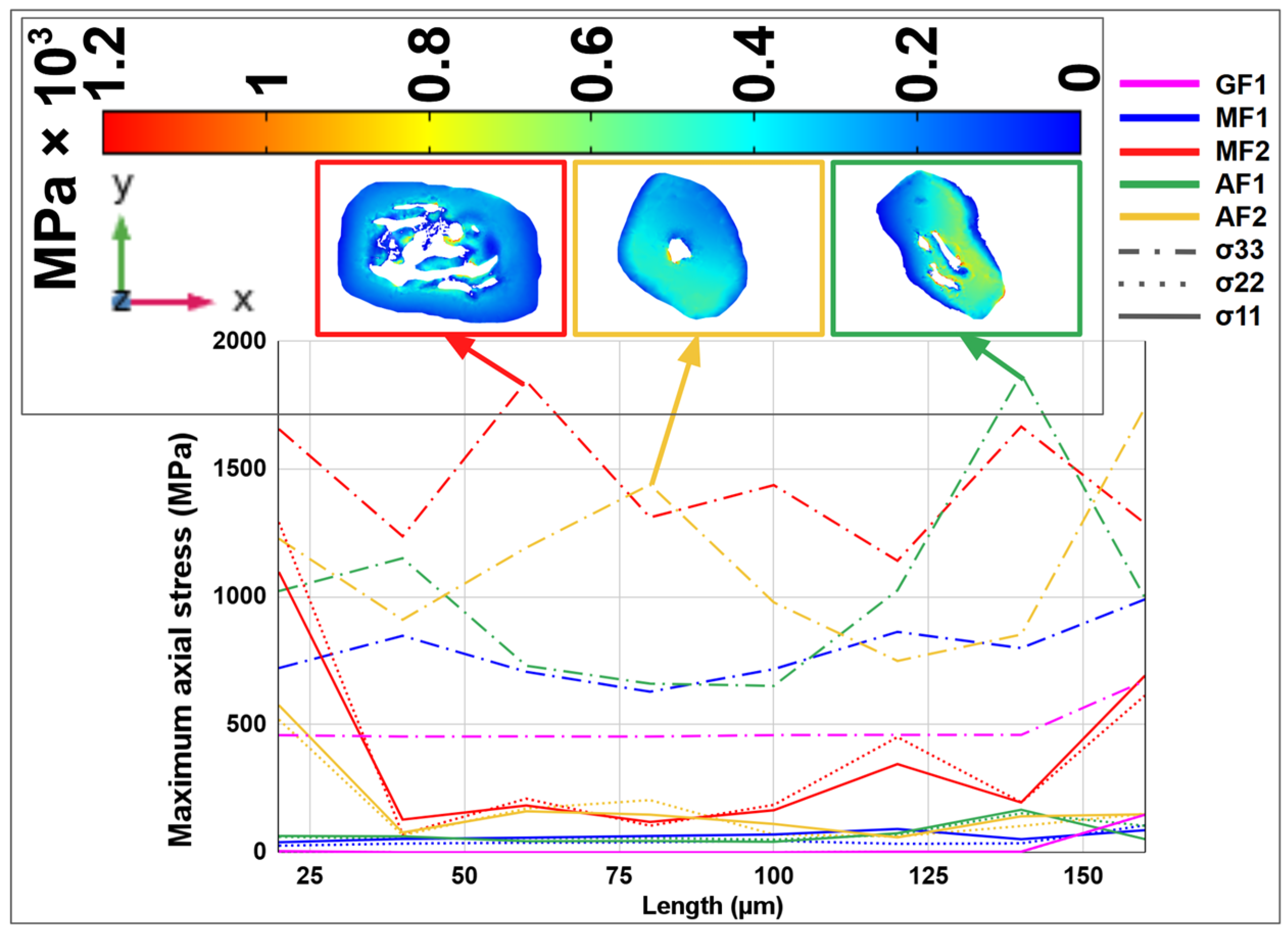

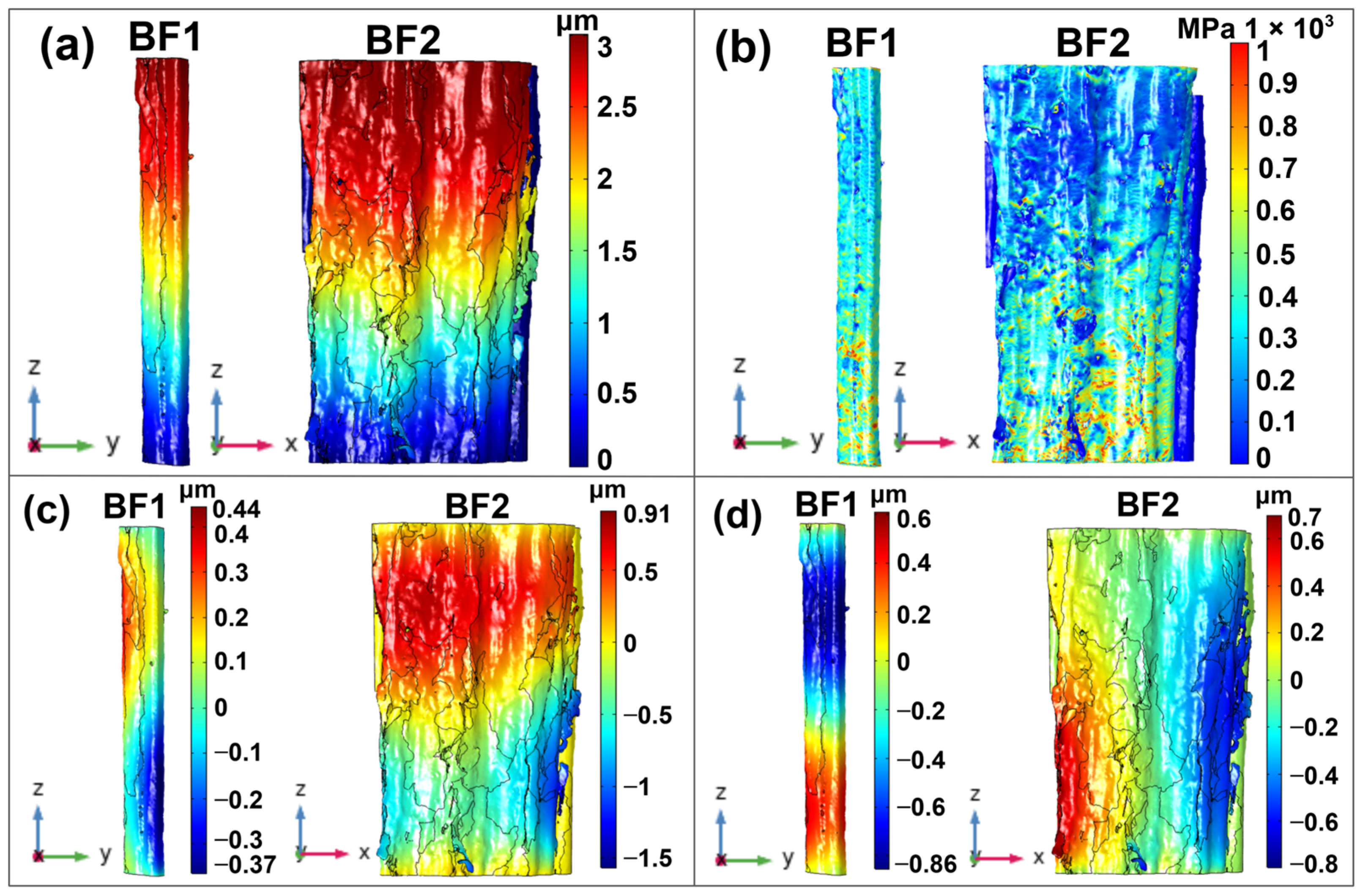

- Defects and aging reduce flax fiber strength: Porosity, surface defects, (e.g., kink-bands, lumens), and degradation increase stress concentrations, weakening fibers. Aged fibers show more damage and lower stiffness than modern ones.

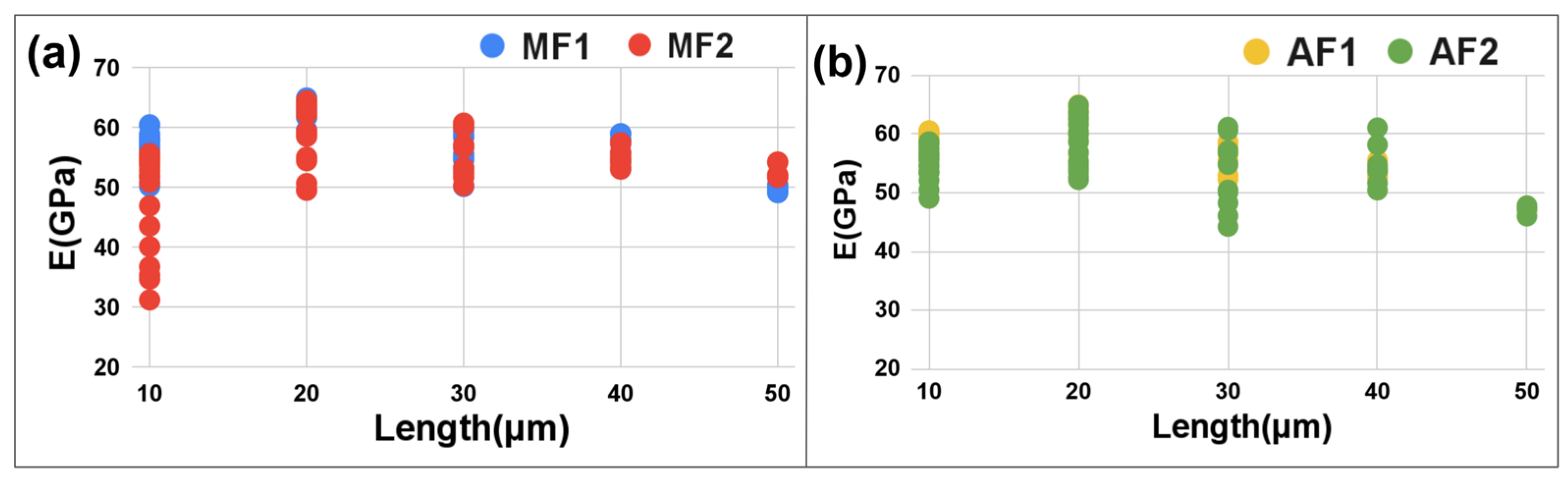

- Stable mechanical properties at 50 µm (REL): The elastic modulus stabilizes at this length, minimizing variability caused by microstructural defects in shorter segments.

- What are the implications of the main findings?

- Improved fiber design: Reducing defects in flax fibers enhances durability, making them more viable for sustainable composites and textiles.

- Conservation and predictive modeling: This study aids in preserving ancient flax textiles by quantifying aging effects and introduces a framework (REL) for predicting natural fiber behavior, benefiting research and industry.

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

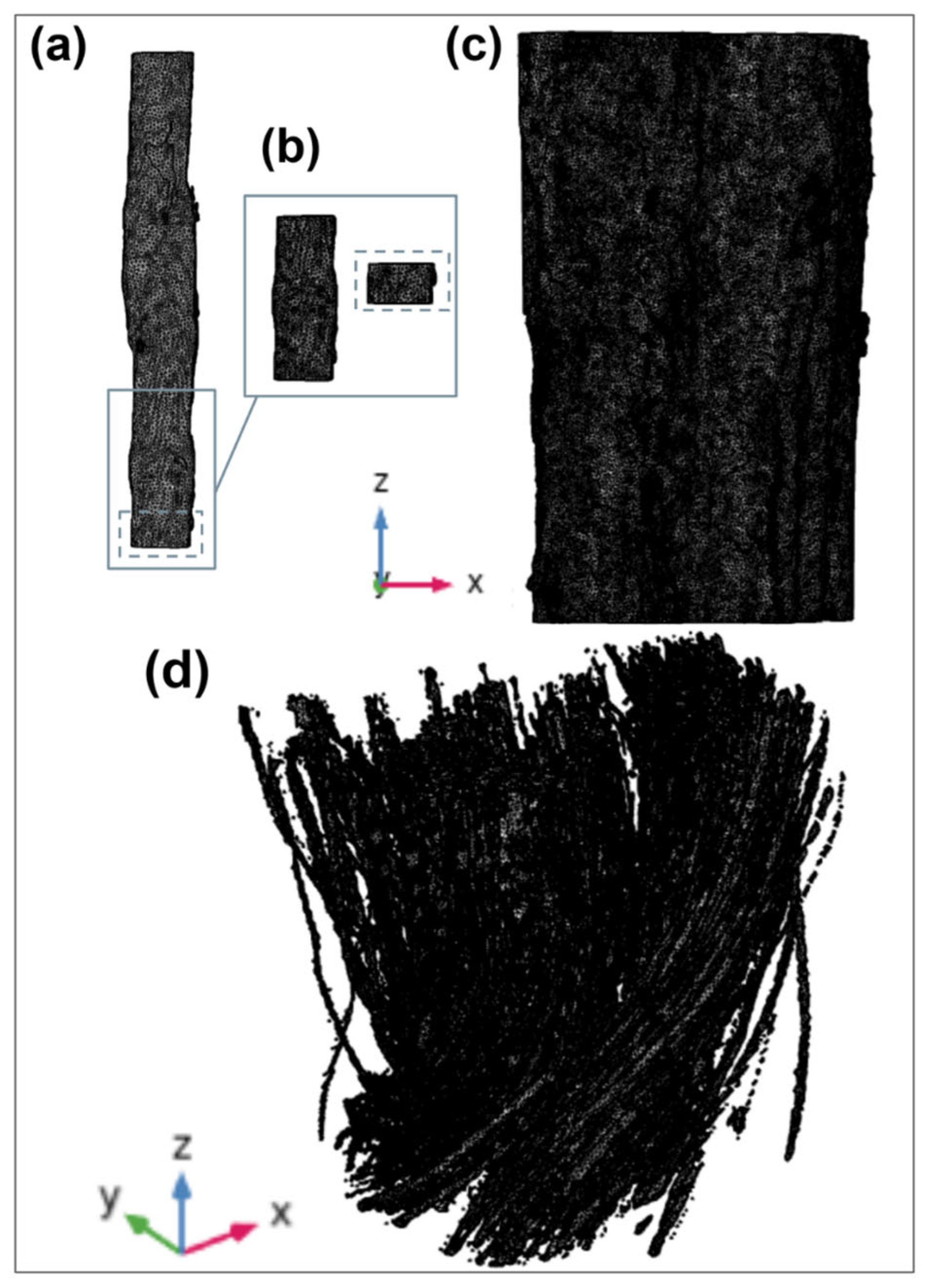

2.2. X-Ray Microtomography

2.3. Finite-Element Computation

3. Results and Discussion

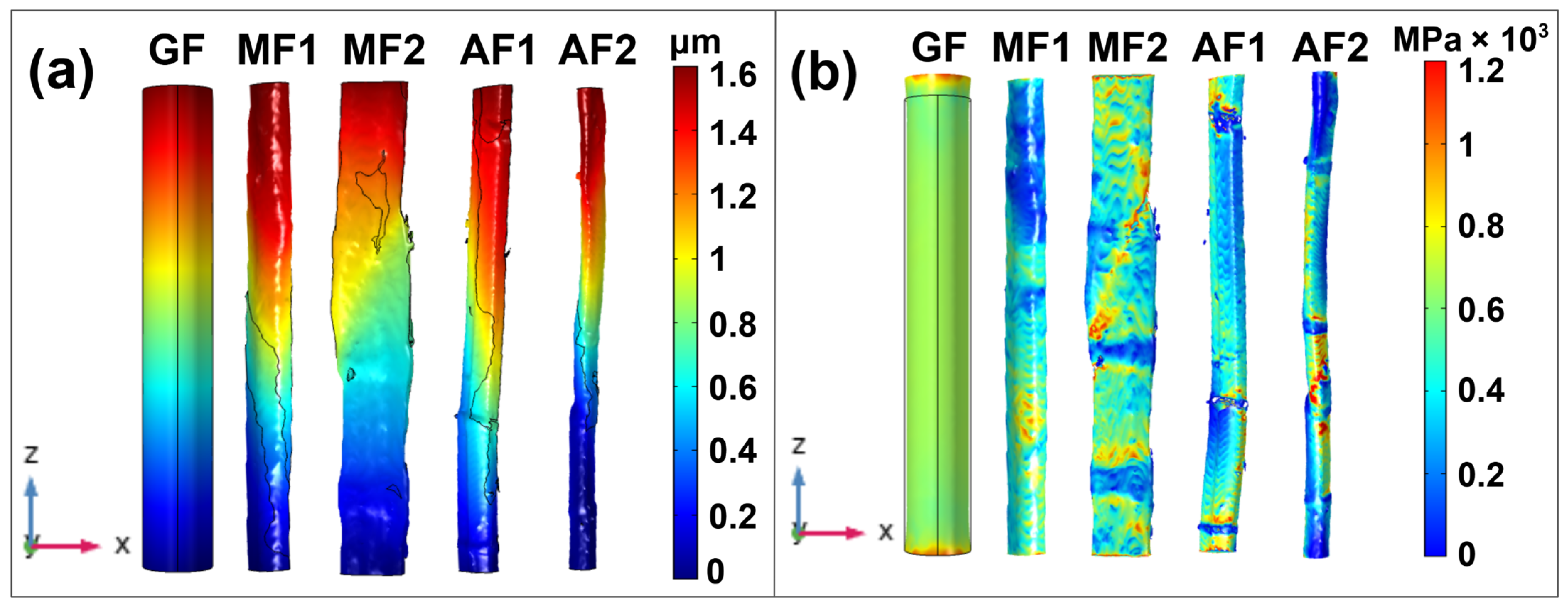

3.1. Microscale Elementary Fibers

3.2. Mesoscale Bundle Fibers

3.3. Macroscale Yarns

4. Conclusions

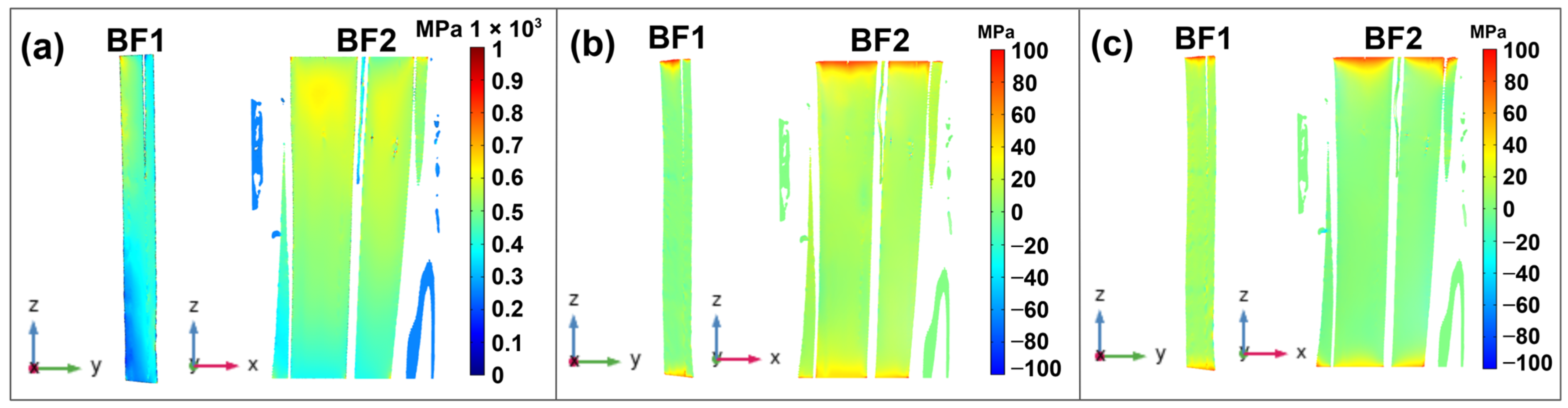

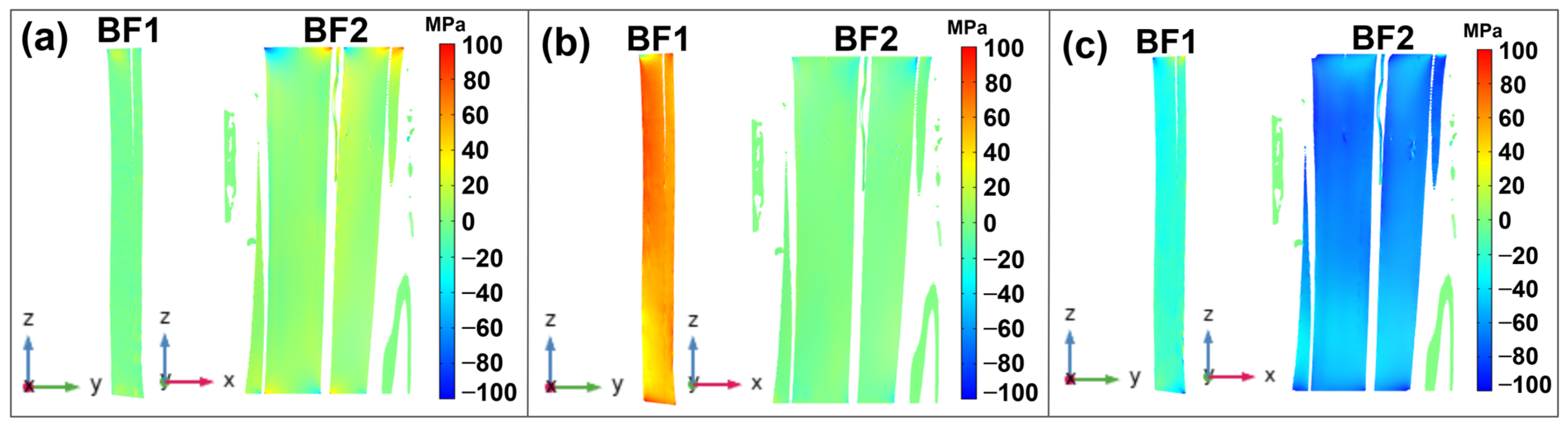

- The modulus decreases from elementary fibers to bundles and, further, to yarns due to increasing structural complexity, with larger bundles experiencing more slippage and defects, while smaller bundles retain better stiffness. Yarns exhibit the lowest modulus due to additional factors like twisting and interfacial behavior.

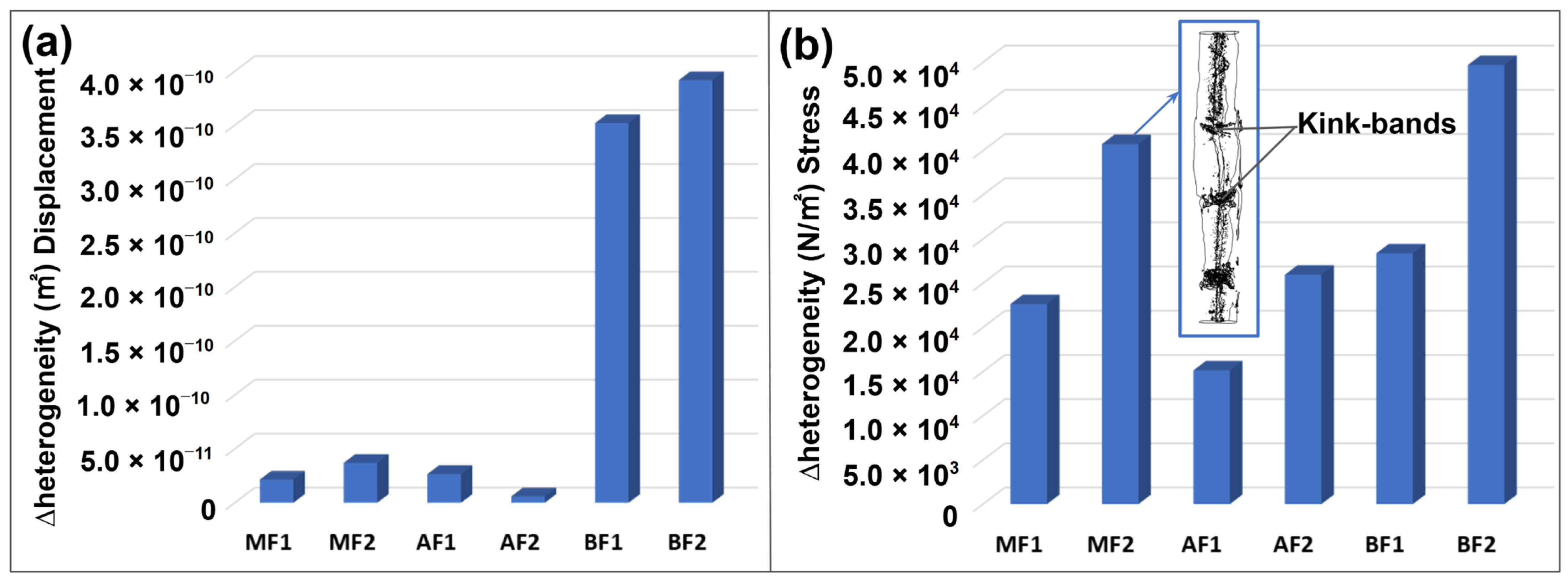

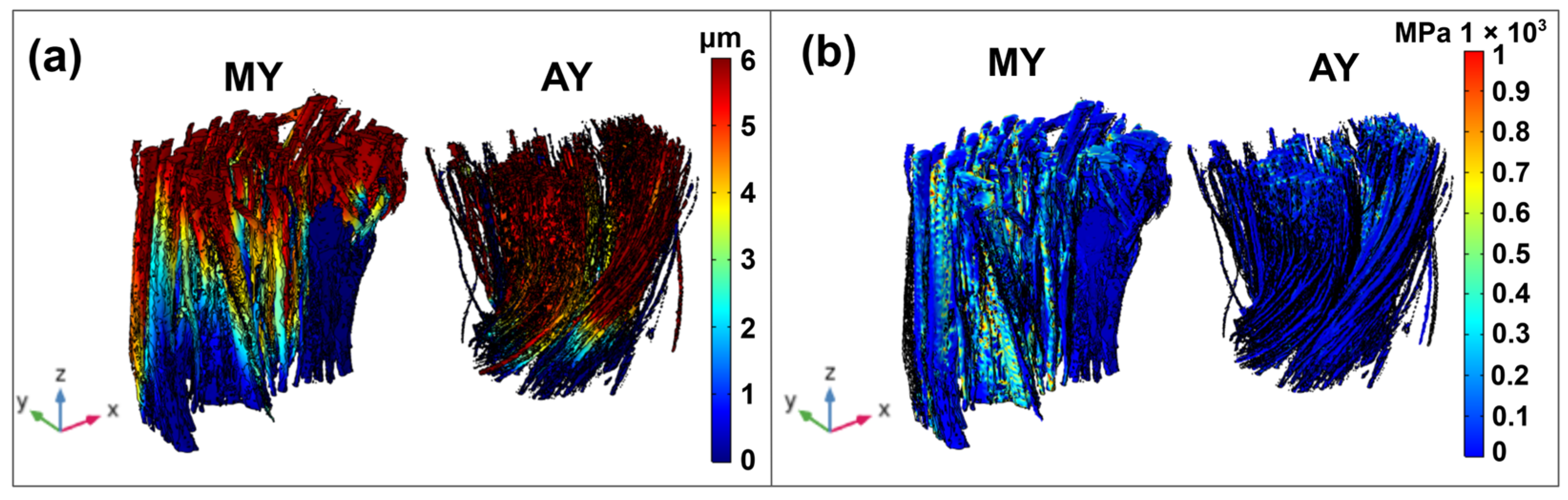

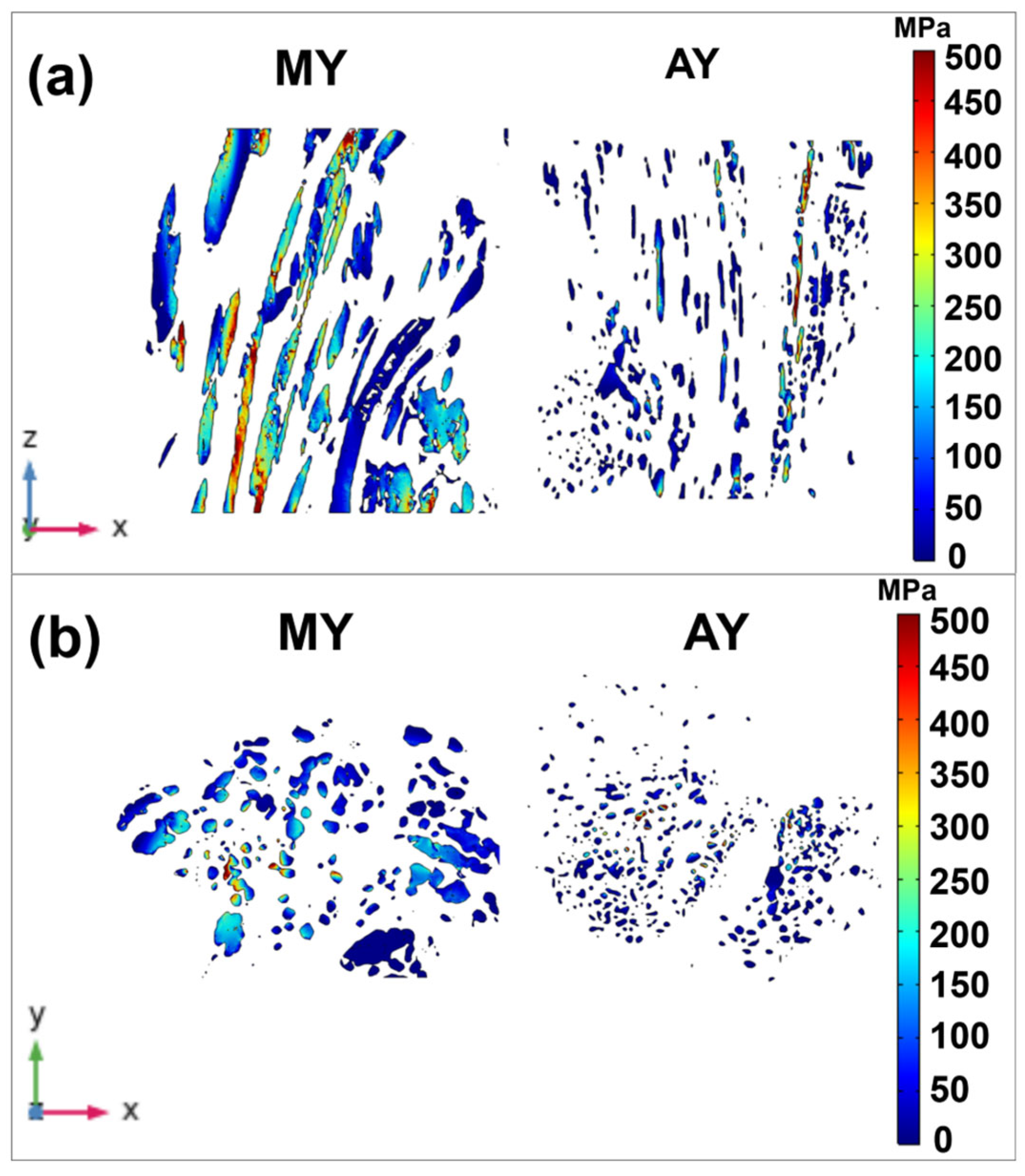

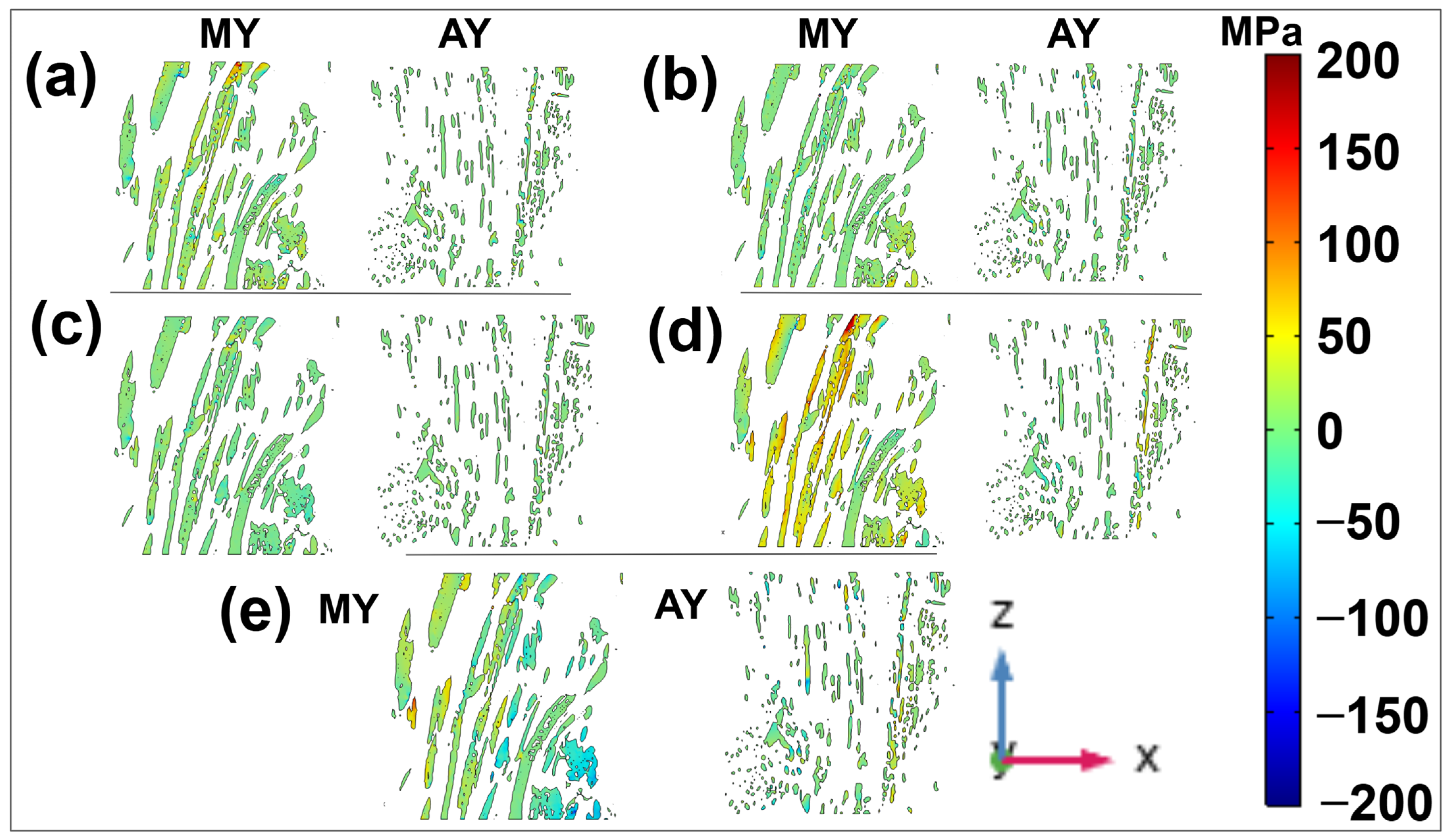

- High-stress regions were observed near defects, fiber–fiber interfaces, pores, and surface irregularities, with rupture initiation most likely occurring at kink-bands, bundle surfaces, and yarns due to high stress concentration at these points.

- From the REL approach, it can be observed that the elastic modulus varies significantly below 30 μm due to structural heterogeneity, particularly the microstructural defects, but stabilizes at ~50 μm, making it suitable for accurate mechanical characterization.

- Aging leads to increased porosity and surface roughness, weakening fiber integrity. Also, these fibers exhibit increased fiber discontinuities due to long-term degradation.

- Larger fiber bundles exhibit higher stress heterogeneity, likely due to its complex structural composition, increased porosity, and fiber misalignment.

- There is lower mechanical strength in aged yarns (~5 GPa vs. ~20 GPa for modern yarns). Higher stress concentrations in ancient fibers suggest increased rupture probability in these fibers.

- Effect of shearing: Shear stresses (σ12, σ13, σ23) fluctuate, contributing to fiber shrinkage. At larger fiber scales, such as the yarn scale, increased shear stress makes rupture more likely to occur perpendicularly to the loading direction.

- Aged yarns show higher shrinkage behavior, with more pronounced stress concentrations at fiber junctions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Dittenber, D.B.; GangaRao, H.V. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Bourmaud, A.; Beaugrand, J.; Shah, D.U.; Placet, V.; Baley, C. Towards the design of high-performance plant fibre composites. Prog. Mater. Sci. 2018, 97, 347–408. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Lateral crushing of empty and polyurethane-foam filled natural flax fabric reinforced epoxy composite tubes. Compos. Part B Eng. 2014, 63, 15–26. [Google Scholar] [CrossRef]

- Richely, E.; Bourmaud, A.; Placet, V.; Guessasma, S.; Beaugrand, J. A critical review of the ultrastructure, mechanics and modelling of flax fibres and their defects. Prog. Mater. Sci. 2022, 124, 100851. [Google Scholar] [CrossRef]

- Guillou, E.; King, A.; Perrin, J.; Proudhon, H.; Weitkamp, T.; Shah, D.U.; Beigbeder, A.; Ouagne, P.; Bourmaud, A. Impact of flax fibre micro-structural features on composite damage observed through micro-CT characterisation. Compos. Part A Appl. Sci. Manuf. 2024, 181, 108118. [Google Scholar] [CrossRef]

- Madsen, B.; Hoffmeyer, P.; Lilholt, H. Hemp yarn reinforced composites–II. Tensile properties. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2204–2215. [Google Scholar] [CrossRef]

- Yan, L.; Su, S.; Chouw, N. Microstructure, flexural properties and durability of coir fibre reinforced concrete beams externally strengthened with flax FRP composites. Compos. Part B Eng. 2015, 80, 343–354. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Cevallos, O.; Olivito, R.S.; Codispoti, R.; Ombres, L. Flax and polyparaphenylene benzobisoxazole cementitious composites for the strengthening of masonry elements subjected to eccentric loading. Compos. Part B Eng. 2015, 71, 82–95. [Google Scholar] [CrossRef]

- Angelova, R.A. Failure of yarns in different textile applications. In Handbook of Materials Failure Analysis; Makhlouf, A.S.H., Aliofkhazraei, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 277–301. [Google Scholar]

- Hautala, M.; Pasila, A.; Pirilä, J. Use of hemp and flax in composite manufacture: A search for new production methods. Compos. Part A Appl. Sci. Manuf. 2004, 35, 11–16. [Google Scholar] [CrossRef]

- Aldroubi, S.; Kasal, B.; Yan, L.; Bachtiar, E.V. Multi-scale investigation of morphological, physical and tensile properties of flax single fiber, yarn and unidirectional fabric. Compos. Part B Eng. 2023, 259, 110732. [Google Scholar] [CrossRef]

- Abbey, B.; Eve, S.; Thuault, A.; Charlet, K.; Korsunsky, A. Synchrotron X-ray tomographic investigation of internal structure of individual flax fibres. In Proceedings of the 6th World Congress of Biomechanics (WCB 2010), Singapore, 1–6 August 2010. [Google Scholar]

- Chakrabarti, B.; Nodder, C. Some Effects of the Helical Fibrillar Structure of Vegetable Fibres. Nature 1949, 163, 19–20. [Google Scholar] [CrossRef]

- Guessasma, S.; Beaugrand, J. Damage kinetics at the sub-micrometric scale in bast fibers using finite element simulation and high-resolution X-Ray micro-tomography. Front. Plant Sci. 2019, 10, 194. [Google Scholar] [CrossRef] [PubMed]

- Ekaputri, T.S.; Tanaka, T. Quantitative analysis of commercial coating penetration into Fagus crenata wood using X-ray microtomography. Sci. Rep. 2024, 14, 13925. [Google Scholar] [CrossRef] [PubMed]

- Charlet, K.; Jernot, J.; Eve, S.; Gomina, M.; Bréard, J. Multi-scale morphological characterisation of flax: From the stem to the fibrils. Carbohydr. Polym. 2010, 82, 54–61. [Google Scholar] [CrossRef]

- Melelli, A.; Jamme, F.; Legland, D.; Beaugrand, J.; Bourmaud, A. Microfibril angle of elementary flax fibres investigated with polarised second harmonic generation microscopy. Ind. Crops Prod. 2020, 156, 112847. [Google Scholar] [CrossRef]

- Melelli, A.; Arnould, O.; Beaugrand, J.; Bourmaud, A. The middle lamella of plant fibers used as composite reinforcement: Investigation by atomic force microscopy. Molecules 2020, 25, 632. [Google Scholar] [CrossRef]

- Rask, M.; Madsen, B. Twisting of fibres in yarns for natural fibre composites. In Proceedings of the 18th International Conference on Composite Materials, Jeju Island, Republic of Korea, 21–26 August 2011. [Google Scholar]

- Elmogahzy, Y. Structure and mechanics of yarns. In Structure and Mechanics of Textile fibre Assemblies; Schwartz, P., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–25. [Google Scholar]

- Richely, E.; Durand, S.; Melelli, A.; Kao, A.; Magueresse, A.; Dhakal, H.; Gorshkova, T.; Callebert, F.; Bourmaud, A.; Beaugrand, J. Novel insight into the intricate shape of flax fibre lumen. Fibers 2021, 9, 24. [Google Scholar] [CrossRef]

- Baley, C.; Goudenhooft, C.; Perré, P.; Lu, P.; Pierre, F.; Bourmaud, A. Compressive strength of flax fibre bundles within the stem and comparison with unidirectional flax/epoxy composites. Ind. Crops Prod. 2019, 130, 25–33. [Google Scholar] [CrossRef]

- Haag, K.; Müssig, J. Scatter in tensile properties of flax fibre bundles: Influence of determination and calculation of the cross-sectional area. J. Mater. Sci. 2016, 51, 7907–7917. [Google Scholar] [CrossRef]

- Turan, R.B.; Okur, A.; Deveci, R.; Açikel, M. Predicting the intra-yarn porosity by image analysis method. Text. Res. J. 2012, 82, 1720–1728. [Google Scholar] [CrossRef]

- Havlová, M.; Špánková, J. Porosity of knitted fabrics in the aspect of air permeability-discussion of selected assumptions. Fibres Text. East. Eur. 2017, 25, 86–91. [Google Scholar] [CrossRef]

- Tumajer, P.; Ursíny, P.; Bílek, M.; Mouckova, E.; Pokorna, M. Influence of structure of the yarn on mechanical characteristics of yarns exposed to dynamic stress. Autex Res. J. 2012, 12, 44–49. [Google Scholar] [CrossRef]

- Zuccarello, B.; Militello, C.; Bongiorno, F. Environmental aging effects on high-performance biocomposites reinforced by sisal fibers. Polym. Degrad. Stab. 2023, 211, 110319. [Google Scholar] [CrossRef]

- Morgillo, L.; Melelli, A.; Scheel, M.; Wightman, R.; Weitkamp, T.; Goudenhooft, C.; Quiles, A.; Shah, D.U.; Abida, M.; Beaugrand, J. Inside the kink-bands of archaeological flax artefacts via sub-micrometer resolution micro-CT: A comprehensive microstructural analysis to better understand degradation mechanisms of fibres. Compos. Part B Eng. 2025, 298, 112347. [Google Scholar] [CrossRef]

- Melelli, A.; Shah, D.U.; Hapsari, G.; Cortopassi, R.; Durand, S.; Arnould, O.; Placet, V.; Benazeth, D.; Beaugrand, J.; Jamme, F. Lessons on textile history and fibre durability from a 4000-year-old Egyptian flax yarn. Nat. Plants 2021, 7, 1200–1206. [Google Scholar] [CrossRef] [PubMed]

- Gleba, M.; Boudin, M.; Di Pietro, G.A. Textiles from Zawaydah, Naqada, Upper Egypt. Archaeol. Text. Rev. 2019, 61, 14–23. [Google Scholar]

- Melelli, A.; Goudenhooft, C.; Durand, S.; Quiles, A.; Cortopassi, R.; Morgillo, L.; Magueresse, A.; Beaugrand, J.; Jamme, F.; Bourmaud, A. Revealing degradation mechanisms of archaeological flax textiles through the evolution of fibres’ parietal polymers by synchrotron deep-UV fluorescence. Polym. Degrad. Stab. 2024, 226, 110826. [Google Scholar] [CrossRef]

- Goudenhooft, C.; Melelli, A.; Durand, S.; Falourd, X.; Le-Bot, L.; Morgillo, L.; Gaballah, S.; Cortopassi, R.; Quiles, A.; Shah, D.U. Comparison of kink-band structures and specificities of cell wall polysaccharides in modern and ancient flax fibres. Carbohydr. Polym. 2024, 344, 122526. [Google Scholar] [CrossRef]

- Gleba, M.; Harris, S. The first plant bast fibre technology: Identifying splicing in archaeological textiles. Archaeol. Anthropol. Sci. 2019, 11, 2329–2346. [Google Scholar] [CrossRef]

- Hao, M.; Tang, M.; Wang, W.; Tian, M.; Zhang, L.; Lu, Y. Silver-nanoparticle-decorated multiwalled carbon nanotubes prepared by poly (dopamine) functionalization and ultraviolet irradiation. Compos. Part B Eng. 2016, 95, 395–403. [Google Scholar] [CrossRef]

- Moudood, A.; Rahman, A.; Khanlou, H.M.; Hall, W.; Öchsner, A.; Francucci, G. Environmental effects on the durability and the mechanical performance of flax fiber/bio-epoxy composites. Compos. Part B Eng. 2019, 171, 284–293. [Google Scholar] [CrossRef]

- Johnson, S.; Kang, L.; Akil, H.M. Mechanical behavior of jute hybrid bio-composites. Compos. Part B Eng. 2016, 91, 83–93. [Google Scholar] [CrossRef]

- Aslan, M.; Chinga-Carrasco, G.; Sørensen, B.F.; Madsen, B. Strength variability of single flax fibres. J. Mater. Sci. 2011, 46, 6344–6354. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Baley, C.; Bourmaud, A. Average tensile properties of French elementary flax fibers. Mater. Lett. 2014, 122, 159–161. [Google Scholar] [CrossRef]

- Rajakumaran, V.; Melelli, A.; Quiles, A.; Weitkamp, T.; Perrin, J.; Proudhon, H.; Bourmaud, A.; Beaugrand, J.; Guessasma, S. Experimental and numerical approach to understand the role of defects in damage mechanisms of flax fibers at bundle scale. Ind. Crops Prod. 2024, 218, 119025. [Google Scholar] [CrossRef]

- Rajakumaran, V.; Guessasma, S.; D’Orlando, A.; Melelli, A.; Scheel, M.; Weitkamp, T.; Perrin, J.; Bourmaud, A.; Proudhon, H.; Beaugrand, J. Impact of Defects on Tensile Properties of Ancient and Modern Egyptian Flax Fibers: Multiscale X-Ray Microtomography and Numerical Modeling. Fibers 2024, 12, 111. [Google Scholar] [CrossRef]

- Pelerin, M.; King, A.; Laiarinandrasana, L.; Proudhon, H. Development of a versatile mechanical testing device for in situ synchrotron tomography and diffraction experiments. Integr. Mater. Manuf. Innov. 2019, 8, 378–387. [Google Scholar] [CrossRef]

- Richely, E.; Bourmaud, A.; Dhakal, H.; Zhang, Z.; Beaugrand, J.; Guessasma, S. Exploring the morphology of flax fibres by X-ray microtomography and the related mechanical response by numerical modelling. Compos. Part A Appl. Sci. Manuf. 2022, 160, 107052. [Google Scholar] [CrossRef]

- Quereilhac, D.; Pinsard, L.; Guillou, E.; Fazzini, M.; De Luycker, E.; Bourmaud, A.; Abida, M.; Perrin, J.; Weitkamp, T.; Ouagne, P. Exploiting synchrotron X-ray tomography for a novel insight into flax-fibre defects ultrastructure. Ind. Crops Prod. 2023, 198, 116655. [Google Scholar] [CrossRef]

- Morgillo, L.; Brionne, L.; Melelli, A.; Ouagne, P.; Scheel, M.; Weitkamp, T.; Shah, D.U.; Abida, M.; Beaugrand, J.; Bourmaud, A. Elucidating links between the mechanical performance of flax fibres and their structural defects. Ind. Crops Prod. 2023, 206, 117722. [Google Scholar] [CrossRef]

- Melelli, A.; Durand, S.; Arnould, O.; Richely, E.; Guessasma, S.; Jamme, F.; Beaugrand, J.; Bourmaud, A. Extensive investigation of the ultrastructure of kink-bands in flax fibres. Ind. Crops Prod. 2021, 164, 113368. [Google Scholar] [CrossRef]

- Beaugrand, J.; Guessasma, S.; Maigret, J. Damage mechanisms in defected natural fibers. Sci. Rep. 2017, 7, 14041. [Google Scholar] [CrossRef]

- Joffe, R.; Andersons, J.; Wallström, L. Strength and adhesion characteristics of elementary flax fibres with different surface treatments. Compos. Part A Appl. Sci. Manuf. 2003, 34, 603–612. [Google Scholar] [CrossRef]

- Charlet, K.; Beakou, A. Interfaces within flax fibre bundle: Experimental characterization and numerical modelling. J. Compos. Mater. 2014, 48, 3263–3269. [Google Scholar] [CrossRef]

- Ahmed, S.; Ulven, C.A. Dynamic in-situ observation on the failure mechanism of flax fiber through scanning electron microscopy. Fibers 2018, 6, 17. [Google Scholar] [CrossRef]

- Hänninen, T.; Thygesen, A.; Mehmood, S.; Madsen, B.; Hughes, M. Mechanical processing of bast fibres: The occurrence of damage and its effect on fibre structure. Ind. Crops Prod. 2012, 39, 7–11. [Google Scholar] [CrossRef]

- Gautreau, M.; Durand, S.; Paturel, A.; Le Gall, S.; Foucat, L.; Falourd, X.; Novales, B.; Ralet, M.-C.; Chevallier, S.; Kervoelen, A. Impact of cell wall non-cellulosic and cellulosic polymers on the mechanical properties of flax fibre bundles. Carbohydr. Polym. 2022, 291, 119599. [Google Scholar] [CrossRef]

- Beaugrand, J.; Guessasma, S. Scenarios of crack propagation in bast fibers: Combining experimental and finite element approaches. Compos. Struct. 2015, 133, 667–678. [Google Scholar] [CrossRef]

- Abida, M.; Baklouti, A.; Gehring, F.; Vivet, A.; Bouvet, C. Inverse approach for flax yarns mechanical properties identification from statistical mechanical characterization of the fabric. Mech. Mater. 2020, 151, 103638. [Google Scholar] [CrossRef]

- Codispoti, R.; Oliveira, D.V.; Olivito, R.S.; Lourenço, P.B.; Fangueiro, R. Mechanical performance of natural fiber-reinforced composites for the strengthening of masonry. Compos. Part B Eng. 2015, 77, 74–83. [Google Scholar] [CrossRef]

- Blanchard, J.; Sobey, A.; Blake, J. Multi-scale investigation into the mechanical behaviour of flax in yarn, cloth and laminate form. Compos. Part B Eng. 2016, 84, 228–235. [Google Scholar] [CrossRef]

| Elastic Properties | |

|---|---|

| 65 GPa | |

| 9.8 GPa | |

| 3.2 GPa | |

| 4.1 GPa | |

| 0.18 | |

| 0.2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajakumaran, V.; Beaugrand, J.; Melelli, A.; Scheel, M.; Weitkamp, T.; Perrin, J.; Bourmaud, A.; Proudhon, H.; Guessasma, S. Hierarchical Modeling of Archaeological and Modern Flax Fiber: From Micro- to Macroscale. Fibers 2025, 13, 76. https://doi.org/10.3390/fib13060076

Rajakumaran V, Beaugrand J, Melelli A, Scheel M, Weitkamp T, Perrin J, Bourmaud A, Proudhon H, Guessasma S. Hierarchical Modeling of Archaeological and Modern Flax Fiber: From Micro- to Macroscale. Fibers. 2025; 13(6):76. https://doi.org/10.3390/fib13060076

Chicago/Turabian StyleRajakumaran, Vasuki, Johnny Beaugrand, Alessia Melelli, Mario Scheel, Timm Weitkamp, Jonathan Perrin, Alain Bourmaud, Henry Proudhon, and Sofiane Guessasma. 2025. "Hierarchical Modeling of Archaeological and Modern Flax Fiber: From Micro- to Macroscale" Fibers 13, no. 6: 76. https://doi.org/10.3390/fib13060076

APA StyleRajakumaran, V., Beaugrand, J., Melelli, A., Scheel, M., Weitkamp, T., Perrin, J., Bourmaud, A., Proudhon, H., & Guessasma, S. (2025). Hierarchical Modeling of Archaeological and Modern Flax Fiber: From Micro- to Macroscale. Fibers, 13(6), 76. https://doi.org/10.3390/fib13060076