Properties of Medium-Density Fiberboards with Different Contents of Recycled Fibers and Urea–Formaldehyde Resin

Abstract

Highlights

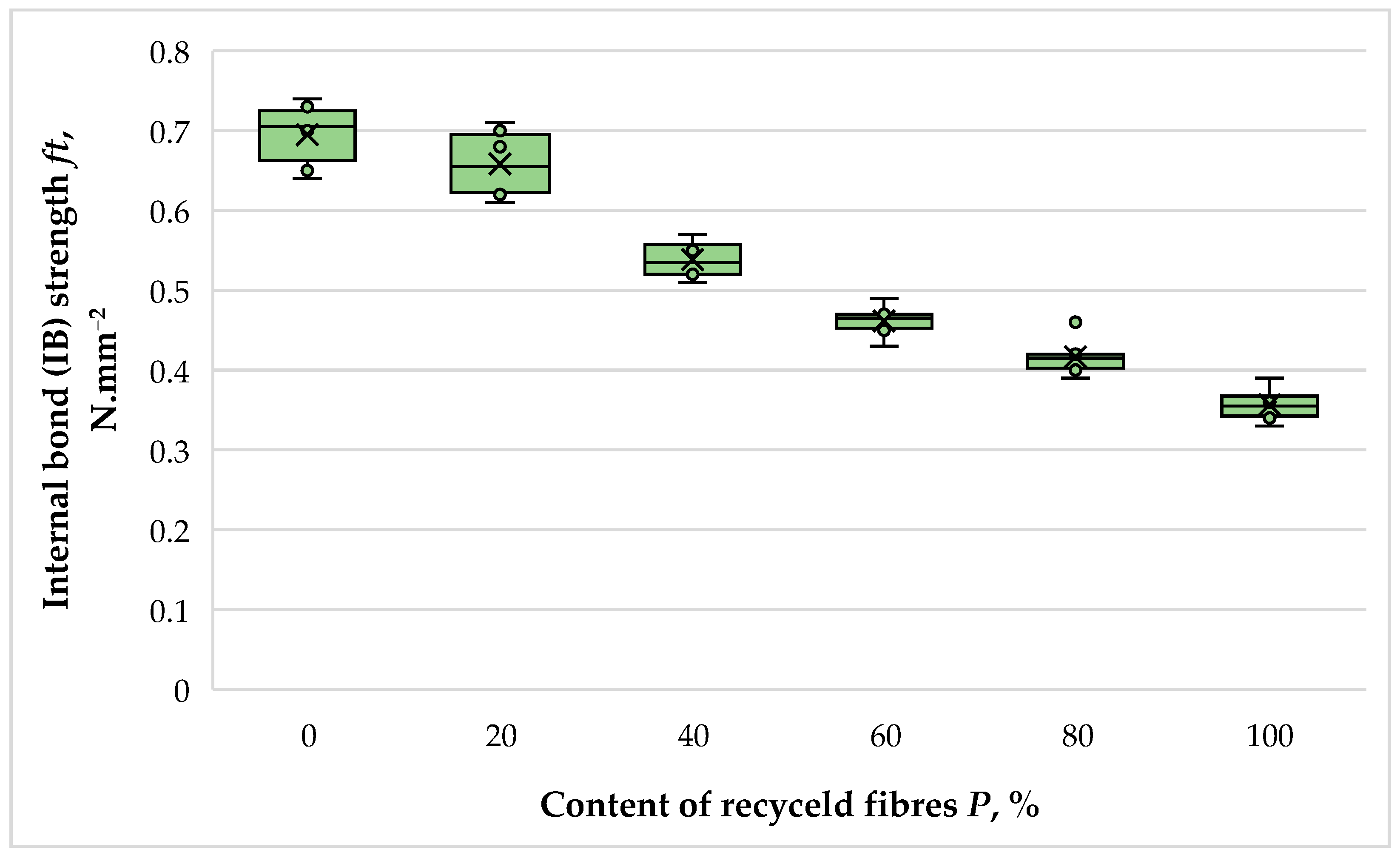

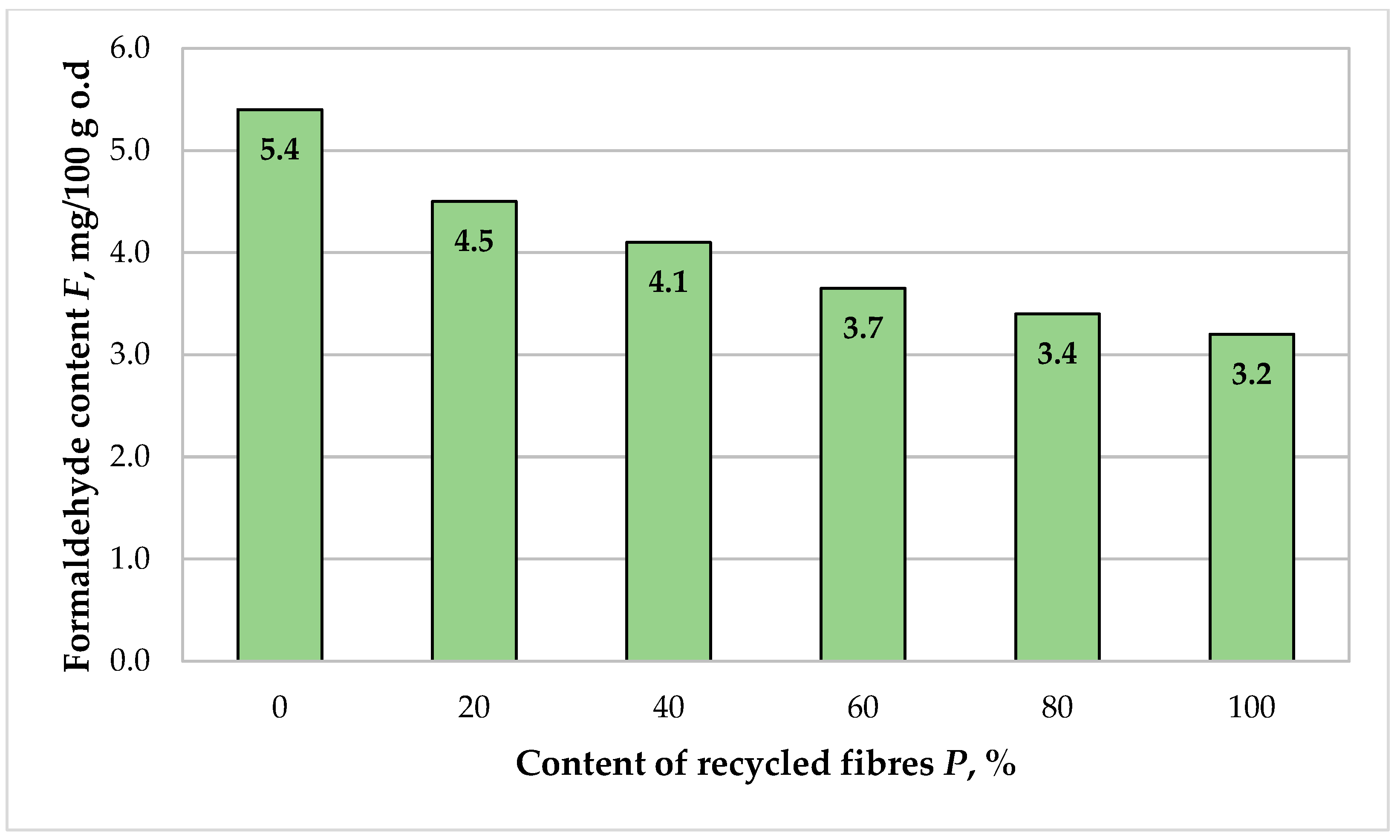

- The complete replacement of virgin fibers with recycled fibers significantly reduces MDF panel performance, with declines in MOE, MOR, IB strength, and other key properties, making 100% substitution unsuitable for MDF production.

- The optimal recycled fiber content is up to 24%, with at least 12% UF resin to ensure mechanical integrity. Panels with up to 20% recycled fiber maintain acceptable properties, but performance declines sharply between 20% and 40%. Further research is needed for recycled fiber content between 40% and 60%.

- Increasing the UF resin content can help to counteract the negative effects of recycled fibers, with formaldehyde scavenging by amines allowing for higher resin content without significantly increasing formaldehyde emissions.

- The findings provide valuable insights for MDF manufacturers, helping to support more sustainable, cost-effective, and high-performance production.

- Future research should focus on improving the recycling process and exploring alternative resins to enhance sustainability and reduce the environmental footprint of MDF production.

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

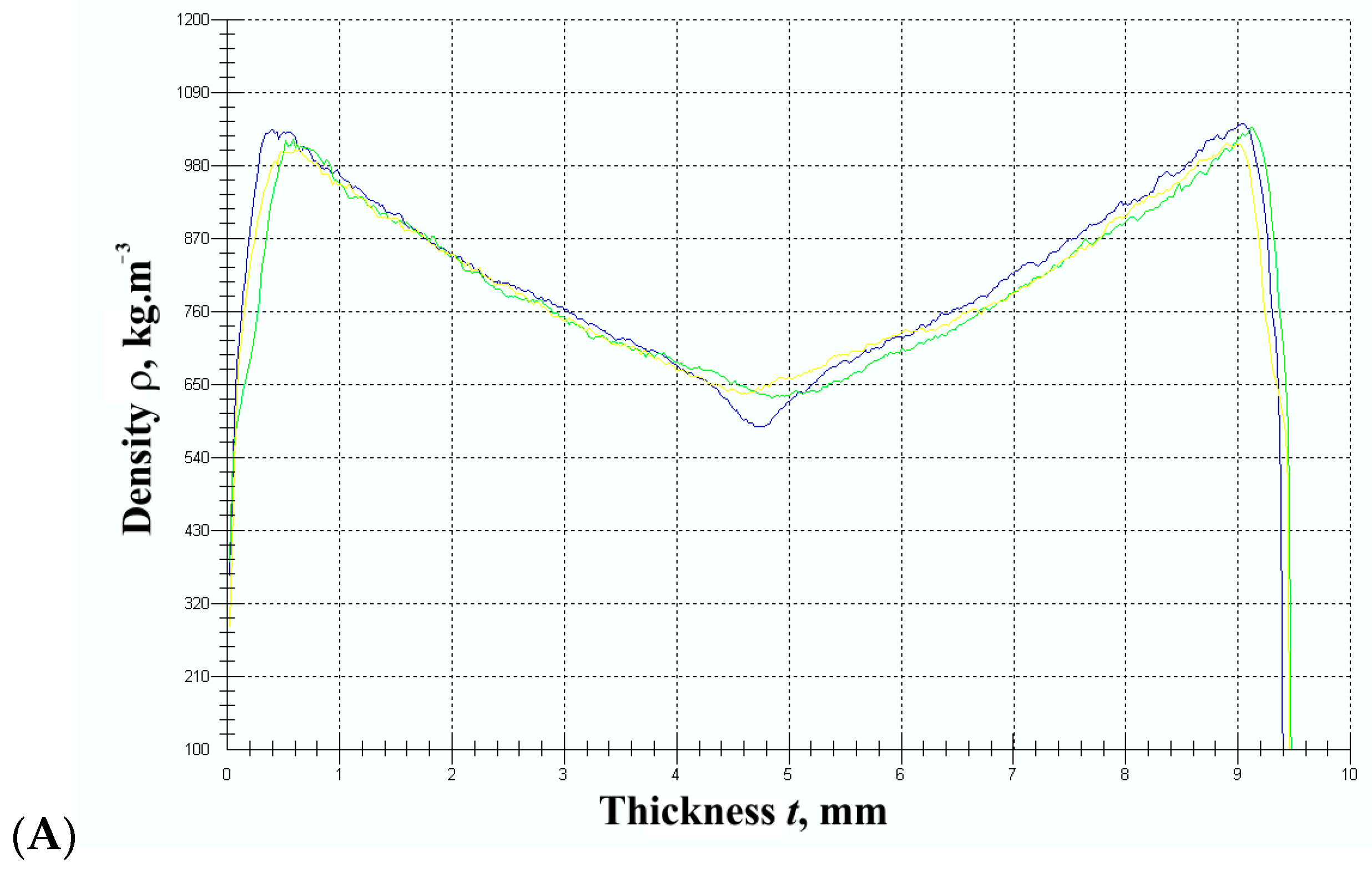

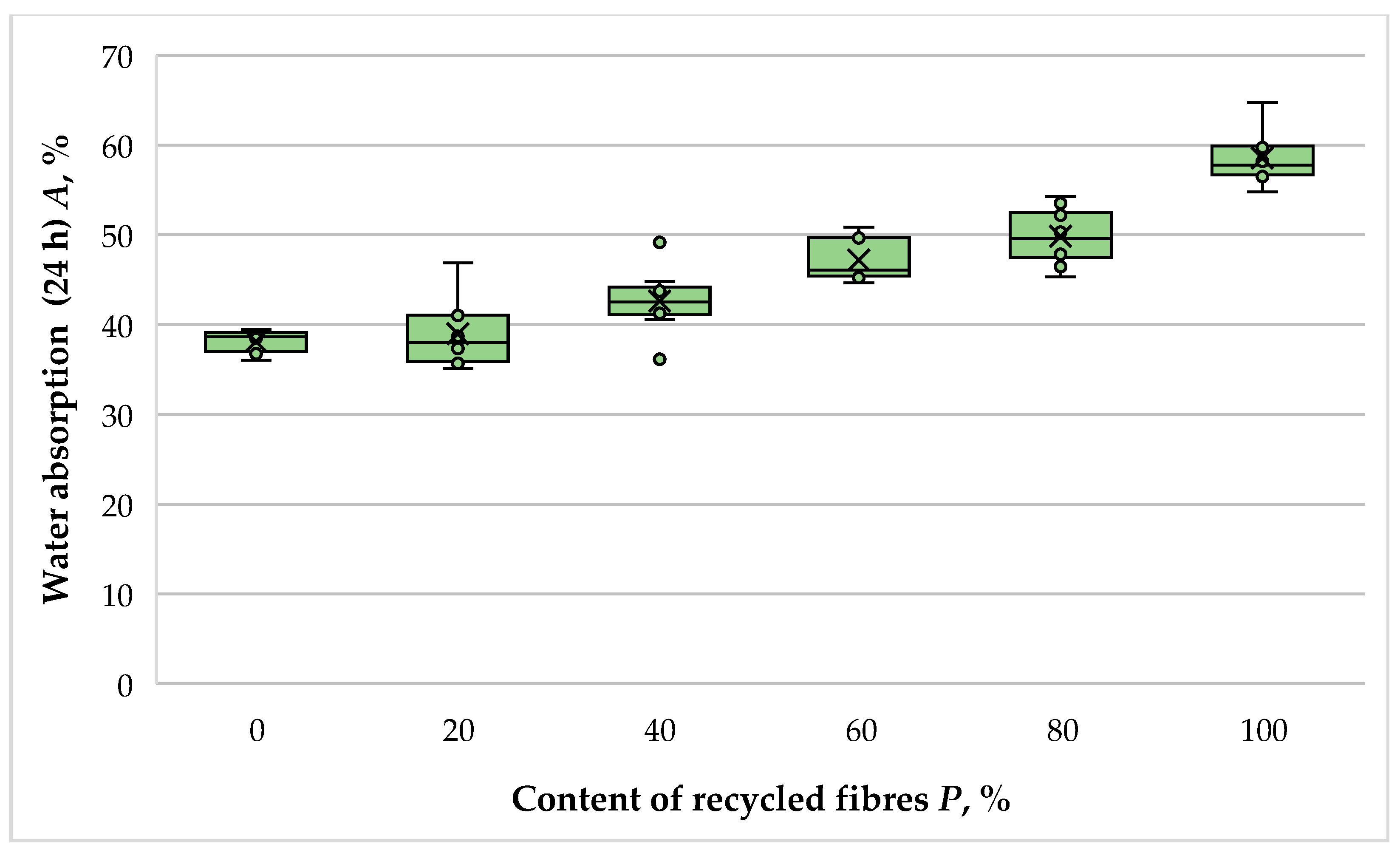

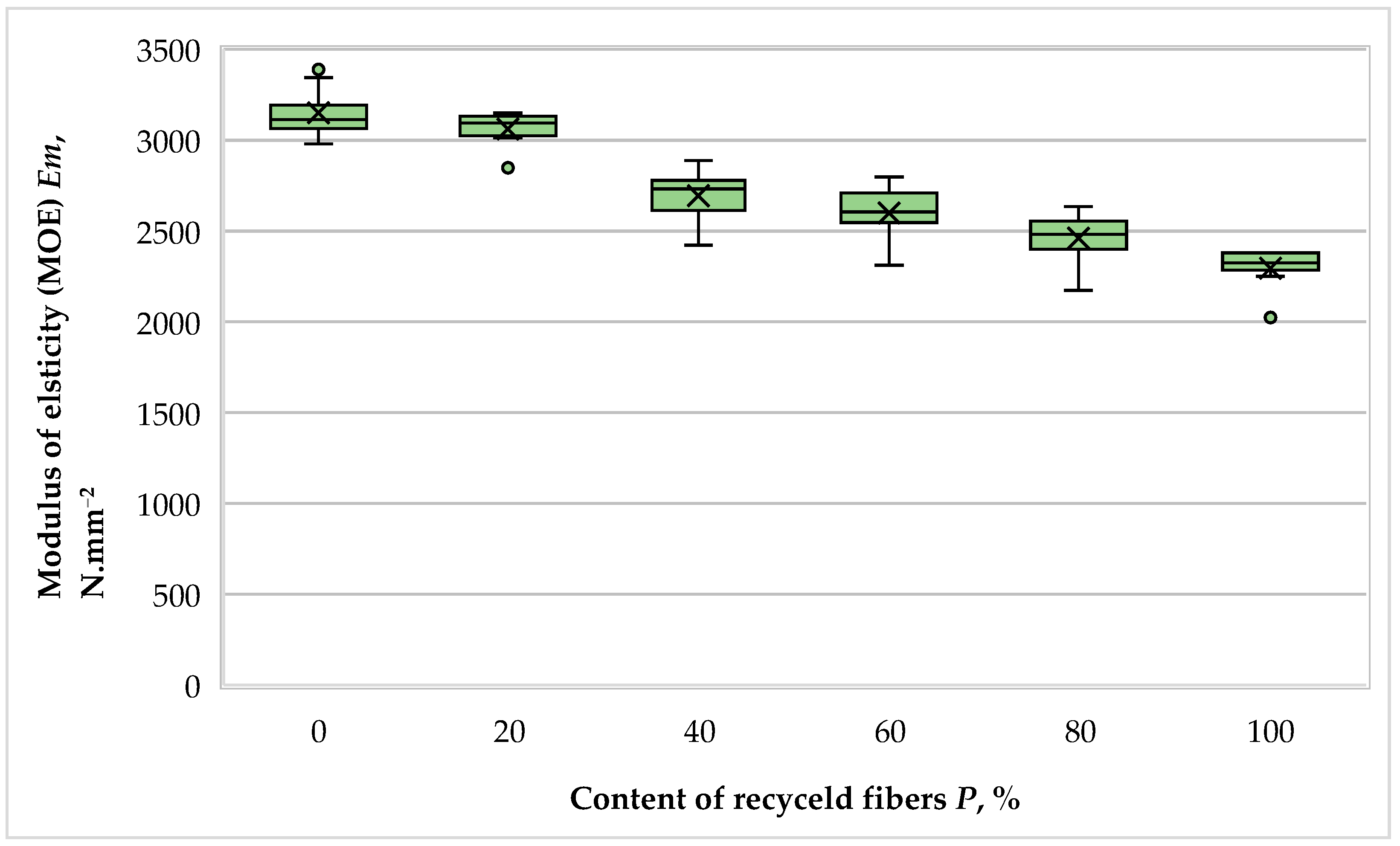

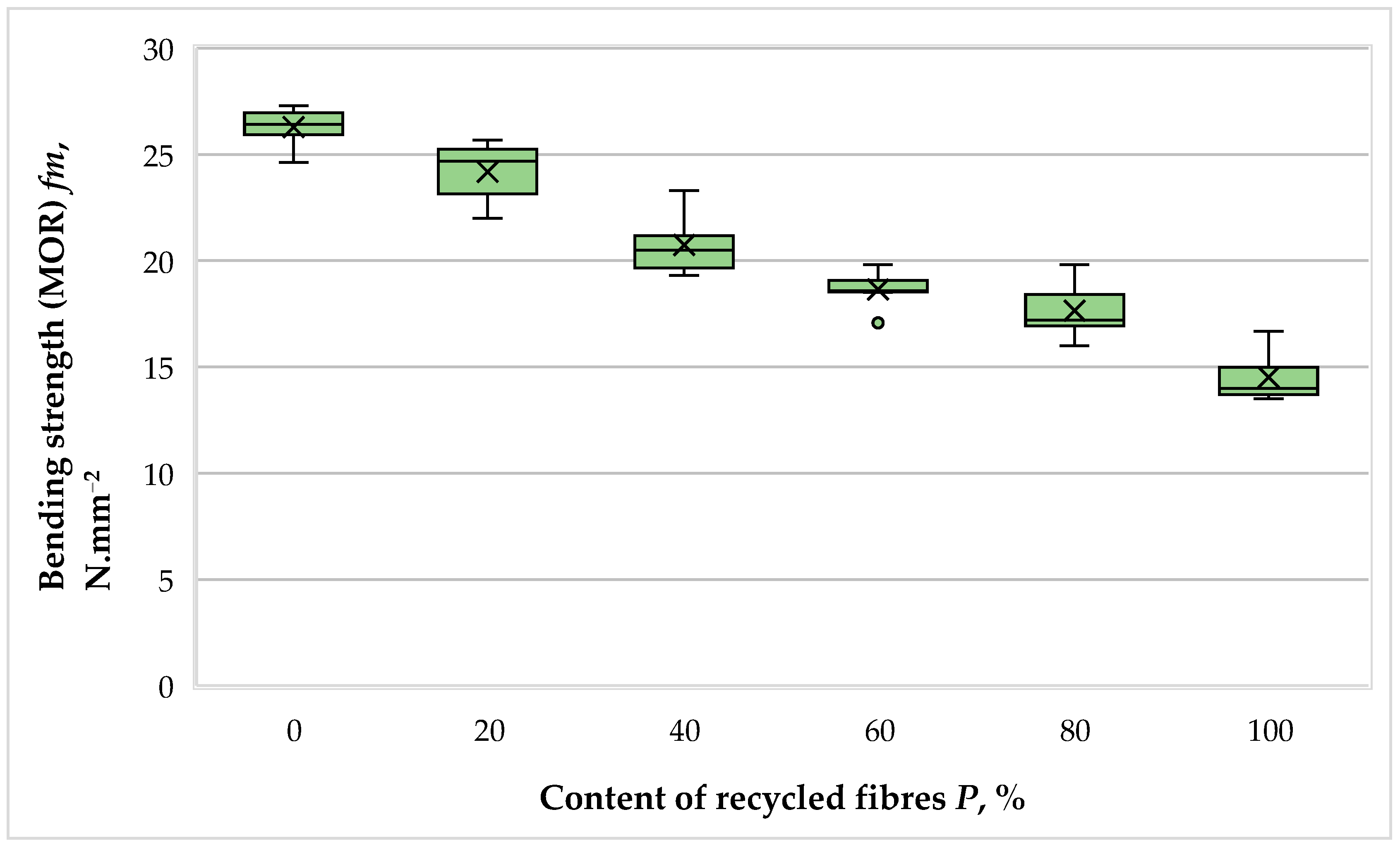

3.1. Effect of the Content of Recycled Fibers (Preliminary Results)

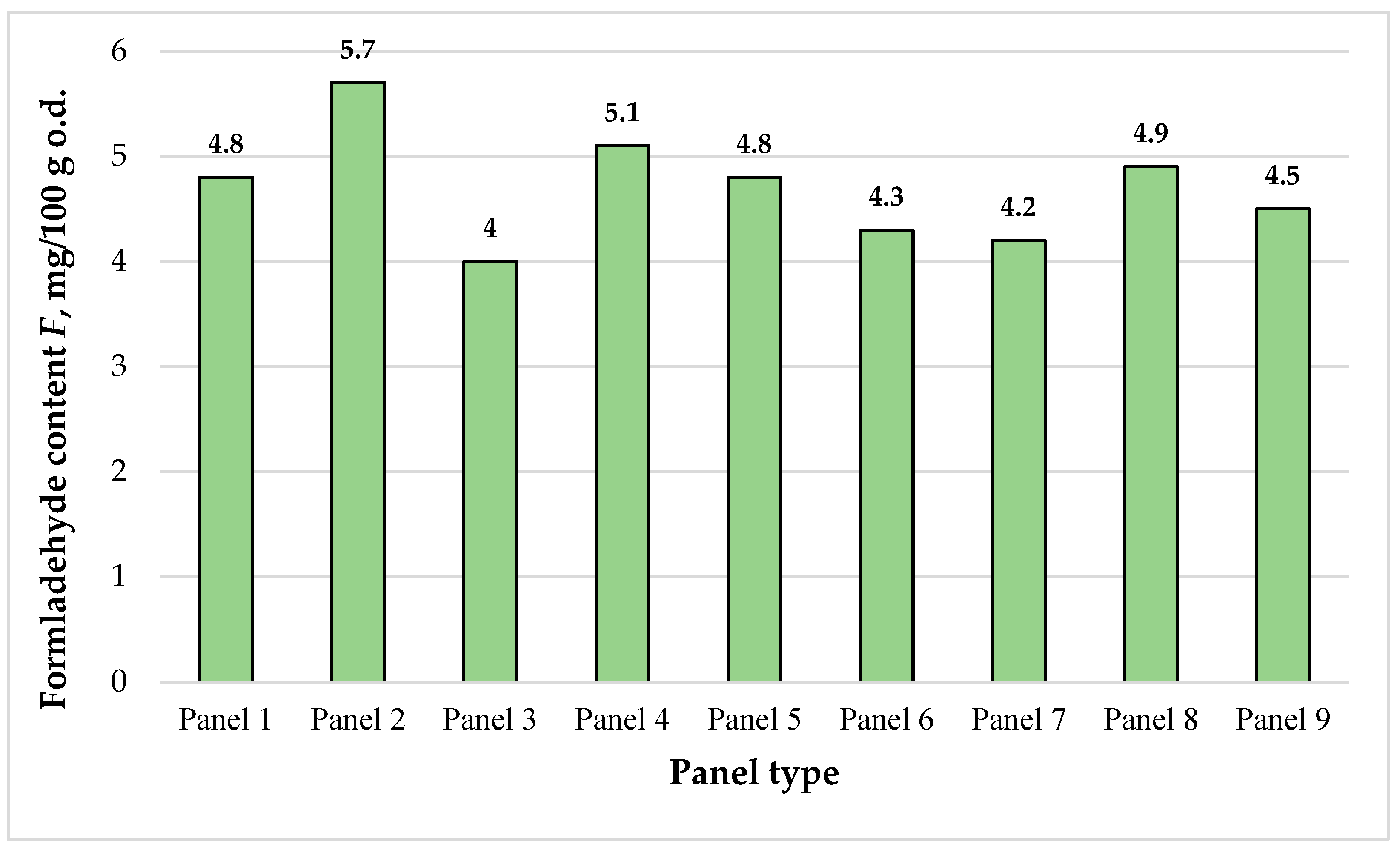

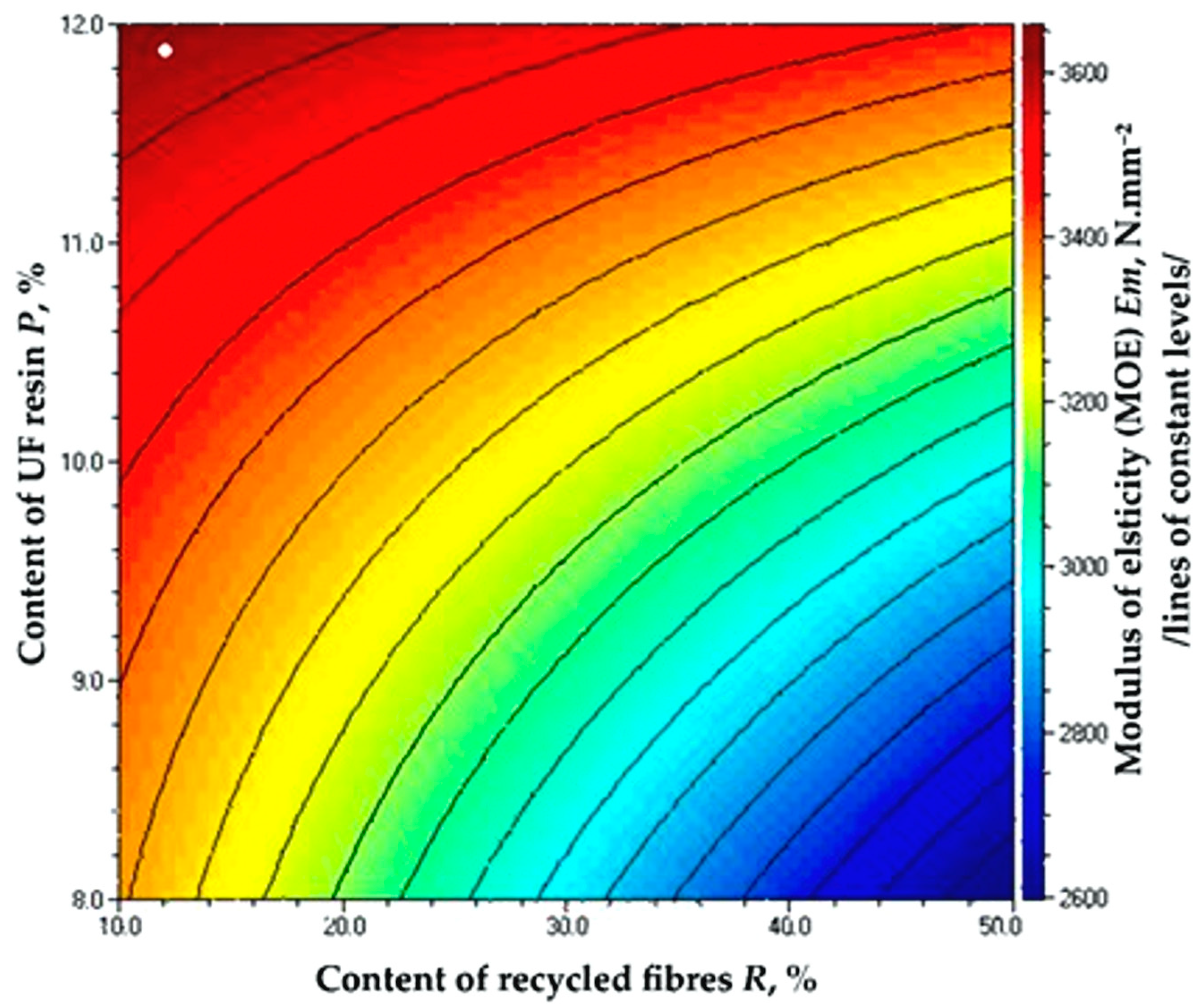

3.2. Combined Effect of the Recycled Fibers and Urea–Formaldehyde Content on MDF Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Besserer, A.; Troilo, S.; Girods, P.; Rogaume, Y.; Brosse, N. Cascading Recycling of Wood Waste: A Review. Polymers 2021, 13, 1752. [Google Scholar] [CrossRef]

- Garcia, C.A.; Hora, G. State-of-the-art of waste wood supply chain in Germany and selected European countries. Waste Manag. 2017, 70, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Hagel, S.; Joy, J.; Cicala, G.; Saake, B. Recycling of Waste MDF by Steam Refining: Evaluation of Fiber and Paper Strength Properties. Waste Biomass Valorization 2021, 2, 5701–5713. [Google Scholar] [CrossRef]

- Neykov, N.; Antov, P.; Savov, V. Circular Economy Opportunities for Economic Efficiency Implement in Wood-Based Panel Industry. In Proceedings of the 11th International Scientific Conference “Business and Management 2020”, Vilnius, Lithuania, 7–8 May 2020; pp. 8–17, ISBN 978-609-476-231-4. [Google Scholar]

- Antov, P.; Savov, V. Possibilities for Manufacturing Eco-friendly Medium Density Fiberboards from Recycled Fibers—A Review. In Proceedings of the 30th International Conference on Wood Science and Technology, ICWST 2019 and 70th Anniversary of Drvna industrija Journal: Implementation of Wood Science in Woodworking Sector, Zagreb, Croatia, 12–13 December 2019; pp. 18–24. [Google Scholar]

- Bütün, F.Y.; Mayer, A.K.; Ostendorf, K.; Gröne, O.-E.Z.; Krause, K.C.; Schöpper, C.; Mertens, O.; Krause, A.; Mai, C. Recovering fibers from fiberboards for wood polymer composites production. Int. Wood Prod. J. 2018, 9, 42–49. [Google Scholar] [CrossRef]

- Bütün Buschalsky, F.Y.; Mai, C. Repeated thermo-hydrolytic disintegration of medium density fiberboards (MDF) for the production of new MDF. Eur. J. Wood Prod. 2021, 79, 1451–1459. [Google Scholar] [CrossRef]

- Kim, M.H.; Song, H.B. Analysis of the Global Warming Potential for Wood Waste Recycling Systems. J. Clean. Prod. 2014, 69, 199–207. [Google Scholar] [CrossRef]

- Mitchell, A.; Stevens, G. A Life Cycle Assessment of Closed Loop MDF Recycling Using the Microrelease Process to Produce Recycled Wood Fiber from MDF Waste; Final Report of WRAP Project MDD005; The Old Academy: Banbury, UK, 2009; ISBN 1-84405-417-9. [Google Scholar]

- Irle, M.; Privat, F.; Couret, L.; Belloncle, C.; Déroubaix, G.; Bonnin, E.; Cathala, B. Advanced recycling of post-consumer solid wood and MDF. Wood Mat. Sci. Eng. 2018, 11, 19–23. [Google Scholar] [CrossRef]

- Wan, H.; Wang, X.-M.; Barry, A.; Shen, J. Recycling wood composite panels: Characterizing recycled materials. BioResources 2014, 9, 7554–7565. [Google Scholar] [CrossRef]

- Irle, M.; Barbu, M.C. Wood-based panels technology. In Wood-Based Panels: An Introduction for Specialists; Thoemen, H., Irle, M., Šernek, M., Eds.; Brunel University Press: London, UK, 2010; Available online: https://www.cost.eu/uploads/2018/07/53630.pdf (accessed on 10 November 2024).

- Lubis, M.A.R.; Hong, M.K.; Park, B.D.; Lee, S.M. Effects of recycled fiber content on the properties of medium density fiberboard. Eur. J. Wood Wood Prod. 2018, 76, 1515–1526. [Google Scholar] [CrossRef]

- Bütün, F.Y.; Sauerbier, P.; Militz, H.; Mai, C. The effect of fiberboard (MDF) disintegration technique on wood polymer composites (WPC) produced with recovered wood particles. Compos. A Appl. Sci. Manuf. 2019, 118, 312–316. [Google Scholar] [CrossRef]

- Hellström, L.M.; Carlberg, T.; Engstrand, P.; Gradin, P.A.; Gregersen, Ø.W. Evaluation of collimated chipping technology for reducing energy consumption in mechanical pulping. J. Sci. Technol. Forest Prod. Process. 2012, 2, 6–9. [Google Scholar]

- Roffael, E.; Athanassiadou, E.; Mantanis, G. Recycling of particle and fiberboards using the extruder technique. In Proceedings of the Umweltschutz in der Holzwerkstoffindustrie, Georg-August Universitat Gottingen, Goettingen, Germany, 8–9 July 2002; pp. 56–65. [Google Scholar]

- Athanassiadou, E.; Roffael, E.; Mantanis, G.I. Medium Density Fibreboards (MDF) from Recycled Fibres. In Proceedings of the 2nd European Cost E 31 Conference, Bordeaux, France, 29 September–1 October 2005; pp. 248–261. [Google Scholar]

- FAO Stat. Forestry Production and Trade. Available online: https://www.fao.org/faostat/en/#data/FO (accessed on 11 November 2024).

- Lykidis, C.; Grigoriou, A. Hydrothermal recycling of waste and performance of the recycled wooden particleboards. Waste Manag. 2008, 28, 57–63. [Google Scholar] [PubMed]

- Hong, M.-K.; Lubis, M.A.R.; Park, B.-D.; Sohn, C.H.; Roh, J. Effects of surface laminate type and recycled fiber content on properties of three-layer medium density fiberboard. Wood Mater. Sci. Eng. 2020, 15, 163–171. [Google Scholar] [CrossRef]

- Iždinský, J.; Vidholdová, Z.; Reinprecht, L. Particleboards from Recycled Wood. Forests 2020, 11, 1166. [Google Scholar] [CrossRef]

- Nuryawan, А.; Rahmawaty; Tambun, K.D.S.; Risnasari, I.; Masruchin, N. Hydrolysis of particleboard bonded with urea-formaldehyde resin for recycling. Heliyon 2020, 6, e03936. [Google Scholar]

- Hwang, C.Y.; Hse, C.Y.; Shupe, T.F. Effects of recycled fiber on the properties of fiberboard panels. For. Prod. J. 2005, 55, 61–64. [Google Scholar]

- Mantanis, G.I.; Athanassiadou, E.; Nakos, P.; Coutinho, A. A New Process for Recycling Waste Fiberboards. In Proceedings of the 38th International Wood Composites Symposium, Pullman, WA, USA, 5–8 April 2004; pp. 119–122. [Google Scholar]

- Lubis, M.A.R.; Hong, M.K.; Park, B.D. Hydrolytic Removal of Cured Urea–Formaldehyde Resins in Medium-Density Fiberboard for Recycling. J. Wood Chem. Technol. 2018, 38, 1–14. [Google Scholar]

- Moezzipour, B.; Abdolkhani, A.; Doost-hoseini, K.; Ramazani, S.A.A.; Tarmian, A.S. Practical properties and formaldehyde emission of medium density fiberboards (MDFs) recycled by electrical method. Eur. J. Wood Wood Prod. 2018, 76, 1287–1294. [Google Scholar]

- Ahmadi, M.; Moezzipour, B. Thermal Stability of Wood Fibers Produced from Recycled Medium Density Fiberboards. Drvna Ind. 2019, 70, 149–155. [Google Scholar]

- Hagel, S.; Saake, B. Fractionation of Waste MDF by Steam Refining. Molecules 2020, 25, 2165. [Google Scholar] [CrossRef]

- Moezzipour, B.; Ahmadi, M.; Abdolkhani, A.; Doosthoseini, K. Chemical changes of wood fibers after hydrothermal recycling of MDF waste. J. Ind. Acad. Wood Sci. 2017, 14, 133–138. [Google Scholar] [CrossRef]

- Dazmiri, M.K.; Kiamahalleh, M.V.; Kiamahalleh, M.V.; Mansouri, H.R.; Moazami, V. Revealing the Impacts of Recycled Urea–Formaldehyde Wastes on the Physical–Mechanical Properties of MDF. Eur. J. Wood Wood Prod. 2018, 77, 293–299. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Park, B.D. Analysis of the hydrolysates from cured and uncured urea-formaldehyde (UF) resins with two F/U mole ratios. Holzforschung 2018, 72, 759–768. [Google Scholar] [CrossRef]

- Liu, M.; Wang, Y.; Wu, Y.; Wan, H. Hydrolysis and recycling of urea formaldehyde resin residues. J. Hazard. Mater. 2018, 335, 96–103. [Google Scholar] [CrossRef] [PubMed]

- Lubis, M.A.R.; Manohar, S.Y.; Laksana, R.P.B.; Fatriasari, W.; Ismayati, M.; Falah, F.; Solihat, N.N.; Sari, F.P.; Hidayat, W. The Removal of Cured Urea-Formaldehyde Adhesive Towards Sustainable Medium Density Fiberboard Production: A Review. J. Silva Lestari 2021, 9, 23–44. [Google Scholar] [CrossRef]

- Savov, V.; Antov, P.; Panchev, C.; Lubis, M.A.R.; Lee, S.H.; Taghiyari, H.R.; Todorova, M.; Petrin, S. Effect of Hydrolysis Regime on the Properties of Fibers Obtained from Recycling Medium-Density Fiberboards. Fibers 2023, 11, 64. [Google Scholar] [CrossRef]

- Savov, V.; Antov, P.; Panchev, C.; Lubis, M.A.R.; Taghiyari, H.R.; Lee, S.H.; Krišt’ák, L’.; Todorova, M. The Impact of Hydrolysis Regime on the Physical and Mechanical Characteristics of Medium-Density Fiberboards Manufactured from Recycled Wood Fibers. Fibers 2023, 11, 103. [Google Scholar] [CrossRef]

- Panchev, C.; Savov, V. Effect of Hydrolysis Regime on Stiffness and Deformation at bending of Recycled Medium-Density Fibreboards (rMDF). Innov. Woodwork. Ind. Eng. Des. 2023, 2, 70–77. [Google Scholar]

- Panchev, C.; Savov, V. Recycling of Medium Density Fibreboards—A Review. Innov. Woodwork. Ind. Eng. Des. 2022, 1, 39–46. [Google Scholar]

- Kumar, R.N.; Pizzi, A. Adhesives for Wood and Lignocellulosic Materials; Wiley Publishing House: Hoboken, NJ, USA, 2019; p. 491. [Google Scholar]

- Pizzi, A.; Papadopoulus, A.N.; Policardi, F. Wood Composites and Their Polymer Binders. Polymers 2020, 12, 1115. [Google Scholar] [CrossRef]

- Kristak, L.; Antov, P.; Bekhta, P.; Lubis, M.A.R.; Iswanto, A.H.; Reh, R.; Sedliacik, J.; Savov, V.; Taghiayri, H.; Papadopoulos, A.N.; et al. Recent Progress in Ultra-Low Formaldehyde Emitting Adhesive Systems and Formaldehyde Scavengers in Wood-Based Panels: A Review. Wood Mater. Sci. Eng. 2023, 18, 763–782. [Google Scholar]

- Savov, V.; Antov, P.; Trichkov, N. Properties of High-Density Fibreboards Bonded with Urea-Formaldehyde and Phenol-Formaldehyde Resins. Innov. Woodwork. Ind. Eng. Des. 2021, 2, 17–26. [Google Scholar]

- Savov, V. Engineering of Selected Properties of Light Medium Density Fibreboards Produced from Hardwood Tree Species. Innov. Woodwork. Ind. Eng. Des. 2020, 1, 53–59. [Google Scholar]

- Suchsland, O.; Woodston, E.G. Fiberboard Manufacturing Practices in the United States; Agricultural Handbook No 640; United States Department of Agriculture, Forest Service: Washington, DC, USA, 1987; p. 263. [Google Scholar]

- Garcia, R.; Calvez, I.; Koubaa, A.; Landry, V.; Cloutier, A. Sustainability, Circularity, and Innovation in Wood-based Panel Manufacturing in the 2020s: Opportunities and Challenges. Curr. For. Rep. 2024, 10, 420–441. [Google Scholar] [CrossRef]

- Jivkov, V.; Petrova, B. Challenges for furniture design with thin structural materials. In Proceedings of the IFC2020, Trabzon, Turkey, 2–4 November 2020; pp. 113–123. [Google Scholar]

- Sala, C.M.; Kowaluk, G. An impact of surface spray and pressing temperature on the properties of high density fibreboards. Ann. Wars. Univ. Life Sci. SGGW (For. Wood Technol.) 2020, 112, 36–53. [Google Scholar]

- Gul, W.; Khan, A.; Shakoor, A. Impact of Hot Pressing Temperature on Medium Density Fiberboard (MDF) Performance. Adv. Mater. Sci. Eng. 2017, 2017, 4056360. [Google Scholar]

- Carvalho, L.; Costa, C. A global model for the hot-pressing of MDF. J. Wood Sci Technol. 2003, 37, 241–258. [Google Scholar]

- EN 310:1999; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- EN 317:1998; Particleboards and Fibreboards—Determination of Swelling in Thickness After Immersion in Water. European Committee for Standardization (CEN): Brussels, Belgium, 1998.

- EN 319:1993; Particleboards and Fibreboards; Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization (CEN): Brussels, Belgium, 2001.

- EN 323:2001; Wood-Based Panels—Determination of Density. European Committee for Standardization (CEN): Brussels, Belgium, 2001.

- EN ISO 12460-5:2015; Wood-Based Panels-Determination of Formaldehyde Release—Part 5. Extraction Method (Called the Perforator Method). European Committee for Standardization: Brussels, Belgium, 2015.

- Gürsoy, S.; Ayrilmis, N. Effect of Lignin Modification of Recycled and Fresh Wood Fibers on Physical, Mechanical, and Thermal Properties of Fiberboard. Forests 2023, 14, 2007. [Google Scholar] [CrossRef]

- EN 622-5:2010; Fibreboards—Specifications—Part 5: Requirements for Dry Process Boards (MDF). European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- Antov, P.; Krišt’ák, L.; Réh, R.; Savov, V.; Papadopoulos, A.N. Eco-Friendly Fiberboard Panels from Recycled Fibers Bonded with Calcium Lignosulfonate. Polymers 2021, 13, 639. [Google Scholar] [CrossRef]

- Taheri, F.; Enayati, A.A.; Pizzi, A.; Lemonon, J.; Layeghi, M. Evaluation of UF resin content in MDF boards after hot-pressing by Kjeldahl method. Eur. J. Wood Prod. 2016, 74, 237–242. [Google Scholar] [CrossRef]

- Hong, M.K.; Lubis, M.A.R.; Park, B.D. Effect of Panel Density and Resin Content on Properties of Medium Density Fiberboard. J. Korean Wood Sci. Technol. 2017, 45, 444–455. [Google Scholar] [CrossRef]

- Nuryawan, А.; Risnasari, I.; Pohan, A.P.; Husna, A.U.; Nasution, T.I.; Banurea, R.; Hartini, K.S. Properties of fibreboard (FBs) and recycle fibreboard (rFBs) and analysis of their wastage after recycling. IOP Conf. Ser. Mater. Sci. Eng. 2020, 935, 012060. [Google Scholar] [CrossRef]

- Roffael, E.; Dix, B.; Behn, C.; Bär, G. Mitverwendung von UF-Harz-gebundenen Gebrauchtspanund-faserplatten in der MDF-Herstellung. Eur. J. Wood Prod. 2010, 68, 121–128. [Google Scholar] [CrossRef]

- Magalhães, R.; Nogueira, B.; Costa, S.; Paiva, N.; Ferra, J.M.; Magalhães, F.D.; Martins, J.; Carvalho, L.H. Effect of Panel Moisture Content on Internal Bond Strength and Thickness Swelling of Medium Density Fiberboard. Polymers 2021, 13, 114. [Google Scholar] [CrossRef]

- Adeeb, E.; Kim, T.W.; Sohn, C.H. Cost–Benefit Analysis of Medium-Density Fiberboard Production by Adding Fiber from Recycled Medium-Density Fiberboard. Forest Prod. J. 2018, 68, 414–418. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Mohammad-Panah, B.; Morrell, J.J. Effects of wollastonite on the properties of medium-density fiberboard (MDF) made from wood fibers and camel-thorn. Maderas. Cienc. Tecnol. 2016, 18, 157–166. [Google Scholar] [CrossRef]

- Segovia, F.; Blanchet, P.; Essoua, G.G.E. Potential of the crude glycerol and citric acid mixture as a binder in medium-density fiberboard manufacturing. Eur. J. Wood Prod. 2021, 79, 1141–1151. [Google Scholar] [CrossRef]

- Wibowo, E.S.; Lubis, M.A.R.; Park, B.D. imultaneous Improvement of Formaldehyde Emission and Adhesion of Medium-Density Fiberboard Bonded with Low-Molar Ratio Urea-Formaldehyde Resins Modified with Nanoclay. J. Korean Wood Sci. Technol. 2021, 49, 453–461. [Google Scholar] [CrossRef]

- Engin, M.; Konukçu, A.Ç. Physical and mechanical properties of fiberboard produced with shredded waste office paper. BioResources 2024, 19, 8642–8653. [Google Scholar] [CrossRef]

| Panel № | Average ρ, kg.m−3 | Standard Deviation Sy, kg.m−3 | Coefficient of Variation Vy, % | Average Error my, kg.m−3 | Probability Py, % |

|---|---|---|---|---|---|

| 1. | 789 | 37.10 | 4.70 | 11.73 | 1.49 |

| 2. | 783 | 43.58 | 5.57 | 13.78 | 1.76 |

| 3. | 794 | 41.64 | 5.25 | 13.17 | 1.66 |

| 4. | 787 | 43.70 | 5.55 | 13.82 | 1.76 |

| 5. | 789 | 49.99 | 6.34 | 15.81 | 2.00 |

| 6. | 780 | 27.26 | 3.50 | 8.62 | 1.11 |

| Source of Variation | Sum of Deviations Squares Q | Degrees of Freedom ν | Variance S2 | Calculated Fisher’s Criterion Fcal | A Critical Value of Fisher’s Criterion, Fcr |

|---|---|---|---|---|---|

| Content of recycled fibers | 1239.10 | 5 | 247.8209 | 0.12 | 3.48 |

| Error | 19,243.62 | 9 | 2138.18 |

| Panel № | Recycled Fiber Content X1 (Coded) | UF Resin Content X2 (Coded) | Recycled Fiber Content R, % (Decoded) | UF Resin Content P, % (Decoded) |

|---|---|---|---|---|

| 1 | - | - | 10 | 8 |

| 2 | - | + | 10 | 12 |

| 3 | + | - | 50 | 8 |

| 4 | + | + | 50 | 12 |

| 5 | - | 0 | 10 | 10 |

| 6 | + | 0 | 50 | 10 |

| 7 | 0 | - | 30 | 8 |

| 8 | 0 | + | 30 | 12 |

| 9 | 0 | 0 | 30 | 10 |

| Panel № | Mean Density ρ, kg.m−3 | Standard Deviation Sy, kg.m−3 | Standard Error my, kg.m−3 | Coefficient of Variation Vy, % | Probability, Py, % |

|---|---|---|---|---|---|

| 1 | 781 | 26.82 | 3.43 | 9.48 | 1.21 |

| 2 | 766 | 58.34 | 7.62 | 20.63 | 2.69 |

| 3 | 779 | 55.39 | 7.11 | 19.58 | 2.51 |

| 4 | 777 | 49.94 | 6.43 | 17.65 | 2.27 |

| 5 | 790 | 74.32 | 9.41 | 26.28 | 3.33 |

| 6 | 781 | 72.14 | 9.23 | 25.50 | 3.26 |

| 7 | 779 | 40.14 | 5.16 | 14.19 | 1.82 |

| 8 | 793 | 47.22 | 5.95 | 16.70 | 2.10 |

| 9 | 772 | 70.46 | 9.13 | 24.91 | 3.23 |

| Source of Variation | Sum of Squares Q | Degrees of Freedom ν | Variance 0 S2 | Calculated Fisher’s Criterion Fcal | Critical Fisher’s Criterion Fcr |

|---|---|---|---|---|---|

| Panel type | 3912.83 | 7 | 558.98 | 0.184 | 2.178 |

| Error | 169,771.38 | 56 | 3031.63 | ||

| Total | 173,684.22 | 63 | - |

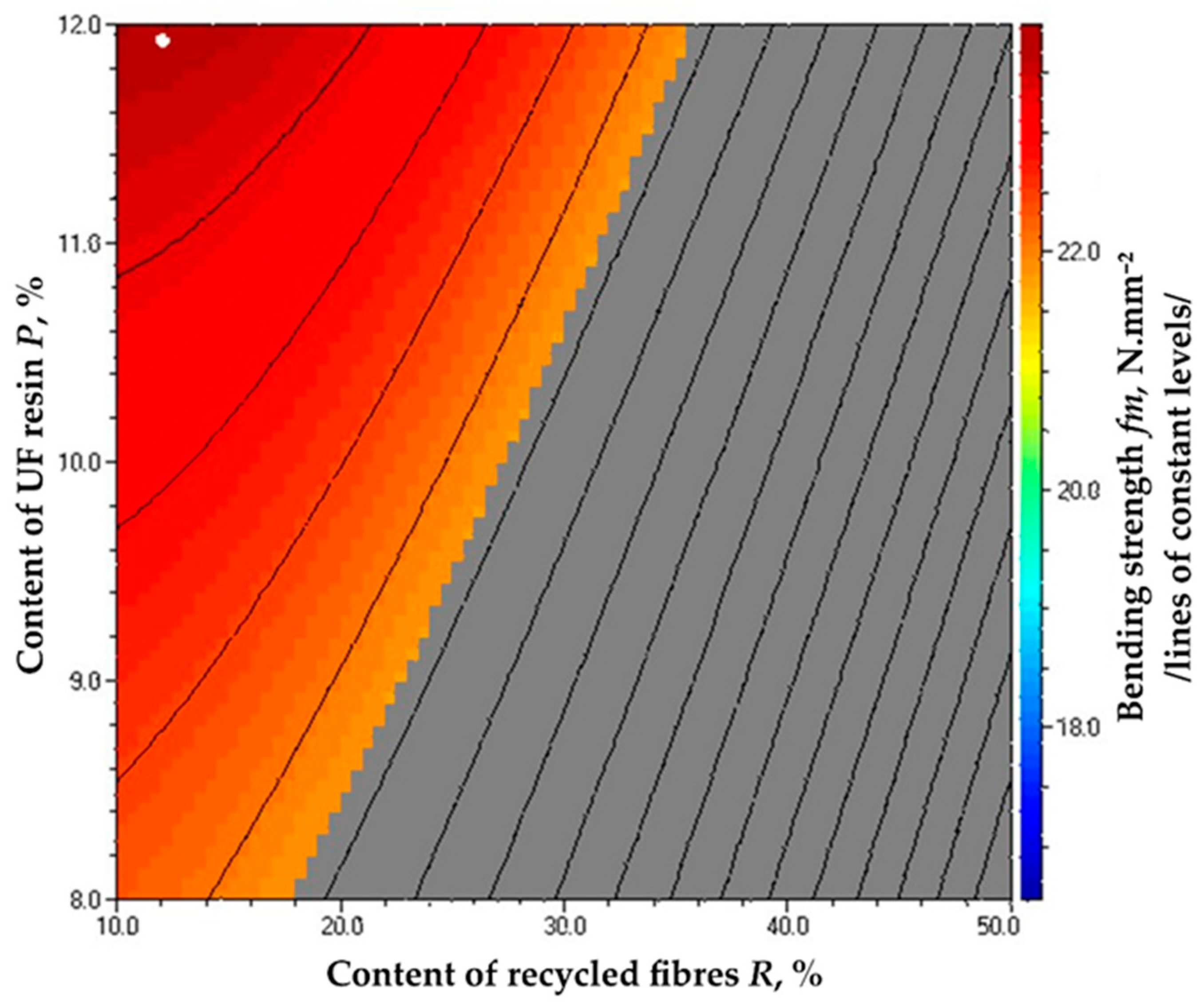

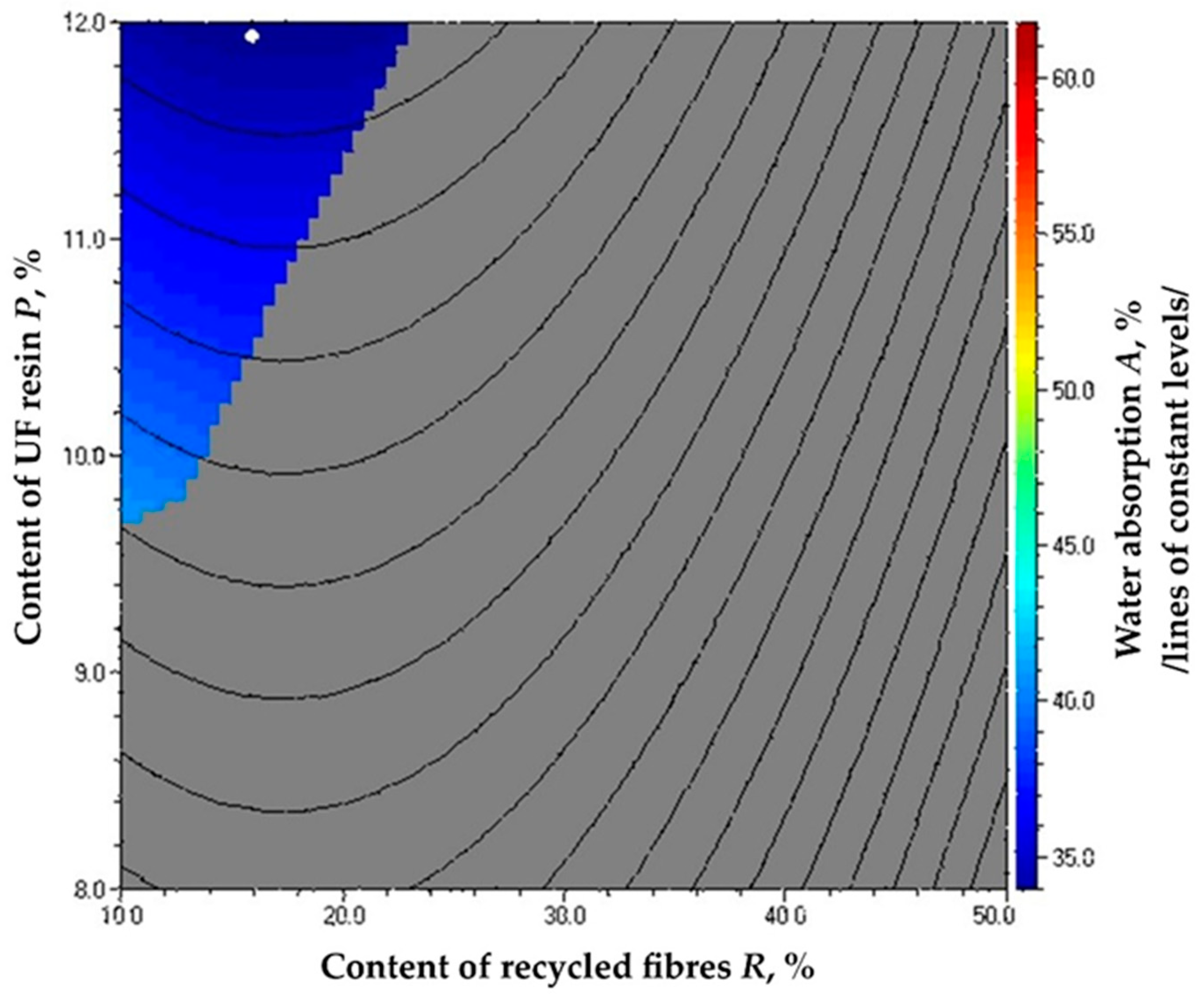

| Panel № | Water Absorption A, % | Thickness Swelling Gt, % | Modulus of Elasticity Em, N.mm−2 | Bending Strength fm, N.mm−2 | Internal Bond (IB) Strength ft, N.mm−2 |

|---|---|---|---|---|---|

| 1 | 49.19 ± 2.41 | 18.47 ± 1.17 | 3346 ± 157 | 23.91 ± 1.06 | 0.62 ± 0.011 |

| 2 | 33.67 ± 1.44 | 11.88 ± 0.50 | 3719 ± 182 | 25.51 ± 1.59 | 0.66 ± 0.011 |

| 3 | 63.43 ± 2.02 | 22.97 ± 1.37 | 2524 ± 200 | 16.74 ± 1.01 | 0.43 ± 0.016 |

| 4 | 45.44 ± 2.68 | 17.09 ± 1.13 | 3486 ± 141 | 19.8 ± 0.84 | 0.52 ± 0.012 |

| 5 | 39.3 ± 1.62 | 13.47 ± 0.80 | 3383 ± 129 | 20.18 ± 0.57 | 0.53 ± 0.017 |

| 6 | 58.65 ± 3.34 | 21.53 ± 1.16 | 2999 ± 152 | 17.45 ± 0.60 | 0.45 ± 0.013 |

| 7 | 44.51 ± 3.08 | 17.43 ± 0.87 | 3083 ± 201 | 20.9 ± 0.96 | 0.55 ± 0.012 |

| 8 | 42.4 ± 2.45 | 15.78 ± 1.04 | 3490 ± 226 | 22.68 ± 1.41 | 0.59 ± 0.016 |

| 9 | 39.98 ± 2.22 | 16.81 ± 1.05 | 3365 ± 145 | 21.4 ± 1.23 | 0.56 ± 0.017 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savov, V.; Antov, P.; Dudeva, V.; Panchev, C. Properties of Medium-Density Fiberboards with Different Contents of Recycled Fibers and Urea–Formaldehyde Resin. Fibers 2025, 13, 40. https://doi.org/10.3390/fib13040040

Savov V, Antov P, Dudeva V, Panchev C. Properties of Medium-Density Fiberboards with Different Contents of Recycled Fibers and Urea–Formaldehyde Resin. Fibers. 2025; 13(4):40. https://doi.org/10.3390/fib13040040

Chicago/Turabian StyleSavov, Viktor, Petar Antov, Viktoria Dudeva, and Christian Panchev. 2025. "Properties of Medium-Density Fiberboards with Different Contents of Recycled Fibers and Urea–Formaldehyde Resin" Fibers 13, no. 4: 40. https://doi.org/10.3390/fib13040040

APA StyleSavov, V., Antov, P., Dudeva, V., & Panchev, C. (2025). Properties of Medium-Density Fiberboards with Different Contents of Recycled Fibers and Urea–Formaldehyde Resin. Fibers, 13(4), 40. https://doi.org/10.3390/fib13040040