Natural Fiber Composites for Sustainable Model Rocketry: Bamboo and Jute as Alternatives to Fiberglass

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of Fiberglass Baseline Laminates

2.2. Bamboo Fiber Laminates

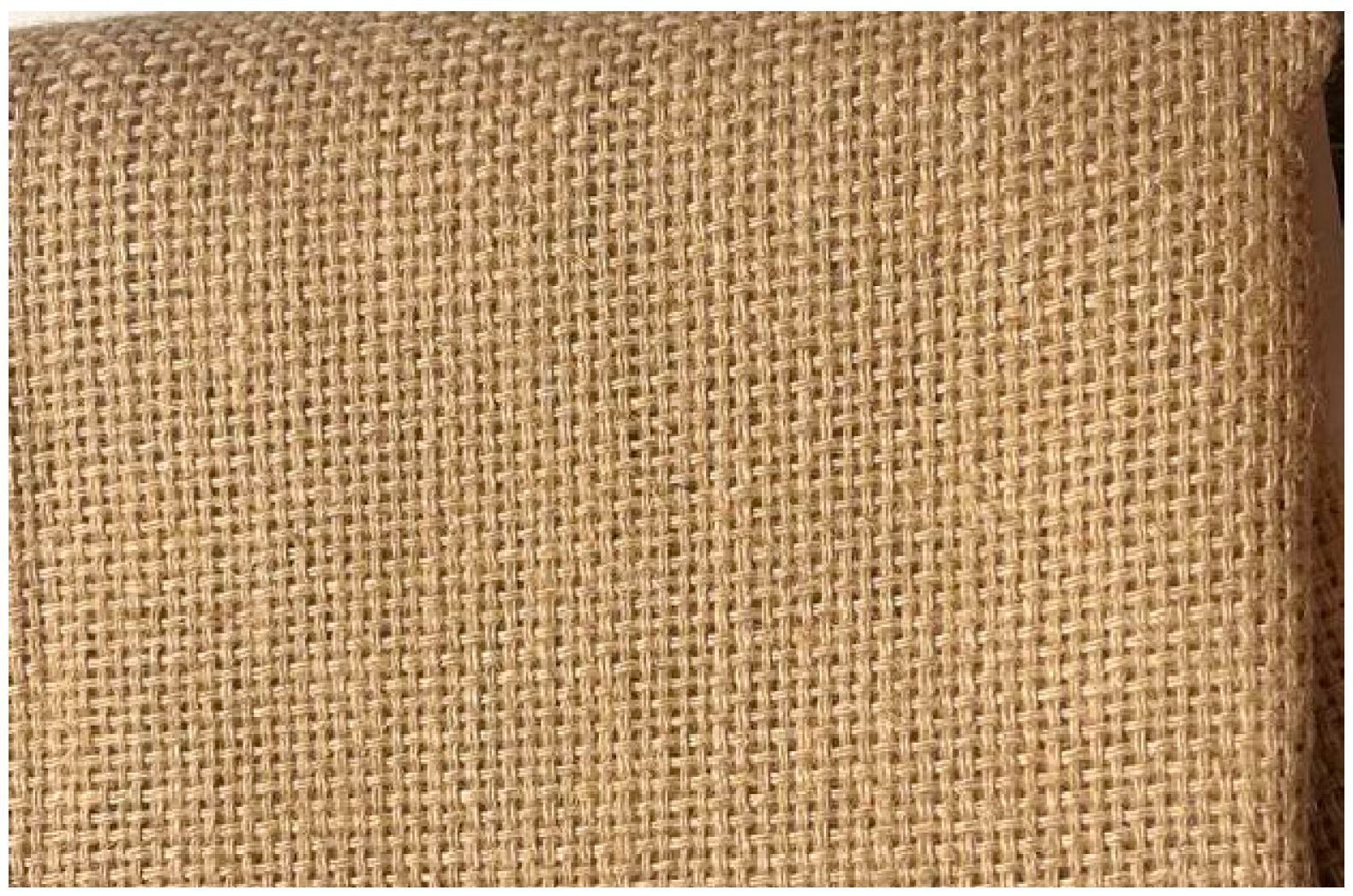

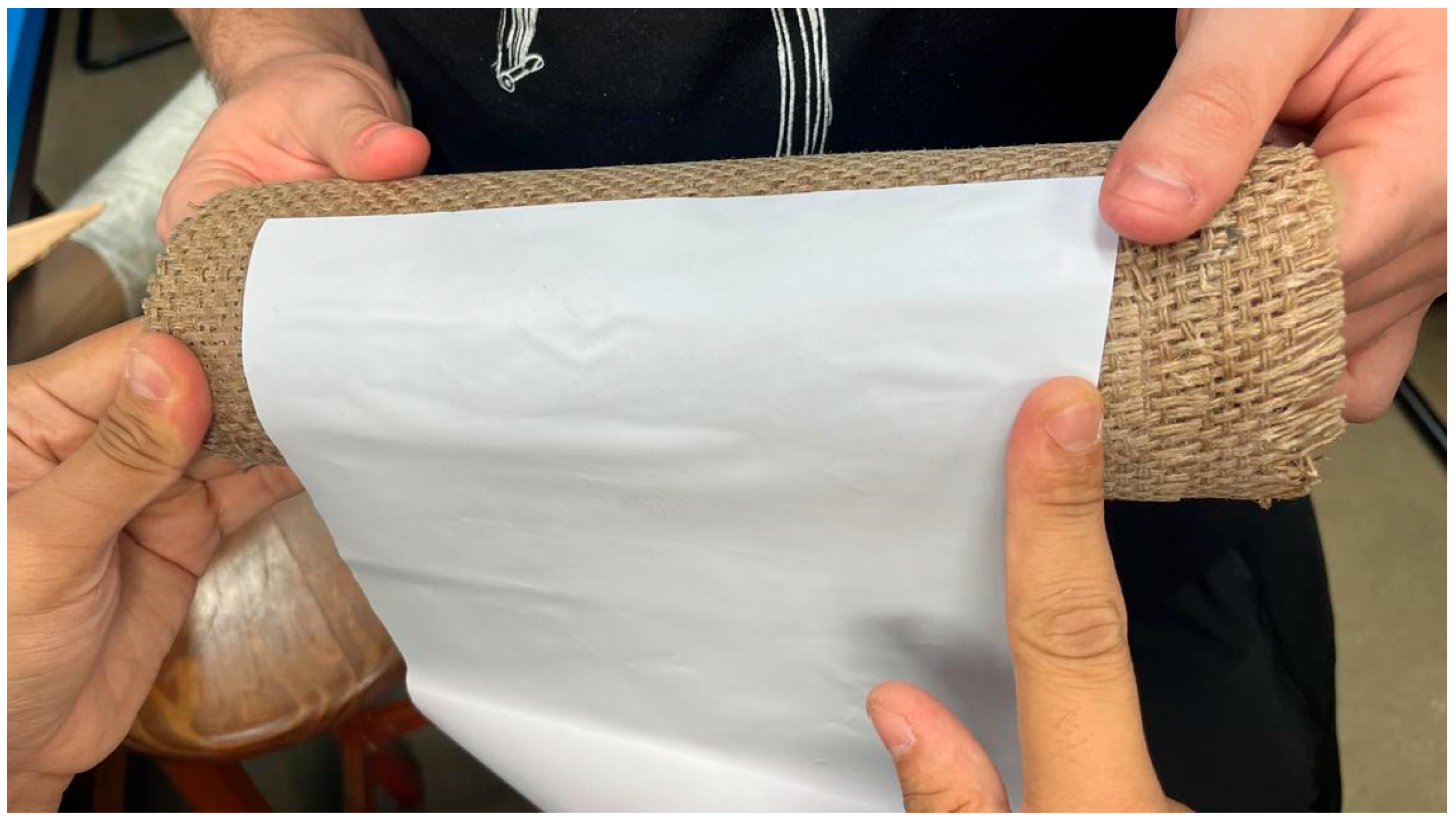

2.3. Jute Fiber Laminates

2.4. Experimental Tests

- 1.

- Sealing and Ejection Test—Initially conceived as a hydrostatic test, the sealing capacity was evaluated through parachute ejection tests due to equipment constraints. Tubes of fiberglass and jute were tested using identical parameters: 4 g of black powder, 17 cm tube length, and equivalent parachute-to-recovery system distance (Figure 6). Successful ejection confirmed system viability.

- 2.

- Surface Roughness Test—Surface roughness was measured using a Surftest S210 profilometer (Mitutoyo, IL, USA), capable of recording Ra (average roughness), Rz (mean peak-to-valley height), Ry (maximum height), and Rt (total roughness) [13]. Each tube underwent five measurements. Samples included: (i) fiberglass tube painted with automotive coating (Helder 1), (ii) fiberglass tube with protective automotive envelope (Helder 2, under fabrication), and (iii) jute tube with furniture envelope.

- 3.

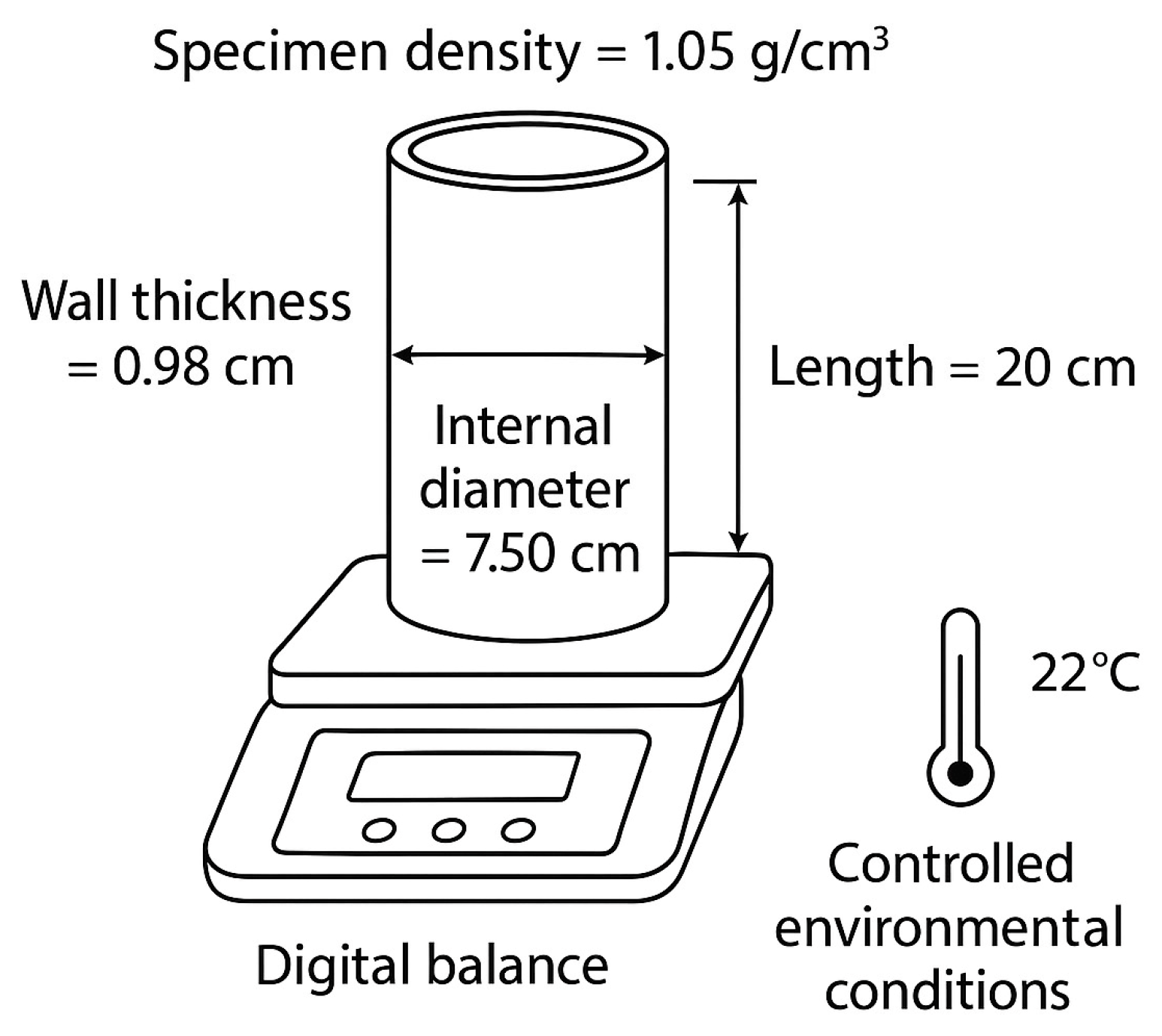

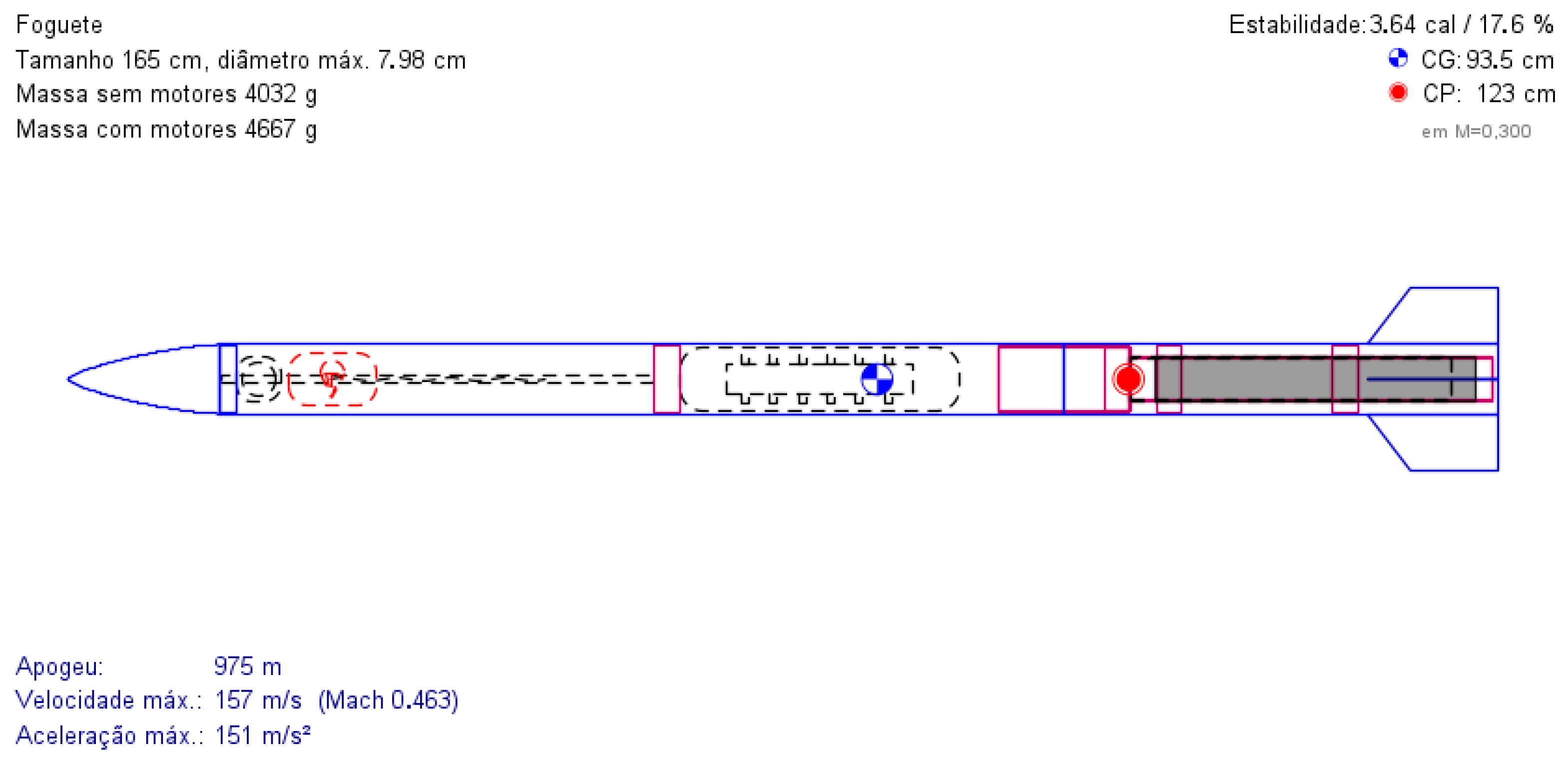

- Flight Simulation—OpenRocket v15.03 [33], an open-source simulation software, was used to compare fiberglass and jute rockets. All rocket components (motor, avionics, recovery, fins, nose cone, and internal structures) were kept constant, with only the fuselage material modified. The densities of each laminated fuselage were determined experimentally using a direct mass-to-volume ratio (Figure 7) based on the cylindrical geometry of the specimens after 48 h of curing under controlled environmental conditions (22 °C and 86% RH). This ensured realistic input parameters for OpenRocket simulations. The jute density used in the simulation was 1.037 g/cm3, a value similar to polystyrene. Aerodynamic properties and surface roughness were integrated into the models (Figure 8).

2.5. Cost Analysis

- Fiber-only cost (per number of layers): fiberglass = BRL 52.97; jute = BRL 8.95 → jute ~492% cheaper.

- Total cost (fiber + resin consumption): fiberglass = BRL 65.95; jute = BRL 92.42 → jute ~41.5% more expensive due to higher resin absorption.

- Real purchase costs (at the time of fabrication): fiberglass ≈ BRL 25; jute ≈ BRL 19.

3. Results

3.1. Sealing and Ejection Test

3.2. Surface Roughness Test

- Fiberglass fuselage finished with automotive paint (Helder 1).

- Fiberglass fuselage with protective automotive envelope (Helder 2, under fabrication).

- Jute fuselage with polymeric furniture envelope.

3.3. Flight Simulations

3.4. Cost Results and Trade-Offs

- Fiber-only comparison: jute was ~492% cheaper than fiberglass (BRL 8.95 vs. BRL 52.97).

- Total cost with resin consumption: fiberglass remained cheaper (BRL 65.95 vs. BRL 92.42), since jute absorbed significantly more resin.

- Real market prices (at the time of purchase): fiberglass ≈ BRL 25; jute ≈ BRL 19, showing that in practice, jute was the more economical option.

4. Discussion

5. Conclusions

- Bamboo composites: Untreated bamboo fibers proved unsuitable, producing brittle laminates with poor resin impregnation and structural weakness. Despite bamboo’s recognized potential due to its high tensile strength, this study confirmed that without chemical modification, it cannot be considered for aerospace use. This reinforces the consensus in the literature that chemical treatments such as alkalization, silane, or enzymatic modification are indispensable to remove surface barriers and improve adhesion [23,24,25], which is recommended for future investigation. The limitation encountered here highlights a key research direction: the adaptation of bamboo through proper surface modification remains essential for its future application in aerospace composites.

- Jute composites: In contrast, jute laminates exhibited excellent processability and functional performance. With two layers of woven mats, jute fuselages achieved uniform cylindrical geometry, adequate resin impregnation, and a final mass of 2734 g with 0.98 cm thickness, compared to fiberglass fuselages with 1053 g and 0.24 cm thickness. Surface roughness results were particularly promising: jute presented an Ra = 37 µm, lower than fiberglass with automotive paint (62 µm) and fiberglass with a protective envelope (52 µm). This smoother finish indicates reduced aerodynamic drag potential, an advantage not usually attributed to natural fibers.

- Performance validation: Functional tests confirmed the technical viability of jute fuselages. Both fiberglass and jute composites successfully withstood parachute ejection, demonstrating resistance to sudden internal pressure peaks. OpenRocket simulations, using measured densities (fiberglass standard vs. jute 1.037 g/cm3), indicated comparable apogees (~1 km), flight times, and descent velocities, with jute showing slightly higher stability margins. While surface roughness cannot be directly integrated into the software, empirical data suggest that smoother jute fuselages may offer additional aerodynamic benefits in real flights.

- Economic perspective: The economic analysis showed dual outcomes. When considering only fiber costs, jute was ~492% cheaper than fiberglass (BRL 8.95 vs. BRL 52.97). However, when resin consumption was included, jute appeared ~41.5% more expensive (BRL 92.42 vs. BRL 65.95). Importantly, real purchase prices at the time of fabrication favored jute (BRL 19 vs. BRL 25). This duality highlights that while natural fibers may increase resin demand, their market accessibility and lower acquisition costs can still make them attractive for student teams operating under limited budgets.

- Educational and sustainability implications: Beyond technical validation, the study showed the broader educational value of integrating sustainable materials in academic rocketry. Student rocketry competitions generate significant composite waste, usually fiberglass, which has long-term environmental impacts due to its non-biodegradable nature. By adopting natural fibers such as jute, students not only reduce the environmental footprint of their projects but also engage in experiential learning about eco-innovation. This represents an important cultural shift, aligning aerospace education with global sustainability goals.

- Novelty and contribution: The originality of this work lies in demonstrating, for the first time, that jute composites can successfully replace fiberglass in student rocket fuselages without compromising structural integrity or flight performance. While natural fibers have been tested in automotive and aerospace secondary structures [10,17,18], their application in fuselages subjected to recovery system loads and aerodynamic demands had not been validated before. This makes the present study a pioneering step in sustainable aerospace materials research.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Shaker, K.; Nawab, Y.; Jabbar, M. Bio-composites: Eco-friendly substitute of glass fiber composites. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review basalt fibre and its composites. Compos. Part B 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Baillie, C. Green Composites: Polymer Composites and the Environment; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000-2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Trujillo, E.; Moesen, M.; Osorio, L.; Van Vuure, A.W.; Verpoest, I. Bamboo fibres for reinforcement in composite materials: Strength Weibull analysis. Compos. Part A 2014, 61, 115–125. [Google Scholar] [CrossRef]

- Shelar, P.; Uttamchand, N. A Short Review on Jute Fiber Reinforced Composites. Mater. Sci. Forum. 2021, 1019, 32–43. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Balo, F.; Sua, L.S. Green Composites in Aviation: Optimizing Natural Fiber and Polymer Selection for Sustainable Aircraft Cabin Materials. Textiles 2024, 4, 561–581. [Google Scholar] [CrossRef]

- Nguyen-Sy, T.; Wakim, J.; To, Q.D.; Vu, M.N.; Nguyen, T.D.; Nguyen, T.T. Predicting the compressive strength of concrete from its compositions and age using the extreme gradient boosting method. Constr. Build. Mater. 2020, 260, 119757. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Luo, X.; Chen, L. Bamboo as a naturally-optimized fiber-reinforced composite: Interfacial mechanical properties and failure mechanisms. Compos. Part B 2024, 279, 111458. [Google Scholar] [CrossRef]

- Behera, D.; Pattnaik, S.S.; Nanda, D.; Mishra, P.P.; Behera, A.K. A review on bamboo fiber reinforced composites and their potential applications. Emergent Mater. 2025, 8, 157–172. [Google Scholar] [CrossRef]

- Shettigar, R.; Singh, R.; Mishra, R. Review on aging behavior and durability enhancement of bamboo fiber-reinforced polymer composites. Molecules 2025, 30, 3062. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, R.M.; Ahammad, R.; Arifuzzaman, M.; Islam, M.S.; Islam, M.M. Manufacturing and properties of jute fiber-reinforced polymer composites—A comprehensive review. Materials 2025, 18, 1016. [Google Scholar] [CrossRef]

- Medina Agurto, P.E.; Briceño, E.R.P.; Moreno, S.A.H.; Herrera, O.H.S.; Niño, M.E.G.; Leon-Medina, J.; Váz, R.F. Influence of jute fiber volume fraction on the mechanical properties of epoxy matrix composites. Appl. Sci. 2025, 15, 5515. [Google Scholar] [CrossRef]

- Sarasini, F.; Fiore, V. A systematic literature review on less common natural fibres and their biocomposites. J. Clean. Prod. 2018, 195, 240–267. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural fiber composites and Their Applications: A review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef]

- Parveez, B.; Kittur, M.; Badruddin, I.; Kamangar, S.; Hussien, M.; Umarfaroog, M.A. Scientific Advancements in Composite Materials for Aircraft Applications: A Review. Polymers 2022, 14, 5007. [Google Scholar] [CrossRef]

- Khan, F.; Hossain, N.; Hasan, F.; Rahman, S.M.M. Advances of Natural Fiber Composites in Diverse Engineering Applications–A Review. Appl. Eng. Sci. 2024, 18, 100184. [Google Scholar] [CrossRef]

- Ahmed, R.; Manik, K.H.; Nath, A.; Shohag, J.R.; Mim, J.J.; Hossain, N. Recent advances in sustainable natural fiber composites: Environmental benefits, applications, and future prospects. Mater. Today Sustain. 2025, 32, 101220. [Google Scholar] [CrossRef]

- Yudha, N.K.; Nugroho, A.D.; Erlangga, W.; Jamasri; Fiedler, B.; Muflikhun, M.A. Sustainable High-Performance Materials: The Role of Bamboo and Glass Fibers in Hybrid Composites. Hybrid Adv. 2025, 9, 100416. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Kalia, S.; Thakur, K.; Celli, A.; Kiechel, M.A.; Schauer, C.L. Surface modification of plant fibers using environment-friendly methods for their application in polymer composites, textile industry and antimicrobial activities: A review. J. Environ. Chem. Eng. 2013, 1, 97–112. [Google Scholar] [CrossRef]

- Junior, A.E.C.; Nascimento, D.M.; Deus, E.P.; Mazzetto, S.E.; Junior, S.C.O. Mechanical properties of bamboo fibers before and after chemical treatment. ABM Int. Congr. 2012, 67, 2930–2940. [Google Scholar] [CrossRef]

- Liu, D.; Song, J.; Anderson, D.P.; Chang, P.; Hua, Y. Bamboo fiber and its reinforced composites: Structure and properties. Cellulose. 2012, 19, 1449–1480. [Google Scholar] [CrossRef]

- Islam, M.A.; Islam, M.; Islam, M.S.; Islam, T. Enhanced properties of bamboo short fiber reinforced polymer composites with alkali and graphene oxide. Mater. Adv. 2025, 6, 4738. [Google Scholar] [CrossRef]

- Sultana, N.; Hasan, M.H.; Habib, A.; Saifullah, A. Short Jute Fiber Preform Reinforced Polypropylene Thermoplastic Composite: Experimental Investigation and Its Theoretical Stiffness Prediction. ACS Omega 2023, 8, 12045–12056. [Google Scholar] [CrossRef]

- Das, S.C.; Paul, D.; Khan, M.A.; Grammatikos, S.A.; Papatzani, S. A Comparative Study between Jute and Glass Fiber Reinforced Composites. Key Eng. Mater. 2021, 891, 125–130. [Google Scholar] [CrossRef]

- Tahir, D.; Rehan, M.; Fatima, N.; Hu, H. Sustainable jute fiber-reinforced auxetic composites with both in-plane and out-of-plane auxetic behaviors. Polym. Compos. 2025, 46, S922–S939. [Google Scholar] [CrossRef]

- Anderson, J.D. Fundamentals of Aerodynamics, 6th ed.; McGraw-Hill: New York, NY, USA, 2017. [Google Scholar]

- Stine, G.H.; Stine, B. Handbook of Model Rocketry, 7th ed.; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar]

- OpenRocket. Version 15.03. Available online: http://openrocket.info (accessed on 10 August 2025).

- Hamzat, A.K.; Murad, M.S.; Adediran, I.A.; Asmatulu, E.; Asmatulu, R. Fiber-reinforced composites for aerospace, energy, and marine applications: An insight into failure mechanisms under chemical, thermal, oxidative, and mechanical load conditions. Adv. Compos. Hybrid Mater. 2025, 8, 152. [Google Scholar] [CrossRef]

| Sample | Ra (µm) | Ry (µm) | Rv (µm) | Rt (µm) |

|---|---|---|---|---|

| Fiberglass + Paint | 64, 59, 63, 62, 62 | 95–105 | 58–62 | 77–82 |

| Fiberglass + Envelope | 50, 54, 51, 53, 52 | 63–67 | 74–77 | 48–52 |

| Jute + Envelope | 35, 38, 37, 36, 39 | 18–22 | 48–53 | 63–67 |

| Sample | Ra (µm) | Ry (µm) | Rv (µm) | Rt (µm) |

|---|---|---|---|---|

| Fiberglass + Paint | 62.0 ± 1.9 | 100.1 ± 3.4 | 60.1 ± 1.2 | 79.3 ± 2.0 |

| Fiberglass + Envelope | 52.0 ± 1.6 | 65.0 ± 1.8 | 75.3 ± 1.5 | 50.0 ± 1.6 |

| Jute + Envelope | 37.0 ± 1.6 | 20.1 ± 1.5 | 50.2 ± 1.7 | 65.0 ± 1.7 |

| Parameter | Jute Simulation | Fiberglass Simulation—Helder 1 |

|---|---|---|

| Configuration | RocketWolf J1—Jute | RocketWolf J1—Fiberglass |

| Motor burnout velocity (m/s) | 59.47 | 59.37 |

| Apogee (m) | 975.0 | 973.0 |

| Launch velocity (m/s) | 52.32 | 52.27 |

| Optimal delay (s) | 12.21 | 12.21 |

| Maximum velocity (m/s) | 152 | 157 |

| Maximum acceleration (m/s2) | 151 | 151 |

| Time to apogee (s) | 14.6 | 14.6 |

| Total flight time (s) | 18.6 | 18.6 |

| Velocity at ground impact (m/s) | 5.36 | 5.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alves, L.; Barreto, T.; Leklou, N.; de Barros, S. Natural Fiber Composites for Sustainable Model Rocketry: Bamboo and Jute as Alternatives to Fiberglass. Fibers 2025, 13, 159. https://doi.org/10.3390/fib13120159

Alves L, Barreto T, Leklou N, de Barros S. Natural Fiber Composites for Sustainable Model Rocketry: Bamboo and Jute as Alternatives to Fiberglass. Fibers. 2025; 13(12):159. https://doi.org/10.3390/fib13120159

Chicago/Turabian StyleAlves, Lais, Tabata Barreto, Nordine Leklou, and Silvio de Barros. 2025. "Natural Fiber Composites for Sustainable Model Rocketry: Bamboo and Jute as Alternatives to Fiberglass" Fibers 13, no. 12: 159. https://doi.org/10.3390/fib13120159

APA StyleAlves, L., Barreto, T., Leklou, N., & de Barros, S. (2025). Natural Fiber Composites for Sustainable Model Rocketry: Bamboo and Jute as Alternatives to Fiberglass. Fibers, 13(12), 159. https://doi.org/10.3390/fib13120159