Abstract

Invasive plant species can impede the establishment and growth of native plants and affect several ecosystem properties. These properties include soil cover, nutrient cycling, fire regimes, and hydrology. Controlling invasive plants is therefore a necessary, but usually expensive, step in restoring an ecosystem. The sustainability of materials with an emphasis on the use of local resources plays an important role in the circular economy. The use of alternative fibers from invasive plants promotes local production in smaller paper mills that offer the protection of local species and the reduction of waste and invasive plants. A synthesis of the literature is needed to understand the various impacts of invasive plants and their practical control in the context of papermaking applications and to identify associated knowledge gaps. To improve our understanding of the practical application of invasive species in the paper industry, we reviewed the existing literature on invasive plant species in the area of fiber production, printability, coating solution production, dyes, and extracts, and collected information on the major invasive plant species in Europe and the methods used for various applications.

1. Introduction

Industry is developing rapidly; population density is increasing and people have more and more needs due to the increasingly stressful and fast pace of life. The above-mentioned factors have a strong impact on the balance and processes in nature, as they greatly deplete the natural resources and raw materials needed to satisfy our diverse needs. We are penetrating deeper and deeper into geographical areas that were untouched in the past and are extremely important for the regulation of biological and climatic balance of the planet. Thus, we feel the consequences of our behavior in environmental problems such as the greenhouse effect, the depletion of the ozone layer, acid rain, smog, heavy metal emissions, soil and water pollution, and the depletion of renewable resources. In addition to all these industrial impacts, transportation, agriculture, energy production, and the consumer society that produces huge amounts of solid waste, including packaging, also contribute to pollution. For all these reasons, it is very important for sustainable development that the economic, social, and environmental sectors harmonize. As a result, a circular economy has evolved that works in the spirit of sustainable development. It is a new concept that aims to maximize the use of raw materials in the production and consumption cycle. Through the process of recycling, repair, and reuse, it aims to create a new “zero waste” lifestyle. We intelligently plan and design products from the beginning and can select or predict the production processes and resources used in advance. In this way, we can effectively manage waste while creating new business opportunities.

According to most scientific evidence related to biodiversity conservation, global warming and climate change can have significant impacts on human health and the environment. In order to improve the well-being and living conditions of present and future generations, it is important that the negative impacts of human and industrial activities be seriously considered at all stages of planning new developments.

The pulp and paper industry is one of the largest industries in the world with high capital investment. As shown in the preliminary CEPI report for 2021, the production of paper and paperboard in member countries increased by 5.8% compared to 2020. Global paper and board production increased by about 3%. Production of packaging grades is estimated to have increased by 7.1% compared to 2020. Within packaging grades, cardboard materials, which are mainly used for transport packaging and corrugated cardboard boxes, are positively influenced by the current e-commerce boom and recorded an increase of 7.8% [1].

In the paper industry, biomass, such as wood and other species, is undergoing constant change due to countries’ efforts to decarbonize, the rise of bio-based materials, and so on. The recent shortage of paper for various media, due to the shift from fiber to packaging applications, opens the space for alternative solutions. Recently, interest in the use of agricultural residues has increased.

Invasive alien plant species (IAPS) are harmful to the environment on a larger scale where they occur. According to the European Union definition, IAPS are species that have been displaced from their natural ecological range by human activities and species whose introduction and spread outside their natural ecological range pose a real threat to biodiversity and the economy [2]. It is reported that there are estimated to be over 12,000 alien species in Europe, of which about 10–15% are invasive. All EU Member States have relatively major problems with IAS on their territory.

The impact of invasive plants has been the subject of many studies, and many researchers have presented solutions for their removal and reuse. These species pose a major challenge to European ecosystems, especially because they destroy agricultural land and displace local vegetation. Their spread disturbs the balance of natural ecosystems in many ways. By competing with each other, transmitting diseases, altering soil and light conditions, and reshaping the functioning of the entire ecosystem, they pose a major threat to native species richness and habitat biodiversity. They displace native vegetation, destroy agricultural land, and cause billions of dollars of damage to the European economy each year. Therefore, they are considered a nuisance species with negative impacts on native species and ecosystems [3].

Nearly two-thirds of the plant species established in Europe were intentionally introduced for ornamental, horticultural, or agricultural purposes. The remaining species were introduced unintentionally, mostly in association with transport vectors or as contaminants of seeds and other commodities [3,4]. Of the invasive plant species that escaped human cultivation, some were intentional releases (i.e., planted in the wild to “beautify” the landscape), some were contaminants or stowaways, and few arrived unassisted [3,4,5,6]. Much less is known about the introduction and spread of non-native lower plants and fungi, and about changes in the number of non-native species in Europe over time. It is known that these taxa can have enormous impacts, with perhaps the most damaging examples being diseases of crops and livestock. Therefore, Europe is solving these problems with various projects that address the spread of invasive plant species, their impact on the environment, the consequences, and the controls to measure the impact.

As the paper presents the European invasive plants in paper production, the spread, measurement and control of the spread of these plants is regulated by the European Commission Regulation 1143/2014 on invasive alien species [2]. Namely, the provisions of IAPS EU include prevention, early detection and rapid eradication, and management to prevent the spread of the species and minimize the damage it can cause.

Species that have been investigated by many researchers are Acacia melanoxylon [4], Alternanthera philoxeroides (weed) [5], Arundo donax (cane) [6], Bromus tectorum (cheatgrass) [7], Eichhornia crassipes (common water hyacinth) [8,9], Fallopias spp. [10,11], Hedychium coronarium (white ginger lily) [12], Miscanthus sinensis [13,14,15,16], Pittosporum undulatum [17], Solidago canadensis (Canadian goldenrod) [18], Spartina alterniflora (cordgrass) [19], Triadica sebifera (Chinese tallow) [20], Ulex europaeus (gorse) [21]. Regarding the use of invasive alien plants, studies on the production of paper and packaging materials have been conducted with Japanese Knotweed, Goldenrod, and Black Locust [22,23,24,25,26,27,28,29,30]. Feedstocks from different biomasses such as crops and invasive alien plants are therefore gaining increasing interest.

In this review, IAPS solutions employed in Europe for the use of the mentioned plant species in the production and recyclability of paper and packaging materials are presented. It also highlights the limitations and future perspectives of the mentioned solutions.

2. Overview of the Various IAPS in Europe for Paper Production

Classical paper substrates are usually made of mechanical or chemical pulp, using different proportions of hardwood and/or softwood fibers with additives such as retention agents, fillers, binders, etc. [31]. In addition to hardwood and softwood fibers, invasive plants can also be used as a fiber source for paper production.

Isolated cellulose fibers from invasive plant biomass have been used in films and fiberboards [29]. Much research has also been conducted on the application of cellulose fibers derived from invasive plant biomass for conventional paper products and their finishing [26,27,28,30,32].

The IAPS presented, such as Knotweed, Goldenrod, and Black Locust, are the most invasive plant species in Europe used in paper production and are therefore presented in more detail in the following subsections.

2.1. Knotweed

The Knotweed family (Polygonaceae) comprises about 40 genera [28]. As Lavoie points out in his review, invasive Knotweed has significant negative impacts on native plants, while the abundant litter produced and deep rhizome system alters soil chemistry to the invaders’ advantage. The most invasive plants from this plant family in Europe are Fallopia japonica, Fallopia sachalinensis, Fallopia x bohemica, and hybrids between Fallopia japonica and Fallopia sachalinensis. All the above species also differ in the type of leaves and flowers they possess (Figure 1).

Figure 1.

Japanese Knotweed with leaves and flowers.

In East Asia, Japan, China, etc., Fallopia japonica is native and was introduced into the Dutch botanical garden in 1823 as an interesting plant [4]. Later these plants were cultivated in various places in Europe as ornamental and bee pasture plants with autumn flowers. Over the years, the plants spread throughout Europe and now pose a threat to the natural ecosystem and biodiversity. Nevertheless, Knotweed is an edible plant that contains many medicinal compounds that have been isolated and identified by many researchers [28,33,34,35,36]. It is a rich source of resveratrol, an antioxidant with antibacterial properties. The extracts have been used to dye textiles and improve antimicrobial activity [37,38,39].

2.2. Goldenrod

Goldenrods (i.e., Canadian goldenrod—Solidago canadensis—and Giant goldenrod—Solidago gigantea) originated in the North of America and can also be found in Europe and Asia. The aforementioned plants are also invasive and can spread locally via rhizomes with large wind-borne seeds [40].

The aforementioned species have a similar habit and grow from 30 to almost 300 cm tall. The stems are unbranched, except in the inflorescence. The leaves are stalkless and three-veined (Figure 2). The inflorescences form broad pyramidal panicles with recurved branches and a central axis. The ray florets are yellow, female, and fertile, while the disk florets are bisexual and fertile. Both species occur in the same habitat types, such as disturbed areas, railroad and road sides, riverbanks, urban and peri-urban areas, agricultural areas, plantations and orchards, forests, and meadows [28].

Figure 2.

Goldenrod with leaves and flowers.

There are differences in plant morphology, phytochemical profiles, and bioactivity between the European native species Solidago virgaurea and the invasive alien species Solidargo canadensis and Solidargo gigantea. The main differences are in the number of chemical compounds antimicrobial, antimutagenic, and antioxidant properties [41]. While the generally accepted trends and strategies regarding invasive plant species are to limit or eliminate the invaders, some research groups following bioeconomy principles are investigating potential uses of invasive Solidago species and attempting to convert wastes into valuable products.

Following Radušiene’s research on the importance of goldenrod to the environment, a new approach has recently been developed to use invasive species as a potential source of value-added products, rather than eliminating them using labor-intensive and environmentally damaging methods. The high biomass produced by exotic goldenrod is a promising source of renewable energy that can be used in rural households as an alternative to expensive firewood and that does not compete with food or feed crops [42].

According to the research of Patel et al., canadensis contains interesting components in all parts of the plant: essential oils with antimicrobial and antioxidant properties, natural dyes for dyeing textiles, extracted substances with algicidal, antimicrobial and antioxidant properties, stems for cellulose blends, and plant residues for the production of heating pellets and biofuel [43,44].

2.3. Black Locust

Black Locust, or Robinia pseudoacacia L., is considered controversial in Europe because it was deliberately planted in this region (Figure 3). It was introduced to Europe from North America in the early 17th century. It was introduced to Europe from North America in the 17th century. It was planted as an ornamental tree in parks and gardens, but was also used to produce firewood, as a leaf food for animals, as a nectar source for bees, to produce waterproof wood, and to control soil erosion [45,46]. Nowadays, this plant covers more than 2.3 million ha with an area of at least 100,000 ha in Bulgaria, the Czech Republic, France, Hungary, Italy, Poland, Romania, Slovenia, Serbia, and Ukraine [33,34,35,36,47,48,49,50].

Figure 3.

Black Locust with leaves and flowers.

Research and studies have shown that the flowers contain flavonoids, condensed tannins, polysaccharides, and essential oil, which have antimicrobial activity against foodborne pathogens [51,52,53].

3. The Preparation and Process Production of IAPS Fibers for Papermaking Industry

Paper making involves several steps and it is important to select suitable raw materials, the criteria being [54]:

- (a)

- The supply should be abundant and uninterrupted;

- (b)

- Fibers should meet certain size requirements;

- (c)

- Pulp yield should be high;

- (d)

- Fibers should not deteriorate and lose strength rapidly during storage;

- (e)

- The insulation of the fibers should be technically and economically feasible;

- (f)

- Collection, transport, and storage should be economical;

- (g)

- There should be few competing uses for the selected material.

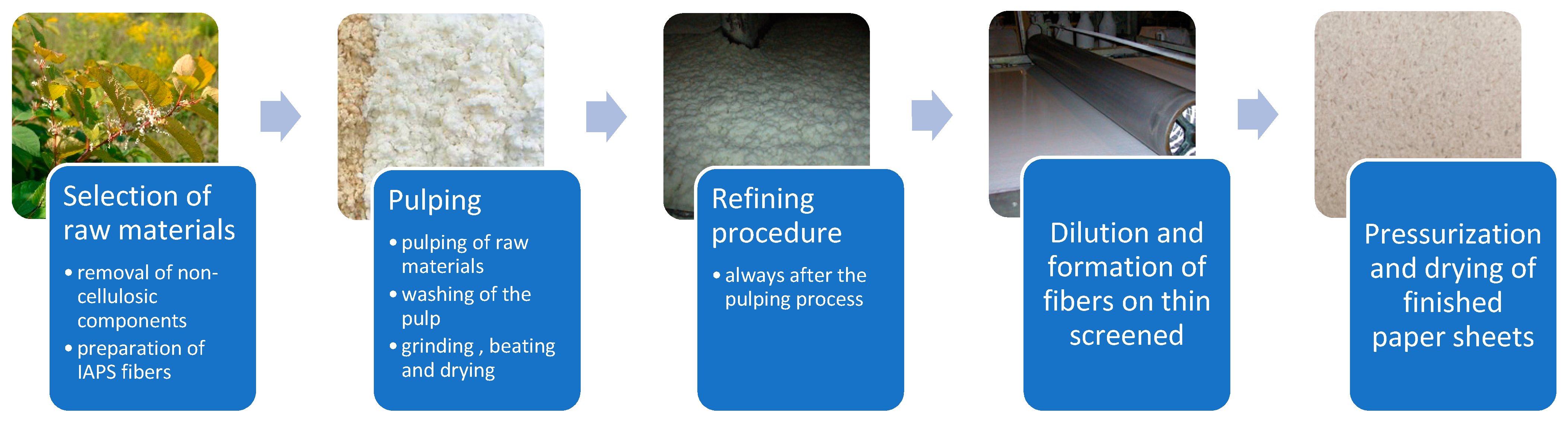

The process of papermaking includes the selection of raw materials, removal of non-cellulosic components, pulping of raw materials (mechanical, biological, or chemical pulping), washing of pulp, screening and grinding, and beating and drying (Figure 4).

Figure 4.

The process of paper making from invasive plant species.

The process of fiber preparation begins with the harvesting of the plants, where the leaves and flowers are separated from the stems in the La-boratorium IAPS.

As Kapun et al. pointed out, the samples are chopped into 50–100 mm-long pieces and dried at room temperature and humidity [29]. The biomass is reduced into small pieces with a diameter of about <0.5 mm by grinding. The process included degreasing and comminution. The process involved delignification and shredding. The results showed that all the IAPS studied, including Fallopia japonica and Solidago canadensis, had relatively high polysaccharide content, remarkable hemicellulose and ash content, and suitable morphology for sustainable papermaking. Kim et al. presented the process for producing cellulose nanofibres from Goldenrod, using alkali oxides, bleaching, and electron beam irradiation [55]. On the other hand, Evdiokimova et al. also presented the production of cellulose nanofibres from invasive plants such as Agave americana L. and Ricinus communis L. using alkaline or acid hydrolysis [56]. Almeida et al. also produced nano-cellulose gels from invasive Acacia and Ailanthus woods [57].

The results showed improved mechanical properties of the paper sheets. A few pulping processes have been proposed, also presented by Baptista et al. and Ferreira et al., as shown in Table 1 [58,59].

Table 1.

Preparation of IAPS fibers for paper production.

Properties of IAPS Fibers and Paper Materials

In this review, the three most frequently analyzed and used IAPS were systematically analyzed on a larger scale based on the literature review.

In particular, Knotweed, Goldenrod, and Black Locust represent a potentially significant source of biomass characterized by their transformability. The properties analyzed were fiber length, width, and orientation, as well as chemical analysis of the IAPS (ethanol, cellulose, hemicellulose, and lignin content), as shown in Table 2.

Table 2.

Fiber properties of IAPS used for paper production [3,4,5].

As shown in Table 2, all three IAPS contain a similar amount of hemicellulose but differ in the content of cellulose, ethanol extracts, and lignin. Knotweed contains more lignin and less cellulose and ethanol, compared to Black Locust, which has the highest amount (almost 5%) of ethanol extracts. The same applies to the cellulose content, which is 41% for Black Locust. Since non-wood materials are slow to dehydrate, problems can arise during paper production. Therefore, paper machines cannot run at high speed and the cost of producing paper from non-wood fibers is high. Nevertheless, recently there are more and more pulp mills for non-wood fibers, which are part of biorefineries.

In addition, some of the important properties of IAPS papers make them an attractive candidate for applications due to their biodegradability and environmental aspects. The global demand for recycled paper has increased in recent years, which has also led to poorer quality of waste paper in terms of mechanical properties [62]. Obtaining paper-based products from wood-free and low-grade fiber resources such as IAPS would be a great step towards protecting forest resources.

The unique physical and mechanical properties of IAPS (summarized in Table 3; Table 4), that have led to its use in a variety of applications, exhibit a higher degree of anisotropy and lower elasticity, suggesting that the cross-linking of the structure is poorer. However, compared to commercially available papers made from wood cellulose fibers, cellulose fibers made from IAPS exhibit similar basic structural properties. The reported thickness and grammage of the papers were used because they are important for real paper production and the limits were 0.002–0.004 mm (Table 3). Paper made from IAPS is more voluminous than paper made from conventional cellulose fibers. Therefore, inhomogeneities in the form of weak stability are to be expected. The ash content in graphic papers can be as high as 30 or even 40%, in contrast to IAPS papers where a maximum of 4% has been analyzed [28]. In fact, commercial papers contain inorganic fillers, which have a positive effect on the printing properties and opacity, but a negative effect on the physical–mechanical properties, which is also reflected in the reduction of the possibility of fiber bonding and interlacing.

Table 3.

Comparison of basic properties of different kinds of papers, produced from IAPS.

Table 4.

Comparison of mechanical and chemical properties of different kinds of papers, produced from IAPS.

The tensile properties of the presented papers in Table 4 show that the Goldenrod has the weakest physical–mechanical properties and high anisotropy. Since the papers made from IAPS have shorter fibers, they are stiffer and show the results of bending stiffness, which is the response to external deformation and is important for use in packaging. Studies indicate that the relaxation temperature of paper depends mainly on the structural mobility of hemicellulose and lignin under the influence of heat and moisture [28,63]. As Placet et.al. have pointed out, a lower relaxation temperature could be the result of the relaxation of hemicellulose, while at higher temperatures it is caused by lignin [64]. From the presented work, it appears that the viscoelastic behavior of IAPS papers is influenced by moisture. Goldenrod cellulosic fibers are closest to tree fibers in terms of basic and physical–mechanical properties and could be more integrated into paper production as a good alternative for reducing wood species to cellulosic fibers.

4. Different Applications on Papers from IAPS

IAPS could be an important factor in the paper industry by developing new value-added products to improve the durability, added value, or printing properties of paper (Table 5). It is very important to point out that the runnability (adhesion and friction process) in papermaking should be adapted to the requirements of the particular IAPS.

Table 5.

Applications of IAPS in the papermaking industry.

Paper made from IAPS has a textured and robust surface, that affects the printing properties. Many studies have been conducted using digital, screen, and flexographic printing techniques to analyze the possibilities and use of the mentioned papers in practice [26].

The study by Karlovits et.al. showed that papers made from invasive plant species, including Canadian Goldenrod, Black Locust with the addition of hardwood and softwood, have excellent electrographic digital printing quality in uncoated papers. From the study by authors Karlovits and Kavčič, it is clear that a large number of scientific studies have been published on paper properties that affect flexographic printability [25]. The study showed that flexographic printing technology and results related to printing properties prove that the alternative cellulose fibers from Fallopia japonica, Canadian goldenrod, and Black Locust can be widely used for packaging applications and printing. With the right smoothness, surface energy, and liquid absorption and optimization, IAPS fibers can achieve good printability and processability in fiber-based packaging products and materials.

On the other hand, printed electronics, an extremely valuable and growing field, allows electronics to be printed on various materials. Sensors, displays, RIFD tags, and various electrodes are printed in layers with different inks and used in many fields (medical, retail, biochemical solutions, etc.) [65,66,67]. There are also applications of printing electrodes on Fallopia japonica and Giant and Canadian goldenrod [25]. One of the most important characteristics for printed electronics is the roughness of the surface, porosity, and pre- and post-treatment of the working electrodes. Research has shown that invasive vegetable papers are suitable for printed electronics using the screen printing technique.

IAPS have been produced and analyzed not only as paper products, but also as coating solutions for packaging papers, which was presented by Lavrič et al., [68]. The researchers isolated lignin from various natural sources, including Japanese Knotweed (Reynoutria japonica). The novel coating materials showed promising paper products with barrier properties, such as a reduction in water vapor permeability and a lower contact angle. There were also no significant differences in tensile properties between the uncoated and coated samples. Overall, the results show promising capabilities of such components, which can be applied to the surface of paper substrates to improve their physico-chemical properties and create a sustainable and water/oil resistant coating.

Klančnik produced and analyzed extracts from the rhizome of Japanese Knotweed (Fallopia japonica) and from Impatiens glandulifera Royle, which were successfully used as dyes for screen printing on paper and textile substrates [39,69].

5. Perspectives

Invasive alien plant species have far-reaching impacts on ecosystems, as has been pointed out many times in this report and in many previous studies. Ecologists and scientists are trying to find solutions in many areas. The purpose of this section is to look into the future of IAPS by addressing some remaining challenges. Since the challenges for each feedstock are often the same in different applications, the advantages and disadvantages are presented in general terms in Table 6. The main advantages of the species mentioned are their use in the paper industry in combination with wood or waste fibers, sustainability, biodegradability, and ecological impact when the plants are removed. On the other hand, there are also disadvantages such as the high amount of time and energy required for production, expensive production, and the lack of certain printing properties that are important for the end user (opacity, whiteness, etc.) [70,71,72,73,74].

Table 6.

Overview of the advantages and disadvantages of IAPS discussed in this review.

It is important to emphasize that harvesting IAPS biomass must lead to depletion of plant reserves, as control or eradication of these species must remain the primary goal. The use of biomass from invasive alien species in already invasive areas for resource extraction could also lead to dangerous practices such as intentional planting of these species. A regulatory framework for the use of current invasive species as a source of bioenergy and raw materials could provide a solution [75]. To fully assess the risk of invasion, further research is needed to investigate the potential and different biomass supply chain for papermaking [76,77,78].

6. Conclusions

Overall, our review revealed some general patterns. First, most invasive plant species in Europe were found to be based on perennial Knotweed, Goldenrod, and Black Dogwood. Second, most of the research reviewed indicated that innovation in invasive plant species is urgently needed to advance paper product manufacturing projects, as these species negatively impact the success and cost of restoration. Third, given the uneven distribution of studies evaluated in Europe, we need to know what developing countries have done to deal with biological invasions related to restoration and application of IAPS such as handmade paper production, small business applications, etc.

Recently, promising results have been obtained in the application of IAPS in combination with other raw materials. Overall, invasive plants have advantages when we consider them as raw materials. They are applicable in many ways. These include papermaking, cooking, textile production, etc.

Finally, there is a gap between scientific and practical knowledge when it comes to finding the best methods to control invasive plant species [70]. This gap can be narrowed by raising awareness of exotic species and involving local communities in invasive species management [70,75].

The decision of which control method to use depends heavily on the growth forms of invasive plant species, the local economic situation at restoration sites, and the resources available for control. There is also a lack of collection sites and landfills where printed and converted paper products produced by IAPS could be deposited.

Author Contributions

Conceptualization, U.V.-B. and K.M.; methodology, U.V.-B. and K.M.; validation, U.V.-B. and K.M.; investigation, U.V.-B. and K.M.; resources, K.M.; data curation, U.V.-B.; writing—original draft preparation, U.V.-B. and K.M.; writing—review and editing, U.V.-B. and K.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cepi Report. Available online: https://www.cepi.org/wp-content/uploads/2022/02/Cepi_Preliminary-_2021_Report.pdf (accessed on 10 June 2022).

- EU 2022: European Commission, Directorate-General for Environment; Sundseth, K. Invasive Alien Species: A European Union Response, Publications Office, 2017. Available online: https://data.europa.eu/doi/10.2779/374800 (accessed on 10 June 2022).

- Conway, T.M.; Almas, A.D.; Coore, D. Ecosystem services, ecological integrity, and native species planting: How to balance these ideas in urban forest management? Urban For. Urban Green. 2019, 41, 1–5. [Google Scholar] [CrossRef]

- Chemetova, C.; Ribeiro, H.; Fabião, A.; Gominho, J. Towards sustainable valorisation of Acacia melanoxylon biomass: Characterization of mature and juvenile plant tissues. Environ. Res. 2020, 191, 110090. [Google Scholar] [CrossRef]

- Fan, S.; Yu, D.; Liu, C. The invasive plant Alternanthera philoxeroides was suppressed more intensively than its native congener by a native generalist: Implications for the biotic resistance hypothesis. PLoS ONE 2013, 8, e83619. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Sanz, M.; Erboz, E.; Fontes, C.; López-Rubio, A. Valorization of Arundo donax for the production of high performance lignocellulosic films. Carbohydr. Polym. 2018, 199, 276–285. [Google Scholar] [CrossRef] [PubMed]

- Ziska, L.H.; Reeves, J.B., III; Blank, B. The impact of recent increases in atmospheric CO2 on biomass production and vegetative retention of Cheatgrass (Bromus tectorum): Implications for fire disturbance. Glob. Change Biol. 2005, 11, 1325–1332. [Google Scholar] [CrossRef]

- Ruan, T.; Zeng, R.; Yin, X.Y.; Zhang, S.X.; Yang, Z.H. Water hyacinth (Eichhornia crassipes) biomass as a biofuel feedstock by enzymatic hydrolysis. BioResources 2016, 11, 2372–2380. [Google Scholar] [CrossRef]

- Pintor-Ibarra, L.F.; Rivera-Prado, J.J.; Ngangyo-Heya, M.; Rutiaga-Quiñones, J.G. Evaluation of the chemical components of Eichhornia crassipes as an alternative raw material for pulp and paper. BioResources 2018, 13, 2800–2813. [Google Scholar] [CrossRef]

- Hromádková, Z.; Hirsch, J.; Ebringerová, A. Chemical evaluation of Fallopia species leaves and antioxidant properties of their non-cellulosic polysaccharides. Chem. Pap. 2010, 64, 663–672. [Google Scholar] [CrossRef]

- Claeson, S.M.; LeRoy, C.J.; Barry, J.R.; Kuehn, K.A. Impacts of invasive riparian knotweed on litter decomposition, aquatic fungi, and macroinvertebrates. Biol. Invasions 2014, 16, 1531–1544. [Google Scholar] [CrossRef]

- Saulino, H.H.L.; Trivinho-Strixino, S. Native macrophyte leaves influence more specialisation of neotropical shredder chironomids than invasive macrophyte leaves. Hydrobiologia 2018, 813, 189–198. [Google Scholar] [CrossRef]

- Kordsachia, O.; Seemann, A.; Patt, R. Fast growing poplar and Miscanthus sinensis—Future raw materials for pulping in Central Europe. Biomass Bioenergy 1993, 5, 137–143. [Google Scholar] [CrossRef]

- Serrano, L.; Egües, I.; Alriols, M.G.; Llano-Ponte, R.; Labidi, J. Miscanthus sinensis fractionation by different reagents. Chem. Eng. J. 2010, 156, 49–55. [Google Scholar] [CrossRef]

- Barba, C.; de la Rosa, A.; Vidal, T.; Colom, J.F.; Farriol, X.; Montané, D. TCF bleached pulps from Miscanthus sinensis by the impregnation rapid steam pulping (IRSP) process. J. Wood Chem. Technol. 2002, 22, 249–266. [Google Scholar] [CrossRef]

- Iglesias, G.; Bao, M.; Lamas, J.; Vega, A. Soda pulping of Miscanthus sinensis. Effects of operational variables on pulp yield and lignin solubilization. Bioresour. Technol. 1996, 58, 17–23. [Google Scholar] [CrossRef]

- Silva, L.B.; Lourenço, P.; Teixeira, A.; Azevedo, E.B.; Alves, M.; Elias, R.B.; Silva, L. Biomass valorization in the management of woody plant invaders: The case of Pittosporum undulatum in the Azores. Biomass Bioenergy 2018, 109, 155–165. [Google Scholar] [CrossRef]

- Liu, Y.; Bekele, L.D.; Lu, X.; Zhang, W.; Yu, C.; Duns, G.J.; Joseph, G.D.; Jin, L.; Chen, J. The effect of lignocellulose filler on mechanical properties of filled-high density polyethylene composites loaded with biomass of an invasive plant solidago canadensis. J. Biobased Mater. Bioenergy 2017, 11, 34–39. [Google Scholar] [CrossRef]

- Ren, G.B.; Wang, J.J.; Wang, A.D.; Wang, J.B.; Zhu, Y.L.; Wu, P.Q.; Ma, Y.; Zhang, J. Monitoring the invasion of smooth cordgrass Spartina alterniflora within the modern Yellow River Delta using remote sensing. J. Coast. Res. 2019, 90, 135–145. [Google Scholar] [CrossRef]

- Picou, L.; Boldor, D. Thermophysical characterization of the seeds of invasive Chinese tallow tree: Importance for biofuel production. Environ. Sci. Technol. 2012, 46, 11435–11442. [Google Scholar] [CrossRef]

- Pesenti, H.; Torres, M.; Oliveira, P.; Gacitua, W.; Leoni, M. Exploring Ulex europaeus to produce nontoxic binderless fibreboard. BioResources 2017, 12, 2660–2672. [Google Scholar] [CrossRef][Green Version]

- Kavčič, U.; Karlovits, I. Invasive plant-based paper as a substrate for electroconductive printing inks. Adv. Print. Media Technol. 2019, 46, 165–170. [Google Scholar]

- Karlovits, I.; Kavčič, U.; Lavrič, G.; Šinkovec, A.; Zorić, V. Digital printability of papers made from invasive plants and agro-industrial residues. Cellul. Chem. Technol. 2020, 54, 523–529. [Google Scholar] [CrossRef]

- Selič, P.; Mavrić, Z.; Možina, K. Comparison of print quality on papers from invasive alien plants species. DAAAM Int. Sci. Book 2020, 49–60. [Google Scholar] [CrossRef]

- Karlovits, I.; Kavčič, U. Flexo printability of agro and invasive papers. Cellulose 2022, 29, 4613–4627. [Google Scholar] [CrossRef]

- Kavčič, U.; Karlovits, I. The influence of process parameters of screen-printed invasive plant paper electrodes on cyclic voltammetry. Nord. Pulp Pap. Res. J. 2020, 35, 299–307. [Google Scholar] [CrossRef]

- Karlovits, I.; Lavrič, G.; Kavčič, U.; Zorić, V. Electrophotography toner adhesion on agro-industrial residue and invasive plant papers. J. Adhes. Sci. Technol. 2021, 35, 2636–2651. [Google Scholar] [CrossRef]

- Starešinič, M.; Boh Podgornik, B.; Javoršek, D.; Leskovšek, M.; Možina, K. Fibers obtained from invasive alien plant species as a base material for paper production. Forests 2021, 12, 527. [Google Scholar] [CrossRef]

- Kapun, T.; Zule, J.; Fabjan, E.; Hočevar, B.; Grilc, M.; Likozar, B. Engineered invasive plant cellulose fibers as resources for papermaking. Eur. J. Wood Wood Prod. 2022, 80, 501–514. [Google Scholar] [CrossRef]

- Sežun, M.; Karlovits, I.; Kavčič, U. Chemical and Enzymatic Deinking Efficiency of Agro And Industrial Waste Fiber-Based Paper Packaging. J. Sci. Food Agric. 2022, 1–8. [Google Scholar] [CrossRef]

- Todorova, D.; Yavorov, N.; Lasheva, V. Improvement of barrier properties for packaging applications. Sustain. Chem. Pharm. 2022, 27, 100685. [Google Scholar] [CrossRef]

- Corcelli, F.; Ripa, M.; Ulgiati, S. Efficiency and sustainability indicators for papermaking from virgin pulp—An emergy-based case study. Resour. Conserv. Recycl. 2018, 131, 313–328. [Google Scholar] [CrossRef]

- Sitzia, T.; Cierjacks, A.; De Rigo, D.; Caudullo, G. Robinia pseudoacacia in Europe: Distribution, habitat, usage and threats. Eur. Atlas For. Tree Species 2016, 166–167. Available online: https://www.researchgate.net/publication/299471371_Robinia_pseudoacacia_in_Europe_distribution_habitat_usage_and_threats (accessed on 11 June 2022).

- Redei, K.; Nicolescu, V.N.; Vor, T.; Potzelsberger, E.; Bastien, J.C.; Brus, R.; Bencat, T.; Đodan, M.; Cvjetković, B.; Andrašev, S.; et al. Ecology and management of black locust (Robinia pseudoacacia L.), a non-native tree species integrated in European forests and landscapes. J. For. Res. 2020, 31, 1081–1101. [Google Scholar]

- Nicolescu, V.N.; Hernea, C.; Bakti, B.; Keserű, Z.; Antal, B.; Rédei, K. Black locust (Robinia pseudoacacia L.) as a multi-purpose tree species in Hungary and Romania: A review. J. For. Res. 2018, 29, 1449–1463. [Google Scholar] [CrossRef]

- Campoy, J.G.; Acosta, A.T.; Affre, L.; Barreiro, R.; Brundu, G.; Buisson, E.; Gonzales, L.; Lema, M.; Novoa, A.; Fagúndez, J.; et al. Monographs of invasive plants in Europe: Carpobrotus. Bot. Lett. 2018, 165, 440–475. [Google Scholar] [CrossRef]

- Verbič, A.; Brenčič, K.; Primc, G.; Gorjanc, M. Importance of protocol design for suitable green in situ synthesis of ZnO on cotton using aqueous extract of japanese knotweed leaves as reducing agent. Forests 2022, 13, 143. [Google Scholar] [CrossRef]

- Naumoska, K.; Jug, U.; Kõrge, K.; Oberlintner, A.; Golob, M.; Novak, U.; Vovk, I.; Likozar, B. Antioxidant and Antimicrobial Biofoil Based on Chitosan and Japanese Knotweed (Fallopia japonica, Houtt.) Rhizome Bark Extract. Antioxidants 2022, 11, 1200. [Google Scholar] [CrossRef]

- Klančnik, M. Screen printing with natural dye extract from Japanese knotweed rhizome. Fibers Polym. 2021, 22, 2498–2506. [Google Scholar] [CrossRef]

- Bielecka, A.; Królak, E. Selected features of canadian goldenrod that predispose the plant to phytoremediation. J. Ecol. Eng. 2019, 20, 88–93. [Google Scholar] [CrossRef]

- Gala-Czekaj, D.; Dziurka, M.; Bocianowski, J.; Synowiec, A. Autoallelopathic potential of aqueous extracts from Canadian goldenrod (Solidago canadensis L.) and giant goldenrod (S. gigantea Aiton). Acta Physiol. Plant. 2022, 44, 1–12. [Google Scholar] [CrossRef]

- Radušienė, J.; Karpavičienė, B.; Marksa, M.; Ivanauskas, L.; Raudonė, L. Distribution Patterns of Essential Oil Terpenes in Native and Invasive Solidago Species and Their Comparative Assessment. Plants 2022, 11, 1159. [Google Scholar] [CrossRef]

- Patel, N.; Zihare, L.; Blumberga, D. Evaluation of bioresources validation. Agron. Res. 2021, 19, 1099–1111. [Google Scholar]

- Baranová, B.; Troščáková-Kerpčárová, E.; Gruľová, D. Survey of the Solidago canadensis L. Morphological Traits and Essential Oil Production: Aboveground Biomass Growth and Abundance of the Invasive Goldenrod Appears to Be Reciprocally Enhanced within the Invaded Stands. Plants 2022, 11, 535. [Google Scholar] [CrossRef] [PubMed]

- Spyroglou, G.; Fotelli, M.; Nanos, N.; Radoglou, K. Assessing Black Locust Biomass Accumulation in Restoration Plantations. Forests 2021, 12, 1477. [Google Scholar] [CrossRef]

- Środek, D.; Rahmonov, O. The properties of Black Locust Robinia pseudoacacia L. to selectively accumulate chemical elements from soils of ecologically transformed areas. Forests 2021, 13, 7. [Google Scholar] [CrossRef]

- Chauvel, B.; Fried, G.; Follak, S.; Chapman, D.; Kulakova, Y.; Le Bourgeois, T.; Marisavlijevic, D.; Monty, A.; Rossi, J.-P.; Regnier, E.; et al. Monographs on invasive plants in Europe N° 5: Ambrosia trifida L. Botany Lett. 2021, 168, 167–190. [Google Scholar] [CrossRef]

- Bahor, B.; Klopčič, M. Black locust (Robinia pseudoacacia L.) in Bela krajina: Distribution, growth, regeneration and management. Acta Silvae Ligni 2019, 13–28. Available online: https://www.cabdirect.org/cabdirect/abstract/20203150202 (accessed on 6 July 2022).

- Kuneš, I.; Baláš, M.; Gallo, J.; Šulitka, M.; Suraweera, C. Black locust (Robinia pseudoacacia) and its role in central Europe and Czech Republic. Zprávy Lesn. Výzkumu 2019, 64, 181–190. [Google Scholar]

- Alilla, R.; De Natale, F.; Epifani, C.; Parisse, B.; Cola, G. The Flowering of Black Locust (Robinia pseudoacacia L.) in Italy: A Phenology Modeling Approach. Agronomy 2022, 12, 1623. [Google Scholar] [CrossRef]

- Lange, C.A.; Knoche, D.; Hanschke, R.; Löffler, S.; Schneck, V. Physiological Performance and Biomass Growth of Different Black Locust Origins Growing on a Post-Mining Reclamation Site in Eastern Germany. Forests 2022, 13, 315. [Google Scholar] [CrossRef]

- Vítková, M.; Conedera, M.; Sádlo, J.; Pergl, J.; Pyšek, P. Dangerous and useful at the same time: Management strategies for the invasive black locust. Schweiz. Z. Forstwes. 2018, 169, 77–85. [Google Scholar] [CrossRef]

- Żelazna, A.; Kraszkiewicz, A.; Przywara, A.; Łagód, G.; Suchorab, Z.; Werle, S.; Ballester, J.; Nosek, R. Life cycle assessment of production of black locust logs and straw pellets for energy purposes. Environ. Prog. Sustain. Energy 2019, 38, 163–170. [Google Scholar] [CrossRef]

- Pandita, S.; Kaula, B.; Passey, S. Use of weeds and agro-based raw materials and their blends for handmade paper making. J. Undergr. Res. Innov. 2015, 1, 169–179. [Google Scholar]

- Kim, H.G.; Lee, U.S.; Kwac, L.K.; Lee, S.O.; Kim, Y.S.; Shin, H.K. Electron beam irradiation isolates cellulose nanofiber from Korea “tall goldenrod” invasive alien plant pulp. Nanomaterials 2019, 9, 1358. [Google Scholar] [CrossRef] [PubMed]

- Evdokimova, O.L.; Alves, C.S.; Krsmanović Whiffen, R.M.; Ortega, Z.; Tomás, H.; Rodrigues, J. Cytocompatible cellulose nanofibers from invasive plant species Agave americana L. and Ricinus communis L.: A renewable green source of highly crystalline nanocellulose. J. Zhejiang Univ. Sci. B 2021, 22, 450–461. [Google Scholar] [CrossRef]

- Almeida, R.O.; Ramos, A.; Alves, L.; Potsi, E.; Ferreira, P.J.T.; Carvalho, M.G.V.S.; Rasteiro, M.G.; Gamelas, J.A.F. Production of nanocellulose gels and films from invasive tree species. Int. J. Biol. Macromol. 2021, 188, 1003–1011. [Google Scholar] [CrossRef]

- Baptista, P.; Costa, A.P.; Simões, R.; Amaral, M.E. Ailanthus altissima: An alternative fiber source for papermaking. Ind. Crops Prod. 2014, 52, 32–37. [Google Scholar] [CrossRef]

- Ferreira, P.J.; Gamelas, J.A.; Carvalho, M.G.; Duarte, G.V.; Canhoto, J.M.; Passas, R. Evaluation of the papermaking potential of Ailanthus altissima. Ind. Crops Prod. 2013, 42, 538–542. [Google Scholar] [CrossRef]

- Garcez, R.O.L.; Hofmann Gatti, T.; Carlos Gonzalez, J.; Cesar Franco, A.; Silva Ferreira, C. Characterization of Fibers from Culms and Leaves of Arundo donax L. (Poaceae) for Handmade Paper Production. J. Nat. Fibers 2022, 1–9. [Google Scholar] [CrossRef]

- Jiménez-Ruiz, J.; Hardion, L.; Del Monte, J.P.; Vila, B.; Santín-Montanyá, M.I. Monographs on invasive plants in Europe N° 4: Arundo donax L. Bot. Lett. 2021, 168, 131–151. [Google Scholar] [CrossRef]

- Skočaj, M. Bacterial nanocellulose in papermaking. Cellulose 2019, 26, 6477–6488. [Google Scholar] [CrossRef]

- Hassani FZ, S.A.; Salim, M.H.; Kassab, Z.; Sehaqui, H.; Ablouh, E.H.; Bouhfid, R.; El Achaby, M. Crosslinked starch-coated cellulosic papers as alternative food-packaging materials. RSC Adv. 2022, 12, 8536–8546. [Google Scholar] [CrossRef] [PubMed]

- Placet, V.; Passard, J.; Perré, P. Viscoelastic properties of wood across the grain measured under water-saturated conditions up to 135 C: Evidence of thermal degradation. J. Mater. Sci. 2008, 43, 3210–3217. [Google Scholar] [CrossRef]

- Kim, S. Inkjet-printed electronics on paper for RF identification (RFID) and sensing. Electronics 2020, 9, 1636. [Google Scholar] [CrossRef]

- Wiklund, J.; Karakoç, A.; Palko, T.; Yiğitler, H.; Ruttik, K.; Jäntti, R.; Paltakari, J. A review on printed electronics: Fabrication methods, inks, substrates, applications and environmental impacts. J. Manuf. Mater. Process. 2021, 5, 89. [Google Scholar] [CrossRef]

- Khan, Y.; Thielens, A.; Muin, S.; Ting, J.; Baumbauer, C.; Arias, A.C. A new frontier of printed electronics: Flexible hybrid electronics. Adv. Mater. 2020, 32, 1905279. [Google Scholar] [CrossRef]

- Lavrič, G.; Zamljen, A.; Juhant Grkman, J.; Jasiukaitytė-Grojzdek, E.; Grilc, M.; Likozar, B.; Gregor-Svetec, D.; Vrabič-Brodnjak, U. Organosolv Lignin Barrier Paper Coatings from Waste Biomass Resources. Polymers 2021, 13, 4443. [Google Scholar] [CrossRef]

- Klančnik, M. Printing with Natural Dye Extracted from Impatiens glandulifera Royle. Coatings 2021, 11, 445. [Google Scholar] [CrossRef]

- Weidlich, E.W.; Flórido, F.G.; Sorrini, T.B.; Brancalion, P.H. Controlling invasive plant species in ecological restoration: A global review. J. Appl. Ecol. 2020, 57, 1806–1817. [Google Scholar] [CrossRef]

- Van Meerbeek, K.; Appels, L.; Dewil, R.; Calmeyn, A.; Lemmens, P.; Muys, B.; Hermy, M. Biomass of invasive plant species as a potential feedstock for bioenergy production. Biofuels Bioprod. Biorefining 2015, 9, 273–282. [Google Scholar] [CrossRef]

- Rousu, P.; Rousu, P.; Anttila, J. Sustainable pulp production from agricultural waste. Resour. Conserv. Recycl. 2002, 35, 85–103. [Google Scholar] [CrossRef]

- Hladyz, S.; Gessner, M.O.; Giller, P.S.; Pozo, J.; Woodward, G.U.Y. Resource quality and stoichiometric constraints on stream ecosystem functioning. Freshw. Biol. 2009, 54, 957–970. [Google Scholar] [CrossRef]

- Lavoie, C. The impact of invasive knotweed species (Reynoutria spp.) on the environment: Review and research perspectives. Biol. Invasions 2017, 19, 2319–2337. [Google Scholar] [CrossRef]

- Dechoum MD, S.; Giehl EL, H.; Sühs, R.B.; Silveira TC, L.; Ziller, S.R. Citizen engagement in the management of non-native invasive pines: Does it make a difference? Biol. Invasions 2019, 21, 175–188. [Google Scholar] [CrossRef]

- Danesh, M.; Moud, A.A.; Mauran, D.; Hojabr, S.; Berry, R.; Pawlik, M.; Hatzikiriakos, S.G. The yielding of attractive gels of nanocrystal cellulose (CNC). J. Rheol. 2021, 65, 855–869. [Google Scholar] [CrossRef]

- Gahrooee, T.R.; Moud, A.A.; Danesh, M.; Hatzikiriakos, S.G. Rheological characterization of CNC-CTAB network below and above critical micelle concentration (CMC). Carbohydr. Polym. 2021, 257, 117552. [Google Scholar] [CrossRef]

- Islam, M.S.; Chen, L.; Sisler, J.; Tam, K.C. Cellulose nanocrystal (CNC)–inorganic hybrid systems: Synthesis, properties and applications. J. Mater. Chem. B 2018, 6, 864–883. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).