Laser-Sustained Plasma (LSP) Nitriding of Titanium: A Review

Abstract

1. Titanium: Benefits and Drawbacks

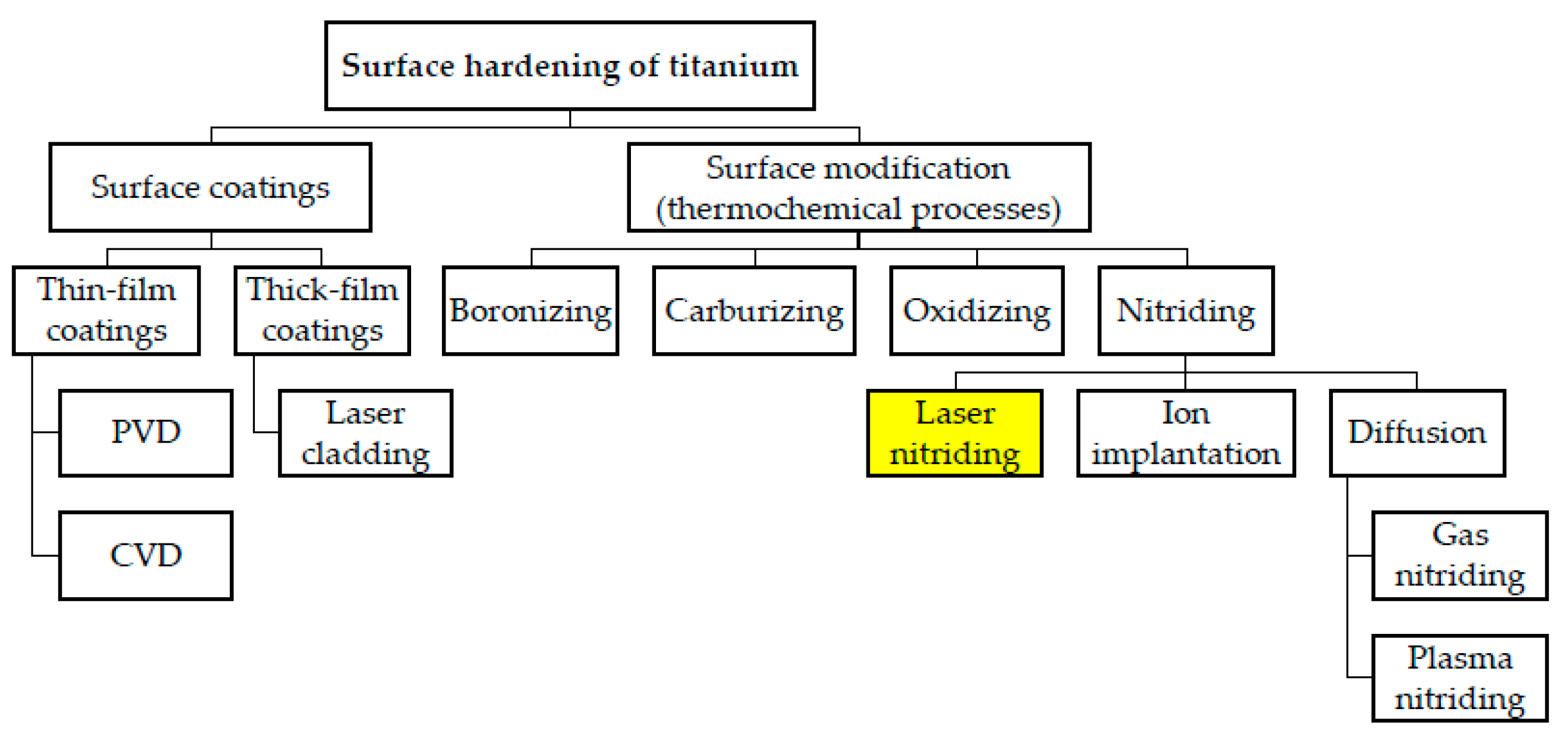

2. Surface Hardening of Titanium

3. Laser Nitriding of Titanium

3.1. Background

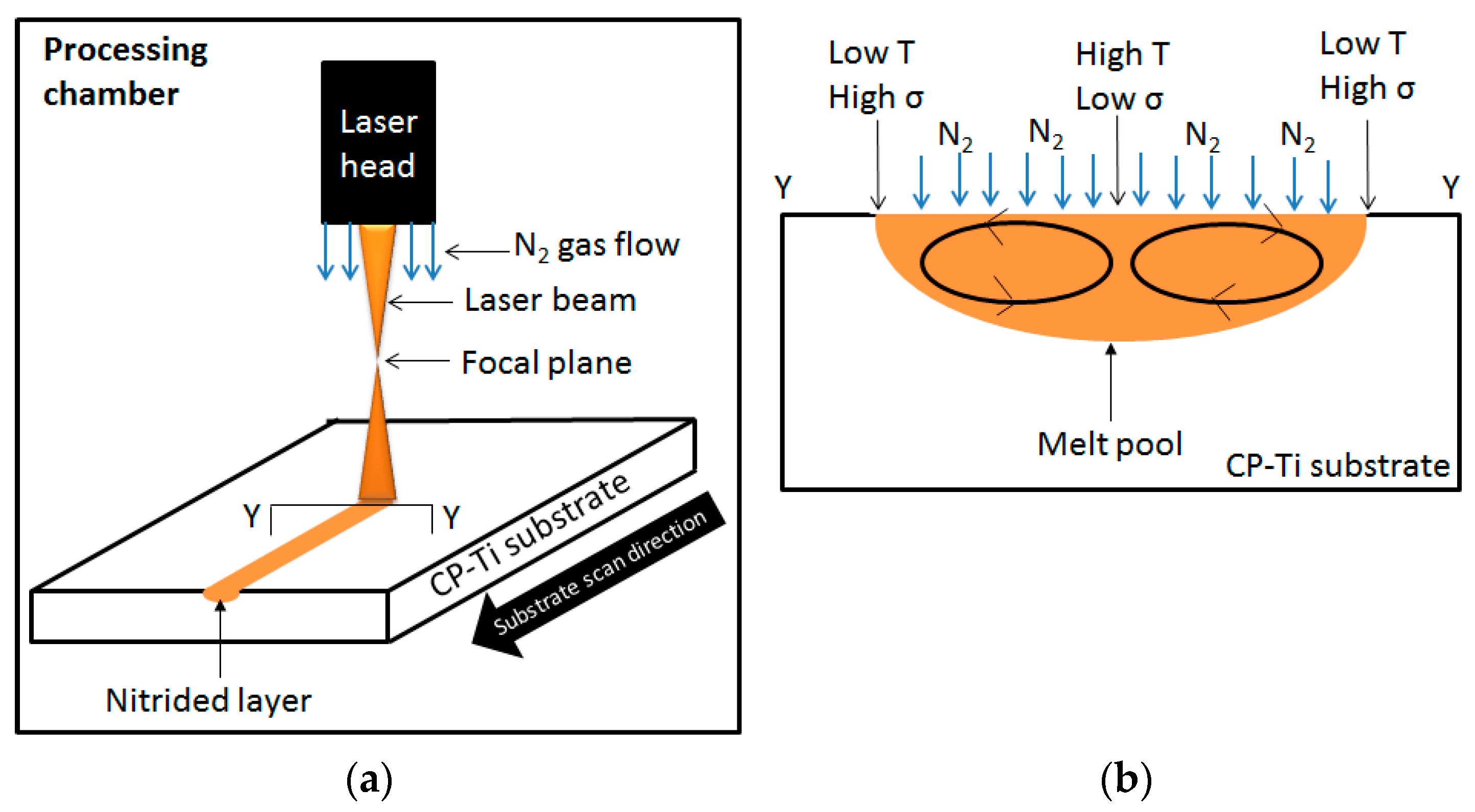

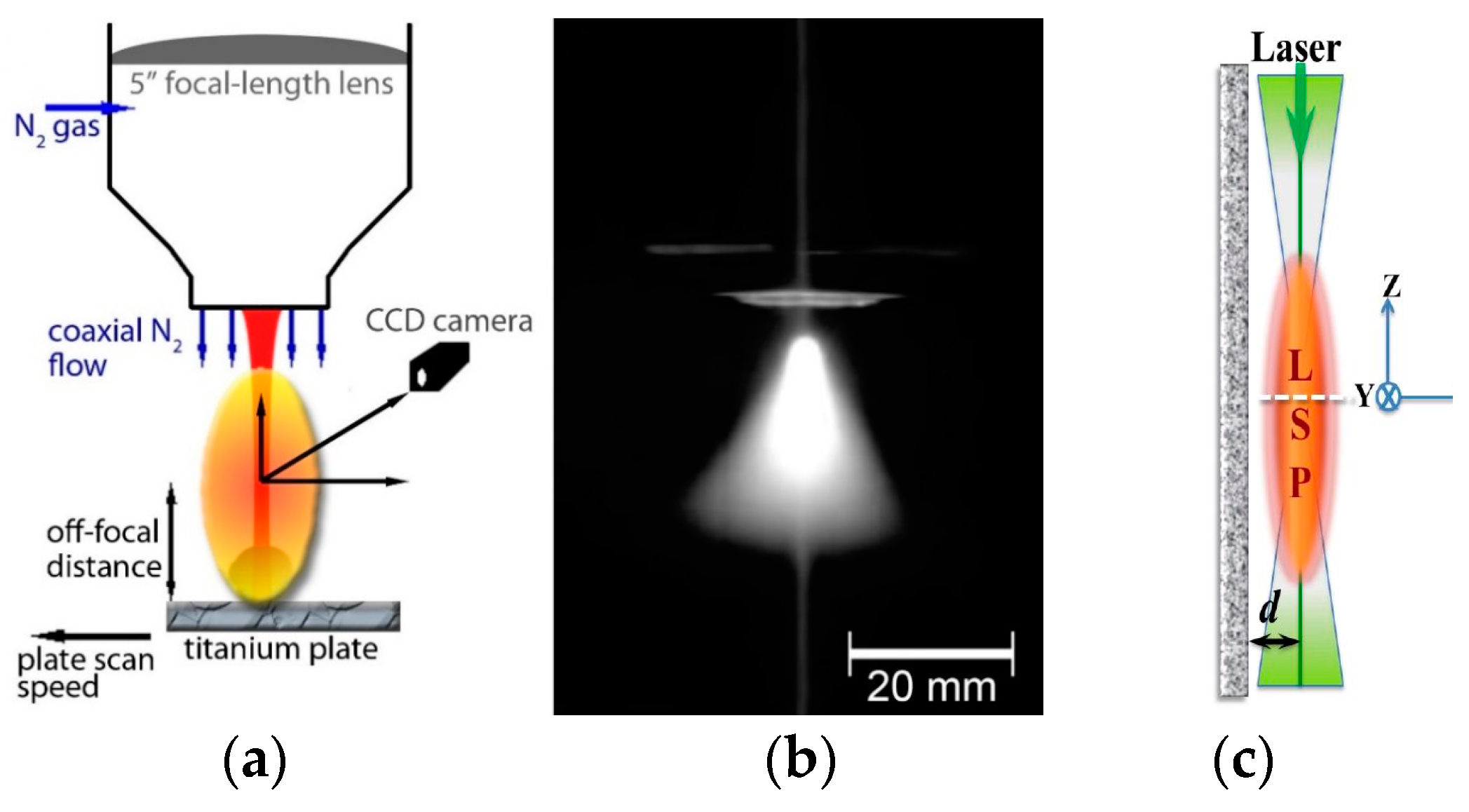

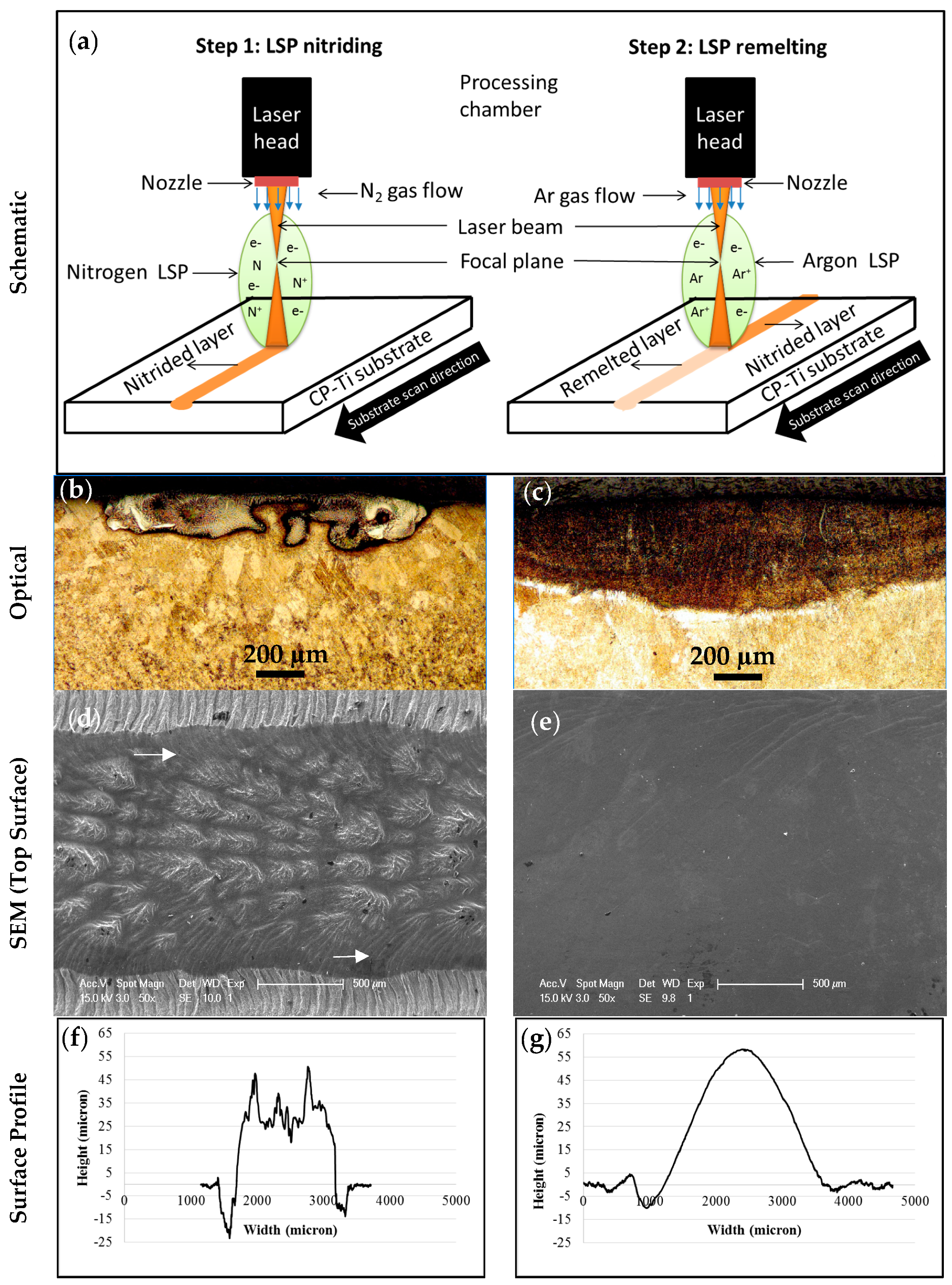

- The titanium substrate, usually in the form of a test coupon, is scanned under a laser beam in the presence of pure or diluted nitrogen gas flow (Figure 3a), where the distance of the focal plane from the substrate is dictated by the desired beam spot size (and hence incident energy density) on the substrate. The laser beam can be operated in the pulsed or continuous-wave (CW) mode. The nitrogen gas issues through a nozzle that is either coaxial (coaxial nozzle) or at an angle to the laser beam (side nozzle). The process is usually conducted in a controlled environment containing pure or diluted nitrogen to avoid oxidation of the titanium substrate.

- Due to the high energy density of the laser beam at or near focus, the irradiated area of the titanium substrate melts to a depth of hundreds of microns and incorporates nitrogen at its molten surface. The nitrogen-rich titanium melt is transported deeper into the melt pool by convection currents. The main driving mechanism for convection is the so-called Marangoni force arising out of surface tension gradients; since the surface tension for liquid titanium decreases with increasing temperature, the center region of the free surface of the melt pool has lower surface tension than at the edges, driving fluid flow from the center to the edges (Figure 3b). Since nitrogen transport by diffusion in the liquid phase is enhanced by convection, the laser nitriding process is much faster than solid-state diffusion processes such as gas nitriding and plasma nitriding.

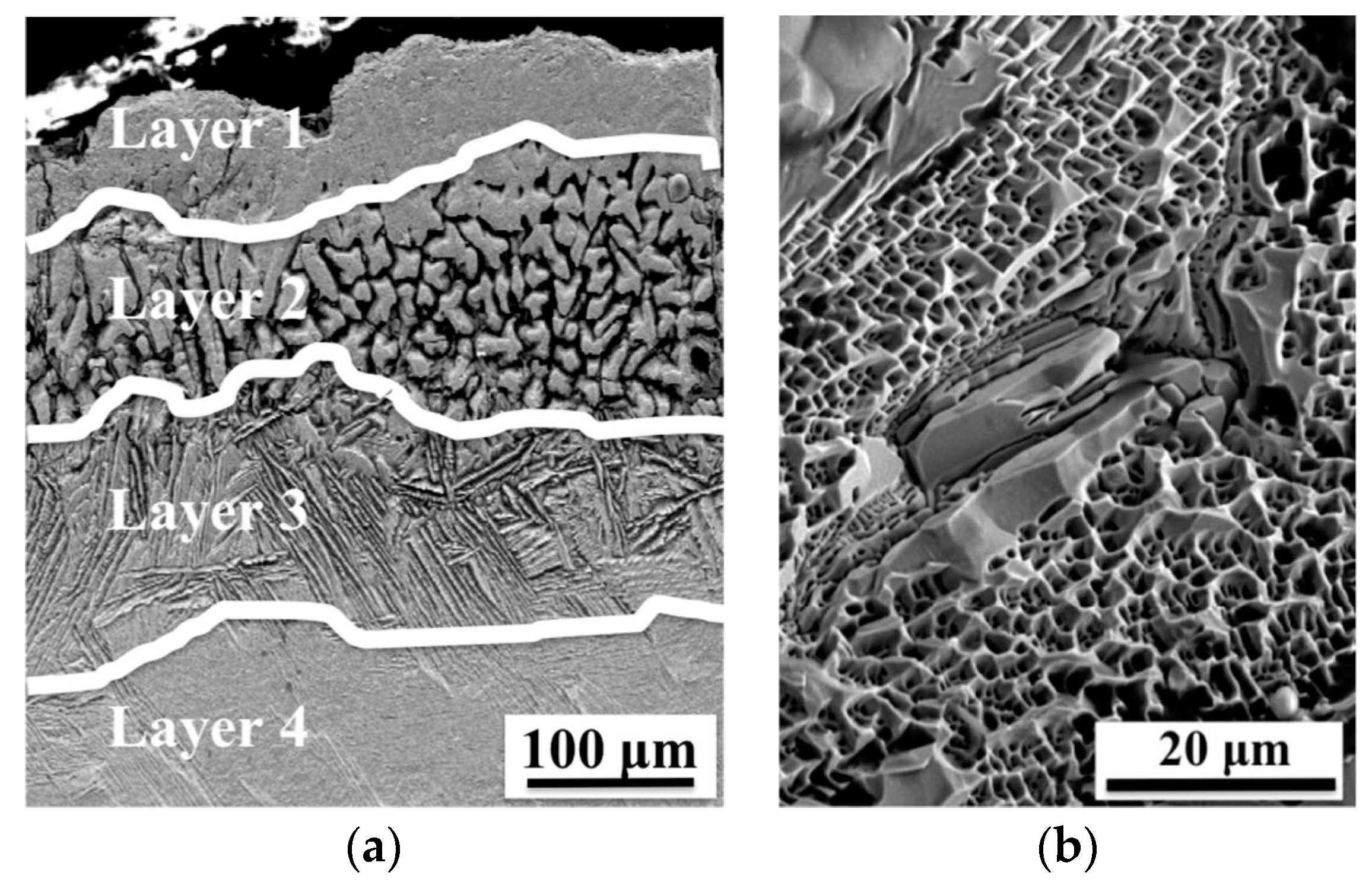

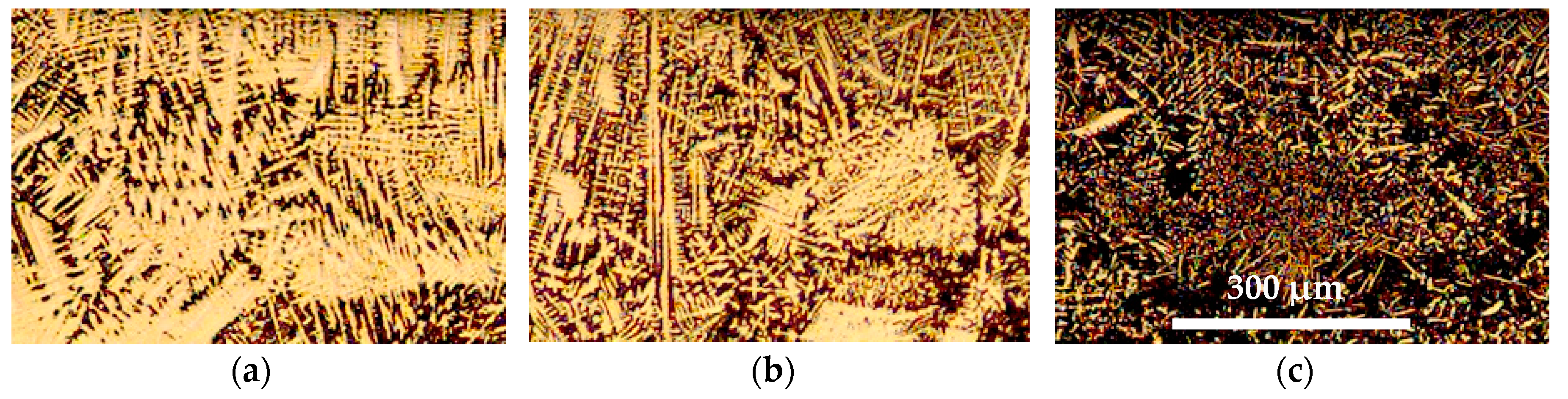

- When the laser beam moves away from the area under consideration (e.g., Y-Y in Figure 3b) as the substrate is scanned, the nitrogen-rich melt experiences rapid and non-equilibrium solidification due to a “self-quenching” effect whereby the surface rapidly loses heat to the bulk via conduction. This results in the precipitation of phases such as stoichiometric or near-stoichiometric TiN, a solid solution of nitrogen in titanium, α-Ti(N), and martensitic titanium, α’-Ti. The TiN phase is gold-colored and hence easily identified on the surface of the treated sample. The TiN and α-Ti(N) phases form a strong metallurgical bond with the substrate, thereby enhancing the hardness and wear resistance of the treated substrate. The microstructure of the resulting nitrided layer can be controlled by varying processing parameters such as laser power, spot size (off-focal distance), scan speed, and the nitrogen gas flow rate. On the other hand, rapid solidification makes the brittle nitrided layer susceptible to cracking and porosity, and causes an increase in surface roughness. Studies in the laser nitriding literature usually focus on overcoming these disadvantages (especially surface cracking) as detailed in Section 3.2.

3.2. Literature Review

3.2.1. Chronological Development of the Laser Nitriding Process

- Surface absorption [Ti] + N2 → [Ti] + [N2]

- Nitrogen decomposition [N2] → [2N]

- Nitrogen transfer [N]surface → [N]inside

- TiN precipitation [Ti(N)] → TiN + [Ti(N)]

- Melt solidification [Ti(N)] → TiN + α-Ti(N)

3.2.2. Role of Near-Surface Plasma in Laser Nitriding of Titanium

- In a metal where the first ionization potential is typically low, the metal vapor is easily ionized by the high intensity of the laser beam, giving rise to primary free electrons near the surface. Free electrons can also be generated by thermionic emission and the photoelectric effect [95].

- These primary free electrons gain energy by absorbing the laser radiation through a process called inverse bremsstrahlung. The energetic free electrons then collide with the neutral atoms and molecules of the processing gas, causing dissociation and ionization and producing secondary free electrons and ions in the process. This triggers a cascade ionization process in the gas, leading to gas breakdown and plasma formation. Gas breakdown is said to have occurred when the free electron density is of the order of 1024/m3 [96]. The presence of the primary free electrons reduces the threshold intensity required to cause optical breakdown of the processing gas by about four orders of magnitude [97], as well as the effective ionization potential of the processing gas [94]. According to Grigoryants [94], the threshold power density for a CO2 laser to cause optical breakdown is approximately 6 × 109 W/m2.

- The absorption of the laser energy by the plasma increases with the degree of ionization (i.e., the free electron density); if the laser is operated in the CW mode, a steady state can be reached when the absorbed laser energy is balanced by losses due to plasma re-radiation. In the steady state, the laser energy can sustain the plasma in a coaxial flow of the processing gas even when the original source of free electrons, the metal substrate, is removed from the laser beam path. Such a plasma has been referred to as a “continuous optical discharge” (COD) plasma [98] or a “laser-sustained plasma” (LSP) [99] in the literature; the latter terminology will be used in this paper.

- Peak temperatures in the range of 15000–17000 K have been measured at the core of steady-state argon LSP’s [99,100]. Although it is more difficult to characterize a nitrogen LSP, its peak temperature is expected to be the same order of magnitude. This makes the LSP an interesting tool from the standpoint of high-temperature materials processing.

4. Laser-sustained Plasma (LSP) Nitriding of Titanium

4.1. Background

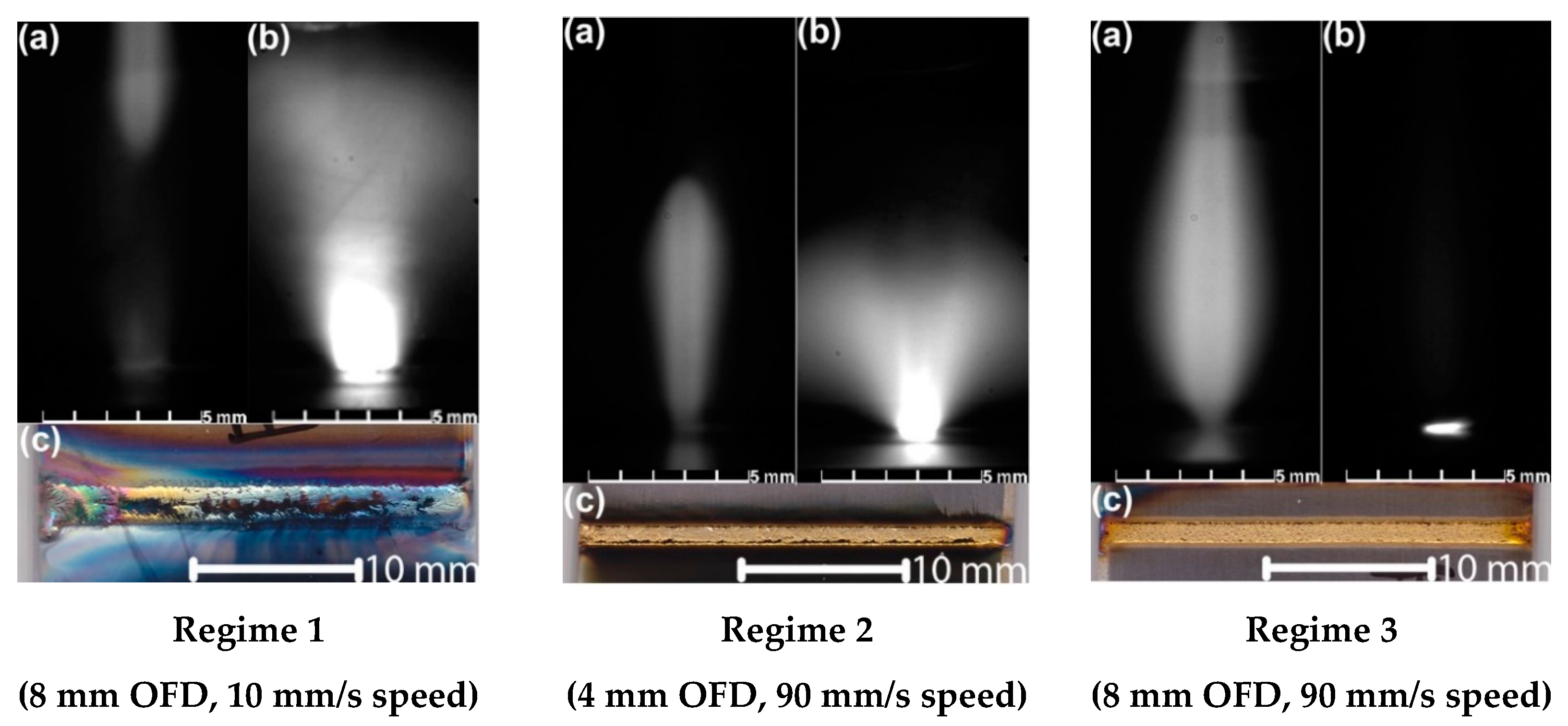

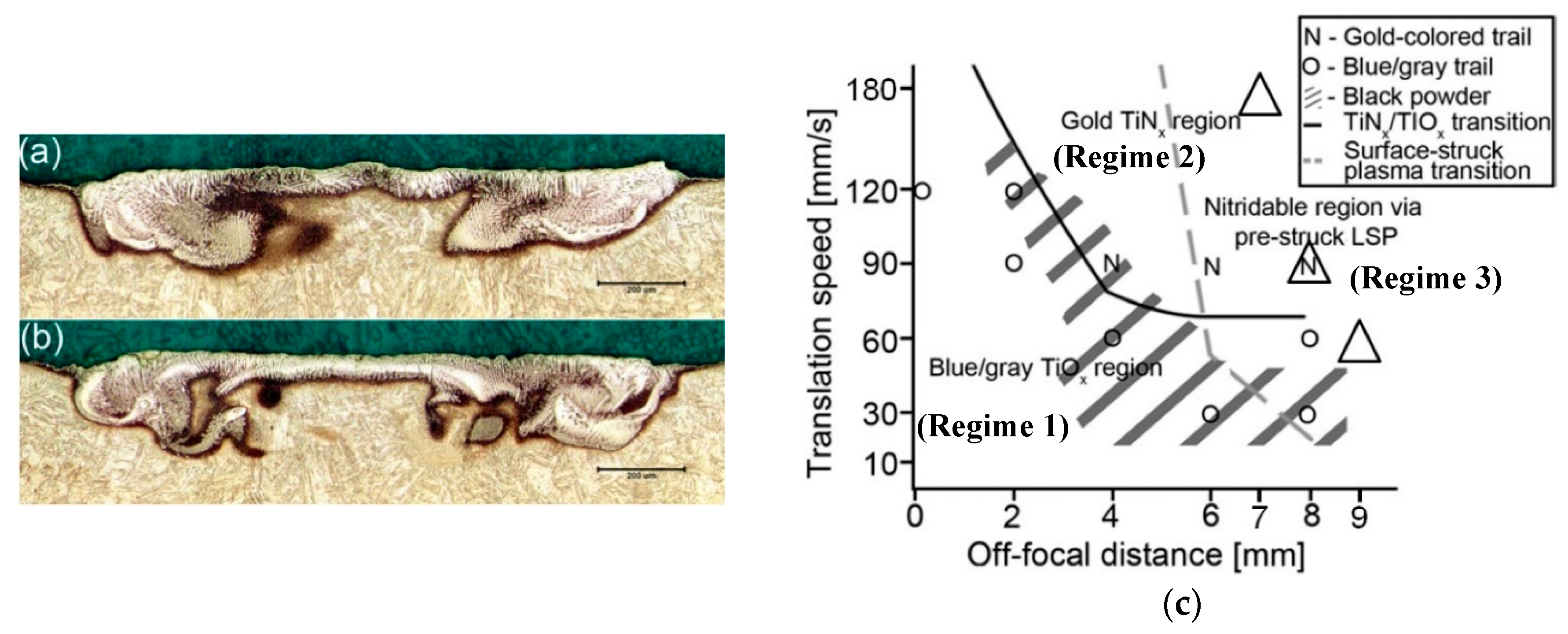

- At low scanning speeds and small OFD’s (i.e., conditions favoring higher power densities and longer beam-substrate interaction times), a Ti-rich plasma formed near the surface and did not allow the nitrogen gas flow to interact with the substrate, resulting in surface oxidation (e.g., Figure 4, left); Chen et al. [72] made a similar observation and argued against plasma formation since they believed that the Ti-rich plasma baffled the contact between nitrogen and the titanium substrate.

- At higher scan speeds and larger OFD’s, the near-surface plasma became richer in nitrogen species such as N and N+; this ensured sufficient interaction between the gas and the substrate and resulted in near-stoichiometric golden-colored titanium nitride layers on the substrate (e.g., Figure 4, middle). This regime can be thought of as similar to the one studied by researchers such as Thomann et al. [97] who concluded that plasma formation was necessary for efficient laser nitriding, as mentioned earlier in Section 3.2.2.

- Finally, at high scan speeds and/or large OFD’s, near-surface titanium plasma was not observed.

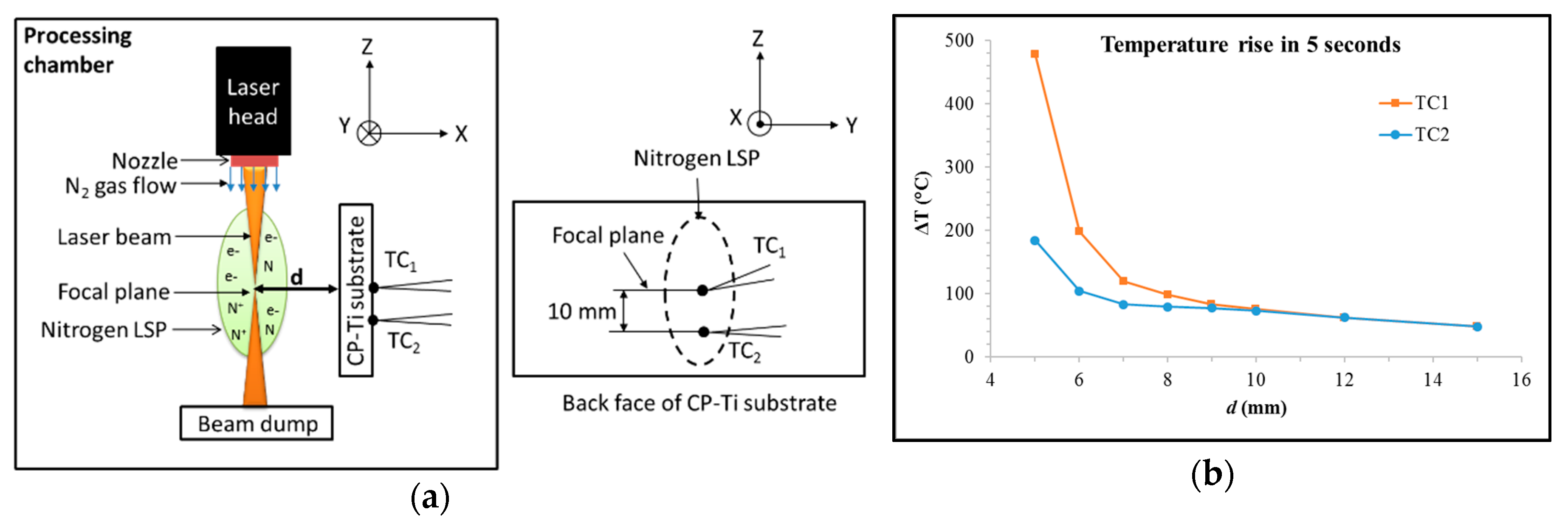

4.2. Effect of Nitrogen LSP on Heat and Mass Transfer During Nitriding

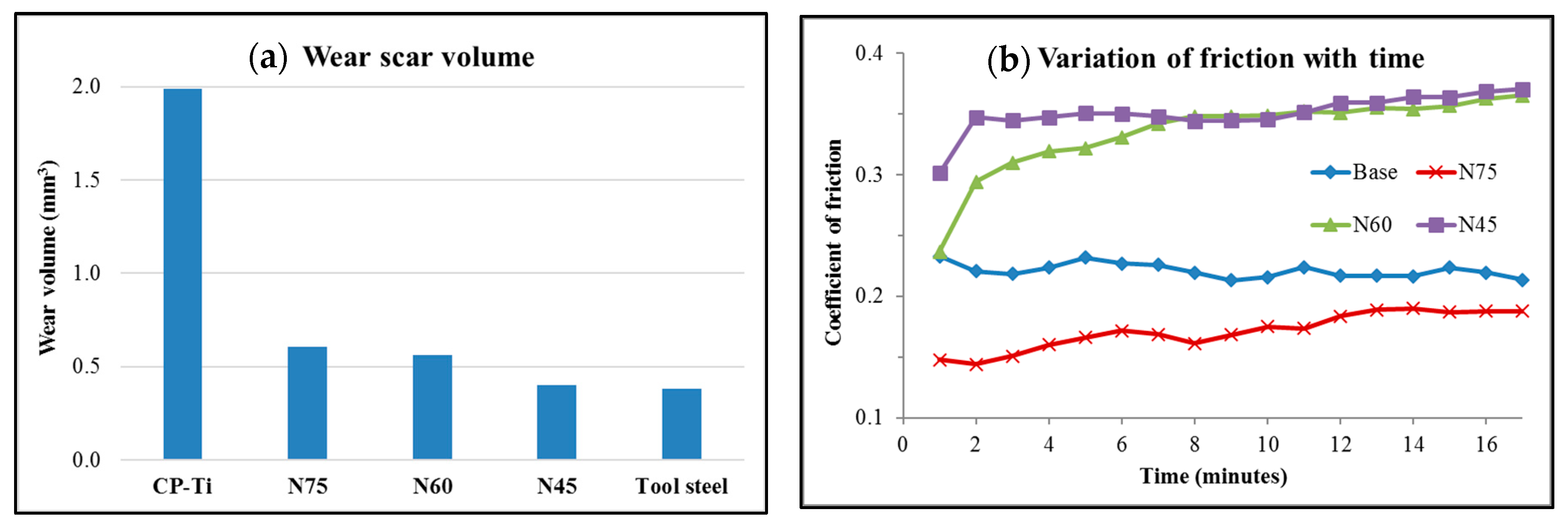

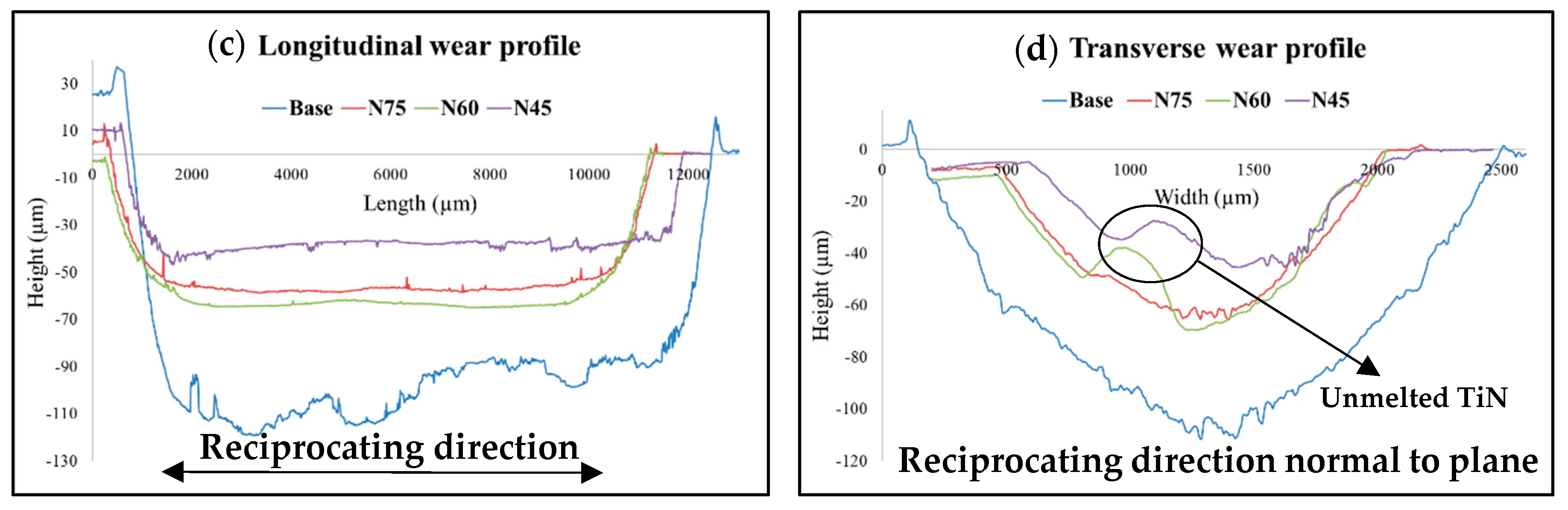

4.3. Two-Step “LSP Nitriding-Remelting” Process

5. Summary and Future Directions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Donachie, M.J., Jr. Titanium–A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 2000. [Google Scholar]

- Boyer, R.R. Titanium for aerospace: Rationale and applications. Adv. Perform. Mater. 1995, 2, 349–368. [Google Scholar] [CrossRef]

- Boyer, R.R. Attributes, characteristics, and applications of titanium and its alloys. JOM 2010, 62, 21–24. [Google Scholar] [CrossRef]

- Long, M.; Rack, H.J. Titanium alloys in total joint replacement–A materials science perspective. Biomaterials 1998, 19, 1621–1639. [Google Scholar] [CrossRef]

- Imam, M.A. The 13th world conference on titanium (Ti-2015). JOM 2016, 68, 2492–2501. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Attar, H.; Dargusch, M.S.; Kent, D. Microstructure, phase composition and mechanical properties of new, low cost Ti-Mn-Nb alloys for biomedical applications. J. Alloy. Compd. 2019, 787, 570–577. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Cao, G.; Zhang, L.C. Nanoindentation study of mechanical properties of Ti based alloys with Fe and Ta additions. J. Alloy. Compd. 2017, 692, 892–897. [Google Scholar] [CrossRef]

- Li, Y.; Yang, C.; Zhao, H.; Qu, S.; Li, X.; Li, Y. New developments of Ti-based alloys for biomedical applications. Materials 2014, 7, 1709–1800. [Google Scholar] [CrossRef]

- Froes, F.H.; Imam, M.A. Cost affordable developments in titanium technology and applications. Key Eng. Mater. 2010, 436, 1–11. [Google Scholar] [CrossRef]

- Budinski, K.G. Tribological properties of titanium alloys. Wear 1991, 151, 203–217. [Google Scholar] [CrossRef]

- Miller, P.D.; Holladay, J.W. Friction and wear properties of titanium. Wear 1958, 2, 133–140. [Google Scholar] [CrossRef]

- Qu, J.; Blau, P.J.; Watkins, T.R.; Cavin, O.B.; Kulkarni, N.S. Friction and wear of titanium alloys sliding against metal, polymer, and ceramic counterfaces. Wear 2005, 258, 1348–1356. [Google Scholar] [CrossRef]

- Hong, H.; Winer, W.O. A fundamental tribological study of Ti/Al2O3 contact in sliding wear. J. Tribol. 1989, 111, 504–509. [Google Scholar] [CrossRef]

- Bhansali, K.J.; Miller, A.E. The role of stacking fault energy on galling and wear behavior. Wear 1982, 75, 241–252. [Google Scholar] [CrossRef]

- Buckley, D.H.; Kuczkowski, T.J.; Johnson, R.L. Influence of Crystal Structure on the Friction and Wear of Titanium and Titanium Alloys in Vacuum; National Aeronautics and Space Administration, Lewis Research Center: Cleveland, OH, USA, 1965.

- Buckley, D.H. The metal-to-metal interface and its effect on adhesion and friction. In Plenary and Invited Lectures; Kerker, M., Rowell, R.L., Zettlemoyer, A.C., Eds.; Academic Press: Cambridge, MA, USA, 1977; pp. 37–54. [Google Scholar]

- Miyoshi, K.; Buckley, D.H. Correlation of tensile and shear strengths of metals with their friction properties. ASLE Trans. 1984, 27, 15–23. [Google Scholar] [CrossRef]

- Molinari, A.; Straffelini, G.; Tesi, B.; Bacci, T. Dry sliding wear mechanisms of the Ti6Al4V alloy. Wear 1997, 208, 105–112. [Google Scholar] [CrossRef]

- Hutchings, I.M. Tribology: Friction and Wear of Engineering Materials, 1st ed.; Butterworth-Heinemann: Oxford, UK, 1992. [Google Scholar]

- Bloyce, A.; Morton, P.H.; Bell, T. Surface engineering of titanium and titanium alloys. In ASM Handbook; ASM International: Materials Park, OH, USA, 1994; Volume 5, pp. 835–851. [Google Scholar]

- Zhecheva, A.; Sha, W.; Malinov, S.; Long, A. Enhancing the microstructure and properties of titanium alloys through nitriding and other surface engineering methods. Surf. Coat. Technol. 2005, 200, 2192–2207. [Google Scholar] [CrossRef]

- Kustas, F.M.; Misra, M.S. Friction and wear of titanium alloys. In ASM Handbook; ASM International: Materials Park, OH, USA, 1992; Volume 18, pp. 778–784. [Google Scholar]

- Budinski, K.G. Surface Engineering for Wear Resistance; Prentice Hall: Englewood Cliffs, NJ, USA, 1988. [Google Scholar]

- Bell, T.; Bergmann, H.W.; Lanagan, J.; Morton, P.H.; Staines, A.M. Surface engineering of titanium with nitrogen. Surf. Eng. 1986, 2, 133–143. [Google Scholar] [CrossRef]

- Weng, F.; Chen, C.; Yu, H. Research status of laser cladding on titanium and its alloys: A review. Mater. Des. 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Nazari, K.A.; Rahman Rashid, R.A.; Palanisamy, S.; Xia, K.; Dargusch, M.S. A novel Ti-Fe composite coating deposited using laser cladding of low cost recycled nano-crystalline titanium powder. Mater. Lett. 2018, 229, 301–304. [Google Scholar] [CrossRef]

- Rahman Rashid, R.A.; Palanisamy, S.; Attar, H.; Bermingham, M.; Dargusch, M.S. Metallurgical features of direct laser-deposited Ti6Al4V with trace boron. J. Manuf. Process. 2018, 35, 651–656. [Google Scholar] [CrossRef]

- Aich, S.; Ravi Chandran, K.S. TiB whisker coating on titanium surfaces by solid-state diffusion: Synthesis, microstructure, and mechanical properties. Metall. Mater. Trans. A 2002, 33, 3489–3498. [Google Scholar] [CrossRef]

- Atar, E.; Kayali, E.S.; Cimenoglu, H. Characteristics and wear performance of borided Ti6Al4V alloy. Surf. Coat. Technol. 2008, 202, 4583–4590. [Google Scholar] [CrossRef]

- Kaestner, P.; Olfe, J.; Rie, K.T. Plasma-assisted boriding of pure titanium and TiA16V4. Surf. Coat. Technol. 2001, 142–144, 248–252. [Google Scholar] [CrossRef]

- Zhecheva, A.; Malinov, S.; Sha, W. Titanium alloys after surface gas nitriding. Surf. Coat. Technol. 2006, 201, 2467–2474. [Google Scholar] [CrossRef]

- de Souza, G.B.; Foerster, C.E.; da Silva, S.L.R.; Serbena, F.C.; Lepienski, C.M.; dos Santos, C.A. Hardness and elastic modulus of ion-nitrided titanium obtained by nanoindentation. Surf. Coat. Technol. 2005, 191, 76–82. [Google Scholar] [CrossRef]

- Shibata, H.; Tokaji, K.; Ogawa, T.; Hori, C. The effect of gas nitriding on fatigue behaviour in titanium alloys. Int. J. Fatigue 1994, 16, 370–376. [Google Scholar] [CrossRef]

- Tamura, Y.; Yokoyama, A.; Watari, F.; Kawasaki, T. Surface properties and biocompatibility of nitrided titanium for abrasion resistant implant materials. Dent. Mater. J. 2002, 21, 355–372. [Google Scholar] [CrossRef] [PubMed]

- Bertóti, I.; Mohai, M.; Sullivan, J.L.; Saied, S.O.; Bertoti, I.; Mohai, M.; Sullivan, J.L.; Saied, S.O. Surface characterisation of plasma-nitrided titanium: An XPS study titanium. Appl. Surf. Sci. 1995, 84, 357–371. [Google Scholar] [CrossRef]

- Nolan, D.; Huang, S.W.; Leskovsek, V.; Braun, S. Sliding wear of titanium nitride thin films deposited on Ti–6Al–4V alloy by PVD and plasma nitriding processes. Surf. Coat. Technol. 2006, 200, 5698–5705. [Google Scholar] [CrossRef]

- Yilbaş, B.S.; Şahin, A.Z.; Al-Garni, A.Z.; Said, S.A.M.; Ahmed, Z.; Abdulaleem, B.J.; Sami, M. Plasma nitriding of Ti-6Al-4V alloy to improve some tribological properties. Surf. Coat. Technol. 1996, 80, 287–292. [Google Scholar] [CrossRef]

- Molinari, A.; Straffelini, G.; Tesi, B.; Bacci, T.; Pradelli, G. Effects of load and sliding speed on the tribological behaviour of Ti-6Al-4V plasma nitrided different temperatures. Wear 1997, 203–204, 447–454. [Google Scholar] [CrossRef]

- Muraleedharan, T.M.; Meletis, E.I. Surface modification of pure titanium and Ti-6A1-4V by intensified plasma ion nitriding. Thin Solid Films 1992, 221, 104–113. [Google Scholar] [CrossRef]

- Huang, H.H.; Hsu, C.H.; Pan, S.J.; He, J.L.; Chen, C.C.; Lee, T.L. Corrosion and cell adhesion behavior of TiN-coated and ion-nitrided titanium for dental applications. Appl. Surf. Sci. 2005, 244, 252–256. [Google Scholar] [CrossRef]

- Dong, H.; Li, X.Y. Oxygen boost diffusion for the deep-case hardening of titanium alloys. Mater. Sci. Eng. A 2000, 280, 303–310. [Google Scholar] [CrossRef]

- Bloyce, A.; Qi, P.Y.; Dong, H.; Bell, T. Surface modification of titanium alloys for combined improvements in corrosion and wear resistance. Surf. Coat. Technol. 1998, 107, 125–132. [Google Scholar] [CrossRef]

- Guleryuz, H.; Cimenoglu, H. Surface modification of a Ti-6Al-4V alloy by thermal oxidation. Surf. Coat. Technol. 2005, 192, 164–170. [Google Scholar] [CrossRef]

- Biswas, A.; Dutta Majumdar, J. Surface characterization and mechanical property evaluation of thermally oxidized Ti-6Al-4V. Mater. Charact. 2009, 60, 513–518. [Google Scholar] [CrossRef]

- Borgioli, F.; Galvanetto, E.; Iozzelli, F.; Pradelli, G. Improvement of wear resistance of Ti-6Al-4V alloy by means of thermal oxidation. Mater. Lett. 2005, 59, 2159–2162. [Google Scholar] [CrossRef]

- Conrad, H. Effect of interstitial solutes on the strength and ductility of titanium. Prog. Mater. Sci. 1981, 26, 123–403. [Google Scholar] [CrossRef]

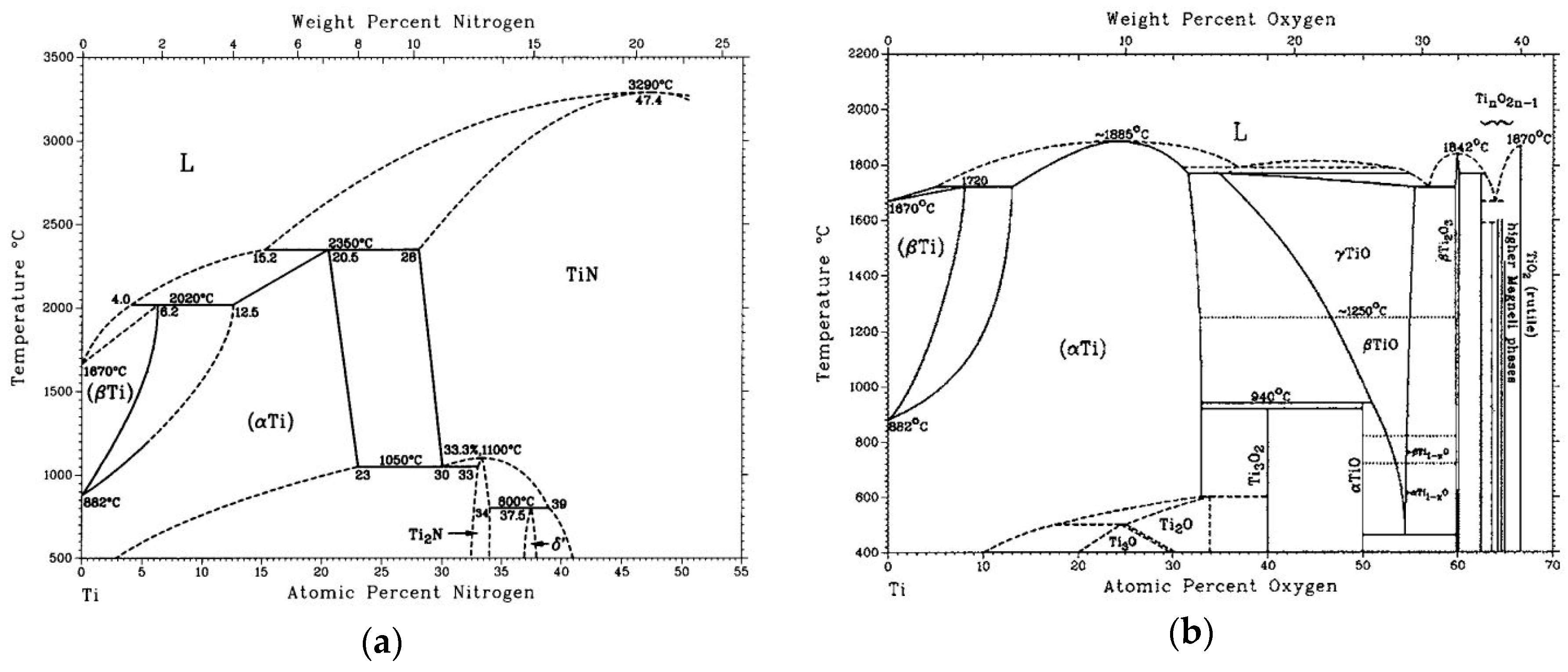

- Wriedt, H.A.; Murray, J.L. The N-Ti (nitrogen-titanium) system. Bull. Alloy Phase Diagr. 1987, 8, 378–388. [Google Scholar] [CrossRef]

- Murray, J.L.; Wriedt, H.A. The O-Ti (Oxygen-Titanium) system. J. Phase Equilib. 1987, 8, 148–165. [Google Scholar]

- Jaffee, R.I. The physical metallurgy of titanium alloys. Prog. Met. Phys. 1958, 7, 65–163. [Google Scholar] [CrossRef]

- Wilson, A.D.; Leyland, A.; Matthews, A. A comparative study of the influence of plasma treatments, PVD coatings and ion implantation on the tribological performance of Ti-6Al-4V. Surf. Coat. Technol. 1999, 114, 70–80. [Google Scholar] [CrossRef]

- Roliński, E. Surface properties of plasma-nitrided titanium alloys. Mater. Sci. Eng. A 1989, 108, 37–44. [Google Scholar] [CrossRef]

- Steen, W.M.; Mazumder, J. Laser welding. In Laser Material Processing, 4th ed.; Springer: London, UK, 2010; pp. 199–249. [Google Scholar]

- Katayama, S.; Matsunawa, A.; Morimoto, A.; Ishimoto, S.; Arata, Y. Surface hardening of titanium by laser nitriding. J. Laser Appl. 1983, 1983, 127–134. [Google Scholar] [CrossRef]

- Morton, P.H.; Bell, T.; Weisheit, A.; Kroll, J.; Mordike, B.L.; Sagoo, K. Laser gas nitriding of titanium and titanium alloys. Surf. Modif. Technol. 1991, V, 593–609. [Google Scholar]

- Bell, T.; Morton, P.H.; Bloyce, A. Towards the design of dynamically loaded titanium engineering components. Mater. Sci. Eng. A 1994, 184, 73–86. [Google Scholar] [CrossRef]

- Liu, J.; Luo, Q.; Zou, Z. Laser gas alloying of titanium alloy with nitrogen. Surf. Coat. Technol. 1993, 57, 191–195. [Google Scholar] [CrossRef]

- Kloosterman, A.B.; De Hosson, J.T.M. Microstructural characterization of laser nitrided titanium. Scr. Metall. Mater. 1995, 33, 567–573. [Google Scholar] [CrossRef]

- Mridha, S.; Baker, T.N. Characteristic features of laser-nitrided surfaces of two titanium alloys. Mater. Sci. Eng. A 1991, 142, 115–124. [Google Scholar] [CrossRef]

- Mridha, S.; Baker, T.N. Crack-free hard surfaces produced by laser nitriding of commercial purity titanium. Mater. Sci. Eng. A 1994, 188, 229–239. [Google Scholar] [CrossRef]

- Weerasinghe, V.M.; West, D.R.F.; De Damborenea, J. Laser surface nitriding of titanium and a titanium alloy. J. Mater. Process. Technol. 1996, 58, 79–86. [Google Scholar] [CrossRef]

- Hu, C.; Baker, T.N. The importance of preheat before laser nitriding a Ti–6Al–4V alloy. Mater. Sci. Eng. A 1999, 265, 268–275. [Google Scholar] [CrossRef]

- Xue, L.; Islam, M.; Koul, A.K.; Bibby, M.; Wallace, W. Laser gas nitriding of Ti-6Al-4V Part 1: Optimization of the process. Adv. Perform. Mater. 1997, 4, 25–47. [Google Scholar] [CrossRef]

- Xue, L.; Islam, M.; Koul, A.K.; Bibby, M.; Wallace, W. Laser gas nitriding of Ti-6Al-4V Part 2: Characteristics of nitrided layers. Adv. Perform. Mater. 1997, 4, 389–408. [Google Scholar] [CrossRef]

- Hu, C.; Xin, H.; Watson, L.M.; Baker, T.N. Analysis of the phases developed by laser nitriding Ti6Al4V alloys. Acta Mater. 1997, 45, 4311–4322. [Google Scholar] [CrossRef]

- Xin, H.; Hu, C.; Baker, T.N. Microstructural assessment of laser nitrided Ti-6Al-4V alloy. J. Mater. Sci. 2000, 35, 3373–3382. [Google Scholar] [CrossRef]

- Kaspar, J.; Bretschneider, J.; Jacob, S.; Bonß, S.; Winderlich, B.; Brenner, B. Microstructure, hardness and cavitation erosion behaviour of Ti–6Al–4V laser nitrided under different gas atmospheres. Surf. Eng. 2007, 23, 99–106. [Google Scholar] [CrossRef]

- Nwobu, A.I.P.; Rawlings, R.D.; West, D.R.F. Nitride formation in titanium based substrates during laser surface melting in nitrogen–argon atmospheres. Acta Mater. 1999, 47, 631–643. [Google Scholar] [CrossRef]

- Yerramareddy, S.; Bahadur, S. The effect of laser surface treatments on the tribological behavior of Ti-6Al4V. Wear 1992, 157, 245–262. [Google Scholar] [CrossRef]

- Xin, H.; Mridha, S.; Baker, T.N. The effect of laser surface nitriding with a spinning laser beam on the wear resistance of commercial purity titanium. J. Mater. Sci. 1996, 31, 22–30. [Google Scholar] [CrossRef]

- Man, H.C.; Cui, Z.D.; Yue, T.M.; Cheng, F.T. Cavitation erosion behavior of laser gas nitrided Ti and Ti6Al4V alloy. Mater. Sci. Eng. A 2003, 355, 167–173. [Google Scholar] [CrossRef]

- Ettaqi, S.; Hays, V.; Hantzpergue, J.J.; Saindrenan, G.; Remy, J.C. Mechanical, structural and tribological properties of titanium nitrided by a pulsed laser. Surf. Coat. Technol. 1998, 100–101, 428–432. [Google Scholar] [CrossRef]

- Chen, X.; Wu, G.; Wang, R.; Guo, W.; Yang, J.; Cao, S.; Wang, Y.; Han, W. Laser nitriding of titanium alloy in the atmosphere environment. Surf. Coat. Technol. 2007, 201, 4843–4846. [Google Scholar] [CrossRef]

- Abboud, J.H.; Fidel, A.F.; Benyounis, K.Y. Surface nitriding of Ti–6Al–4V alloy with a high power CO2 laser. Opt. Laser Technol. 2008, 40, 405–414. [Google Scholar] [CrossRef]

- Chan, C.W.; Lee, S.; Smith, G.C.; Donaghy, C. Fibre laser nitriding of titanium and its alloy in open atmosphere for orthopaedic implant applications: Investigations on surface quality, microstructure and tribological properties. Surf. Coat. Technol. 2017, 309, 628–640. [Google Scholar] [CrossRef]

- Raaif, M.; El-Hossary, F.M.; Negm, N.Z.; Khalil, S.M.; Kolitsch, A.; Höche, D.; Kaspar, J.; Mändl, S.; Schaaf, P. CO2 laser nitriding of titanium. J. Phys. D. Appl. Phys. 2008, 41, 085208. [Google Scholar] [CrossRef]

- Katahira, K.; Tanida, Y.; Takesue, S.; Komotori, J. Rapid surface nitriding of titanium alloy by a nanosecond fiber laser under atmospheric conditions. CIRP Ann. 2018, 67, 563–566. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Geetha, M.; Kamachi Mudali, U.; Pandey, N.D.; Asokamani, R.; Raj, B. Microstructural and corrosion evaluation of laser surface nitrided Ti-13Nb-13Zr alloy. Surf. Eng. 2004, 20, 68–74. [Google Scholar] [CrossRef]

- Vadiraj, A.; Kamaraj, M.; Gnanamoorthy, R. Fretting wear studies on uncoated, plasma nitrided and laser nitrided biomedical titanium alloys. Mater. Sci. Eng. A 2007, 445–446, 446–453. [Google Scholar] [CrossRef]

- Sathish, S.; Geetha, M.; Pandey, N.D.; Richard, C.; Asokamani, R. Studies on the corrosion and wear behavior of the laser nitrided biomedical titanium and its alloys. Mater. Sci. Eng. C 2010, 30, 376–382. [Google Scholar] [CrossRef]

- Zhang, C.H.; Tang, L.W.; Hu, F.; Zhang, S.; Man, H.C. Study on wear and corrosion properties of Ti6Al4V alloy by laser gas nitriding. Adv. Mater. Res. 2011, 299–300, 188–192. [Google Scholar] [CrossRef]

- Majumdar, J.D. Laser gas alloying of Ti-6Al-4V. Phys. Procedia 2011, 12, 472–477. [Google Scholar] [CrossRef]

- Dahotre, S.N.; Vora, H.D.; Rajamure, R.S.; Huang, L.; Banerjee, R.; He, W.; Dahotre, N.B. Laser induced nitrogen enhanced titanium surfaces for improved osseo-integration. Ann. Biomed. Eng. 2014, 42, 50–61. [Google Scholar] [CrossRef]

- Chan, C.W.; Lee, S.; Smith, G.; Sarri, G.; Ng, C.H.; Sharba, A.; Man, H.C. Enhancement of wear and corrosion resistance of beta titanium alloy by laser gas alloying with nitrogen. Appl. Surf. Sci. 2016, 367, 80–90. [Google Scholar] [CrossRef]

- Hussein, M.A.; Yilbas, B.; Kumar, A.M.; Drew, R.; Al-Aqeeli, N. Influence of laser nitriding on the surface and corrosion properties of Ti-20Nb-13Zr alloy in artificial saliva for dental applications. J. Mater. Eng. Perform. 2018, 27, 4655–4664. [Google Scholar] [CrossRef]

- Duraiselvam, M.; Valarmathi, A.; Shariff, S.M.; Padmanabham, G. Laser surface nitrided Ti-6Al-4V for light weight automobile disk brake rotor application. Wear 2014, 309, 269–274. [Google Scholar] [CrossRef]

- da Silva Briguente, L.A.N.; Oñoro, J.; Perpétuo Briguente, F.; Assis Resende, F.; Lidovino dos Reis, J.; Pereira Reis, D.A.; de Oliveira, A.C. The influence of laser nitriding on creep behavior of Ti-4Al-4V alloy with widmanstätten microstructure. Metals 2019, 9, 236. [Google Scholar] [CrossRef]

- Höche, D.; Müller, S.; Rapin, G.; Shinn, M.; Remdt, E.; Gubisch, M.; Schaaf, P. Marangoni convection during free electron laser nitriding of titanium. Metall. Mater. Trans. B 2009, 40, 497–507. [Google Scholar] [CrossRef]

- Höche, D.; Shinn, M.; Müller, S.; Schaaf, P. Diffusion, convection, and solidification in cw-mode free electron laser nitrided titanium. J. Appl. Phys. 2009, 105, 083503. [Google Scholar] [CrossRef]

- Lisiecki, A. Titanium matrix composite Ti/TiN produced by diode laser gas nitriding. Metals 2015, 5, 54–69. [Google Scholar] [CrossRef]

- Kuznetsov, G.V.; Nagornova, T.A. Numerical modeling of high-temperature heat and mass transfer at laser nitriding of titanium. J. Eng. Thermophys. 2007, 16, 73–77. [Google Scholar] [CrossRef]

- Dahotre, S.N.; Vora, H.D.; Pavani, K.; Banerjee, R. An integrated experimental and computational approach to laser surface nitriding of Ti–6Al–4V. Appl. Surf. Sci. 2013, 271, 141–148. [Google Scholar] [CrossRef]

- Xuan, F.Z.; Cao, L.Q.; Wang, Z.; Tu, S.T. Mass transport in laser surface nitriding involving the effect of high temperature gradient: Simulation and experiment. Comput. Mater. Sci. 2010, 49, 104–111. [Google Scholar] [CrossRef]

- Grigoryants, A.G. Basics of Laser Material Processing; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Hügel, H.; Dausinger, F. Interaction phenomena. In Handbook of the Eurolaser Academy: Volume 2, 1st ed.; Schuocker, D., Ed.; Springer US: New York, NY, USA, 1998; pp. 1–102. [Google Scholar]

- Dahotre, N.B.; Harimkar, S.P. Laser Fabrication and Machining of Materials; Springer Science & Business Media: New York, NY, USA, 2008. [Google Scholar]

- Thomann, A.L.; Boulmer-Leborgne, C.; Andreazza-Vignolle, C.; Andreazza, P.; Hermann, J.; Blondiaux, G. Metal surface nitriding by laser induced plasma. J. Appl. Phys. 1996, 80, 4673–4684. [Google Scholar] [CrossRef]

- Giren, B.G. Absorption of laser radiation in an optical discharge plasma in a gas mixture stream. J. Phys. D Appl. Phys. 1991, 24, 1086. [Google Scholar] [CrossRef]

- Keefer, D.; Welle, R.; Peters, C. Power absorption in laser-sustained argon plasmas. AIAA J. 1986, 24, 1663–1669. [Google Scholar] [CrossRef]

- Akarapu, R.; Nassar, A.R.; Copley, S.M.; Todd, J.A. Numerical model of a laser-sustained argon plasma. J. Laser Appl. 2009, 21, 169–175. [Google Scholar] [CrossRef]

- Ion, J. Laser Processing of Engineering Materials: Principles, Procedure and Industrial Application; Elsevier: Boston, MA, USA, 2005. [Google Scholar]

- Höche, D.; Rapin, G.; Schaaf, P. FEM simulation of the laser plasma interaction during laser nitriding of titanium. Appl. Surf. Sci. 2007, 254, 888–892. [Google Scholar] [CrossRef]

- Ohtsu, N.; Saito, W.; Yamane, M. Selectable surface nitridation of titanium using focused pulsed Nd:YAG laser irradiation with nitrogen gas blow. Surf. Coat. Technol. 2014, 246, 52–56. [Google Scholar] [CrossRef]

- Yu, H.; Sun, F. Laser and plasma nitriding of titanium in the atmosphere environment. In Proceedings of the 2009 Symposium on Photonics and Optoelectronics, Wuhan, China, 14–16 August 2009; pp. 1–4. [Google Scholar]

- Ohtsu, N.; Saito, W.; Yamane, M. Thickness of titanium nitride layers formed by focused low-powe nitrogen atmospheresr pulsed Nd:YAG laser irradiation in nitrogen atmospheres. Surf. Coat. Technol. 2014, 244, 57–62. [Google Scholar] [CrossRef]

- Kamat, A.M.; Copley, S.M.; Todd, J.A. A two-step laser-sustained plasma nitriding process for deep-case hardening of commercially pure titanium. Surf. Coat. Technol. 2017, 313, 82–95. [Google Scholar] [CrossRef]

- Filip, R. Laser nitriding of the surface layer of Ti6Al4V titanium alloy. Arch. Mater. Sci. Eng. 2008, 30, 25–28. [Google Scholar]

- Nassar, A.R.; Akarapu, R.; Copley, S.M.; Todd, J.A. Investigations of laser-sustained plasma and its role in laser nitriding of titanium. J. Phys. D Appl. Phys. 2012, 45, 185401. [Google Scholar] [CrossRef]

- Kamat, A.M.; Copley, S.M.; Todd, J.A. Effect of CO2 laser-sustained nitrogen plasma on heat and mass transfer during laser-nitriding of commercially-pure titanium. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–20 August 2015; Venkatesh, V., Pilchak, A.L., Eds.; John Wiley & Sons, Inc.: San Diego, CA, USA, 2016; pp. 893–898. [Google Scholar]

- Kamat, A.M.; Copley, S.M.; Todd, J.A. Effect of processing parameters on microstructure during laser-sustained plasma (LSP) nitriding of commercially-pure titanium. Acta Mater. 2016, 107, 72–82. [Google Scholar] [CrossRef]

- Black, A.N.; Copley, S.M.; Todd, J.A. A new method for isolating plasma interactions from those of the laser beam during plasma nitriding. Mater. Charact. 2017, 134, 143–151. [Google Scholar] [CrossRef]

- Kamat, A.M.; Segall, A.E.; Copley, S.M.; Todd, J.A. Enhancement of CP-titanum wear resistance using a two-step CO2 laser-sustained plasma nitriding process. Surf. Coat. Technol. 2017, 325, 229–238. [Google Scholar] [CrossRef]

- Kamat, A.M. A two-step CO2 Laser-Sustained Plasma Nitriding Process for Deep-Case Hardening of Commercially Pure Titanium. Ph.D. Thesis, Pennsylvania State University, University Park, PA, USA, December 2016. [Google Scholar]

| Issue | Cause | Proposed Solutions | References |

|---|---|---|---|

| Crack formation in nitrided layer | Residual tensile stresses | Preheating titanium substrate | [54,61,62] |

| Diluting nitrogen flow with argon | [54,59,60,62,66,73,75] | ||

| Laser remelting 1 | [106] | ||

| Surface roughness and melt pool inhomogeneity | Marangoni convection | Low laser power, high scan speeds, nitrogen dilution with argon | [54,73,88] |

| Laser remelting | [60,106] | ||

| Oxygen contamination of nitrided layer | High affinity of titanium to oxygen above 600 °C | Covering thrice the melt pool width with N2 flow | [54] |

| Controlled N2 atmosphere | [56,57,58,60,61,73,75,107] | ||

| Specially designed gas flow devices, avoid turbulent flow | [66,72,73,74,75,76] | ||

| Nitriding in the presence of plasma 1 | [104,108,109,110] | ||

| Plasma formation during nitriding | Cascade ionization due to high laser energy density | To be avoided (energy attenuation to substrate, risk of lens breakage, insufficient contact between titanium substrate and nitrogen gas flow) | [54,72,73] |

| To be encouraged (better energy coupling between substrate and laser, higher diffusion rates of nitrogen in melt pool, enhanced nitriding efficiency, reduced surface oxidation 1) | [74,97,102,103,105,108,109,110] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamat, A.M.; Copley, S.M.; Segall, A.E.; Todd, J.A. Laser-Sustained Plasma (LSP) Nitriding of Titanium: A Review. Coatings 2019, 9, 283. https://doi.org/10.3390/coatings9050283

Kamat AM, Copley SM, Segall AE, Todd JA. Laser-Sustained Plasma (LSP) Nitriding of Titanium: A Review. Coatings. 2019; 9(5):283. https://doi.org/10.3390/coatings9050283

Chicago/Turabian StyleKamat, Amar M., Stephen M. Copley, Albert E. Segall, and Judith A. Todd. 2019. "Laser-Sustained Plasma (LSP) Nitriding of Titanium: A Review" Coatings 9, no. 5: 283. https://doi.org/10.3390/coatings9050283

APA StyleKamat, A. M., Copley, S. M., Segall, A. E., & Todd, J. A. (2019). Laser-Sustained Plasma (LSP) Nitriding of Titanium: A Review. Coatings, 9(5), 283. https://doi.org/10.3390/coatings9050283