1. Introduction

Polypropylene (PP), as a thermoplastic polymer and polyolefin, is used in many industries. PP fibers are not only used in the textile industry [

1,

2]. The use of fiber-reinforced concrete in the construction industry has become very important [

3]. The application of PP fibers in construction as reinforcement in concrete already has a long history [

4,

5,

6,

7]. However, ways to overcome the disadvantages, such as the low affinity between the fibers and the cement matrix, are still being sought. Because of the non-polar, hydrophobic, physical, and chemical inactive polyolefin character of PP, PP does not allow intermolecular bonds between the fibers and the matrix. One of the ways to increase adhesion is the physical modification of PP fibers with inorganic nanoparticles.

Nanometer-sized particles used as nanoadditives are not new. In a number of industries, they have been used for the past 75–100 years [

8]. Inorganic nanoadditives, often referred to as nucleating agents, significantly affect the properties of filled polymers. However, it is very important that nanoparticles fulfill not only the function of fillers, but also other purposes for which they have been selected. Some nanoadditives have been used to improve the thermal stability and/or reduce the flammability of polymers. The nucleation effect of embedded nanoparticles and the polymer was observed from different perspectives. The choice of nanoadditive in this work was related to the direct improvement of the cement matrix.

In the construction industry, pozzolanic admixtures are used in concrete, and they are directly related to the properties of concrete because they participate in the pozzolanic reaction. Silica fume is an important inorganic additive to concrete and is also used in the modification of PP fibers. It is an active mineral addition that participates in pozzolanic reactions. The shapes of these additives look like balls in nano-dimensions [

9]. The second nanoadditive, which finds popularity in many applications, is halloysite nanotubes. They show a similar geometry to carbon nanotubes, but they are more ecofriendly. So, they have a future as a replacement for carbon nanotubes. Halloysite is an alkali aluminosilicate clayed mineral. Its structure and particle shape depend on the conditions of the formation, crystallization, and geological occurrence. For this research, we used halloysite nanotubes, which are ultrathin, long tubes with a diameter usually less than 100 nm. The external and internal structure is different. Its use has the potential to reduce and slow down the flammability of the material, improving the dispersibility. In addition, it is also undoubtedly used in biomedicine and other industries [

10,

11,

12]. That is why we chose it as one of the additive silica fumes (SFs), and the second was halloysite nanotubes (HNTs).

This entire work, from the selection of the nanoadditive to the evaluation of the adhesion of the modified fibers to the silicate matrix, was aimed at improving the industrial use of PP fibers in silicate composites. In the first step, it was necessary to focus on the preparation of the modified PP fibers with inorganic nanoadditives and the evaluation of their properties. Since the main task of this work was to improve the adhesion properties of PP fibers in regard to the cement matrix, it was necessary to evaluate possible changes in the adhesion between the PP or modified PP fibers and the cement matrix. The direct evaluation of the adhesion between the fibers and the cement matrix is exceedingly difficult. Therefore, the Washburn method was used to evaluate the adhesion between the fibers and the cement matrix, which allows the analysis of the absorption capacity of the unmodified and modified PP fibers. The Washburn method is based on a description of the absorption of various liquids into a porous material by means of capillary forces [

13,

14,

15]. Depending on the height of the liquid level, or weight in time, it is possible to determine the value of the contact angle, which characterizes the hydrophobicity or hydrophilicity of the monitored materials. The capillary effect, the ability of liquids to flow into small openings in solids, is caused by adhesion. The resulting force acting on the liquid in the capillary is given by the sum of the forces, namely the pressure force at the lower and upper interface, the viscous friction force, and the volume force due to gravity. The complicated equation of the balance of these forces can be stated simply if certain conditions are met:

At the beginning of the absorption, there is a high speed, which quickly slows down, and, therefore, a change in the dynamic contact angle to a static one can be assumed.

The radius of the capillary is very small.

Terms in the balance equation that reach relatively small values can be neglected.

As the model of thin capillaries is based on the above-mentioned simplifications, the balance equation for the acting forces can be written in the following form:

where

σl is the surface tension of the liquid used,

θ is the contact angle,

ρ is the density of the liquid,

R is the radius of the tube,

h is the height of the liquid level in the tubes, μ is the viscosity of the liquid, and

g is the gravitational acceleration.

By neglecting the second inertial term and substitution, the given equation can be written in the following form:

where

and

For easier measurement of the absorbed weight, not the height of the liquid level, the equation can be adjusted to the following form:

where

and

The terms of the equation are as follows: ϵ is the porosity, S0 is the specific surface of the material with the unit m−1, ρ is the density of the liquid, Ω is the total area of the tube filled with porous material, σl is the surface tension of the liquid, θ is the contact angle, μ is the dynamic viscosity, Rs is the mean static radius, and g is the gravitational acceleration.

With further modifications, it is possible to express the dependence of

m(t) using the Lambert

W function which is part of various fitting programs:

From the measured dependence of

m(t), it is possible to obtain the parameter

A, which includes the desired contact angle. The parameter

A is called the specific rate of absorption capacity; it has the unit kg

2·s

−1. Since the specific absorption rate includes the influence of the porosity of the given sample, which is undesirable, it is advisable to introduce a standardized specific absorption rate:

where by further substitution of

and modification, the following equation can be obtained:

Then, it is necessary to experimentally determine the dependence of

and identify its maximum. The surface tension of the liquid with the largest value of

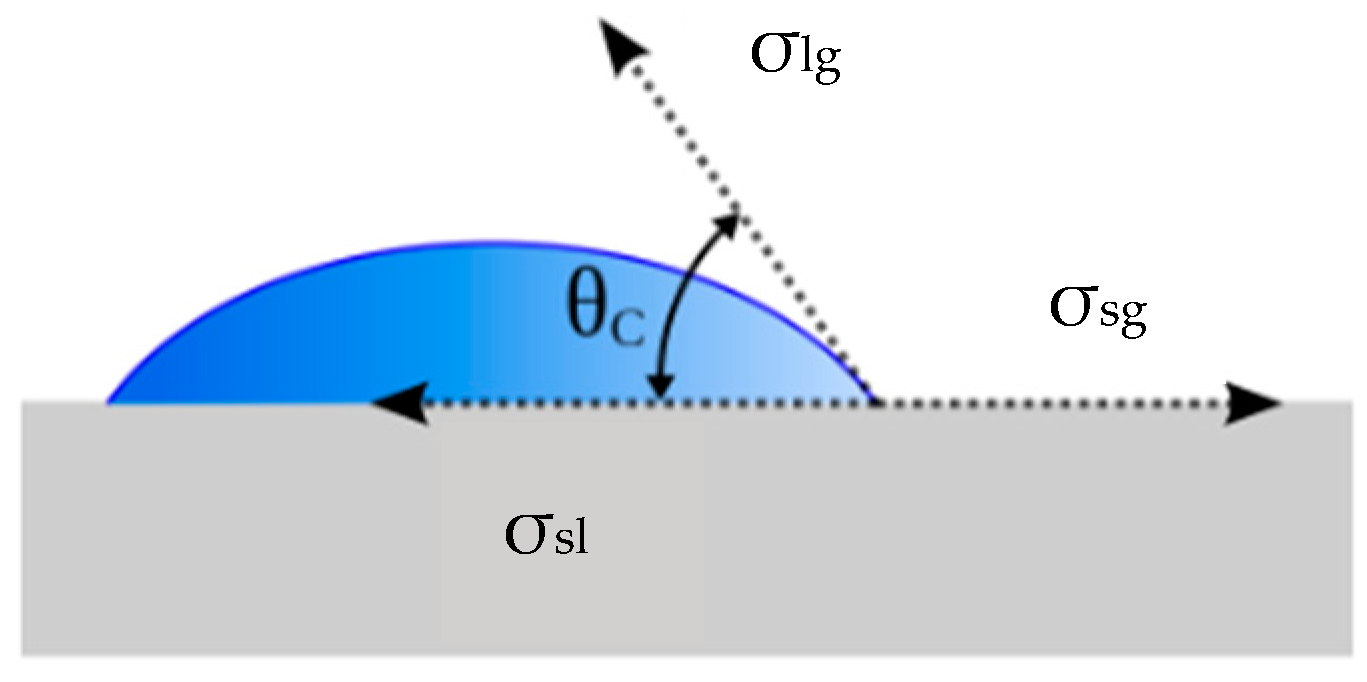

corresponds to the surface energy of the substrate (

) (

Figure 1). Based on this procedure, the value of the contact angle of the substrate can be determined for any liquid [

16].

The results of this work demonstrate the method of evaluating the sorption of modified PP fibers. The fibers were modified in order to improve the properties of silicate composites. The evaluation of the achieved change in the sorption capabilities of modified PP fibers had to be evaluated in the first step without using silicate composites in laboratory conditions. Based on other research, we decided to use the Washburn method.

2. Materials and Methods

Isotactic polypropylene TATREN HT 2511 (PP, produced by Slovnaft Co., Bratislava, Slovakia) was prepared using a Ziegler–Natta catalyst with melt flow index MFI = 25 g/10 min.

Tegopren 6875 (TEG, produced by Evonik Industries AG, Essen, Germany) organomodified siloxane was used as a dispersant.

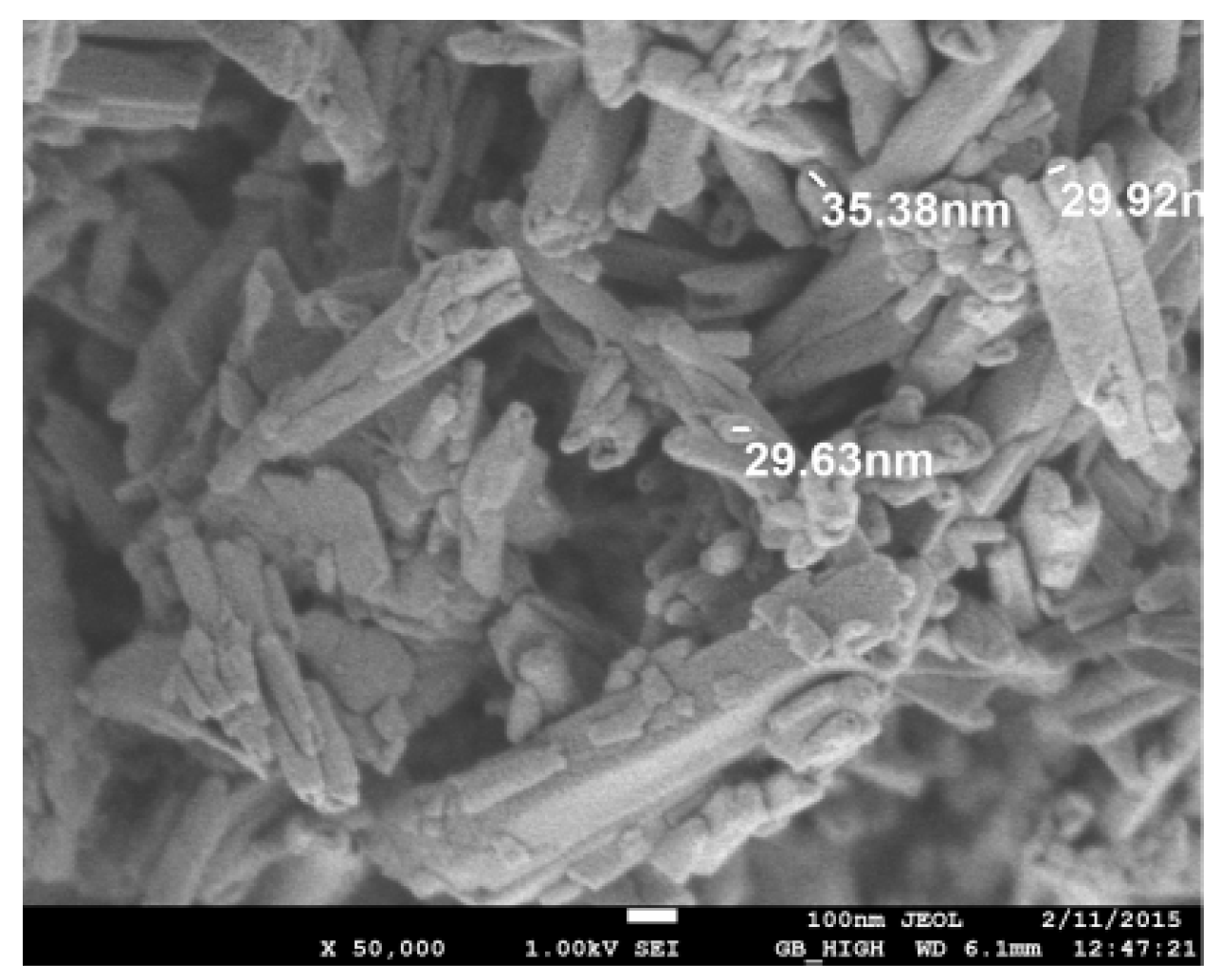

Halloysite nanotubes (HNTs, produced by Aldrich Chemistry, St. Louis, MO, USA), Al

2Si

2O

5(OH)

4.2H

2O, with a molecular weight of 294.19 g·mol

−1, diameter of 30–70 nm, length of 1–3 μm, and surface area of 64 m

2·g

−1 (

Figure 2), were used as a nanoadditive.

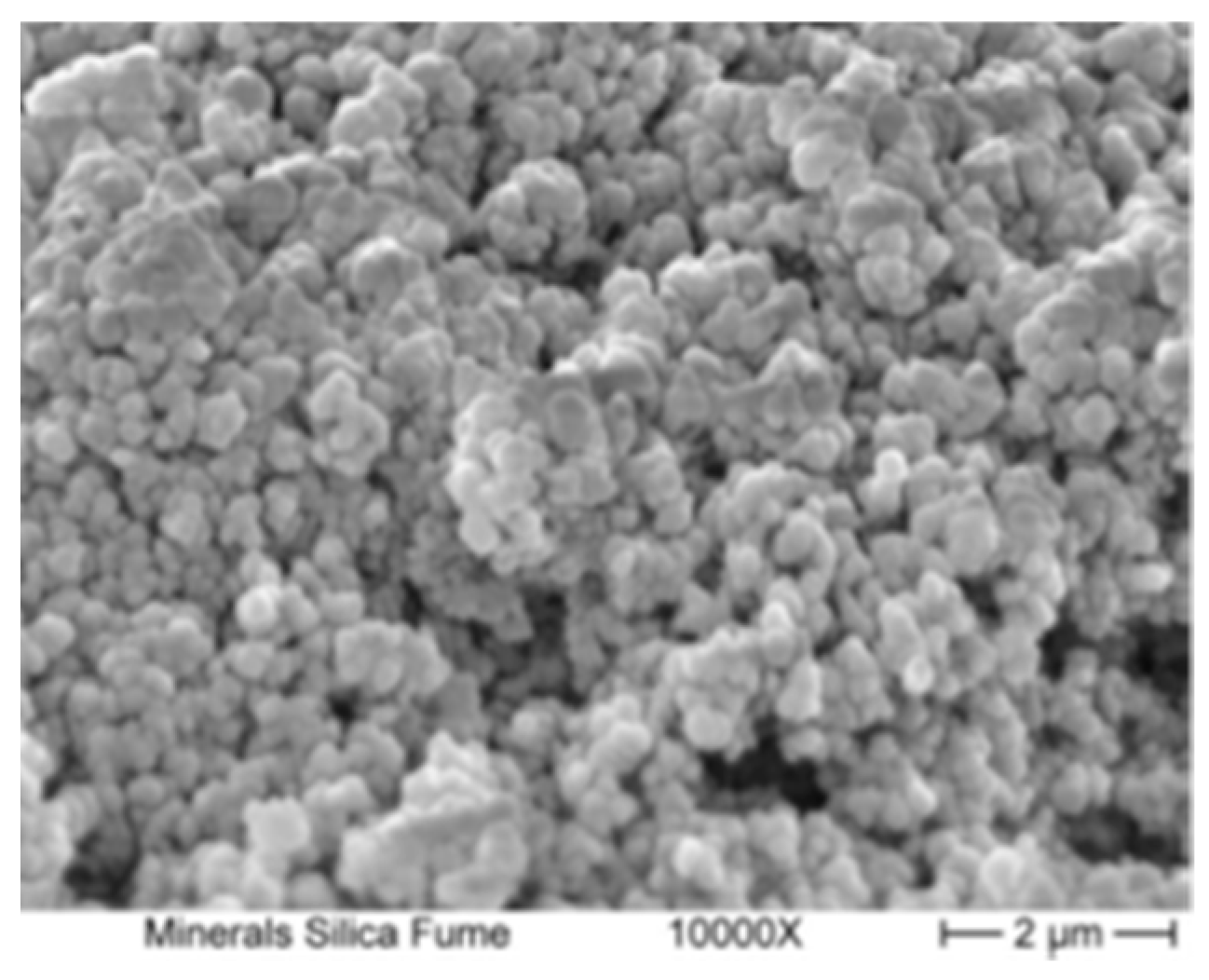

Silica fume with the commercial name SOCAL 22S (SF, Evonik Industries AG, Germany), amorphous SiO

2 as a powder with spherical particles with a diameter of 13.5 nm and a specific surface area of 190 m

2·g

−1, was used as a nanoadditive (

Figure 3).

PP pellets with the selected nanoadditives and dispersant were mechanically mixed. The prepared blends were melted before spinning so that the nanoadditive particles were dispersed as evenly as possible in the sample. Melting was performed on a LabTech Engineering Company Ltd. twin-screw extruder (Phraeksa, Thailand) with the following parameters: L/D ratio, 40; screw diameter, 16 mm; screw speed, 100 rpm. The extruder string of PP blends was cooled and pelletized.

Pure PP and prepared blends of modified PP were spun using the pilot continual laboratory spinning line. The pinning conditions were as follows: spinning temperature, 240 °C; extruder speed, 60 rpm; number of nozzle openings, 13; take-up speed, 150 m·min−1. The non-oriented fibers were subsequently drawn, axial deformation at the maximum drawing ratio λmax, at the drawing temperature of 120 °C. So, the modified oriented PP fibers were prepared.

Table 1 shows the composition of the prepared fibers. Based on the evaluated properties of these fibers, PP fibers with halloysite with a determined composition for the Washburn method were prepared.

Table 2 shows the composition of the prepared PP and modified PP fibers with halloysite and silica fume which were used for determining the adsorption capacity by using the Washburn method.

2.1. Macromorphological Structure of Fibers

The surface of the prepared modified PP fibers was evaluated by high-resolution X-ray SEM analysis using a JEDL JSM—7500F.

2.2. Orientation of Fibers

The essence of determining the orientation of fibers is the measurement of the speed of sound in a fiber. The factor of the average orientation is dependent on the internal structure arrangement of fibers (expressed by a super-molecular structure parameter) and indicates the measure of fiber anisotropy. The sound speed in PP and modified PP fibers was measured using a PPMSR Dynamic Modulus Tester (H.M. Morgan Co., Inc., Cambridge, MA, USA).

The factor of the average orientation of fibers is determined according to the following relationship:

where

fɑ is the average fiber orientation,

Cn is the sound speed in a completely unoriented fiber, and

C is the sound speed in the investigated fiber. The value of

Cn for unoriented PP fiber is 1.6 km·s

−1.

2.3. Mechanical Properties

Mechanical properties are represented by tenacity and elongation at break and Young’s modulus. These properties were evaluated for prepared pure PP and modified PP fibers and were evaluated using an Instron 3343 instrument (Norwood, MA, USA). The following measuring conditions were set: length of fiber, 125 mm; rate of clamp, 300 mm·min−1. The mechanical characteristics of pure PP and modified PP fibers were determined in accordance with Standard ISO 2062:1993, which states that the fibers must be broken in a specified time, and this corresponds to the set rate of the clamp.

2.4. Thermomechanical Properties

Thermomechanical characteristics such as the deformations (shrinkage, %) of the fibers were measured. The thermomechanical properties of pure PP and modified PP fibers were measured using a Shimadzu TMA-50 (Kyoto, Japan). The conditions of measurement were established in a temperature range where the temperature increased from room temperature to 110 °C at the heating rate of 5 °C·min−1, and the fiber length was 9.8 mm at constant load. The dependence of the dimensional stability of the fiber on the temperature was obtained, from which the thermomechanical characteristics were determined.

2.5. Liquid Absorption Capacity of Fibers

Using Adventurer AX324 scales from OHAUS, the dependence of the weight of the liquid absorbed into the fibers on time was measured. The essence of the method of assessing the liquid absorption capacity of fibers is the so-called Washburn method of soaking the fibers. The mathematical model is based on a description of the balance of forces acting in the capillary under certain conditions. Subsequently, the value of the specific rate of absorption capacity An was calculated from the measured dependence of the mass of the liquid versus time using the computer program Excel.

3. Results and Discussion

The main task was to find a method for evaluating the adhesion of PP and modified PP fibers to a cement matrix without preparing concrete blocks. We used the Washburn method to determine the absorption capacity of the prepared fibers. We evaluated three fibers: one pure PP fiber and two modified PP fibers with halloysite and silica fume.

The results of the work [

17] show that the nanoadditive of silica fume in different quantities differently changed the mechanical as well as thermomechanical properties of PP fibers. The best improvement of the properties of modified PP fibers with different compositions of prepared modified fibers, even compared to pure PP fibers, was achieved with the use of the dispersant Tegopren. The inorganic nanoadditive of silica fume together with the dispersant Tegopren also improved evaluated mechanical properties such as tenacity, Young’s modulus, and sorption. In the DOEs, we obtained the composition of modified PP fibers, which should have the optimal properties for use in silicate composites. Based on the results, it can be held that the fibers with the inorganic filler can be produced with the required mechanical and thermomechanical properties, which may provide a pozzolanic reaction in the concrete, thereby improving the endpoint of the concrete. The impact assessment of the application of the prepared fibers in concrete is the task of another study. Therefore, the composition of the prepared modified PP fiber with silica fume, which was used to evaluate the sorption capacity using the Washburn method, was calculated using statistical optimization and was determined based on previous results published in the work [

17].

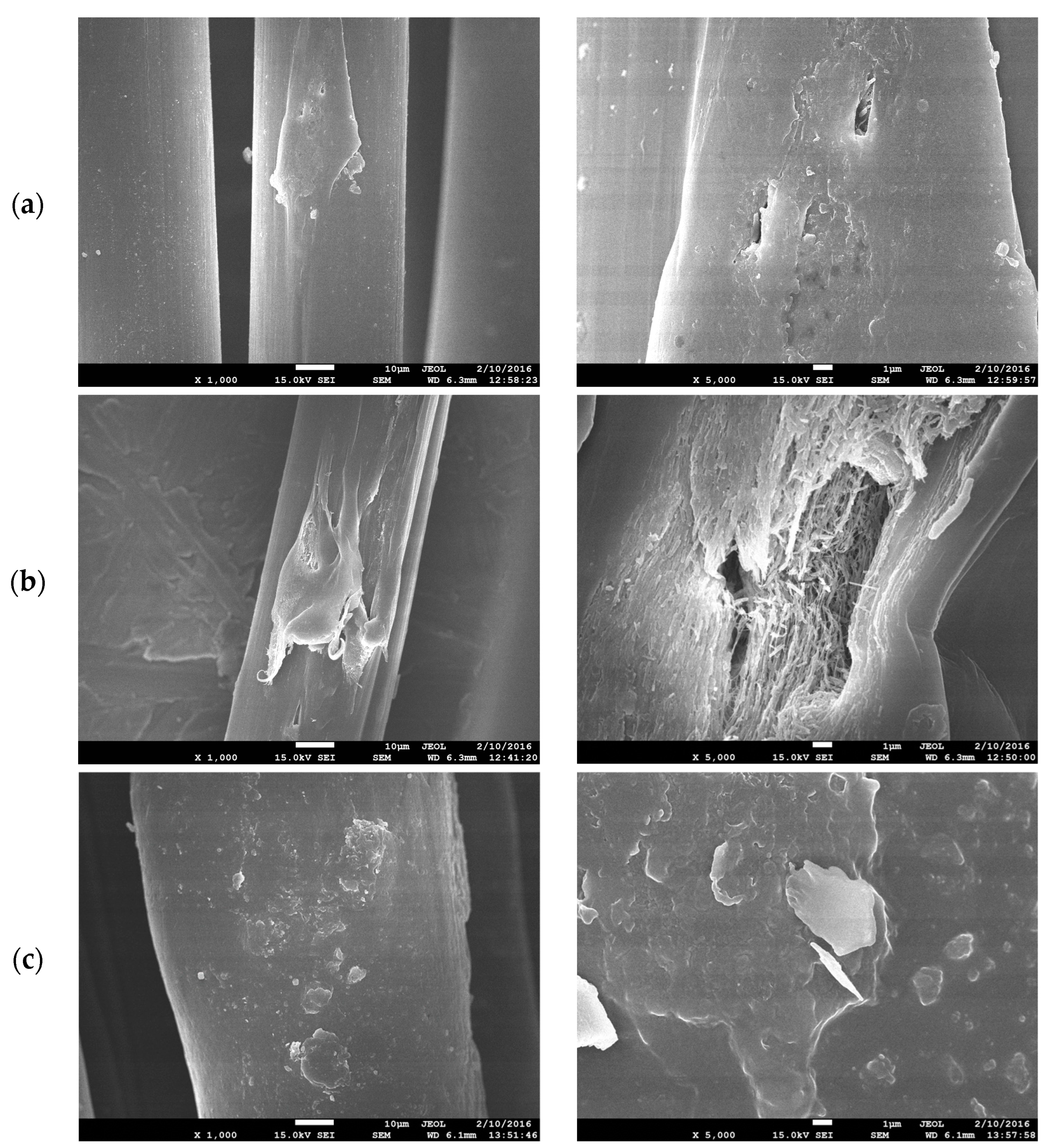

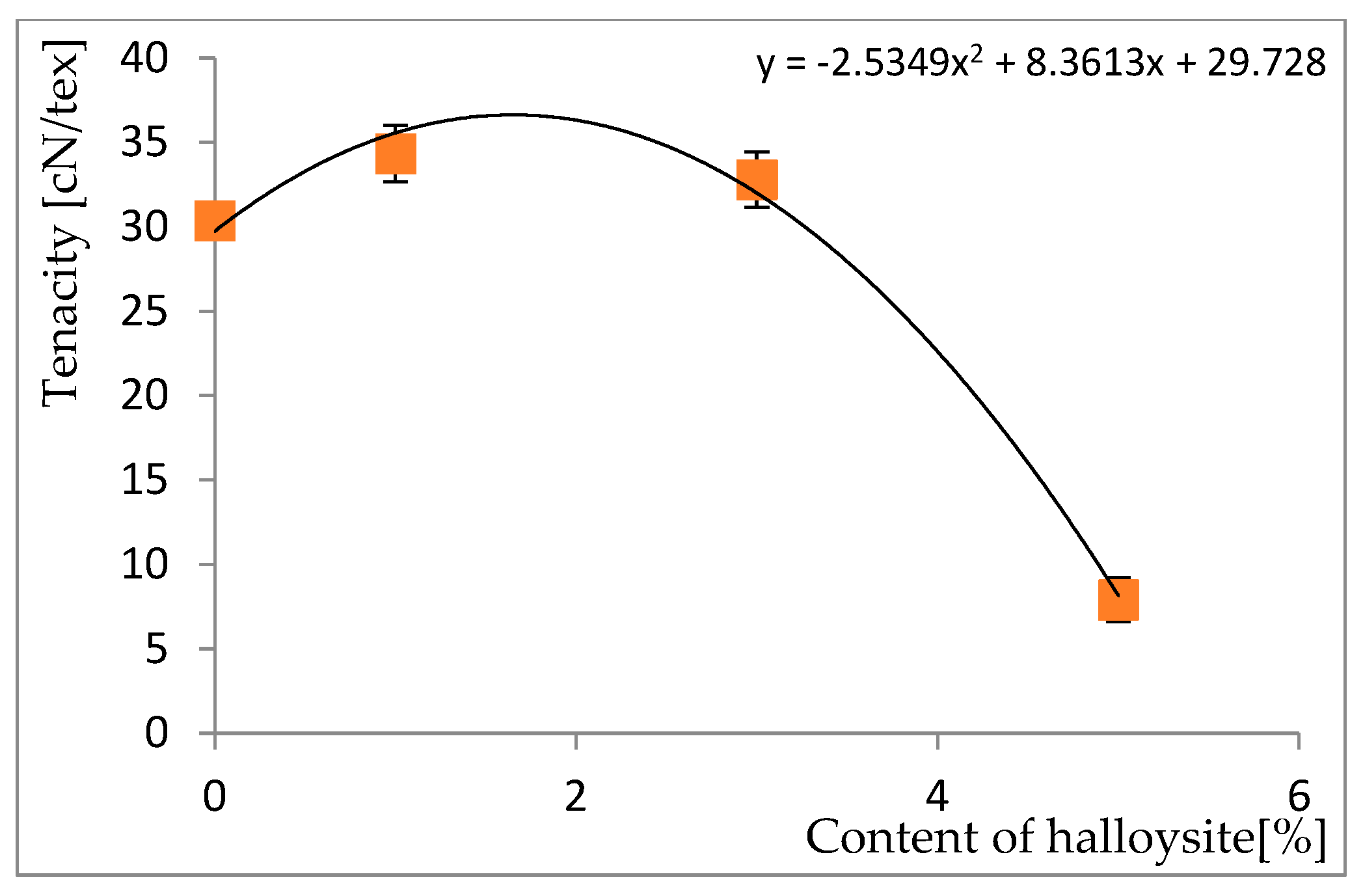

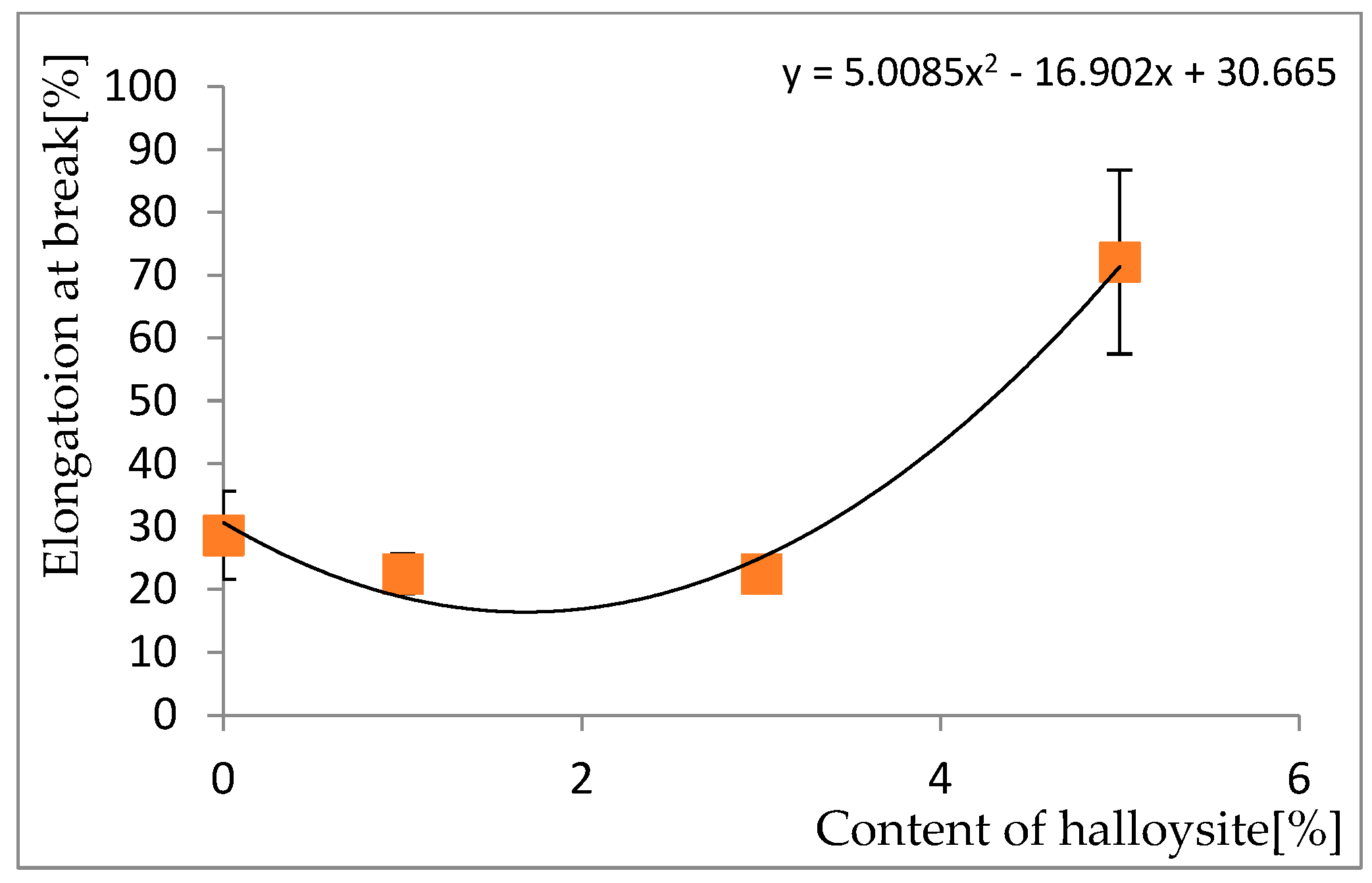

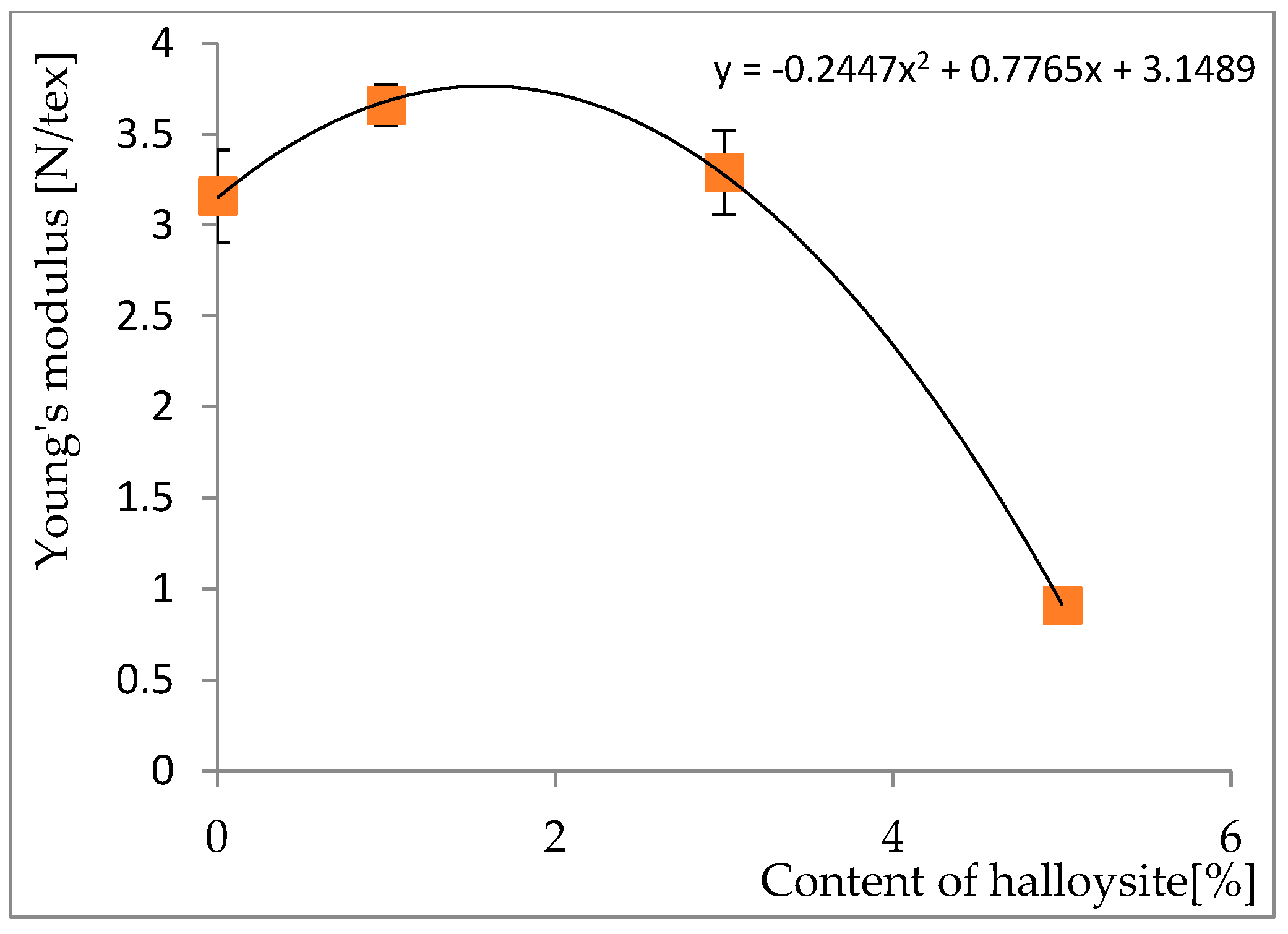

On the contrary, the calculation of the composition of modified PP fiber with halloysite was part of this work. Three fibers with different contents of halloysite were prepared, the supramolecular structures were evaluated by surface structure analysis based on SEM images (

Figure 4), and the mechanical properties (tenacity and elongation at break, Young’s modulus) (

Figure 5,

Figure 6 and

Figure 7) were determined.

We evaluated the surface structure of the PP/HNT/TEG fiber using SEM images (

Figure 4). It can be seen from the images that the nanoadditive content of 3% more significantly disrupts the surface structure of the modified PP fibers. It is possible to observe places with larger deficits, which may be caused by the agglomeration of particles at a higher nanoadditive content. The most homogeneous structure was achieved with PP/HNT/TEG fiber with 1% and 5% halloysite. But for 5%, there are more particles on the surface compared to the lower content of nanoparticles. At lower concentrations, ruptures occurred more often where there was a higher content of halloysite. At 5% halloysite, the particles were distributed more evenly in the mass.

Furthermore, the mechanical properties were evaluated, representing tenacity and elongation at break and Young’s modulus (

Figure 5,

Figure 6 and

Figure 7). The evaluation of the mechanical properties allowed us to unequivocally confirm that the halloysite content of 5% led to a significant deterioration of the properties compared to pure PP fiber, as well as compared to modified fibers with a lower content of the nanoadditive. At 3%, there is only a small decrease in tensile strength or Young’s modulus and an increase in elongation at break. Based on the obtained results for modified PP fibers with halloysite with different contents, it was concluded that modified PP fiber with 1% halloysite would be prepared for the analysis of absorption capacity using the Washburn method, as it obtained the smallest decrease in the observed properties in comparison with pure PP fiber. The course of dependence for individual properties can be described by mathematical equations, which are shown in individual figures.

The entire work was focused on the modification of PP fibers with the intention of improving silicate composites. Therefore, we decided to use the Washburn method to compare the sorption capabilities of pure PP fiber with those of modified PP fibers. The mathematical model of the Washburn method of soaking fibers is based on the description of the balance of forces acting in the capillary under certain assumptions.

In the next step, we prepared pure and modified PP fibers, which we then analyzed. Before measuring the absorption capacity of the prepared PP fibers using the Washburn method, we measured the speed of sound propagation in the fibers and evaluated the factor of the average orientation of these fibers. Subsequently, we measured mechanical properties such as tenacity and elongation at break and Young’s modulus. Finally, we measured the thermomechanical stability of the prepared pure and modified PP fibers, i.e., the shrinkage of these PP fibers (

Table 3).

The factor of the average orientation of the modified PP fibers decreased compared to that of the pure PP fiber. We recorded a decrease in all measured properties of modified PP fibers compared to pure PP fiber. Although there was a greater decrease in some properties for the halloysite-modified fibers, for elongation at break and shrinkage, there were greater changes in the silica-fume-modified fibers. The decrease in the orientation factor or mechanical properties of modified fibers is caused by the added nanoadditive. The nanoadditive can be unevenly dispersed in the mass, which leads to the deterioration of some properties compared to pure PP fibers. And the geometry of the nanoparticles affects the change in properties. While shrinking, the nanoadditive showed a positive effect because there was a smaller dimensional change. Nanoadditives prevent macromolecular chains from organizing themselves into the most energetically suitable form—a statistical ball—and thus exhibit their elastic behavior.

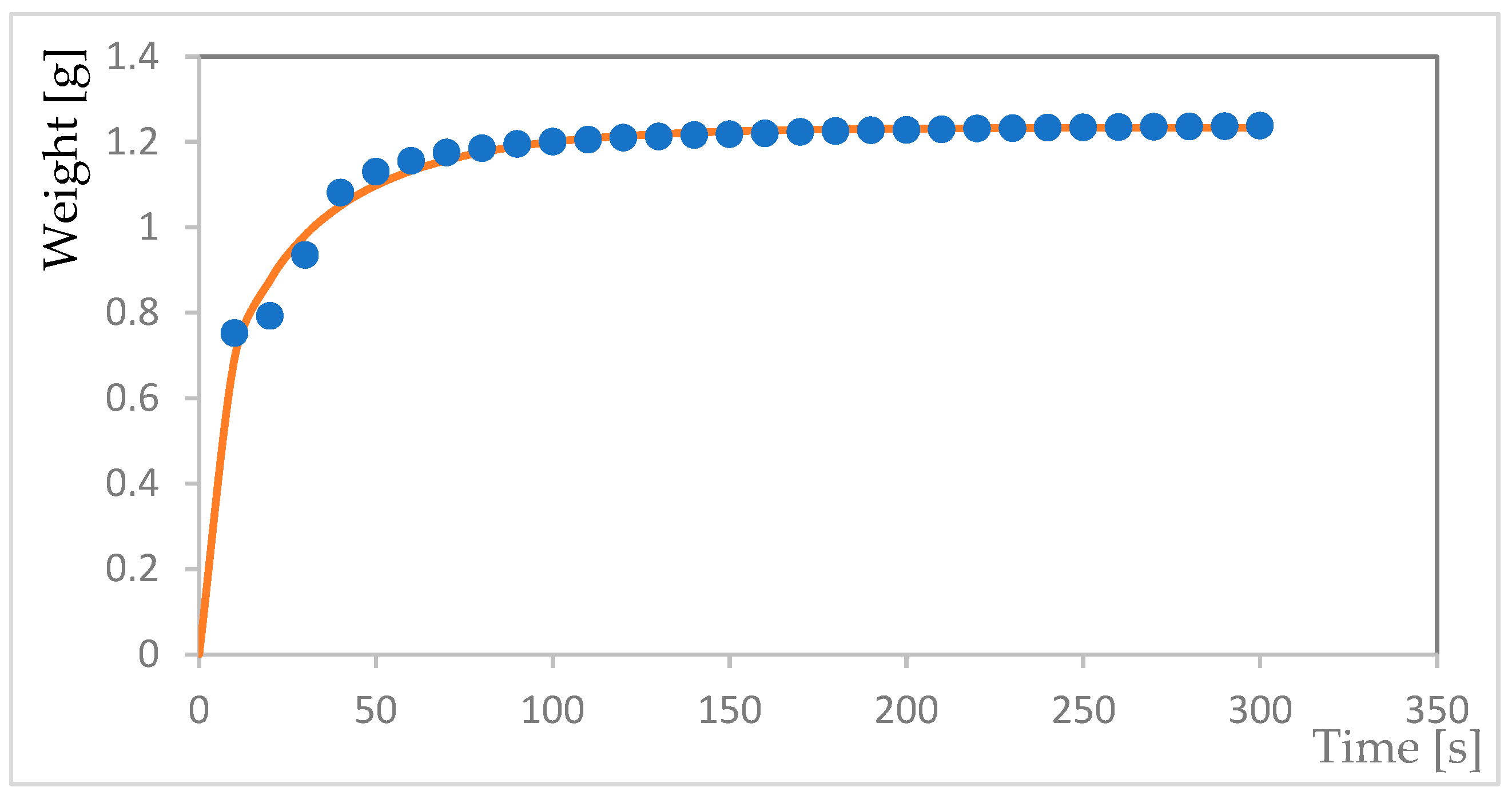

Before analysis, the fibers were cut to the same length and inserted into a glass tube with a length of 5 cm and a diameter of 0.8 cm. The samples prepared in this way were placed in the holder of the Adventurer AX 324 analytical balance. At the same time, we prepared different liquids, which were successively used to measure the dependence of the weight of the soaked liquid in PP and modified PP fibers. At the beginning of the measurement, the prepared sample approached the level of the liquid. We recorded the increase in the weight of the soaked liquid every 10 s, for a period of 300 s. Three replicate measurements were performed for each fiber and each liquid. Subsequently, from the measured dependence of the weight of the liquid on time, using the computer program Excel, we calculated the values of the specific rate of absorption capacity An for all prepared fiber samples.

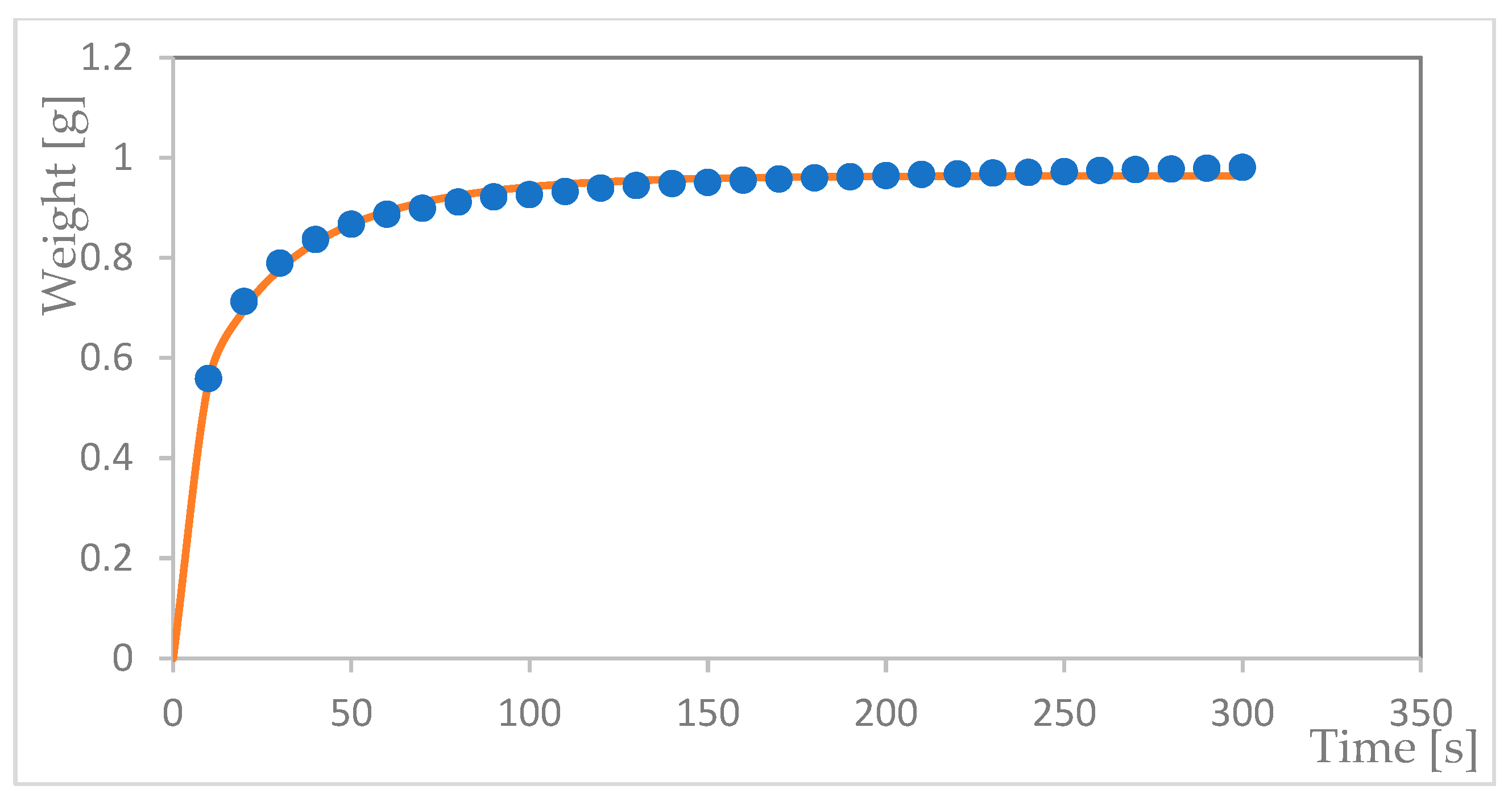

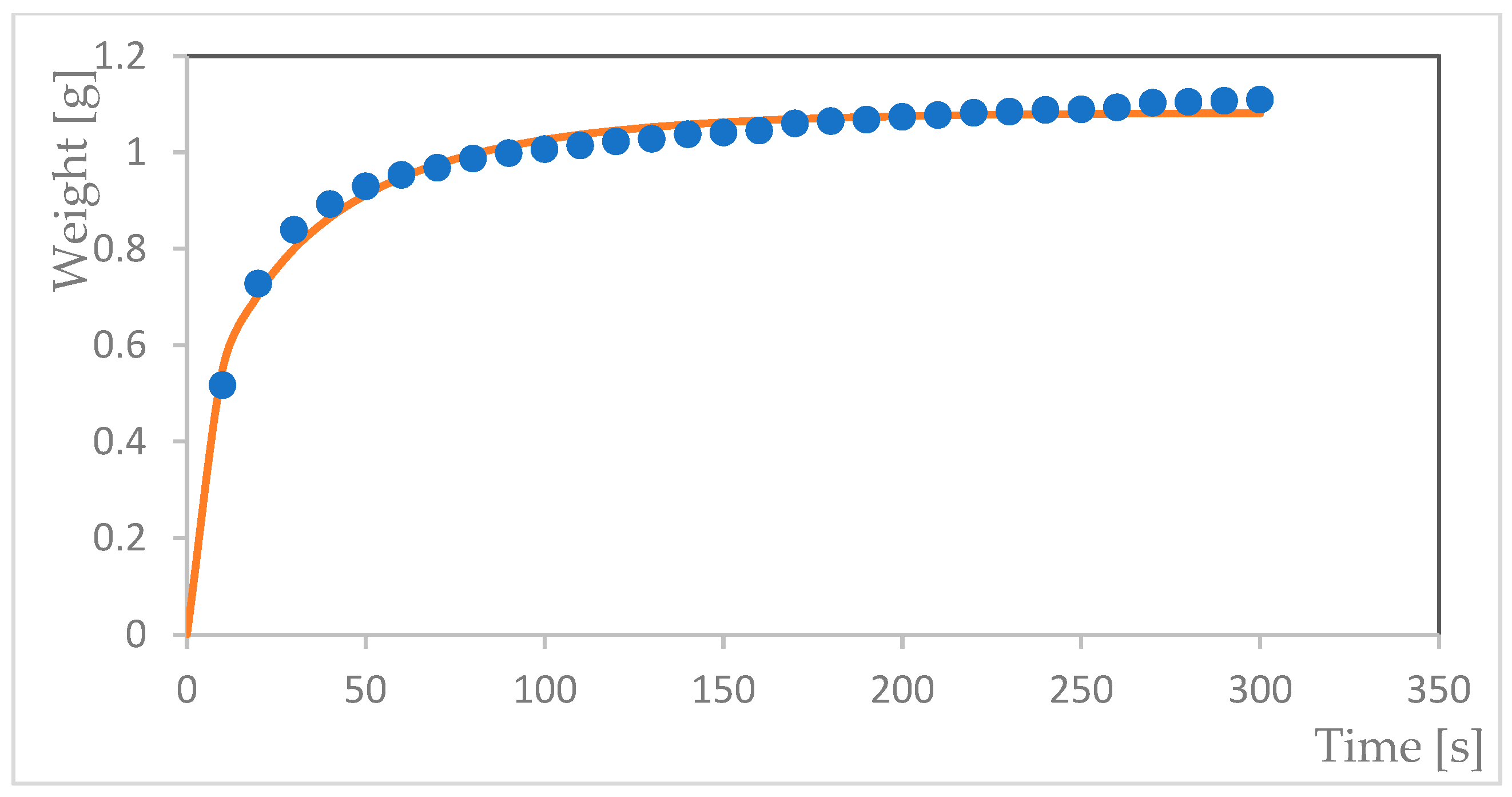

The fitting of the experimental dependence of

m(

t) was performed using the Lambert

W function, which is part of fitting programs (

Figure 8,

Figure 9 and

Figure 10):

For the function defined in this way, it is valid that

t = 0 is also

m = 0, and

From the obtained values in

Table 4, we can see that the pure PP fiber reached the highest value of the specific rate of absorption capacity compared to both modified PP fibers. These results reflect the difference in the selected nanoparticles, the different geometry, and the associated possible dispersion of the nanoparticles. Modified PP fibers with halloysite as a nanoadditive achieved a higher specific rate of absorption capacity compared to modified PP fibers with silica fume. Liquid transport in modified PP fibers is hindered by particles of silica fume or halloysite compared to pure ones, where the path for the rising of liquid is unobstructed. On the contrary, when comparing modified PP fibers with nanoadditives with different particle shapes, it can be concluded that the spherical particles of silica fume create a greater barrier to the rise of liquid than halloysite tubes.

These results reflect the knowledge about PP, which has a high transport capacity, and based on the findings, it can be concluded that Washburn’s method describes the transport ability of PP or modified PP fibers as the sorption capacity of the fibers. This transport ability in modified PP fibers decreases due to the dispersed nanoadditives.

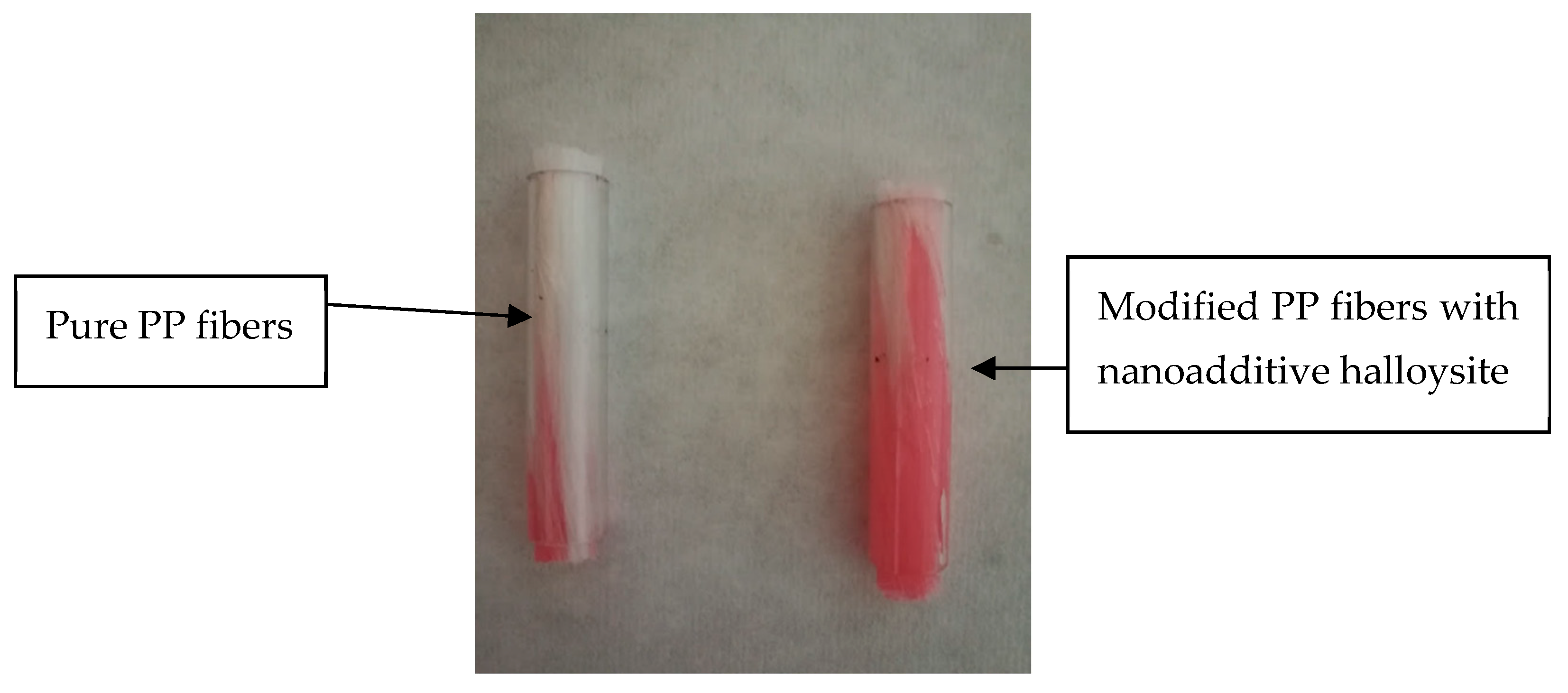

These results can be indicated by

Figure 11, which shows a higher sorption capacity of the modified fibers compared to the pure PP fiber due to more significant color changes on the modified PP fibers with the nanoadditive of halloysite in a time interval of 1 week from the measurement. Since the color change on the modified PP fibers with the nanoadditive is more pronounced, we can assume that the modification of the PP fibers led to better sorption in the modified PP fibers. With the given method, we noted a better transport property of the pure PP fibers. The water absorptivity is connected more to halloysite or silica fume nanoparticles, and thus the water content increases in the modified fibers. In the case of pure PP fibers, the transport is faster (without the hindrance of nanoadditive particles), but it binds less water because it has nowhere to bind.