Glancing Angle Deposition of Zn-Doped Calcium Phosphate Coatings by RF Magnetron Sputtering

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

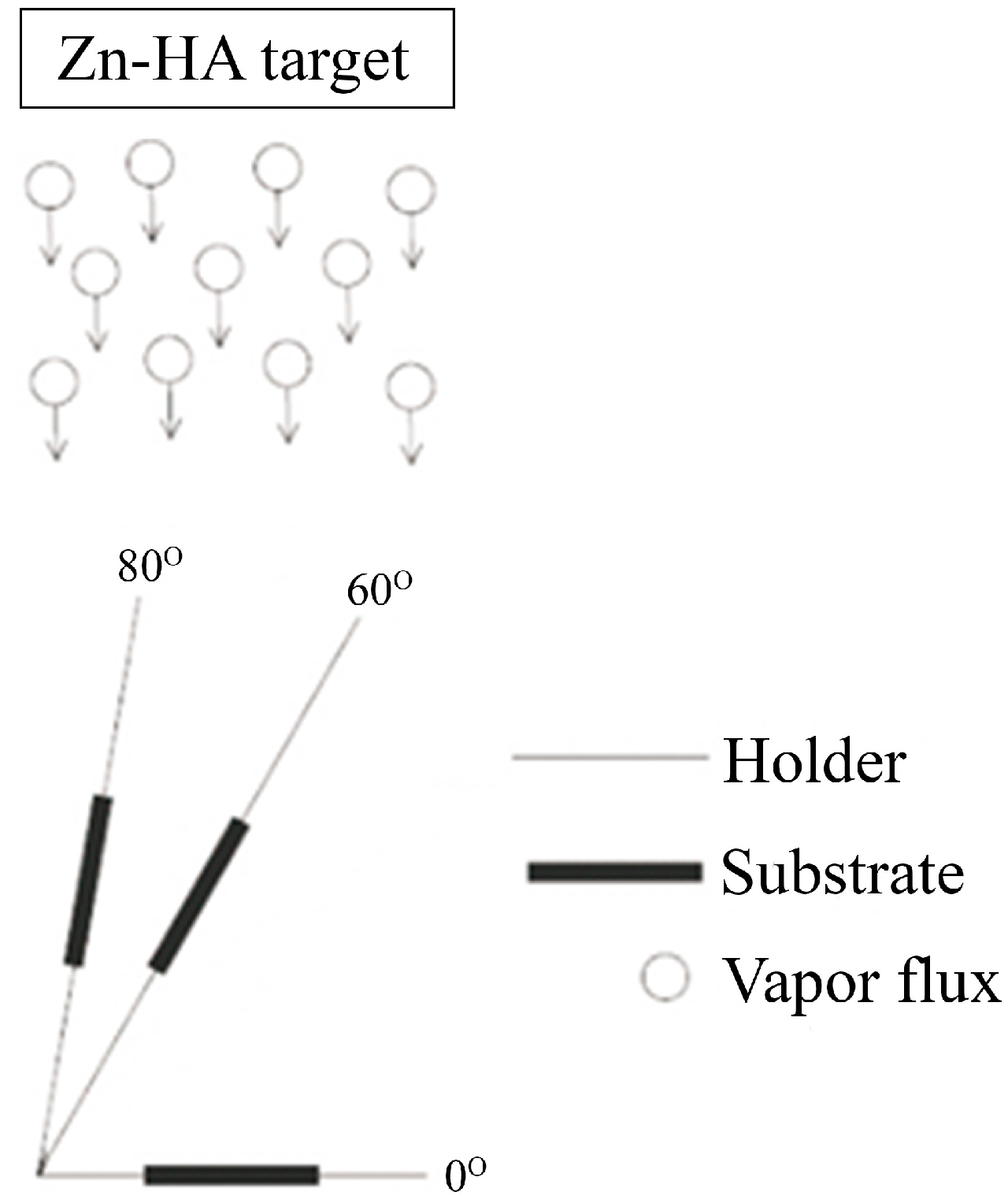

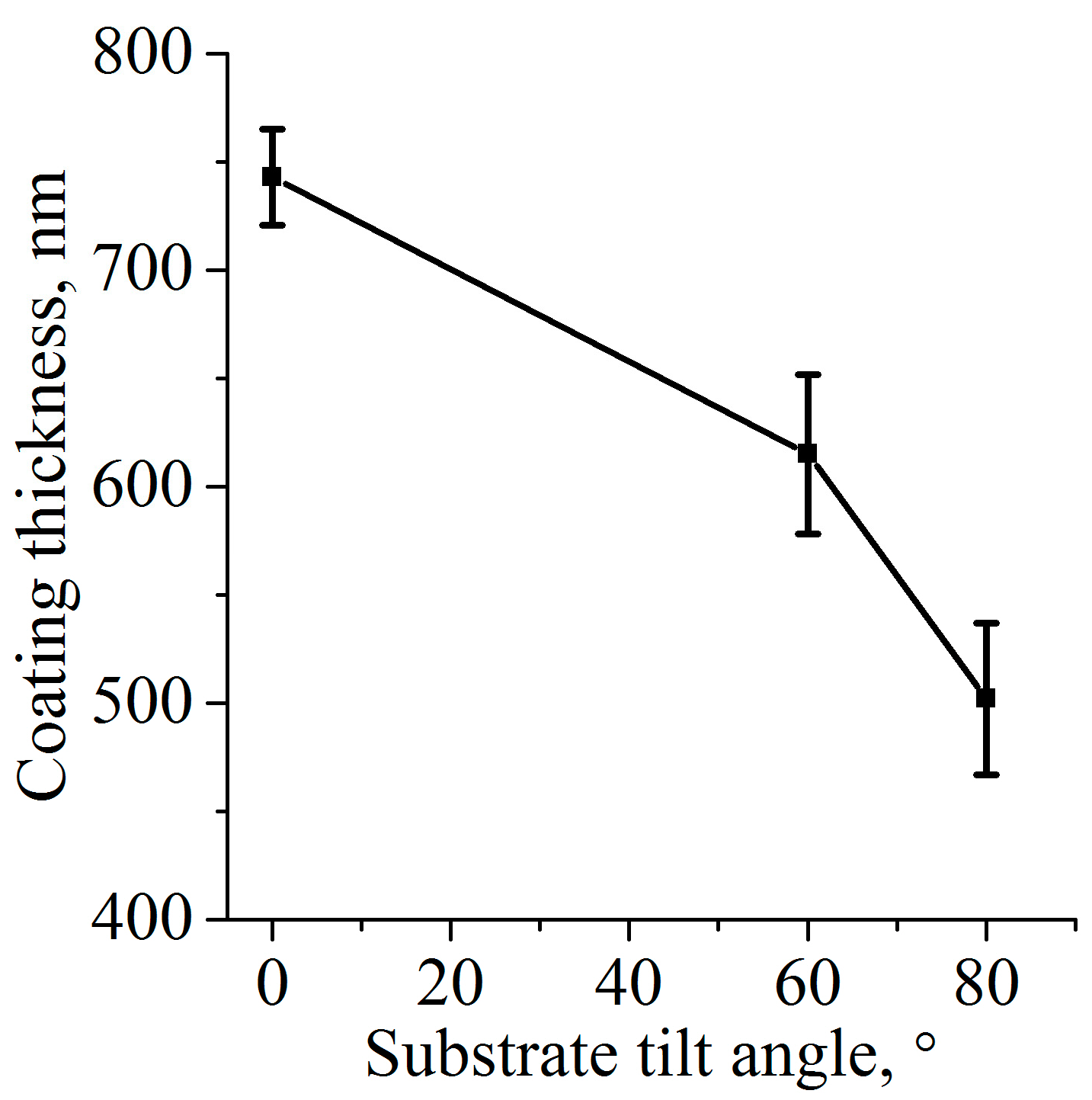

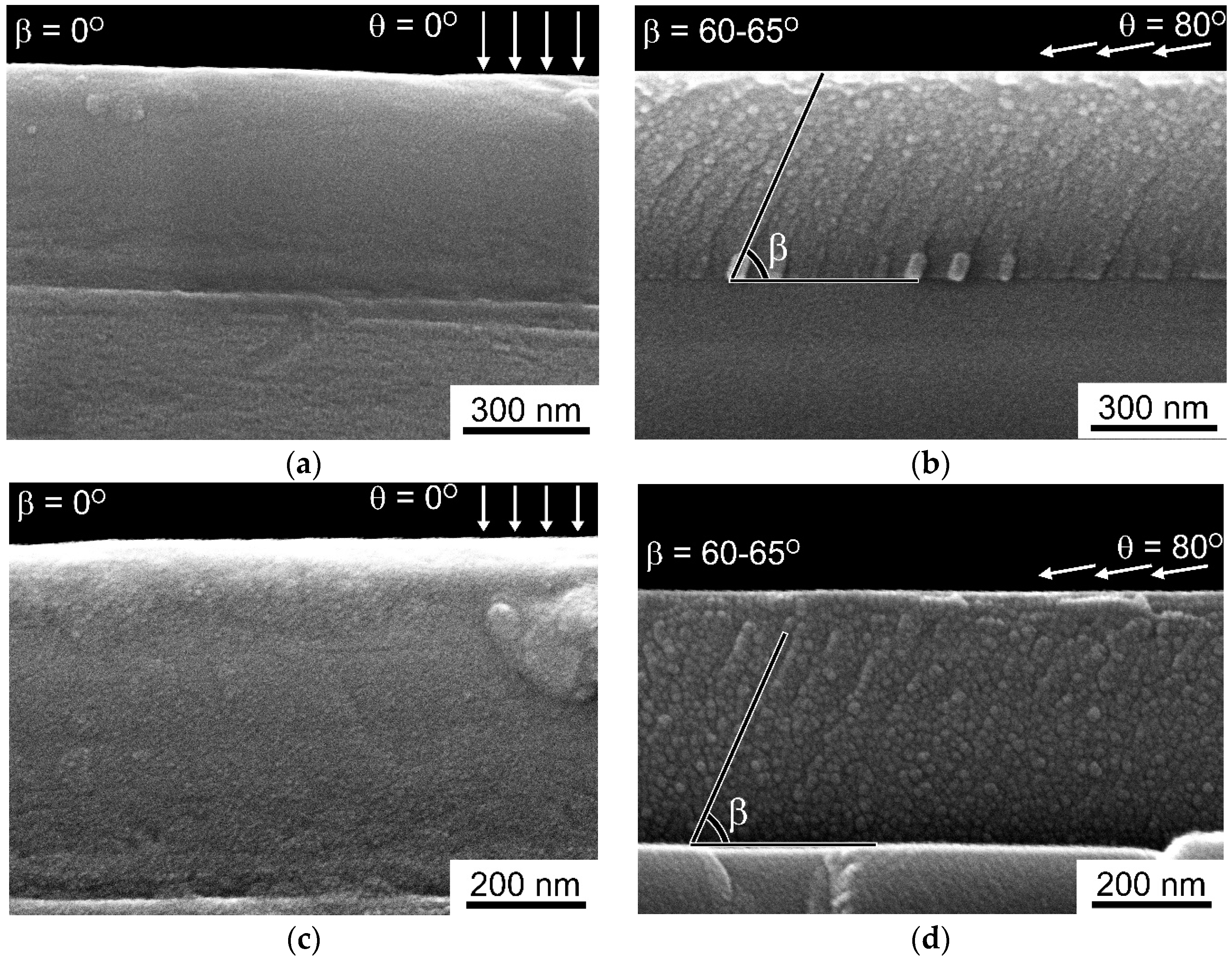

3.1. Effect of GLAD on Coating Thickness and Its Uniformity along the Substrate Surface

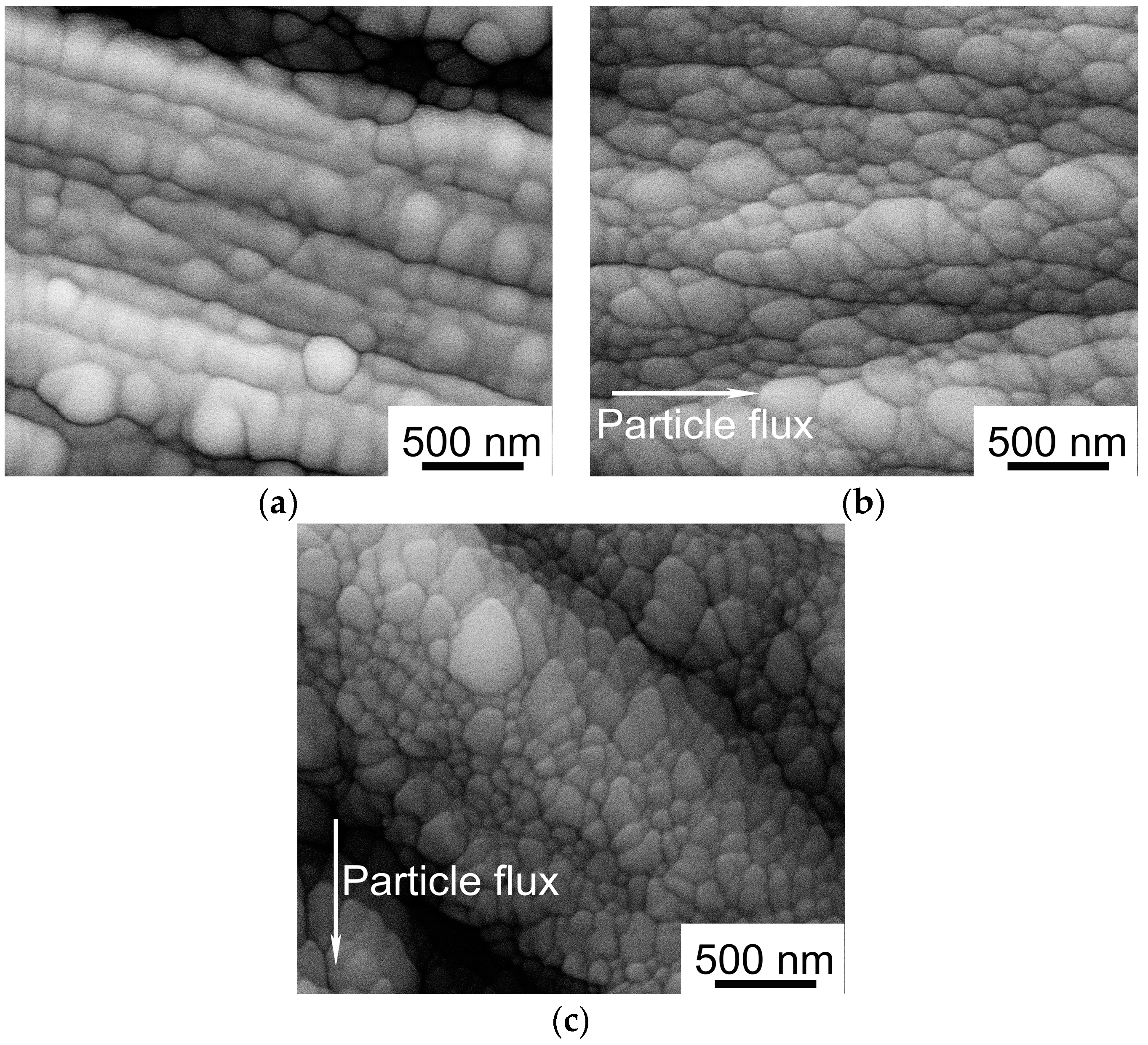

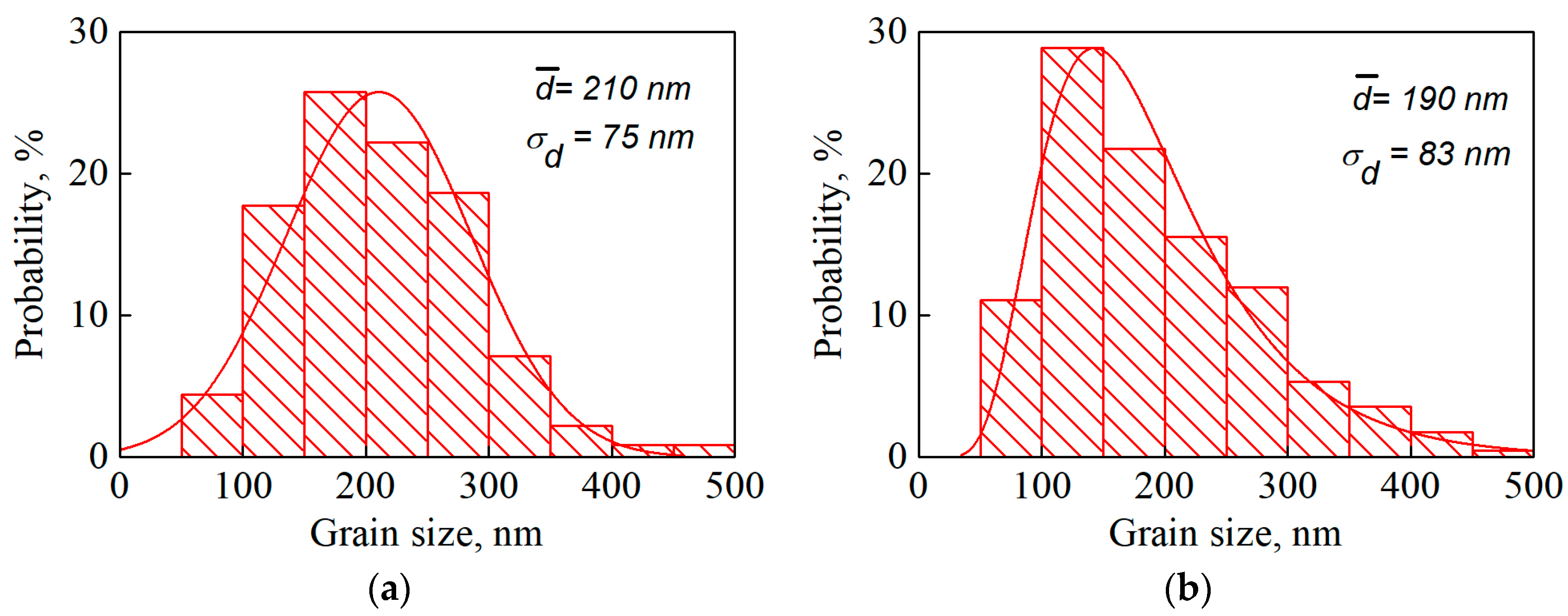

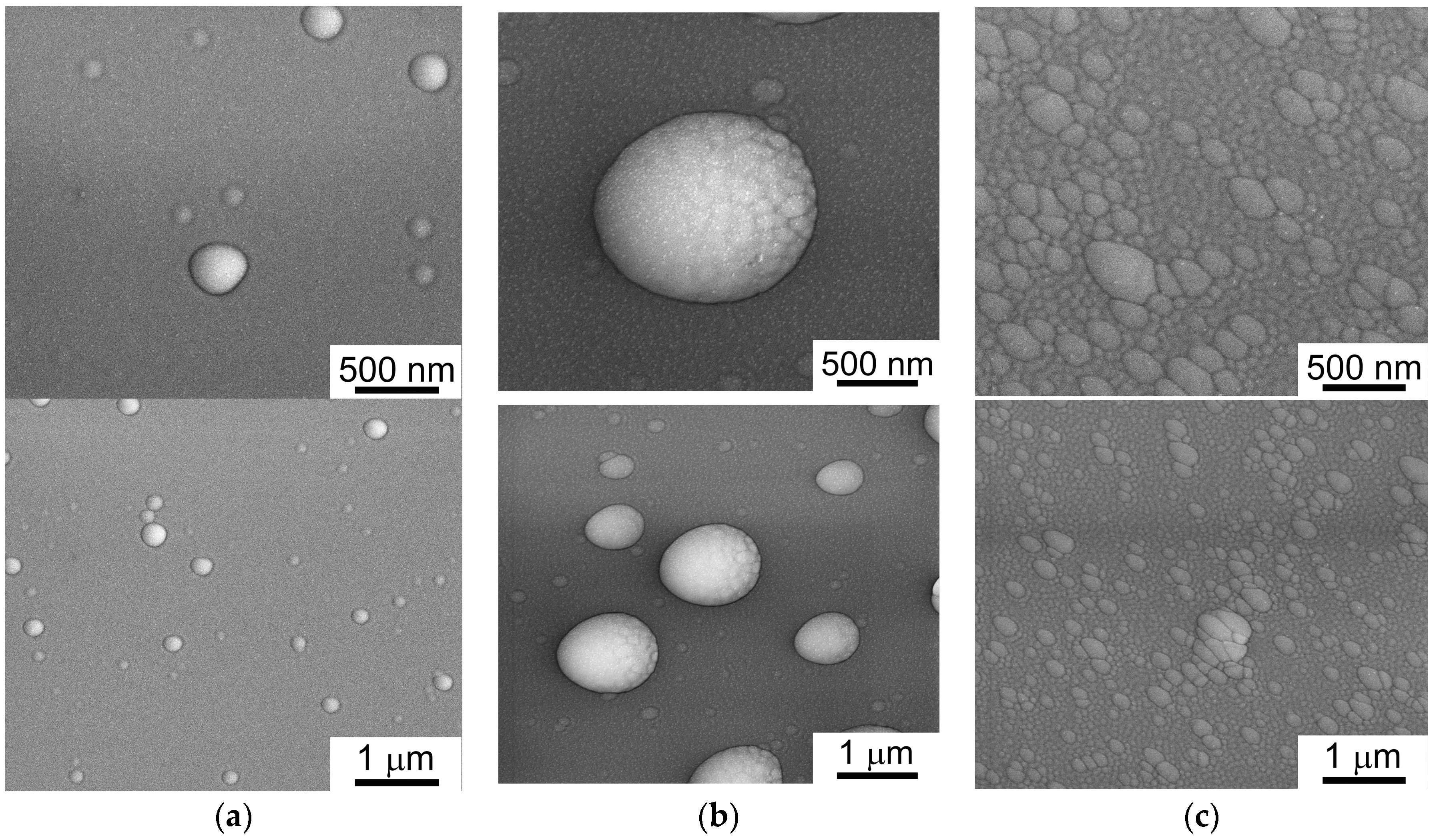

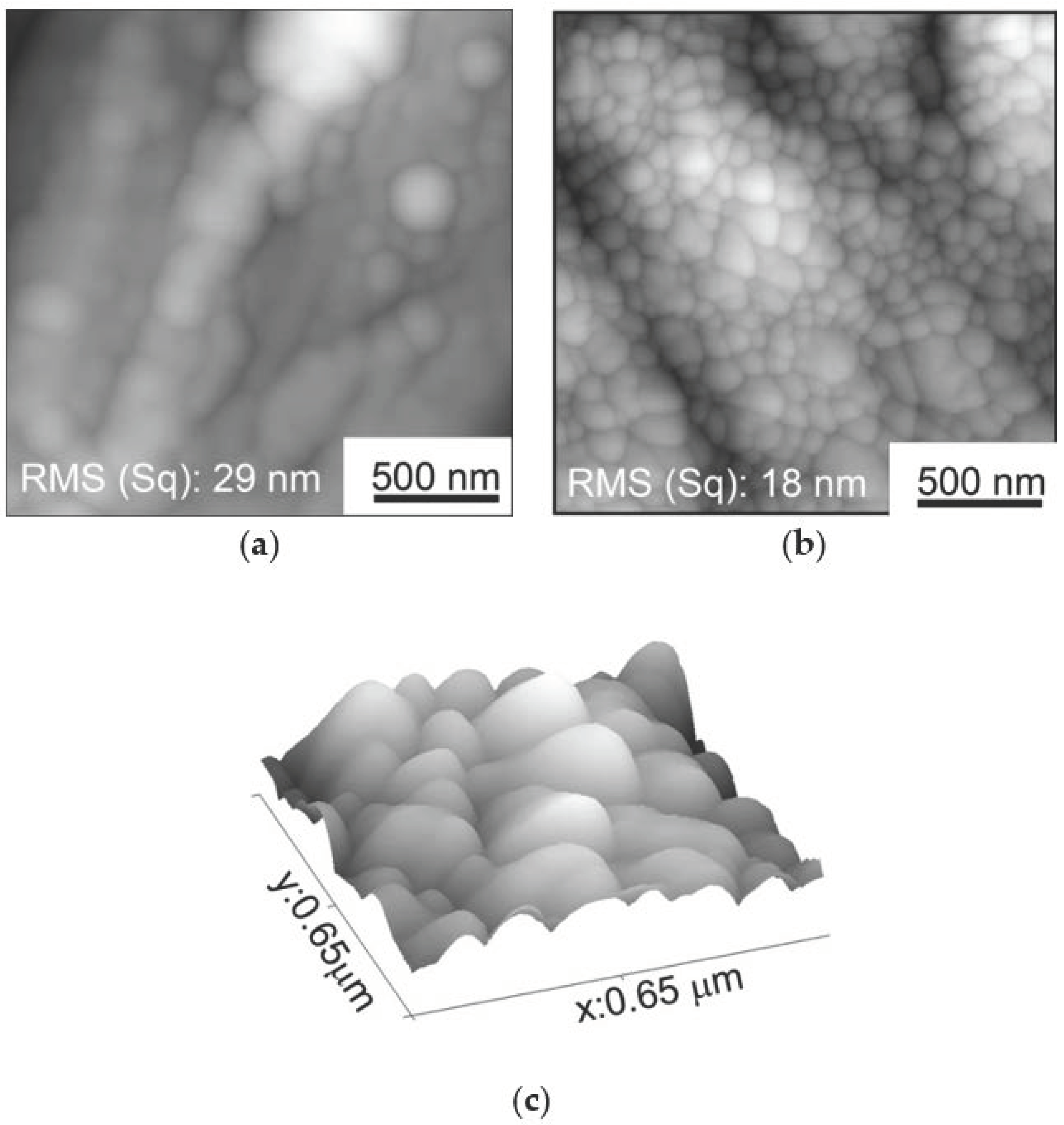

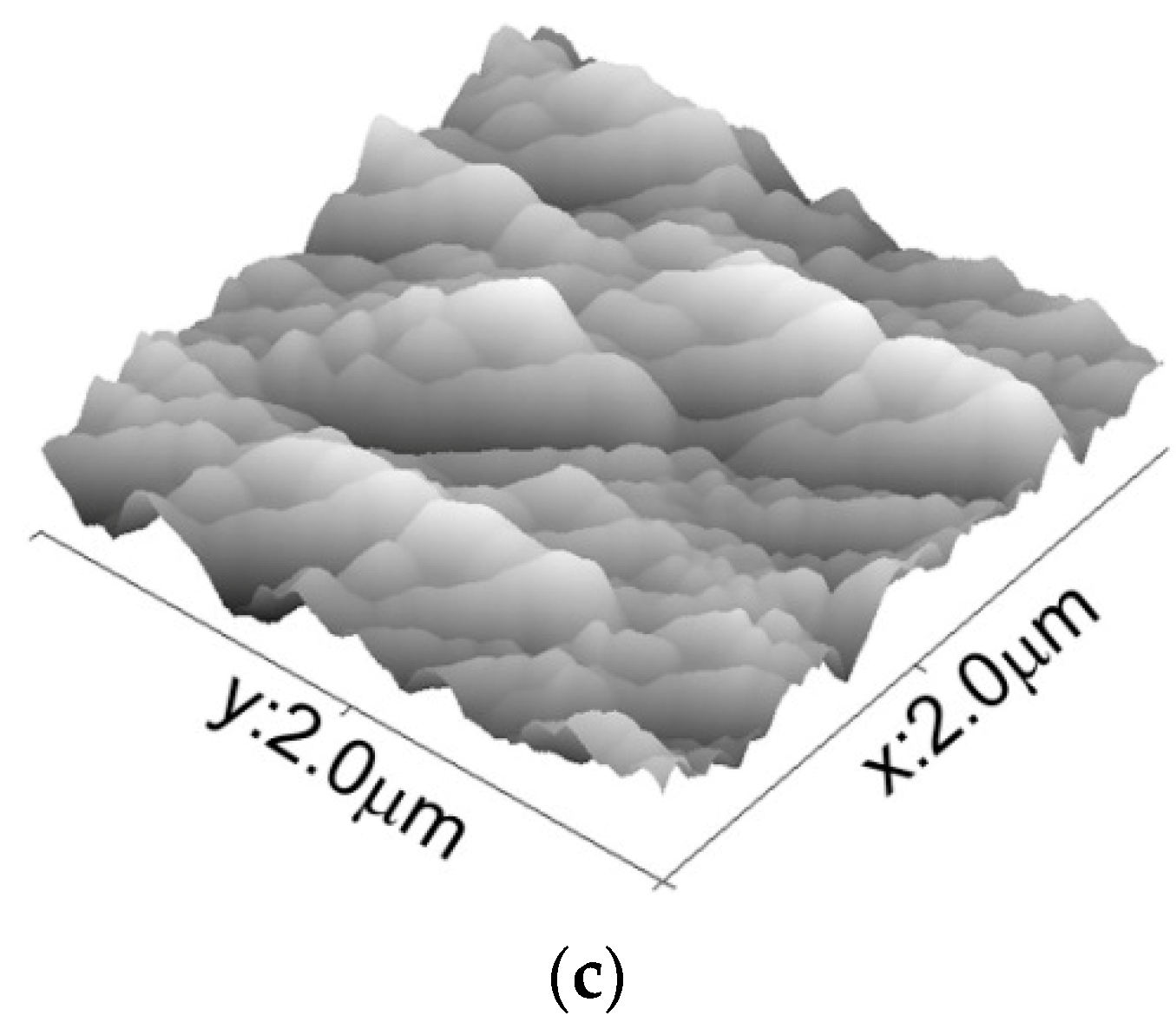

3.2. Effect of GLAD on Coating Topography and Roughness

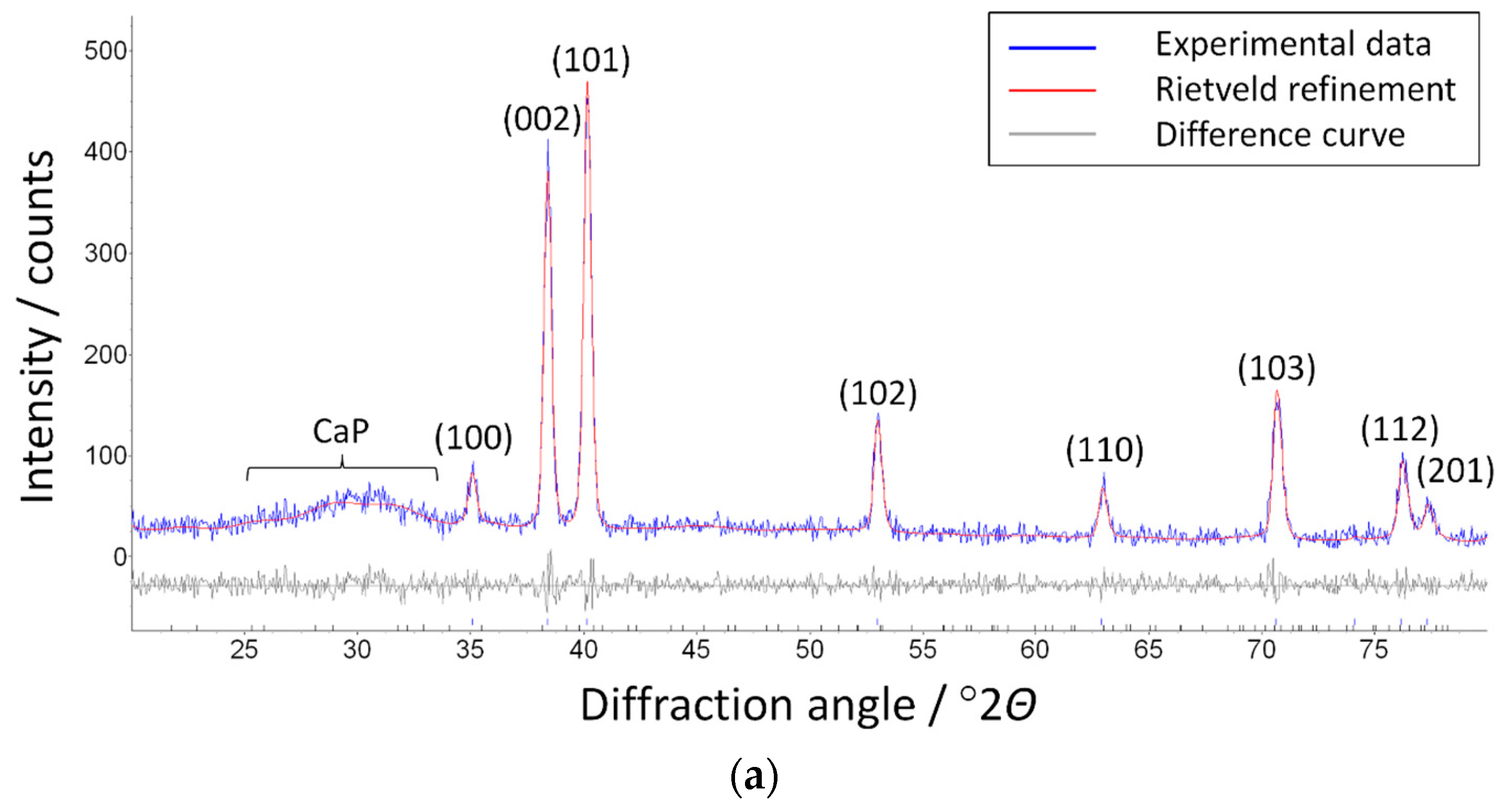

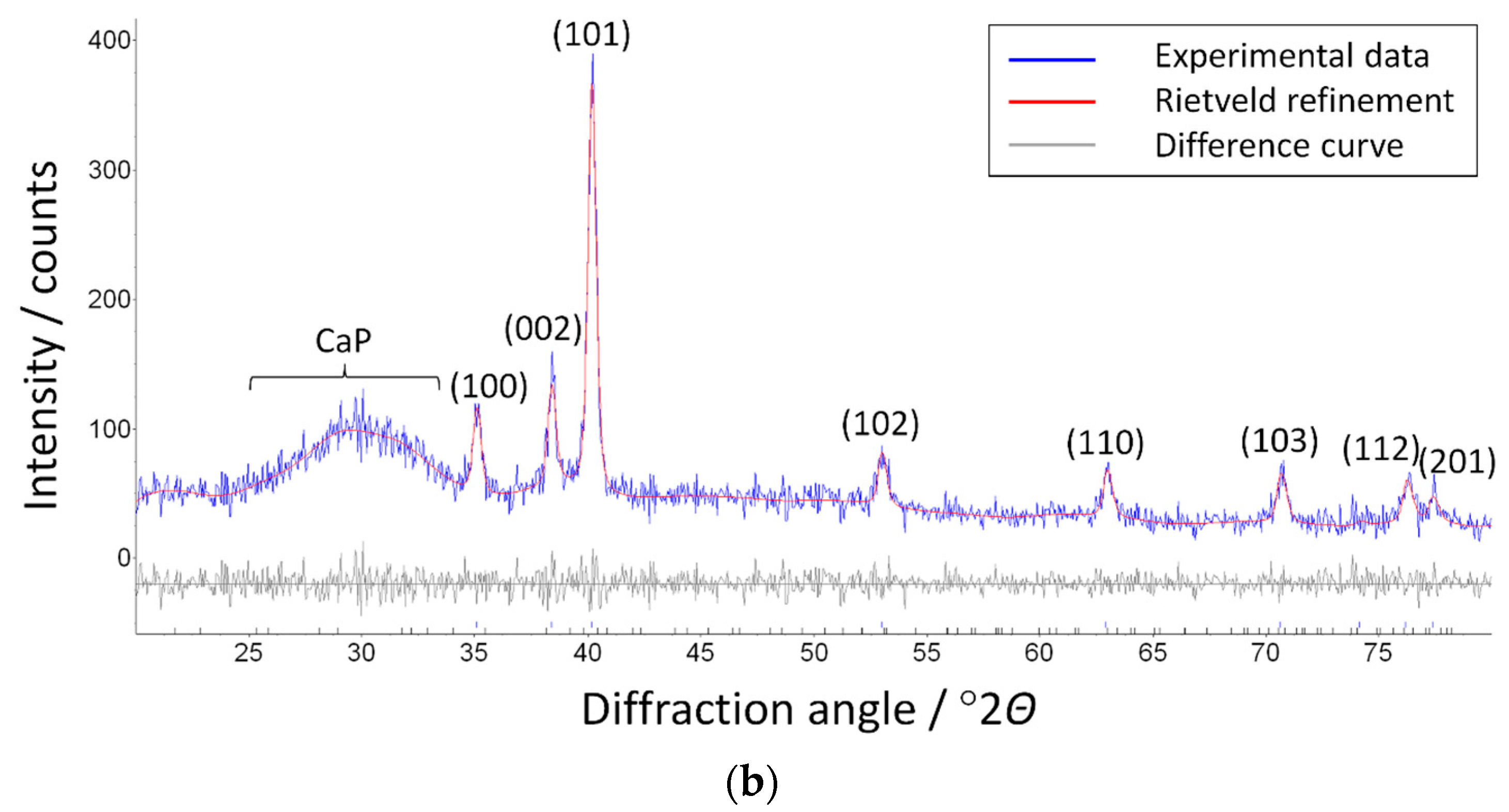

3.3. Effect of GLAD on Coating Crystallinity and Scratch Resistance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, J.; Yang, L.; Guo, X.; Cui, W.; Yang, S.; Wang, J.; Qu, Y.; Shao, Z.; Xu, S. Osteogenesis effects of strontium-substituted hydroxyapatite coatings on true bone ceramic surfaces in vitro and in vivo. Biomed. Mater. 2018, 13, 015018. [Google Scholar] [CrossRef]

- Vladescu, A.; Surmenev, R.; Surmeneva, M.; Braic, M.; Ivanova, A.; Grubova, I.; Cotrut, C.M. Radio frequency magnetron sputter deposition as a tool for surface modification of medical implants. In Modern Technologies for Creating the Thin-Film Systems and Coatings; Nikitenkov, N., Ed.; InTech: Rijeka, Croatia, 2017. [Google Scholar]

- Raphel, J.; Holodniy, M.; Goodman, S.B.; Heilshorn, S.C. Multifunctional coatings to simultaneously promote osseointegration and prevent infection of orthopaedic implants. Biomaterials 2016, 84, 301–314. [Google Scholar] [CrossRef] [PubMed]

- Šupová, M. Substituted hydroxyapatites for biomedical applications: A review. Ceram. Int. 2015, 41, 9203–9231. [Google Scholar] [CrossRef]

- Rau, J.V.; Cacciotti, I.; De Bonis, A.; Fosca, M.; Komlev, V.S.; Latini, A.; Santagata, A.; Teghil, R. Fe-doped hydroxyapatite coatings for orthopedic and dental implant applications. Appl. Surf. Sci. 2014, 307, 301–305. [Google Scholar] [CrossRef]

- Graziani, G.; Bianchi, M.; Sassoni, E.; Russo, A.; Marcacci, M. Ion-substituted calcium phosphate coatings deposited by plasma-assisted techniques: A review. Mater. Sci. Eng. C 2017, 74, 219–229. [Google Scholar] [CrossRef]

- Robinson, L.; Salma-Ancane, K.; Stipniece, L.; Meenan, B.J.; Boyd, A.R. The deposition of strontium and zinc Co-substituted hydroxyapatite coatings. J. Mater. Sci. Mater. Med. 2017, 28, 51. [Google Scholar] [CrossRef]

- Koo, H.; Allan, R.N.; Howlin, R.P.; Stoodley, P.; Hall-Stoodley, L. Targeting microbial biofilms: Current and prospective therapeutic strategies. Nat. Rev. Microbiol. 2017, 15, 740–755. [Google Scholar] [CrossRef] [PubMed]

- Geng, Z.; Cui, Z.; Li, Z.; Zhu, S.; Liang, Y.; Liu, Y.; Li, X.; He, X.; Yu, X.; Wang, R.; et al. Strontium incorporation to optimize the antibacterial and biological characteristics of silver-substituted hydroxyapatite coating. Mater. Sci. Eng. C 2016, 58, 467–477. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, X.; Zhao, R.; Mao, H.; Yan, Y.; Pang, X. Antibacterial efficacy, corrosion resistance, and cytotoxicity studies of copper-substituted carbonated hydroxyapatite coating on titanium substrate. J. Mater. Sci. 2015, 50, 1688–1700. [Google Scholar] [CrossRef]

- Peñaflor Galindo, T.G.; Kataoka, T.; Fujii, S.; Okuda, M.; Tagaya, M. Preparation of nanocrystalline zinc-substituted hydroxyapatite films and their biological properties. Colloids Interface Sci. Commun. 2016, 10, 15–19. [Google Scholar] [CrossRef]

- Litvinova, L.S.; Shupletsova, V.V.; Dunets, N.A.; Khaziakhmatova, O.G.; Yurova, K.A.; Khlusova, M.Y.; Slepchenko, G.B.; Cherempey, E.G.; Sharkeev, Y.P.; Komarova, E.G.; et al. Imbalance of morphofunctional responses of Jurkat T lymphoblasts at short-term culturing with relief zinc- or copper-containing calcium phosphate coating on titanium. Dokl. Biochem. Biophys. 2017, 472, 35–39. [Google Scholar] [CrossRef]

- Graziani, G.; Boi, M.; Bianchi, M. A Review on Ionic Substitutions in Hydroxyapatite Thin Films: Towards Complete Biomimetism. Coatings 2018, 8, 269. [Google Scholar] [CrossRef]

- Rau, J.V.; Cacciotti, I.; Laureti, S.; Fosca, M.; Varvaro, G.; Latini, A. Bioactive, nanostructured Si-substituted hydroxyapatite coatings on titanium prepared by pulsed laser deposition. J. Biomed. Mater. Res. B Appl. Biomater. 2015, 103, 1621–1631. [Google Scholar] [CrossRef] [PubMed]

- Modaresifar, K.; Azizian, S.; Ganjian, M.; Fratila-Apachitei, L.E.; Zadpoor, A.A. Bactericidal effects of nanopatterns: A systematic review. Acta Biomater. 2018, 83, 29–36. [Google Scholar] [CrossRef]

- Yu, W.; Sun, T.W.; Qi, C.; Ding, Z.; Zhao, H.; Zhao, S.; Shi, Z.; Zhu, Y.J.; Chen, D.; He, Y. Evaluation of zinc-doped mesoporous hydroxyapatite microspheres for the construction of a novel biomimetic scaffold optimized for bone augmentation. Int. J. Nanomed. 2017, 12, 2293–2306. [Google Scholar] [CrossRef] [PubMed]

- Costa, D.O.; Prowse, P.D.H.; Chrones, T.; Sims, S.M.; Hamilton, D.W.; Rizkalla, A.S.; Dixon, S.J. The differential regulation of osteoblast and osteoclast activity bysurface topography of hydroxyapatite coatings. Biomaterials 2013, 34, 7215–7226. [Google Scholar] [CrossRef] [PubMed]

- Rau, J.V.; Generosi, A.; Laureti, S.; Komlev, V.S.; Ferro, D.; Cesaro, S.N.; Paci, B.; Albertini, V.R.; Agostinelli, E.; Barinov, S.M. Physicochemical investigation of pulsed laser deposited carbonated hydroxyapatite films on titanium. ACS Appl. Mater. Interfaces 2009, 1, 1813–1820. [Google Scholar] [CrossRef]

- Kim, H.N.; Jiao, A.; Hwang, N.S.; Kim, M.S.; Kang, D.H.; Kim, D.H.; Suh, K.Y. Nanotopography-guided tissue engineering and regenerative medicine. Adv. Drug Deliv. Rev. 2013, 65, 536–558. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Bachhuka, A.; Wei, F.; Wang, X.; Liu, G.; Vasilev, K.; Xiao, Y. Nanotopography-based strategy for the precise manipulation of osteoimmunomodulation in bone regeneration. Nanoscale 2017, 9, 18129–18152. [Google Scholar] [CrossRef]

- Lee, L.C.Y.; Gadegaard, N.; de Andrés, M.C.; Turner, L.A.; Burgess, K.V.; Yarwood, S.J.; Wells, J.; Salmeron-Sanchez, M.; Meek, D.; Oreffo, R.O.C.; et al. Nanotopography controls cell cycle changes involved with skeletal stem cell self-renewal and multipotency. Biomaterials 2017, 116, 10–20. [Google Scholar] [CrossRef]

- Karazisis, D.; Petronis, S.; Agheli, H.; Emanuelsson, L.; Norlindh, B.; Johansson, A.; Rasmusson, L.; Thomsen, P.; Omar, O. The influence of controlled surface nanotopography on the early biological events of osseointegration. Acta Biomater. 2017, 53, 559–571. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, R.; Garcia-Martin, J.M.; Garcia-Valenzuela, A.; Macias-Montero, M.; Ferrer, F.J.; Santiso, J.; Rico, V.; Cotrino, J.; Gonzalez-Elipe, A.R.; Palmero, A. Nanostructured Ti thin films by magnetron sputtering at oblique angles. J. Phys. D. Appl. Phys. 2015, 49, 045303. [Google Scholar] [CrossRef]

- Li, Z.; Xing, L.; Zhang, N.; Yang, Y.; Zhang, Z. Preparation and Photocatalytic Property of TiO2 Columnar Nanostructure Films. Mater. Trans. 2011, 52, 1939–1942. [Google Scholar] [CrossRef]

- Garcia-Valenzuela, A.; Alvarez, R.; Rico, V.; Cotrino, J.; Gonzalez-Elipe, A.R.; Palmero, A. Growth of nanocolumnar porous TiO2 thin films by magnetron sputtering using particle collimators. Surf. Coat. Technol. 2017, 343, 172–177. [Google Scholar] [CrossRef]

- Sit, J.C.; Vick, D.; Robbie, K.; Brett, M.J. Thin film microstructure control using glancing angle deposition by sputtering. J. Mater. Res. 1999, 14, 1197–1199. [Google Scholar] [CrossRef]

- Zhao, Y.; Ye, D.; Wang, G.-C.; Lu, T.-M. Designing nanostructures by glancing angle deposition. Proc. SPIE Nanotub. Nanowires 2003, 5219, 59–73. [Google Scholar] [CrossRef]

- Barranco, A.; Borras, A.; Gonzalez-Elipe, A.R.; Palmero, A. Perspectives on oblique angle deposition of thin films: From fundamentals to devices. Prog. Mater. Sci. 2016, 76, 59–153. [Google Scholar] [CrossRef]

- Renault, C.; Harris, K.D.; Brett, M.J.; Balland, V.; Limoges, B. Time-resolved UV-visible spectroelectrochemistry using transparent 3D-mesoporous nanocrystalline ITO electrodes. Chem. Commun. 2011, 47, 1863–1865. [Google Scholar] [CrossRef]

- Larsen, G.K.; Fitzmorris, R.; Zhang, J.Z.; Zhao, Y. Structural, optical, and photocatalytic properties of Cr:TiO2 nanorod array fabricated by oblique angle codeposition. J. Phys. Chem. C 2011, 115, 16892–16903. [Google Scholar] [CrossRef]

- Schubert, M.F.; Xi, J.Q.; Kim, J.K.; Schubert, E.F. Distributed Bragg reflector consisting of high- and low-refractive-index thin film layers made of the same material. Appl. Phys. Lett. 2007, 90, 141115. [Google Scholar] [CrossRef]

- Rider, D.A.; Tucker, R.T.; Worfolk, B.J.; Krause, K.M.; Lalany, A.; Brett, M.J.; Buriak, J.M.; Harris, K.D. Indium tin oxide nanopillar electrodes in polymer/fullerene solar cells. Nanotechnology 2011, 22, 085706. [Google Scholar] [CrossRef]

- Jensen, M.O.; Brett, M.J. Porosity engineering in glancing angle deposition thin films. Appl. Phys. A Mater. Sci. Process. 2005, 80, 763–768. [Google Scholar] [CrossRef]

- Lintymer, J.; Martin, N.; Chappe, J.M.; Takadoum, J. Glancing angle deposition to control microstructure and roughness of chromium thin films. Wear 2008, 264, 444–449. [Google Scholar] [CrossRef]

- Hung, K.-Y.; Lai, H.-C.; Feng, H.-P. Characteristics of RF-Sputtered Thin Films of Calcium Phosphate on Titanium Dental Implants. Coatings 2017, 7, 126. [Google Scholar] [CrossRef]

- Surmenev, R.A.; Surmeneva, M.A.; Grubova, I.Y.; Chernozem, R.V.; Krause, B.; Baumbach, T.; Loza, K.; Epple, M. RF magnetron sputtering of a hydroxyapatite target: A comparison study on polytetrafluorethylene and titanium substrates. Appl. Surf. Sci. 2017, 414, 335–344. [Google Scholar] [CrossRef]

- Thian, E.S.; Konishi, T.; Kawanobe, Y.; Lim, P.N.; Choong, C.; Ho, B.; Aizawa, M. Zinc-substituted hydroxyapatite: A biomaterial with enhanced bioactivity and antibacterial properties. J. Mater. Sci. Mater. Med. 2013, 24, 437–445. [Google Scholar] [CrossRef] [PubMed]

- Prosolov, K.A.; Belyavskaya, O.A.; Muehle, U.; Sharkeev, Y.P. Thin bioactive Zn substituted hydroxyapatite coating deposited on ultrafine-grained titanium substrate: Structure analysis. Front. Mater. 2018, 5, 3. [Google Scholar] [CrossRef]

- Prosolov, K.A.; Belyavskaya, O.A.; Rau, J.V.; Sharkeev, Y.P. Thin bioactive Zn-substituted hydroxyapatite coating deposited on Ti substrate by radiofrequency sputtering. High Temp. Mater. Process. 2017, 21, 3. [Google Scholar] [CrossRef]

- Solar, P.; Choukourov, A.; Hanus, J.; Pavlova, E.; Slavinska, D.; Biederman, H. Nanocomposite structured thin films by magnetron sputtering at glancing angle deposition. In Proceedings of the International Plasma Chemistry Society, Bochum, Germany, 27–31 July 2009; p. 226. [Google Scholar]

- Pang, H.F.; Zhang, G.A.; Tang, Y.L.; Fu, Y.Q.; Wang, L.P.; Zu, X.T.; Placido, F. Substrate-tilt angle effect on structural and optical properties of sputtered ZnO film. Appl. Surf. Sci. 2012, 259, 747–753. [Google Scholar] [CrossRef]

- Toledano, D.; Galindo, R.E.; Yuste, M.; Albella, J.M.; Sánchez, O. Compositional and structural properties of nanostructured ZnO thin films grown by oblique angle reactive sputtering deposition: Effect on the refractive index. J. Phys. D Appl. Phys. 2013, 46, 045306. [Google Scholar] [CrossRef]

- Leem, J.W.; Yu, J.S. Structural, optical, and electrical properties of AZO films by tilted angle sputtering method. Thin Solid Films 2010, 518, 6285–6288. [Google Scholar] [CrossRef]

- García-Martín, J.M.; Alvarez, R.; Romero-Gómez, P.; Cebollada, A.; Palmero, A. Tilt angle control of nanocolumns grown by glancing angle sputtering at variable argon pressures. Appl. Phys. Lett. 2010, 97, 173103. [Google Scholar] [CrossRef]

- Siad, A.; Besnard, A.; Nouveau, C.; Jacquet, P. Critical angles in DC magnetron glad thin films. Vacuum 2016, 131, 305–311. [Google Scholar] [CrossRef]

- Park, Y.J.; Sobahan, K.M.A.; Nam, H.J.; Kim, J.J.; Hwangbo, C.K. Optical and structural properties of ZnO thin films fabricated by using oblique angle deposition. J. Korean Phys. Soc. 2010, 57, 1657–1660. [Google Scholar]

- Bolbasov, E.N.; Maryin, P.V.; Stankevich, K.S.; Kozelskaya, A.I.; Shesterikov, E.V.; Khodyrevskaya, Y.I.; Nasonova, M.V.; Shishkova, D.K.; Kudryavtseva, Y.A.; Anissimov, Y.G.; et al. Surface modification of electrospun poly-(L-lactic) acid scaffolds by reactive magnetron sputtering. Colloids Surf. B Biointerfaces 2018, 162, 43–51. [Google Scholar] [CrossRef]

- Bolbasov, E.N.; Antonova, L.V.; Stankevich, K.S.; Ashrafov; Matveeva, V.G.; Velikanova, E.A.; Khodyrevskaya, Y.I.; Kudryavtseva, Y.A.; Anissimov, Y.G.; Tverdokhlebov, S.I.; et al. The use of magnetron sputtering for the deposition of thin titanium coatings on the surface of bioresorbable electrospun fibrous scaffolds for vascular tissue engineering: A pilot study. Appl. Surf. Sci. 2017, 398, 63–72. [Google Scholar] [CrossRef]

- Ivanova, A.A.; Surmeneva, M.A.; Surmenev, R.A.; Depla, D. Structural evolution and growth mechanisms of RF-magnetron sputter-deposited hydroxyapatite thin films on the basis of unified principles. Appl. Surf. Sci. 2017, 425, 497–506. [Google Scholar] [CrossRef]

- Chu, J.; Peng, X.; Sajjad, M.; Yang, B.; Feng, P.X. Nanostructures and sensing properties of ZnO prepared using normal and oblique angle deposition techniques. Thin Solid Films 2012, 520, 3493–3498. [Google Scholar] [CrossRef]

- Black, D.R.; Windover, D.; Henins, A.; Filliben, J.; Cline, J.P. Certification of Standard Reference Material 1976B. Powder Diffr. 2015, 30, 199–204. [Google Scholar] [CrossRef]

- Ter Brugge, P.J.; Wolke, J.G.C.; Jansen, J.A. Effect of calcium phosphate coating crystallinity and implant surface roughness on differentiation of rat bone marrow cells. J. Biomed. Mater. Res. 2002, 60, 70–78. [Google Scholar] [CrossRef]

- Gruener, C.; Liedtke, S.; Bauer, J.; Mayr, S.G.; Rauschenbach, B. Morphology of thin films formed by oblique physical vapor deposition. ACS Appl. Nano Mater. 2018, 1, 1370–1376. [Google Scholar] [CrossRef]

- Gross, K.; Berndt, C. Thermal processing of hydroxyapatite for coating production. J. Biomed. Mater. Res. 1998, 39, 580–587. [Google Scholar] [CrossRef]

- Sarkar, S.; Pradhan, S.K. Tailoring of optical and wetting properties of sputter deposited silica thin films by glancing angle deposition. Appl. Surf. Sci. 2014, 290, 509–513. [Google Scholar] [CrossRef]

- Yonggang, Y.; Wolke, J.G.C.; Yubao, L.; Jansen, J.A. The influence of discharge power and heat treatment on calcium phosphate coatings prepared by RF magnetron sputtering deposition. J. Mater. Sci. Mater. Med. 2007, 18, 1061–1069. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.T.; Liu, J.X.; Mi, Z.L.; Zhao, A.M.; Bi, Y.J. Texture evolution of commercial pure Ti during cold rolling and recrystallization annealing. Int. J. Miner. Metall. Mater. 2012, 19, 530–535. [Google Scholar] [CrossRef]

- Ghosh, A.; Gurao, N.P. Effect of crystallographic texture on ratcheting response of commercially pure titanium. Mater. Des. 2017, 115, 121–132. [Google Scholar] [CrossRef]

- Grubova, I.Y.; Surmeneva, M.A.; Ivanova, A.A.; Kravchuk, K.; Prymak, O.; Epple, M.; Buck, V.; Surmenev, R.A. The effect of patterned titanium substrates on the properties of silver-doped hydroxyapatite coatings. Surf. Coat. Technol. 2015, 276, 595–601. [Google Scholar] [CrossRef]

- Surmeneva, M.A.; Sharonova, A.A.; Chernousova, S.; Prymak, O.; Loza, K.; Tkachev, M.S.; Shulepov, I.A.; Epple, M.; Surmenev, R.A. Incorporation of silver nanoparticles into magnetron-sputtered calcium phosphate layers on titanium as an antibacterial coating. Colloids Surf. B Biointerfaces 2017, 156, 104–113. [Google Scholar] [CrossRef]

- Syromotina, D.S.; Surmeneva, M.A.; Gorodzha, S.N.; Pichugin, V.F.; Ivanova, A.A.; Grubova, I.Y.; Kravchuk, K.S.; Gogolinskii, K.V.; Prymak, O.; Epple, M.; et al. Physical-mechanical characteristics of RF magnetron sputter-deposited coatings based on silver-doped hydroxyapatite. Russ. Phys. J. 2014, 56, 1198–1205. [Google Scholar] [CrossRef]

- Melnik, Y.A.; Metel, A.S. Improvement of the magnetron sputtered coating adhesion through pulsed bombardment by high-energy ions. J. Phys. Conf. Ser. 2017, 830, 012099. [Google Scholar] [CrossRef]

| Ref. | Method | Aim of Research | Target | Substrate | Deposition Parameters | Result |

|---|---|---|---|---|---|---|

| [23] | DC magnetron sputtering | The expansion of the well-known model of the Thornton spatial zone, including the inclination angle of the substrate as an additional degree of freedom | Ti | Si (100) | L = 22 cm | For α = 70°, a columnar morphology was formed consisting of vertically aligned and well-separated columns with diameters ranging from 50 to 100 nm. For angles of α = 80° and α = 85°, the structure was rather similar. |

| t = 90–200 min | ||||||

| P = 0.15–1.5 Pa | ||||||

| W = 300 W | ||||||

| [40] | DC magnetron sputtering | The effect of changing various parameters on the roughness | Mo and Ti/C:H | Silicon and Glass | L = 7–10 cm | The manipulation of the substrate led to the formation of a zigzag columnar structure. The films prepared in the range of 40–85° showed an increase in the RMS value of roughness from 7 to 55 nm. |

| P = 0.08; 0.16 Pa | ||||||

| [41] | DC magnetron sputtering | Influence on structural and optical properties | ZnO | Si (100) | L = 15 cm | The typical columnar structure was inclined and compact. SEM images showed that the typical columnar structure was inclined, and the column inclination angle was changed from 0 to 34°. From XRD analysis, it was shown that the strains in the ZnO films decreased with the substrate tilt angle. |

| t = 180 min | ||||||

| P = 0.64 Pa | ||||||

| W = 400 W | ||||||

| [42] | Reactive magnetron sputtering | Effect on the refractive index | ZnO | Si (100) | L = 14; 28.5 cm | The films were porous and of an inclined columnar structure, with columns tilting in the direction of the incident flux. |

| t = 30 min | ||||||

| P = 0.3 Pa | ||||||

| W = 100 W | ||||||

| [43] | RF magnetron sputtering | Structural, optical, and electrical properties of zinc oxide (AZO) films doped with aluminum on Si substrate | AZO (aluminum-doped zinc oxide) | Si (100) | L = 15 cm | The deposited AZO films had nanocolumnar structures. In tilted angle sputtering, the nanocolumns were tilted away from the surface normal to the incident AZO flux direction. When the substrate was not rotated, the nanocolumn inclination increased with apparently distinguishable grain boundaries as the tilted angle became larger. |

| P = 0.67 Pa | ||||||

| W = 50–150 W | ||||||

| [44] | DC magnetron sputtering | Study of the effect of gas pressure (Ar) on the columnar growth of gold nanostructures, and a comparison of morphology with theoretical modeling. | Au | Si (100) | L = 19 cm | At low pressures, a ballistic deposition regime dominated, yielding high directional atoms that form tilted nanocolumns. Higher pressure led to a diffusive regime, which gave rise to vertical columnar growth. |

| t = 30 min | ||||||

| P = 0.15–0.4 Pa | ||||||

| W = 100 W | ||||||

| [24] | DC magnetron sputtering | To increase the photocatalytic activity | Ti | Si | L = 11 cm | TiO2 samples had adiscrete columnar nanostructure and efficiently performed a photocatalytic decolorization under UV radiation. |

| P = 0.11 Pa | ||||||

| W = 200 W | ||||||

| [25] | Reactive magnetron sputtering | The influence of collimators on the growth of highly porous structures | Ti | Si and Quartz | L = 7; 10 cm | Particle collimators allowed for the growth of highly porous nanocolumnar thin films independently from the thermal degree of the sputtered particles. Using collimators, similar well-defined tilted nanocolumnar structures were prepared independently of the plasma pressure during the deposition. |

| t = 210; 360 min | ||||||

| P = 0.2; 0.5; 0.8 Pa | ||||||

| [45] | DC magnetron sputtering | Identification of the presence of critical zones in certain properties of inclined columnar coatings | Al, Ti, Cr | Si (100) | L = 10.5 cm | Chromium coatings presented elongated columns perpendicular to the main direction of the incident flux. Titanium coatings had a dense nodular morphology. At an angle of 85°, the aluminum coatings had a rough surface with crystallite columns randomly distributed and oriented towards the target. The high aluminum adatoms mobility explained the dense film at normal deposition and the formation of large crystals with high porosity at an oblique angle. The chromium films still present elongated columns perpendicular to the main direction of the incident flux. |

| t = 16; 19; 35 min | ||||||

| P = 0.09 Pa | ||||||

| W = 1500 W | ||||||

| [46] | RF magnetron sputtering | Optical and the structural properties | ZnO | Si (100) | L = 10 cm | The GLAD ZnO films were mixtures of columnar structure and pores. The highly-oriented columnar structure of slanted columns indicated that the GLAD ZnO films were anisotropic with the long axis parallel to the columnar growth direction. This anisotropic structure will introduce an anisotropic dependence into the optical, electrical, thermal, and magnetic properties of the films. |

| t = 16; 19; 35 min | ||||||

| P = 0.67 Pa | ||||||

| W = 80 W |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prosolov, K.A.; Belyavskaya, O.A.; Linders, J.; Loza, K.; Prymak, O.; Mayer, C.; Rau, J.V.; Epple, M.; Sharkeev, Y.P. Glancing Angle Deposition of Zn-Doped Calcium Phosphate Coatings by RF Magnetron Sputtering. Coatings 2019, 9, 220. https://doi.org/10.3390/coatings9040220

Prosolov KA, Belyavskaya OA, Linders J, Loza K, Prymak O, Mayer C, Rau JV, Epple M, Sharkeev YP. Glancing Angle Deposition of Zn-Doped Calcium Phosphate Coatings by RF Magnetron Sputtering. Coatings. 2019; 9(4):220. https://doi.org/10.3390/coatings9040220

Chicago/Turabian StyleProsolov, Konstantin A., Olga A. Belyavskaya, Juergen Linders, Kateryna Loza, Oleg Prymak, Christian Mayer, Julietta V. Rau, Matthias Epple, and Yurii P. Sharkeev. 2019. "Glancing Angle Deposition of Zn-Doped Calcium Phosphate Coatings by RF Magnetron Sputtering" Coatings 9, no. 4: 220. https://doi.org/10.3390/coatings9040220

APA StyleProsolov, K. A., Belyavskaya, O. A., Linders, J., Loza, K., Prymak, O., Mayer, C., Rau, J. V., Epple, M., & Sharkeev, Y. P. (2019). Glancing Angle Deposition of Zn-Doped Calcium Phosphate Coatings by RF Magnetron Sputtering. Coatings, 9(4), 220. https://doi.org/10.3390/coatings9040220