Tribological Performance of PVD Film Systems Against Plastic Counterparts for Adhesion-Reducing Application in Injection Molds

Abstract

1. Introduction

2. Materials and Methods

3. Results

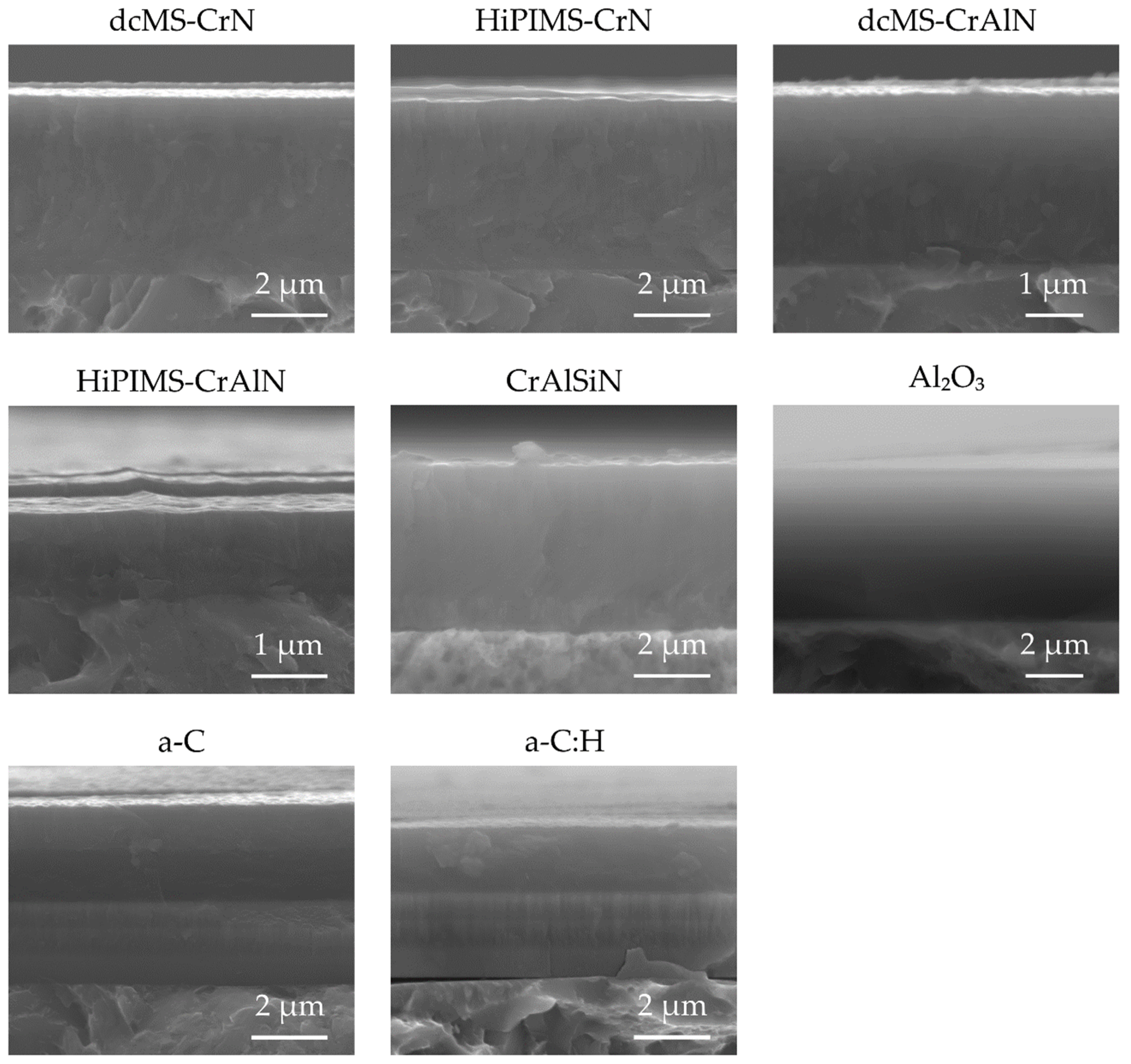

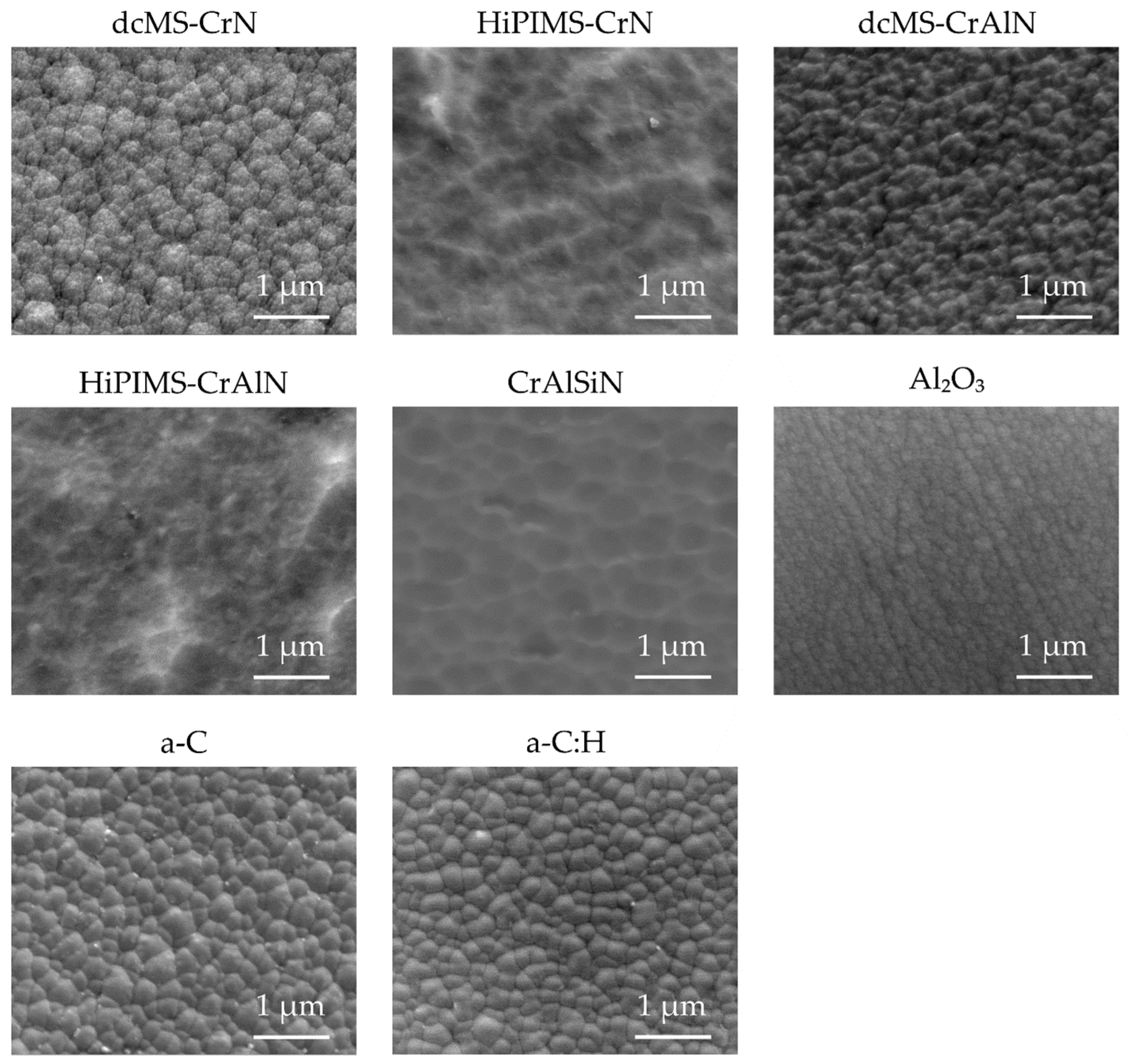

3.1. Topography and Surface Roughness

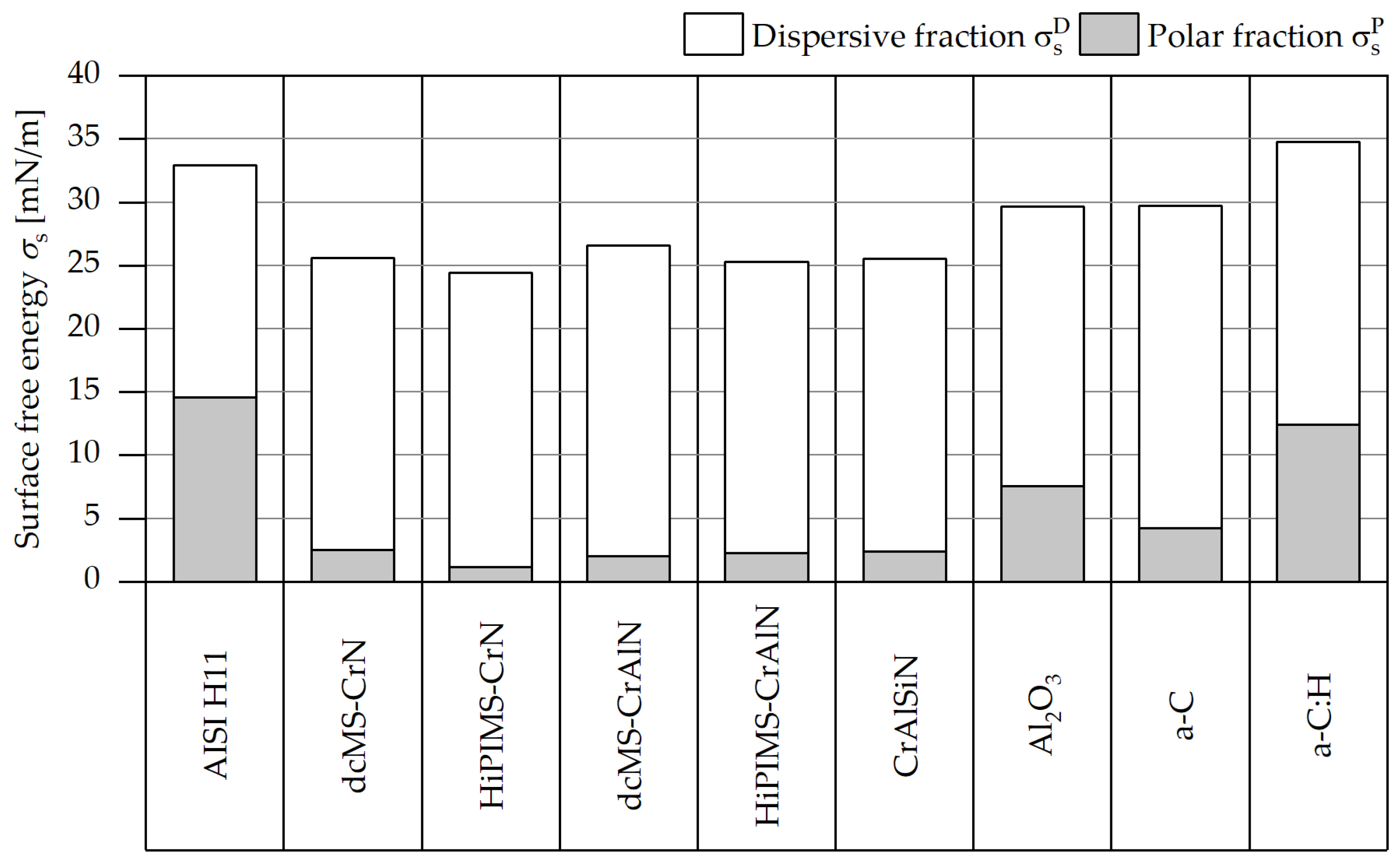

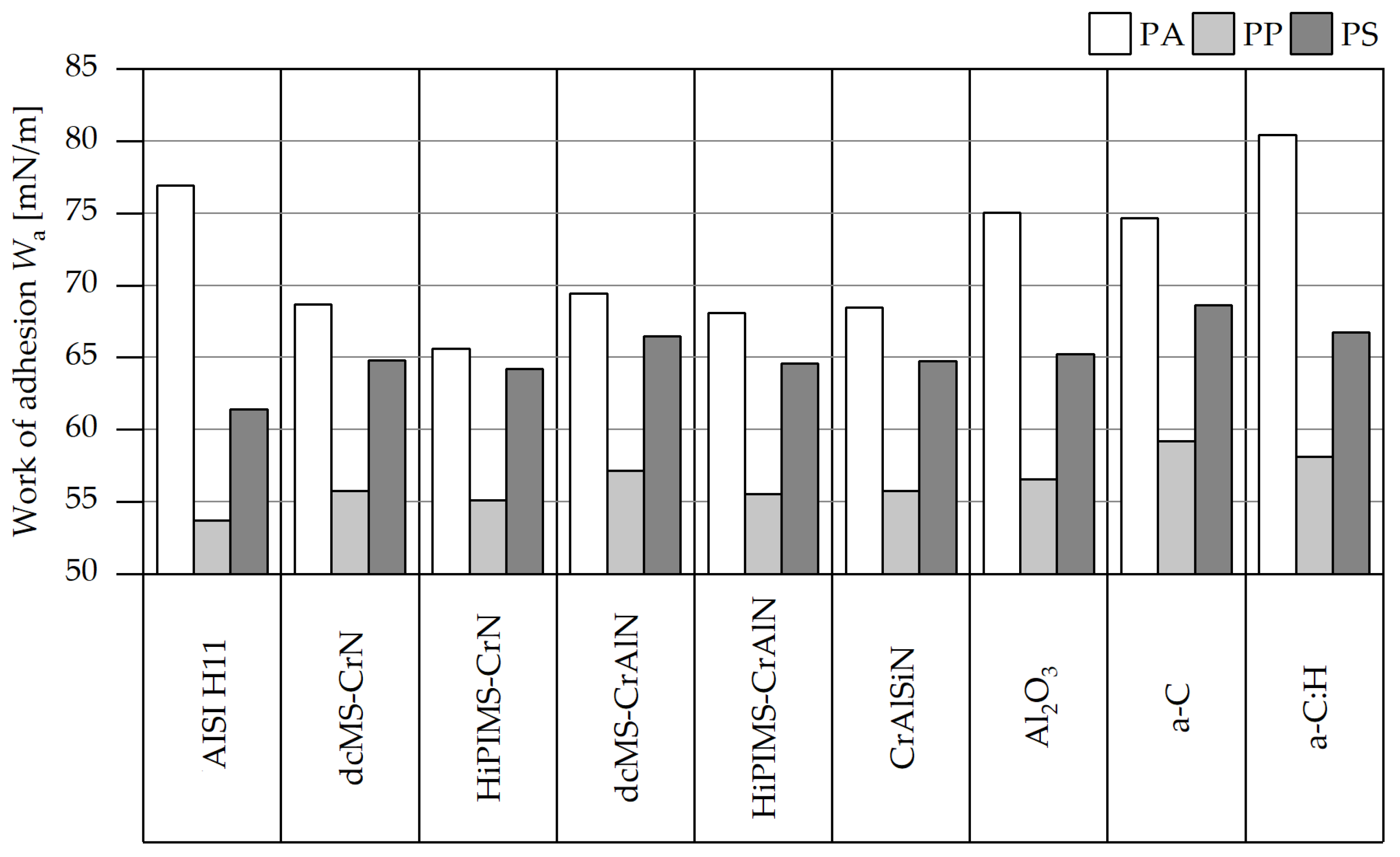

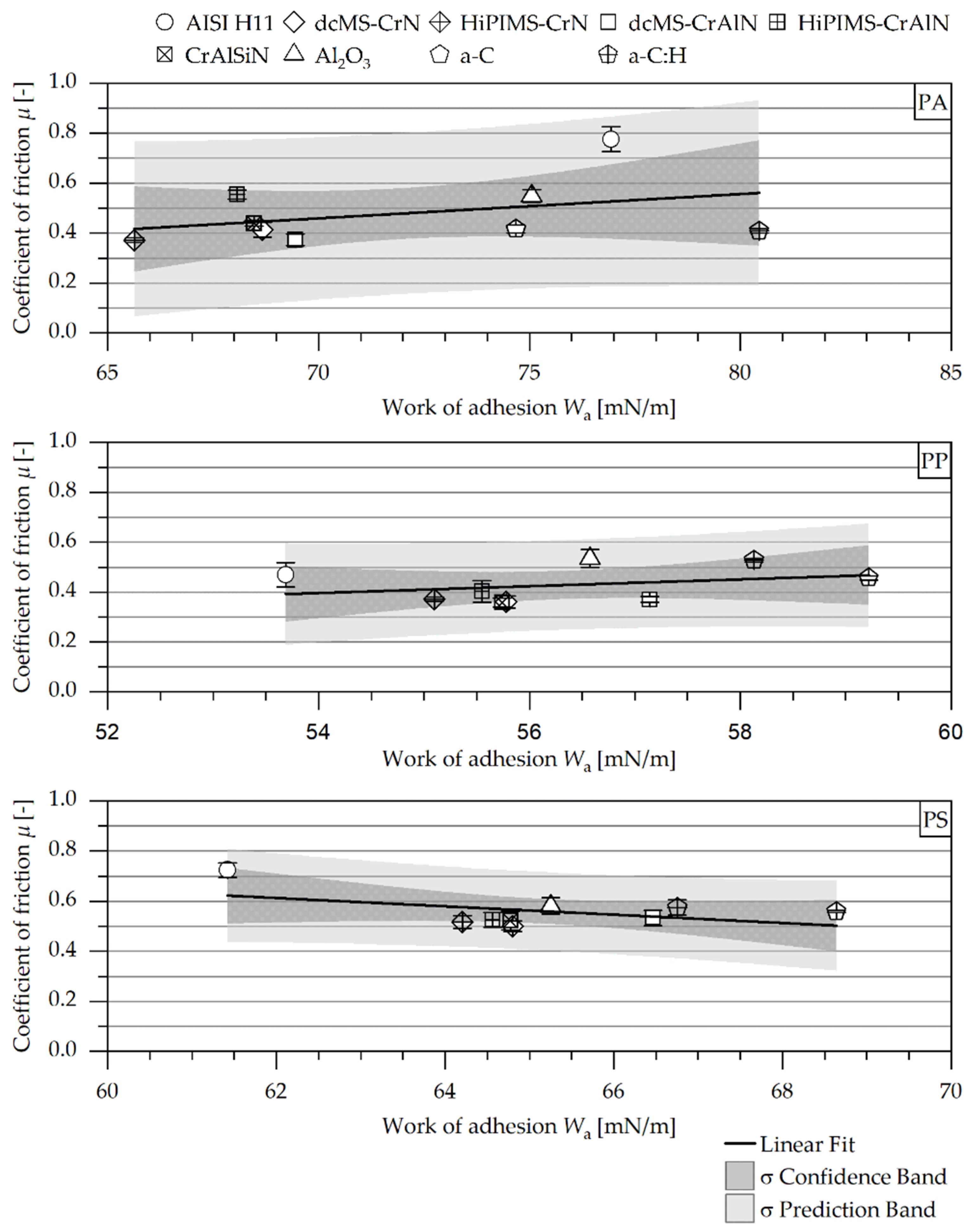

3.2. Surface Free Energy and Work of Adhesion

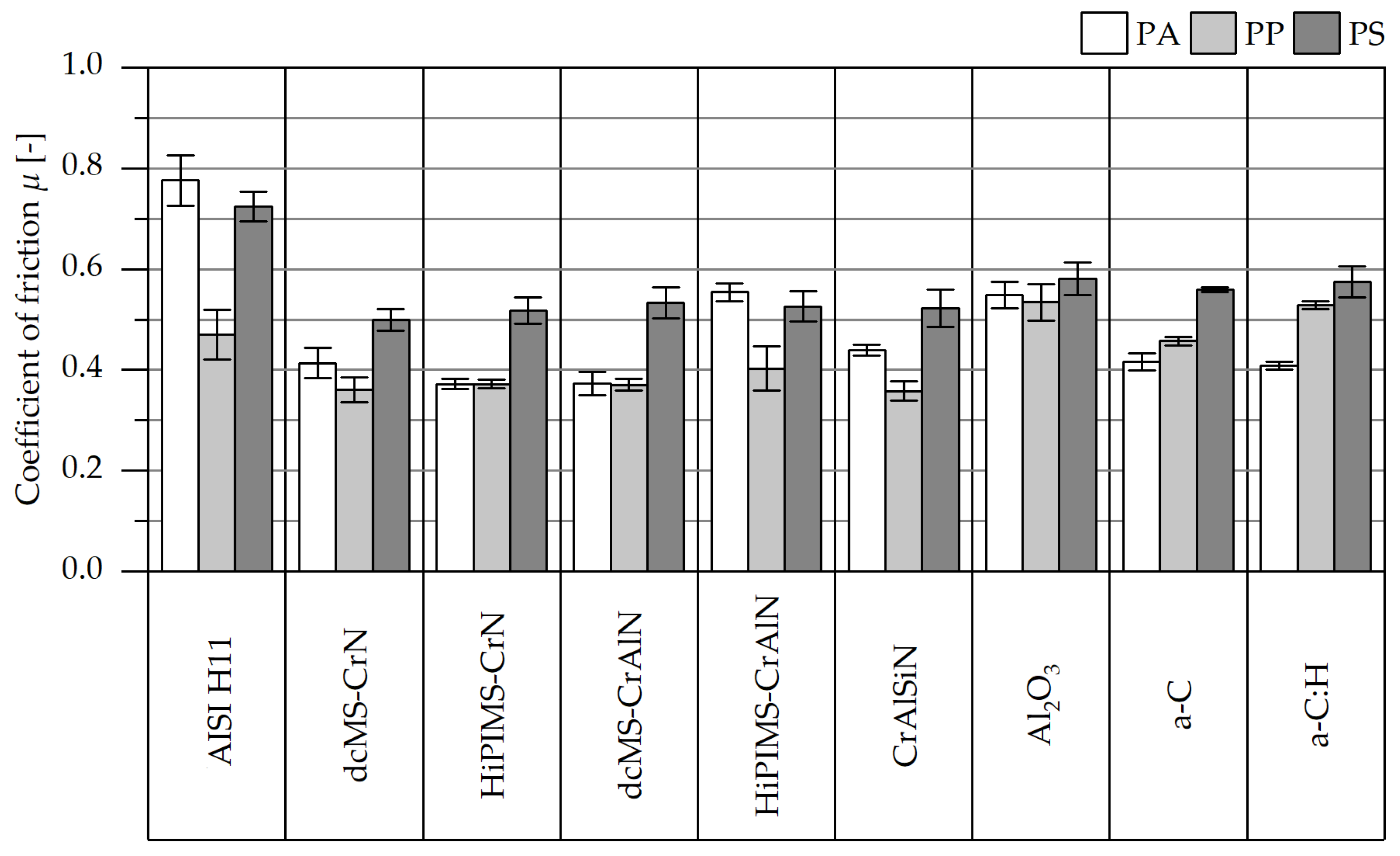

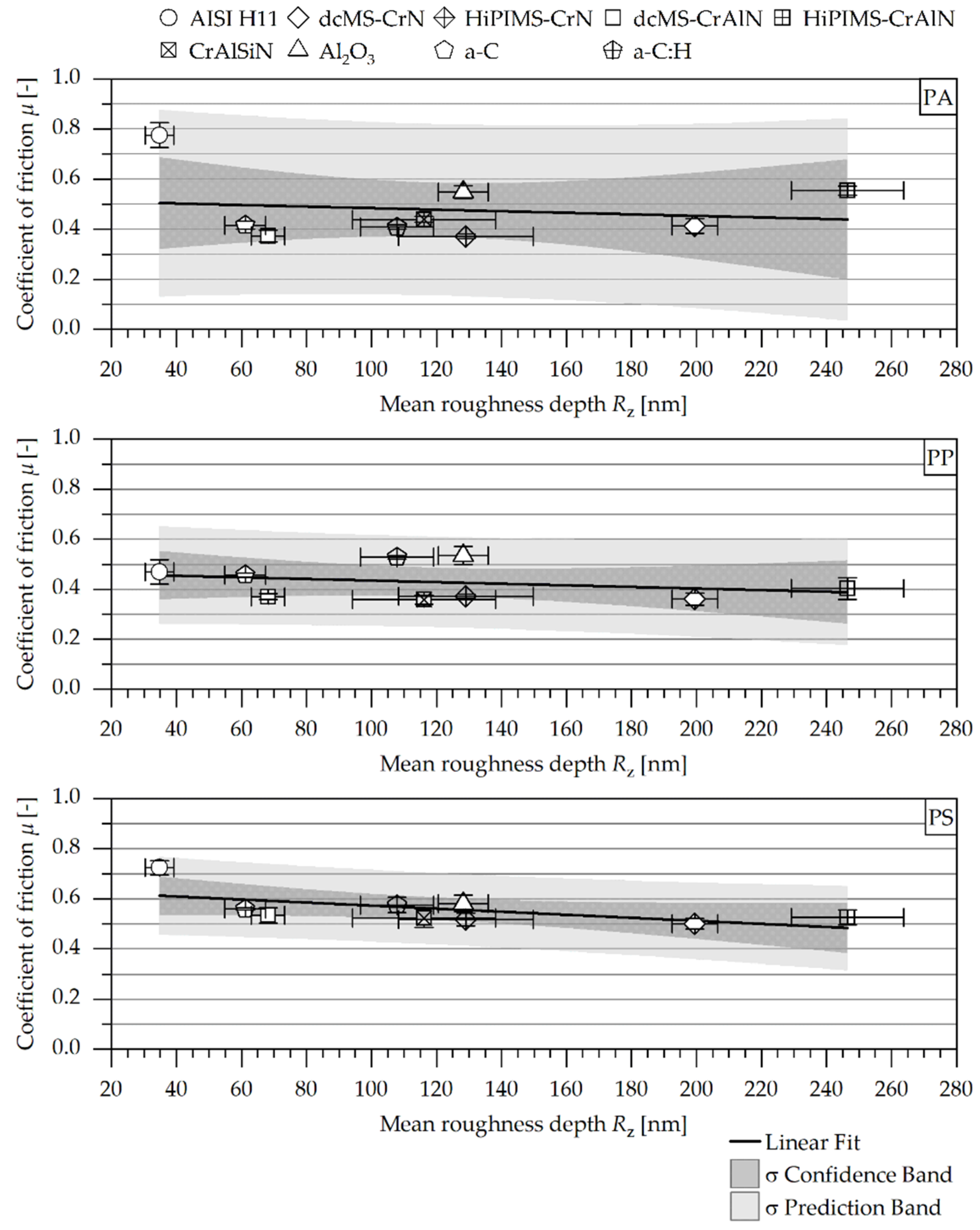

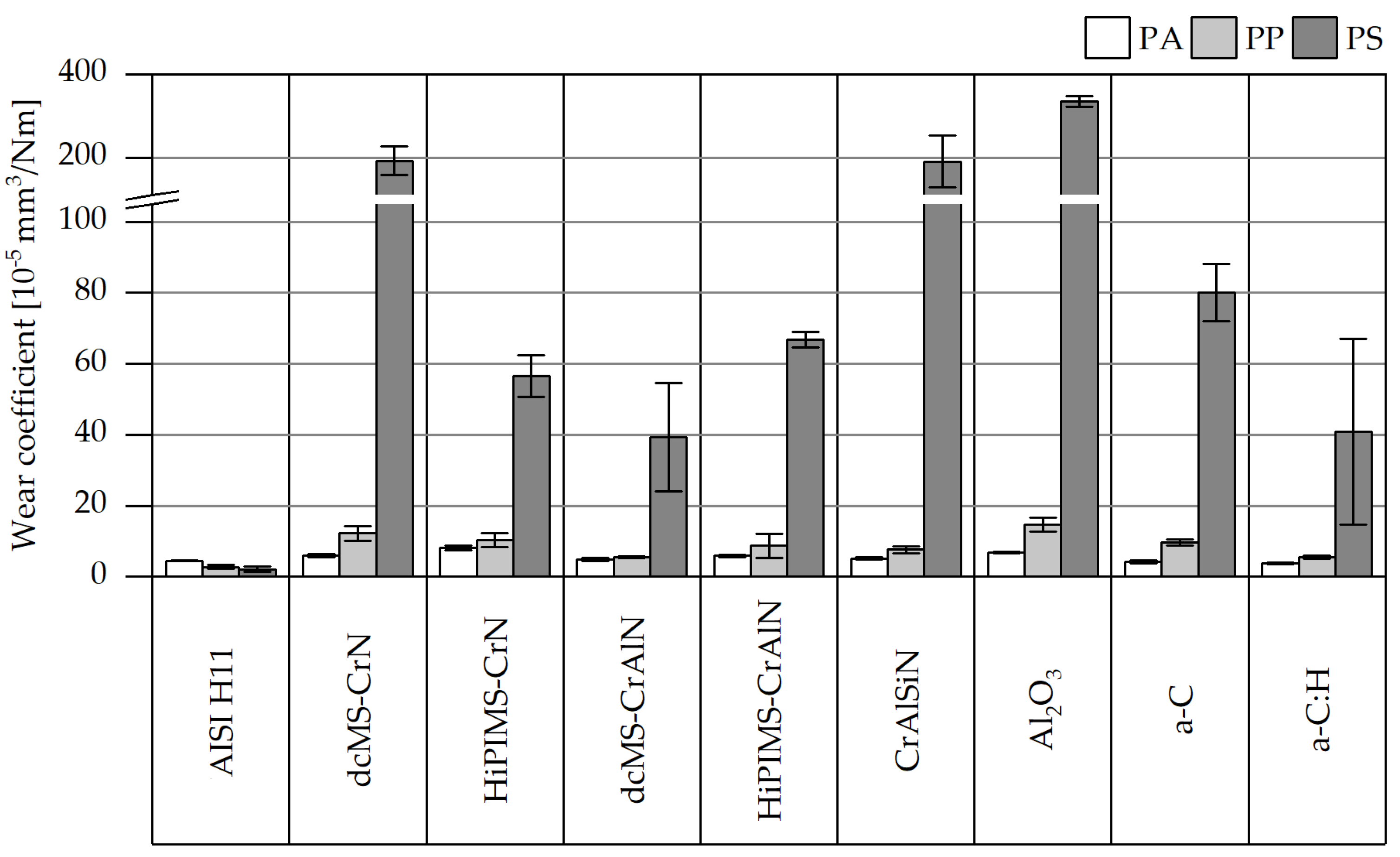

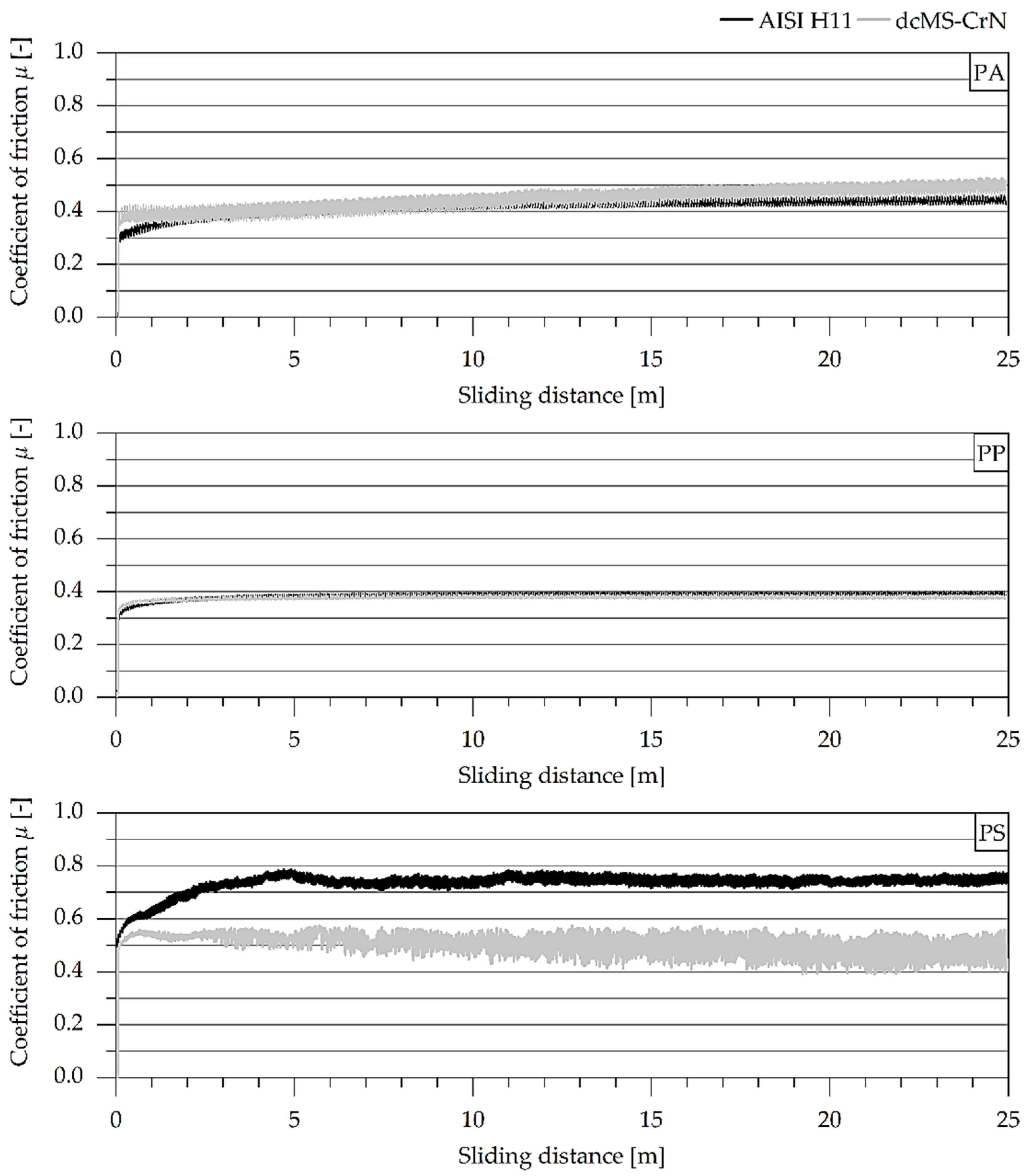

3.3. Tribological Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zheng, R.; Tanner, R.I.; Fan, X.-J. Injection Molding. Integration of Theory and Modeling Methods; Springer Science & Business Media: Berlin, Germany, 2011; ISBN 978-3-642-21262-8. [Google Scholar]

- Gramann, P.J.; Osswald, T.A. Introduction. In Injection Molding Handbook, 2nd ed.; Osswald, T.A., Turng, L.-S., Gramann, P.J., Eds.; Springer Science & Business Media: Berlin, Germany, 2008; pp. 1–18. ISBN 978-3-446-40781-7. [Google Scholar]

- Rosato, D.V.; Rosato, D.V.; Rosato, M.G. Injection Molding Handbook, 3rd ed.; Springer US: Boston, MA, USA, 2000; ISBN 9781461370772. [Google Scholar]

- Kerkstra, R.; Brammer, S. Injection Molding Advanced Troubleshooting Guide; Carl Hanser Verlag: Munich, Germany, 2018; ISBN 9781569906453. [Google Scholar]

- Kazmer, D. Injection Mold Design Engineering, 2nd ed.; Carl Hanser Verlag: Munich, Germany, 2016; ISBN 978-1-56990-570-8. [Google Scholar]

- Sakai, T.; Kikugawa, K. Injection Molding Machinery and Systems. In Injection Molding: Technology and Fundamentals; Kamal, M.R., Agassant, J.-F., Eds.; Carl Hanser Verlag: Munich, Germany, 2009; pp. 73–131. ISBN 978-3-446-41685-7. [Google Scholar]

- Bienk, E.J.; Mikkelsen, N.J. Application of advanced surface treatment technologies in the modern plastics moulding industry. Wear 1997, 207, 6–9. [Google Scholar] [CrossRef]

- Bobzin, K.; Nickel, R.; Bagcivan, N.; Manz, F.D. PVD—Coatings in Injection Molding Machines for Processing Optical Polymers. Plasma Process. Polym. 2007, 4, S144–S149. [Google Scholar] [CrossRef]

- Silva, F.J.G.; Martinho, R.P.; Baptista, A.P.M. Characterization of laboratory and industrial CrN/CrCN/diamond-like carbon coatings. Thin Solid Films 2014, 550, 278–284. [Google Scholar] [CrossRef]

- Silva, F.; Martinho, R.; Andrade, M.; Baptista, A.; Alexandre, R. Improving the wear resistance of moulds for the injection of glass fibre–reinforced plastics using PVD coatings: A comparative study. Coatings 2017, 7, 28. [Google Scholar] [CrossRef]

- D’Avico, L.; Beltrami, R.; Lecis, N.; Trasatti, S. Corrosion behavior and surface properties of PVD coatings for mold technology applications. Coatings 2019, 9, 7. [Google Scholar] [CrossRef]

- Bagcivan, N.; Bobzin, K.; Brögelmann, T.; Kalscheuer, C. Development of (Cr,Al) ON coatings using middle frequency magnetron sputtering and investigations on tribological behavior against polymers. Surface Coat. Technol. 2014, 260, 347–361. [Google Scholar] [CrossRef]

- Bobzin, K.; Grundmeier, G.; Brögelmann, T.; los Arcos, T.; Wiesing, M.; Kruppe, N.C. Nitridische und oxinitridische HPPMS-Beschichtungen für den Einsatz in der Kunststoffverarbeitung (Teil 2). Vakuum Forschung Praxis 2017, 29, 24–28. [Google Scholar] [CrossRef][Green Version]

- Paints and Varnishes-Pull-off Test for Adhesion (ISO 4624:2016), German Version EN ISO 4624:2016; DIN German Institute for Standardization: Berlin, Germany, 2016.

- Sasaki, T.; Koga, N.; Shirai, K.; Kobayashi, Y.; Toyoshima, A. An experimental study on ejection forces of injection molding. Precis. Eng. 2000, 24, 270–273. [Google Scholar] [CrossRef]

- Burkard, E.; Walther, T.; Schinköthe, W. Influence of mold wall coatings while demoulding in the injection molding process. Stuttg. Kunststoff Kolloquium 1999, 16, 1–8. [Google Scholar]

- Kobayashi, Y.; Shirai, K.; Sasaki, T.; Kobayashi, Y.; Shirai, K.; Sasaki, T. Relationship between core surface roughness and ejection force for injection molding. J. Jpn. Soc. Prec. Eng. 2001, 67, 510–514. [Google Scholar] [CrossRef]

- Mitschang, P.; Schledjewski, R.; Schlarb, A.K. Molds for continuos fibre reinforced polymer composites. In Mold-Making Handbook, 3rd ed.; Mennig, G., Stoeckhert, K., Eds.; Carl Hanser Verlag: Munich, Germany, 2013; pp. 200–238. ISBN 978-1-56990-446-6. [Google Scholar]

- Hoffmann, F. Beitrag zur Charakterisierung des tribologischen Verhaltens von Diamantähnlichen Kohlenstoffschichten für die Holzbearbeitung. Ph.D. Thesis, TU Dortmund University, Dortmund, Germany, 2012. [Google Scholar]

- Geometrical Product Specifications (GPS)–Surface Texture: Profile Method–Terms, Definitions and Surface Texture Parameters (ISO 4287:1997 + Cor 1:1998 + Cor 2:2005 + Amd 1:2009), German Version EN ISO 4287:1998 + AC:2008 + A1:2009; DIN German Institute for Standardization: Berlin, Germany, 2010.

- Geometrical Product Specifications (GPS)-Surface Texture; Profile Method-Rules and Procedures for the Assessment of Surface Texture (ISO 4288:1996), German Version EN ISO 4288:1997; DIN German Institute for Standardization: Berlin, Germany, 1998.

- Paints and Varnishes–Wettability–Part 2: Determination of the Free Surface Energy of Solid Surfaces by Measuring the Contact Angle, German Version DIN 55660-2; DIN German Institute for Standardization: Berlin, Germany, 2011.

- Zhang, J. Work of adhesion and work of cohesion. In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.-W., Eds.; Springer US: Boston, MA, USA, 2013; pp. 4127–4132. ISBN 978-0-387-92896-8. [Google Scholar]

- Erhard, G. Designing with Plastics; Carl Hanser Verlag: Munich, Germany, 2006; ISBN 978-3-446-22590-9. [Google Scholar]

- Barshilia, H.C.; Selvakumar, N.; Deepthi, B.; Rajam, K.S. A comparative study of reactive direct current magnetron sputtered CrAlN and CrN coatings. Surf. Coat Technol. 2006, 201, 2193–2201. [Google Scholar] [CrossRef]

- Lin, J.; Mishra, B.; Moore, J.J.; Sproul, W.D. Microstructure, mechanical and tribological properties of Cr1−xAlxN films deposited by pulsed-closed field unbalanced magnetron sputtering (P-CFUBMS). Surf. Coat Technol. 2006, 201, 4329–4334. [Google Scholar] [CrossRef]

- Ehiasarian, A.; Münz, W.D.; Hultman, L.; Helmersson, U.; Petrov, I. High power pulsed magnetron sputtered CrNx films. Surf. Coat Technol. 2003, 163–164, 267–272. [Google Scholar] [CrossRef]

- Rafaja, D.; Dopita, M.; Růžička, M.; Klemm, V.; Heger, D.; Schreiber, G.; Šímac, M. Microstructure development in Cr–Al–Si–N nanocomposites deposited by cathodic arc evaporation. Surf. Coat Technol. 2006, 201, 2835–2843. [Google Scholar] [CrossRef]

- Tillmann, W.; Lopes Dias, N.F.; Stangier, D. Influence of plasma nitriding pretreatments on the tribo-mechanical properties of DLC coatings sputtered on AISI H11. Surface Coat. Technol. 2019, 357, 1027–1036. [Google Scholar] [CrossRef]

- Tillmann, W.; Lopes Dias, N.F.; Stangier, D.; Maus-Friedrichs, W.; Gustus, R.; Thomann, C.A.; Moldenhauer, H.; Debus, J. Improved adhesion of a-C and a-C: H films with a CrC interlayer on 16MnCr5 by HiPIMS-pretreatment. Surface Coat. Technol. 2019, 375, 877–887. [Google Scholar] [CrossRef]

- Bobzin, K.; Bagcivan, N.; Theiss, S.; Yilmaz, K. Plasma coatings CrAlN and a-C: H for high efficient power train in automobile. Surface Coat. Technol. 2010, 205, 1502–1507. [Google Scholar] [CrossRef]

- Lugscheider, E.; Bobzin, K. The influence on surface free energy of PVD-coatings. Surface Coat. Technol. 2001, 142, 755–760. [Google Scholar] [CrossRef]

- Bobzin, K. Benetzungs- und Korrosionsverhalten von PVD-beschichteten Werkstoffen für den Einsatz in umweltverträglichen Tribosystemen. Ph.D. Thesis, RWTH Aachen, Aachen, Germany, 2000. [Google Scholar]

- Theiss, S. Analyse gepulster Hochleistungsplasmen zur Entwicklung neuartiger PVD-Beschichtungen für die Kunststoffverarbeitung. Ph.D. Thesis, RWTH Aachen, Aachen, Germany, 2013. [Google Scholar]

- Hellerich, W.; Harsch, G.; Haenle, S. Werkstoff-Führer Kunststoffe. Eigenschaften, Prüfungen, Kennwerte; Carl Hanser Verlag: Munich, Germany, 2010; ISBN 978-3-446-42436-4. [Google Scholar]

- Goryacheva, I.G. Contact Mechanics in Tribology; Springer Science & Business Media: Berlin, Germany, 2011; ISBN 978-90-481-5102-8. [Google Scholar]

- Brinksmeier, E.; Riemer, O.; Twardy, S. Tribological behavior of micro structured surfaces for micro forming tools. Int. J. Mach. Tools Manuf. 2010, 50, 425–430. [Google Scholar] [CrossRef]

- Thorp, J.M. Tribological properties of selected polymeric matrix composites against steel surfaces. In Friction and Wear of Polymer Composites; Friedrich, K., Ed.; Elsevier Science: Amsterdam, The Netherlands, 1986; pp. 89–135. ISBN 9780444597113. [Google Scholar]

| Film System | dcMS- CrN | HiPIMS- CrN | dcMS- CrAlN | HiPIMS- CrAlN | CrAlSiN | Al2O3 | a-C (Top Layer) | a-C:H (Top Layer) |

|---|---|---|---|---|---|---|---|---|

| Sputter mode | dcMS | HiPIMS | dcMS | HiPIMS | dcMS | mfMS | mfMS | mfMS |

| Target × cathode power (kW) or voltage (V) | 2 Cr × 4.0 kW | 2 Cr × 4.0 kW | 2 AlCr20 × 5.0 kW | 2 AlCr20 × 7.0 kW | 2 AlCr24 × 5.0 kW 1 Cr × 1.0 kW 1 Si × 2.0 kW | 2 Al × 410 V | 2 C × 3 kW | 2 C × 3 kW |

| Pulse frequency (Hz) | – | 1000 | – | 600 | – | – | – | – |

| Pulse duration (µs) | – | 50 | – | 50 | – | – | – | – |

| Mid frequency (kHz) | – | – | – | – | – | 50 | 20 | 20 |

| Pressure (mPa) | 400 | 400 | 500 | 500 | 500 | control | 300 | 300 |

| Ar flow (sccm) | 300 | 300 | 120 | 80 | 120 | 300 | control | control |

| Kr flow (sccm) | 50 | 50 | 180 | 40 | 80 | – | – | – |

| N2 flow (sccm) | control | control | control | control | control | – | – | – |

| O2 flow (sccm) | – | – | – | – | – | 60 | – | – |

| C2H2 flow (sccm) | – | – | – | – | – | – | – | 35 |

| Bias voltage (−V) | 90 | 100 | 120 | 150 | 120 | 100 | 130 | 130 |

| Deposition time (s) | 10.000 | 20.000 | 21.000 | 20.000 | 21.200 | 7.200 | 18.000 | 12.500 |

| Film System | Chemical Composition [at.%] | Hardness [GPa] | Elastic Modulus [GPa] | ||||

|---|---|---|---|---|---|---|---|

| Cr | Al | Si | N | O | |||

| dcMS-CrN | 52.4 ± 0.8 | – | – | 47.6 ± 0.8 | – | 22.9 ± 1.3 | 301.8 ± 17.7 |

| HiPIMS-CrN | 64.0 ± 1.1 | – | – | 36.0 ± 1.1 | – | 24.6 ± 1.7 | 332.4 ± 15.8 |

| dcMS-CrAlN | 12.3 ± 0.5 | 36.0 ± 1.0 | – | 51.8 ± 1.5 | – | 26.7 ± 2.2 | 306.9 ± 14.4 |

| HiPIMS-CrAlN | 33.2 ± 1.0 | 14.5 ± 0.2 | – | 52.4 ± 1.2 | – | 33.3 ± 4.1 | 354.6 ± 36.7 |

| dcMS-CrAlSiN | 15.5 ± 0.6 | 24.3 ± 0.7 | 8.1 ± 0.2 | 52.2 ± 1.4 | – | 27.6 ± 1.7 | 291.5 ± 11.5 |

| Al2O3 | – | 45.0 ± 0.2 | – | – | 55.0 ± 0.2 | 14.9 ± 0.9 | 193.4 ± 7.1 |

| a-C | Hydrogen-free amorphous carbon | 20.5 ± 1.5 | 190.7 ± 8.4 | ||||

| a-C:H | Hydrogenated amorphous carbon | 16.4 ± 1.0 | 148.5 ± 6.1 | ||||

| Test Liquid | |||

|---|---|---|---|

| Distilled water | 72.8 | 21.8 | 51 |

| Ethylene glycol | 48 | 29 | 19 |

| Dimethylformamide | 37.3 | 32.4 | 4.9 |

| 1-Octanol | 21.6 | 21.6 | 0 |

| 1-Decanol | 28.5 | 22.2 | 6.3 |

| Plastic Counterpart | |||

|---|---|---|---|

| PA | 47.5 | 36.8 | 10.7 |

| PP | 31.2 | 30.5 | 0.7 |

| PS | 42.0 | 41.4 | 0.6 |

| Surface System | Static Contact Angle [°] | ||||

|---|---|---|---|---|---|

| Water | Ethylene Glycol | Dimethylformamide | 1-Octanol | 1-Decanol | |

| Uncoated AISI H11 | 69.4 ± 1.7 | 59.6 ± 2.07 | 32.6 ± 2.1 | 2.0 ± 2.1 | 14.4 ± 1.8 |

| dcMS-CrN | 93.2 ± 0.8 | 77.2 ± 0.8 | 35.2 ± 1.6 | 11.8 ± 0.8 | 21.8 ± 1.8 |

| HiPIMS-CrN | 100.2 ± 0.8 | 75.6 ± 1.1 | 50.4 ± 1.7 | 13.2 ± 1.5 | 26.4 ± 2.5 |

| dcMS-CrAlN | 94.6 ± 1.1 | 75.0 ± 2.6 | 34.2 ± 1.9 | 0 | 9.6 ± 2.1 |

| HiPIMS-CrAlN | 94.6 ± 1.3 | 75.2 ± 0.8 | 42.0 ± 1.6 | 4.8 ± 1.9 | 24.4 ± 1.5 |

| CrAlSiN | 94.4 ± 1.8 | 72.8 ± 1.9 | 41.4 ± 1.7 | 7.2 ± 1.8 | 25.4 ± 2.3 |

| Al2O3 | 81.2 ± 1.6 | 59.6 ± 1.1 | 28.4 ± 1.1 | 0 | 12.8 ± 0.8 |

| a-C | 88.2 ± 1.8 | 58.8 ± 2.3 | 15.4 ± 1.7 | 0 | 0.8 ± 1.1 |

| a-C:H | 73.2 ± 1.8 | 39.4 ± 0.9 | 10.4 ± 1.5 | 0 | 1.8 ± 1.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tillmann, W.; Lopes Dias, N.F.; Stangier, D.; Gelinski, N. Tribological Performance of PVD Film Systems Against Plastic Counterparts for Adhesion-Reducing Application in Injection Molds. Coatings 2019, 9, 588. https://doi.org/10.3390/coatings9090588

Tillmann W, Lopes Dias NF, Stangier D, Gelinski N. Tribological Performance of PVD Film Systems Against Plastic Counterparts for Adhesion-Reducing Application in Injection Molds. Coatings. 2019; 9(9):588. https://doi.org/10.3390/coatings9090588

Chicago/Turabian StyleTillmann, Wolfgang, Nelson Filipe Lopes Dias, Dominic Stangier, and Nikolai Gelinski. 2019. "Tribological Performance of PVD Film Systems Against Plastic Counterparts for Adhesion-Reducing Application in Injection Molds" Coatings 9, no. 9: 588. https://doi.org/10.3390/coatings9090588

APA StyleTillmann, W., Lopes Dias, N. F., Stangier, D., & Gelinski, N. (2019). Tribological Performance of PVD Film Systems Against Plastic Counterparts for Adhesion-Reducing Application in Injection Molds. Coatings, 9(9), 588. https://doi.org/10.3390/coatings9090588