Enhancement of Critical Current Density by Establishing a YBa2Cu3O7−x/LaAlO3/YBa2Cu3O7−x Quasi-Trilayer Architecture Using the Sol-Gel Method

Abstract

1. Introduction

2. Experiments

2.1. Film Preparation

2.2. Film Testing

3. Results and Discussion

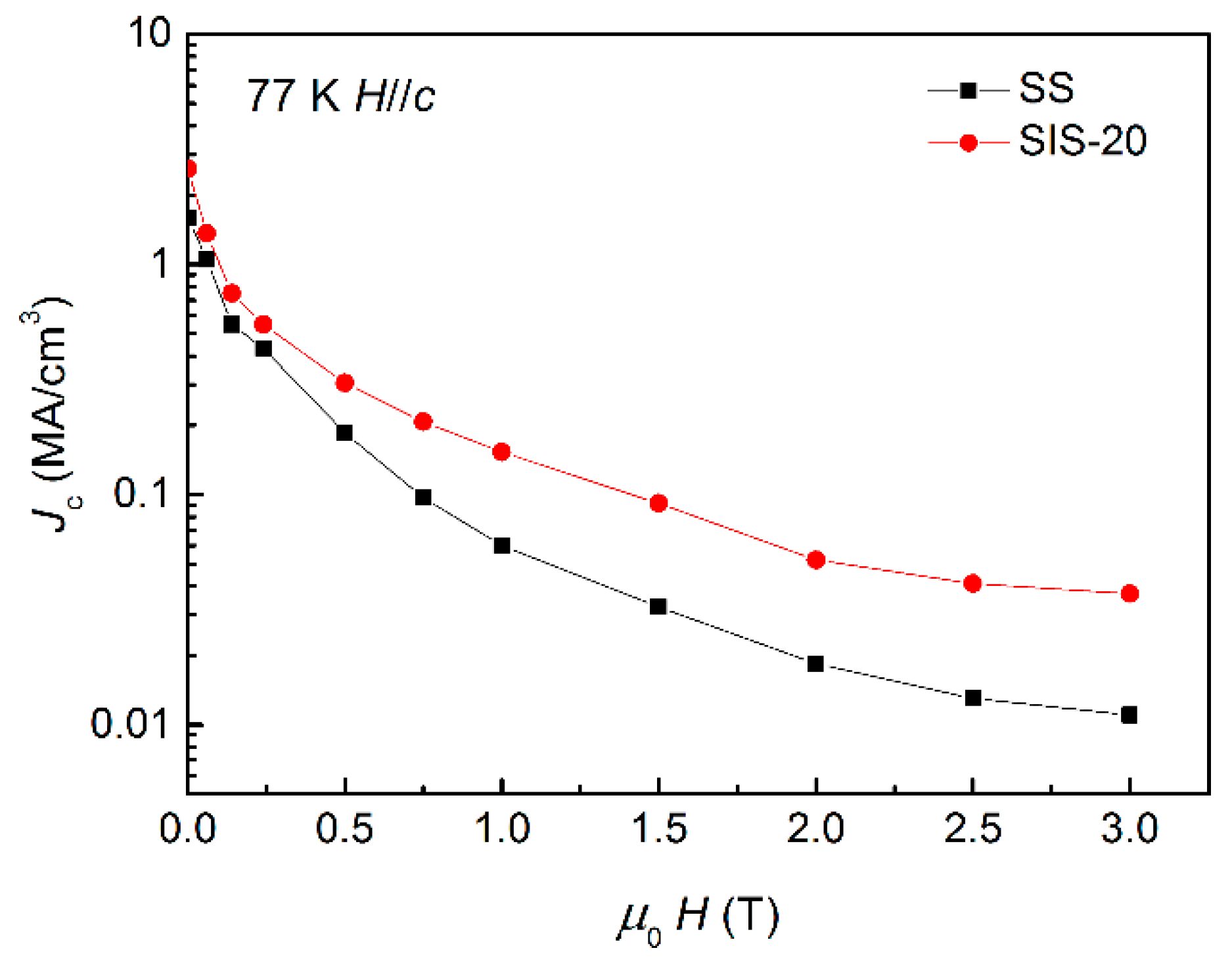

3.1. Jc of YBCO/LAO/YBCO Trilayer

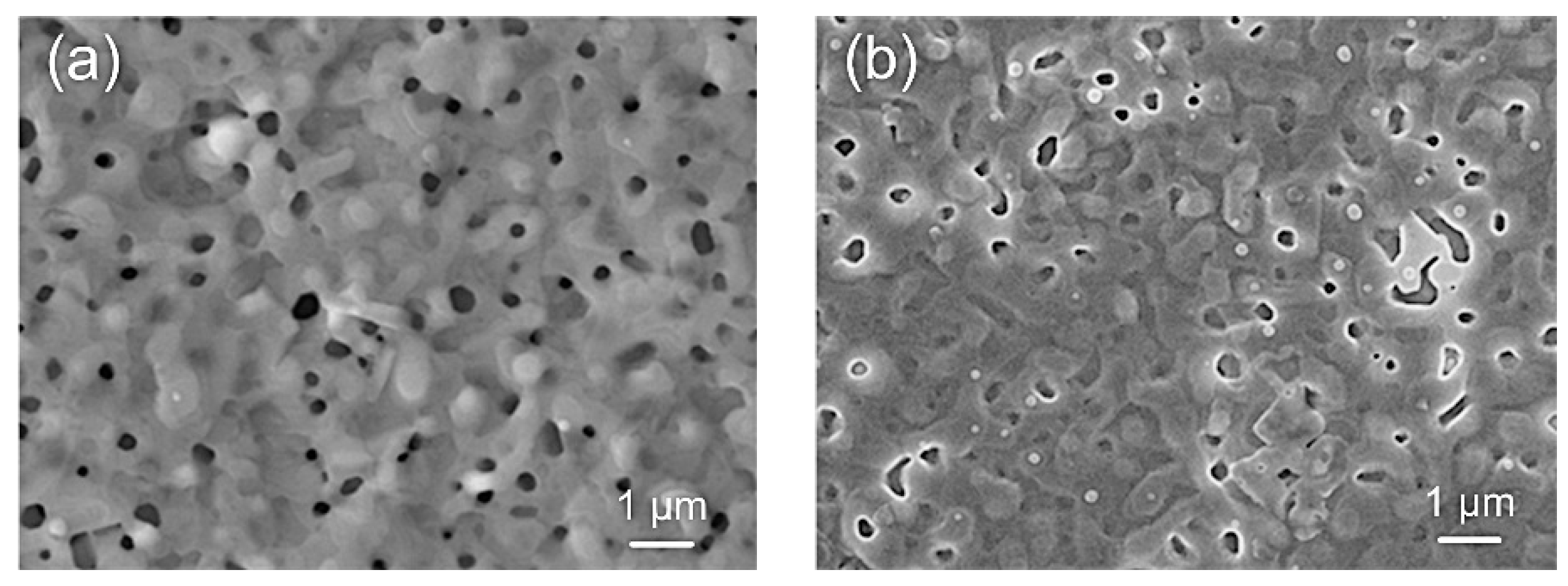

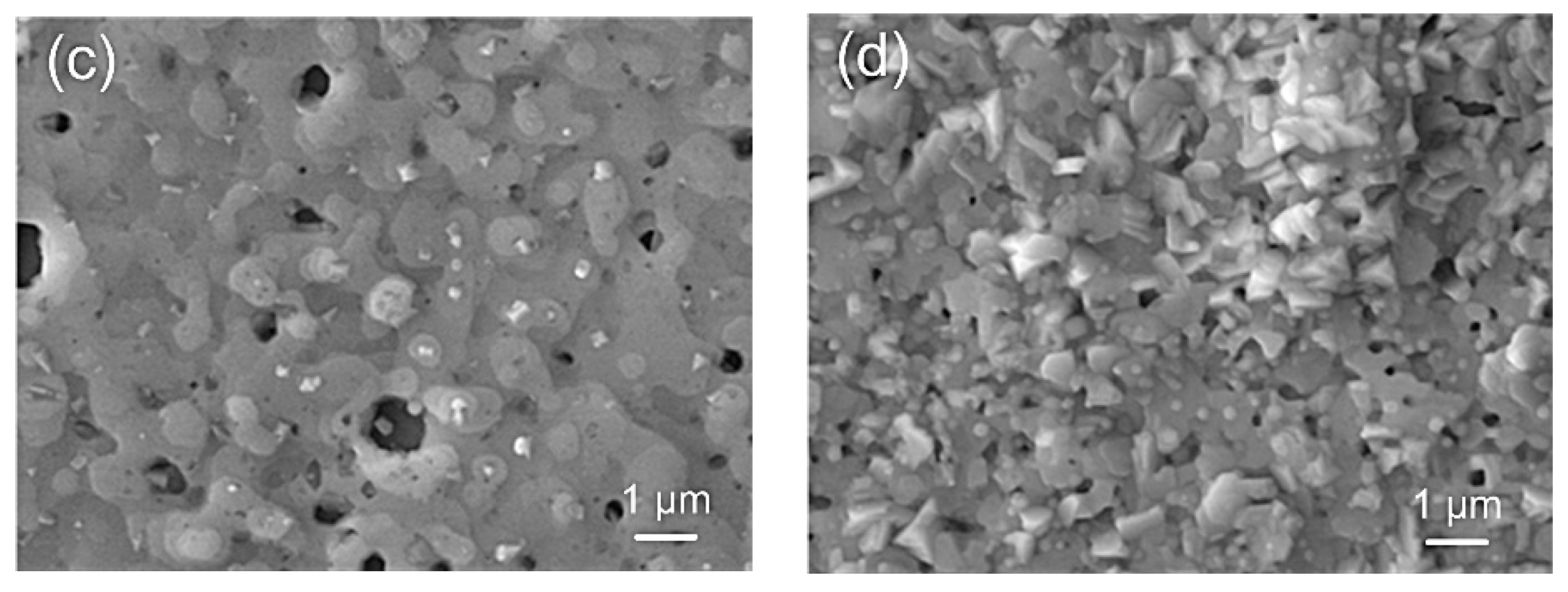

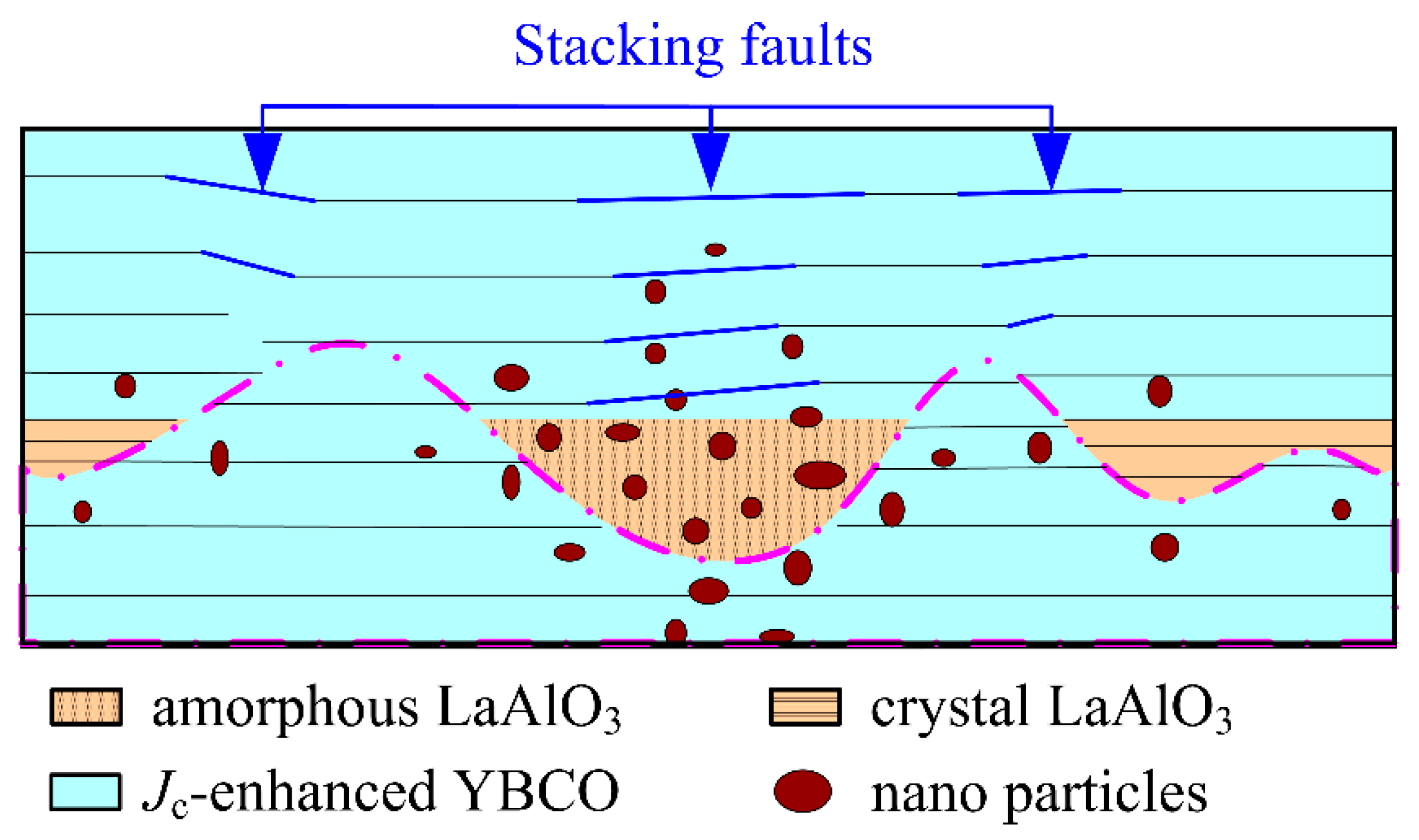

3.2. Mechanism of the Jc Variation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pop, C.; Villarejo, B.; Pino, F.; Mundet, B.; Ricart, S.; De Palau, M.; Puig, T.; Obradors, X. Growth of all-chemical high critical current YBa2Cu3O7−δ thick films and coated conductors. Supercond. Sci. Technol. 2019, 32, 015004. [Google Scholar] [CrossRef]

- Albiss, B.A.; Obaidat, I.M. Applications of YBCO-coated conductors: A focus on the chemical solution deposition method. J. Mater. Chem. 2010, 20, 1836–1845. [Google Scholar] [CrossRef]

- Chen, M.; Donzel, L.; Lakner, M.; Paul, W. High temperature superconductors for power applications. J. Eur. Ceram. Soc. 2004, 24, 1815–1822. [Google Scholar] [CrossRef]

- Larbalestier, D.; Gurevich, A.; Feldmann, D.M.; Polyanskii, A. High-Tc superconducting materials for electric power applications. Nature 2001, 414, 368–377. [Google Scholar] [CrossRef] [PubMed]

- Obradors, X.; Puig, T. Coated conductors for power applications: Materials challenges. Supercond. Sci. Technol. 2014, 27, 044003. [Google Scholar] [CrossRef]

- Blatter, G.; Feigel’man, M.V.; Geshkenbein, V.B.; Larkin, A.I.; Vinokur, V.M. Vortices in high-temperature superconductors. Rev. Mod. Phys. 1994, 66, 1125–1388. [Google Scholar] [CrossRef]

- Miura, M.; Maiorov, B.; Baily, S.; Haberkorn, N.; Willis, J.; Marken, K.; Izumi, T.; Shiohara, Y.; Civale, L. Mixed pinning landscape in nanoparticle-introduced YGdBa2Cu3Oy films grown by metal organic deposition. Phys. Rev. B 2011, 83, 184519. [Google Scholar] [CrossRef]

- Zhao, Y.; Chu, J.; Qureishy, T.; Wu, W.; Zhang, Z.; Mikheenko, P.; Johansen, T.H.; Grivel, J.-C. Structural and superconducting characteristics of YBa2Cu3O7 films grown by fluorine-free metal-organic deposition route. Acta Mater. 2018, 144, 844–852. [Google Scholar] [CrossRef]

- Horide, T.; Kawamura, T.; Matsumoto, K.; Ichinose, A.; Yoshizumi, M.; Izumi, T.; Shiohara, Y. Jc improvement by double artificial pinning centers of BaSnO3 nanorods and Y2O3 nanoparticles in YBa2Cu3O7 coated conductors. Supercond. Sci. Technol. 2013, 26, 075019. [Google Scholar] [CrossRef]

- Gutierrez, J.; Llordes, A.; Gazquez, J.; Gibert, M.; Roma, N.; Ricart, S.; Pomar, A.; Sandiumenge, F.; Mestres, N.; Puig, T. Strong isotropic flux pinning in solution-derived YBa2Cu3O7-x nanocomposite superconductor films. Nat. Mater. 2007, 6, 367. [Google Scholar] [CrossRef]

- MacManus-Driscoll, J.; Foltyn, S.; Jia, Q.; Wang, H.; Serquis, A.; Civale, L.; Maiorov, B.; Hawley, M.; Maley, M.; Peterson, D. Strongly enhanced current densities in superconducting coated conductors of YBa2Cu3O7-x+BaZrO3. Nat. Mater. 2004, 3, 439. [Google Scholar] [CrossRef] [PubMed]

- Dam, B.; Huijbregtse, J.; Klaassen, F.; Van der Geest, R.; Doornbos, G.; Rector, J.; Testa, A.; Freisem, S.; Martinez, J.; Stäuble-Pümpin, B. Origin of high critical currents in YBa2Cu3O7-δ superconducting thin films. Nature 1999, 399, 439–443. [Google Scholar] [CrossRef]

- Obradors, X.; Puig, T.; Ricart, S.; Coll, M.; Gazquez, J.; Palau, A.; Granados, X. Growth, nanostructure and vortex pinning in superconducting YBa2Cu3O7 thin films based on trifluoroacetate solutions. Supercond. Sci. Technol. 2012, 25, 123001. [Google Scholar] [CrossRef]

- Foltyn, S.; Civale, L.; MacManus-Driscoll, J.; Jia, Q.; Maiorov, B.; Wang, H.; Maley, M. Materials science challenges for high-temperature superconducting wire. Nat. Mater. 2007, 6, 631–642. [Google Scholar] [CrossRef] [PubMed]

- Haugan, T.; Barnes, P.; Wheeler, R.; Meisenkothen, F.; Sumption, M. Addition of nanoparticle dispersions to enhance flux pinning of the YBa2Cu3O7-x superconductor. Nature 2004, 430, 867–870. [Google Scholar] [CrossRef] [PubMed]

- Maiorov, B.; Baily, S.; Zhou, H.; Ugurlu, O.; Kennison, J.; Dowden, P.; Holesinger, T.; Foltyn, S.; Civale, L. Synergetic combination of different types of defect to optimize pinning landscape using BaZrO3-doped YBa2Cu3O7. Nat. Mater. 2009, 8, 398–404. [Google Scholar] [CrossRef] [PubMed]

- Lei, L.; Zhao, G.; Xu, H.; Wu, N.; Chen, Y. Influences of Y2O3 nanoparticle additions on the microstructure and superconductivity of YBCO films derived from low-fluorine solution. Mater. Chem. Phys. 2011, 127, 91–94. [Google Scholar] [CrossRef]

- Xu, Y.; Suo, H.-L.; Yue, Z.; Grivel, J.-C.; Liu, M. Enhancement by La-Al-O Doping in Y-Ba-Cu-O Films Both in Self-Field and Under Magnetic Field. IEEE Trans. Appl. Supercond. 2016, 26, 1–4. [Google Scholar] [CrossRef]

- Wang, X.; Wu, J.Z. Effect of interlayer magnetic coupling on the Jc of YBa2Cu3O7/insulator/YBa2Cu3O7 trilayers. Appl. Phys. Lett. 2006, 88, 062513. [Google Scholar] [CrossRef]

- Jia, Q.; Foltyn, S.; Arendt, P.; Smith, J. High-temperature superconducting thick films with enhanced supercurrent carrying capability. Appl. Phys. Lett. 2002, 80, 1601–1603. [Google Scholar] [CrossRef]

- Jang, H.W.; Choi, K.-J.; Folkman, C.M.; Oates, D.E.; Eom, C.-B. Intermodulation distortion in epitaxial Y-Ba-Cu-O thick films and multilayers. IEEE Trans. Appl. Supercond. 2009, 19, 2855–2858. [Google Scholar] [CrossRef]

- Matsui, V.; Flis, V.; Moskaliuk, V.; Kasatkin, A.; Skoryk, N.; Svechnikov, V. Current-carrying abilities of nano-structured HTS thin films. J. Nanosci. Nanoen. 2015, 1, 38–43. [Google Scholar]

- Krylova, T.; Chernykh, I.; Chernykh, M.; Zanaveskin, M. Current flowing mechanism through interlayers in YBa2Cu3Ox–SrTiO3 multilayer structures on textured tapes. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Pan, A.V.; Pysarenko, S.; Dou, S.X. Drastic improvement of surface Structure and current-carrying ability in YBa2Cu3O7 films by introducing multilayered structure. Appl. Phys. Lett. 2006, 88, 232506. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, C.; Zhao, G.; You, C. An advanced low-fluorine solution route for fabrication of high-performance YBCO superconducting films. Supercond. Sci. Technol. 2012, 25, 062001. [Google Scholar] [CrossRef]

- Wu, C.; Zhao, G.; Fang, P. Effect of the firing process on the critical current density of YBa2Cu3O7-x films derived from the sol-gel method. Mater. Chem. Phys. 2015, 167, 160–164. [Google Scholar] [CrossRef]

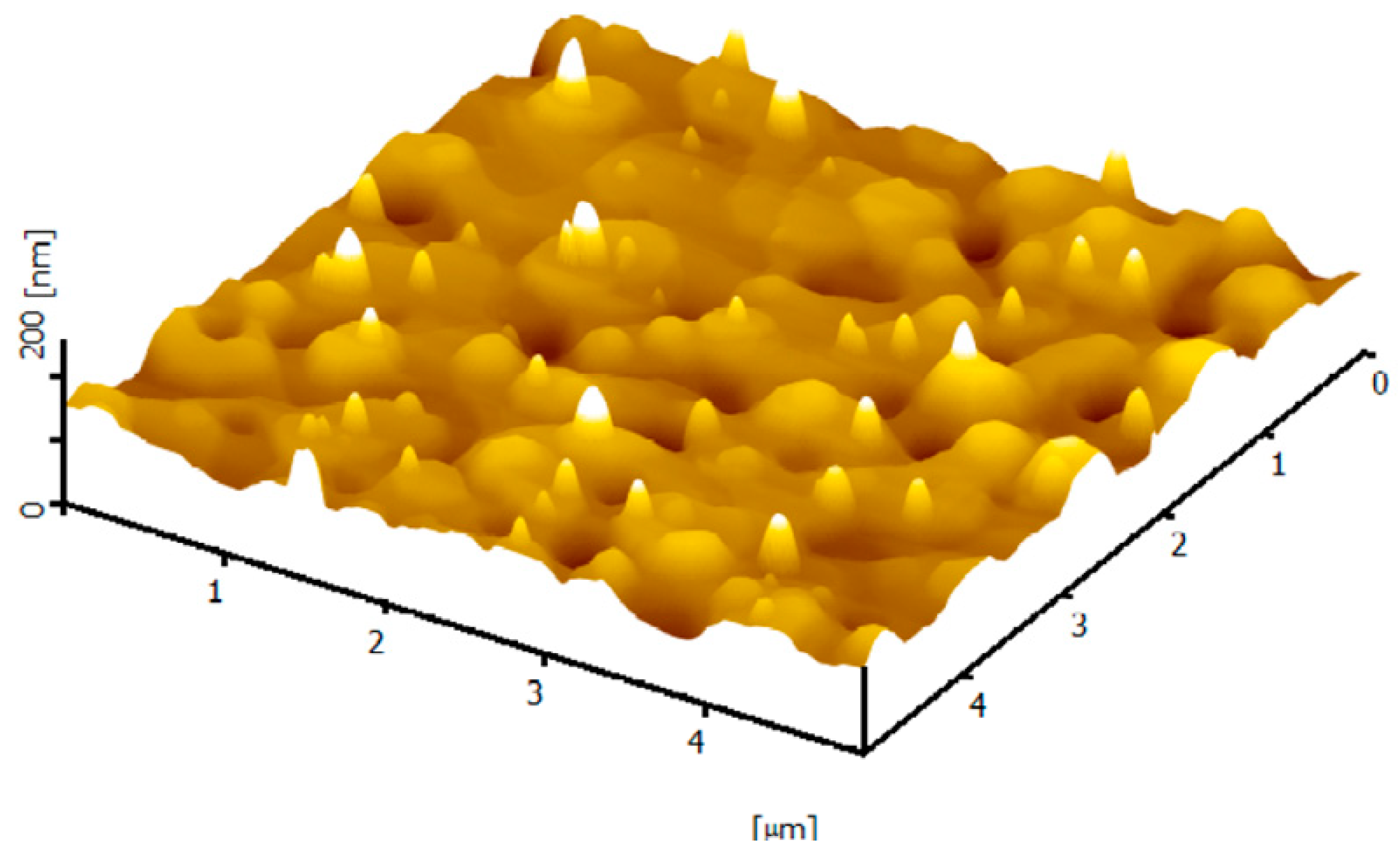

- Wu, C.; Zhao, G.; Lei, L. Enhancement of critical current density in superconducting YBa2Cu3O7-x films by nanostructure development of substrate surface using sol–gel method. J. Sol. Gel. Sci. Technol. 2013, 67, 203–207. [Google Scholar] [CrossRef]

- Gyorgy, E.; Van Dover, R.; Jackson, K.; Schneemeyer, L.; Waszczak, J. Anisotropic critical currents in Ba2YCu3O7 analyzed using an extended Bean model. Appl. Phys. Lett. 1989, 55, 283–285. [Google Scholar] [CrossRef]

- Topal, U.; Yakinci, M.E. Effects of grain boundaries on electrical and magnetic properties of melt-processed SmBa2Cu3Ox superconductors. Mater. Chem. Phys. 2010, 119, 182–187. [Google Scholar] [CrossRef]

- Llordes, A.; Palau, A.; Gázquez, J.; Coll, M.; Vlad, R.; Pomar, A.; Arbiol, J.; Guzman, R.; Ye, S.; Rouco, V. Nanoscale strain-induced pair suppression as a vortex-pinning mechanism in high-temperature superconductors. Nat. Mater. 2012, 11, 329–336. [Google Scholar] [CrossRef]

- Lei, L.; Liu, L.; Wang, X.; Wang, S.; Jia, J.; Zhao, G.; Wu, C.; Jin, L.; Li, C.; Zhang, P. Strongly improved current-carrying capacity induced by nanoscale lattice strains in YBa2Cu3O7-δ–Ba0.7Sr 0.3TiO3 composite films derived from chemical solution deposition. J. Mater. Chem. C 2016, 4, 1392–1397. [Google Scholar] [CrossRef]

- Maiorov, B.; Wang, H.; Foltyn, S.; Li, Y.; DePaula, R.; Stan, L.; Arendt, P.; Civale, L. Influence of naturally grown nanoparticles at the buffer layer in the flux pinning in YBa2Cu3O7 coated conductors. Supercond. Sci. Technol. 2006, 19, 891–895. [Google Scholar] [CrossRef]

- Jeong, C.K.; Cho, S.B.; Han, J.H.; Park, D.Y.; Yang, S.; Park, K.-I.; Ryu, J.; Sohn, H.; Chung, Y.-C.; Lee, K.J. Flexible highly-effective energy harvester via crystallographic and computational control of nanointerfacial morphotropic piezoelectric thin film. Nano Res. 2017, 10, 437–455. [Google Scholar] [CrossRef]

- Lemyre, J.-L.; Lamarre, S.; Beaupré, A.; Ritcey, A.M. Mechanism of YF3 nanoparticle formation in reverse micelles. Langmuir 2011, 27, 11824–11834. [Google Scholar] [CrossRef] [PubMed]

- Araki, T.; Niwa, T.; Yamada, Y.; Hirabayashi, I.; Shibata, J.; Ikuhara, Y.; Kato, K.; Kato, T.; Hirayama, T. Growth model and the effect of CuO nanocrystallites on the properties of chemically derived epitaxial thin films of YBa2Cu3O7-x. J. Appl. Phys. 2002, 92, 3318–3325. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.; Wang, Y. Enhancement of Critical Current Density by Establishing a YBa2Cu3O7−x/LaAlO3/YBa2Cu3O7−x Quasi-Trilayer Architecture Using the Sol-Gel Method. Coatings 2019, 9, 437. https://doi.org/10.3390/coatings9070437

Wu C, Wang Y. Enhancement of Critical Current Density by Establishing a YBa2Cu3O7−x/LaAlO3/YBa2Cu3O7−x Quasi-Trilayer Architecture Using the Sol-Gel Method. Coatings. 2019; 9(7):437. https://doi.org/10.3390/coatings9070437

Chicago/Turabian StyleWu, Chuanbao, and Yunwei Wang. 2019. "Enhancement of Critical Current Density by Establishing a YBa2Cu3O7−x/LaAlO3/YBa2Cu3O7−x Quasi-Trilayer Architecture Using the Sol-Gel Method" Coatings 9, no. 7: 437. https://doi.org/10.3390/coatings9070437

APA StyleWu, C., & Wang, Y. (2019). Enhancement of Critical Current Density by Establishing a YBa2Cu3O7−x/LaAlO3/YBa2Cu3O7−x Quasi-Trilayer Architecture Using the Sol-Gel Method. Coatings, 9(7), 437. https://doi.org/10.3390/coatings9070437