Application and Evaluation of a Pectin-Based Edible Coating Process for Quality Change Kinetics and Shelf-Life Extension of Lime Fruit (Citrus aurantifolium)

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Coating Emulsion,

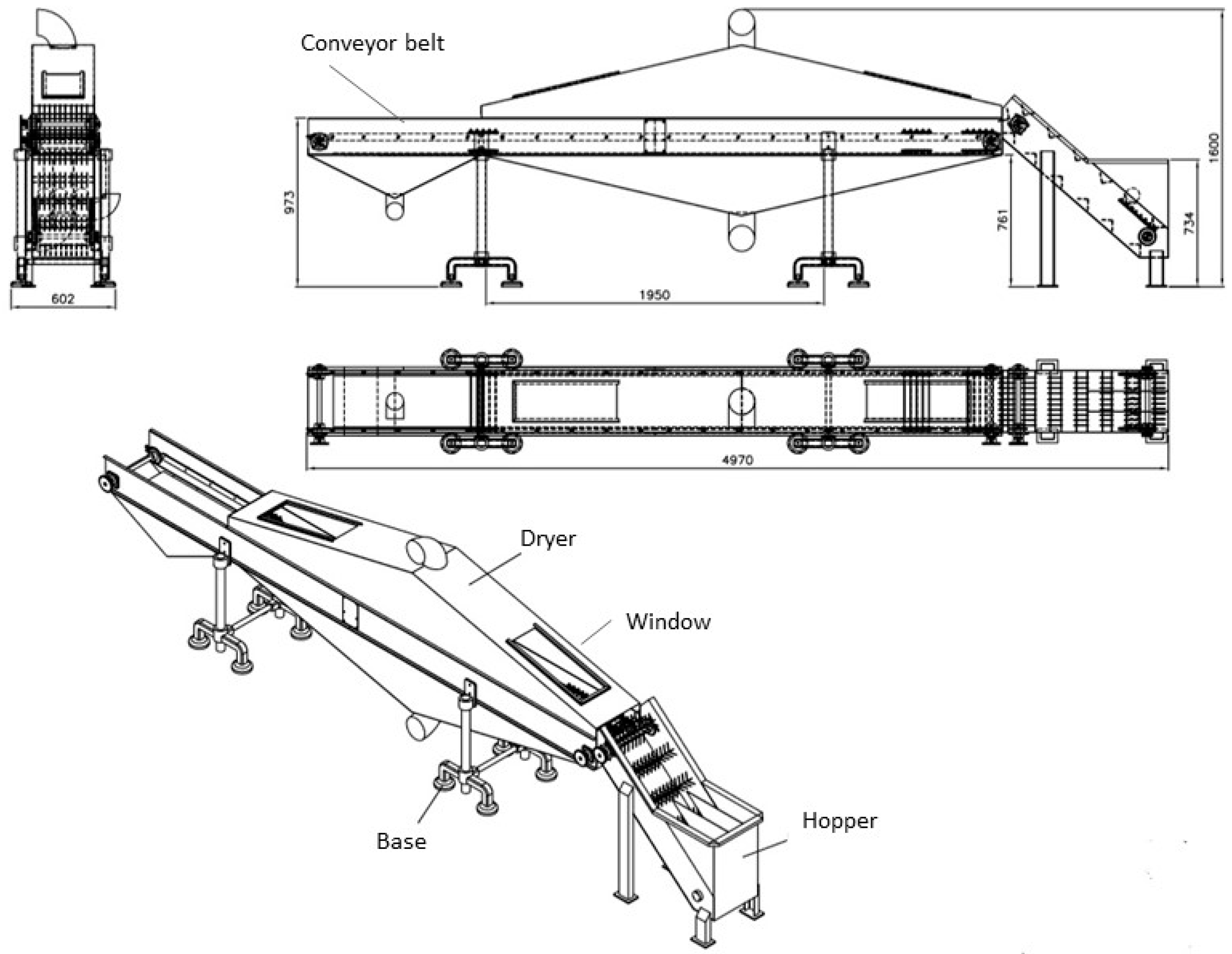

2.2. Coating of Fruits

2.3. Experimental Set-Up for Coating of Fruits

2.4. Physical and Physiological Characteristics of Lime Fruits

2.5. Brix, Triable Acidity, and Ascorbic Acid

2.6. Kinetic Data Analysis

2.7. Statistical Analysis

3. Results and Discussion

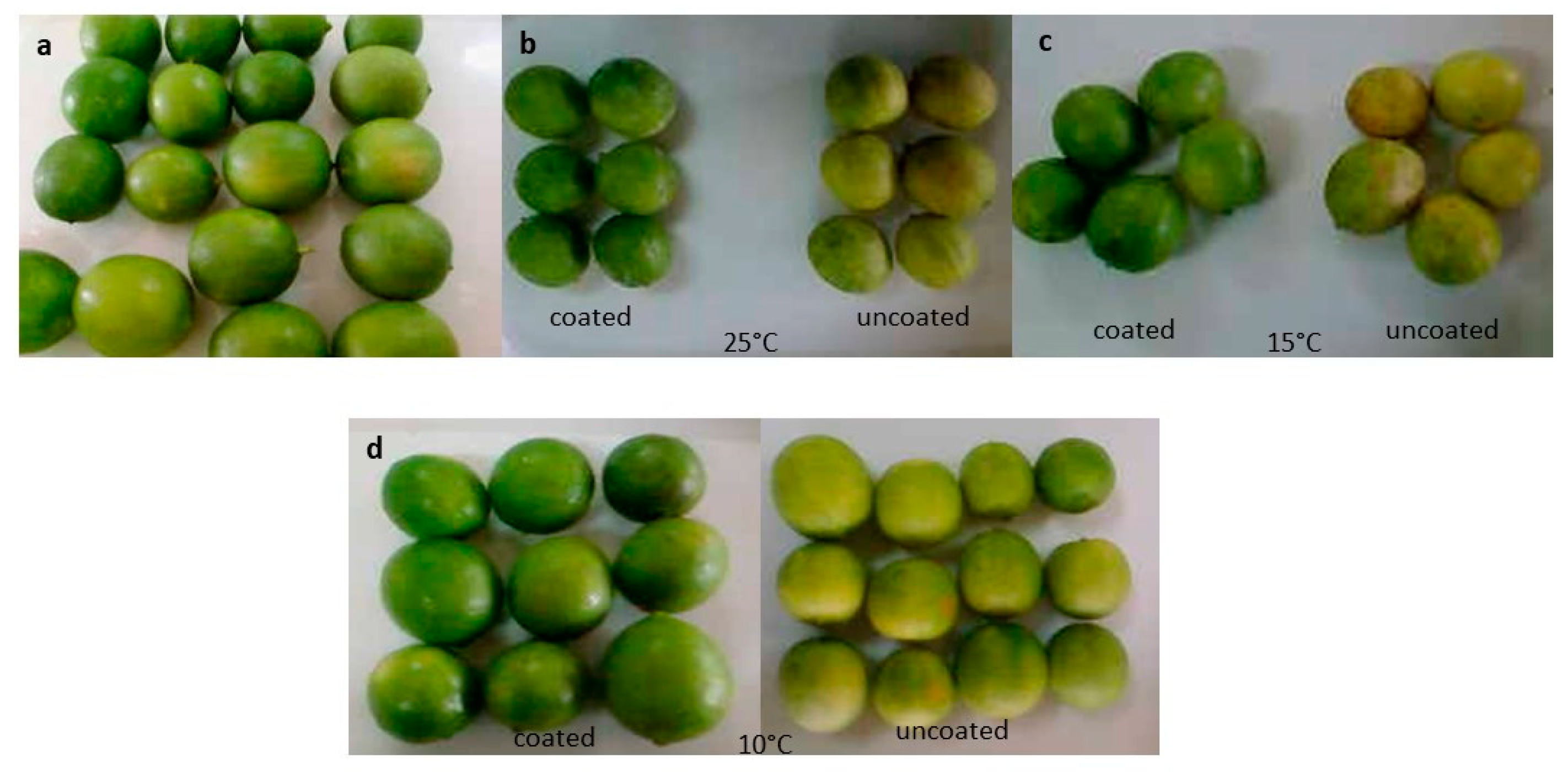

3.1. Overall Acceptability

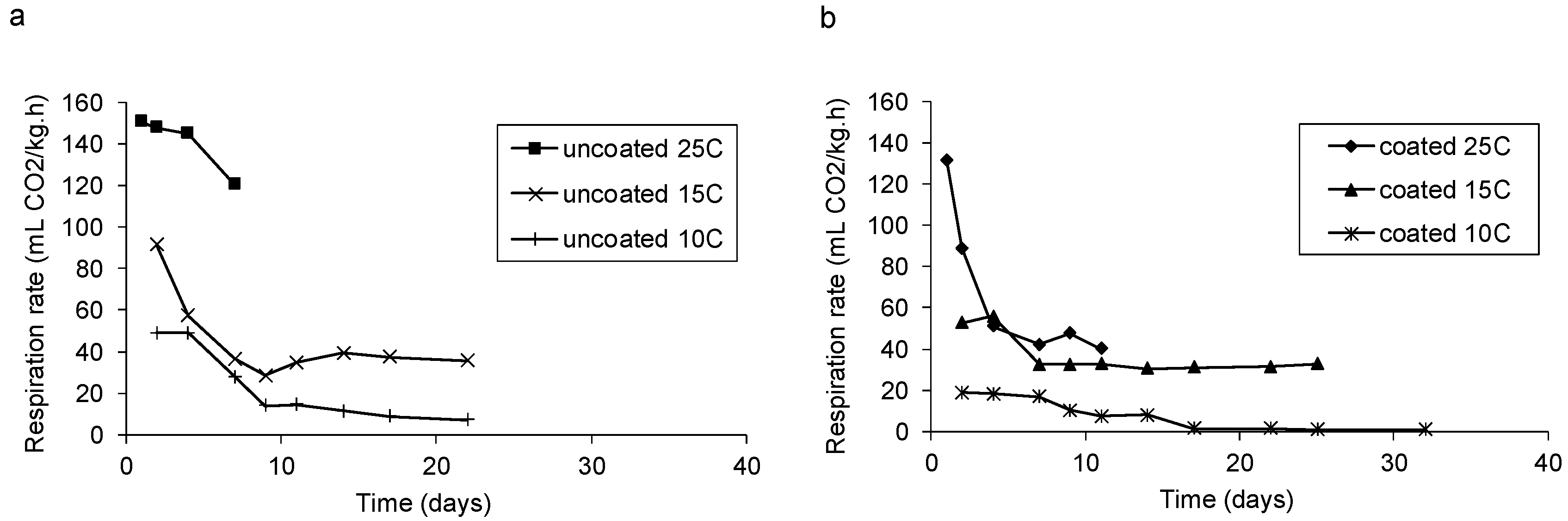

3.2. Respiration Rate

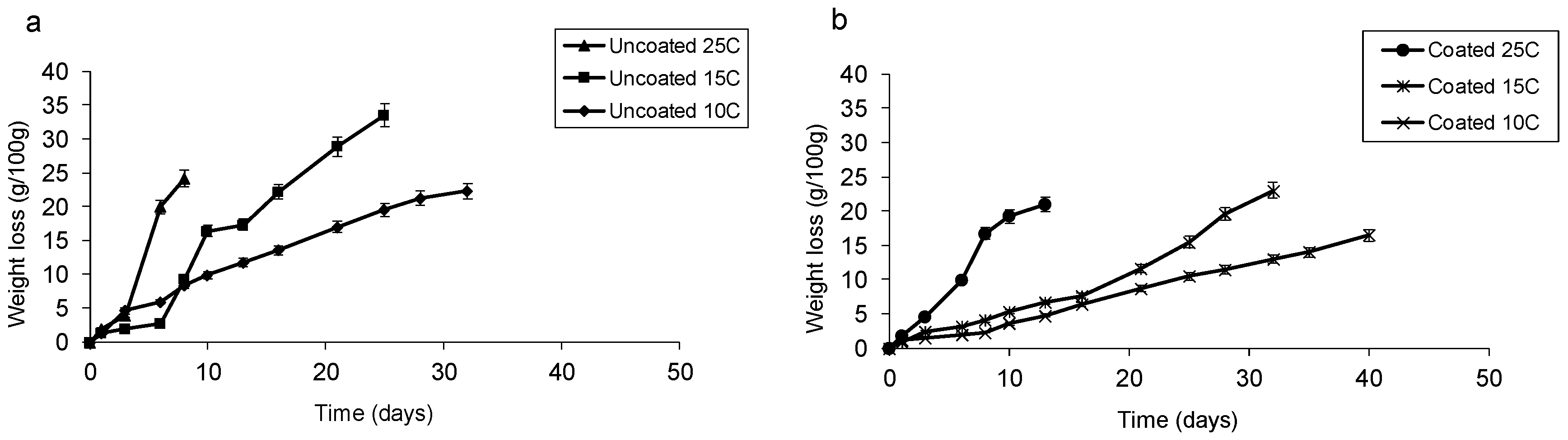

3.3. Weight Loss

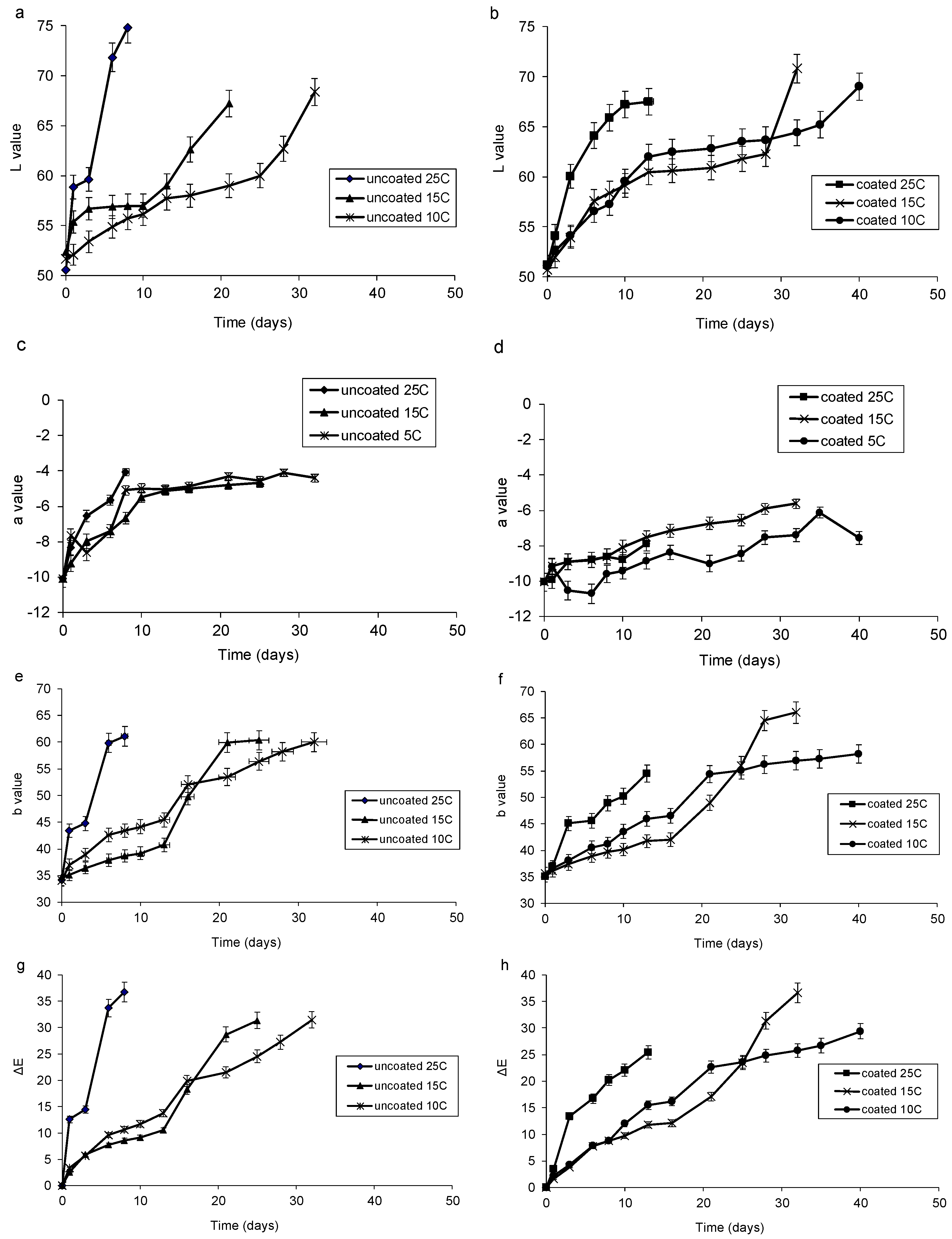

3.4. Color Changes

3.5. Chemical Changes

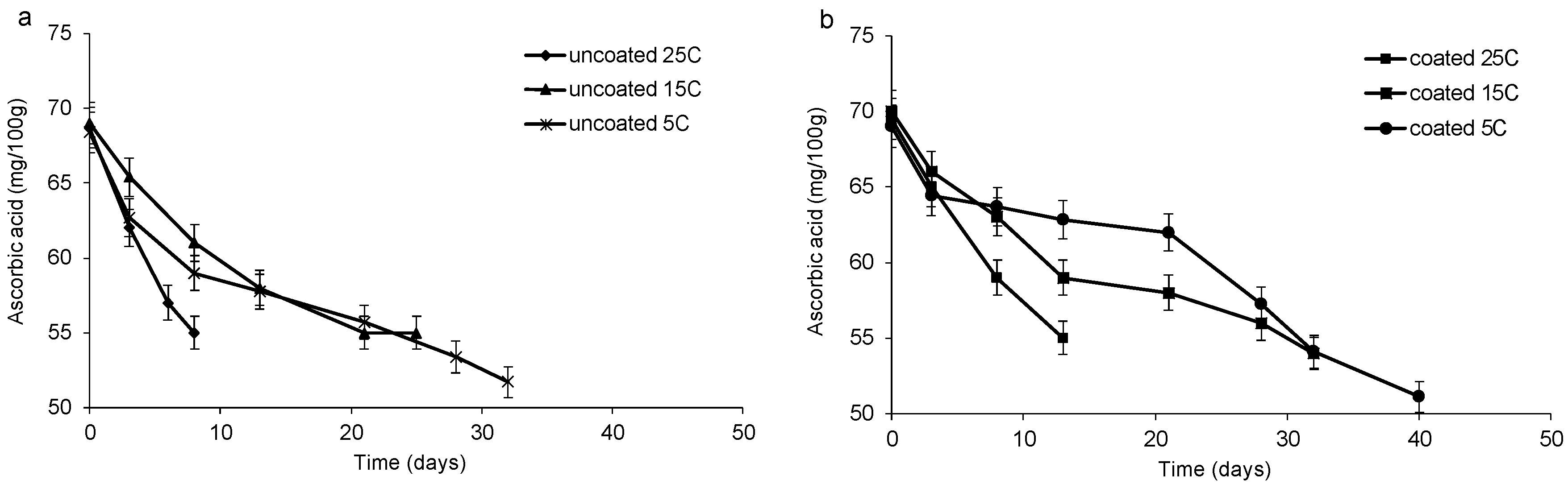

3.5.1. Ascorbic Acid

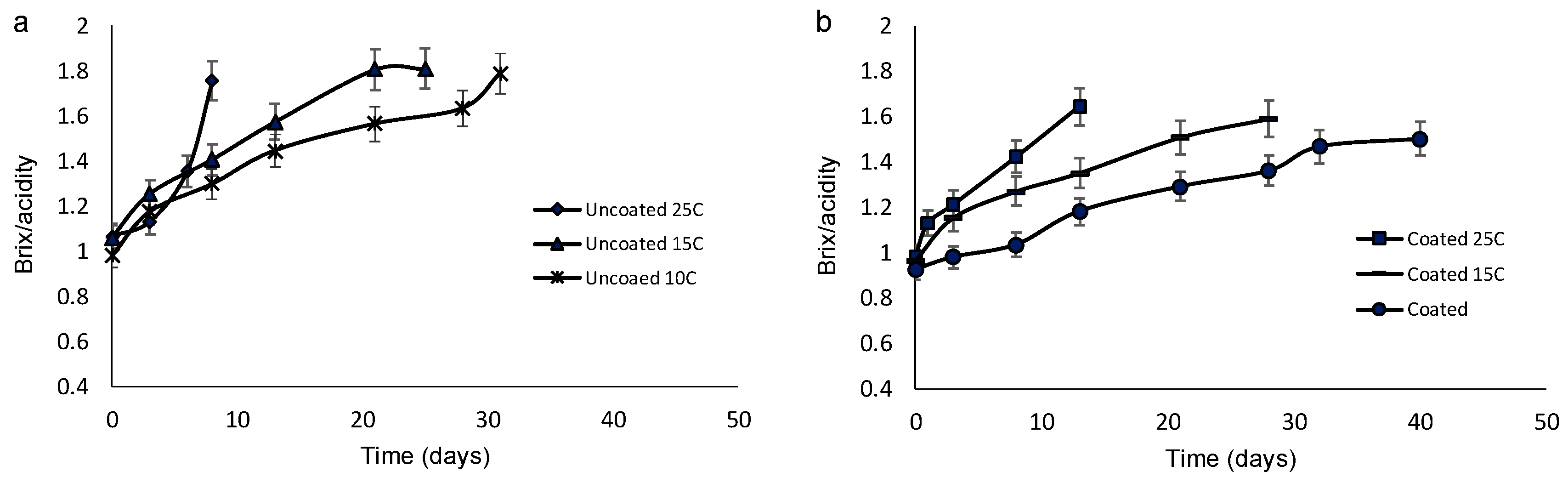

3.5.2. Brix to Acidity Ratio

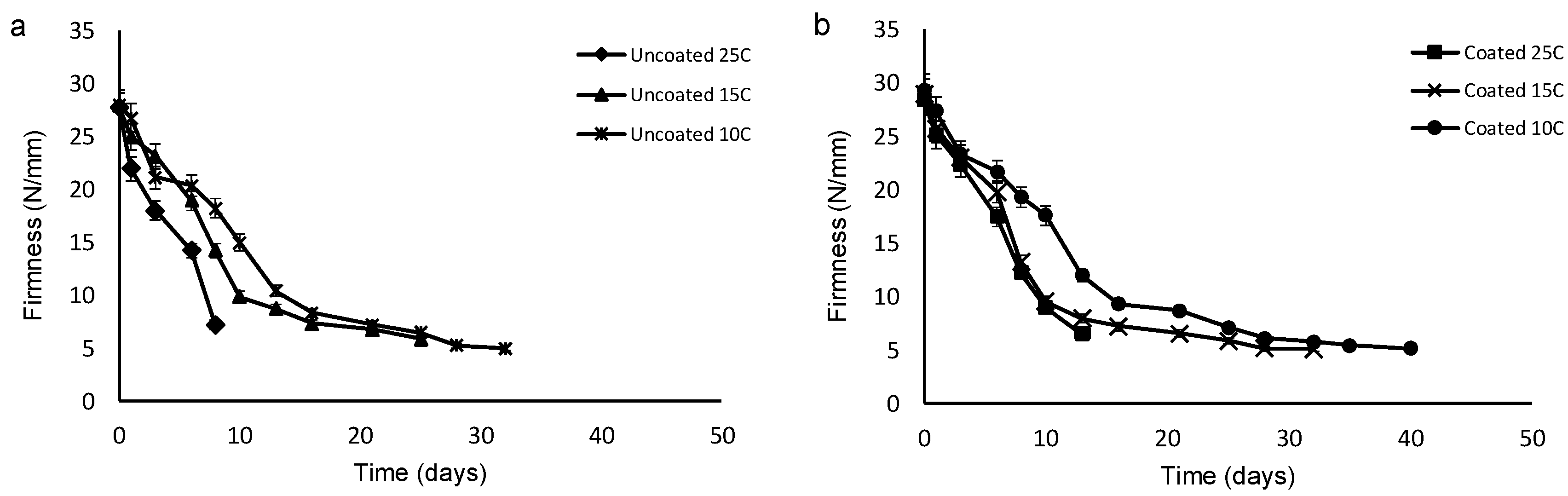

3.6. Firmness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vand, S.H.; Abdullah, T.L. Identification and introduction of thornless lime (Citrus aurantifolia) in Hormozgan, Iran. Indian J. Sci. Technol. 2012, 5, 3670–3673. [Google Scholar]

- Kluge, R.A.; Jomori, M.L.L.; Jacomino, A.P.; Vitti, M.C.D.; Vitti, D.C.C. Intermittent warming of ‘Tahiti’ lime to prevent chilling injury during cold storage. Sci. Agric. 2003, 60, 729–734. [Google Scholar] [CrossRef]

- Maftoonazad, N.; Ramaswamy, H. Effect of pectin-based coating on the kinetics of quality change associated with stored avocados. J. Food Process. Preserv. 2008, 32, 621–643. [Google Scholar] [CrossRef]

- Yousuf, B.; Qadri, O.S.; Srivastava, A.K. Recent developments in shelf-life extension of fresh-cut fruits and vegetables by application of different edible coatings: A review. LWT 2018, 89, 198–209. [Google Scholar] [CrossRef]

- Benítez, S.; Achaerandio, I.; Pujolà, M.; Sepulcre, F. Aloe vera as an alternative to traditional edible coatings used in fresh-cut fruits: A case of study with kiwifruit slices. LWT-Food Sci. Technol. 2015, 61, 184–193. [Google Scholar] [CrossRef]

- Valero, D.; Díaz-Mula, H.M.; Zapata, P.J.; Guillén, F.; Martínez-Romero, D.; Castillo, S.; Serrano, M. Effects of alginate edible coating on preserving fruit quality in four plum cultivars during postharvest storage. Postharvest Boil. Technol. 2013, 77, 1–6. [Google Scholar] [CrossRef]

- Ochoa-Reyes, E.; Martínez-Vazquez, G.; Saucedo-Pompa, S.; Montañez, J.; Rojas-Molina, R.; de Leon-Zapata, M.A.; Rodríguez-Herrera, R.; Aguilar, C.N. Improvement of shelf life quality of green bell peppers using edible coating formulations. J. Microbiol. Biotechnol. Food Sci. 2013, 2, 2448–2541. [Google Scholar]

- Deng, Z.; Jung, J.; Simonsen, J.; Zhao, Y. Cellulose nanomaterials emulsion coatings for controlling physiological activity, modifying surface morphology, and enhancing storability of postharvest bananas (Musa acuminate). Food Chem. 2017, 232, 359–368. [Google Scholar] [CrossRef]

- Sanchís, E.; González, S.; Ghidelli, C.; Sheth, C.C.; Mateos, M.; Palou, L.; Pérez-Gago, M.B. Browning inhibition and microbial control in fresh-cut persimmon (Diospyros kaki Thunb. cv. Rojo Brillante) by apple pectin-based edible coatings. Postharvest Boil. Technol. 2016, 112, 186–193. [Google Scholar] [CrossRef]

- Zhao, Y. Edible coatings for extending shelf-life of fresh produce during postharvest storage. In Reference Module in Food Science; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

- Martiñon, M.E.; Moreira, R.G.; Castell-Perez, M.E.; Gomes, C. Development of a multilayered antimicrobial edible coating for shelf-life extension of fresh-cut cantaloupe (Cucumis melo L.) stored at 4 °C. LWT-Food Sci. Technol. 2014, 56, 341–350. [Google Scholar] [CrossRef]

- Oms-Oliu, G.; Soliva-Fortuny, R.; Martín-Belloso, O. Edible coatings with antibrowning agents to maintain sensory quality and antioxidant properties of fresh-cut pears. Postharvest Biol. Technol. 2008, 50, 87–94. [Google Scholar] [CrossRef]

- Maftoonazad, N.; Ramaswamy, H. Postharvest shelf-life extension of avocados using methyl cellulose-based coating. LWT-Food Sci. Technol. 2015, 38, 617–624. [Google Scholar] [CrossRef]

- Maftoonazad, N.; Ramaswamy, H.; Moalemiyan, M.; Kushalappa, A. Effect of pectin-based edible emulsion coating on changes in quality of avocado exposed to Lasiodiplodia theobromae infection. Carbohydr. Polym. 2007, 68, 341–349. [Google Scholar] [CrossRef]

- Maftoonazad, N.; Ramaswamy, H.S.; Marcotte, M. Evaluation of factors affecting barrier, mechanical and optical properties of pectin-based films using response surface methodology. J. Food Process Eng. 2007, 30, 539–563. [Google Scholar] [CrossRef]

- Moalemiyan, M.; Ramaswamy, H. Quality retention and shelf-life extension in mediterranean cucumbers coated with a pectin-based film. J. Food Res. 2012, 1, 159. [Google Scholar] [CrossRef]

- Moalemiyan, M.; Ramaswamy, H.S.; Maftoonazad, N. Pectin-based edible coating for shelf-life extension of ataulfo mango. J. Food Process Eng. 2012, 35, 572–600. [Google Scholar] [CrossRef]

- Sousa Gallagher, M.J.; Mahajan, P.V.; Yan, Z. 14 - Modelling chemical and physical deterioration of foods and beverages. In Food and Beverage Stability and Shelf Life; Woodhead Publishing: Cambridge, UK, 2011; pp. 459–481. [Google Scholar] [CrossRef]

- Maftoonazad, N. Production of Pectin-Based Edible Film/Coating in a Pilot Scale to Extend Shelf Life of Citrus Fruits; Agricultural Engineering Research Institute of Iran – AERI: Shiraz, Iran, 2015. [Google Scholar]

- Helrich, K. Official Methods of Analysis of the Association of Official Analytical Chemisty; Association of Official Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Abdi, S.; Rooein, Z.; Erfanimoghadam, J.; Aziznia, S. Application of pectin coating containing essential oil for increasing quality of strawberry fruit. J. Postharvest Technol. 2017, 5, 83–94. [Google Scholar]

- Treviño-Garza, M.Z.; García, S.; del Socorro Flores-González, M.; Arévalo-Niño, K. Edible active coatings based on pectin, pullulan, and chitosan increase quality and shelf life of strawberries (Fragaria ananassa). J. Food Sci. 2015, 80, M1823–M1830. [Google Scholar] [CrossRef]

- Guerreiro, A.C.; Gago, C.M.; Faleiro, M.L.; Miguel, M.G.; Antunes, M.D. Raspberry fresh fruit quality as affected by pectin-and alginate-based edible coatings enriched with essential oils. Sci. Hortic. 2015, 194, 138–146. [Google Scholar] [CrossRef]

- Fagundes, C.; Carciofi, B.A.M.; Monteiro, A.R. Estimate of respiration rate and physicochemical changes of fresh-cut apples stored under different temperatures. Food Sci. Technol. 2013, 33, 60–67. [Google Scholar] [CrossRef]

- Marpudi, S.L.; Abirami, L.; Pushkala, R.; Srividya, N. Enhancement of Storage Life and Quality Maintenance of Papaya Fruits Using Aloe Vera Based Antimicrobial Coating; NISCAIR-CSIR: New Delhi, India, 2011. [Google Scholar]

- Xing, Y.; Li, X.; Xu, Q.; Yun, J.; Lu, Y.; Tang, Y. Effects of chitosan coating enriched with cinnamon oil on qualitative properties of sweet pepper (Capsicum annuum L.). Food Chem. 2011, 124, 1443–1450. [Google Scholar] [CrossRef]

- Barreiro, J.A.; Milano, M.; Sandoval, A. Kinetics of colour change of double concentrated tomato paste during thermal treatment. J. Food Eng. 1997, 33, 359–371. [Google Scholar] [CrossRef]

- Avila, I.; Silva, C. Modelling kinetics of thermal degradation of colour in peach puree. J. Food Eng. 1999, 39, 161–166. [Google Scholar] [CrossRef]

- Maskan, M. Kinetics of colour change of kiwifruits during hot air and microwave drying. J. Food Eng. 2001, 48, 169–175. [Google Scholar] [CrossRef]

- Mditshwa, A.; Magwaza, L.S.; Tesfay, S.Z.; Opara, U.L. Postharvest factors affecting vitamin C content of citrus fruits: a review. Sci. Hortic. 2017, 218, 95–104. [Google Scholar] [CrossRef]

- Mahajan, B.V.C.; Dhillon, W.S.; Kumar, M. Effect of surface coatings on the shelf life and quality of kinnow fruits under different environment conditions. J. Postharvest Technol. 2013, 1, 8–15. [Google Scholar]

- Qiu, S.; Wang, J. Effects of storage temperature and time on internal quality of satsuma mandarin (Citrus unshiu marc.) by means of E-nose and E-tongue based on two-way MANOVA analysis and random forest. Innov. Food Sci. Emerg. Technol. 2015, 31, 139–150. [Google Scholar] [CrossRef]

- Rab, A.; Sajid, M.; Khan, N.U.; Nawab, K.; Arif, M.; Khattak, M.K. Influence of storage temperature on fungal prevalence and quality of citrus fruit (cv. Blood Red). Pak. J. Bot. 2012, 44, 831–836. [Google Scholar]

- Yimenu, S.M.; Abera, S.; Solomon, W. Effect of bee wax and linseed oil coatings and frequency of dipping on the biochemical and organoleptic quality of fresh orange juice (Citrus sinensis cv. Valencia). J. Postharvest Technol. 2017, 5, 17–28. [Google Scholar]

- Ghosh, A.; Dey, K.; Bhowmick, N. Effect of corn starch coating on storage life and quality of Assam lemon (Citrus limon Burn.). J. Crop Weed 2015, 11, 101–107. [Google Scholar]

- Menezes, J.; Athmaselvi, K. Study on effect of pectin based edible coating on the shelf life of sapota fruits. Biosci. Biotechnol. Res. Asia 2016, 13, 1195–1199. [Google Scholar] [CrossRef]

- Dang, K.T.; Singh, Z.; Swinny, E.E. Edible coatings influence fruit ripening, quality, and aroma biosynthesis in mango fruit. J Agric. Food Chem. 2008, 56, 1361–1370. [Google Scholar] [CrossRef]

- Ergun, M.; Satici, F. Use of aloe vera gel as biopreservative for ‘Granny Smith’ and ‘Red Chief’ apples. Anim. Plant Sci. 2012, 22, 363–368. [Google Scholar]

| System Parameter | Parameter Value |

|---|---|

| Capacity | 0 kg/h |

| Average fruit diameter | 4 cm |

| Conveyor belt in drying section | 40 cm × 3.4 m |

| Conveyor belt in cooling section | 40 cm × 0.6 m |

| Total | 40 cm × 4 m |

| Drying time | 960 s |

| Cooling time | 180 s |

| Conveyor speed | 0.2 m/min |

| Inlet drying air | 20 °C and 30% RH |

| Fresh air flow rate | 1083 kg/h (920 m3/h) |

| In-flow air | 6123 kg/h (5200 m3/h) |

| Electric power | 9 kw |

| Storage Temperature (°C) | k Value (day−1) | R2 | |

|---|---|---|---|

| 10 | coated | 0.411 | 0.995 |

| uncoated | 0.692 | 0.981 | |

| 15 | coated | 0.680 | 0.969 |

| uncoated | 1.42 | 0.971 | |

| 25 | coated | 1.77 | 0.969 |

| uncoated | 3.25 | 0.949 | |

| Other Kinetic Parameters | |||

| Ea = 70.6 kJ/mole (uncoated) | Ea = 68.3 kJ/mole (coated) | ||

| Storage Temperature (°C) | Parameter | Zero-Order Model | First-Order Model | ||||

|---|---|---|---|---|---|---|---|

| K0 (day−1) | R2 | K1 (day−1) | D (day) | R2 | |||

| 10 | Coated | L | – | – | 0.00625 | 369 | 0.872 |

| a | 0.0921 | 0.883 | – | – | – | ||

| b | – | – | 0.0133 | 173 | 0.931 | ||

| ΔE | 0.731 | 0.950 | - | – | – | ||

| Uncoated | L | – | – | 0.00712 | 324 | 0.838 | |

| a | 0.167 | 0.853 | – | – | – | ||

| b | – | – | 0.0167 | 137 | 0.951 | ||

| ΔE | 0.908 | 0.982 | – | – | – | ||

| 15 | Coated | L | – | – | 0.00757 | 304 | 0.935 |

| a | 0.126 | 0.965 | – | – | – | ||

| b | – | – | 0.0195 | 117 | 0.941 | ||

| ΔE | 0.994 | 0.879 | – | – | – | ||

| Uncoated | L | – | – | 0.00936 | 246 | 0.903 | |

| a | 0.221 | 0.874 | – | – | – | ||

| b | – | – | 0.0240 | 96.0 | 0.903 | ||

| ΔE | 1.22 | 0.943 | – | – | – | ||

| 25 | Coated | L | – | – | 0.0212 | 109 | 0.854 |

| a | 0.149 | 0.899 | – | – | – | ||

| b | – | – | 0.0317 | 72.5 | 0.897 | ||

| ΔE | 1.90 | 0.915 | – | – | – | ||

| Uncoated | L | – | – | 0.0458 | 50.3 | 0.927 | |

| a | 0.673 | 0.935 | – | – | – | ||

| b | – | – | 0.0691 | 33.3 | 0.907 | ||

| ΔE | 4.42 | 0.940 | – | – | – | ||

| Other Kinetic Parameters | |||||||

| L | Ea = 128.9 kJ/mole (uncoated); R2= 0.864 | Ea = 84.7 kJ/mole (coated); R2 = 0.871 | |||||

| a | Ea = 96.3 kJ/mole (uncoated); R2= 0.900 | Ea = 32.9 kJ/mole (uncoated); R2 = 0.963 | |||||

| b | Ea = 97.9 kJ/mole (uncoated); R2= 0.930 | Ea = 59.9 kJ/mole (uncoated); R2 = 0.997 | |||||

| ΔE | Ea = 110 kJ/mole (uncoated); R2= 0.889 | Ea = 65.9 kJ/mole (uncoated); R2 = 0.963 | |||||

| Storage Temperature (°C) | K1 Value (day−1) | D (day) | R2 | |

|---|---|---|---|---|

| 10 | coated | −0.00667 | 343 | 0.933 |

| uncoated | −0.00741 | 317 | 0.912 | |

| 15 | coated | −0.00727 | 313 | 0.939 |

| uncoated | −0.00907 | 254 | 0.933 | |

| 25 | coated | −0.0180 | 128 | 0.991 |

| uncoated | −0.0281 | 82.0 | 0.987 | |

| Other Kinetic Parameters | ||||

| Ea = 92.2 kJ/mole (uncoated) | Ea = 68.7 kJ/mole (coated) | |||

| R2 = 0.868 | R2 = 0.822 | |||

| Storage Temperature (°C) | k1 Value (day−1) | D (day) | R2 | |

|---|---|---|---|---|

| 10 | coated | 0.0143 | 160 | 0.957 |

| uncoated | 0.0152 | 152 | 0.977 | |

| 15 | coated | 0.0164 | 141 | 0.915 |

| uncoated | 0.0206 | 111 | 0.957 | |

| 25 | coated | 0.0360 | 64.0 | 0.953 |

| uncoated | 0.0604 | 38.0 | 0.887 | |

| Other Kinetic Parameters | ||||

| Ea = 99.3 kJ/mole (uncoated) | Ea = 59.8 kJ/mole (coated) | |||

| R2 = 0.930 | R2 = 0.825 | |||

| Storage Temperature (°C) | k1 Value (day−1) | D (day) | R2 | |

|---|---|---|---|---|

| 10 | coated | −0.0475 | 49.0 | 0.951 |

| uncoated | −0.0574 | 40.1 | 0.964 | |

| 15 | coated | −0.0568 | 41.0 | 0.903 |

| uncoated | −0.0670 | 34.0 | 0.925 | |

| 25 | coated | −0.115 | 20.0 | 0.980 |

| uncoated | −0.147 | 16.0 | 0.923 | |

| Other Kinetic Parameters | ||||

| Ea = 65.3 kJ/mole (uncoated) | Ea = 60.9 kJ/mole (coated) | |||

| R2 = 0.835 | R2 = 0.859 | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maftoonazad, N.; Ramaswamy, H.S. Application and Evaluation of a Pectin-Based Edible Coating Process for Quality Change Kinetics and Shelf-Life Extension of Lime Fruit (Citrus aurantifolium). Coatings 2019, 9, 285. https://doi.org/10.3390/coatings9050285

Maftoonazad N, Ramaswamy HS. Application and Evaluation of a Pectin-Based Edible Coating Process for Quality Change Kinetics and Shelf-Life Extension of Lime Fruit (Citrus aurantifolium). Coatings. 2019; 9(5):285. https://doi.org/10.3390/coatings9050285

Chicago/Turabian StyleMaftoonazad, Neda, and Hosahalli S. Ramaswamy. 2019. "Application and Evaluation of a Pectin-Based Edible Coating Process for Quality Change Kinetics and Shelf-Life Extension of Lime Fruit (Citrus aurantifolium)" Coatings 9, no. 5: 285. https://doi.org/10.3390/coatings9050285

APA StyleMaftoonazad, N., & Ramaswamy, H. S. (2019). Application and Evaluation of a Pectin-Based Edible Coating Process for Quality Change Kinetics and Shelf-Life Extension of Lime Fruit (Citrus aurantifolium). Coatings, 9(5), 285. https://doi.org/10.3390/coatings9050285