Abstract

The production of cement increases every year, which leads to the emission of dust/gas/ particulate matter. The emission of unfiltered dust would create a significant environmental impact. Hence, it is the responsibility of industries to control the emission of dust. Air filters and electrostatic precipitators (ESP) play a significant role in controlling pollutants. Synthetic filter media which are dangerous to our environment are widely used in most industries. The disposal of synthetic filters is an arduous task as the biodegradability of synthetic materials is poor. Hence, it is essential to develop an eco-friendly air filter material. In this paper, a new type of bag filter was designed by using natural sisal fiber as filtering media. The biodegradability of sisal fiber is better than the synthetic polyester media and also sisal fiber is less expensive. The natural fibers were coated with zinc oxide and iron oxide nanoparticles to improve the dust adsorption rate. Various tests were conducted as per standards to validate the performance of the filler media. The results were impressive. Hence, the proposed sisal fiber-based filter media can be used in cement industries for dust adsorption to minimize the environmental impact.

1. Introduction

Numerous diseases threaten human beings today. Climate change and global warming are some of the problems faced by humans due to pollution. Soil, water, and air pollution are the main causes of these problems. Among them, air pollution is more severe as it directly affects the respiratory systems of living creatures. Air pollution is caused by several factors. Dust is one of the major sources of air pollution which affects human health as well as the environment due to its small particle size. The dust is produced by a variety of industries. One of the largest sources producing dust is the cement industry which emits particulate matter and gaseous pollutants such as NOX, SOX, carbon oxides, and Volatile Organic Compounds (VOCs) [1]. The various sources of pollutants and the methods to reduce pollution can also be seen in [1]. Bag filter plays a vital role in the cement industry in filtering dust with minute particles. Xiao et al. [2] described the manufacturing procedure, structure of the products, their performance, merits and demerits, and extensive applications of various non-woven filter materials made of glass fiber. They described the significant role of air filters in industries. They also suggested the importance of the development of eco-friendly filter materials. However, the cost of glass fiber is high. Aravind Kumar et al. [3] developed bag filters using coconut and jute fibers. They analyzed the physical, mechanical, and chemical characteristics of the fibers. They coated the fibers with zinc oxide nanoparticles to improve the adsorbent ability of the fibers. The air permeability test was conducted by them to validate the performance of the natural fiber-based filter medium. They concluded that the coated nanofibers have a better adsorbent ability. Becheri et al. [4] reported the blend and characterization of nano-sized zinc oxide particles and their application on cotton and wool fabrics for UV protection. They produced the nanoparticles by varying the temperature and reacting medium. They conducted various tests to validate the performance of the coated cotton and wool fabrics. Ghorbani et al. [5] proposed a simple method for synthesizing ZnO nanoparticles in an aqueous solution utilizing zinc nitrate and KOH. Rastgoo et al. [6] performed the sonochemical synthesis of Fe3O4/ZnO nanocomposites on cotton/polyester fabric using the ultrasonic bath at 80°C. They developed a non-toxic cotton/polyester fabric with improved self-cleaning, antibacterial, antifungal, and increased mechanical qualities. Abhishek and Ramachandran [7] developed a pulse jet pleated bag filter that captures submicron dust particles effectively. Surface loading techniques were proposed to enhance the filter life and improve pulse cleaning. Mao [8] described the various types of natural fibers used as filter media in bag filters. The various methods for the synthesis of iron oxide particles and their characterization were studied in [9,10]. El-Nahhal et al. [11] coated the cotton fabric using zinc oxide nanoparticles using corn starch that acted as a modifying agent. Starch improved the adhesion properties of the cotton and hence led to better deposition of zinc oxide nanoparticles. They concluded that the durability of the fabrics was improved by the zinc oxide coatings. Chen [12] investigated the filtering impact of GLASS filter media, PPS media, METAMAX, and FMS filter media using a German AFC-131 filter media test apparatus. He performed a series of tests to determine their breaking strength, permeability, and temperature properties. He compared the results with the performance of existing materials. He also suggested that there is a scope for developing low-cost filter media to reduce the severe environmental impacts caused by various industries including cement industries. Robert et al. [13] described the effect of zinc oxide coatings on the mechanical properties of the composites. Wedman and Gore [14] proposed various tests to be conducted to validate the effectiveness of coating on fiber-based filter materials. They addressed that the air permeability test, bursting strength test, and tensile test are the most important tests to analyze the filter medium.

From the above literature review, it was observed that many researchers proposed several fibers for filter materials. They also proved that the metal oxide coatings would improve the performance of the fiber media. Hence, in this paper, an attempt is made to develop a filter medium using natural fiber. The filter medium used in this project is sisal fiber, which can be an alternative to synthetic filter materials. Sisal fiber is chosen in the present work as it has several advantages. Sisal fiber is a low-cost material. It is 100% natural fiber and hence has better biodegradability. Sisal fibers have better durability and they are versatile in nature. Sisal fiber does not affect the health of the people handling it. Characterization tests such as Scanning Electron Microscopy (SEM) were conducted for the confirmation of particles dispersed over the surface of the fiber and to identify the particle size of the metal oxides. Fourier-transform infrared spectroscopy (FTIR) was used for the confirmation of the highest peak of metal oxide found in the prepared particles and thermogravimetric analysis (TGA) to find out the withholding temperature of the uncoated and coated fibers. Various mechanical tests such as air permeability, bursting strength, and tensile strength were carried out as per standards to validate the performance of the developed sisal fiber-based filter material.

2. Materials and Methods

Sisal fiber and synthetic polyester were purchased from the local market as a bi-directional cloth at Madurai, Tamil Nadu, India. The chemicals required for the synthesis were purchased from Merck & Co., Inc. at H. Chandanmal & Co., Chennai, Tamil Nadu India. The materials required for the fabrication of the bag filter were purchased from Devi hardware, Sivakasi, Tamil Nadu, India.

2.1. Synthesis of Zinc Oxide

Zinc oxide was synthesized by the precipitation method [15] using zinc nitrate and ammonium oxalate by dissolving the required quantity (1:2) of chemical salts and distilled water in separate beakers. The chemicals were then transferred into a single beaker and continuously stirred for 1 hour. The pH was measured and the value was 3. The sodium hydroxide (NaOH) was added in drops until the pH value of 8 was attained. Then, the homogeneous mixture was filtered using filter paper to attain the precipitate. The precipitate was dried at room temperature. The precipitate was put in a crucible and was kept in the muffle furnace at 700–800 °C for 1 hour to attain the zinc oxide particles.

2.2. Synthesis of Iron Oxide

Iron oxide was prepared by the gel combustion method [16,17] using iron nitrate and citric acid by dissolving the salts using the required quantity (1:3) of distilled water in separate beakers. The chemicals were then transferred into a single beaker and continuously stirred for 1 h. The pH was measured and the value was 3. The ammonia solution was added in drops until the pH value of 10 was attained. The solution was kept in a hot plate at a constant temperature of 800 °C until the gel was formed. The gel was continuously stirred until it completely dried and the iron oxide particles were formed. The dried powder was collected in a crucible and it was kept in a muffle furnace at 700–800 °C for 2 h to attain the iron oxide particles.

2.3. Zinc Oxide Coating on the Fiber

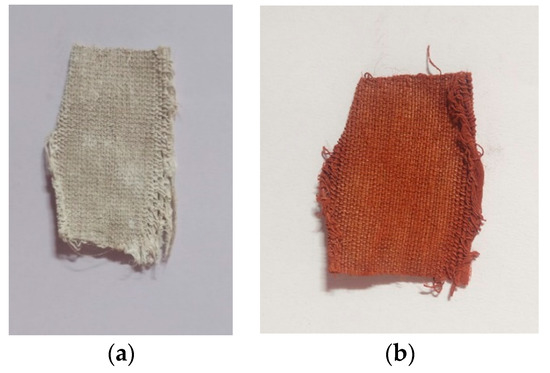

The sisal fiber was coated with metal oxide by a dip coating method. The sisal fiber sample of size 50 × 50 mm was cut and washed with distilled water several times and dried at 80 °C under vacuum. The dried fiber was then treated with 3% of corn starch in 20 mL of distilled water for 5 h at 70 °C and dried at 80° under vacuum. The starched fiber was soaked in 20 mL of deionized water containing 5% (w/w) of zinc oxide particles and gently stirred for 10 min. Then, the fiber was squeezed and dried in an oven at 130 °C for 15 min [11]. The sisal fiber coated with zinc oxide is depicted in Figure 1a.

Figure 1.

(a) Sisal fiber after zinc oxide coating wash; (b) sisal fiber after iron oxide coating.

2.4. Iron Oxide Coating on the Fiber

The dip coating method is used for the iron oxide coating. The sisal fiber sample of size 50 × 50 mm was cut and washed with distilled water several times and dried at ambient temperature for 24 h. Then, 0.35 g of iron oxide particles were obtained in a solution containing 9 mL of ethanol and 1.5 mL of deionized water. The solution was vigorously stirred for 30 min for particle dispersion. Then, the fiber was soaked in the solution and dried at 80 °C then at 120 °C for 1 h [18]. The sisal fiber coated with iron oxide is depicted in Figure 1b.

2.5. Scanning Electron Microscopy (SEM)

A Scanning Electron Microscope (SEM) is an electron magnification tool that creates images of a sample by inspecting the surface with engaged light emission. The electrons interact with the molecules in the sample, forming various signs that provide information about the sample’s surface geography and organization. In a raster examination design, the electron pillar was checked, and the position of the shaft was combined with the power of the distinguishing sign to generate an image. The particle size of the metal oxides was measured by Scanning Electron Microscope (SEM, model: JEOL JSM-6390). The surface Morphology of the metal oxide-coated fibers was also studied using SEM analysis.

2.6. Fourier Transform Infrared Spectroscopy (FTIR)

Fourier-transform infrared spectroscopy (FTIR) is a technique used for measuring the retention or outflow of a strong fluid or gas in the infrared spectrum. An FTIR spectrometer collects high-goal horrible data over a vast otherworldly range. This is a significant advantage over a dispersive spectrometer, which measures power over a small range of frequencies only. The frequency range covered by this FTIR (FTIR-8400S, Kyoto, Japan) instrument was 2.5 μm to 15 μm (wavenumber range 4000 cm−1 to 660 cm−1). Because of a critical atomic vibration, the lower frequency limit was chosen to encompass the most elevated known vibration recurrence.

2.7. Thermogravimetric Analysis (TGA)

Thermogravimetric investigation (TGA) is a technique for warm examination where the mass of a sample is estimated over the long run as the temperature changes. This estimation gives data about actual peculiarities, for example, stage changes, retention, adsorption, and desorption; as well as substance peculiarities including chemisorptions, warm deterioration, and strong gas responses (e.g., oxidation or decrease). A TGA can be utilized for materials characterization through the investigation of trademark disintegration designs. It is a helpful procedure for the investigation of polymeric materials, including thermoplastics, thermosets, elastomers, composites, plastic movies, filaments, coatings, and paints. The thermogravimetric information gathered from a warm response is assembled into a plot of mass or level of introductory mass on the y hub versus either temperature or time on the x-pivot. This plot, which is regularly smoothed, is alluded to as a TGA bend. The main subordinate of the TGA bend (the DTG bend) might be plotted to decide whether emphasis focuses are helpful for top-to-bottom translations as well as differential warm examination. The TGA was carried out with a thermogravimetric analyzer (PERKIN ELMER PYRIS 1 TGA).

2.8. Air Permeability Test

This test is used to measure the rate of airflow passing through the filter on either side. It is a mandatory test for every fabric such as bag filters, woven/non-woven textile materials, knitted fabric, parachutes, and vacuum cleaners. The fabrics may be tested under different conditions. In the present work, the air permeability test was conducted as per ASTM D 737 standards, and the procedure described in [14] was adopted.

2.9. Bursting Strength Test

The bursting strength test is used to determine the resistance of the fiber cloth against the applied load. It is a common test used for all types of fabrics. In the present work, the bursting strength test was conducted as per ASTM D 3786 standards, and the procedure described in [14] was adopted. The test can be conducted either with a pneumatic or hydraulic diaphragm bursting tester.

2.10. Tensile Strength Test

The quality and performance of the material are determined with the help of the tensile test. It is a measure of the directional strength of the media. The tensile strength test is performed as per ASTM D 5035 standards. The procedure proposed in [14] was used to measure the tensile properties.

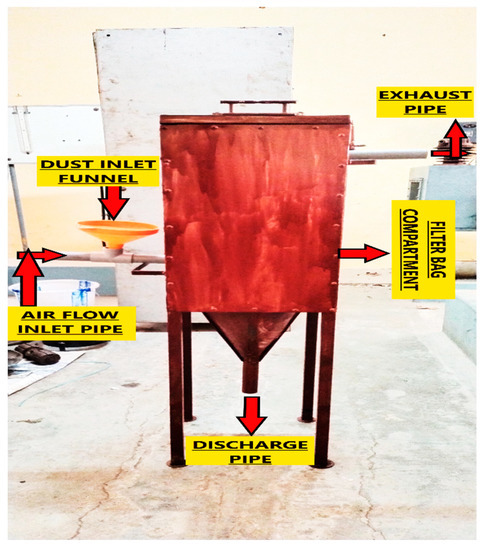

2.11. Dust Adsorption Test

The dust adsorption test was conducted to test the fiber-based filter’s effectiveness. To perform the dust adsorption test, a bag house filter was designed. Mild steel wire mesh was used to make the filter cage. An aluminium sheet of 1 mm thickness was used to make the compartment of the filter bag house. PVC pipes were used for the inlet and outlet of dust in the bag house. For dust adsorption testing, sisal fiber-based filter media was fabricated and fixed in the filter cage. Figure 2 shows the full fabrication setup of the dust bag house filter. The zinc oxide-coated sisal fiber-based filter media are shown in Figure 3.

Figure 2.

Fabricated bag house filter.

Figure 3.

Zinc oxide-coated sisal fiber-based filter media.

The initial weight of the filter medium was noted (W1). A sample of 1 kg cement dust was sprayed on the filter medium using compressed air at 1.2 kg/cm2 pressure inside the inlet of the baghouse. The weight of the filter medium was noted (W2). From the initial and final weight values, the rate of dust adsorption was calculated using Equation (1). Multiple trials were performed for each sample and the average value was obtained.

3. Results and Discussion

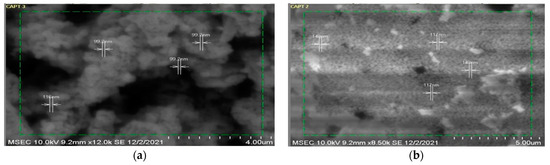

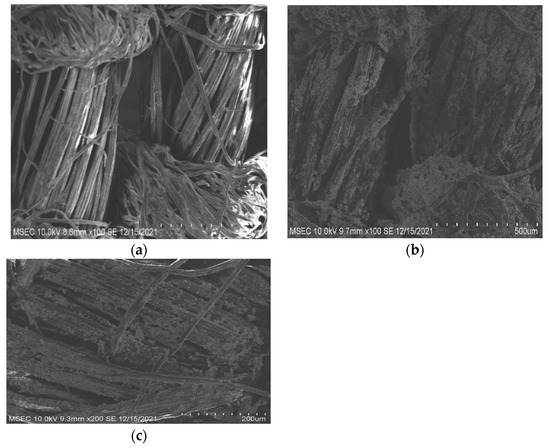

3.1. SEM Results

The size of the metal oxide particles was identified using SEM analysis. Figure 4 shows that the size of the zinc oxide particles ranges from 99.2 nm to 116 nm. The size of the iron oxide particles ranges from 117 nm to 140 nm. The SEM images of the zinc oxide and iron oxide particles are shown in Figure 4a and Figure 4b, respectively. After the coating of metal oxide on natural fibers, the surface morphology of the coated fibers was analyzed using SEM images to ensure the dispersion of metal oxide particles on the surface of sisal fiber. Figure 5a shows the uncoated sisal fiber. The SEM images of the coated sisal fibers are depicted in Figure 5b, and Figure 5c, respectively. From the SEM images, it is understood that the coating is effective.

Figure 4.

(a) SEM image of zinc oxide particles; (b) SEM image of iron oxide particles.

Figure 5.

(a) SEM image of uncoated sisal fiber; (b) SEM image of zinc oxide-coated sisal fiber; (c) SEM image of iron oxide-coated sisal fiber.

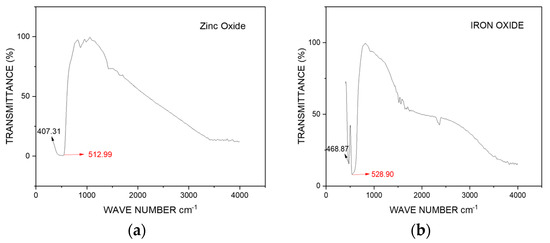

3.2. FTIR Results

The presence of zinc oxide and iron oxide is further ensured by the Fourier transform infrared spectroscopy (FTIR) method. The highest peak of the graph confirms the presence of metal oxides. The FTIR spectrum was recorded in the range from 400 to 4000 cm−1. The FTIR results are depicted in Figure 6. Figure 6a shows the spectrum ranges of 512 cm−1 which would confirm the presence of zinc oxide from the prepared sample by precipitation method from the reference of major peak of 540 cm−1 [13] and peak ranges from 450 to 500 cm−1 [15]. Figure 6b shows the spectrum of 528 cm−1 that would confirm the presence of iron oxide from the prepared sample by the gel combustion method from the reference of metal–oxygen vibration corresponding to 480 and 621 cm−1 [16] and Fe-O appearing at 526.88 and 434.60 cm−1 [18].

Figure 6.

(a) FTIR result of zinc oxide; (b) FTIR result of iron oxide.

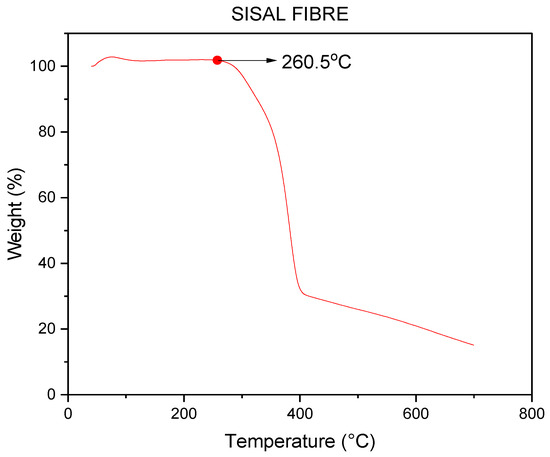

3.3. TGA Results

Since the bag filter would be subject to a maximum temperature of about 250 °C, the TGA was carried out on the sisal fiber to analyze the maximum withstanding temperature of the sisal fibers. The test result of TGA was considered between the temperature range from 40 to 700 °C under a nitrogen atmosphere with a flow rate of 19.8 mL/min. The TGA result of the sisal fiber is shown in Figure 7. Figure 7 shows that the obtained peak of 260.5 °C was the withstanding temperature of the sisal fiber, which means it can hold the process temperature in the cement plant.

Figure 7.

TGA result of sisal fiber.

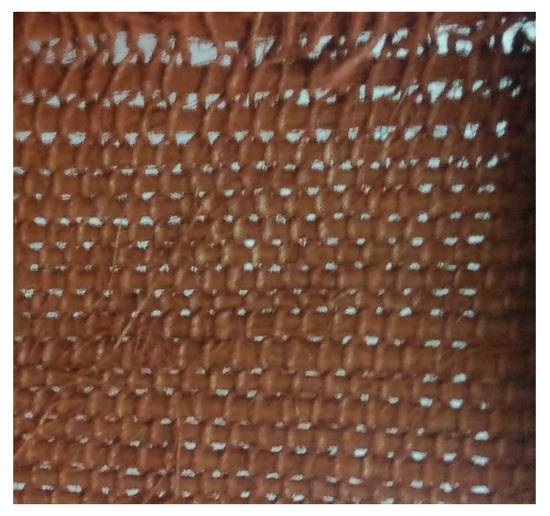

3.4. Rejecting Iron Oxide Coating

The iron oxide-coated sisal fiber-based filter media are shown in Figure 8. From Figure 8, it is observed that the coated natural fibers increased the pore size of the filter media which leads to passing the large size dust particles through it. Thus, iron oxide coating does not meet the filter media requirements. Hence, the other experiments were carried out on the zinc oxide-coated sisal fiber-based filter media only.

Figure 8.

Iron oxide-coated sisal fiber-based filter media.

3.5. Air Permeability of Samples

The air permeability test results of different filter mediums are presented in Table 1. The synthetic polyester has an air permeability of 32.64 ± 0.24 ft3/ft2/min. The air permeability of uncoated sisal fiber-based filter medium is 38.06 ± 0.32 ft3/ft2/min. The coated sisal fiber-based filter medium has an air permeability of 33.06 ± 0.18 ft3/ft2/min. From the test results, it is evident that both the coated and uncoated sisal fiber-based filter medium have better permeability properties than the synthetic polyester material. Hence, it could be concluded that the sisal fiber-based filter media can replace the synthetic filter medium. This would minimize the environmental impact as the biodegradability of synthetic polyester is poorer than that of natural fiber-based materials. Hence, the sisal fiber-based filter media can be used for bag filter application in cement industries. However, it is observed that the coating does not improve the air permeability property of the filter media.

Table 1.

Air permeability test result.

3.6. Bursting Strength of Samples

The bursting strength of the samples is presented in Table 2. From the results, it is observed that the bursting strength of the synthetic polyester is only 1.31 ± 0.08 MPa only. The uncoated sisal fiber-based filter medium has a bursting strength of 1.62 ± 0.14 which is much better than the bursting strength of synthetic polyester. The Zinc Oxide coated sisal fiber-based filter medium has a bursting strength of 1.65 ± 0.12 MPa. The results indicate that the metal oxide coating improved the bursting strength slightly. As the bursting strength of uncoated sisal fiber-based filter media is much better than that of synthetic polyester, the sisal fiber-based filter media can be used for dust adsorption in cement industries.

Table 2.

Bursting strength test result.

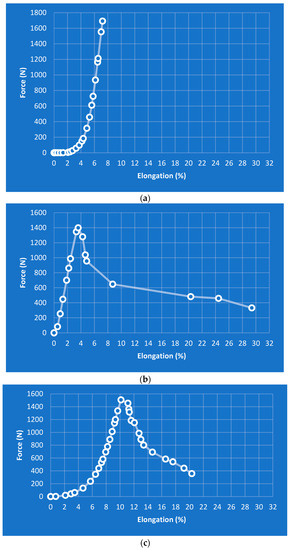

3.7. Tensile Strength of Samples

Figure 9a,b depict the load versus elongation graphs of synthetic polyester and sisal fiber respectively. From the figures, it is evident that both the synthetic polyester and the sisal fiber can withstand the maximum load of 1400 N. As the tensile properties are similar, sisal fiber could replace synthetic polyester for bag filter applications. Also, from Figure 9b,c, it is observed that the Zinc Oxide coating has increased the ten-sile strength of the sisal fiber by 15.7%.

Figure 9.

Load versus elongation graphs of (a) synthetic fiber; (b) sisal fiber—uncoated; (c) sisal fiber—coated with zinc oxide.

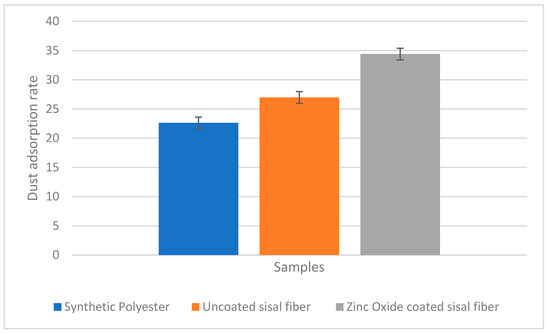

3.8. Dust Adsorption Rate of Samples

The dust adsorption rate of the samples is shown in Figure 10. The dust adsorption rate of zinc oxide-coated sisal fiber is 34.4% which is greater than the other two sam-ples. The uncoated sisal fiber has an adsorption rate of only 26.98% which is less than that of zinc oxide-coated sisal fiber. However, the dust adsorption rate of uncoated sisal fiber is better than the dust adsorption rate of synthetic polyester material. Hence, it is concluded that the sisal fiber-based filter media are suitable for dust adsorption. Further, the zinc oxide coating has improved the adsorption rate significantly. The results of the air permeability test, bursting strength test, tensile strength test, and dust adsorption test reveal that the sisal fiber-based filter material could be a good substitute to replace the synthetic filter materials. Hence, the sisal fiber-based filter material can be used in the cement industry to minimize the environmental impact of dust.

Figure 10.

Dust adsorption rate of samples.

4. Conclusions

In this work, an attempt has been made to increase the dust adsorption rate of bag house filters used in the cement industry. A sample bag house filter was fabricated using sisal fiber. The sisal fiber was coated with zinc oxide. The performance of the synthetic polyester, sisal fiber, and zinc oxide-coated filter media was analyzed by conducting various tests as per ASTM standards. The uncoated sisal fiber showed better air permeability. However, the zinc oxide-coated sisal fiber had better bursting strength than synthetic polyester and uncoated sisal fiber. The tensile properties of synthetic polyester and uncoated sisal fiber were similar. The tensile strength of the sisal fiber was significantly improved by the zinc oxide coating. The coated sisal fiber had a better dust adsorption rate. Hence, the sisal fiber-based filter media could be a better replacement for synthetic polyester. This would minimize the environmental impact caused by synthetic filter materials. Though better results were obtained, it would be interesting to evaluate the performance of other natural fibers such as coir fiber, banana fiber, and jute fiber as a filter medium. The proposed sisal fiber-based filter media can be used in the real cement industry and the performance of the zinc oxide-coated sisal fiber may be investigated which would be another possible scope of this research. The sisal fiber may be coated with other metal oxides and the performance may be analyzed. The developed sisal fiber-based filter media could be used in other industries to minimize air pollution.

Author Contributions

Conceptualization, M.M.K.; methodology, M.M.K.; validation, M.M.K.; formal analysis, G.M.; data curation, G.M.; writing—original draft preparation, M.M.K.; writing—review and editing, G.M.; supervision, M.M.K.; project administration, G.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zimwara, D.; Mugwagwa, L.; Chikowore, T.R. Air pollution control techniques for the cement manufacturing industry: A case study for Zimbabwe. CIE42 Proc. 2012, 37, 1–13. [Google Scholar]

- Xiao, H.; Li, X.; Liu, L.; Liu, Y.; Zhao, D. Development of Environmental Protection Air Filter Media. In Proceedings of the 2010 International Conference on Information Technology and Scientific Management, Tianjin, China, 20–21 December 2010. [Google Scholar]

- Aravind Kumar, B.; Jeyasubramanian, K.; Senthil Murugan, S. Investigation of Dust Adsorbing Ability of Bag Filter using Nano Technology. SSRG Int. J. Mech. Eng. 2017, 4, 1–7. [Google Scholar]

- Becheri, A.; Dürr, M.; Lo Nostro, P.; Baglioni, P. Synthesis and characterization of zinc oxide nanoparticles: Application to textiles as UV-absorbers. J. Nanopart. Res. 2008, 10, 679–689. [Google Scholar] [CrossRef]

- Ghorbani, H.R.; Mehr, F.P.; Pazoki, H.; Rahmani, B.M. Synthesis of ZnO nanoparticles by precipitation method. Orient. J. Chem. 2015, 31, 1219–1221. [Google Scholar] [CrossRef]

- Rastgoo, M.; Montazer, M.; Harifi, T.; Mahmoudi Rad, M. Dual metal oxide loaded cotton/polyester fabric with photo, bio and magnetic properties. J. Ind. Text. 2020, 50, 170–186. [Google Scholar] [CrossRef]

- Abhishek, P.S.; Ramachandran, P.N. Design of pleated bag filter system for particulate emission control in cement industry. Int. Res. J. Eng. Technol. 2015, 2, 763–768. [Google Scholar]

- Mao, N. Nonwoven fabric filters. In Fibrous Filter Media; Woodhead Publishing: Soston, UK, 2017; pp. 133–171. [Google Scholar]

- Sun, J.; Zhou, S.; Hou, P.; Yang, Y.; Weng, J.; Li, X.; Li, M. Synthesis and characterization of biocompatible Fe3O4 nanoparticles. J. Biomed. Mater. Res. Part A 2007, 80, 333–341. [Google Scholar] [CrossRef] [PubMed]

- Jeyasubramanian, K.; Thoppey, U.U.G.; Hikku, G.S.; Selvakumar, N.; Subramania, A.; Krishnamoorthy, K. Enhancement in growth rate and productivity of spinach grown in hydroponics with iron oxide nanoparticles. Rsc Adv. 2016, 6, 15451–15459. [Google Scholar] [CrossRef]

- El-Nahhal, I.M.; Salem, J.; Anbar, R.; Kodeh, F.S.; Elmanama, A. Preparation and antimicrobial activity of ZnO-NPs coated cotton/starch and their functionalized ZnO-Ag/cotton and Zn (II) curcumin/cotton materials. Sci. Rep. 2020, 10, 5410. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.X. Application and Performance Test of High Temperature Filter Media Used on Bag—House duster. In Proceedings of the 2014 International Conference on Education, Management and Computing Technology (ICEMCT-14), Tianjin, China, 14–15 June 2014; pp. 413–417. [Google Scholar]

- Robert, R.J.; Hikku, G.S.; Jeyasubramanian, K.; Jacobjose, J.; Prince, R.M.R. ZnO nanoparticles impregnated polymer composite as superhydrophobic anti-corrosive coating for Aluminium-6061 alloy. Mater. Res. Express 2019, 6, 075705. [Google Scholar] [CrossRef]

- Wedman, E.I.; Gore, W.L. A Practical Guide to Filter Media Failure Analysis. In Powder & Bulk Solids Conference and Exhibition; Donald E. Stephens Convention Center: Rosemont, IL, USA, 2001. [Google Scholar]

- Srivastava, V.; Gusain, D.; Sharma, Y.C. Synthesis, characterization and application of zinc oxide nanoparticles (n-ZnO). Ceram. Int. 2013, 39, 9803–9808.v. [Google Scholar] [CrossRef]

- Kayani, Z.N.; Arshad, S.; Riaz, S.; Naseem, S. Synthesis of iron oxide nanoparticles by sol–gel technique and their characterization. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Mishra, D.; Arora, R.; Lahiri, S.; Amritphale, S.S.; Chandra, N. Synthesis and characterization of iron oxide nanoparticles by solvothermal method. Prot. Met. Phys. Chem. Surf. 2014, 50, 628–631. [Google Scholar] [CrossRef]

- Nadi, A.; Sbai, S.J.; Bentiss, A.; Belaiche, M.; Briche, S.; Gmouh, S. Application of Fe3O4 nanoparticles on cotton fabrics by the Pad-Dry-Cure process for the elaboration of magnetic and conductive textiles. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 827, p. 012021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).