Raman Scattering for Tensile Testing of Polyacrylonitrile-Based and Pitch-Based Single Carbon Fibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

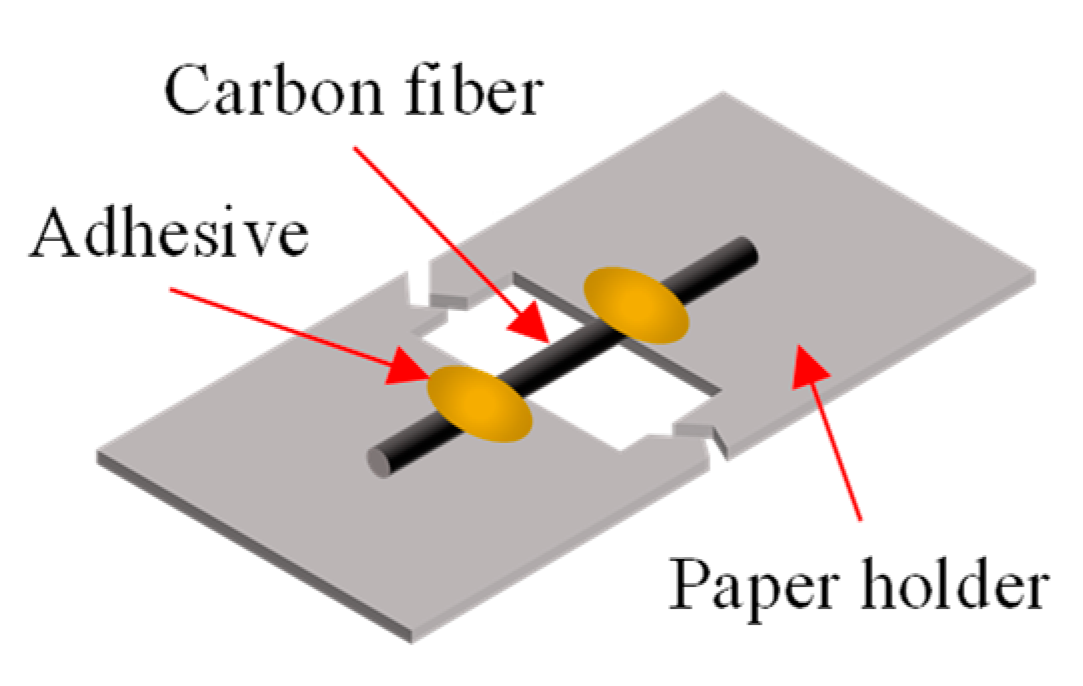

2.2. In Situ Raman Stress Measurement for Tensile Testing

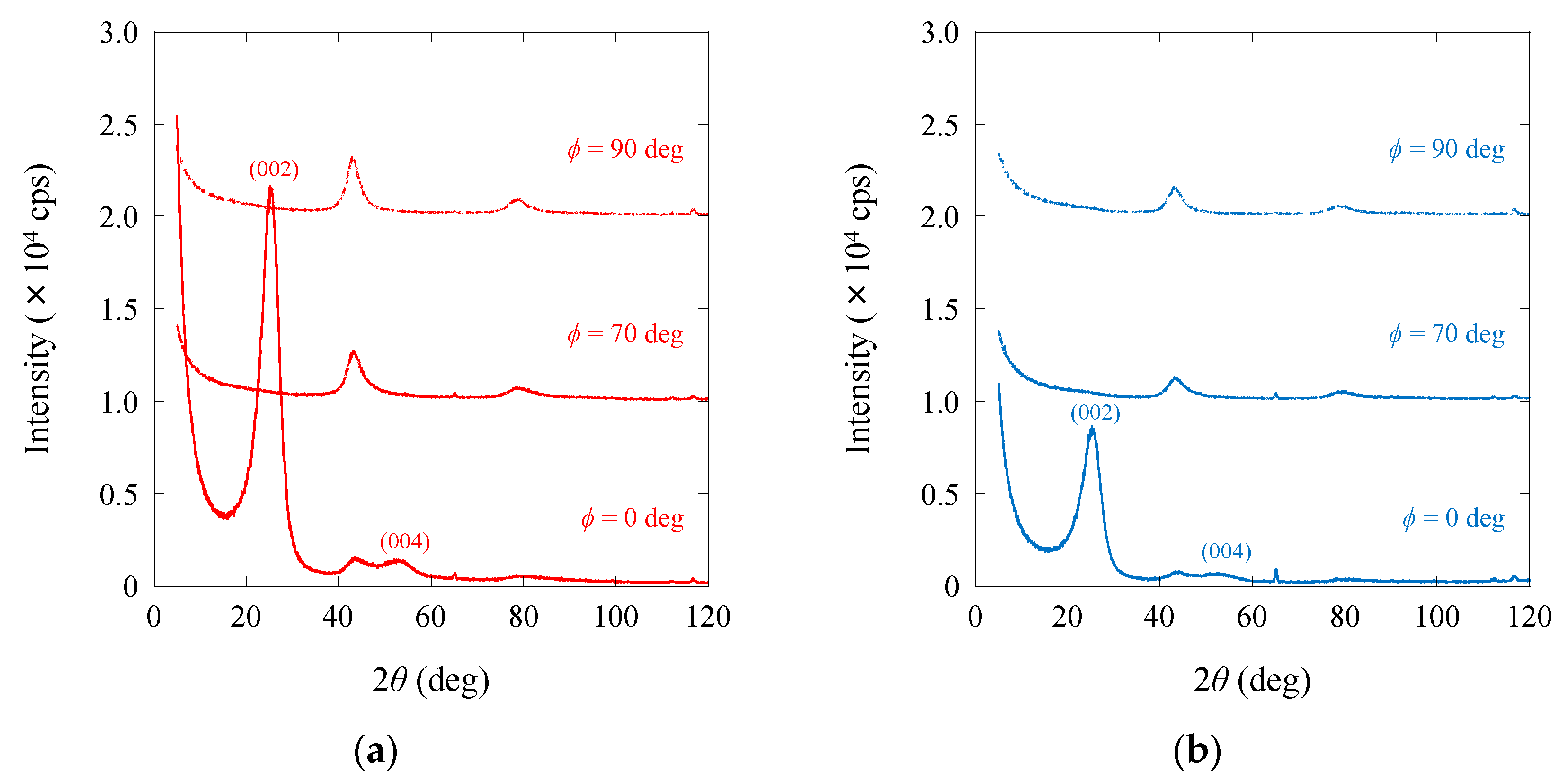

2.3. X-ray Diffraction

3. Results and Discussion

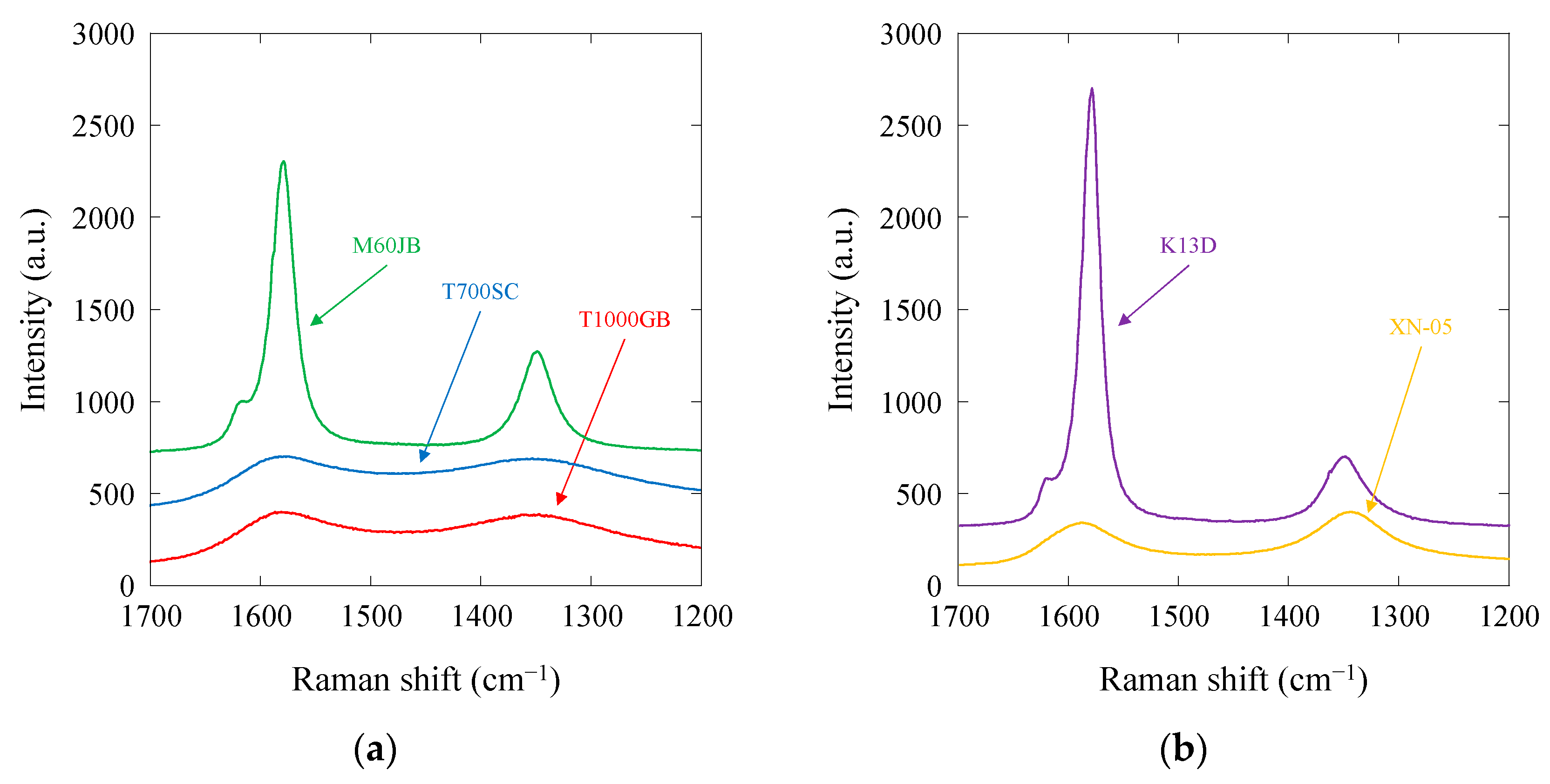

3.1. Raman Spectrum

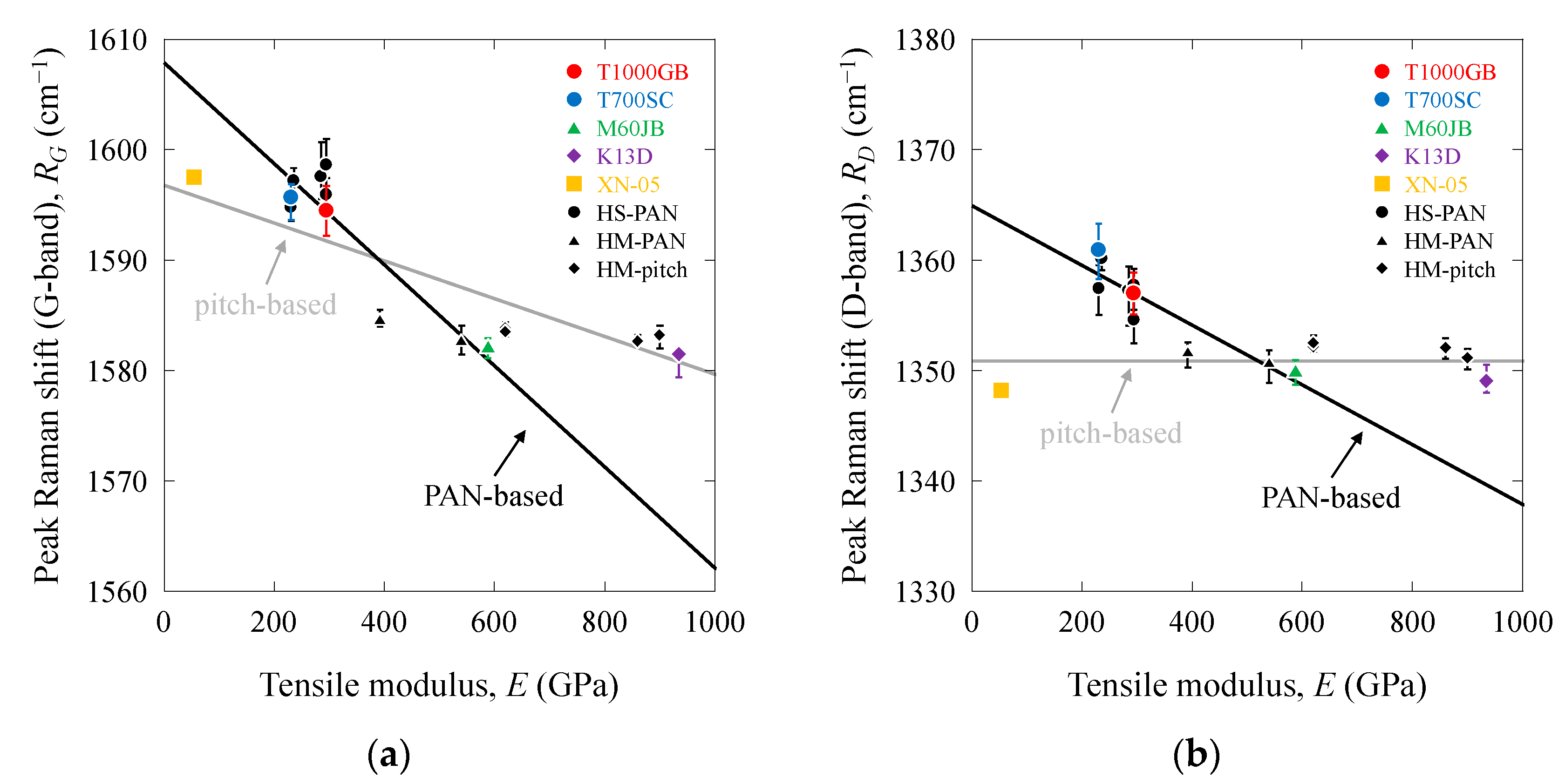

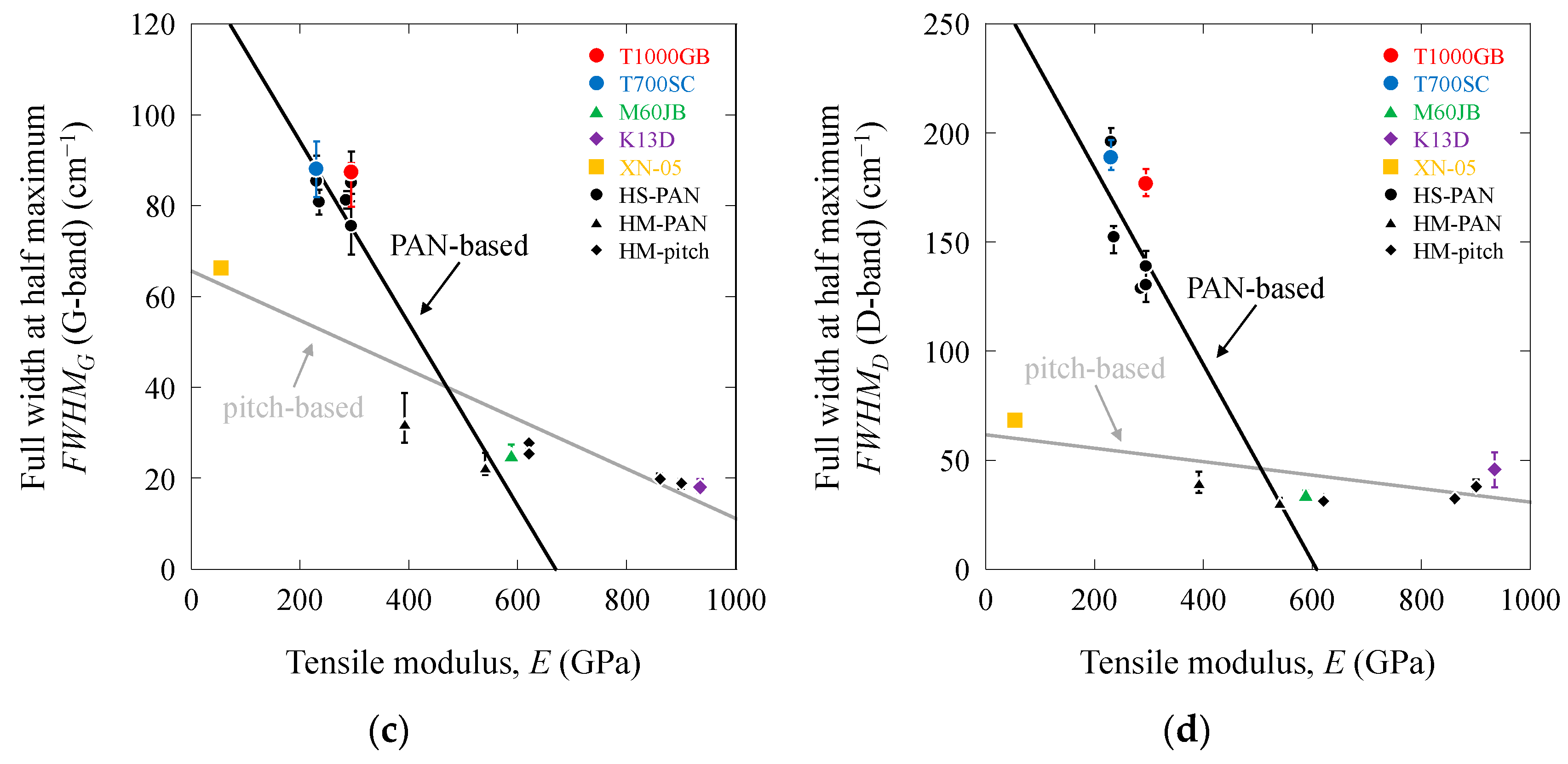

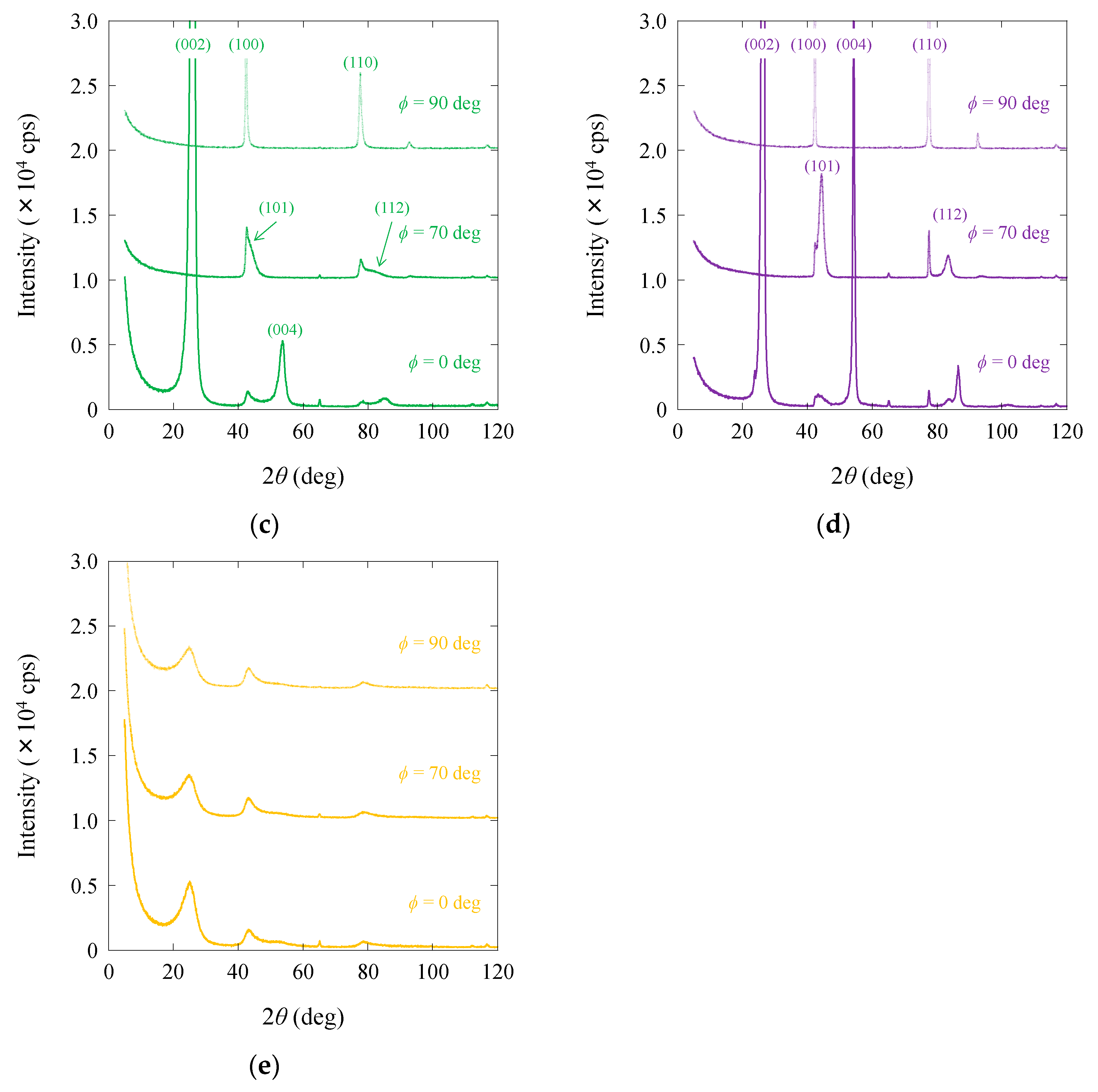

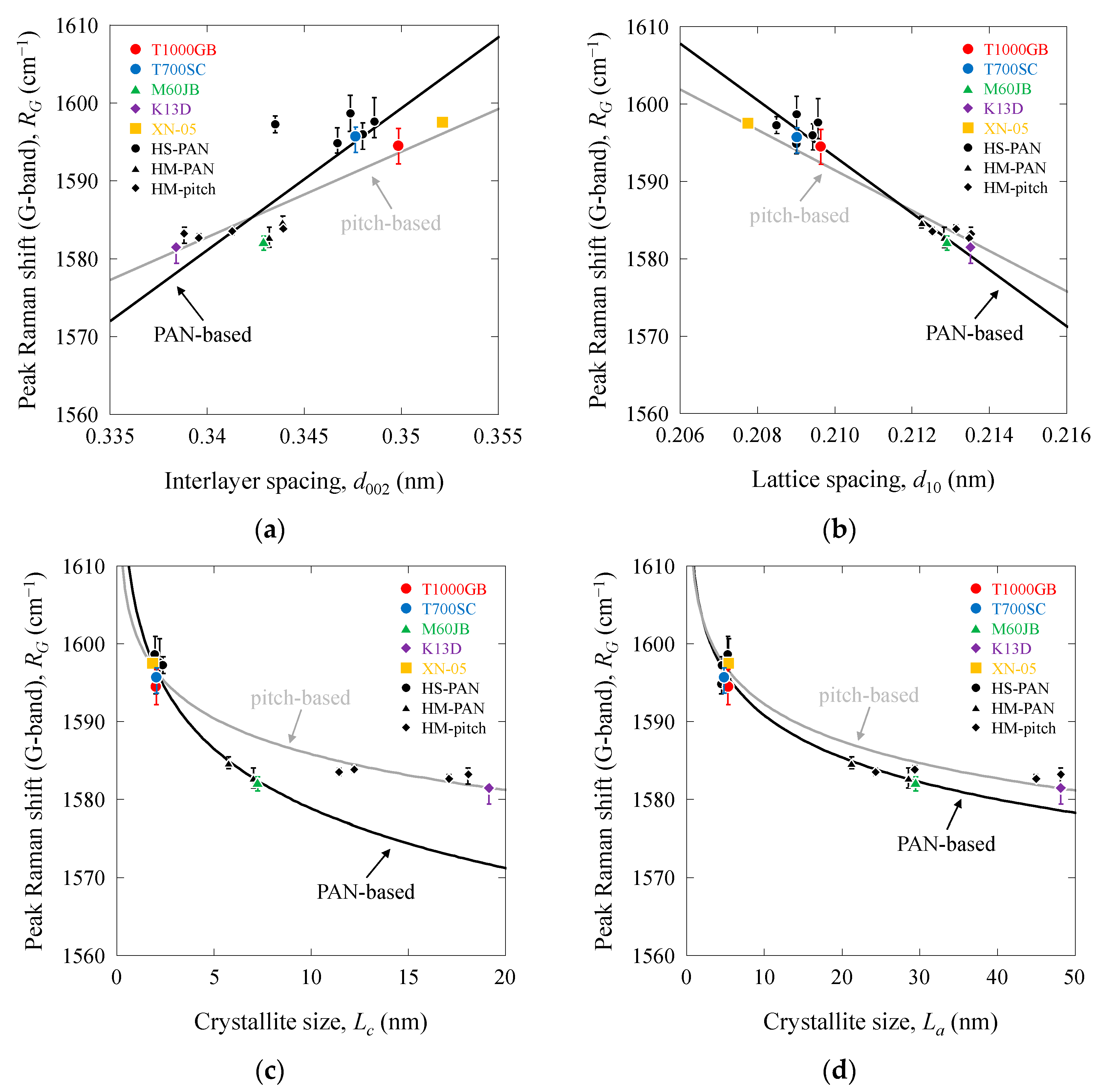

3.2. Relationship between Raman, Tensile, and Structure Parameter

3.3. In Situ Raman Stress Measurement for Tensile Testing of Carbon Fibers

4. Conclusions

- (1)

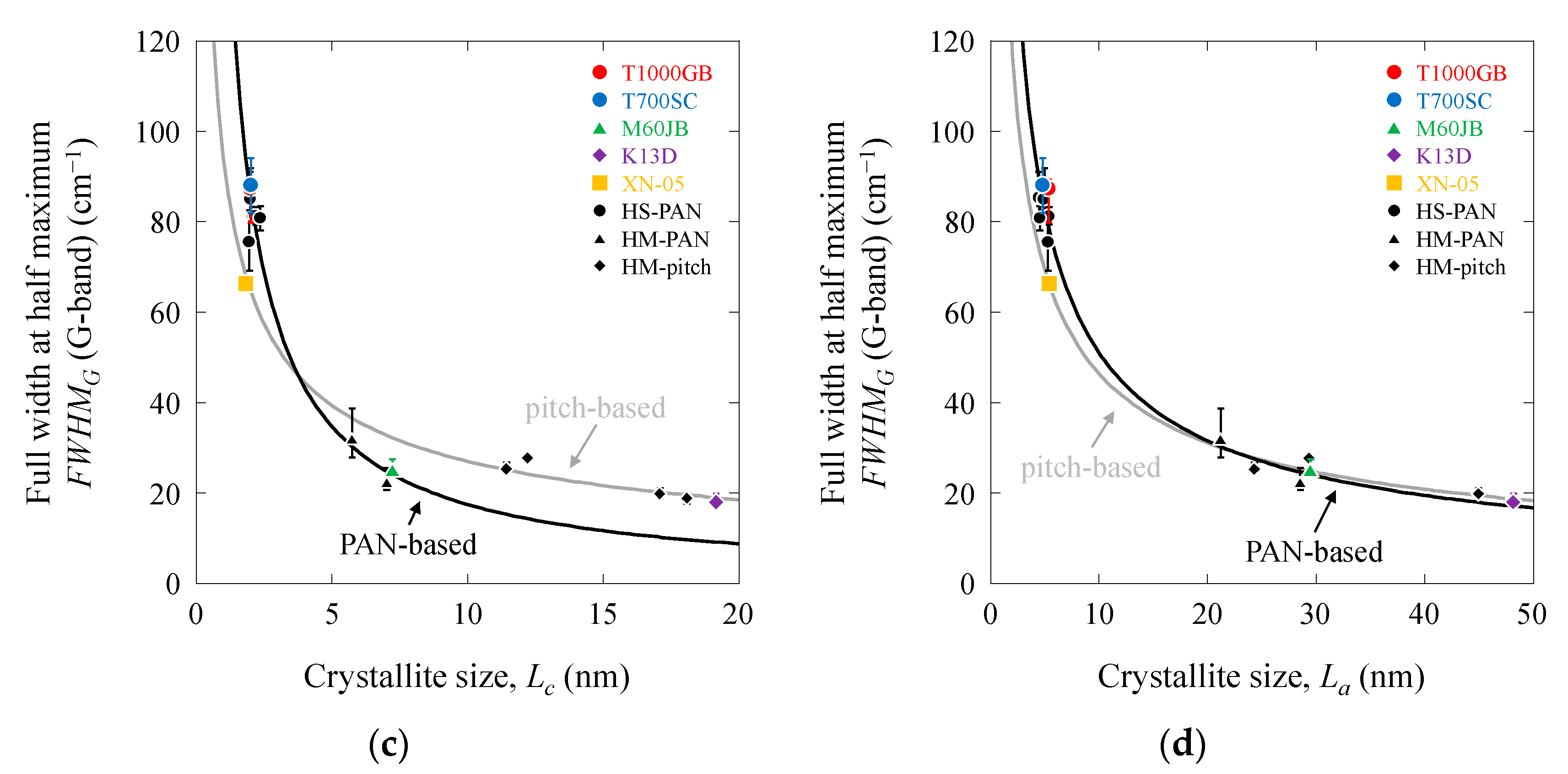

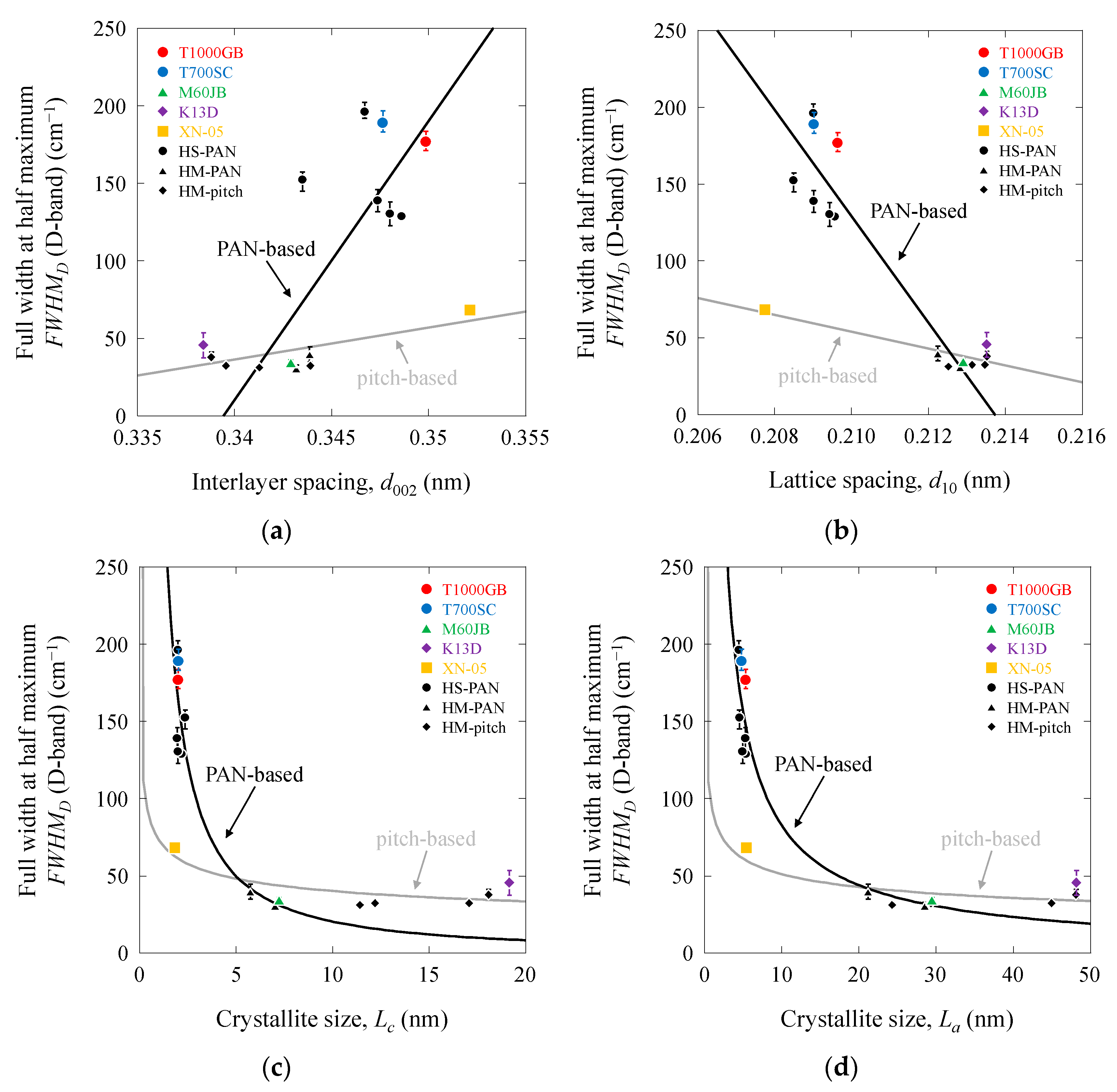

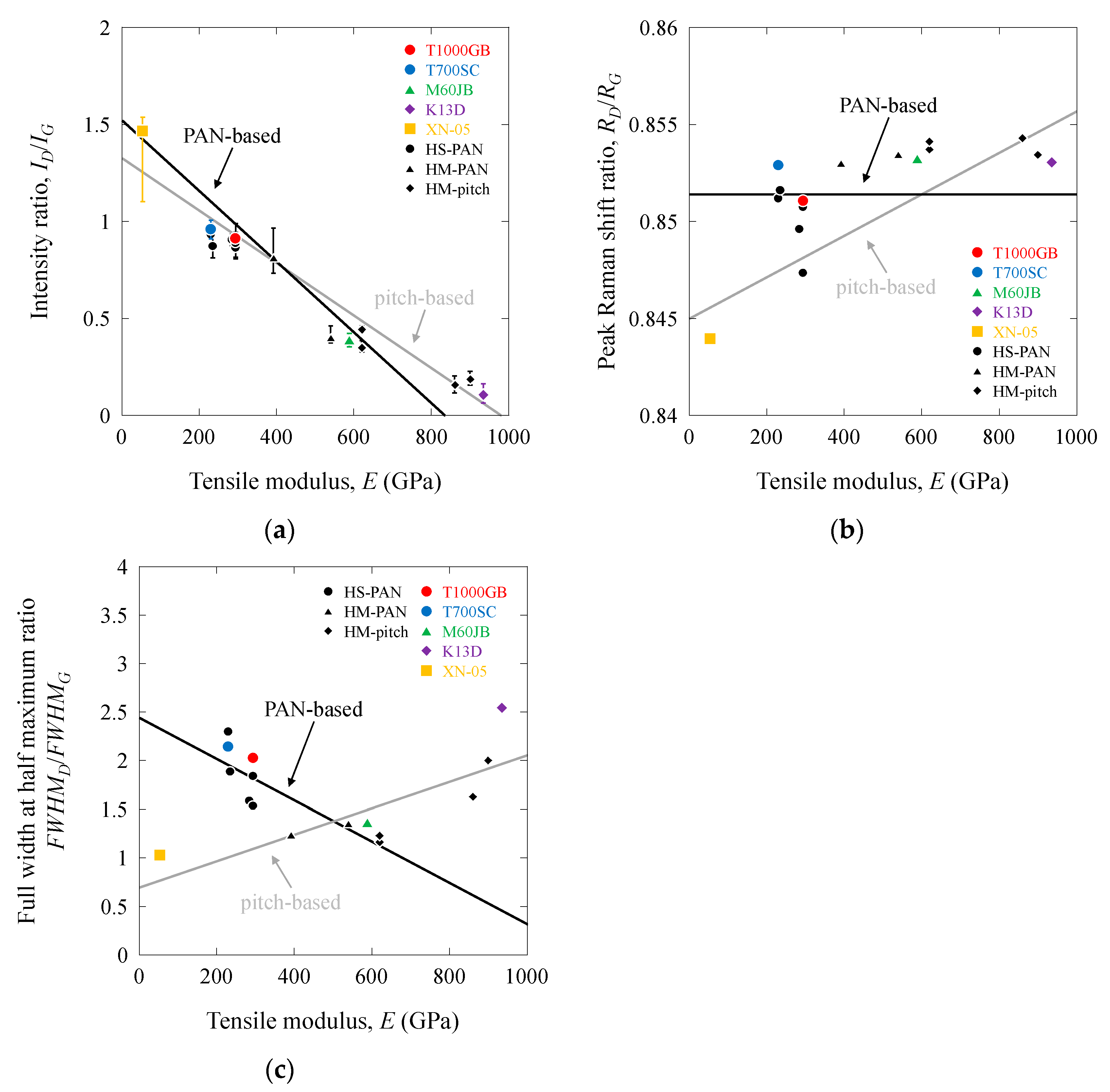

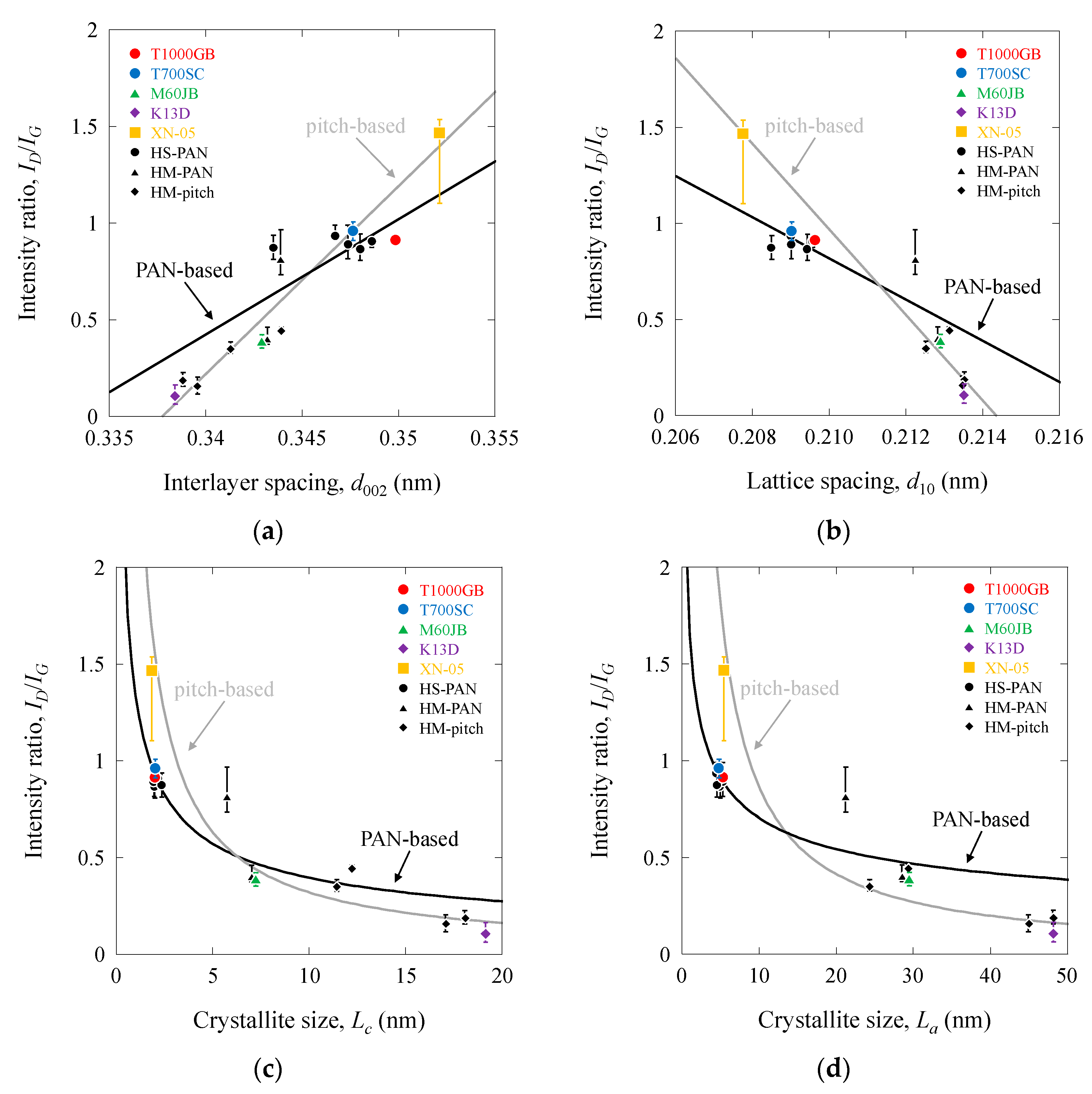

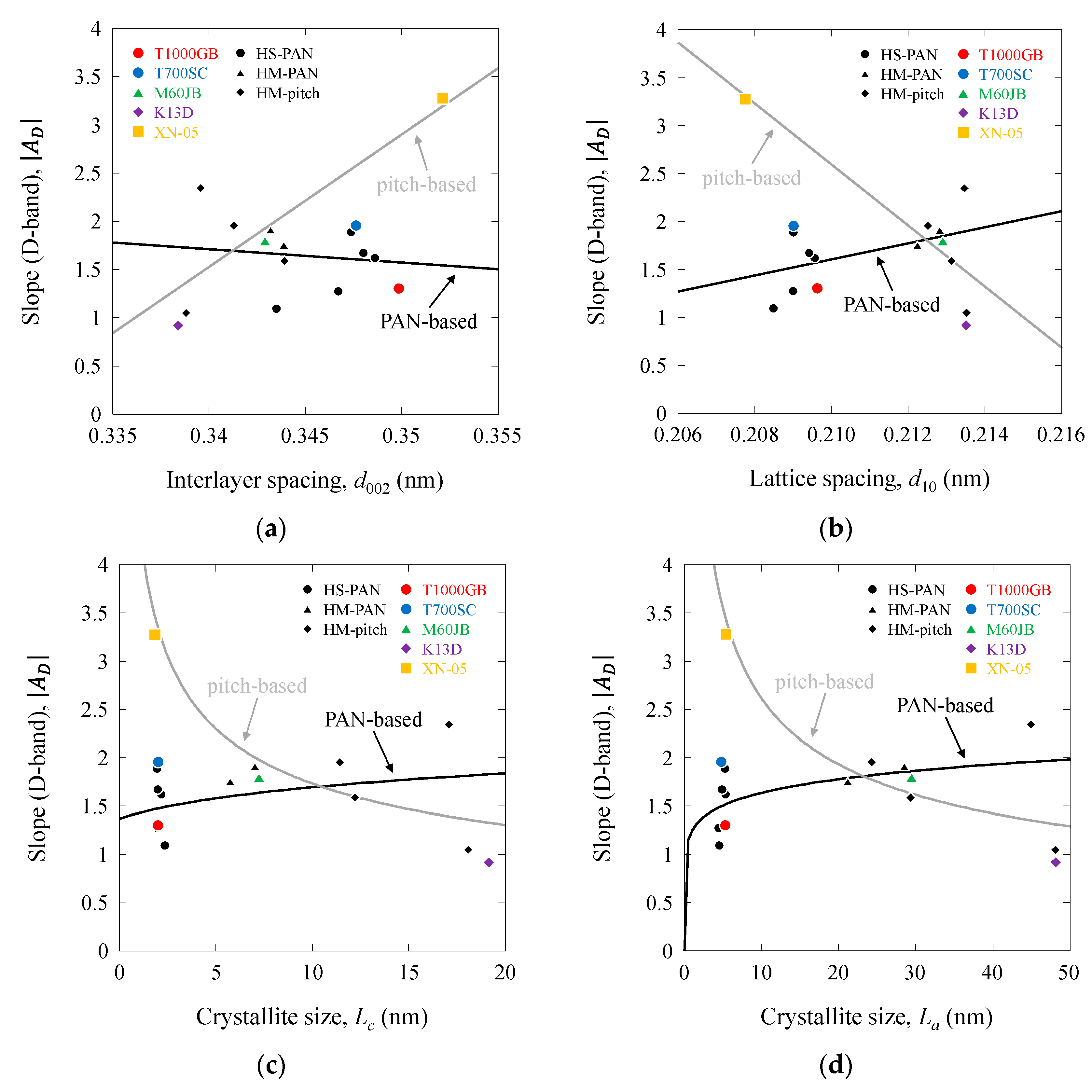

- The Raman scattering parameters and ratios for the G- and D-bands (peak values of Raman shifts RG, RD, full widths at half maximum FWHMG, FWHMD, intensity ratio ID/IG, peak value ratio RD/RG, and full widths at half maximum ratio FWHMD/FWHMG) were categorized according to the PAN-based and pitch-based carbon fibers and correlated with the tensile modulus E, interlayer spacing d002, lattice spacing d10, crystalline size, Lc and La. In addition, a linear relationship was observed between the Raman scattering parameters and ratios and E, d002, and d10. A linear relationship was also observed between ratios La and LC on a log–log scale. The lines for PAN-based and pitch-based carbon fibers intersected at 400–600 GPa.

- (2)

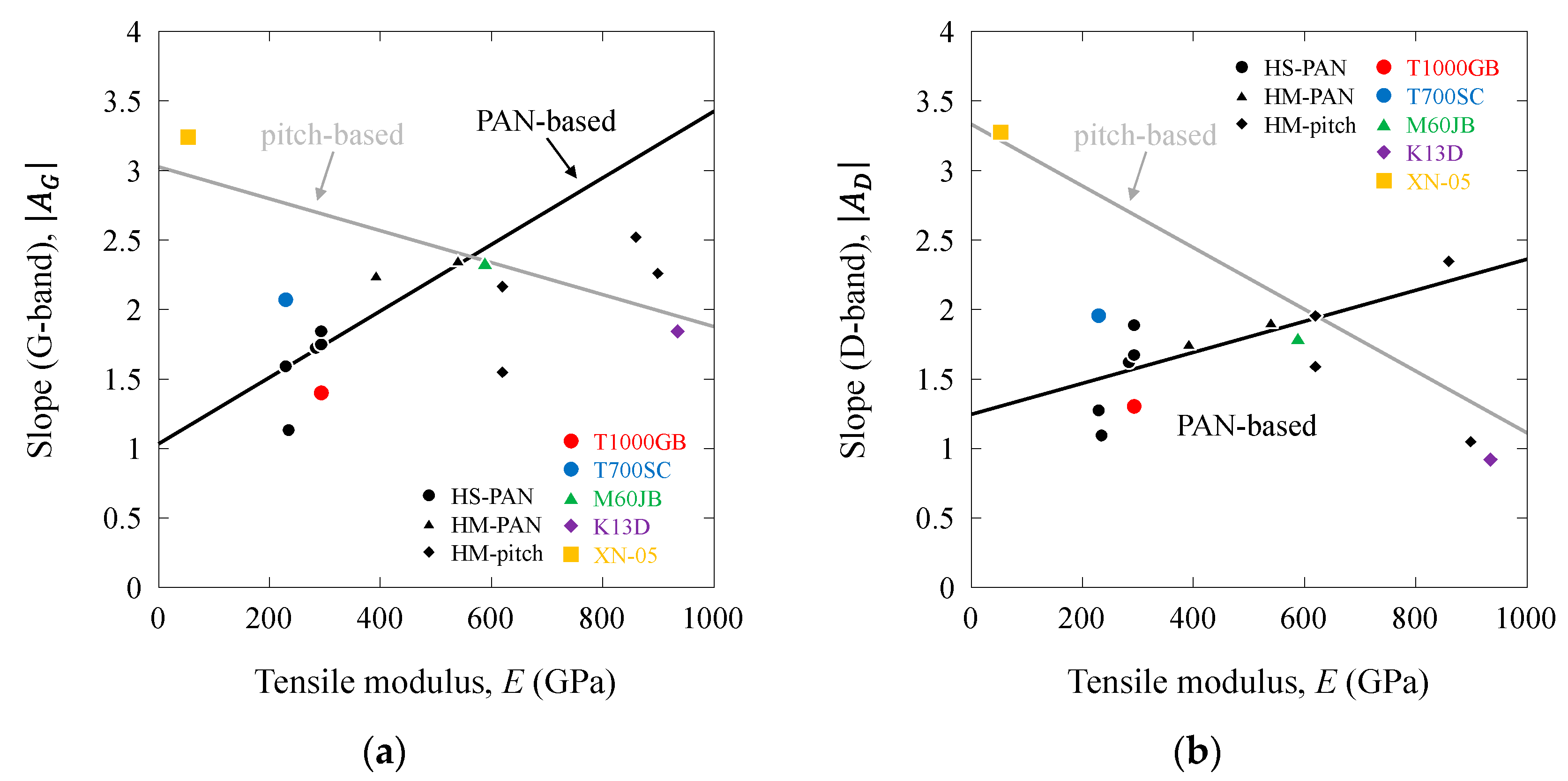

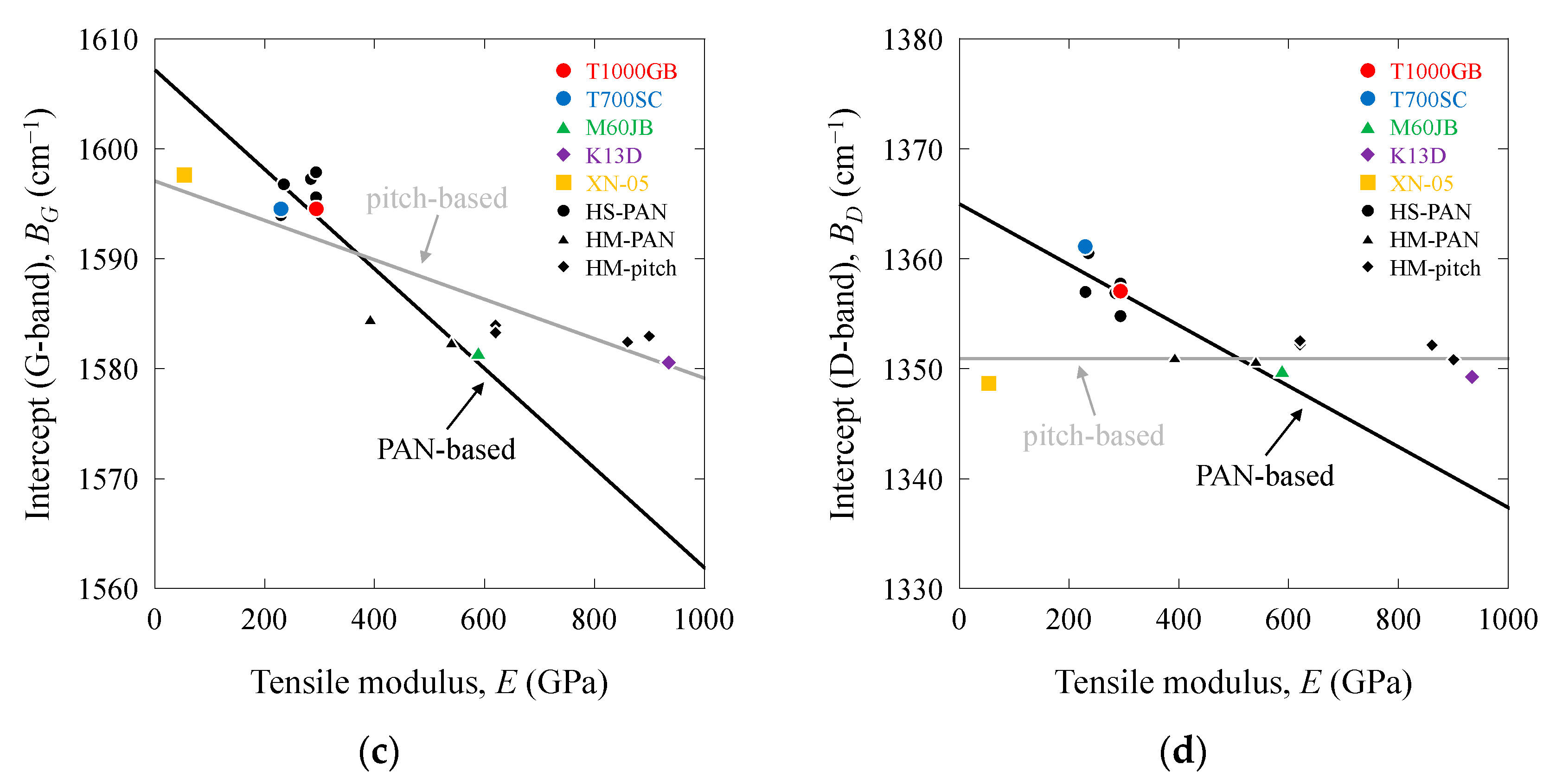

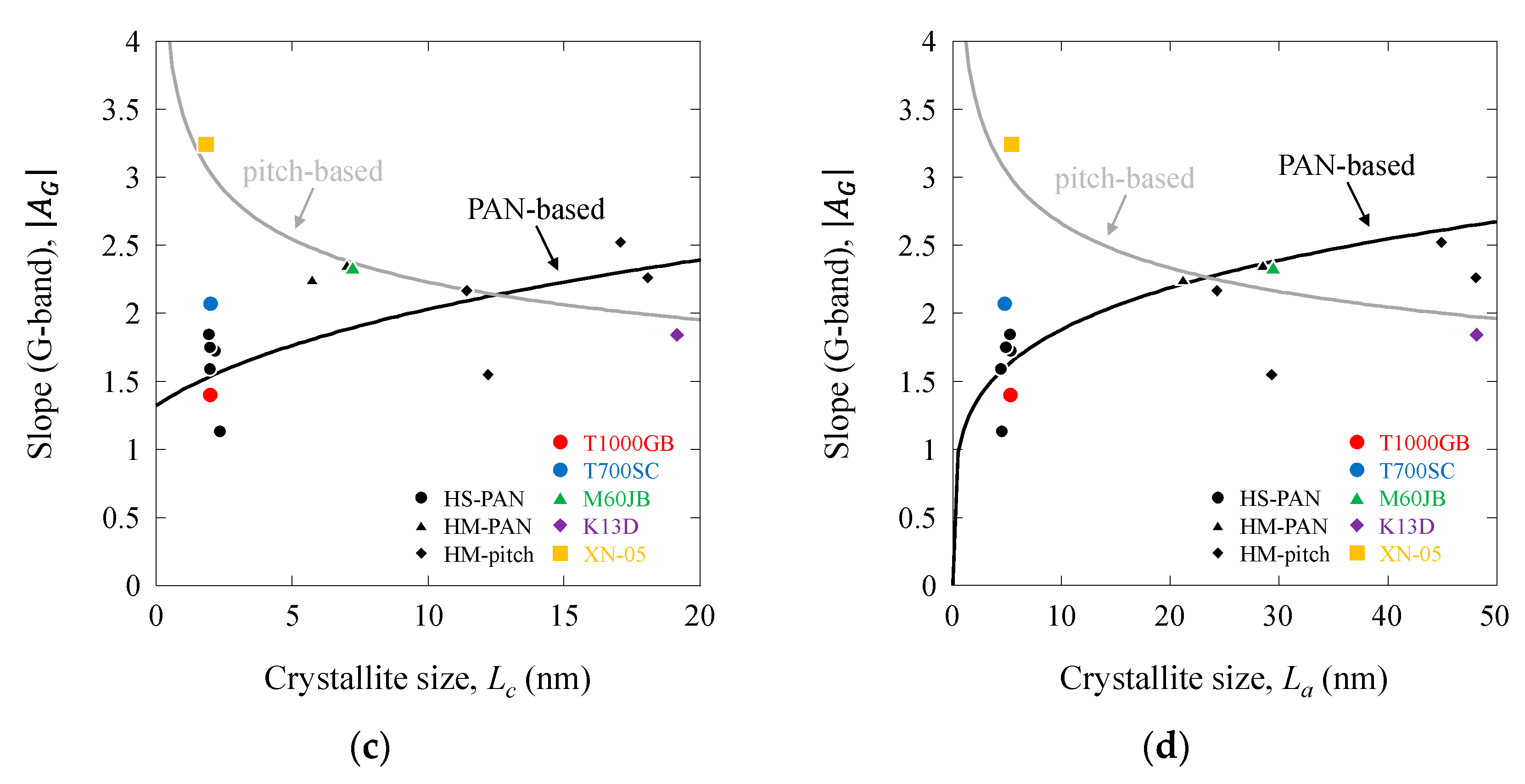

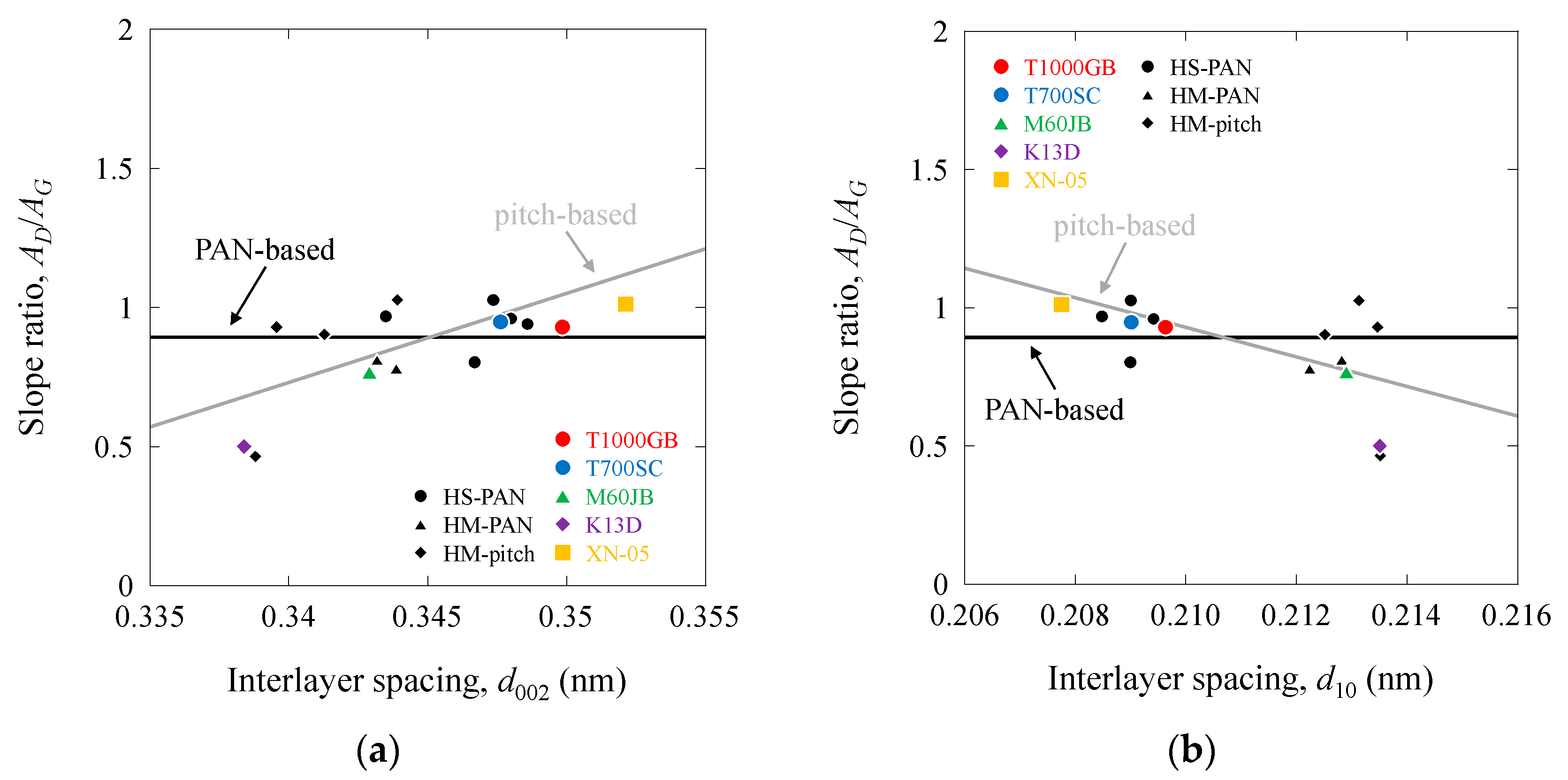

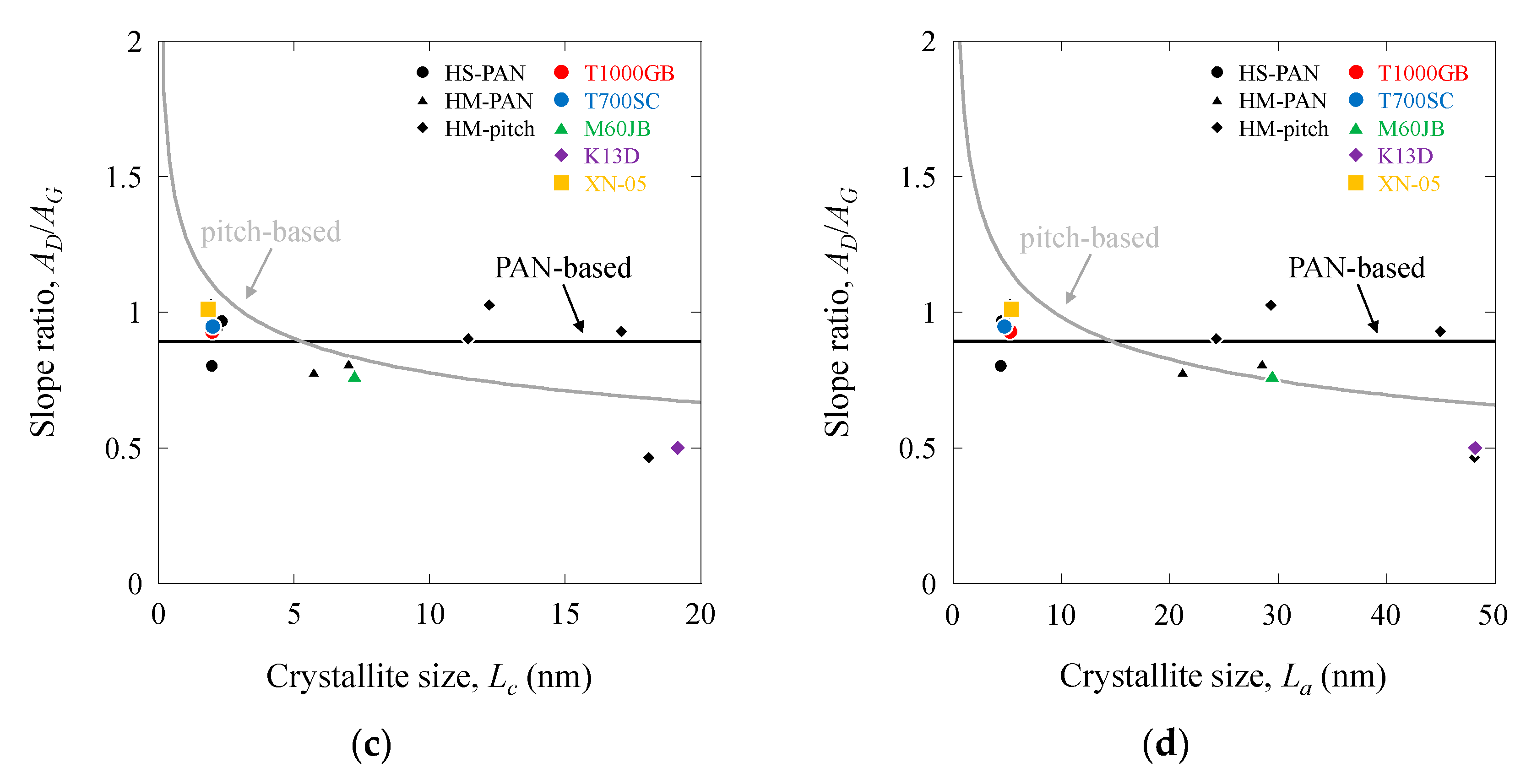

- The Raman stress measurement parameters and ratios for the G- and D-bands (peak values’ slopes |AG|, |AD|, peak value intercepts BG, BD, slope ratio AD/AG, and intercept ratio BD/BG) were categorized for PAN-based and pitch-based carbon fibers and correlated with the tensile modulus E, interlayer spacing d002, lattice spacing d10, crystalline size, Lc and La. In addition, a linear relationship was observed between the Raman stress measurement parameters and ratios and E, d002, and d10, as well as between these parameters and ratios and La and LC on the log–log scale. The lines for PAN-based and pitch-based carbon fibers intersected at 400–600 GPa.

- (3)

- All the Raman scattering and stress measurement parameters were found to be strongly correlated with the tensile modulus and structural parameters (as determined by X-ray diffraction). The tensile modulus and structural parameters could be roughly predicted from Raman scattering parameters. These correlations could be generalized to several types of PAN- and pitch-based carbon fibers, and these findings could be employed as a tool for non-destructive evaluation in the inspection and reliability assessment of carbon fiber composites.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fitzer, E. PAN-based carbon fibers-Present state and trend of the technology from the viewpoint of possibilities and limits to influence and to control the fiber properties by the process parameters. Carbon 1989, 27, 621–645. [Google Scholar] [CrossRef]

- Chand, S. Review-Carbon fibers for composites. J. Mater. Sci. 2000, 35, 1303–1313. [Google Scholar] [CrossRef]

- Naito, K.; Tanaka, Y.; Yang, J.M.; Kagawa, Y. Tensile properties of ultrahigh strength PAN-based, ultrahigh modulus pitch-based and high ductility pitch-based carbon fibers. Carbon 2008, 46, 189–195. [Google Scholar] [CrossRef]

- Naito, K.; Tanaka, Y.; Yang, J.M.; Kagawa, Y. The effect of gauge length on tensile strength and Weibull modulus of polyacrylonitrile (PAN)- and pitch-based carbon fibers. J. Mater. Sci. 2012, 47, 632–642. [Google Scholar] [CrossRef]

- Naito, K.; Tanaka, Y.; Yang, J.M. Transverse compressive properties of polyacrylonitrile (PAN)-based and pitch-based single carbon fibers. Carbon 2017, 118, 168–183. [Google Scholar] [CrossRef]

- Naito, K. Stress analysis and fracture toughness of notched polyacrylonitrile (PAN)-based and pitch-based single carbon fibers. Carbon 2018, 126, 346–359. [Google Scholar] [CrossRef]

- Shioya, M.; Takaku, A. Characterization of crystallites in carbon fibres by wide-angle X-ray diffraction. J. Appl. Cryst. 1989, 22, 222–230. [Google Scholar] [CrossRef]

- Takaku, A.; Shioya, M. X-ray measurements and the structure of polyacrylonitrile- and pitch-based carbon fibres. J. Mater. Sci. 1990, 25, 4873–4879. [Google Scholar] [CrossRef]

- Perret, R.; Ruland, W. Single and multiple X-ray small-angle scattering of carbon fibres. J. Appl. Crystallogr. 1969, 2, 209–218. [Google Scholar] [CrossRef]

- Shioya, M.; Takaku, A. Disorder in the layer stacking in carbon fibers. Carbon 1990, 28, 165–168. [Google Scholar] [CrossRef]

- Paris, O.; Loidl, D.; Peterlik, H.; Muller, M.; Lichtenegger, H.; Fratzl, P. The internal structure of single carbon fibers determined by simultaneous small-and wide-angle scattering. J. Appl. Crystallogr. 2000, 33, 695–699. [Google Scholar] [CrossRef]

- Johnson, D.J.; Crawford, D.; Jones, B.F. Observations of a three-phase structure in high-modulus PAN-based carbon fibres. J. Mater. Sci. 1973, 8, 286–290. [Google Scholar] [CrossRef]

- Guigon, M.; Oberlin, A.; Desarmot, G. Microtexture and structure of some high tensile strength, PAN-base carbon fibres. Fibre Sci. Technol. 1984, 20, 55–72. [Google Scholar] [CrossRef]

- Guigon, M.; Oberlin, A.; Desarmot, G. Microtexture and structure of some high-modulus, PAN-base carbon fibres. Fibre Sci. Technol. 1984, 20, 177–198. [Google Scholar] [CrossRef]

- Melanitis, N.; Tetlow, P.L.; Galiotis, C. Characterization of PAN-based carbon fibres with laser Raman spectroscopy. J. Mater. Sci. 1996, 31, 851–860. [Google Scholar] [CrossRef]

- Hao, X.; Lu, Y.; Zhao, W.; Qin, X. The effect of heat treatment temperature and time on the microstructure and mechanical properties of PAN-based carbon fibers. J. Mater. Sci. 2014, 49, 794–804. [Google Scholar] [CrossRef]

- Qian, X.; Wang, X.; Zhong, J.; Zhi, J.; Heng, F.; Zhang, Y.; Son, S. Effect of fiber microstructure studied by Raman spectroscopy upon the mechanical properties of carbon fibers. J. Raman Spectrosc. 2019, 50, 665–673. [Google Scholar] [CrossRef]

- Frank, O.; Tsoukleri, G.; Riaz, I.; Papagelis, K.; Parthenios, J.; Ferrari, A.C.; Geim, A.K.; Novoselov, K.S.; Galiotis, C. Development of a universal stress sensor for graphene and carbon fibres. Nat. Commun. 2011, 2, 255. [Google Scholar] [CrossRef]

- Tuinstra, F.; Koenig, J.L. Characterization of graphite fiber surfaces with Raman spectroscopy. J. Compos. Mater. 1970, 4, 492–499. [Google Scholar] [CrossRef]

- Okuda, H.; Young, R.J.; Wolverson, D.; Tanaka, F.; Yamamoto, G.; Okabe, T. Investigating nanostructures in carbon fibres using Raman spectroscopy. Carbon 2018, 130, 178–184. [Google Scholar] [CrossRef]

- Tuinstra, F.; Koenig, J.L. Raman spectrum of graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef]

- Mitra, V.K.; Risen, W.M., Jr.; Baughman, R.H. A laser Raman study of the stress dependence of vibrational frequencies of a monocrystalline polydiacetylene. J. Chem. Phys. 1977, 66, 2731–2736. [Google Scholar] [CrossRef]

- Wang, Y.; Alsmeyer, D.C.; McCreery, R.I. Raman spectroscopy of carbon materials: Structural basis of observed spectra. Chem. Mater. 1990, 2, 557–563. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095. [Google Scholar] [CrossRef]

- Huang, Y.; Young, R.J. Effect of fibre microstructure upon the modulus of PAN and pitch-based carbon fibres. Carbon 1995, 33, 97–107. [Google Scholar] [CrossRef]

- Galiotis, C.; Batchelder, D.N. Strain dependences of the first- and second-order Raman spectra of carbon fibres. J. Mater. Sci. Lett. 1988, 7, 545–547. [Google Scholar] [CrossRef]

- Robinson, I.M.; Zakikhani, M.; Day, R.J.; Young, R.J.; Galiotis, C. Strain dependence of the Raman frequencies for different types of carbon fibres. J. Mater. Sci. Lett. 1987, 6, 1212–1214. [Google Scholar] [CrossRef]

- Sakata, H.; Dresselhaus, G.; Dresselhaus, M.S.; Enda, M. Effect of uniaxial stress on the Raman spectra of graphite fibers. J. Appl. Phys. 1988, 63, 2769–2772. [Google Scholar] [CrossRef]

- Washer, G.G.; Blum, F., Jr. Raman spectroscopy for the nondestructive testing of carbon fiber. Adv. Mater. Sci. Eng. 2009, 2008, 693207. [Google Scholar] [CrossRef]

- ASTM C1557-20; Standard Test Method for Tensile Strength and Young’s Modulus of Fibers. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020. [CrossRef]

- Kumar, S.; Anderson, D.P.; Crasto, A.S. Carbon fibre compressive strength and its dependence on structure and morphology. J. Mater. Sci. 1993, 28, 423–439. [Google Scholar] [CrossRef]

- Johnson, W. The structure of PAN based carbon fibres and relationship to physical properties. In Strong Fibers; Watt, W., Perov, B.V., Eds.; Elsevier: Amsterdam, The Netherlands, 1985; Volume 1, pp. 389–443. [Google Scholar]

- Wagner, H.H.; Amer, M.S.; Schadler, L.S. Residual compression stress profile in high-modulus carbon fiber embedded in isotactic polypropylene by micro-Raman spectroscopy. Appl. Compos. Mater. 2000, 7, 209–217. [Google Scholar] [CrossRef]

| High-Strength PAN-Based | High-Modulus PAN-Based | High-Modulus Pitch-Based | High-Ductility Pitch-Based | ||

|---|---|---|---|---|---|

| T1000GB | T700SC | M60JB | K13D | XN-05 | |

| Density *1 ρf (g/cm3) | 1.80 | 1.80 | 1.93 | 2.20 | 1.65 |

| Tensile modulus *1 E (GPa) | 294 | 230 | 588 | 935 | 54 |

| Tensile strength σf (GPa) | 7.71 *2 (0.88) | 5.60 (0.67) | 4.60 *2 (0.56) | 4.00 *2 (0.82) | 1.34 *2 (0.17) |

| Diameter df (μm) | 5.03 (0.23) | 6.97 (0.52) | 5.13 (0.37) | 11.72 (0.36) | 9.64 (0.45) |

| Interlayer spacing d002 (nm) | 0.350 *3 | 0.348 *3 | 0.343 *3 | 0.338 *3 | 0.352 *3 |

| Lattice spacing d10 (nm) | 0.210 | 0.209 | 0.213 | 0.214 | 0.208 |

| Crystallite size Lc (nm) | 2.014 *3 | 2.033 *3 | 7.236 *3 | 19.159 *3 | 1.838 *3 |

| Crystalline size La (nm) | 5.331 | 4.797 | 29.474 | 48.181 | 5.440 |

| Peak Raman shift (G-band) RG (cm−1) | 1594.5 (1.1) | 1595.7 (0.9) | 1582.2 (0.6) | 1581.5 (0.5) | 1597.5 (0.2) |

| Peak Raman shift (D-band) RD (cm−1) | 1357.0 (1.2) | 1360.9 (1.3) | 1350.0 (0.8) | 1349.1 (0.8) | 1348.2 (0.3) |

| G-band full width at half maximum FWHMG (cm−1) | 87.4 (2.4) | 88.1 (3.4) | 25.2 (0.5) | 18.0 (0.6) | 66.4 (0.5) |

| D-band full width at half maximum FWHMD (cm−1) | 176.7 (3.6) | 188.7 (3.8) | 34.4 (0.6) | 45.9 (4.2) | 68.1 (0.5) |

| Peak Raman shift ratio RD/RG | 0.851 | 0.853 | 0.853 | 0.853 | 0.844 |

| Full width at half maximum ratio FWHMD/FWHMG | 2.023 | 2.142 | 1.367 | 2.545 | 1.027 |

| Intensity ratio ID/IG | 0.911 (0.014) | 0.959 (0.032) | 0.390 (0.018) | 0.106 (0.029) | 1.467 (0.109) |

| Slope, AG Slope, AD | −1.399 −1.299 | −2.067 −1.954 | −2.337 −1.795 | −1.840 −0.919 | −3.234 −3.273 |

| Intercept BG (cm−1) Intercept BD (cm−1) | 1594.5 1357.0 | 1594.5 1361.1 | 1581.5 1349.8 | 1580.6 1349.3 | 1597.6 1348.7 |

| Slope ratio AD/AG | 0.929 | 0.946 | 0.768 | 0.499 | 1.011 |

| Intercept ratio BD/BG | 0.851 | 0.854 | 0.854 | 0.854 | 0.844 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naito, K.; Nagai, C. Raman Scattering for Tensile Testing of Polyacrylonitrile-Based and Pitch-Based Single Carbon Fibers. Fibers 2024, 12, 88. https://doi.org/10.3390/fib12100088

Naito K, Nagai C. Raman Scattering for Tensile Testing of Polyacrylonitrile-Based and Pitch-Based Single Carbon Fibers. Fibers. 2024; 12(10):88. https://doi.org/10.3390/fib12100088

Chicago/Turabian StyleNaito, Kimiyoshi, and Chiemi Nagai. 2024. "Raman Scattering for Tensile Testing of Polyacrylonitrile-Based and Pitch-Based Single Carbon Fibers" Fibers 12, no. 10: 88. https://doi.org/10.3390/fib12100088

APA StyleNaito, K., & Nagai, C. (2024). Raman Scattering for Tensile Testing of Polyacrylonitrile-Based and Pitch-Based Single Carbon Fibers. Fibers, 12(10), 88. https://doi.org/10.3390/fib12100088