Effects of Cobalt Content on the Microstructure, Mechanical Properties and Cavitation Erosion Resistance of HVOF Sprayed Coatings

Abstract

:1. Introduction

2. Methodology

2.1. Materials and HVOF Spraying Procedure

2.2. Coating Characterization and Property Tests

2.3. Mechanical Testing

2.4. Cavitation Erosion Tests

3. Results

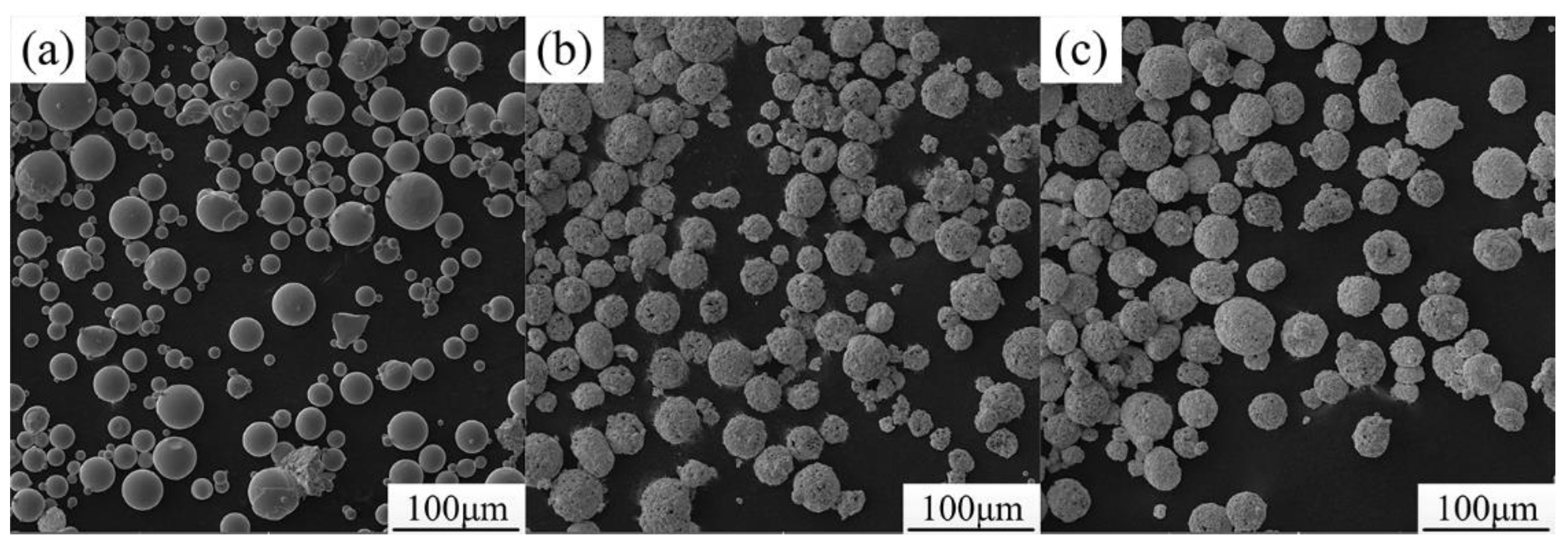

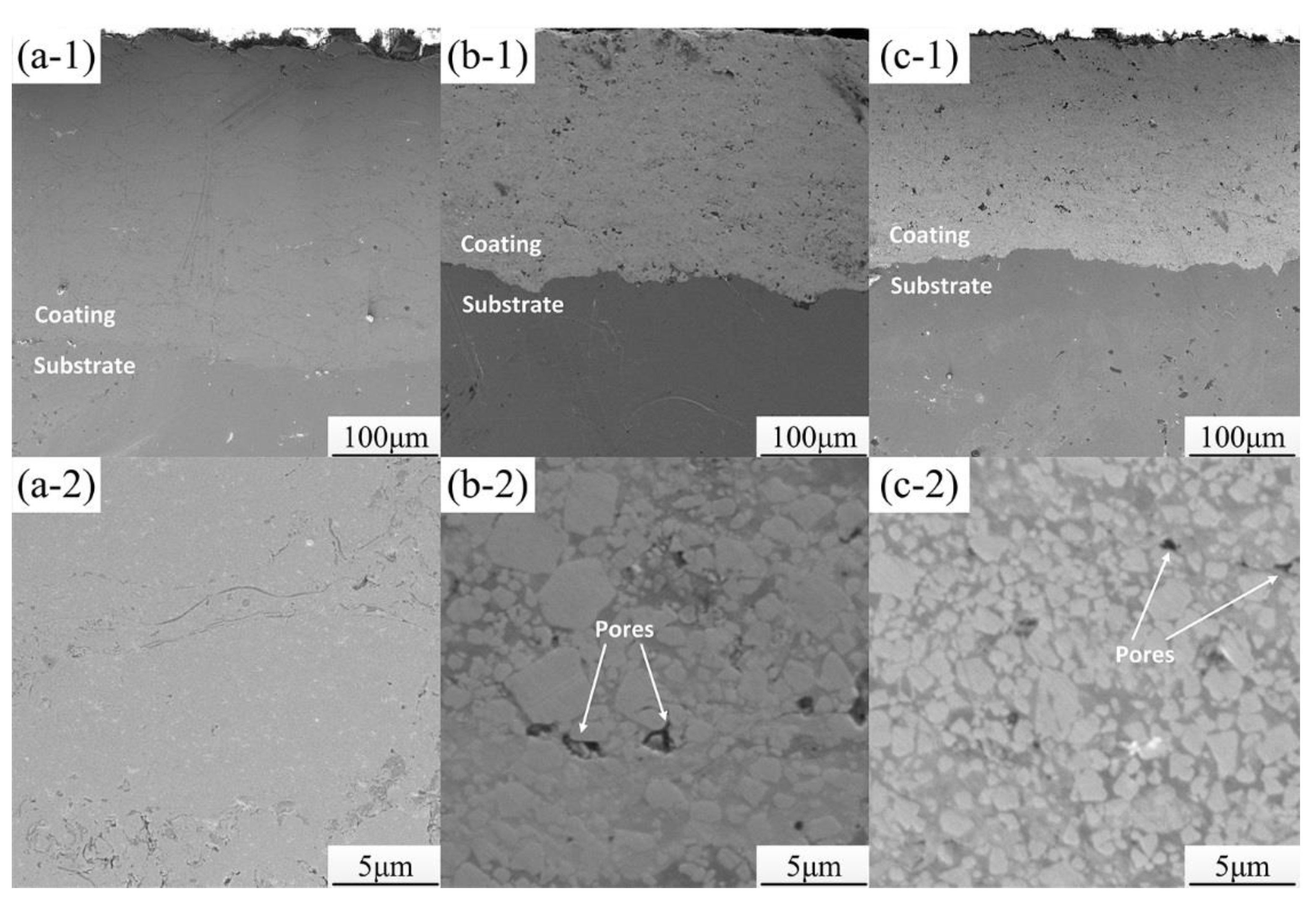

3.1. Microstructure

3.2. Mechanical Properties

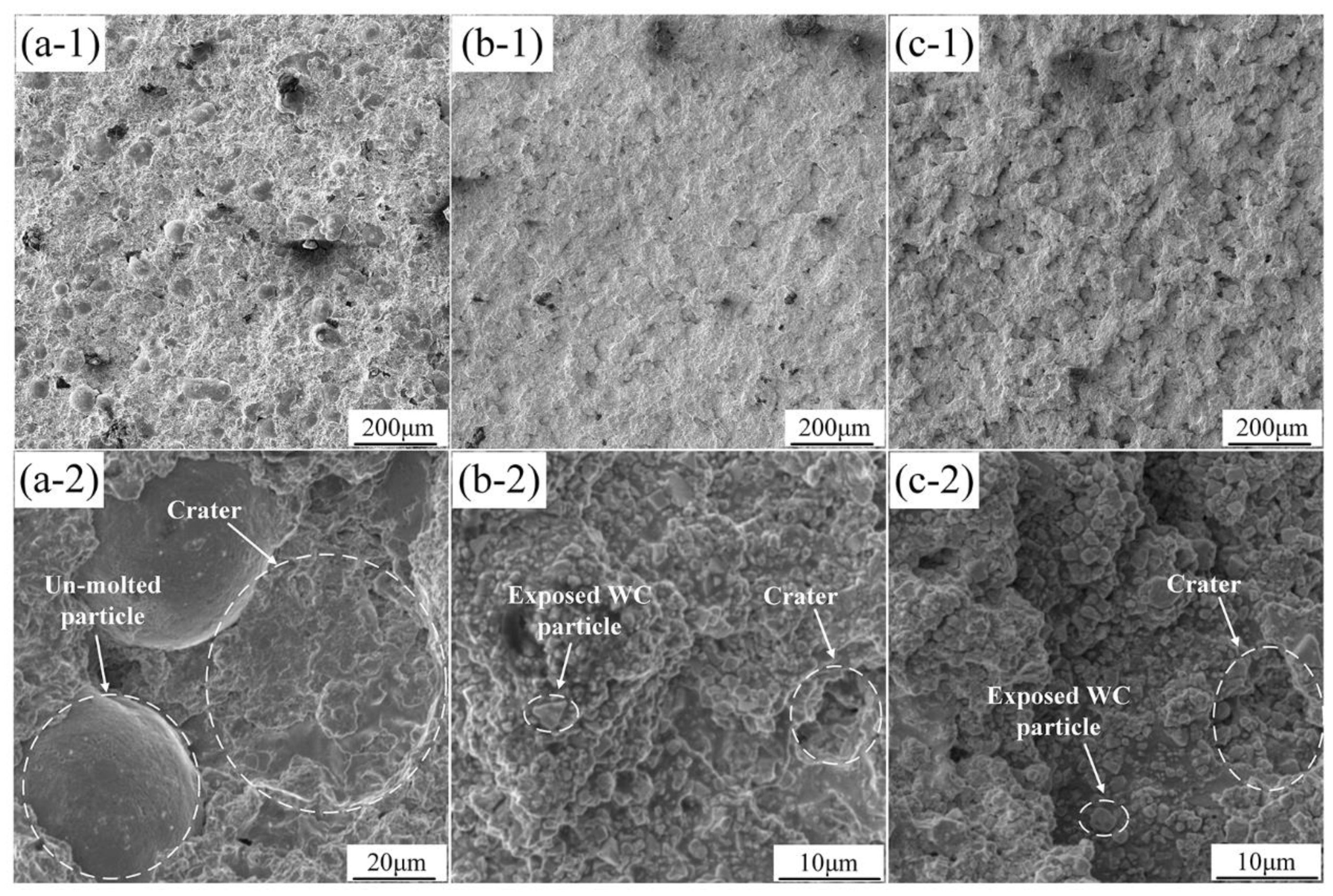

3.3. Cavitation Erosion Behavior

4. Discussion

5. Conclusions

- The cobalt-based alloy coating has the largest surface roughness because surface-bonded particles with a lower plastic deformation contain slight flattening. For the cermet coatings, the existence of finer WC particles decreased the surface roughness, and it caused pores to appear at the interface between WC particles and the matrix phase. Their cohesion increased with the increase in Co content while the porosity (from 0.99% to 0.84%) and the surface roughness (Ra from 4.49 to 2.47μm) decreased in the cermet coatings.

- The hardness value of the cobalt-based alloy coating was 553 HV0.3, and this was attributed to the coating with the dense structure and the Co-based fcc-phase. The hardness of the WC-12Co (1181 HV0.3) and WC-17Co (1120 HV0.3) coatings were higher than the cobalt-based alloy coating because of the distribution of the WC particles in the matrix friction. The hardness slightly decreased with increasing Co content due to the decrease in WC hard phase content.

- The existence of WC particle resisted crack propagation and improved the fracture toughness in the cermet coatings. The fracture toughness slightly increased (from 4.57 to 4.64 MPa∙m1/2) with increasing Co content for the cermet coatings. This is because the ductile matrix phase had higher energy absorption than the WC particles and hindered crack growth and propagation. The WC-17Co coating with minor porosity also provided a greater lamellar cohesion to improve the fracture toughness.

- The CE rate of the coatings in the initial stage was affected by the surface roughness. The WC-12Co and WC-17Co coatings with higher hardness and fracture toughness exhibited better CE resistance than the cobalt-based alloy coating, increasing more than 20% and 16%, respectively. The WC-12Co coating possessed a higher CE resistance than the WC-17Co coating because the hardness had a great influence on CE resistance. Especially, the WC-12Co coating possessed the best CE resistance and is expected to be applicable in the hydraulic machineries. Therefore, the effect of the ingredient added to cobalt-based coatings on the CE resistance are worth further study.

Author Contributions

Funding

Conflicts of Interest

References

- Sreedhar, B.K.; Albert, S.K.; Pandit, A.B. Improving cavitation erosion resistance of austenitic stainless steel in liquid sodium by hardfacing—Comparison of Ni and Co based deposits. Wear 2015, 342, 92–99. [Google Scholar] [CrossRef]

- Nahvi, S.; Jafari, M. Microstructural and mechanical properties of advanced HVOF-sprayed WC-based cermet coatings. Surf. Coat. Technol. 2016, 286, 95–102. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, F.; Hao, S.; Dong, F.; Xu, Y.; Geng, W.; Zhang, N.; Gey, N.; Grosdidier, T.; Dong, C. Evolution of nanostructure and metastable phases at the surface of a HCPEB-treated WC-6% Co hard alloy with increasing irradiation pulse numbers. Coatings 2017, 7, 178. [Google Scholar] [CrossRef]

- Wang, Q.; Tang, Z.; Cha, L. Cavitation and sand slurry erosion resistances of WC-10Co-4Cr coatings. J. Mater. Eng. Perform. 2015, 24, 2435–2443. [Google Scholar] [CrossRef]

- Suo, X.; Yin, S.; Li, H.; Lupoi, R. Numerical and experimental investigation on bonding behavior of cold sprayed porous WC-17Co particles onto different substrates. Coatings 2018, 8, 367. [Google Scholar] [CrossRef]

- Kumar, K.; Kumar, S.; Singh, G.; Singh, J.P.; Singh, J. Erosion wear investigation of HVOF sprayed WC-10Co4Cr coating on slurry pipeline materials. Coatings 2017, 7, 54. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, S.; Cheng, Y.; Xiang, J.; Zhao, X.; Yang, G. Wear and corrosion performance of WC-10Co4Cr coatings deposited by different HVOF and HVAF spraying processes. Surf. Coat. Technol. 2013, 218, 127–136. [Google Scholar] [CrossRef]

- Milanti, A.; Koivuluoto, H.; Vuoristo, P.; Bolelli, G.; Bozza, F.; Lusvarghi, L. Microstructural characteristics and tribological behavior of HVOF-sprayed novel Fe-based alloy coatings. Coatings 2014, 4, 98–120. [Google Scholar] [CrossRef]

- Lin, J.; Wang, Z.; Cheng, J.; Kang, M.; Fu, X.; Hong, S. Effect of Initial Surface Roughness on cavitation erosion resistance of arc-sprayed Fe-based amorphous/nanocrystalline coatings. Coatings 2017, 7, 200. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, J.; Wan, Z.; Qiao, Y.; Xiong, T.; Zheng, Y. Cavitation erosion and jet impingement erosion behavior of the NiTi coating produced by air plasma spraying. Coatings 2018, 8, 10. [Google Scholar] [CrossRef]

- Ding, X.; Ke, D.; Yuan, C.; Ding, Z.; Cheng, X. microstructure and cavitation erosion resistance of HVOF deposited WC-Co coatings with different sized WC. Coatings 2018, 8, 307. [Google Scholar] [CrossRef]

- Ding, X.; Cheng, X.D.; Shi, J.; Li, C.; Yuan, C.Q.; Ding, Z.X. Influence of WC size and HVOF process on erosion wear performance of WC-10Co4Cr coatings. Int. J. Adv. Manuf. Technol. 2018, 96, 1615–1624. [Google Scholar] [CrossRef]

- Lamana, M.S.; Pukasiewicz, A.G.; Sampath, S. Influence of cobalt content and HVOF deposition process on the cavitation erosion resistance of WC-Co coatings. Wear 2018, 398, 209–219. [Google Scholar] [CrossRef]

- Chivavibul, P.; Watanabe, M.; Kuroda, S.; Shinoda, K. Effects of carbide size and Co content on the microstructure and mechanical properties of HVOF-sprayed WC-Co coatings. Surf. Coat. Technol. 2007, 202, 509–521. [Google Scholar] [CrossRef]

- Varis, T.; Suhonen, T.; Ghabchi, A.; Valarezo, A.; Sampath, S.; Liu, X.; Hannula, S.P. Formation mechanisms, structure, and properties of HVOF-sprayed WC-CoCr coatings: An approach toward process maps. J. Therm. Spray Technol. 2014, 23, 1009–1018. [Google Scholar] [CrossRef]

- ASTM G32-16 Standard Test Method for Cavitation Erosion Using Vibratory Apparatus; ASTM International: West Conshohocken, PA, USA, 2016.

- Reza, S.R. Laser surface treatment of Stellite 6 coating deposited by HVOF on 316L alloy. J. Mater. Eng. Perform. 2016, 25, 2583–2595. [Google Scholar]

- Ding, X.; Cheng, X.D.; Yu, X.; Li, C.; Yuan, C.Q.; Ding, Z.X. Structure and cavitation erosion behavior of HVOF sprayed multi-dimensional WC-10Co4Cr coating. Trans. Nonferrous Met. Soc. China 2018, 28, 487–494. [Google Scholar] [CrossRef]

- Houdková, Š.; Smazalová, E.; Pala, Z. Effect of heat treatment on the microstructure and properties of HVOF-sprayed Co-Cr-W coating. J. Therm. Spray Technol. 2016, 25, 546–557. [Google Scholar] [CrossRef]

- Sassatelli, P.; Bolelli, G.; Gualtieri, M.L.; Heinonen, E.; Honkanen, M.; Lusvarghi, L.; Manfredini, T.; Rigon, R.; Vippola, M. Properties of HVOF-sprayed Stellite-6 coatings. Surf. Coat. Technol. 2018, 338, 45–62. [Google Scholar] [CrossRef] [Green Version]

- Ramesh, M.; Prakash, S.; Nath, S.; Sapra, P.K.; Venkataraman, B. Solid particle erosion of HVOF sprayed WC-Co/NiCrFeSiB coatings. Wear 2010, 269, 197–205. [Google Scholar] [CrossRef]

- Lima, M.; Godoy, C.; Modenesi, P.; Avelar-Batista, J.; Davison, A.; Matthews, A. Coating fracture toughness determined by vickers indentation: An important parameter in cavitation erosion resistance of WC-Co thermally sprayed coatings. Surf. Coat. Technol. 2004, 177, 489–496. [Google Scholar] [CrossRef]

- Karaoglanli, A.C.; Oge, M.; Doleker, K.M.; Hotamis, M. Comparison of tribological properties of HVOF sprayed coatings with different composition. Surf. Coat. Technol. 2017, 318, 299–308. [Google Scholar] [CrossRef]

- Lu, J.; Cao, J.; Lu, H.; Zhang, L.; Luo, K. Wear Properties and Microstructural Analyses of Fe-based coatings with various WC contents on H13 die steel by laser cladding. Surf. Coat. Technol. 2019, 369, 228–237. [Google Scholar] [CrossRef]

- He, M.; Wang, J.; He, R.; Yang, H.; Ruan, J. Effect of cobalt content on the microstructure and mechanical properties of coarse grained WC-Co cemented carbides fabricated from chemically coated composite powder. J. Alloys Compd. 2018, 766, 556–563. [Google Scholar] [CrossRef]

- Vashishtha, N.; Khatirkar, R.; Sapate, S. Tribological behaviour of HVOF sprayed WC-12Co, WC-10Co-4Cr and Cr3C2-25NiCr coatings. Tribol. Int. 2017, 105, 55–68. [Google Scholar] [CrossRef]

- Hou, G.; Zhao, X.; Zhou, H.; Lu, J.; An, Y.; Chen, J.; Yang, J. Cavitation erosion of several oxy-fuel sprayed coatings tested in deionized water and artificial seawater. Wear 2014, 311, 81–92. [Google Scholar] [CrossRef]

| Element | C | Si | Cr | Mn | Mo | Fe | Ni | W | Co |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.25 | 1.50 | 27.30 | ≤0.50 | ≤5.50 | 1.50 | 2.00 | ≤0.50 | Balance |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Bai, X.; Chen, T.; Yuan, C. Effects of Cobalt Content on the Microstructure, Mechanical Properties and Cavitation Erosion Resistance of HVOF Sprayed Coatings. Coatings 2019, 9, 534. https://doi.org/10.3390/coatings9090534

Liu J, Bai X, Chen T, Yuan C. Effects of Cobalt Content on the Microstructure, Mechanical Properties and Cavitation Erosion Resistance of HVOF Sprayed Coatings. Coatings. 2019; 9(9):534. https://doi.org/10.3390/coatings9090534

Chicago/Turabian StyleLiu, Ji, Xiuqin Bai, Tongzhou Chen, and Chengqing Yuan. 2019. "Effects of Cobalt Content on the Microstructure, Mechanical Properties and Cavitation Erosion Resistance of HVOF Sprayed Coatings" Coatings 9, no. 9: 534. https://doi.org/10.3390/coatings9090534

APA StyleLiu, J., Bai, X., Chen, T., & Yuan, C. (2019). Effects of Cobalt Content on the Microstructure, Mechanical Properties and Cavitation Erosion Resistance of HVOF Sprayed Coatings. Coatings, 9(9), 534. https://doi.org/10.3390/coatings9090534