Performance of Carbon Fiber-Reinforced Date Palm Midrib Composites

Abstract

Highlights

- Epoxy-based date palm–carbon fiber composites outperformed in tensile and flexural strength in both directions.

- Polyester-based composites excelled in impact resistance and had lower thickness swelling, suggesting better dimensional stability.

- These results highlight the ability to customize sustainable hybrid composites by selecting the right resin system.

- Epoxy-based composites are better suited for high-strength structural applications, while polyester-based ones are ideal for impact-resistant or dynamic-load com-ponents.

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

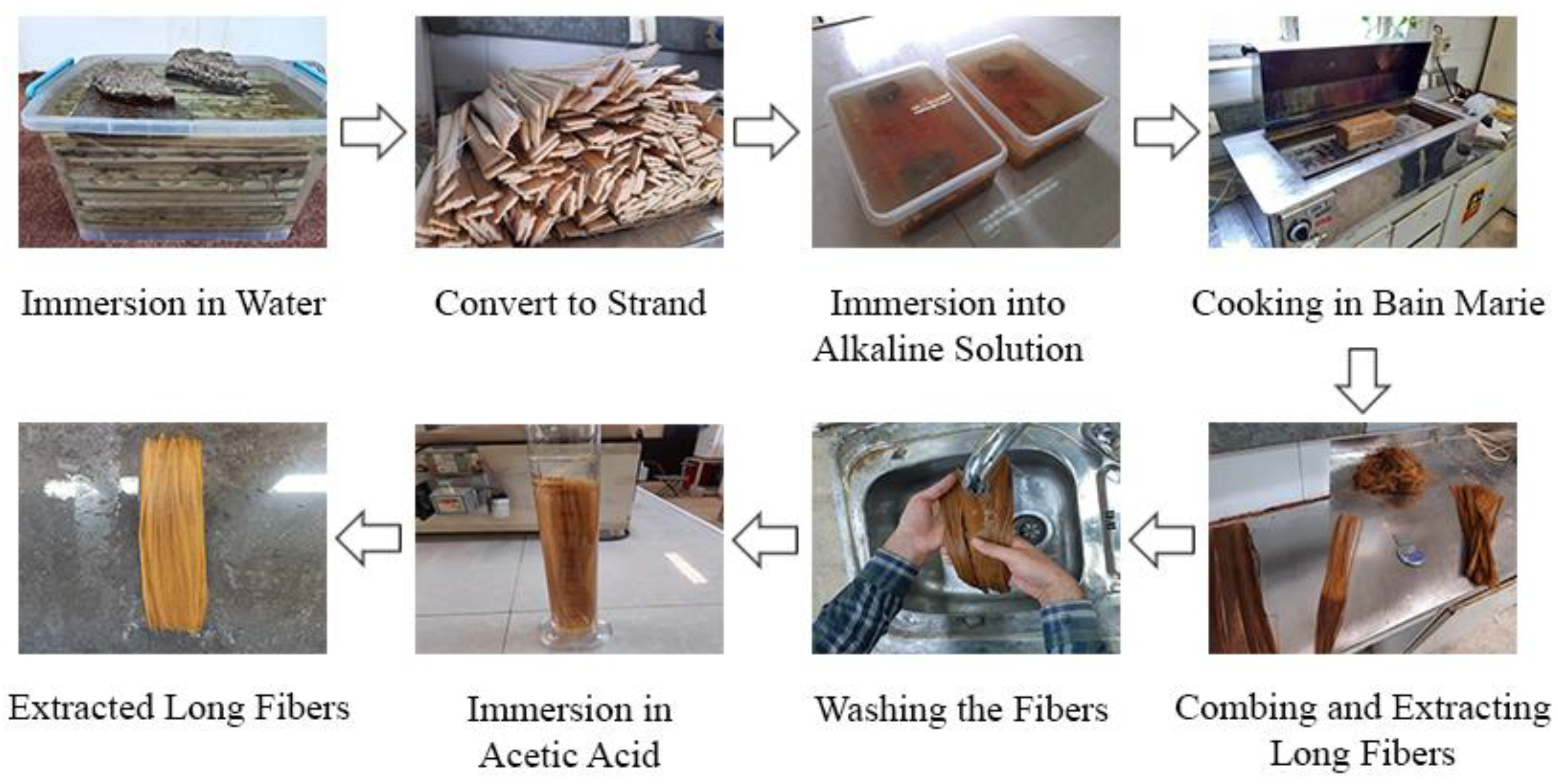

2.1.1. Fibers Preparation and Extraction

2.1.2. Composite Panels Manufacturing

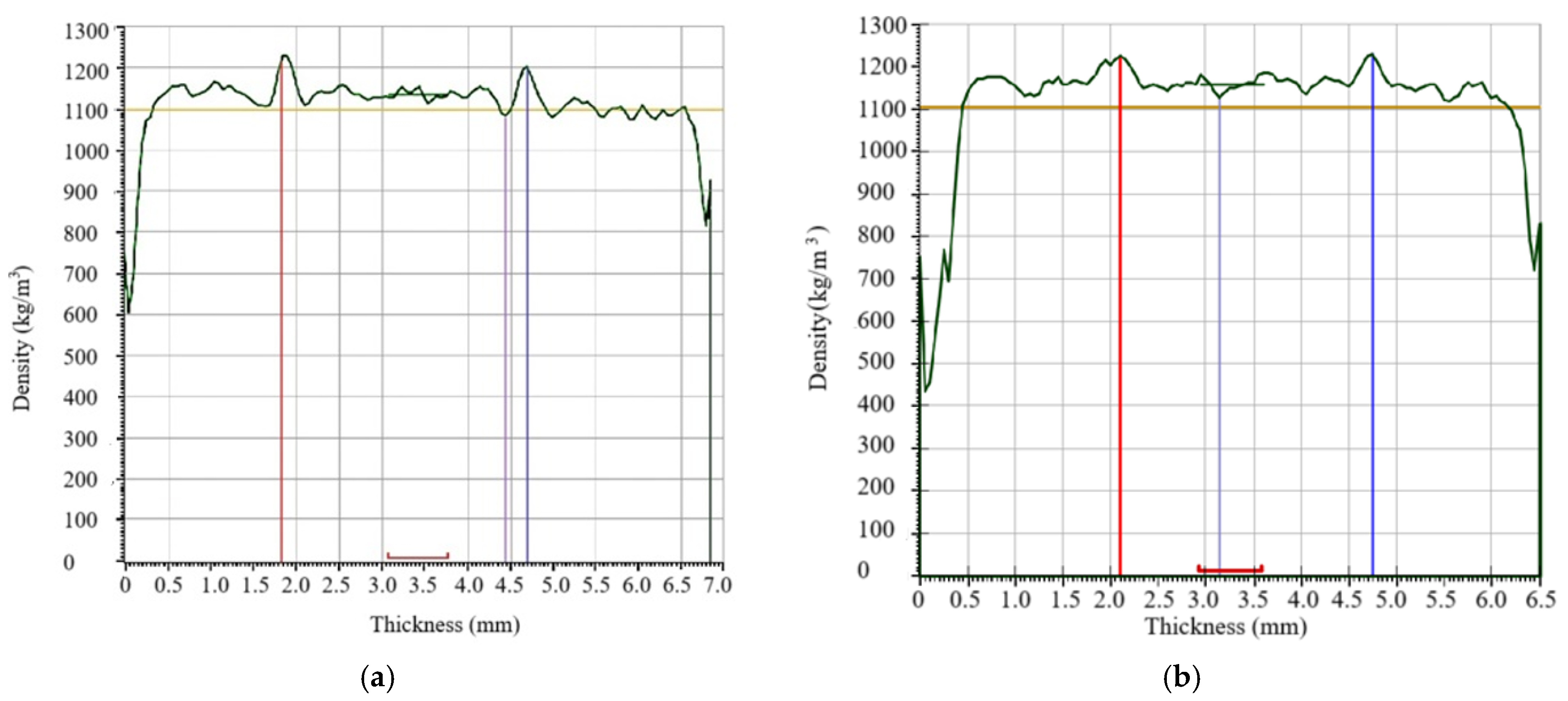

2.1.3. Vertical Density Profile (VDP) of the Samples

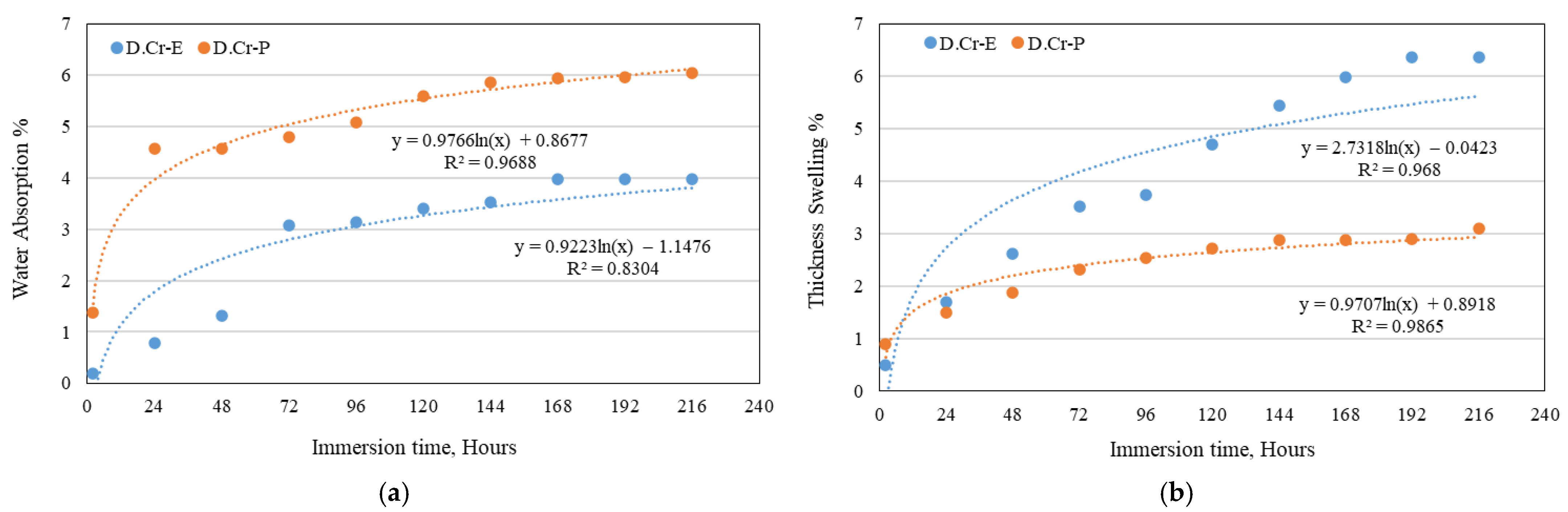

2.1.4. Water Absorption (WA) and Thickness Swelling (TS) of the Samples

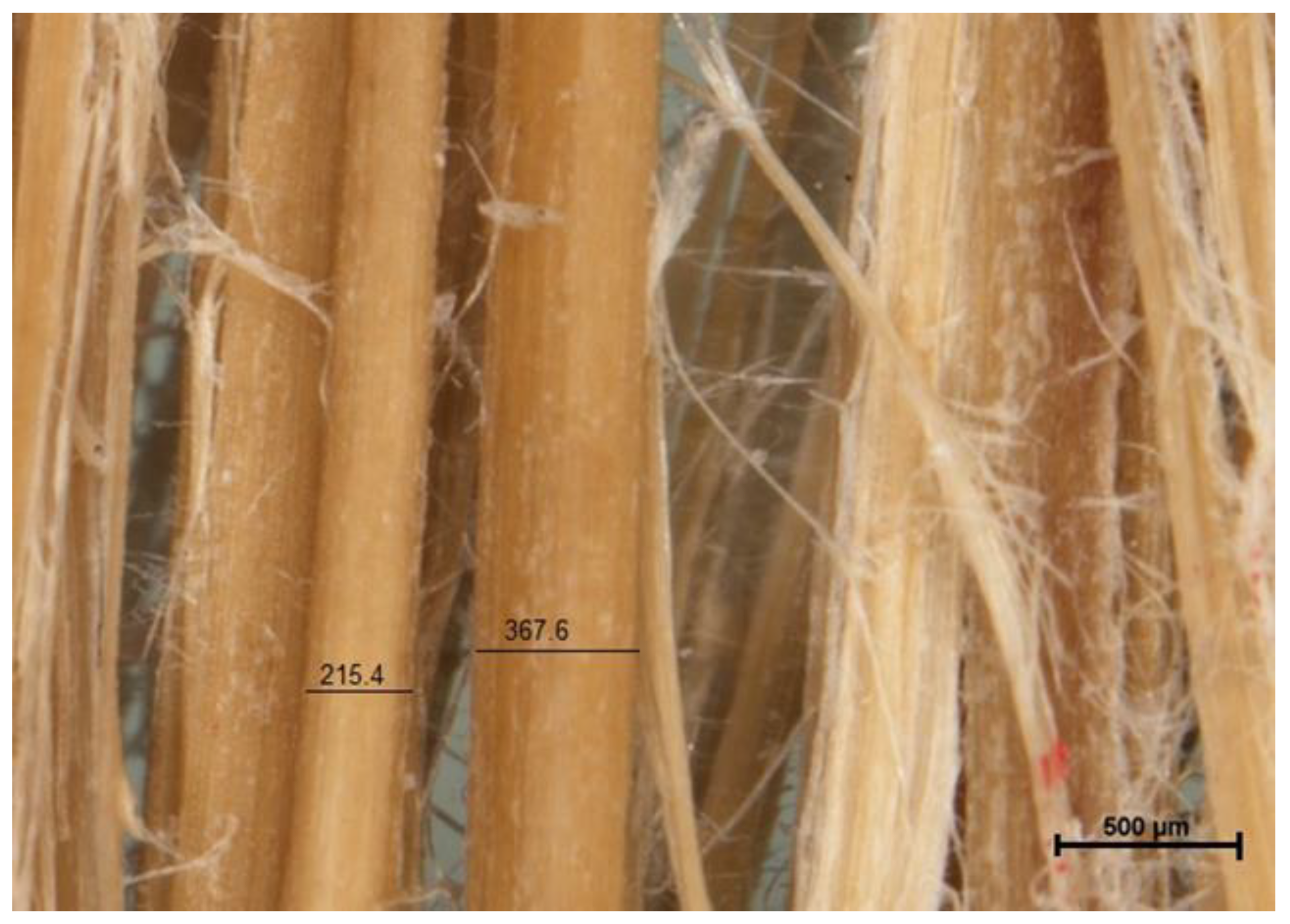

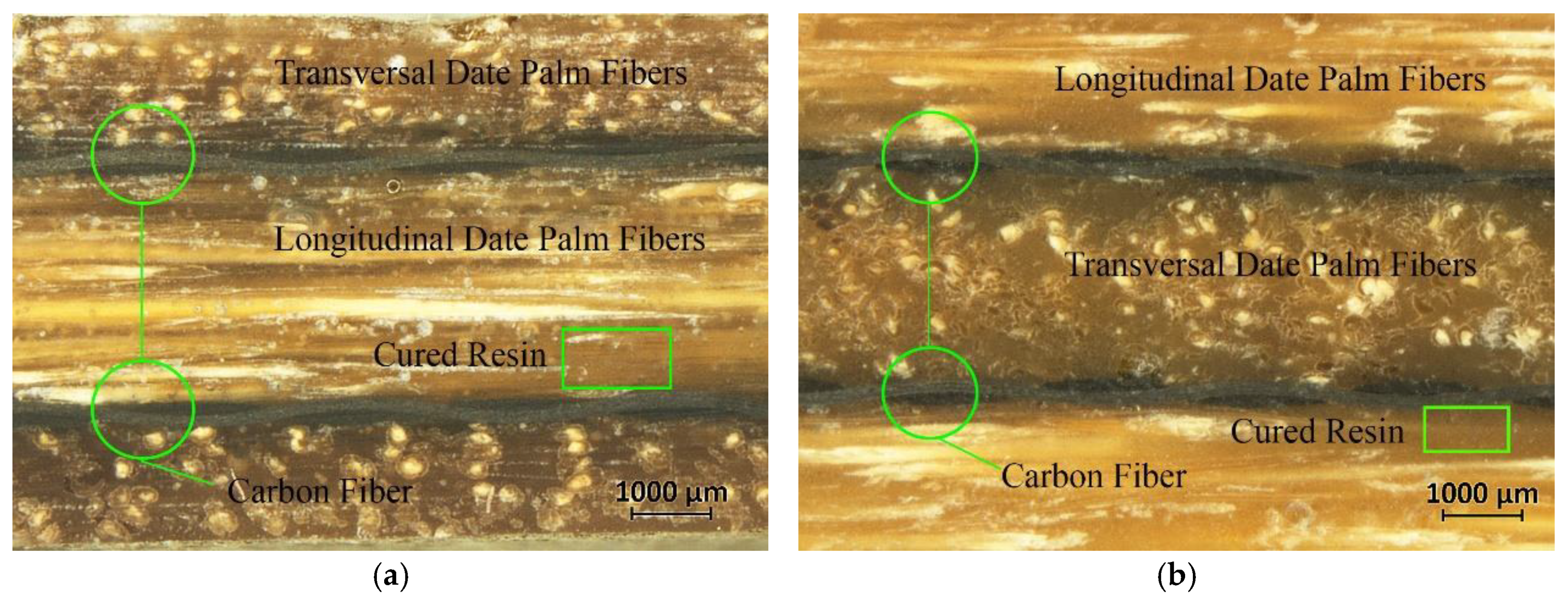

2.1.5. Microscopic Evaluation of the Samples

2.1.6. Mechanical Performance of the Samples

2.1.7. Statistical Analysis

3. Results

3.1. Vertical Density Profiles of the Samples

3.2. Dimensional Stability and Water Afinity of the Samples

3.3. Microscopic Investigation of the Samples

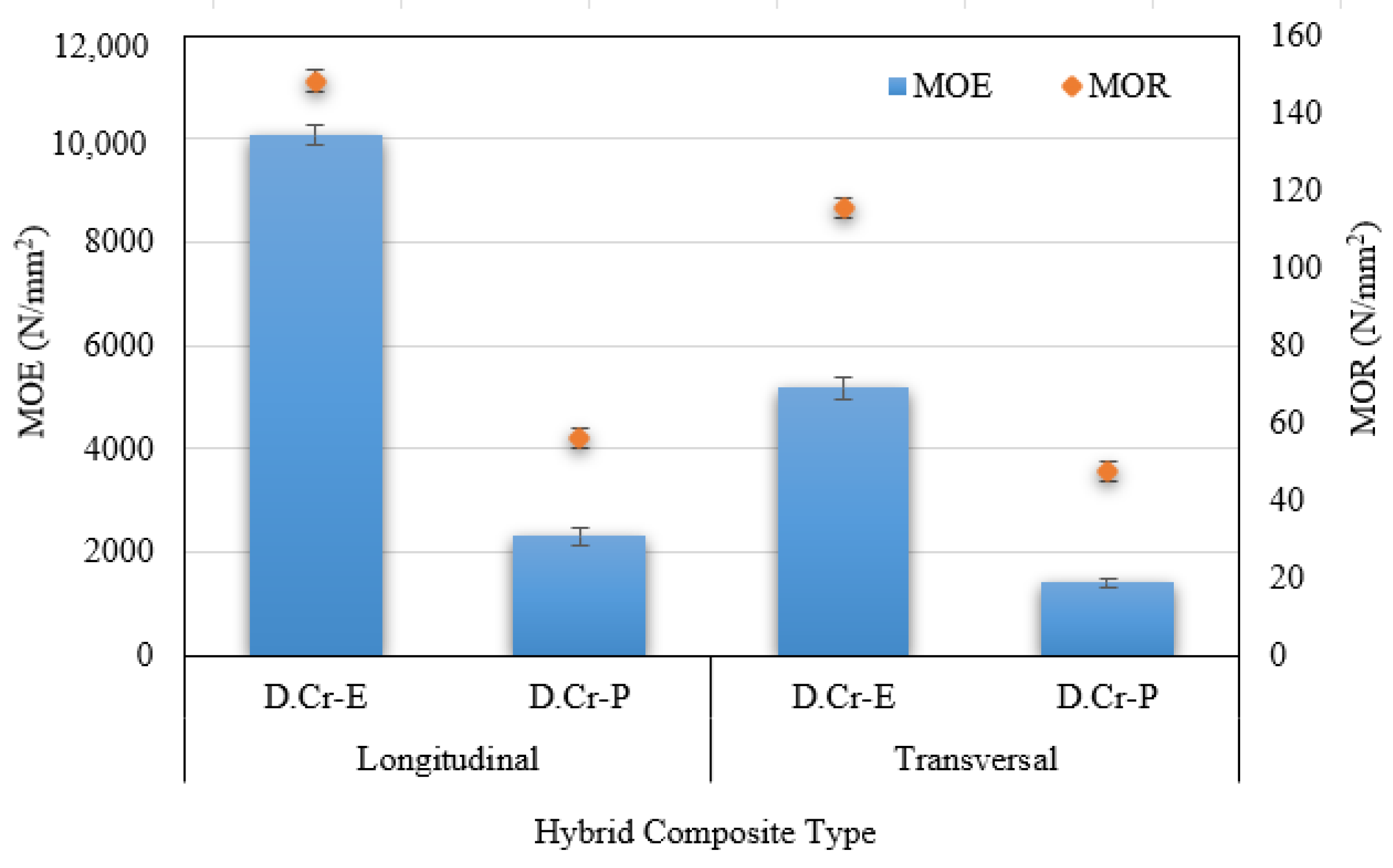

3.4. Flexural Testing of the Samples

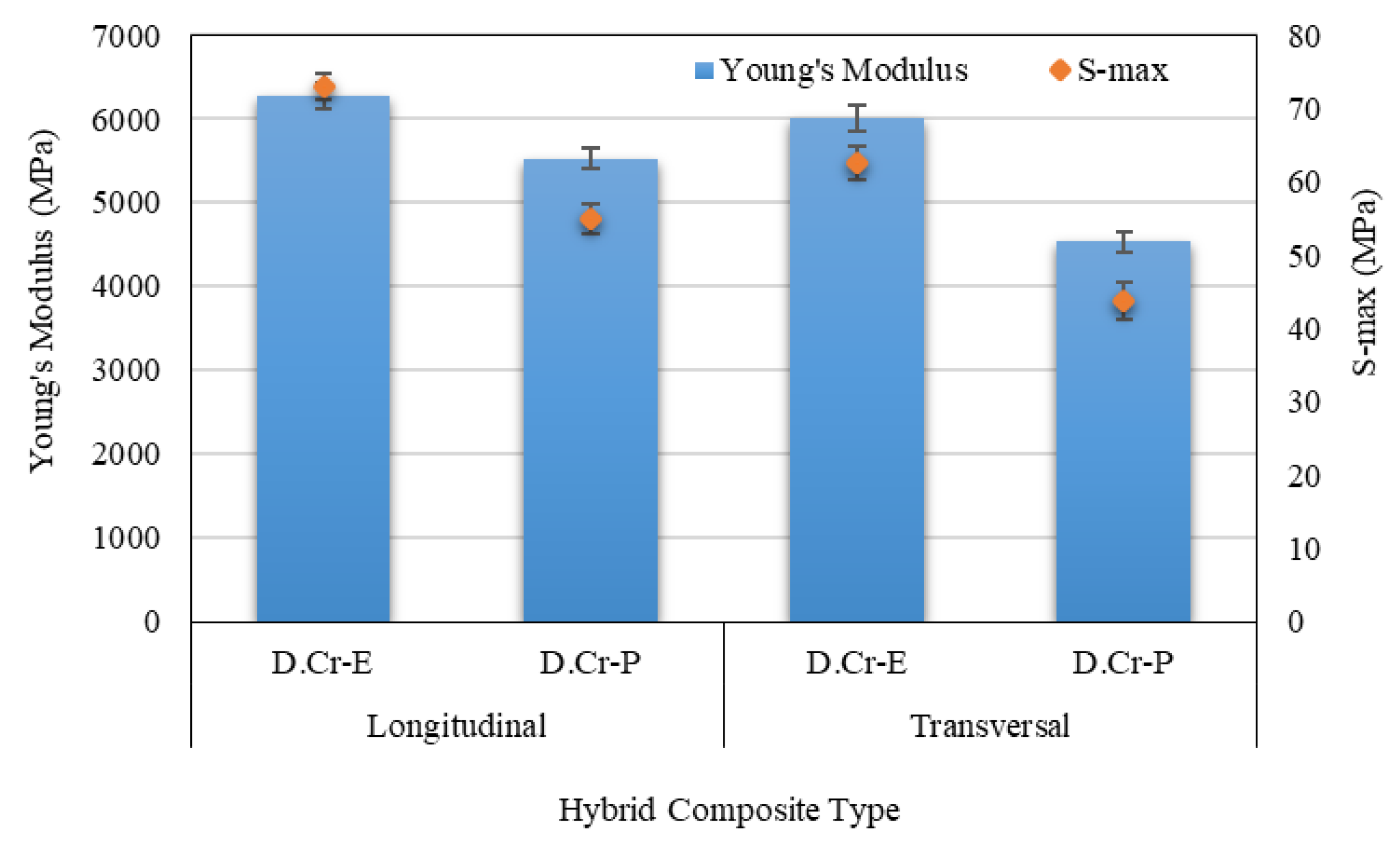

3.5. Tensile Testing of the Samples

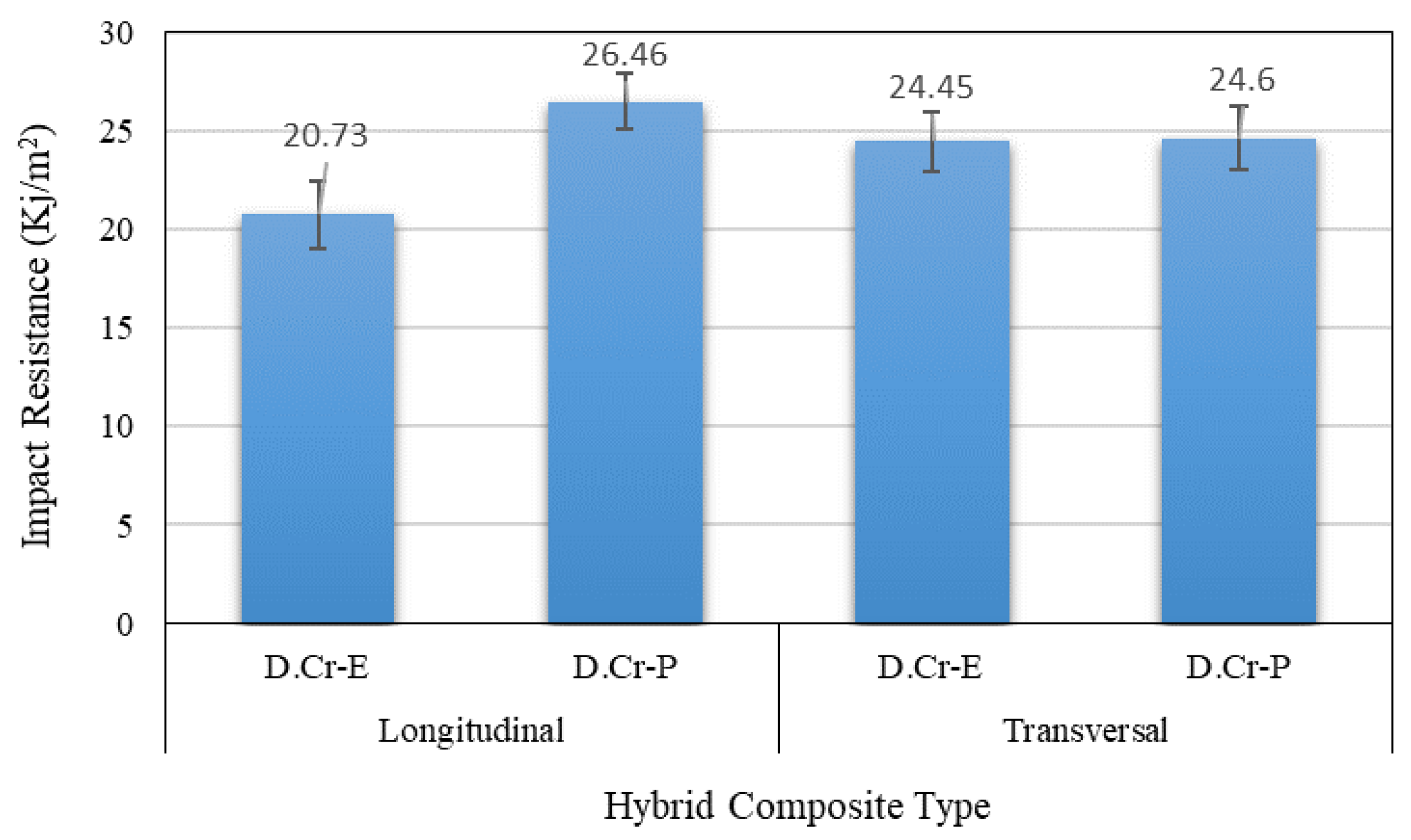

3.6. Charpy Impact of the Samples

4. Discussions

4.1. Vertical Density Profiles of the Samples

4.2. Dimensional Stability and Water Afinity of the Samples

4.3. Microscopic Investigation of the Samples

4.4. Flexural Testing of the Samples

4.5. Tensile Testing of the Samples

4.6. Charpy Impact of the Samples

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mohammad, L.H.; Enas, A.H.; Wafaa, S.A.E. Date Palm Nano Composites. Applications and Future Trends. In Date Palm Fiber Composites: Processing, Properties and Applications; Midani, M., Saba, N., Alothman, O.Y., Eds.; Composites Science and Technology: Singapore; Springer: Singapore, 2020; pp. 419–440. [Google Scholar] [CrossRef]

- Bamaga, S. Physical and mechanical properties of mortars containing date palm fibers. Mater. Res. Express 2022, 9, 015102. [Google Scholar] [CrossRef]

- Agoudjil, B.; Benchabane, A.; Boudenne, A.; Ibos, L.; Fois, M. Renewable materials to reduce building heatloss: Characterization of date palm wood. Energy Build. 2010, 43, 491–497. [Google Scholar] [CrossRef]

- Blasi, A.; Verardi, A.; Lopresto, C.G.; Siciliano, S.; Sangiorgio, P. Lignocellulosic Agricultural Waste Valorization to Obtain Valuable Products: An Overview. Recycling 2023, 8, 61. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Khan, S.H.; Alnaser, I.A.; Karim, M.R.; Saifullah, A.; Zhang, Z.Y. Potential of Date Palm Fibers (DPFs) as a Sustainable Reinforcement for Bio- Composites and its Property Enhancement for Key Applications: A Review. Macromol. Mater. Eng. 2024, 309, 2400081. [Google Scholar] [CrossRef]

- Oushabi, A.; Sair, S.; Oudrhiri Hassani, F.; Abboud, Y.; Tanane, O.; El Bouari, A. The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): Study of the interface of DPF–Polyurethane composite. South Afr. J. Chem. Eng. 2017, 23, 116–123. [Google Scholar] [CrossRef]

- Elseify, L.A.; Midani, M.; Shihata, L.A.; El-Mously, H. Review on cellulosic fibers extracted from date palms (Phoenix dactylifera L.) and their applications. Cellulose 2019, 26, 2209–2232. [Google Scholar] [CrossRef]

- Alsaeed, T.; Yousif, B.F.; Ku, H. The potential of using date palm fibres as reinforcement for polymeric composites. Mater. Des. 2013, 43, 177–184. [Google Scholar] [CrossRef]

- Ghori, W.; Saba, N.; Jawaid, M.; Asim, M. A review on date palm (Phoenix dactylifera) fibers and its polymer composites. The Wood and Biofiber International Conference. IOP Conf. Ser. Mater. Sci. Eng. 2018, 368, 012009. [Google Scholar] [CrossRef]

- Abdellah, M.Y.; Seleem, A.-E.H.A.; Marzok, W.W.; Hashem, A.M.; Backar, A.H. Tensile and Impact Properties of Hybrid Date Palm Fibre Composite Structures Embedded with Chopped Rubber. Int. J. Eng. Res. Appl. 2022, 12, 54–66. [Google Scholar]

- Elseify, L.A.; Midani, M.; Hassanin, A.H.; Hamouda, T.; Khiari, R. Long textile fibres from the midrib of date palm: Physiochemical, morphological, and mechanical properties. Ind. Crops Prod. 2020, 151, 112466. [Google Scholar] [CrossRef]

- Faiad, A.; Alsmari, M.; Mohamed, M.Z.A.; Mohamed, L.B.; Alzahrani, B.; Alrobei, H. Review date palm tree waste recycling: Treatment and processing for potential engineering applications. Sustainability 2022, 14, 1134. [Google Scholar] [CrossRef]

- Ali, M. Epoxy–Date Palm Fiber Composites: Study on Manufacturing and Properties. Int. J. Polym. Sci. 2023, 2023, 5670293. [Google Scholar] [CrossRef]

- Nasser, R.A. An evaluation of the use of midribs from common date palm cultivars grown in Saudi Arabia for energy production. BioResource 2014, 9, 4343–4357. [Google Scholar] [CrossRef]

- Nasser, R.A.; Salem, M.Z.M.; Hiziroglu, S.; Al-Mefarrej, H.A.; Mohareb, A.S.; Alam, M.; Aref, I.M. Chemical Analysis of Different Parts of Date Palm (Phoenix dactylifera L.) Using Ultimate, Proximate and Thermo-Gravimetric Techniques for Energy Production. Energies 2016, 9, 374. [Google Scholar] [CrossRef]

- Tahir, A.H.F.; Al-Ani, F.H.; Al-Obaidy, A.H.M.J. Analysis of different date palm parts for char production. IOP Conf. Ser. Earth Environ. Sci. 2021, 779, 012015. [Google Scholar] [CrossRef]

- Mahdavi, S.; Kermanian, H.; Varshoei, A. Comparison of mechanical properties of date palm fiber- polyethylene composite. BioResources 2010, 5, 2391–2403. [Google Scholar] [CrossRef]

- Waseetuddin, N.S.; Abubakar, A.A.; Al-Athel, K.S.; Akhtar, S.S. Investigation of epoxy grouts incorporating date palm waste: Mechanical performance analysis. Case Stud. Constr. Mater. 2024, 20, e03314. [Google Scholar] [CrossRef]

- Lewin, M. Handbook of Fiber Chemistry, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Gheith, M.H.; Aziz, M.A.; Ghori, W.; Saba, N.; Asim, M.; Jawaid, M.; Alothman, O.Y. Flexural, thermal and dynamic mechanical properties of date palm fibres reinforced epoxy composites. J. Mater. Res. Technol. 2019, 8, 853–860. [Google Scholar] [CrossRef]

- Adamu, M.; Marouf, M.L.; Ibrahim, Y.E.; Ahmed, O.S.; Alanazi, H.; Marouf, A.L. Modeling and optimization of the mechanical properties of date fiber reinforced concrete containing silica fume using response surface methodology. Case Stud. Constr. Mater. 2022, 17, e01633. [Google Scholar] [CrossRef]

- Jonoobi, M.; Shafie, M.; Shirmohammadli, Y.; Ashori, A.; Zarea-Hosseinabadi, H.; Mekonnen, T. A Review on Date Palm: Properties, Characterization and Its Potential Applications. J. Renew. Mater. 2019, 7, 1055–1075. [Google Scholar] [CrossRef]

- Haque, M.M.; Hasan, M.; Islam, M.S.; Ali, M.E. Physico-mechanical properties of chemically treated palm and coir fiber reinforced polypropylene composites. Bioresour. Technol. 2009, 100, 4903–4906. [Google Scholar] [CrossRef]

- Al-Kaabi, K.; Al-Khanbashi, A.; Hammami, A. Date palm fibers as polymeric matrix reinforcement: DPF/polyester composite properties. Polym. Compos. 2005, 26, 604–613. [Google Scholar] [CrossRef]

- Bulut, M.; Alsaadi, M.; Erkliğ, A. A comparative study on the tensile and impact properties of Kevlar, carbon, and S-glass/epoxy composites reinforced with SiC particles. Mater. Res. Express 2018, 5, 025301. [Google Scholar] [CrossRef]

- Sasikumar, K.; Manoj, N.R.; Mukundan, T.; Rahaman, M.; Khastgir, D. Mechanical Properties of Carbon-Containing Polymer Composites. In Carbon-Containing Polymer Composites; Rahaman, M., Khastgir, D., Aldalbahi, A., Eds.; Springer Nature Singapore Ltd.: Singapore, 2019; pp. 125–155. [Google Scholar]

- Cerbu, C.; Ursache, S.; Botis, M.F.; Hadăr, A. Simulation of the hybrid carbon-aramid composite materials based on mechanical characterization by digital image correlation method. Polymers 2021, 13, 4184. [Google Scholar] [CrossRef]

- Zeleniuc, O.; Mazaherifar, M.H.; Coșereanu, C.; Suciu, A. Date-Palm-Based Sustainable Hybrid Composite with Cotton and Kevlar Fibre Participation. Appl. Sci. 2024, 14, 1008. [Google Scholar] [CrossRef]

- Krushnamurty, K.; Srikanth, I.; Rangababu, B.; Majee, S.K.; Bauri, R.; Subrahmanyam, C. Effect of nanoclay on the toughness of epoxy and mechanical, impact properties of E-glass-epoxy composites. Adv. Mater. Lett. 2015, 6, 684. [Google Scholar] [CrossRef]

- Goud, B.N.; Sura, S.; Aravind, P.; Jawahar, B.L.; Sanskruti, K.; Pavan, C. An experimental study on mechanical properties of Kevlar composite for aircraft structural applications. Mater. Today Proc. 2022, 64, 909–916. [Google Scholar] [CrossRef]

- Alam, M.I.; Maraz, K.M.; Ruhul, A.K. A review on the application of high-performance fiber-reinforced polymer composite materials. GSC Adv. Res. Rev. 2022, 10, 020–036. [Google Scholar] [CrossRef]

- Markovičová, L.; Zatkalíková, V.; Hanusová, P. Carbon Fiber Polymer Composites. QPI 2019, 1, 276–280. [Google Scholar] [CrossRef]

- Chen, A.; Baehr, S.; Turner, A.; Zhang, Z.; Gu, G. Carbon-fiber reinforced polymer composites: A comparison of manufacturing methods on mechanical properties. Int. J. Lightweight Mater. Manuf. 2021, 4, 468–479. [Google Scholar] [CrossRef]

- Mahboubizadeh, S.; Sadeq, A.; Arzaqi, Z.; Samadoghli, M. Advancements in fiber-reinforced polymer (FRP) composites: An extensive review. Discov Mater 2024, 4, 22. [Google Scholar] [CrossRef]

- Dhiman, B.; Guleria, V.; Sharma, P. Applications and Future Trends of Carbon Fiber Reinforced Polymer Composites: A Review. Int. Res. J. Eng. Technol. 2020, 7, 1883–1889. [Google Scholar]

- Hernandez, D.A.; Soufen, C.A.; Orlandi, M.O. Carbon Fiber Reinforced Polymer and Epoxy Adhesive Tensile Test Failure Analysis Using Scanning Electron Microscopy. Mater. Res. 2017, 20, 951–961. [Google Scholar] [CrossRef]

- Penner, E.; Caylak, I.; Mahnken, R. Experimental Investigations of Carbon Fiber Reinforced Polymer Composites and Their Constituents to Determine Their Elastic Material Properties and Complementary Inhomogeneous Experiments with Local Strain Considerations. Fibers Polym. 2023, 24, 157–178. [Google Scholar] [CrossRef]

- Kwiatkowski, D.; Palutkiewicz, P.; Kwiatkowski, T.; Gnatowski, A.; Garbacz, T. Study of Carbon Fiber Reinforced Polymer Composite Layer Structures Subjected to Three-Point Bending. Adv. Sci. Technol. Res. J. 2024, 18, 111–122. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, W.; Li, B.; Zhu, J.; Wang, C.; Song, G.; Wu, G.; Yang, X.; Huang, Y.; Ma, L. Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Compos. Part B Eng. 2022, 233, 109639. [Google Scholar] [CrossRef]

- Mazaherifar, M.H.; Hosseinabadi, H.Z.; Coșereanu, C.; Cerbu, C.; Timar, M.C.; Georgescu, S.V. Investigation on Phoenix dactylifera/Calotropis procera Fibre-Reinforced Epoxy Hybrid Composites. Forests 2022, 13, 2098. [Google Scholar] [CrossRef]

- EN 317; Particleboards and Fibreboards. Determination of Swelling in Thickness After Immersion in Water. European Committee for Standardization: Brussels, Belgium, 1996.

- EN 310; Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- EN ISO 527-4; Plastics—Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Orthotropic FibreReinForced Plastic Composites. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 179-1; Plastics—Determination of Charpy Impact Properties, Part 1: Non-Instrumented Impact Test. International Organization for Standardization: Geneva, Switzerland, 2010.

- Al-Oqla, F.M.; Alothman, O.Y.; Jawaid, M.; Sapuan, S.M.; Es-Saheb, M.H. Processing and properties of date palm fibers and its composites. In Biomass and Bioenergy: Processing and Properties 2014; Jawaid, M., Hakeem, K., Rashid, U., Eds.; Springer International Publishing Switzerland: Cham, Switzerland, 2014; pp. 1–25. [Google Scholar]

- Chung, D. Introduction to Carbon Fibers. In Carbon Fiber Composites; Butterworth-Heinemann, member of the Reed Elsevier Group: Portsmouth, NH, USA, 2012; p. 5. [Google Scholar]

- Alshammari, B.A.; Saba, N.; Alotaibi, M.D.; Alotibi, M.F.; Jawaid, M.; Alothman, O.Y. Evaluation of mechanical, physical, and morphological properties of epoxy composites reinforced with different date palm fillers. Materials 2019, 12, 2145. [Google Scholar] [CrossRef]

- Alodan, H.A.; Alsuhybani, M.; Alshammari, B.; Alkhuraiji, T. Effect of Fiber Loading on Physical, Mechanical, and Thermal Properties of Low Density Polyethylene/Palm Tree Waste Fiber Composites. Sci. Adv. Mater. 2018, 10, 1341–1350. [Google Scholar] [CrossRef]

- Dayo, A.Q.; Zegaoui, A.; Nizamani, A.A.; Kiran, S.; Wang, J.; Derradji, M.; Cai, W.; Liu, W. The influence of different chemical treatments on the hemp fiber/polybenzoxazine based green composites: Mechanical, thermal and water absorption properties. Mater. Chem. Phys. 2018, 217, 270–277. [Google Scholar] [CrossRef]

- Callister, W.D., Jr.; Rethwisch, D.G. Materials Science and Engineering: An Introduction, 10th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Dhakal, H.N.; Zhang, Z.; Richardson, M.O. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Haameem, J.A.M.; Abdul Majid, M.S.; Afendi, M.; Marzuki, H.F.A.; Ahmad Hilmi, E.; Fahmi, I.; Gibson, A.G. Effects of water absorption on Napier grass fibre/polyester composites. Compos. Struct. 2016, 144, 138–146. [Google Scholar] [CrossRef]

- Supian, A.B.M.; Jawaid, M.; Rashid, B.; Fouad, H.; Saba, N.; Dhakal, H.N.; Khiari, R. Mechanical and physical performance of date palm/bamboo fibre reinforced epoxy hybrid composites. J. Mater. Res. Technol. 2021, 15, 1330–1341. [Google Scholar] [CrossRef]

- Alawar, A.; Hamed, A.M.; Al-Kaabi, K. Characterization of treated date palm tree fiber as composite reinforcement. Compos. Part B Eng. 2009, 40, 601–606. [Google Scholar] [CrossRef]

- Amroune, S.; Bezazi, A.; Dufresne, A.; Scarpa, F.; Imad, A. Investigation of the Date Palm Fiber for Green Composites Reinforcement: Thermo-physical and Mechanical Properties of the Fiber. J. Nat. Fibers 2019, 18, 717–734. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Suardana, N.P.G.; Jung, D.Y.; Choi, K.-S.; Lim, J.K. Effect of diameters and alkali treatment on the tensile properties of date palm fiber reinforced epoxy composites. Int. J. Precis. Eng. Manuf. 2012, 13, 1199–1206. [Google Scholar] [CrossRef]

- Chen, R.S.; Ab Ghani, M.; Salleh, M.; Ahmad, S.; Tarawneh, M. Mechanical, water absorption, and morphology of recycled polymer blend rice husk flour biocomposites. J. Appl. Polym. Sci. 2015, 132, 41494. [Google Scholar] [CrossRef]

- Sana, R.; Foued, K.; Yosr, B.M.; Jaouadi, M.; Msahli, S.; Bernard, D. Flexural properties of typha natural fiber-reinforced polyester composites. Fibers Polym. 2015, 16, 2451–2457. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Saba, N.; Jawaid, M. Effect of benzoyl treatment on flexural and compressive properties of sugar palm/glass fibres/epoxy hybrid composites. Polym. Test. 2018, 71, 362–369. [Google Scholar] [CrossRef]

- AlMa’adeed, M.A.; Nógellová, Z.; Janigová, I.; Krupa, I. Improved mechanical properties of recycled linear low-density polyethylene composites filled with date palm wood powder. Mater. Des. 2014, 58, 209–216. [Google Scholar] [CrossRef]

- Alarifi, I.M. Investigation into the morphological and mechanical properties of date palm fiber-reinforced epoxy structural composites. J. Vinyl Addit. Technol. 2021, 27, 77–88. [Google Scholar] [CrossRef]

- Wazzan, A. Effect of fiber orientation on the mechanical properties and fracture characteristics of date palm fiber reinforced composites. Int. J. Polym. Mater. 2005, 54, 213–225. [Google Scholar] [CrossRef]

- Penczek, P.; Czub, P.; Pielichowski, J. Unsaturated Polyester Resins: Chemistry and Technology. In Crosslinking in Materials Science; Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany, 2005; Volume 184. [Google Scholar] [CrossRef]

| Code | Layers | Resin |

|---|---|---|

| D.Cr.-E | 1, 3, and 5: Date palm midrib long fiber mats | Epoxy |

| D.Cr-P | 2 and 5: Carbon fiber twill | Unsaturated polyester |

| Panel Type | Density kg/m3 | WA % | TS % | Flexural Test N/mm2 | Tensile Test MPa | Impact Resistance kJ/m2 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 216 h | MOE L * | MOE T * | MOR L | MOR T | Smax L | Smax T | Y * L | Y T | L | T | |||

| D,Cr-E | 1103 | 3.98 | 6.35 | 10077 | 5190 | 148.3 | 115.5 | 72.9 | 62.5 | 6275 | 6012 | 20.7 | 24.5 |

| D,Cr-P | 1133 | 6.05 | 3.09 | 2307 | 1420 | 56.3 | 47.5 | 55 | 43.8 | 5521 | 4535 | 26.5 | 24.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mazaherifar, M.H.; Zeleniuc, O.; Cerbu, C.; Georgescu, S.-V.; Lungu, A.; Coșereanu, C. Performance of Carbon Fiber-Reinforced Date Palm Midrib Composites. Fibers 2025, 13, 57. https://doi.org/10.3390/fib13050057

Mazaherifar MH, Zeleniuc O, Cerbu C, Georgescu S-V, Lungu A, Coșereanu C. Performance of Carbon Fiber-Reinforced Date Palm Midrib Composites. Fibers. 2025; 13(5):57. https://doi.org/10.3390/fib13050057

Chicago/Turabian StyleMazaherifar, Mohammad Hassan, Octavia Zeleniuc, Camelia Cerbu, Sergiu-Valeriu Georgescu, Antonela Lungu, and Camelia Coșereanu. 2025. "Performance of Carbon Fiber-Reinforced Date Palm Midrib Composites" Fibers 13, no. 5: 57. https://doi.org/10.3390/fib13050057

APA StyleMazaherifar, M. H., Zeleniuc, O., Cerbu, C., Georgescu, S.-V., Lungu, A., & Coșereanu, C. (2025). Performance of Carbon Fiber-Reinforced Date Palm Midrib Composites. Fibers, 13(5), 57. https://doi.org/10.3390/fib13050057