Microstructure and Mechanical Property Investigation of TaSiN Thin Films Deposited by Reactive Magnetron Sputtering

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

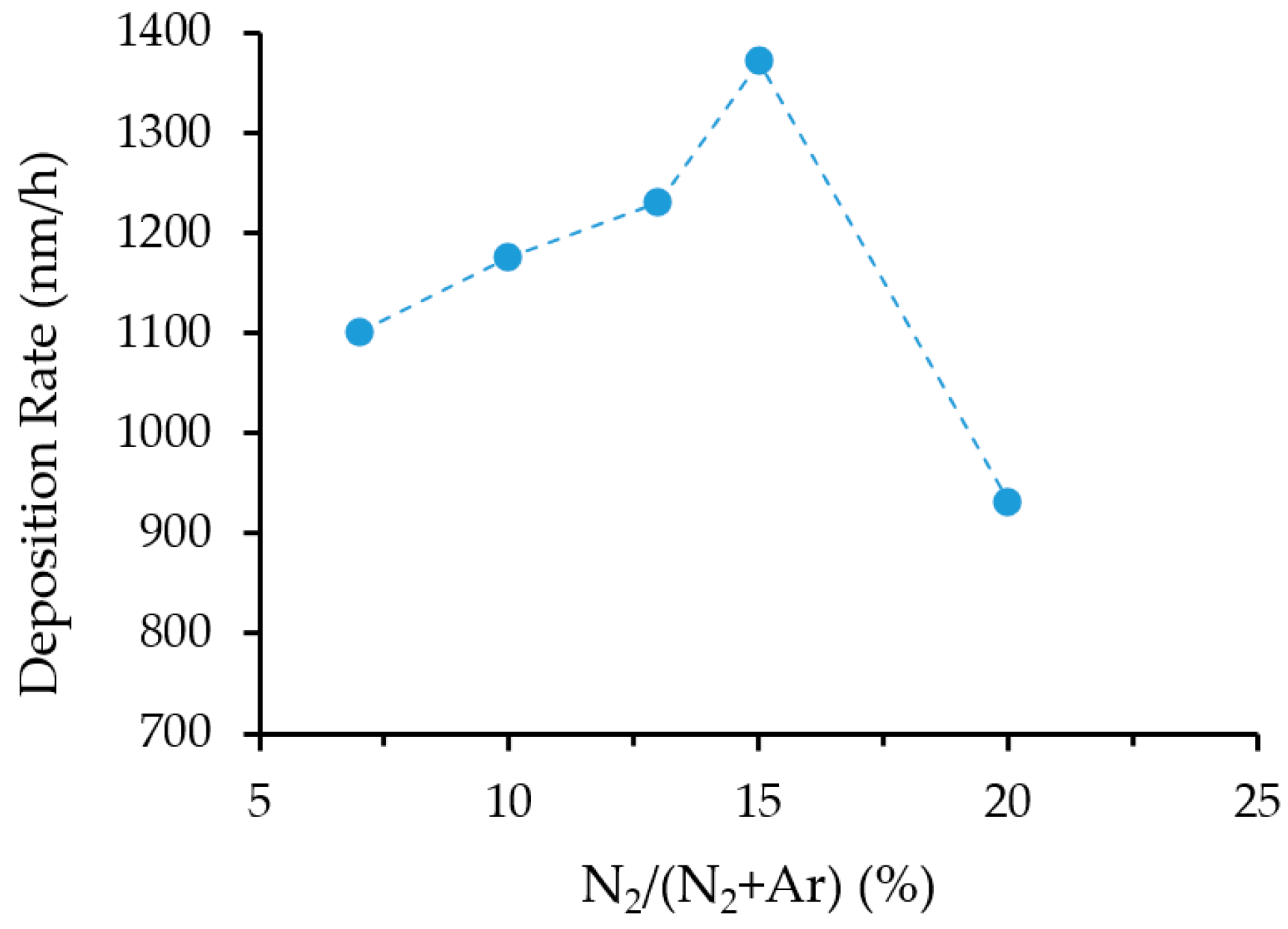

3.1. Effect of N2 Content on Crystal Structure

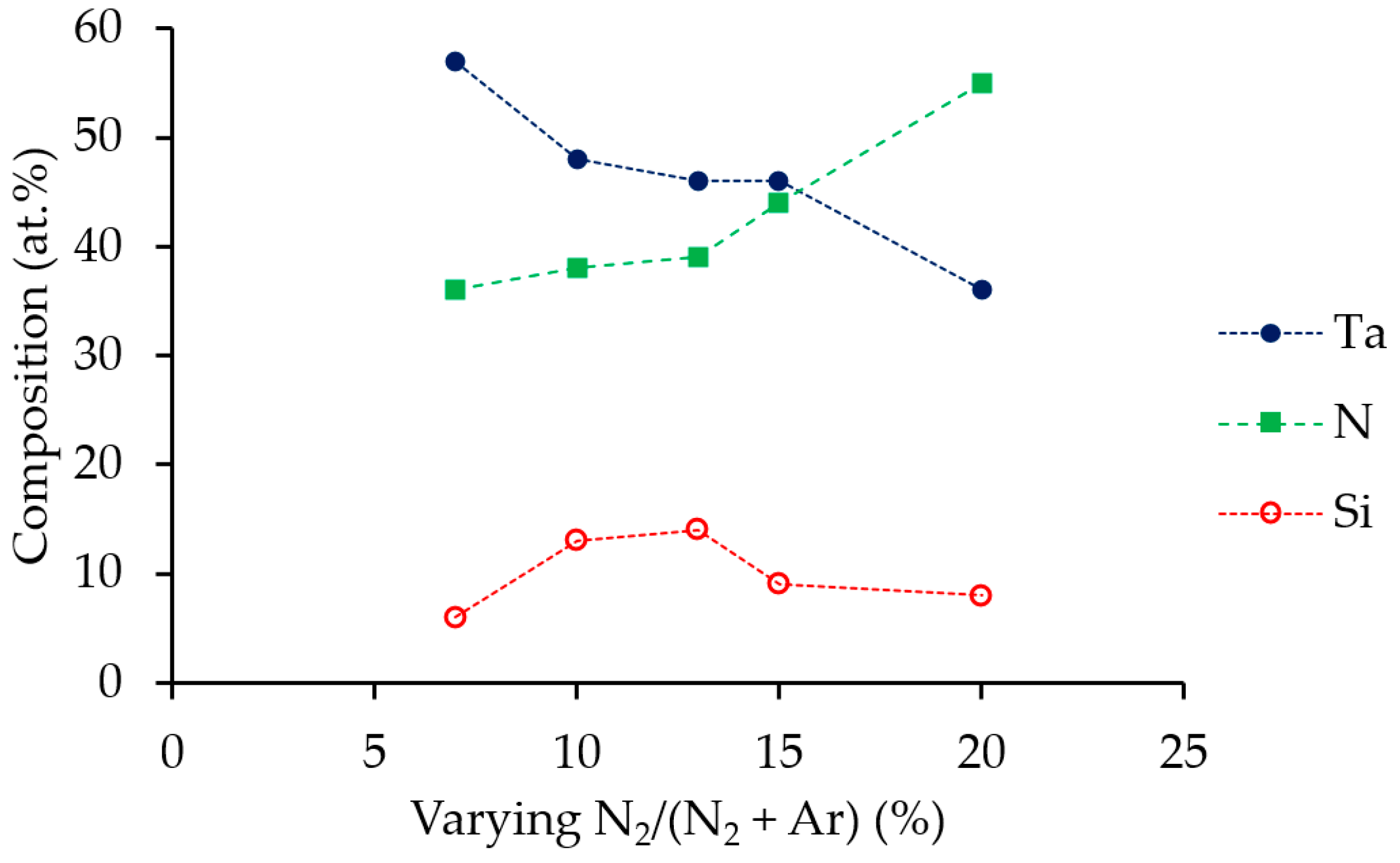

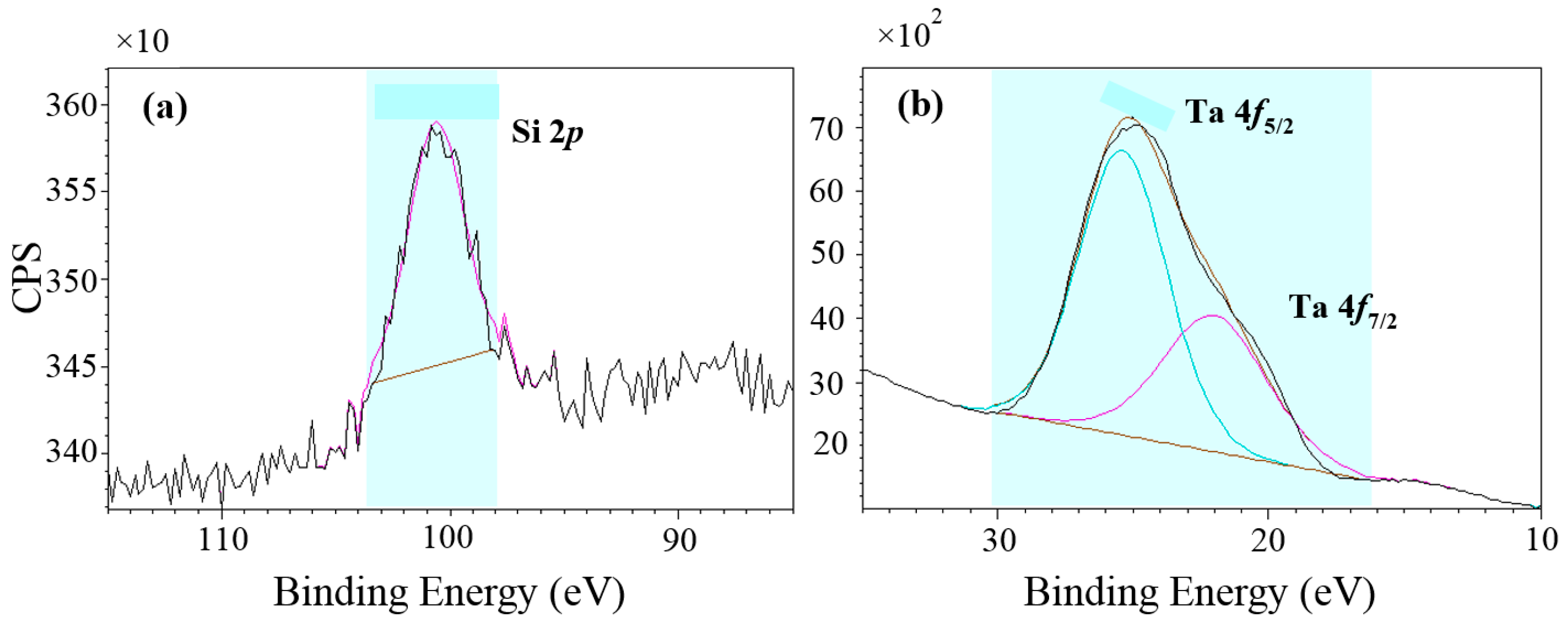

3.2. Effect of N2 Content on Composition and Chemical States

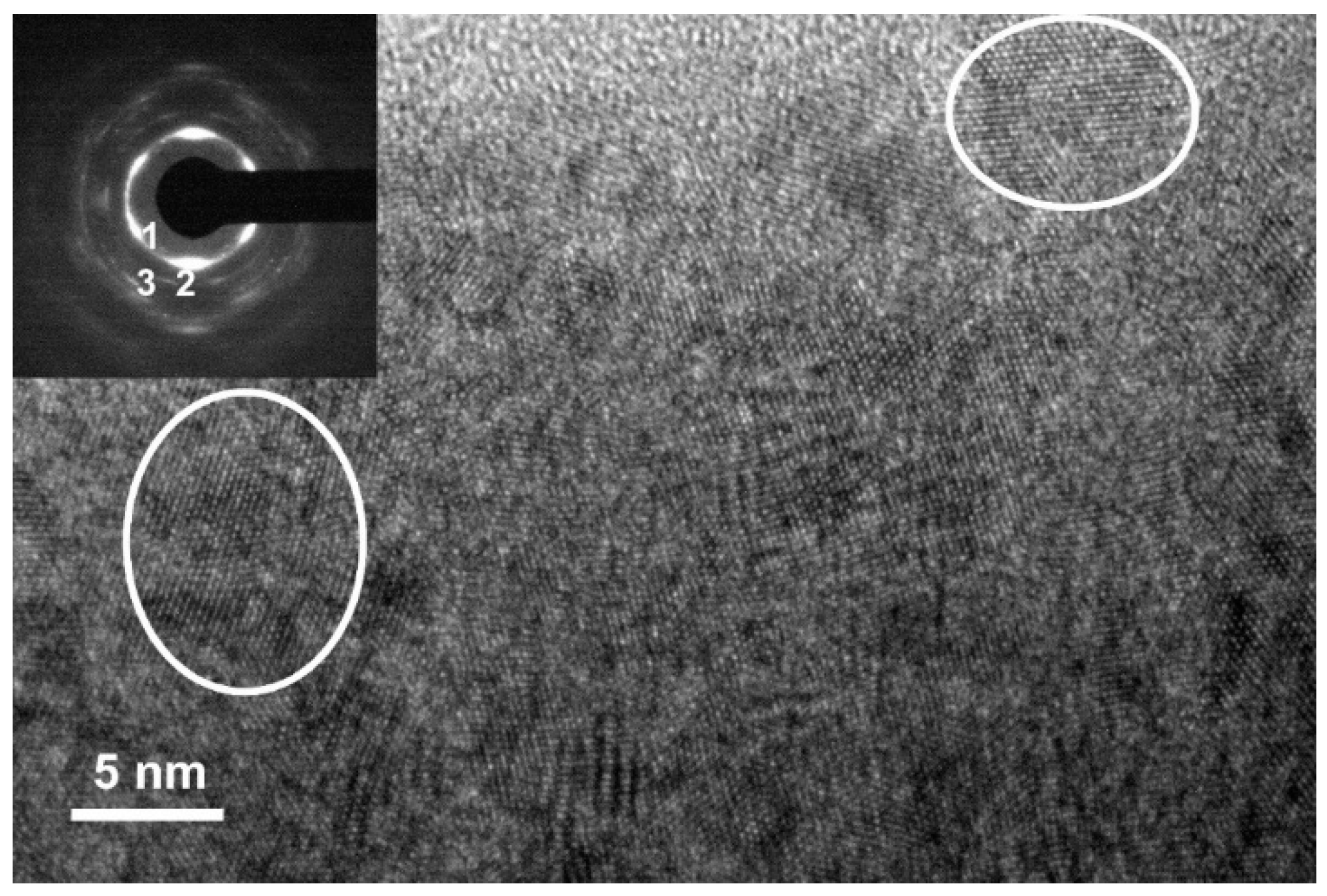

3.3. Microstructural Investigation

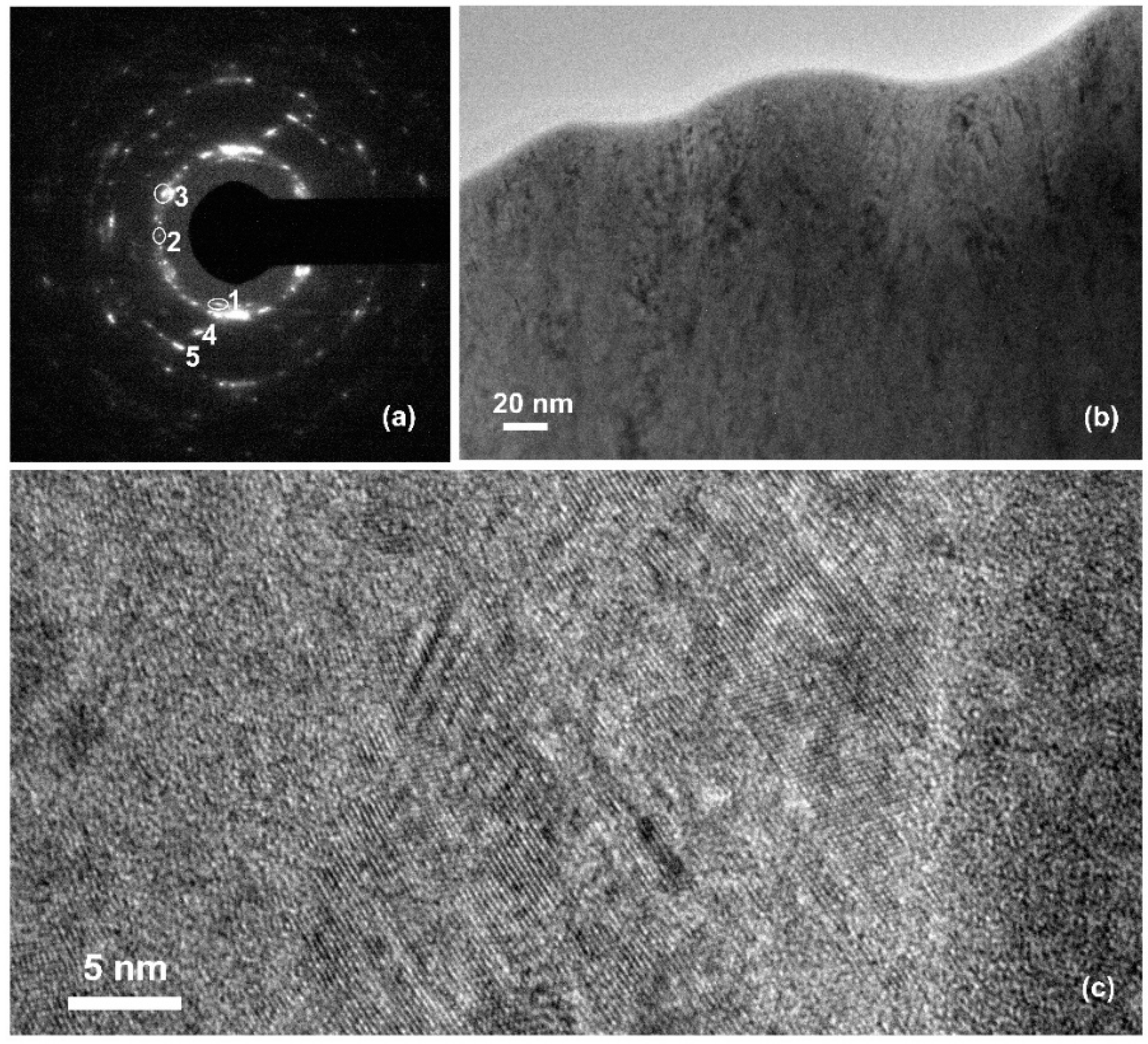

3.3.1. Ta–Si–N film deposited with 7% N2

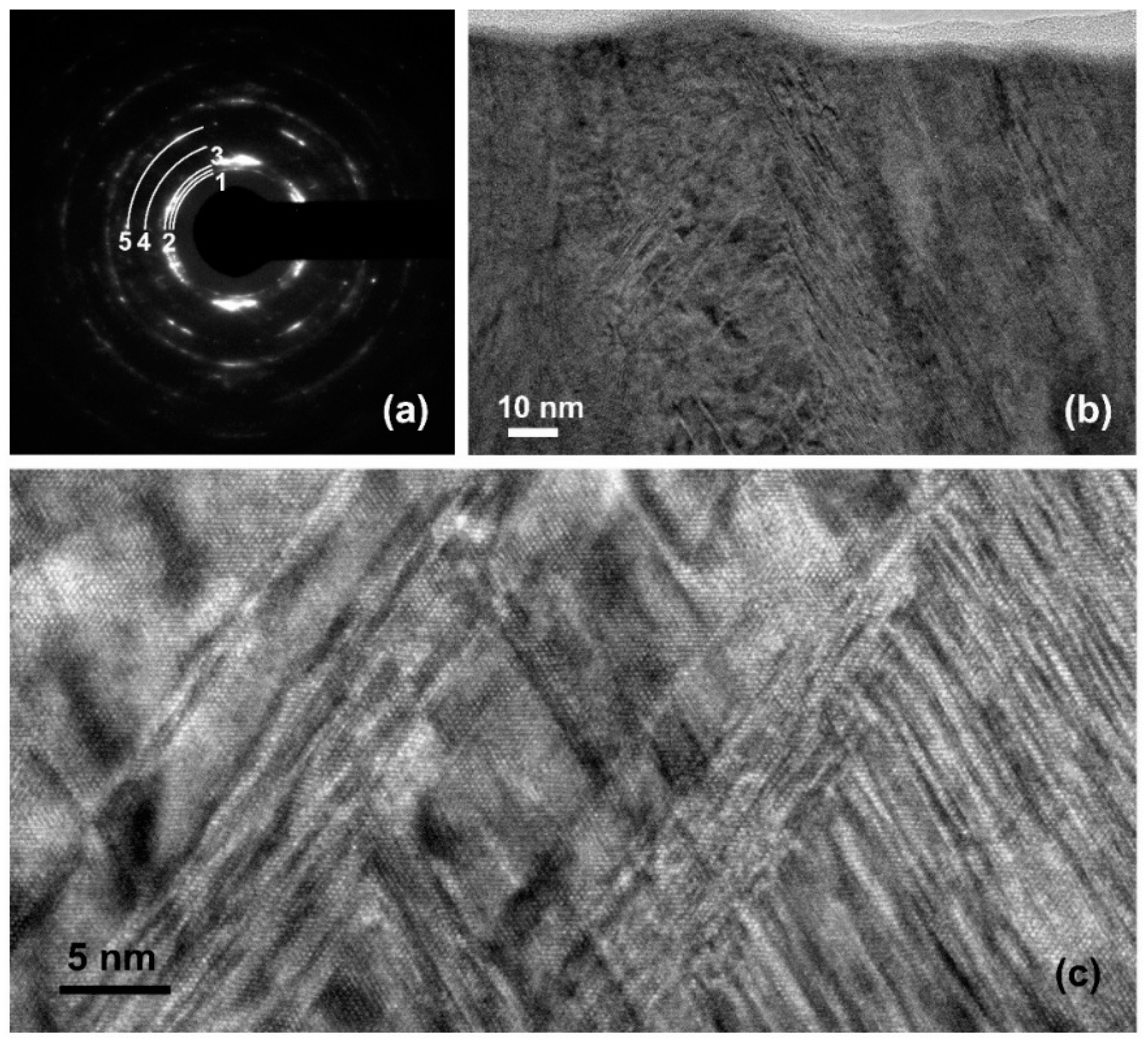

3.3.2. Ta–Si–N film deposited with 13% N2

3.3.3. Ta–Si–N film deposited with 15% N2

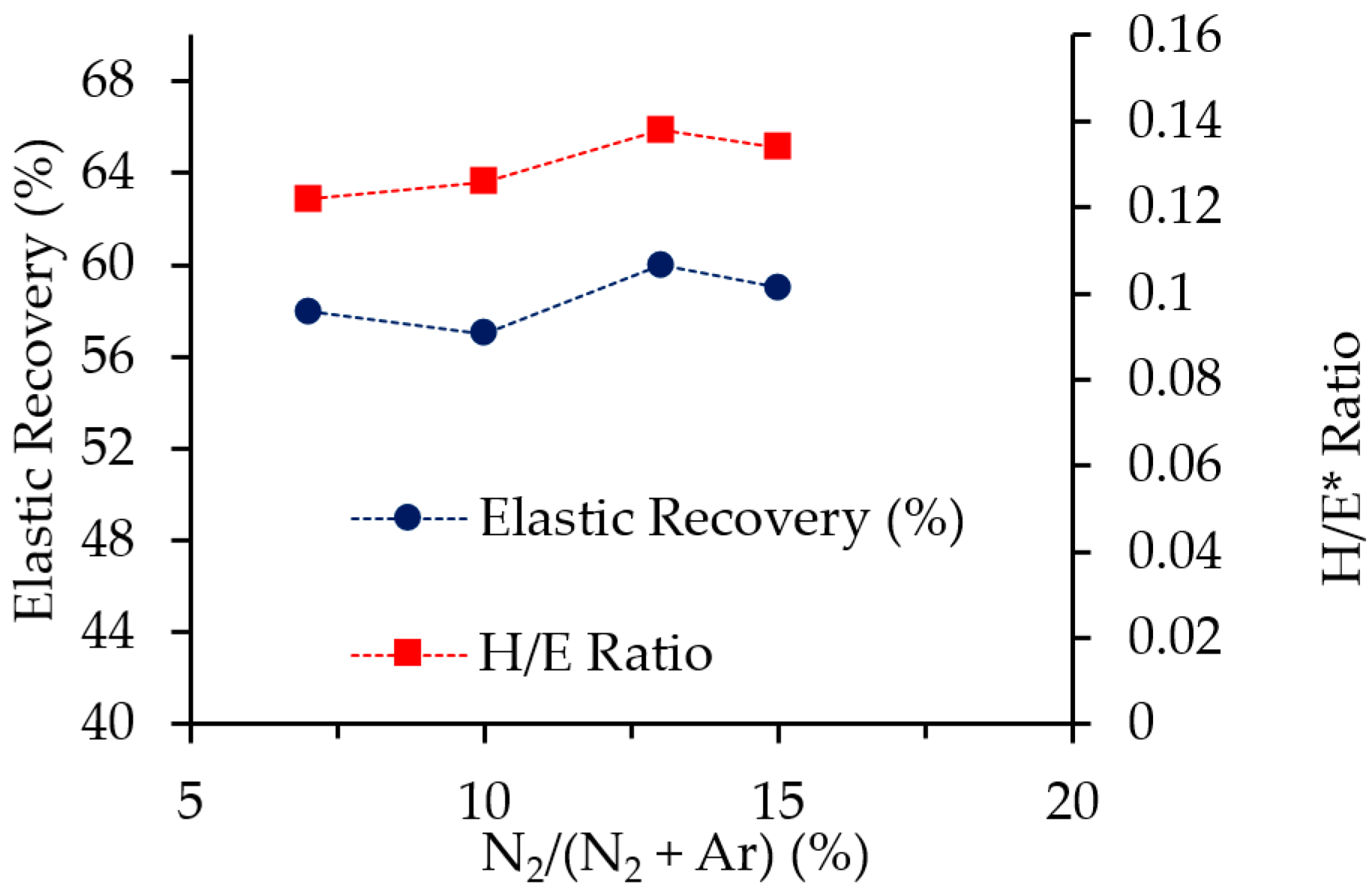

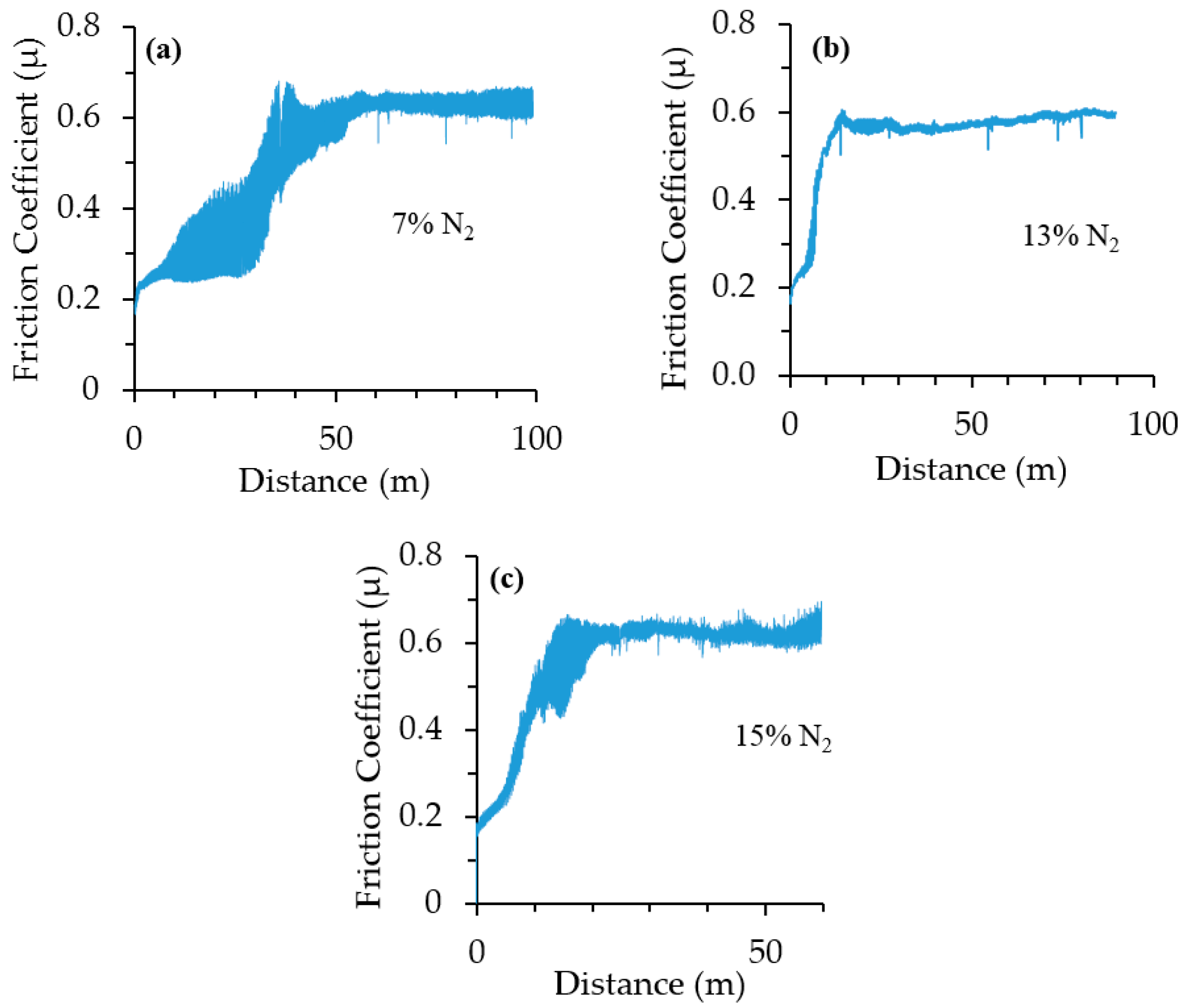

3.4. Mechanical and Tribological Properties

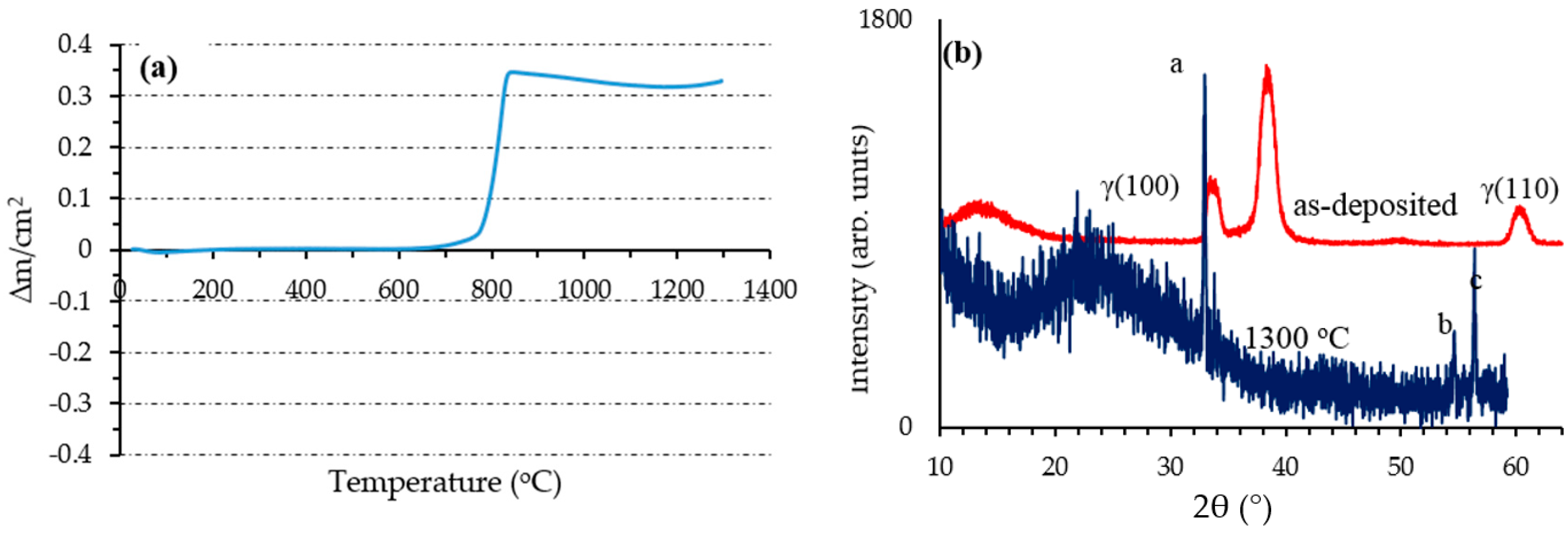

3.5. Oxidation Resistance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Holleck, H.; Schier, V. Multilayer PVD coatings for wear protection. Surf. Coat. Technol. 1995, 76, 328–336. [Google Scholar] [CrossRef]

- Meletis, E.I. Wear-corrosion behavior of ion-plated thin films. J. Mater. Eng. 1989, 11, 159–167. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Browne, T.; Heckerman, B.; Meletis, E.I. Mechanical and tribological properties of nanocomposite TiSiN coatings. Surf. Coat. Technol. 2010, 204, 2123–2129. [Google Scholar] [CrossRef]

- Nakao, S.; Numata, M.; Ohmi, T. Thin and low-resistivity tantalum nitride diffusion barrier and giant-grain copper interconnects for advanced ULSI metallization. J. Appl. Phys. 1999, 38, 2401–2405. [Google Scholar] [CrossRef]

- Leng, Y.X.; Sun, H.; Yang, P.; Chen, J.Y.; Wang, J.; Wan, G.J.; Huang, N.; Tian, X.B.; Wang, L.P.; Chu, P.K. Biomedical properties of tantalum nitride films synthesized by reactive magnetron sputtering. Thin Solid Films 2001, 398–399, 471–475. [Google Scholar] [CrossRef]

- Mori, H.; Imahori, J.; Oku, T.; Murakami, M. Diffusion barriers between Si and Cu. In Proceedings of the AIP Conference, Tokyo, Japan, 4–6 June 1997; Okabayashi, H., Shingubara, S., Ho, P.S., Eds.; AIP Publishing: Tokyo, Japan, 1998; Volume 418, p. 475. [Google Scholar] [CrossRef]

- Oya, G.I.; Onodera, Y. Phase transformations in nearly stoichiometric NbNx. J. Appl. Phys. 1976, 47, 2833–2840. [Google Scholar] [CrossRef]

- Massalski, T.B.; Okamoto, H.; Subramanian, P.R.; Kacprzak, L. Binary Alloy Phase Diagrams, 2nd ed.; ASM International: Materials Park, OH, USA, 1990; p. 2703. [Google Scholar]

- Bernoulli, D.; Müller, U.; Schwarzenberger, M.; Hauert, R.; Spolenak, R. Magnetron sputter deposited tantalum and tantalum nitride thin films: An analysis of phase, hardness and composition. Thin Solid Films 2013, 548, 157–161. [Google Scholar] [CrossRef]

- Nie, H.B.; Xu, S.Y.; You, L.P.; Yang, Z.; Wang, S.J.; Ong, C.K. Structural and electrical properties of tantalum nitride thin films fabricated by using reactive radio-frequency magnetron sputtering. Appl. Phys. A 2001, 73, 229–236. [Google Scholar] [CrossRef]

- Valleti, K.; Subrahmanyam, A.; Joshi, S.V.; Phani, A.R.; Passacantando, M.; Santucci, S. Studies on phase dependent mechanical properties of dc magnetron sputtered TaN thin films: Evaluation of super hardness in orthorhombic Ta4N phase. J. Phys. D Appl. Phys. 2008, 41, 045409. [Google Scholar] [CrossRef]

- Riekkinen, T.; Molarius, J.; Laurila, T.; Nurmela, A.; Suni, I.; Kivilahti, J.K. Reactive sputter deposition and properties of TaxN thin films. Microelectron. Eng. 2002, 64, 289–297. [Google Scholar] [CrossRef]

- Wittmer, M.; Melchior, H.J. Applications of TiN thin films in silicon device technology. Thin Solid Films 1982, 93, 397–405. [Google Scholar] [CrossRef]

- Münz, W.D. Titanium aluminum nitride films—A new alternative to TiN coatings. J. Vac. Sci. Technol. A 1986, 4, 2717–2725. [Google Scholar] [CrossRef]

- Choi, J.B.; Cho, K.; Lee, M.H.; Kim, K.H. Effects of Si content and free Si on oxidation behavior of Ti–Si–N coating layers. Thin Solid Films 2004, 447–448, 365–370. [Google Scholar] [CrossRef]

- Castaldi, L.; Kurapov, D.; Reiter, A.; Shklover, V.; Schwaller, P.; Patscheider, J. High temperature phase changes and oxidation behavior of Cr–Si–N coatings. Surf. Coat. Technol. 2007, 202, 781–785. [Google Scholar] [CrossRef]

- Chen, Y.I.; Lin, K.I.; Wang, H.H.; Cheng, Y.R. Characterization of Ta–Si–N coatings prepared using direct current magnetron co-sputtering. Appl. Surf. Sci. 2014, 305, 805–816. [Google Scholar] [CrossRef]

- Frety, N.; Bernard, F.; Nazon, J.; Sarradin, J.; Tedenac, J.C. Copper diffusion into silicon substrates through TaN and Ta/TaN multilayer barriers. J. Phase Equilib. 2006, 27, 590–597. [Google Scholar] [CrossRef]

- Zeman, H.; Musil, J.; Zeman, P. Physical and mechanical properties of sputtered Ta–Si–N films with a high (≥40 at %) content of Si. J. Vac. Sci. Technol. A 2004, 22, 646–649. [Google Scholar] [CrossRef]

- Nah, J.W.; Hwang, S.K.; Lee, C.M. Development of a complex heat resistant hard coating based on (Ta, Si)N by reactive sputtering. Mater. Chem. Phys. 2000, 62, 115–121. [Google Scholar] [CrossRef]

- Zaman, A.; Meletis, E.I. Microstructure and mechanical properties of TaN thin films prepared by reactive magnetron sputtering. Coatings 2017, 7, 209. [Google Scholar] [CrossRef]

- Adjaottor, A.A.; Ma, E.; Meletis, E.I. On the mechanism of intensified plasma-assisted processing. Surf. Coat. Technol. 1997, 89, 197–203. [Google Scholar] [CrossRef]

- Veprek, S.; Karvankova, P.; Veprek-Heijman, M.G.J. Possible role of oxygen impurities in degradation of nc-TiN/a-Si3N4 nanocomposites. J. Vac. Sci. Technol. B 2005, 23, L17–L21. [Google Scholar] [CrossRef]

- Chang, C.C.; Jeng, J.S.; Chen, J.S. Microstructural and electrical characteristics of reactively sputtered Ta–N thin films. Thin Solid Films 2002, 413, 46–51. [Google Scholar] [CrossRef]

- Arshi, N.; Lu, J.; Lee, C.G.; Koo, B.H.; Ahmed, F. Effects of nitrogen content on the phase and resistivity of TaN thin films deposited by electron beam evaporation. JOM 2014, 66, 1893–1899. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Browne, T.; Heckerman, B.; Gannon, P.; Jiang, J.C.; Meletis, E.I.; Bowman, C.; Gorokhovsky, V. Influence of Si content on the structure and internal stress of nanocomposite TiSiN coatings deposited by large area filtered arc method. J. Phys. D Appl. Phys. 2009, 42, 125415. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, J.C.; Mareš, P.; Houška, J.; Vlček, J.; Meletis, E.I. Effect of the Si content on the microstructure of hard, multifunctional Hf–B–Si–C films prepared by pulsed magnetron sputtering. Appl. Surf. Sci. 2015, 357, 1343–1354. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Lim, Y.L.; Chaudhri, M.M. The influence of grain size on the indentation hardness of high-purity copper and aluminium. Philosl. Mag. A 2002, 82, 2071–2080. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, J.; Houska, J.; Kohout, J.; Vlcek, J.; Meletis, E.I. A study of the microstructure evolution of hard Zr–B–C–N films by high-resolution transmission electron microscopy. Acta Mater. 2014, 77, 212–222. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Zeman, P.; Musil, J.; Daniel, R. High-temperature oxidation resistance of Ta–Si–N films with a high Si content. Surf. Coat. Technol. 2006, 200, 4091–4096. [Google Scholar] [CrossRef]

- Chen, Y.-I.; Gao, Y.-X.; Chang, L.-C. Oxidation behavior of Ta–Si–N coatings. Surf. Coat. Technol. 2017, 332, 72–79. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaman, A.; Shen, Y.; Meletis, E.I. Microstructure and Mechanical Property Investigation of TaSiN Thin Films Deposited by Reactive Magnetron Sputtering. Coatings 2019, 9, 338. https://doi.org/10.3390/coatings9050338

Zaman A, Shen Y, Meletis EI. Microstructure and Mechanical Property Investigation of TaSiN Thin Films Deposited by Reactive Magnetron Sputtering. Coatings. 2019; 9(5):338. https://doi.org/10.3390/coatings9050338

Chicago/Turabian StyleZaman, Anna, Yi Shen, and Efstathios I. Meletis. 2019. "Microstructure and Mechanical Property Investigation of TaSiN Thin Films Deposited by Reactive Magnetron Sputtering" Coatings 9, no. 5: 338. https://doi.org/10.3390/coatings9050338

APA StyleZaman, A., Shen, Y., & Meletis, E. I. (2019). Microstructure and Mechanical Property Investigation of TaSiN Thin Films Deposited by Reactive Magnetron Sputtering. Coatings, 9(5), 338. https://doi.org/10.3390/coatings9050338