Microstructure and Properties of CrAlSiN Coatings Deposited by HiPIMS and Direct-Current Magnetron Sputtering

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

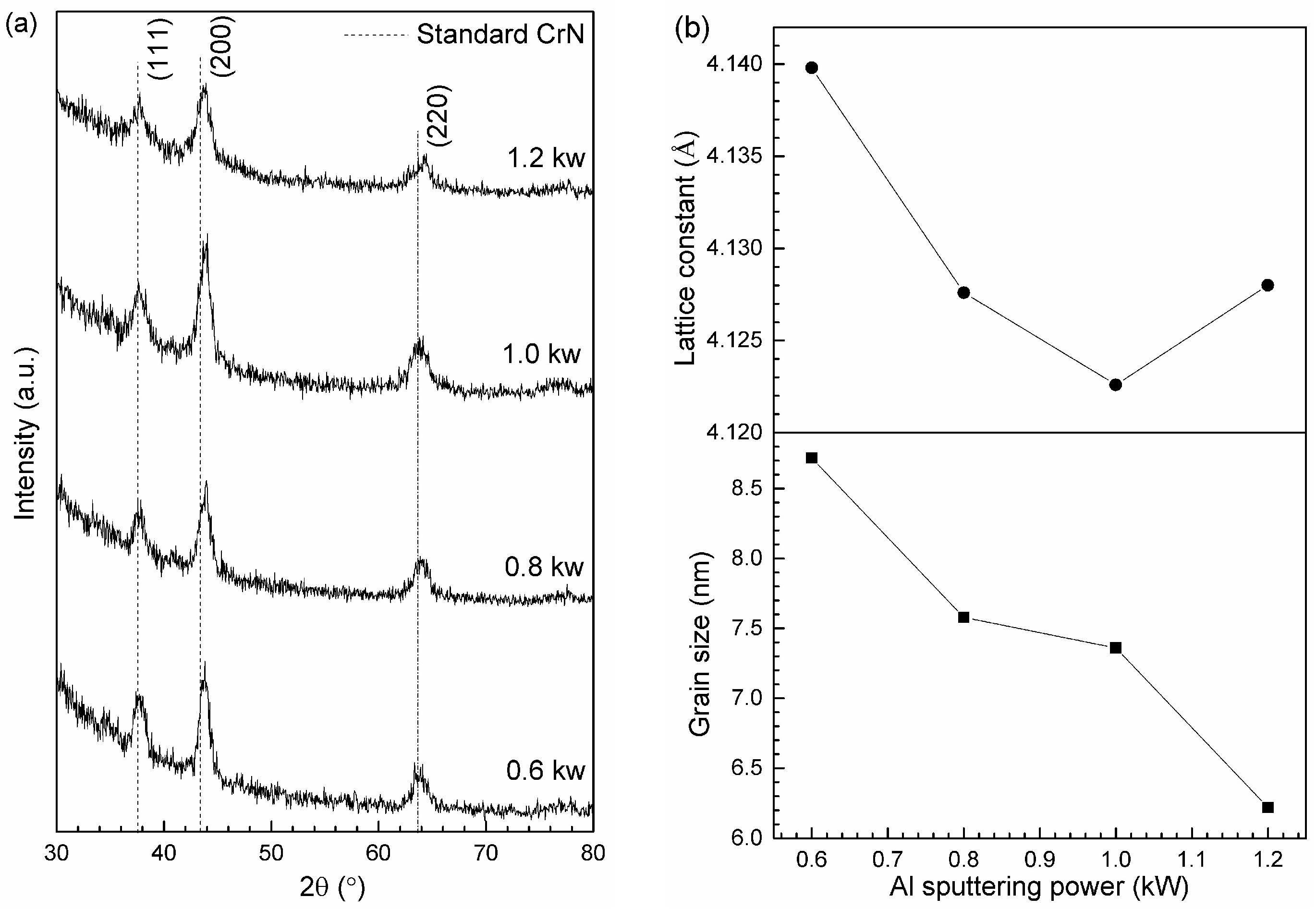

3.1. Composition and Phase Characterization

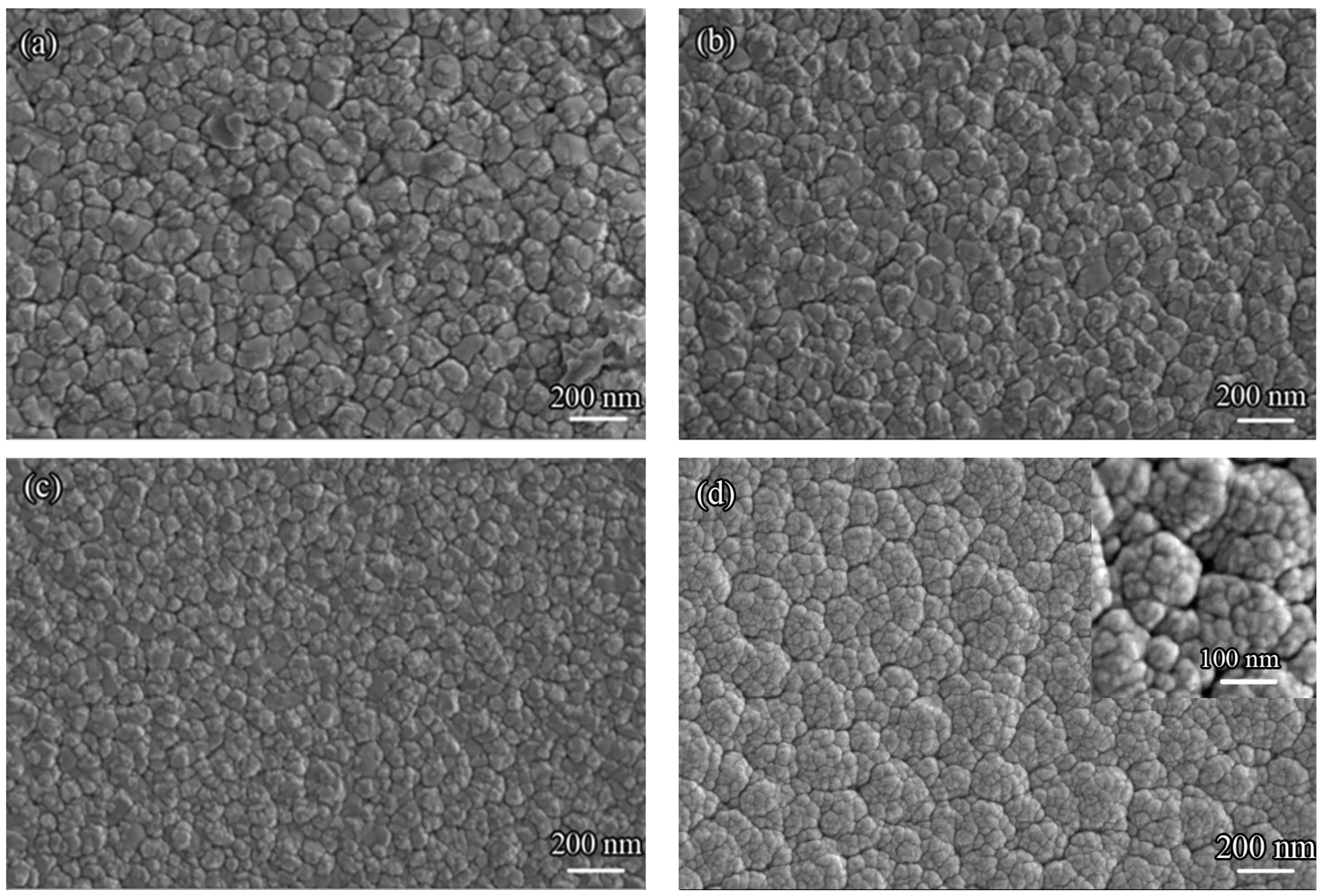

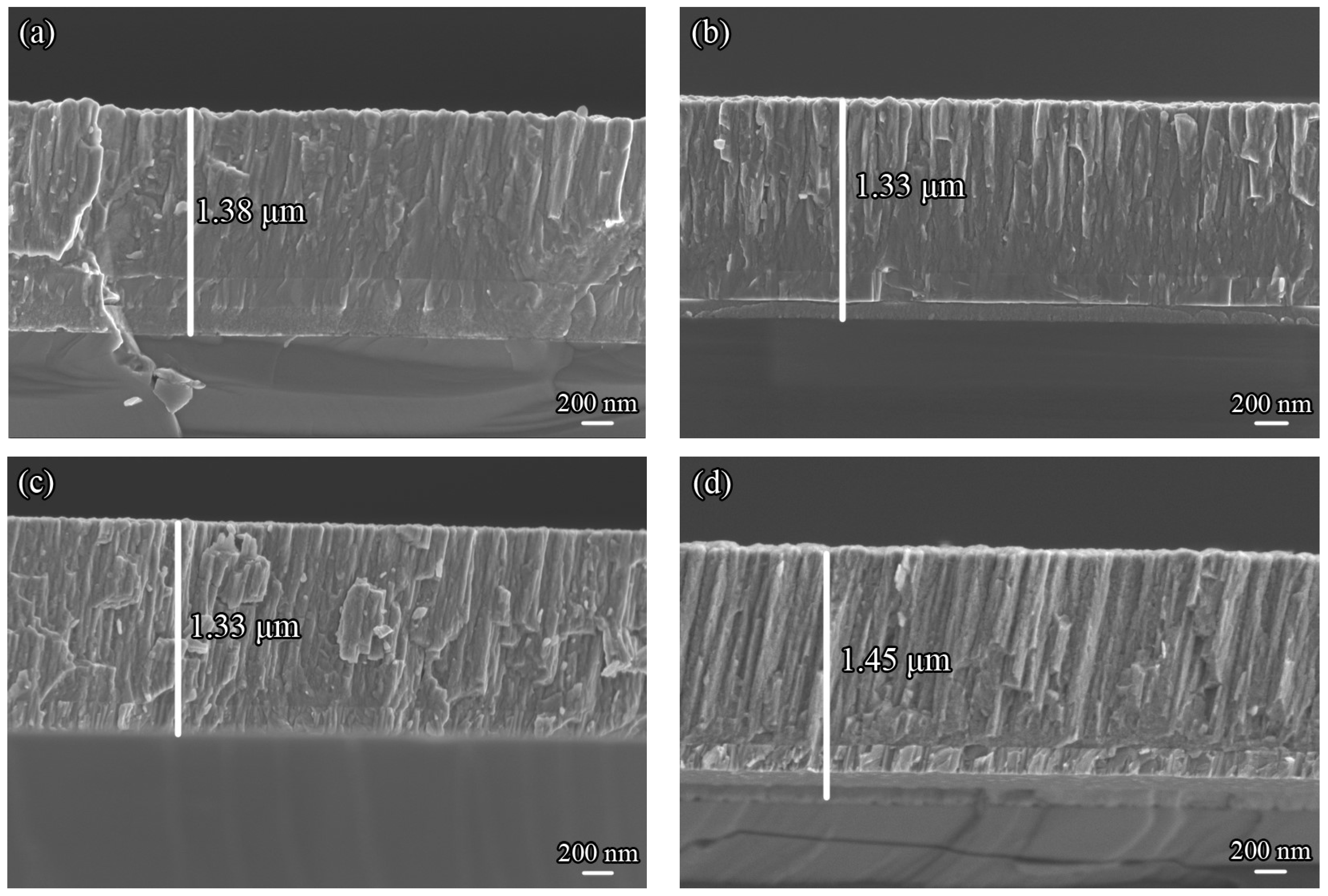

3.2. Microstructure

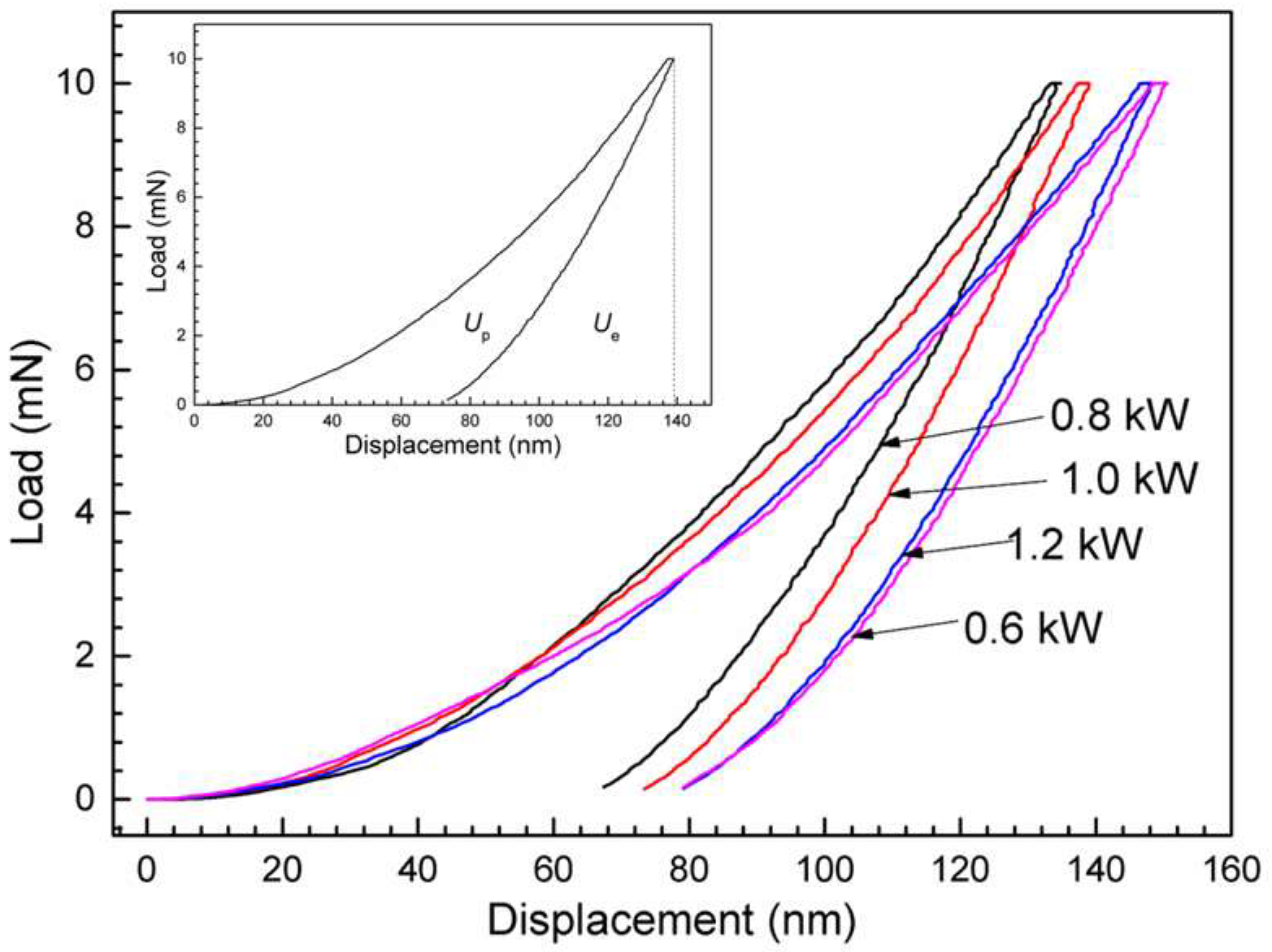

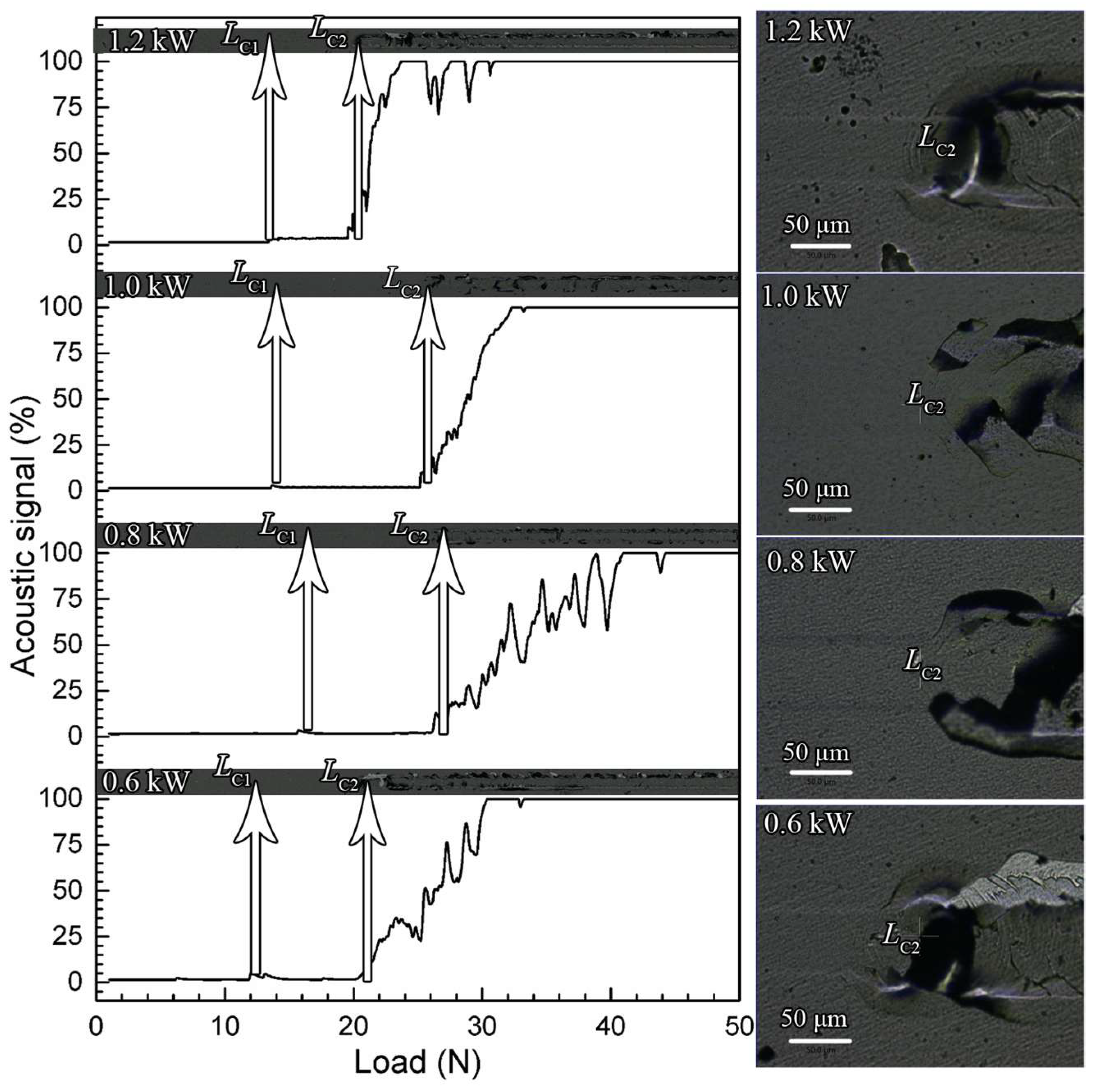

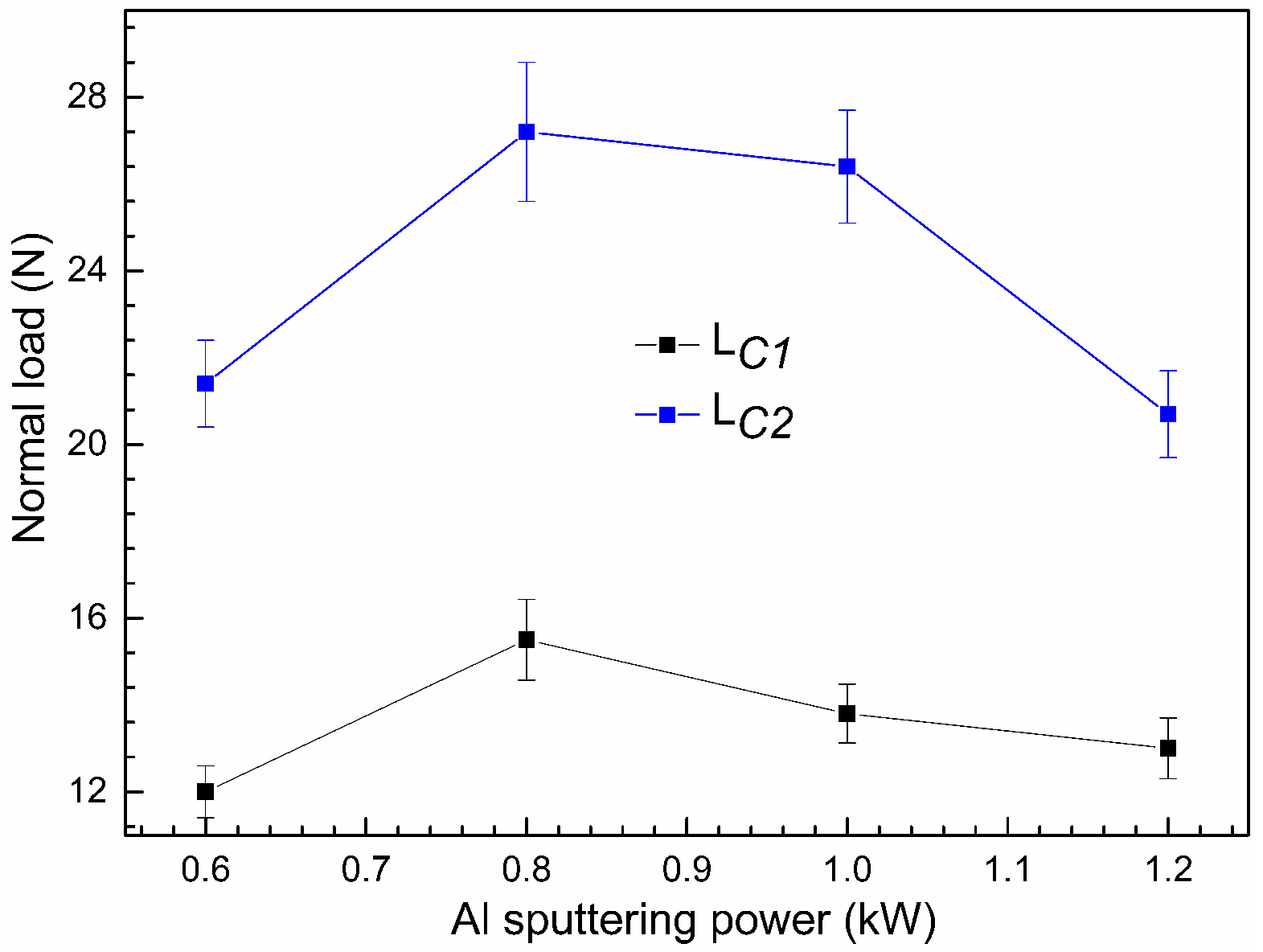

3.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tien, S.K.; Lin, C.H.; Tsai, Y.Z.; Duh, J.G. Effect of nitrogen flow on the properties of quaternary CrAlSiN coatings at elevated temperatures. Surf. Coat. Technol. 2017, 202, 735–739. [Google Scholar] [CrossRef]

- Kim, S.K.; Van Le, V.; Van Vinh, P.; Lee, J.W. Effect of cathode arc current and bias voltage on the mechanical properties of CrAlSiN thin films. Surf. Coat. Technol. 2008, 202, 5400–5404. [Google Scholar] [CrossRef]

- Fan, Q.; Zhang, J.; Wu, Z.; Liu, Y.; Yan, B.; Wang, T. Influence of Al content on the microstructure and properties of the CrAlN coatings deposited by arc ion plating. Acta Met. Sin. (English Lett.) 2017, 30, 1221–1230. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, L.; Wang, Q.; Li, M. A superhard CrAlSiN superlattice coating deposited by a multi-arc ion plating: II. Thermal stability and oxidation resistance. Surf. Coat. Technol. 2013, 214, 153–159. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Lai, H.-M. Wear behavior and cutting performance of CrAlSiN and TiAlSiN hard coatings on cemented carbide cutting tools for Ti alloys. Surf. Coat. Technol. 2014, 259, 152–158. [Google Scholar] [CrossRef]

- Feng, Y.-P.; Zhang, L.; Ke, R.-X.; Wan, Q.-L.; Wang, Z.; Lu, Z.-H. Thermal stability and oxidation behavior of AlTiN, AlCrN and AlCrSiWN coatings. Int. J. Refract. Met. Hard Mater. 2014, 43, 241–249. [Google Scholar] [CrossRef]

- Kang, M.S.; Wang, T.-G.; Shin, J.H.; Nowak, R.; Kim, K.H. Synthesis and properties of Cr–Al–Si–N films deposited by hybrid coating system with high power impulse magnetron sputtering (HIPIMS) and DC pulse sputtering. Trans. Nonferrous Met. Soc. China 2012, 22, s729–s734. [Google Scholar] [CrossRef]

- Chang, C.-C.; Duh, J.-G. Duplex coating technique to improve the adhesion and tribological properties of CrAlSiN nanocomposite coating. Surf. Coat. Technol. 2017, 326, 375–381. [Google Scholar] [CrossRef]

- Chang, C.-C.; Chen, H.-W.; Lee, J.-W.; Duh, J.-G. Development of Si-modified CrAlSiN nanocomposite coating for anti-wear application in extreme environment. Surf. Coat. Technol. 2015, 284, 273–280. [Google Scholar] [CrossRef]

- Li, B.; Wang, T.; Ding, J.; Cai, Y.; Shi, J.; Zhang, X. Influence of N2/Ar flow ratio on microstructure and properties of the AlCrSiN coatings deposited by high-power impulse magnetron sputtering. Coatings 2018, 8, 3. [Google Scholar] [CrossRef]

- Lundin, D.; Sarakinos, K. An introduction to thin film processing using high-power impulse magnetron sputtering. J. Mater. Res. 2012, 27, 780–792. [Google Scholar] [CrossRef]

- Wang, L.; Li, L.; Kuang, X. Effect of substrate bias on microstructure and mechanical properties of WC-DLC coatings deposited by HiPIMS. Surf. Coat. Technol. 2018, 352, 33–41. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Lou, B.-S.; Yang, Y.-C.; Qiu, Y.-X.; Diyatmika, W.; Lee, J.-W. Hybrid high power impulse and radio frequency magnetron sputtering system for TiCrSiN thin film depositions: Plasma characteristics and film properties. Surf. Coat. Technol. 2018, 350, 762–772. [Google Scholar] [CrossRef]

- Makino, Y.; Nogi, K. Synthesis of pseudobinary Cr–Al–N films with B1 structure by rf-assisted magnetron sputtering method. Surf. Coat. Technol. 1998, 98, 1008–1012. [Google Scholar] [CrossRef]

- Park, J.H.; Chung, W.S.; Cho, Y.-R.; Kim, K.H. Synthesis and mechanical properties of Cr–Si–N coatings deposited by a hybrid system of arc ion plating and sputtering techniques. Surf. Coat. Technol. 2004, 188, 425–430. [Google Scholar] [CrossRef]

- Wang, Q.M.; Kim, K.H. Microstructural control of Cr–Si–N films by a hybrid arc ion plating and magnetron sputtering process. Acta Mater. 2009, 57, 4974–4987. [Google Scholar] [CrossRef]

- Ma, F.; Li, J.; Zeng, Z.; Gao, Y. Structural, mechanical and tribocorrosion behaviour in artificial seawater of CrN/AlN nano-multilayer coatings on F690 steel substrates. Appl. Surf. Sci. 2018, 428, 404–414. [Google Scholar] [CrossRef]

- Chen, H.-W.; Chan, Y.-C.; Lee, J.-W.; Duh, J.-G. Oxidation resistance of nanocomposite CrAlSiN under long-time heat treatment. Surf. Coat. Technol. 2011, 206, 1571–1576. [Google Scholar] [CrossRef]

- Je, J.H.; Noh, D.Y.; Kim, H.K.; Liang, K.S. Preferred orientation of TiN films studied by a real time synchrotron X-ray scattering. J. Appl. Phys. 1997, 81, 6126–6133. [Google Scholar] [CrossRef][Green Version]

- He, L.; Chen, L.; Xu, Y. Interfacial structure, mechanical properties and thermal stability of CrAlSiN/CrAlN multilayer coatings. Mater. Charact. 2017, 125, 1–6. [Google Scholar] [CrossRef]

- Stueber, M.; Holleck, H.; Leiste, H.; Seemann, K.; Ulrich, S.; Ziebert, C. Concepts for the design of advanced nanoscale PVD multilayer protective thin films. J. Alloy. Compd. 2009, 483, 321–333. [Google Scholar] [CrossRef]

- Ding, X.-Z.; Zeng, X.; Liu, Y. Structure and properties of CrAlSiN nanocomposite coatings deposited by lateral rotating cathod arc. Thin Solid Films 2011, 519, 1894–1900. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, L.; Wang, Q.; Li, M. A superhard CrAlSiN superlattice coating deposited by multi-arc ion plating: I. Microstructure and mechanical properties. Surf. Coat. Technol. 2013, 214, 160–167. [Google Scholar] [CrossRef]

- Chang, C.-C.; Chen, H.-W.; Lee, J.-W.; Duh, J.-G. Influence of Si contents on tribological characteristics of CrAlSiN nanocomposite coatings. Thin Solid Films 2015, 584, 46–51. [Google Scholar] [CrossRef]

- Musil, J.; Jílek, R.; Meissner, M.; Tölg, T.; Čerstvý, R. Two-phase single layer Al–O–N nanocomposite films with enhanced resistance to cracking. Surf. Coat. Technol. 2012, 206, 4230–4234. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, C.; Pei, Z.; Lei, H.; Gong, J.; Sun, C. Microstructure and properties of AlB2-type WB2 thin films deposited by direct-current magnetron sputtering. Surf. Coat. Technol. 2014, 245, 108–116. [Google Scholar] [CrossRef]

- Li, T.; Li, M.; Zhou, Y. Phase segregation and its effect on the adhesion of Cr–Al–N coatings on K38G alloy prepared by magnetron sputtering method. Surf. Coat. Technol. 2007, 201, 7692–7698. [Google Scholar] [CrossRef]

- Attar, F.; Johannesson, T. Adhesion evaluation of thin ceramic coatings on tool steel using the scratch testing technique. Surf. Coat. Technol. 1996, 78, 87–102. [Google Scholar] [CrossRef]

- Wu, W.; Chen, W.; Yang, S.; Lin, Y.; Zhang, S.; Cho, T.-Y.; Lee, G.; Kwon, S.-C. Design of AlCrSiN multilayers and nanocomposite coating for HSS cutting tools. Appl. Surf. Sci. 2015, 351, 803–810. [Google Scholar] [CrossRef]

- Li, Z.; Munroe, P.; Jiang, Z.; Zhao, X.; Xu, J.; Zhou, Z.; Jiang, J.; Fang, F.; Xie, Z. Designing superhard, self-toughening CrAlN coatings through grain boundary engineering. Acta Mater. 2012, 60, 5735–5744. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Base pressure (Pa) | 1.0 × 10−3 |

| Working pressure (Pa) | 0.5 |

| Bias voltage (V) | −30 |

| Ar flow (SCCM) | 47 |

| N2 flow (SCCM) | 94 |

| Deposition temperature (°C) | 300 |

| Deposition time (min) | 180 |

| Sputtering power of Al target (kW) | 0.6, 0.8, 1.0, 1.2 |

| Sputtering power of Cr target (kW) | 1.0 |

| Sputtering power of Si target (kW) | 0.6 |

| Rotation speed of the sample (r/min) | 30 |

| Distance between the substrate and target (mm) | 70 |

| Al Target Power (kW) | H (GPa) | E* (GPa) | H/E* | H3/E*2 | We% |

|---|---|---|---|---|---|

| 0.6 | 23.6 ± 0.9 | 373.3 ± 16.8 | 0.0633 ± 0.0016 | 0.0949 ± 0.0058 | 51.85 ± 0.99 |

| 0.8 | 26.7 ± 1.5 | 383.5 ± 16.6 | 0.0696 ± 0.0014 | 0.1296 ± 0.0082 | 55.85 ± 1.66 |

| 1.0 | 25.3 ± 0.6 | 371.5 ± 19.0 | 0.0681 ± 0.0015 | 0.1176 ± 0.0067 | 55.19 ± 1.34 |

| 1.2 | 23.7 ± 2.0 | 346.7 ± 35.1 | 0.0683 ± 0.0021 | 0.1128 ± 0.0141 | 52.95 ± 2.11 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Q.; Liang, Y.; Wu, Z.; Liu, Y.; Wang, T. Microstructure and Properties of CrAlSiN Coatings Deposited by HiPIMS and Direct-Current Magnetron Sputtering. Coatings 2019, 9, 512. https://doi.org/10.3390/coatings9080512

Fan Q, Liang Y, Wu Z, Liu Y, Wang T. Microstructure and Properties of CrAlSiN Coatings Deposited by HiPIMS and Direct-Current Magnetron Sputtering. Coatings. 2019; 9(8):512. https://doi.org/10.3390/coatings9080512

Chicago/Turabian StyleFan, Qixiang, Yangmengtian Liang, Zhenghuan Wu, Yanmei Liu, and Tiegang Wang. 2019. "Microstructure and Properties of CrAlSiN Coatings Deposited by HiPIMS and Direct-Current Magnetron Sputtering" Coatings 9, no. 8: 512. https://doi.org/10.3390/coatings9080512

APA StyleFan, Q., Liang, Y., Wu, Z., Liu, Y., & Wang, T. (2019). Microstructure and Properties of CrAlSiN Coatings Deposited by HiPIMS and Direct-Current Magnetron Sputtering. Coatings, 9(8), 512. https://doi.org/10.3390/coatings9080512