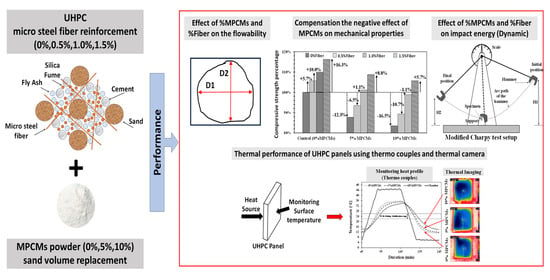

Performance of Fiber-Reinforced Ultra-High-Performance Concrete Incorporated with Microencapsulated Phase Change Materials

Abstract

:1. Introduction

2. Materials and Methods

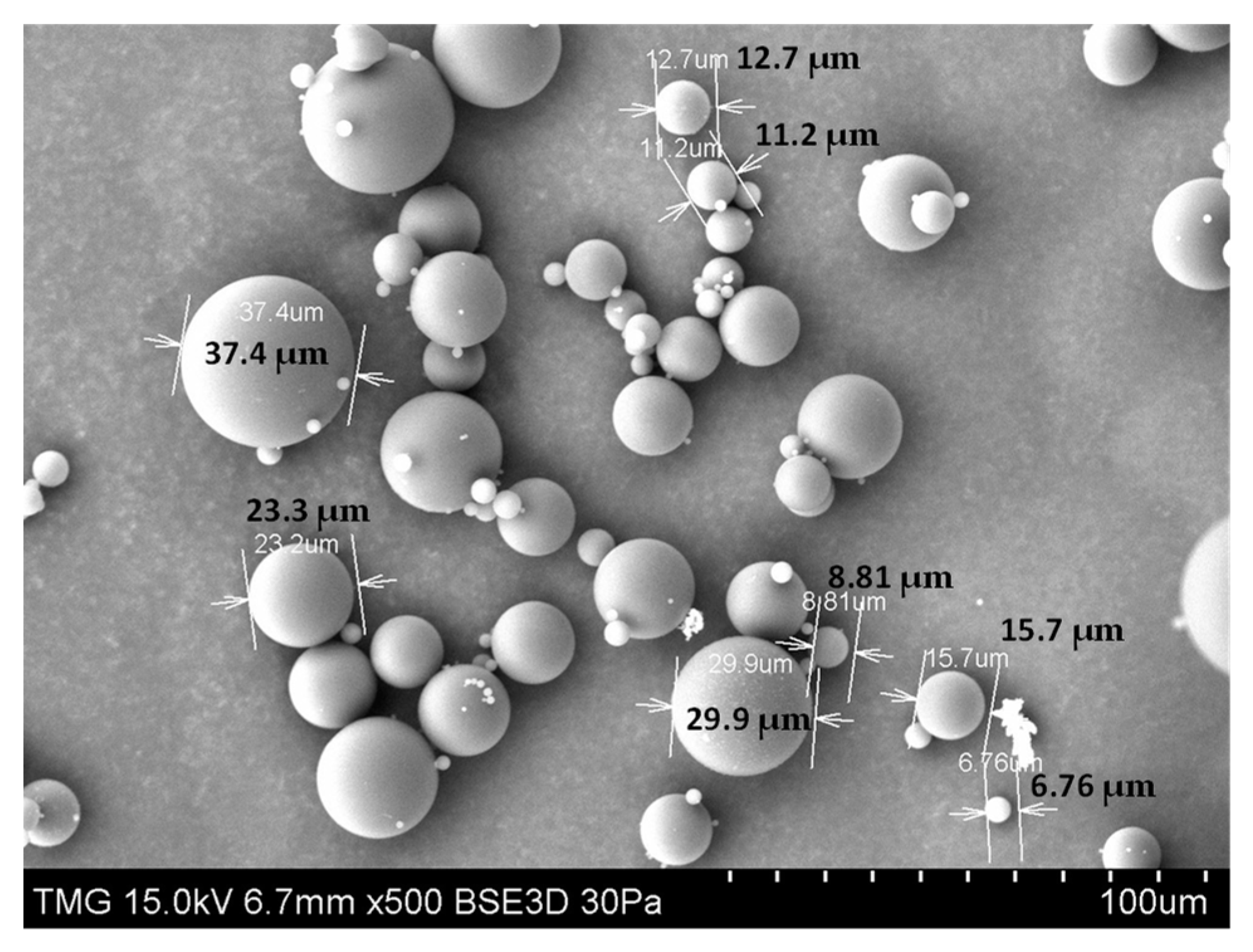

2.1. Materials

2.2. Mixing Procedure

2.3. Tests and Specimens Preparations

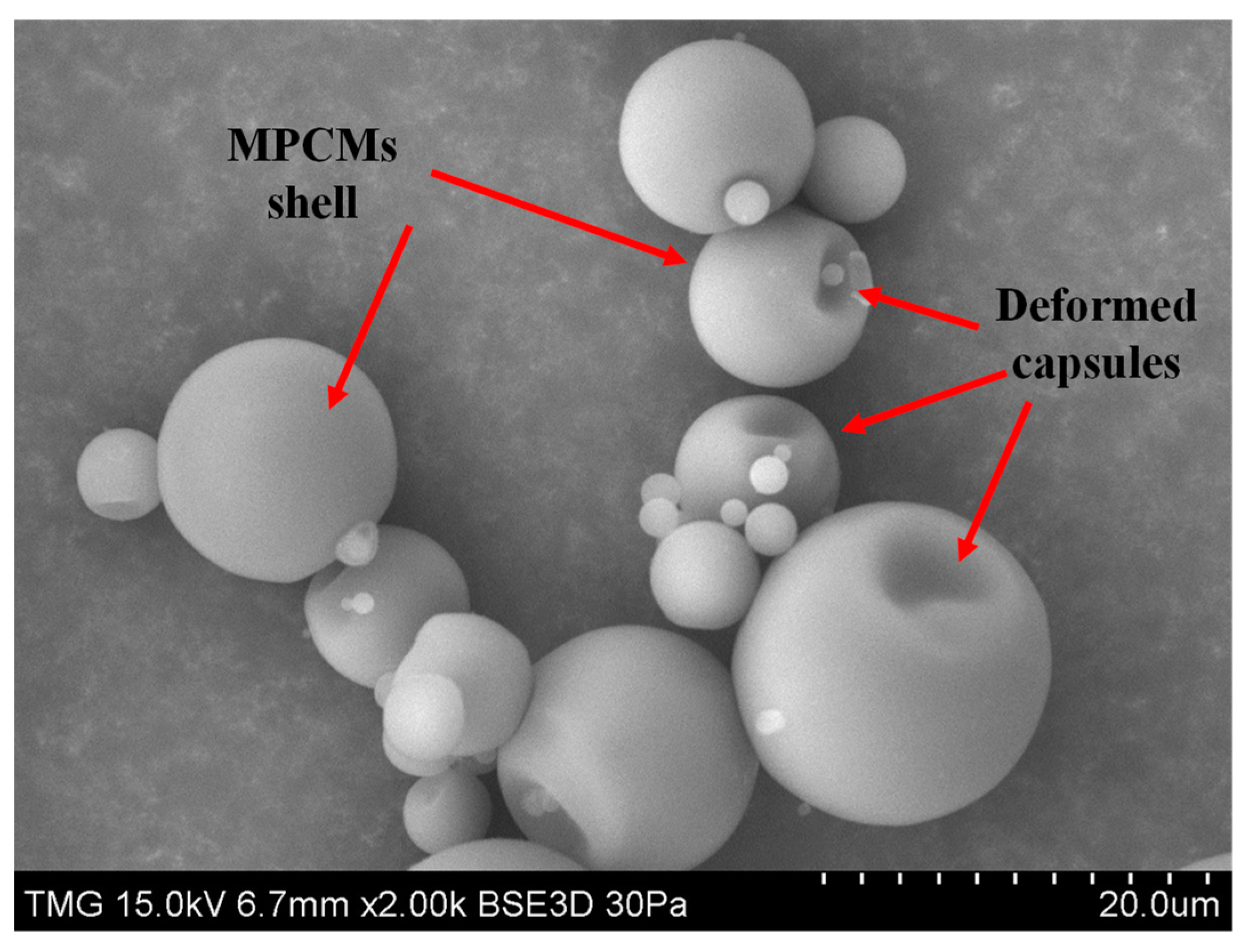

2.3.1. Characterization of MPCM-UHPC

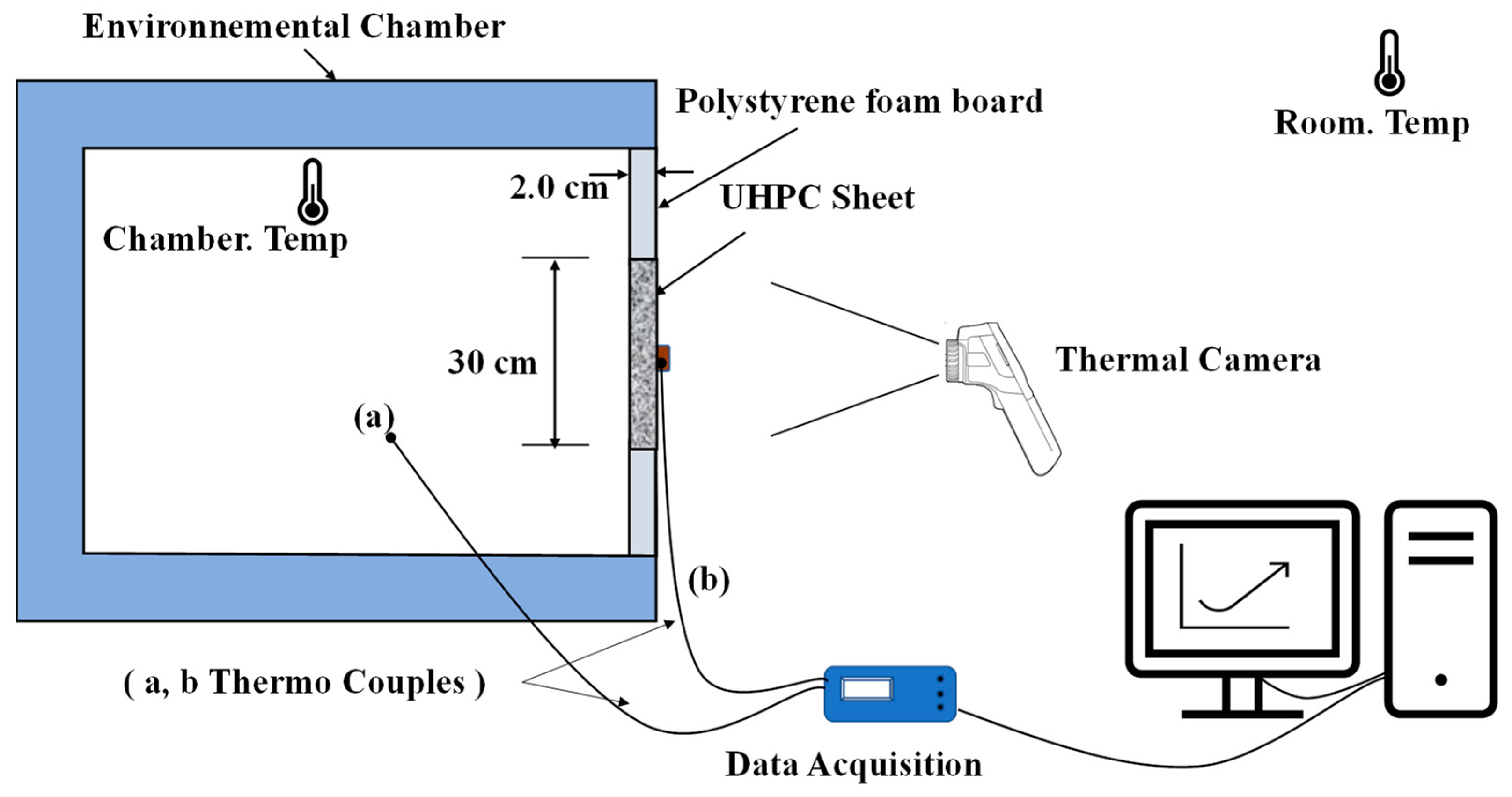

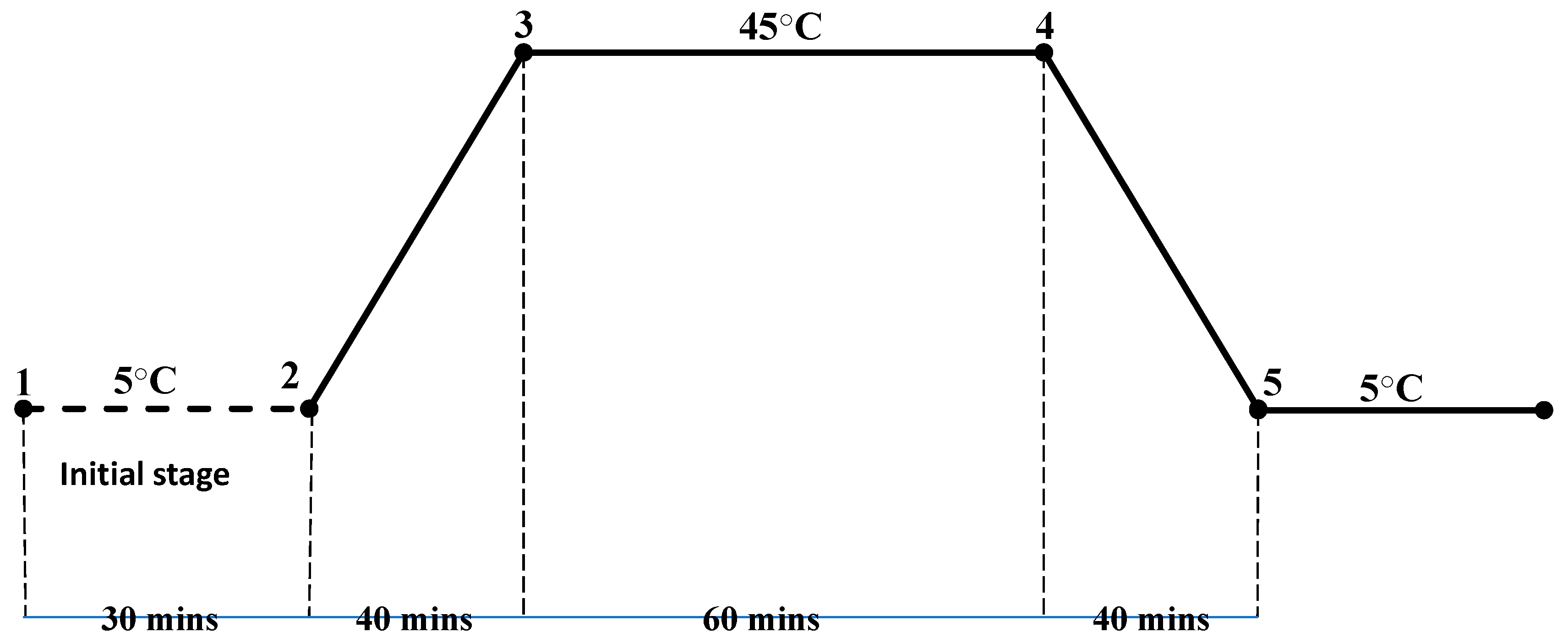

2.3.2. Thermal Performance Test of MPCM-UHPC Sheets

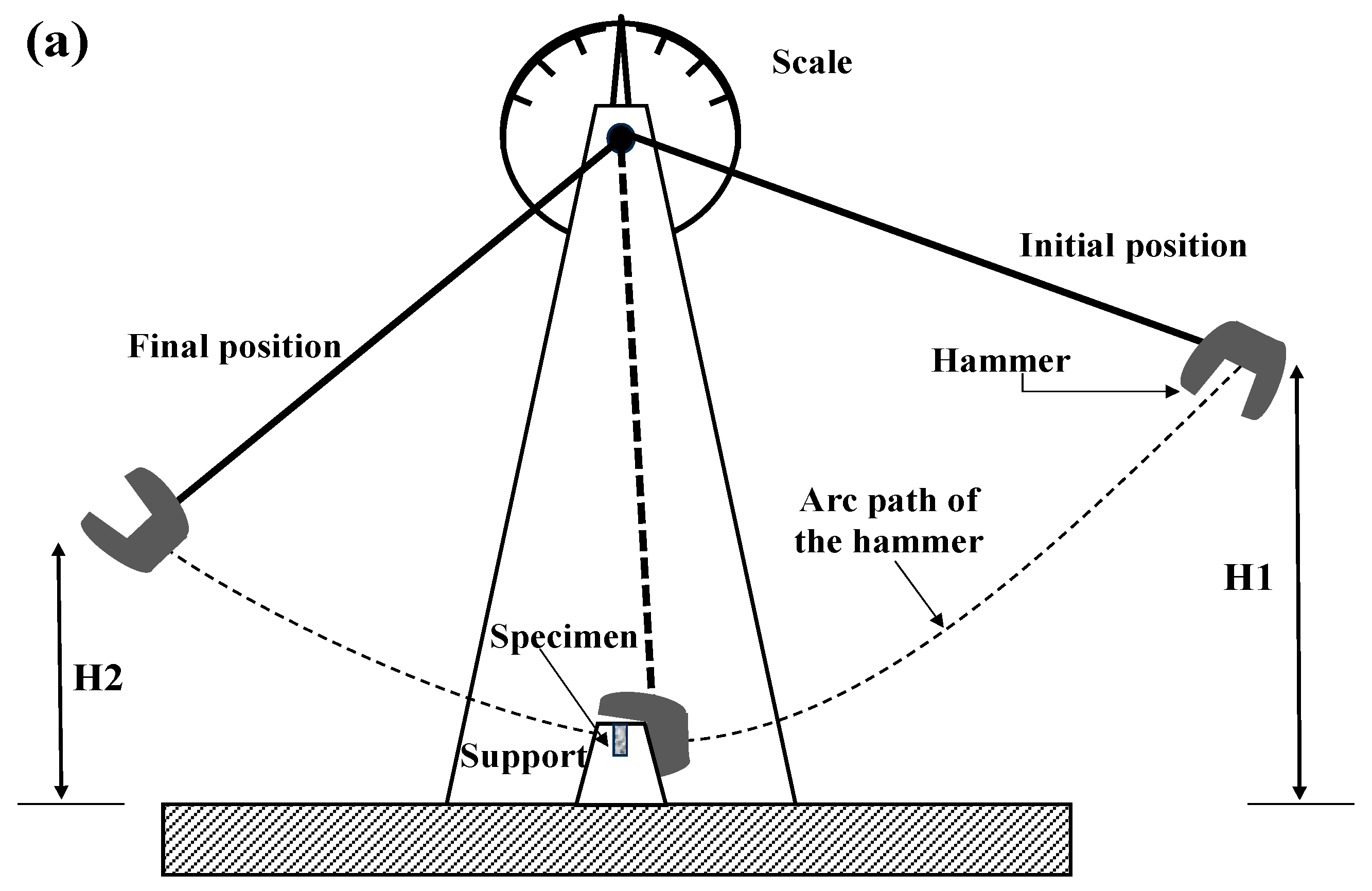

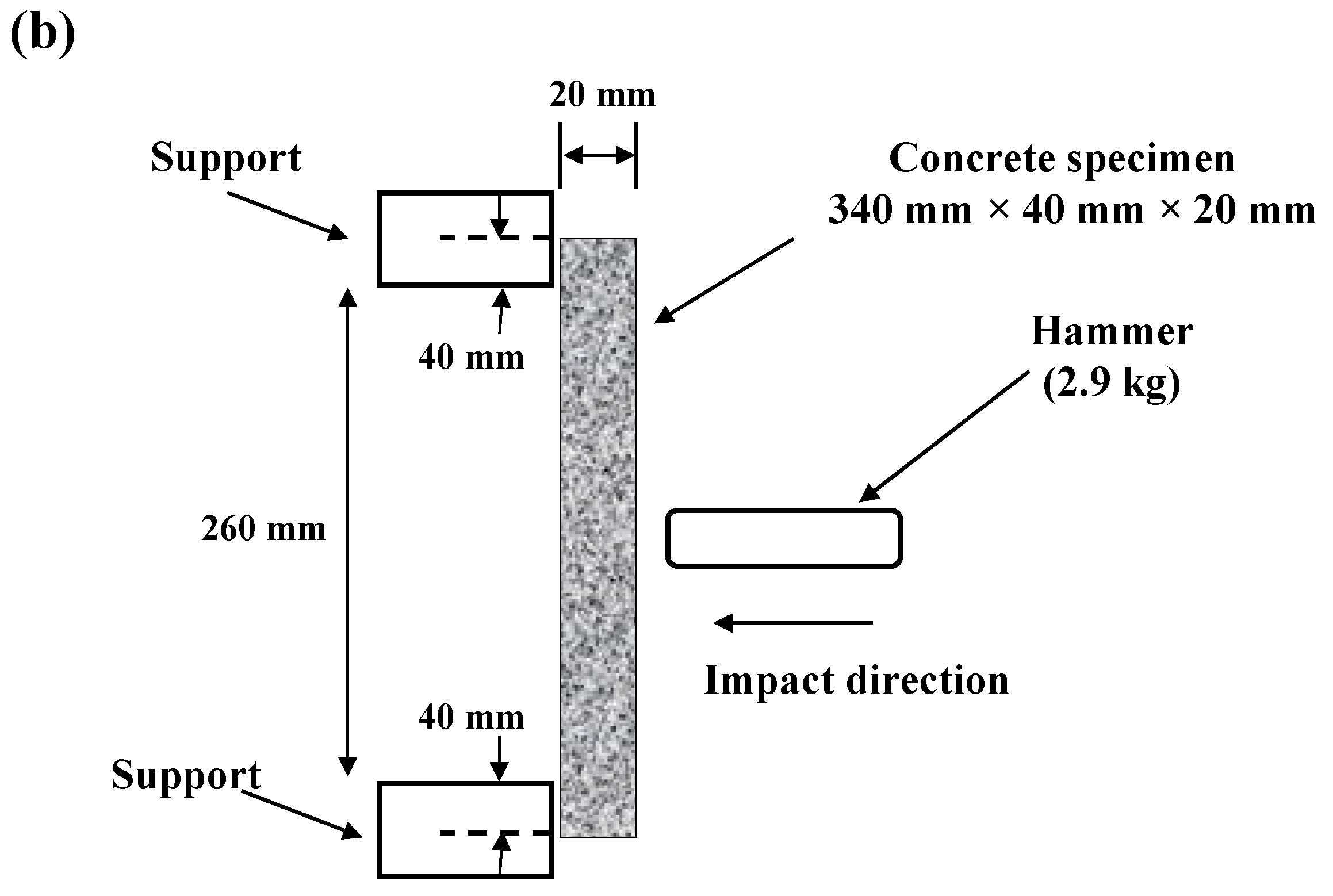

2.3.3. Impact Resistance

3. Results and Discussion

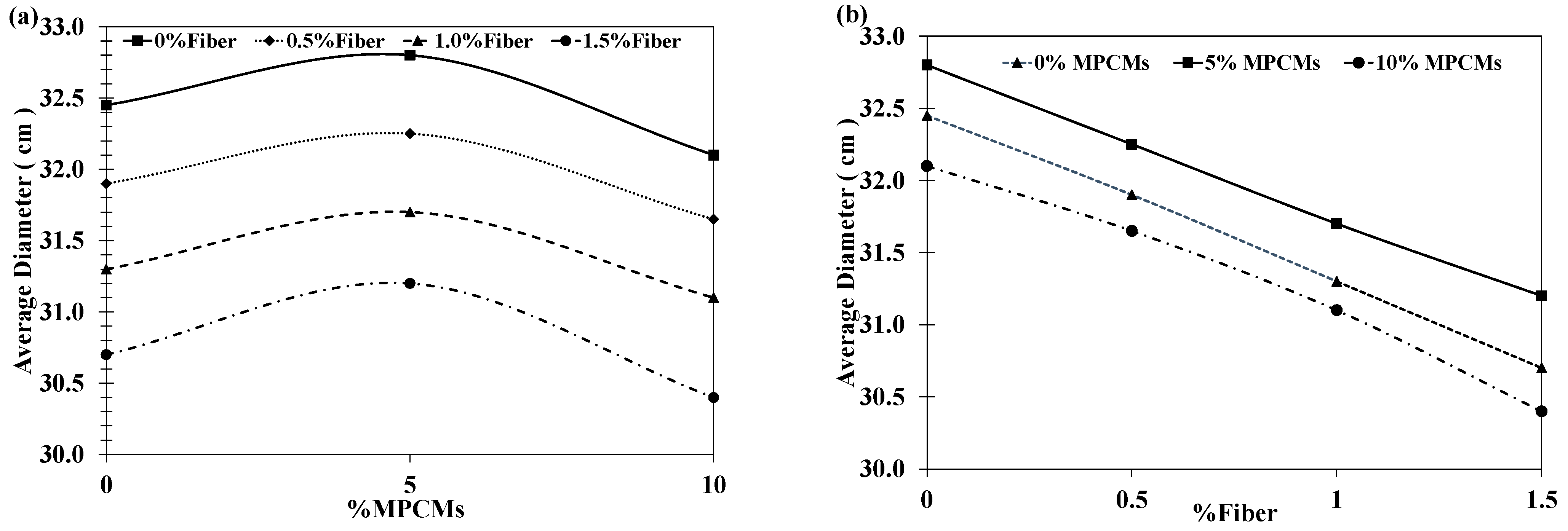

3.1. Effects of MPCMs Content and Micro Steel Fiber Content on Flowability of UHPC

3.2. Analysis of Strength Results

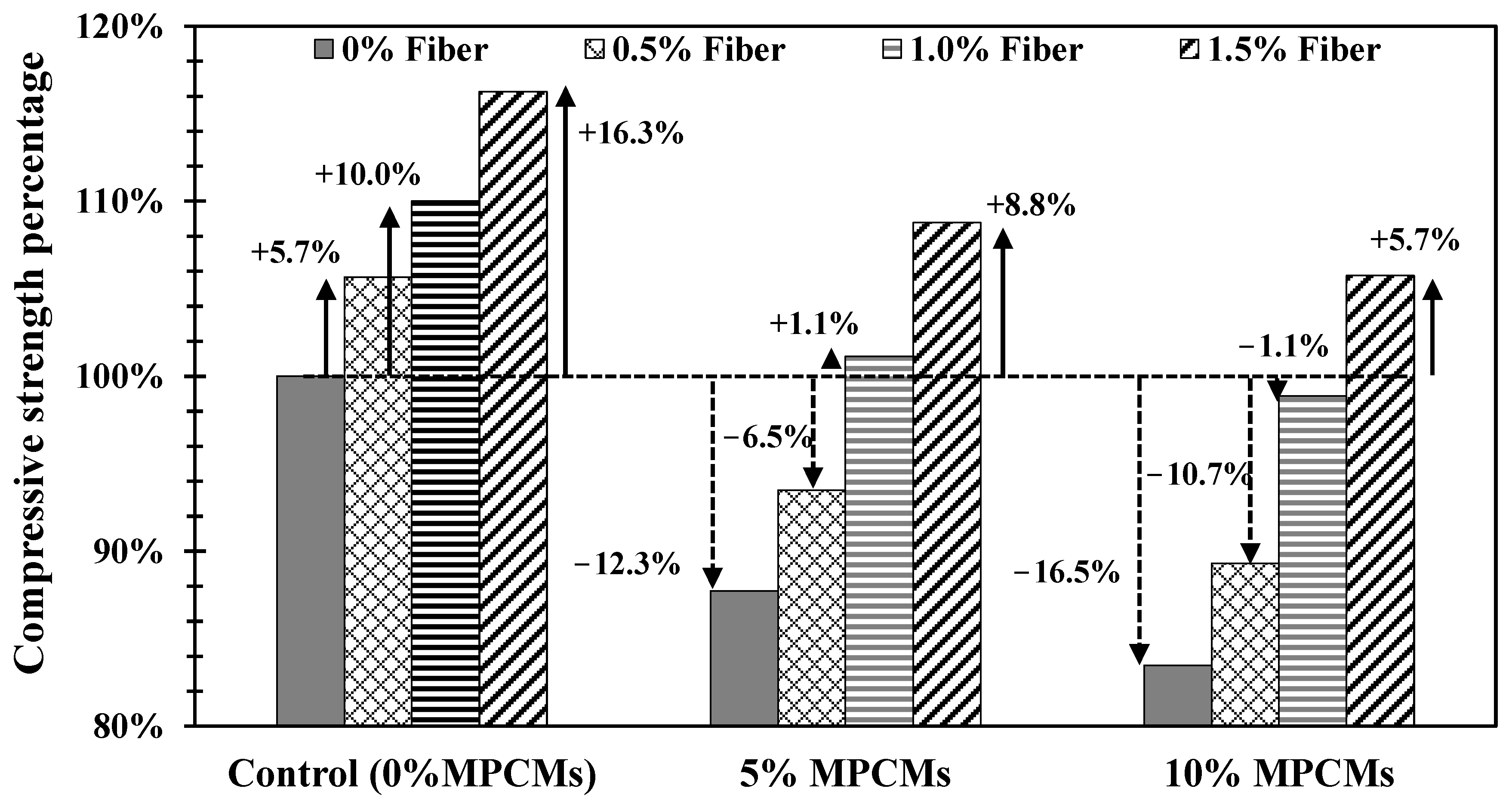

3.2.1. Compressive Strength

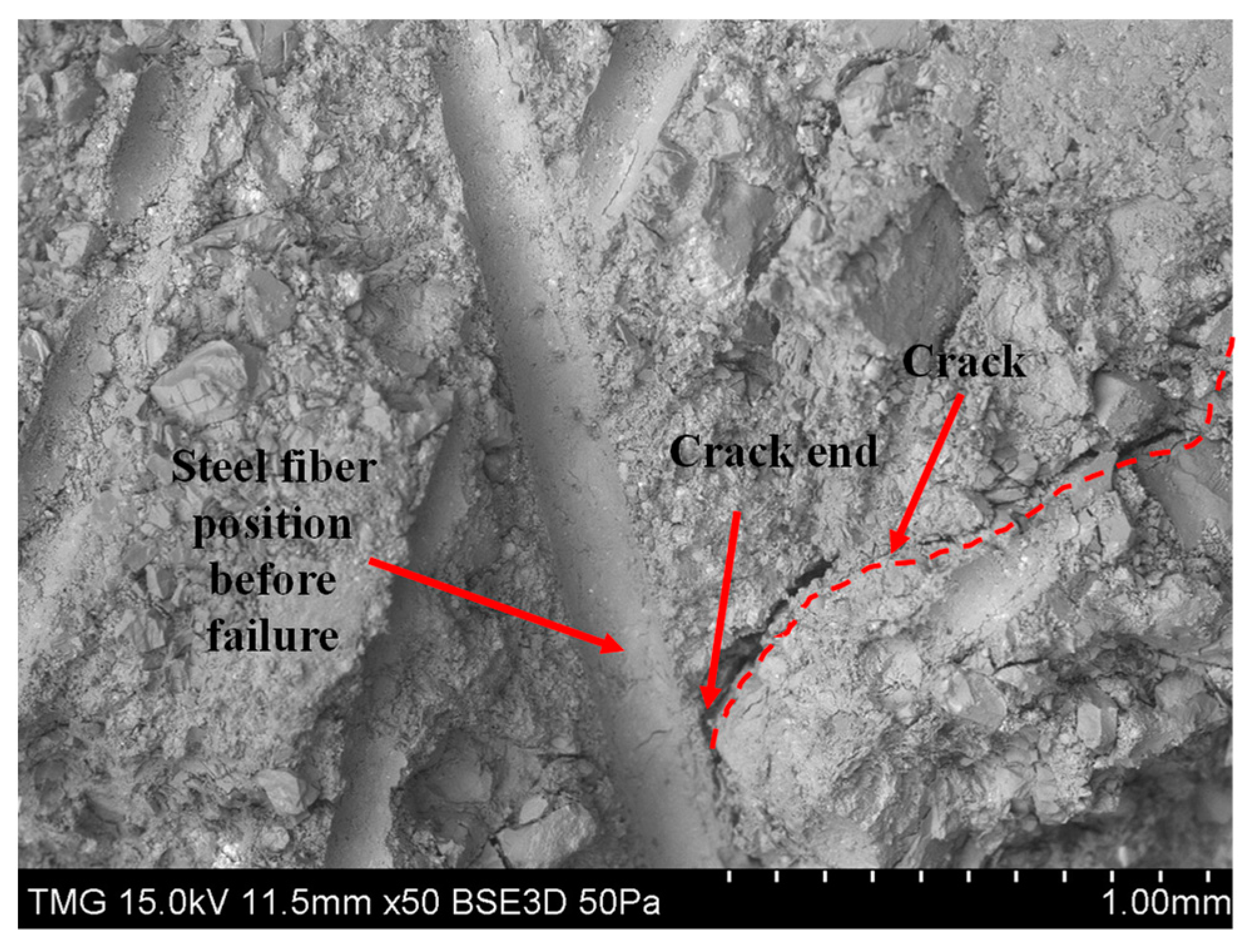

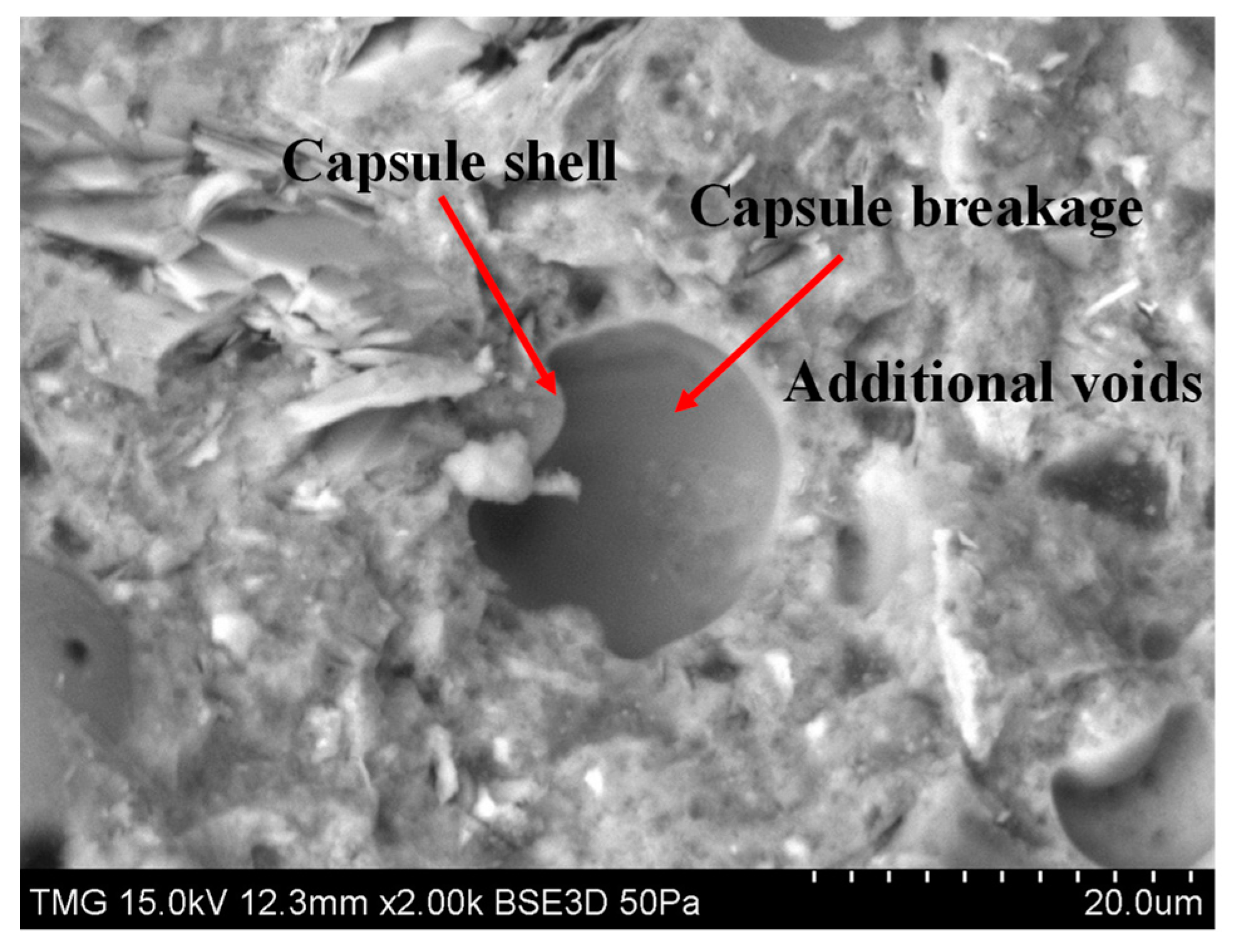

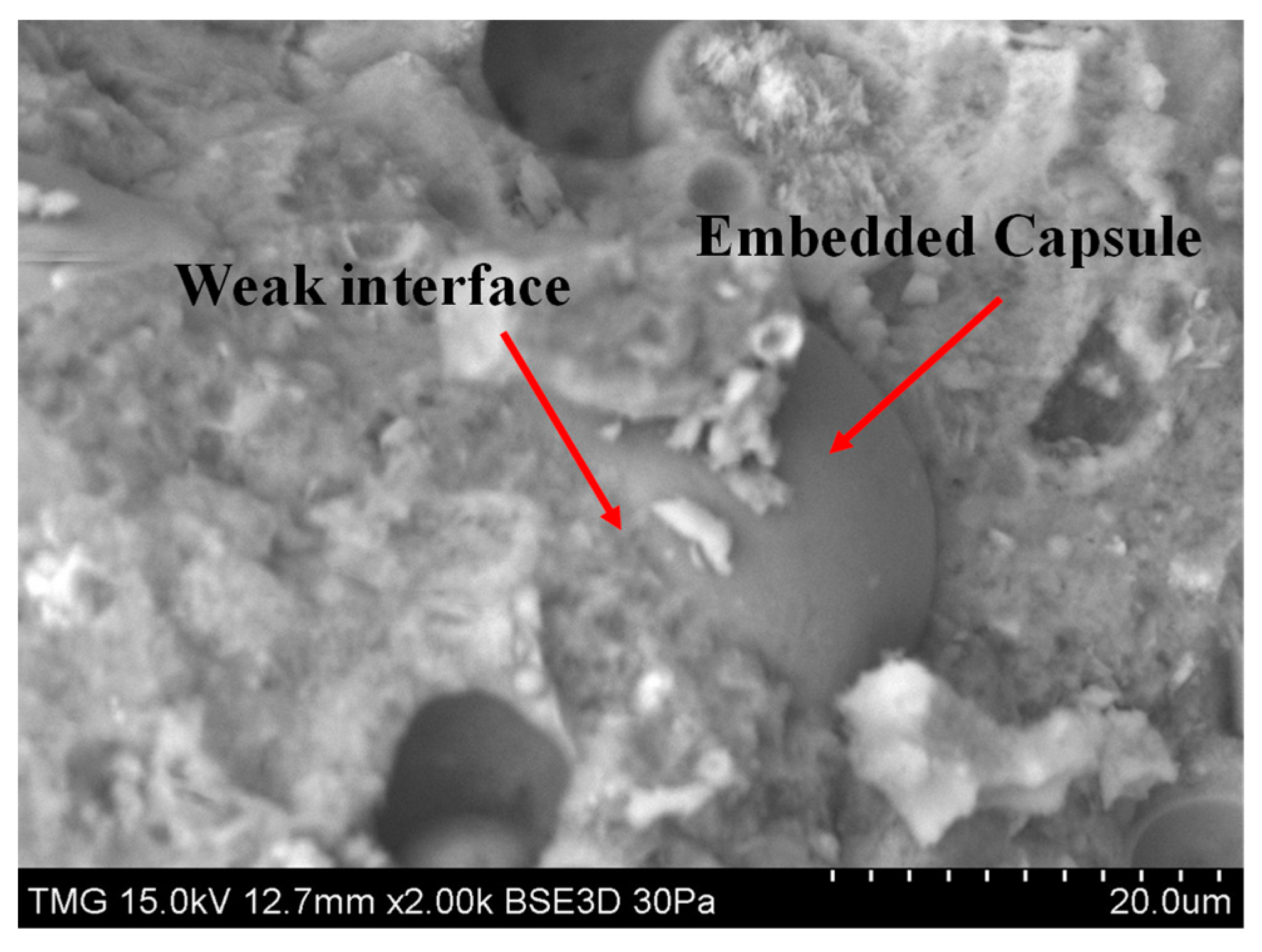

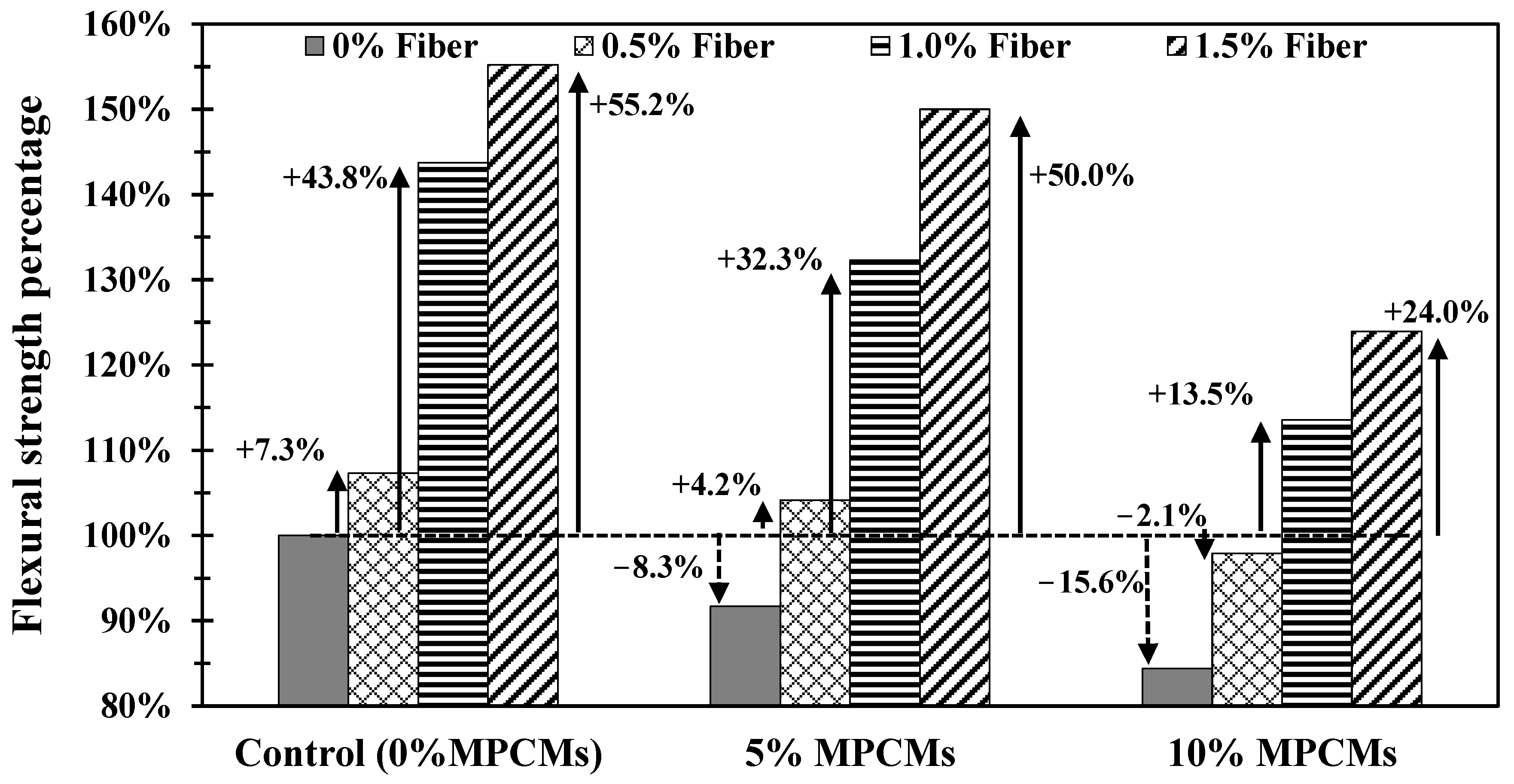

3.2.2. Flexural Strength

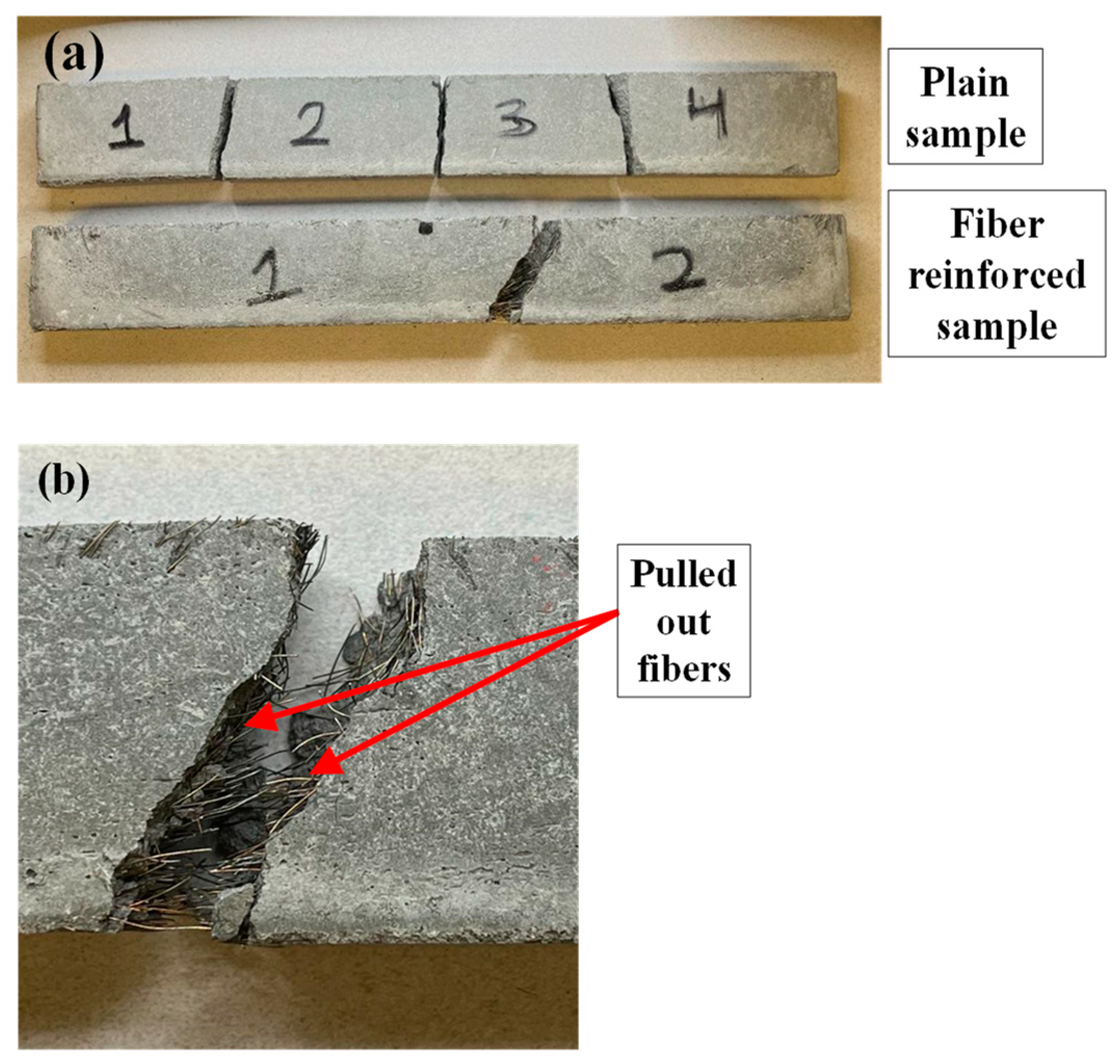

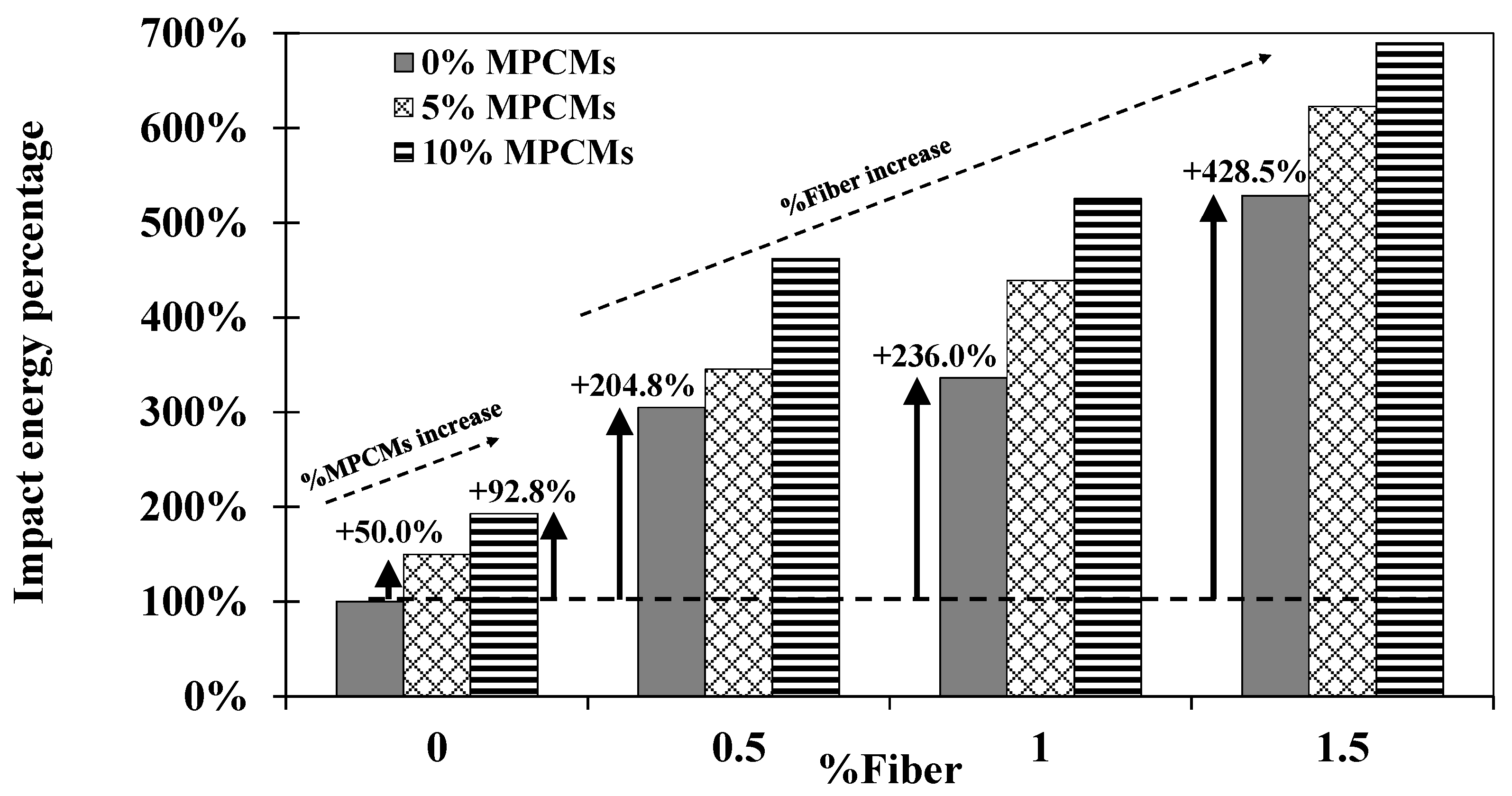

3.2.3. Impact Resistance

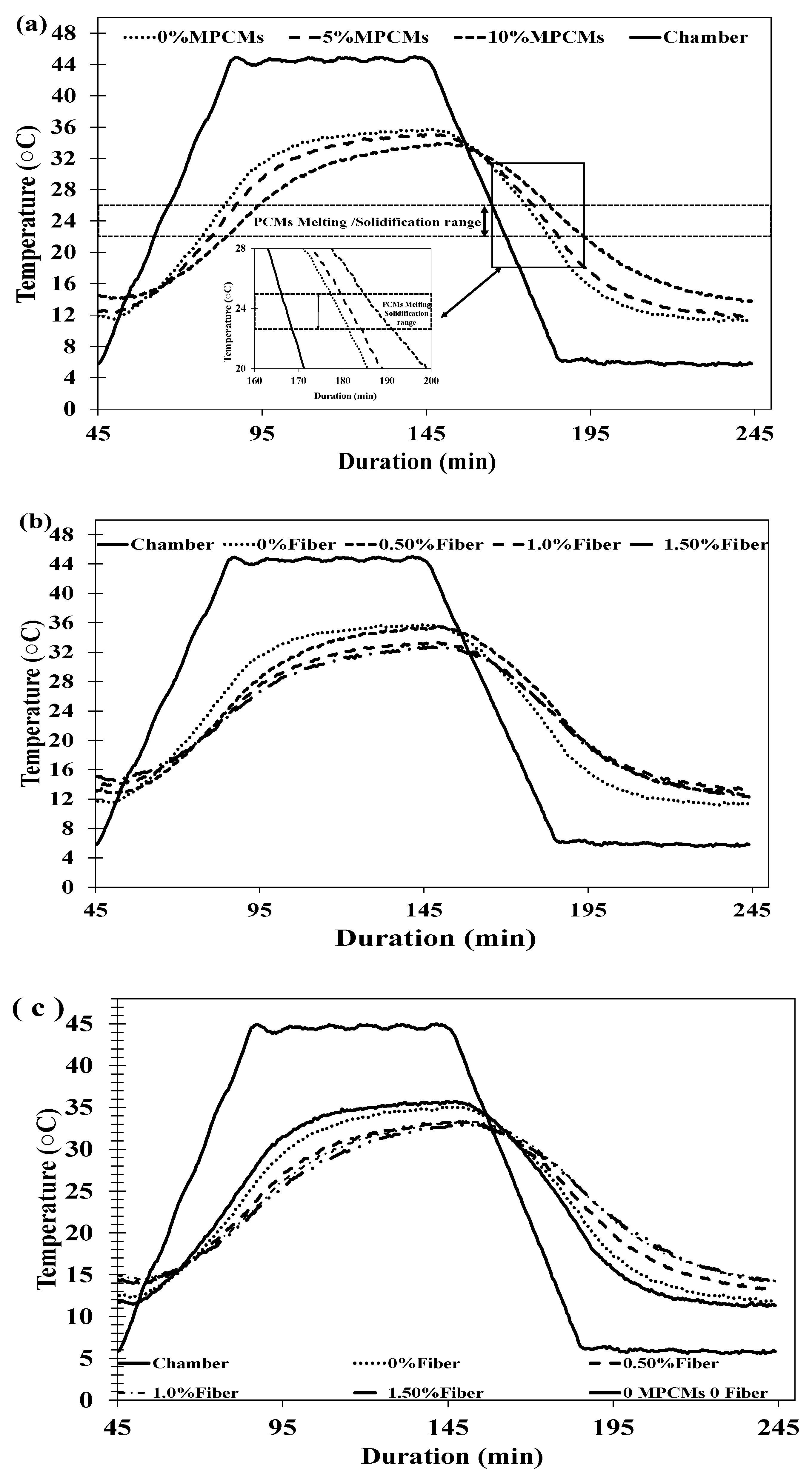

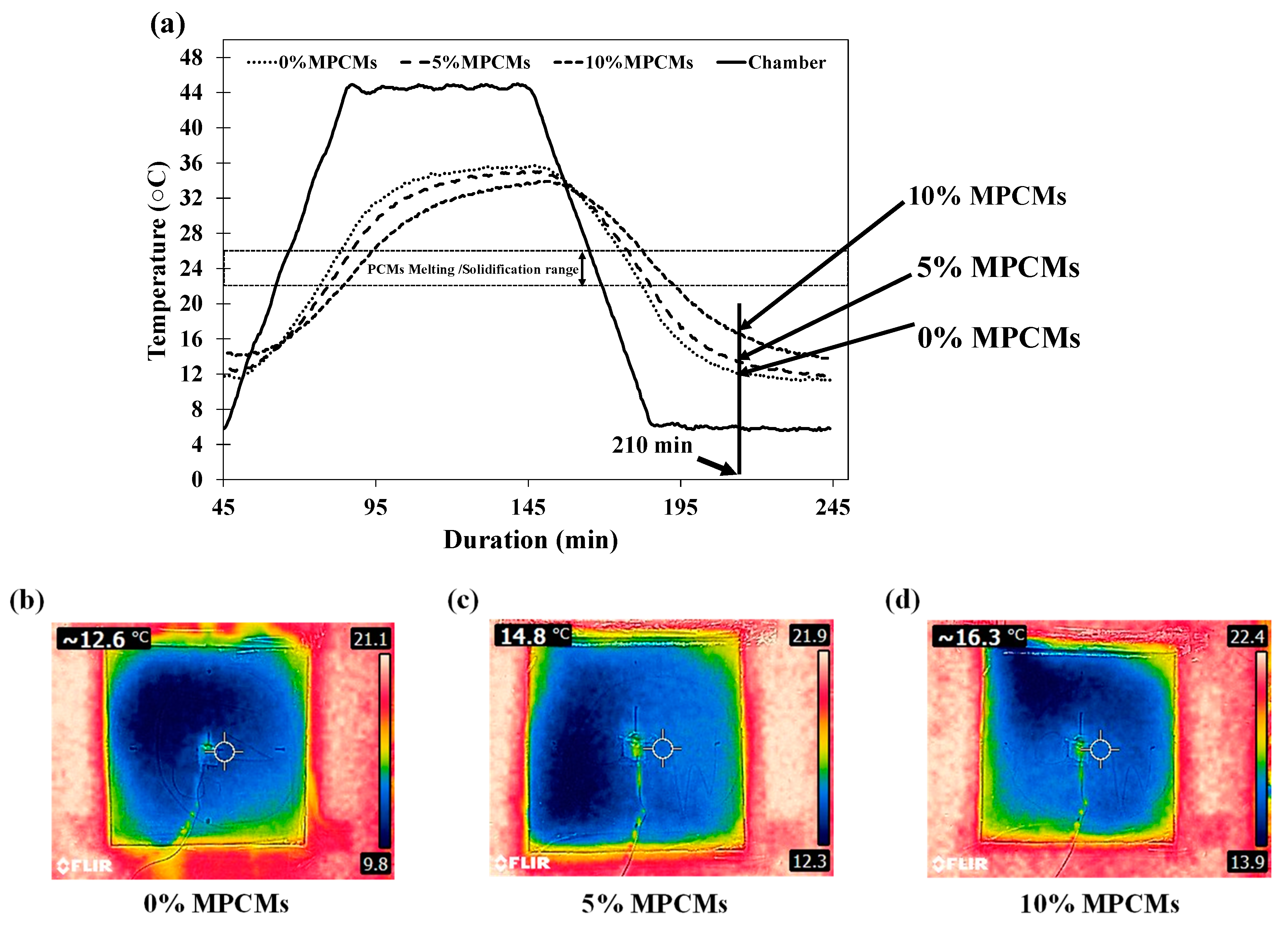

3.2.4. Thermal Performance

4. Conclusions

- Slump flow test showed that the addition of MPCMs had no significant effect on the flowability of UHPC, while the inclusion of micro steel fibers significantly decreased the flowability.

- In terms of compressive strength, adding 1.0% fiber counteracts the reduction in strength caused by the inclusion of MPCMs, while using 1.5% fiber results in higher compressive strength than the control group. On the other hand, incorporating 0.5% fiber helps to offset some of the strength loss.

- For flexural strength, adding 0.5% fiber eliminates the reduction in the strength due to MPCM incorporation, while adding 1.0% and 1.5% fiber achieved flexural strength higher than the control.

- The study analyzed the impact energy absorption of the mixtures and found that the increase in the amount of micro steel fiber or MPCMs can improve the energy dissipation capacity of concrete.

- Increasing the amount of MPCMs enhanced the thermal performance of the produced UHPC panels through the ability to absorb and release the energy during the phase change process.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, H.; Zhou, Y.; Huang, R.; Wu, H.; Sun, Y.; Huang, G.; Xu, T. Optimum insulation thicknesses and energy conservation of building thermal insulation materials in Chinese zone of humid subtropical climate. Sustain. Cities Soc. 2020, 52, 101840. [Google Scholar] [CrossRef]

- Drissi, S.; Ling, T.-C.; Mo, K.H.; Eddhahak, A. A review of microencapsulated and composite phase change materials: Alteration of strength and thermal properties of cement-based materials. Renew. Sustain. Energy Rev. 2019, 110, 467–484. [Google Scholar] [CrossRef]

- Saffari, M.; de Gracia, A.; Ushak, S.; Cabeza, L.F. Passive cooling of buildings with phase change materials using whole-building energy simulation tools: A review. Renew. Sustain. Energy Rev. 2017, 80, 1239–1255. [Google Scholar] [CrossRef]

- Mahlia, T.; Saktisahdan, T.; Jannifar, A.; Hasan, M.; Matseelar, H. A review of available methods and development on energy storage; technology update. Renew. Sustain. Energy Rev. 2014, 33, 532–545. [Google Scholar] [CrossRef]

- Salunkhe, P.B.; Shembekar, P.S. A review on effect of phase change material encapsulation on the thermal performance of a system. Renew. Sustain. Energy Rev. 2012, 16, 5603–5616. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Martorell, I.; Miró, L.; Sari-Bey, S.; Fois, M.; Paksoy, H.O.; Sahan, N.; Weber, R.; Constantinescu, M.; et al. Unconventional experimental technologies available for phase change materials (PCM) characterization. Part 1. Thermophysical properties. Renew. Sustain. Energy Rev. 2015, 43, 1399–1414. [Google Scholar] [CrossRef]

- Aydin, D.; Utlu, Z.; Kincay, O. Thermal performance analysis of a solar energy sourced latent heat storage. Renew. Sustain. Energy Rev. 2015, 50, 1213–1225. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, Z.; Zuo, J.; Huang, K.; Zhang, L. Phase change materials for solar thermal energy storage in residential buildings in cold climate. Renew. Sustain. Energy Rev. 2015, 48, 692–703. [Google Scholar] [CrossRef]

- Solé, A.; Miró, L.; Barreneche, C.; Martorell, I.; Cabeza, L.F. Review of the T -history method to determine thermophysical properties of phase change materials (PCM). Renew. Sustain. Energy Rev. 2013, 26, 425–436. [Google Scholar] [CrossRef]

- Li, G. Energy and exergy performance assessments for latent heat thermal energy storage systems. Renew. Sustain. Energy Rev. 2015, 51, 926–954. [Google Scholar] [CrossRef]

- Huang, X.; Alva, G.; Jia, Y.; Fang, G. Morphological characterization and applications of phase change materials in thermal energy storage: A review. Renew. Sustain. Energy Rev. 2017, 72, 128–145. [Google Scholar] [CrossRef]

- Cui, Y.; Xie, J.; Liu, J.; Wang, J.; Chen, S. A review on phase change material application in building. Adv. Mech. Eng. 2017, 9, 1687814017700828. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castell, A.; Barreneche, C.; De Gracia, A.; Fernández, A.I. Materials used as PCM in thermal energy storage in buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Famileh, I.Z.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A review on phase change material (PCM) for sustainable passive cooling in building envelopes. Renew. Sustain. Energy Rev. 2016, 60, 1470–1497. [Google Scholar] [CrossRef]

- Johra, H.; Heiselberg, P. Influence of internal thermal mass on the indoor thermal dynamics and integration of phase change materials in furniture for building energy storage: A review. Renew. Sustain. Energy Rev. 2017, 69, 19–32. [Google Scholar] [CrossRef]

- Kenisarin, M.; Mahkamov, K. Passive thermal control in residential buildings using phase change materials. Renew. Sustain. Energy Rev. 2016, 55, 371–398. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Rao, V.V.; Parameshwaran, R.; Ram, V.V. PCM-mortar based construction materials for energy efficient buildings: A review on research trends. Energy Build. 2018, 158, 95–122. [Google Scholar] [CrossRef]

- Memon, S.A. Phase change materials integrated in building walls: A state of the art review. Renew. Sustain. Energy Rev. 2014, 31, 870–906. [Google Scholar] [CrossRef]

- Soares, N.; Costa, J.J.; Gaspar, A.R.; Santos, P. Review of passive PCM latent heat thermal energy storage systems towards buildings’ energy efficiency. Energy Build. 2013, 59, 82–103. [Google Scholar] [CrossRef]

- Song, M.; Niu, F.; Mao, N.; Hu, Y.; Deng, S. Review on building energy performance improvement using phase change materials. Energy Build. 2018, 158, 776–793. [Google Scholar] [CrossRef]

- Arumugam, P.; Ramalingam, V.; Vellaichamy, P. Effective PCM, insulation, natural and/or night ventilation techniques to enhance the thermal performance of buildings located in various climates—A review. Energy Build. 2022, 258, 111840. [Google Scholar] [CrossRef]

- Da Cunha, S.R.L.; de Aguiar, J.L.B. Phase change materials and energy efficiency of buildings: A review of knowledge. J. Energy Storage 2020, 27, 101083. [Google Scholar] [CrossRef]

- Marani, A.; Nehdi, M.L. Integrating phase change materials in construction materials: Critical review. Constr. Build. Mater. 2019, 217, 36–49. [Google Scholar] [CrossRef]

- Marani, A.; Zhang, L.V.; Nehdi, M.L. Multiphysics study on cement-based composites incorporating green biobased shape-stabilized phase change materials for thermal energy storage. J. Clean. Prod. 2022, 372, 133826. [Google Scholar] [CrossRef]

- Balapour, M.; Mutua, A.W.; Farnam, Y. Evaluating the thermal efficiency of microencapsulated phase change materials for thermal energy storage in cementitious composites. Cem. Concr. Compos. 2020, 116, 103891. [Google Scholar] [CrossRef]

- Tian, Y.; Lai, Y.; Qin, Z.; Pei, W. Numerical investigation on the thermal control performance and freeze-thaw resistance of a composite concrete pier with microencapsulated phase change materials. Sol. Energy 2021, 231, 970–984. [Google Scholar] [CrossRef]

- Sivanathan, A.; Dou, Q.; Wang, Y.; Li, Y.; Corker, J.; Zhou, Y.; Fan, M. Phase change materials for building construction: An overview of nano-/micro-encapsulation. Nanotechnol. Rev. 2020, 9, 896–921. [Google Scholar] [CrossRef]

- Cui, H.; Tang, W.; Qin, Q.; Xing, F.; Liao, W.; Wen, H. Development of structural-functional integrated energy storage concrete with innovative macro-encapsulated PCM by hollow steel ball. Appl. Energy 2017, 185, 107–118. [Google Scholar] [CrossRef]

- Hunger, M.; Entrop, A.; Mandilaras, I.; Brouwers, H.; Founti, M. The behavior of self-compacting concrete containing micro-encapsulated Phase Change Materials. Cem. Concr. Compos. 2009, 31, 731–743. [Google Scholar] [CrossRef]

- Kuznik, F.; David, D.; Johannes, K.; Roux, J.-J. A review on phase change materials integrated in building walls. Renew. Sustain. Energy Rev. 2011, 15, 379–391. [Google Scholar] [CrossRef]

- Aguayo, M.; Das, S.; Maroli, A.; Kabay, N.; Mertens, J.C.; Rajan, S.D.; Sant, G.; Chawla, N.; Neithalath, N. The influence of microencapsulated phase change material (PCM) characteristics on the microstructure and strength of cementitious composites: Experiments and finite element simulations. Cem. Concr. Compos. 2016, 73, 29–41. [Google Scholar] [CrossRef]

- Eddhahak, A.; Drissi, S.; Colin, J.; Caré, S.; Neji, J. Effect of phase change materials on the hydration reaction and kinetic of PCM-mortars. J. Therm. Anal. Calorim. 2014, 117, 537–545. [Google Scholar] [CrossRef]

- Lecompte, T.; Le Bideau, P.; Glouannec, P.; Nortershauser, D.; Le Masson, S. Mechanical and thermo-physical behaviour of concretes and mortars containing phase change material. Energy Build. 2015, 94, 52–60. [Google Scholar] [CrossRef]

- Meshgin, P.; Xi, Y. Effect of phase-change materials on properties of concrete. ACI Mater. J. 2012, 109, 71. [Google Scholar]

- Pomianowski, M.; Heiselberg, P.; Jensen, R.L.; Cheng, R.; Zhang, Y. A new experimental method to determine specific heat capacity of inhomogeneous concrete material with incorporated microencapsulated-PCM. Cem. Concr. Res. 2014, 55, 22–34. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.-S.; Onaizi, A.M.; Makul, N.; Abdelgader, H.S.; Ozbakkaloglu, T. Recent trends in ultra-high performance concrete (UHPC): Current status, challenges, and future prospects. Constr. Build. Mater. 2022, 352, 129029. [Google Scholar] [CrossRef]

- Hakeem, I.Y.; Althoey, F.; Hosen, A. Mechanical and durability performance of ultra-high-performance concrete incorporating SCMs. Constr. Build. Mater. 2022, 359, 129430. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Wu, Y.; Li, Y.; He, X.; Su, Y.; Strnadel, B. Preparation of sustainable ultra-high performance concrete (UHPC) with ultra-fine glass powder as multi-dimensional substitute material. Constr. Build. Mater. 2023, 401, 132857. [Google Scholar] [CrossRef]

- Yazıcı, H.; Yardımcı, M.Y.; Aydın, S.; Karabulut, A.Ş. Mechanical properties of reactive powder concrete containing mineral admixtures under different curing regimes. Constr. Build. Mater. 2009, 23, 1223–1231. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Ghafari, E.; Ghahari, S.A.; Costa, H.; Júlio, E.; Portugal, A.; Durães, L. Effect of supplementary cementitious materials on autogenous shrinkage of ultra-high performance concrete. Constr. Build. Mater. 2016, 127, 43–48. [Google Scholar] [CrossRef]

- Xue, C.; Yu, M.; Xu, H.; Xu, L.; Saafi, M.; Ye, J. Experimental study on thermal performance of ultra-high performance concrete with coarse aggregates at high temperature. Constr. Build. Mater. 2022, 314, 125585. [Google Scholar] [CrossRef]

- Ren, M.; Wen, X.; Gao, X.; Liu, Y. Thermal and mechanical properties of ultra-high performance concrete incorporated with microencapsulated phase change material. Constr. Build. Mater. 2021, 273, 121714. [Google Scholar] [CrossRef]

- CSA A3000-13; Cementitious Materials Compendium. CSA Group: Mississauga, ON, Canada, 2013.

- Standard Specification for Silica Fume Used in Cementitious Mixtures. Available online: https://www.astm.org/c1240-20.html (accessed on 19 February 2023).

- Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. Available online: https://www.astm.org/c0618-22.html (accessed on 5 April 2023).

- Rahman, O.A.; Al-Shdaifat, M.; Almakhadmeh, M.; Soliman, A. Phase change materials sheets for energy-efficient heat curing process: A potential idea and performance evaluation. Constr. Build. Mater. 2022, 353, 129102. [Google Scholar] [CrossRef]

- Standard Test Method for Flow of Hydraulic Cement Mortar. Available online: https://www.astm.org/c1437-15.html (accessed on 19 February 2023).

- Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens). Available online: https://www.astm.org/c0109_c0109m-21.html (accessed on 19 February 2023).

- Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. Available online: https://www.astm.org/c0348-21.html (accessed on 19 February 2023).

- Yu, R.; van Beers, L.; Spiesz, P.; Brouwers, H.J.H. Impact resistance of a sustainable Ultra-High Performance Fibre Reinforced Concrete (UHPFRC) under pendulum impact loadings. Constr. Build. Mater. 2016, 107, 203–215. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Gao, X.M. Effect of Steel Fiber on the Performance Of Ultra-High Performance Concrete; Hunan University: Changsha, China, 2013. [Google Scholar]

- Yunsheng, Z.; Wei, S.; Sifeng, L.; Chujie, J.; Jianzhong, L. Preparation of C200 green reactive powder concrete and its static–dynamic behaviors. Cem. Concr. Compos. 2008, 30, 831–838. [Google Scholar] [CrossRef]

- Banthia, N.; Trottier, J.-F. Concrete reinforced with deformed steel fibres. Part II: Toughness characterization. ACI Mater. J. 1995, 92, 146–154. [Google Scholar]

- Essid, N.; Loulizi, A.; Neji, J. Compressive strength and hygric properties of concretes incorporating microencapsulated phase change material. Constr. Build. Mater. 2019, 222, 254–262. [Google Scholar] [CrossRef]

- Pilehvar, S.; Szczotok, A.M.; Rodríguez, J.F.; Valentini, L.; Lanzón, M.; Pamies, R.; Kjøniksen, A.-L. Effect of freeze-thaw cycles on the mechanical behavior of geopolymer concrete and Portland cement concrete containing micro-encapsulated phase change materials. Constr. Build. Mater. 2019, 200, 94–103. [Google Scholar] [CrossRef]

- Gürbüz, E.; Erdem, S. Development and thermo-mechanical analysis of high-performance hybrid fibre engineered cementitious composites with microencapsulated phase change materials. Constr. Build. Mater. 2020, 263, 120139. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Investigation of mechanical properties and shrinkage of ultra-high performance concrete: Influence of steel fiber content and shape. Compos. Part B Eng. 2019, 174, 107021. [Google Scholar] [CrossRef]

- Barnett, S.J.; Lataste, J.-F.; Parry, T.; Millard, S.G.; Soutsos, M.N. Assessment of fibre orientation in ultra high performance fibre reinforced concrete and its effect on flexural strength. Mater. Struct. 2010, 43, 1009–1023. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Shin, H.-O.; Yang, J.-M.; Yoon, Y.-S. Material and bond properties of ultra high performance fiber reinforced concrete with micro steel fibers. Compos. Part B Eng. 2014, 58, 122–133. [Google Scholar] [CrossRef]

- Kang, S.-T.; Kim, J.-K. The relation between fiber orientation and tensile behavior in an Ultra High Performance Fiber Reinforced Cementitious Composites (UHPFRCC). Cem. Concr. Res. 2011, 41, 1001–1014. [Google Scholar] [CrossRef]

- Fernandes, F.; Manari, S.; Aguayo, M.; Santos, K.; Oey, T.; Wei, Z.; Falzone, G.; Neithalath, N.; Sant, G. On the feasibility of using phase change materials (PCMs) to mitigate thermal cracking in cementitious materials. Cem. Concr. Compos. 2014, 51, 14–26. [Google Scholar] [CrossRef]

- Wang, H.; Wang, L. Experimental study on static and dynamic mechanical properties of steel fiber reinforced lightweight aggregate concrete. Constr. Build. Mater. 2013, 38, 1146–1151. [Google Scholar] [CrossRef]

- Song, H.W.; Wang, H.T. Statistical Evaluation for Impact Resistance of Steel Fiber Reinforced Lightweight Aggregate Concrete. Adv. Mater. Res. 2011, 250–253, 609–613. [Google Scholar] [CrossRef]

- Erdem, S.; Gürbüz, E. Influence of microencapsulated phase change materials on the flexural behavior and micromechanical impact damage of hybrid fibre reinforced engineered cementitious composites. Compos. Part B Eng. 2019, 166, 633–644. [Google Scholar] [CrossRef]

- Dorf, V.; Krasnovskiy, R.; Kapustin, D.; Sultygova, P.; Umnyakova, N. Influence of fiber content on the conductivity of steel fiber-reinforced concrete. Spec. Publ. 2018, 326, 62.1–62.8. [Google Scholar]

- Shubin, I.L.; Dorf, V.A.; Krasnovskij, R.O.; Kapustin, D.E.; Sultygova, P.S. Study of the Thermophysical Characteristics of Steel Fiber Reinforced Concrete. Mater. Sci. Forum 2020, 992, 41–47. [Google Scholar] [CrossRef]

- Cui, H.; Zou, J.; Gong, Z.; Zheng, D.; Bao, X.; Chen, X. Study on the thermal and mechanical properties of steel fibre reinforced PCM-HSB concrete for high performance in energy piles. Constr. Build. Mater. 2022, 350, 128822. [Google Scholar] [CrossRef]

- Liang, X.; Wu, C. Investigation on thermal conductivity of steel fiber reinforced concrete using mesoscale modeling. Int. J. Thermophys. 2018, 39, 142. [Google Scholar] [CrossRef]

- Nagy, B.; Nehme, S.G.; Szagri, D. Thermal Properties and Modeling of Fiber Reinforced Concretes. Energy Procedia 2015, 78, 2742–2747. [Google Scholar] [CrossRef]

| Item | GU | FA | SF |

|---|---|---|---|

| SiO2 | 19.80% | 43.39 | 96.00 |

| Al2O3 | 4.90% | 22.08 | 1.10 |

| CaO | 62.30% | 15.63 | 1.20 |

| Fe2O3 | 2.30% | 7.74 | 1.45 |

| SO3 | 3.70% | 1.72 | 0.25 |

| K2O | 0.83% | - | 1.20 |

| Na2O | 0.34% | 1.01 | 0.45 |

| MgO | 2.80% | - | 0.18 |

| P2O5 | 0.11% | - | |

| Na2Oeq | 0.87% | - | |

| Loss on ignition | 1.90% | 0.58 | |

| Specific gravity | 3.15 | 2.50 | 2.20 |

| Surface area (m2/kg) | 360 | 280 | 17.8 × 103 |

| Properties | Values |

|---|---|

| Core | Paraffin wax |

| Shell Melamine | Formaldehyde (MF) |

| Tm, peak (°C) | 24 |

| Bulk Density (kg/cm3) | ~600 |

| Latent Heat Capacity (J/g) | 192 |

| Mean particle size (μm) | 15–30 |

| Appearance | White Powder |

| Mix | Cement | SF | FA | Sand | HRWR | Water | MPCMs% | Micro Steel Fiber% |

|---|---|---|---|---|---|---|---|---|

| M1 | 1.0 | 0.23 | 0.18 | 1.27 | 0.04 | 0.29 | 0.0% | 0.0% |

| M2 | 0.50% | |||||||

| M3 | 1.0% | |||||||

| M4 | 1.50% | |||||||

| M5 | 1.0 | 0.23 | 0.18 | 1.20 | 0.04 | 0.29 | 5.0% | 0.0% |

| M6 | 0.50% | |||||||

| M7 | 1.0% | |||||||

| M8 | 1.50% | |||||||

| M9 | 1.0 | 0.23 | 0.18 | 1.14 | 0.04 | 0.29 | 10.0% | 0.0% |

| M10 | 0.50% | |||||||

| M11 | 1.0% | |||||||

| M12 | 1.50% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rady, M.; Soliman, A.M. Performance of Fiber-Reinforced Ultra-High-Performance Concrete Incorporated with Microencapsulated Phase Change Materials. Fibers 2023, 11, 94. https://doi.org/10.3390/fib11110094

Rady M, Soliman AM. Performance of Fiber-Reinforced Ultra-High-Performance Concrete Incorporated with Microencapsulated Phase Change Materials. Fibers. 2023; 11(11):94. https://doi.org/10.3390/fib11110094

Chicago/Turabian StyleRady, Mahmoud, and Ahmed M. Soliman. 2023. "Performance of Fiber-Reinforced Ultra-High-Performance Concrete Incorporated with Microencapsulated Phase Change Materials" Fibers 11, no. 11: 94. https://doi.org/10.3390/fib11110094

APA StyleRady, M., & Soliman, A. M. (2023). Performance of Fiber-Reinforced Ultra-High-Performance Concrete Incorporated with Microencapsulated Phase Change Materials. Fibers, 11(11), 94. https://doi.org/10.3390/fib11110094