The Fabrication of a UV Notch Filter by Using Solid State Diffusion

Abstract

1. Introduction

2. Experimental

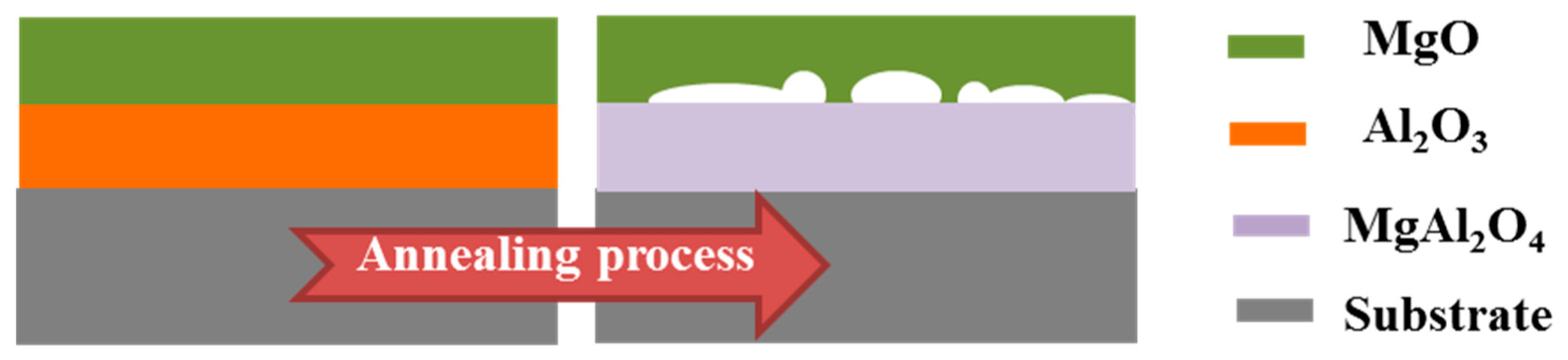

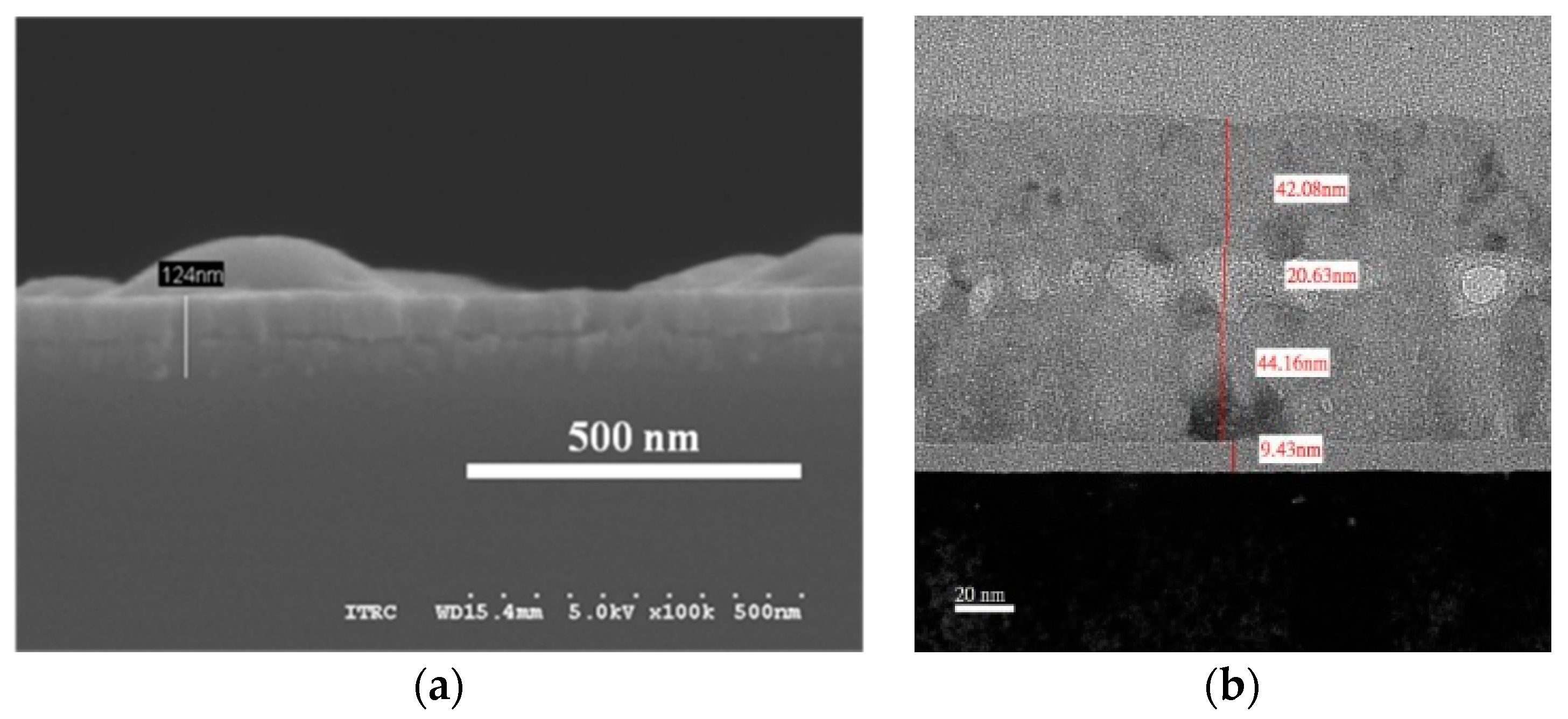

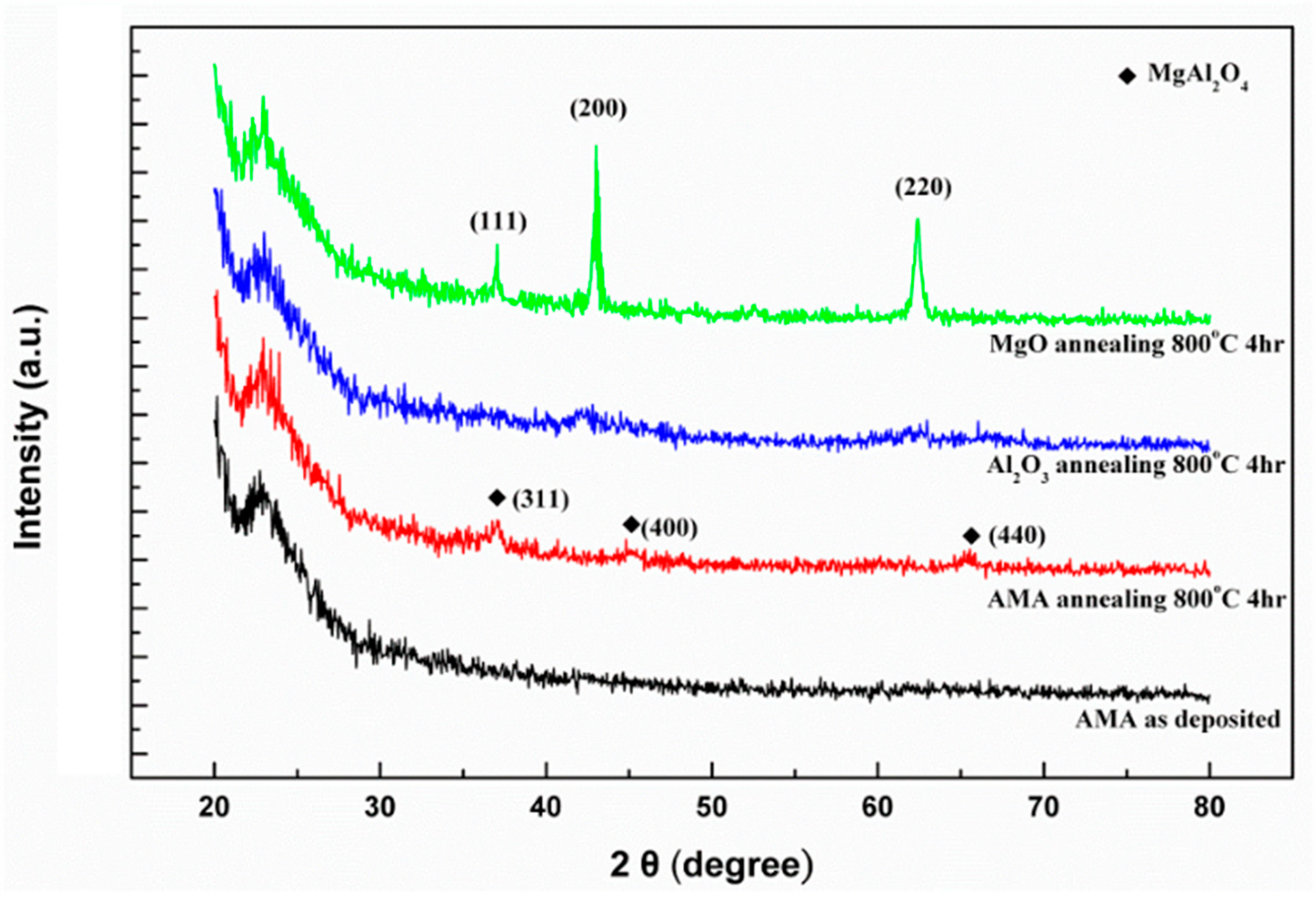

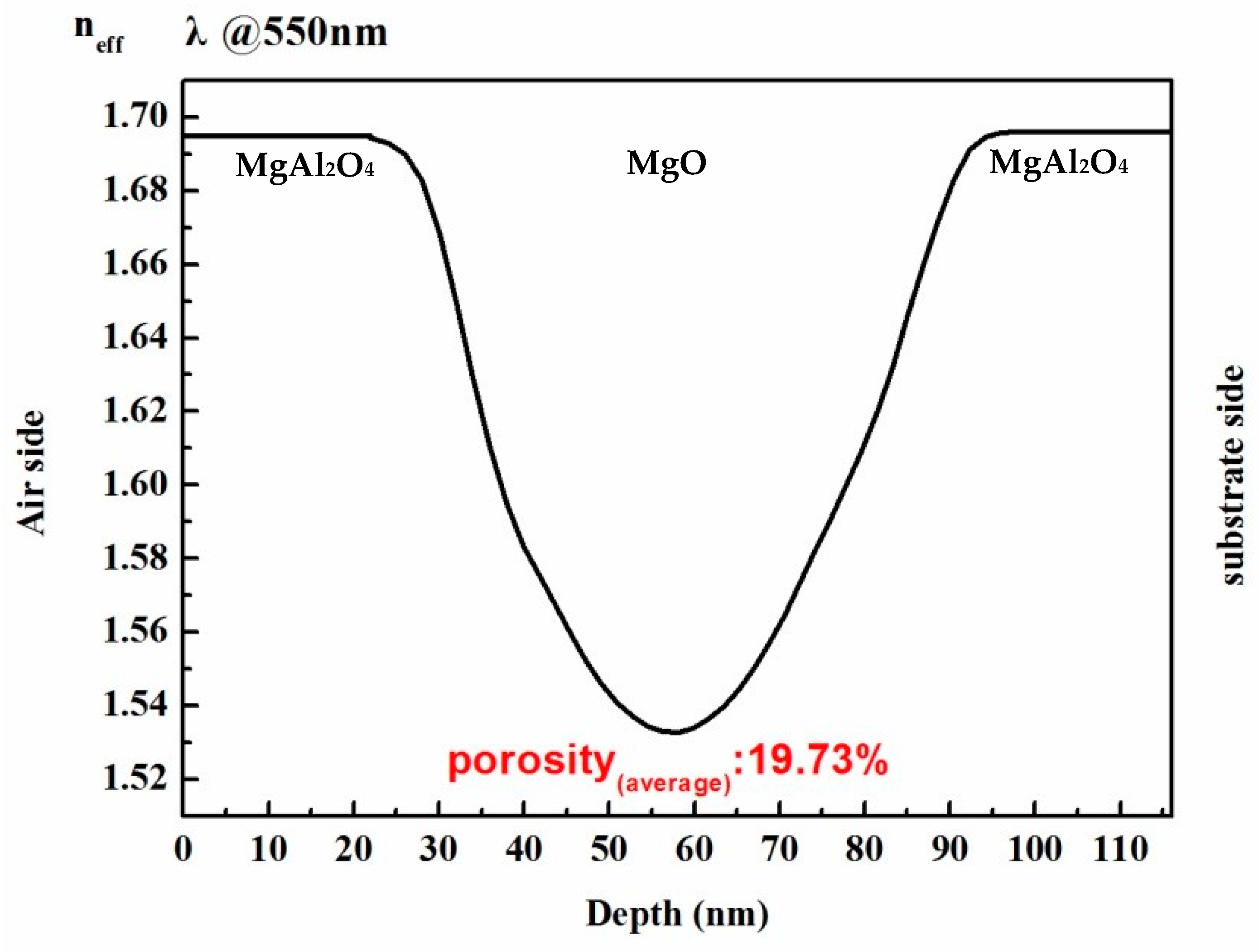

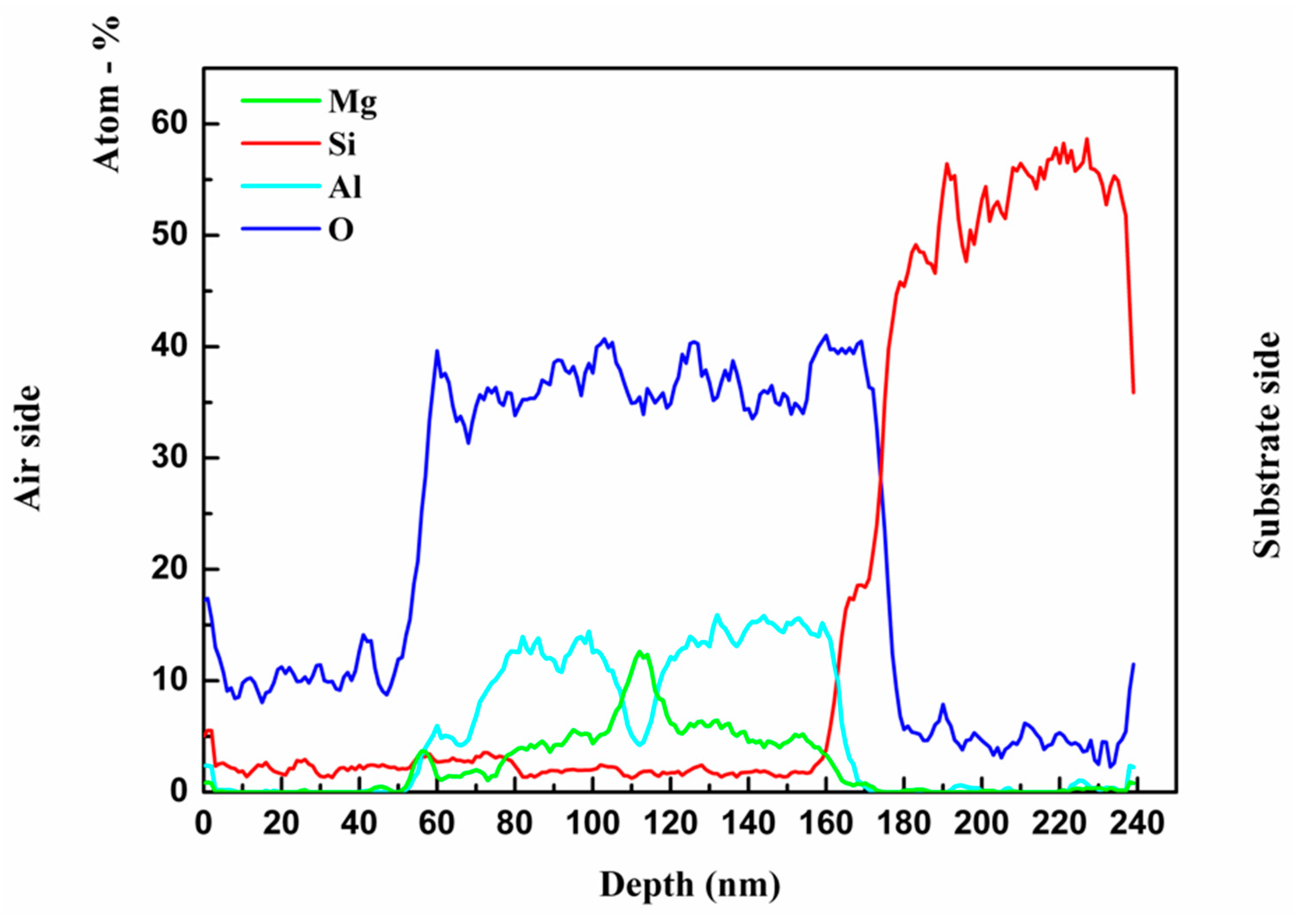

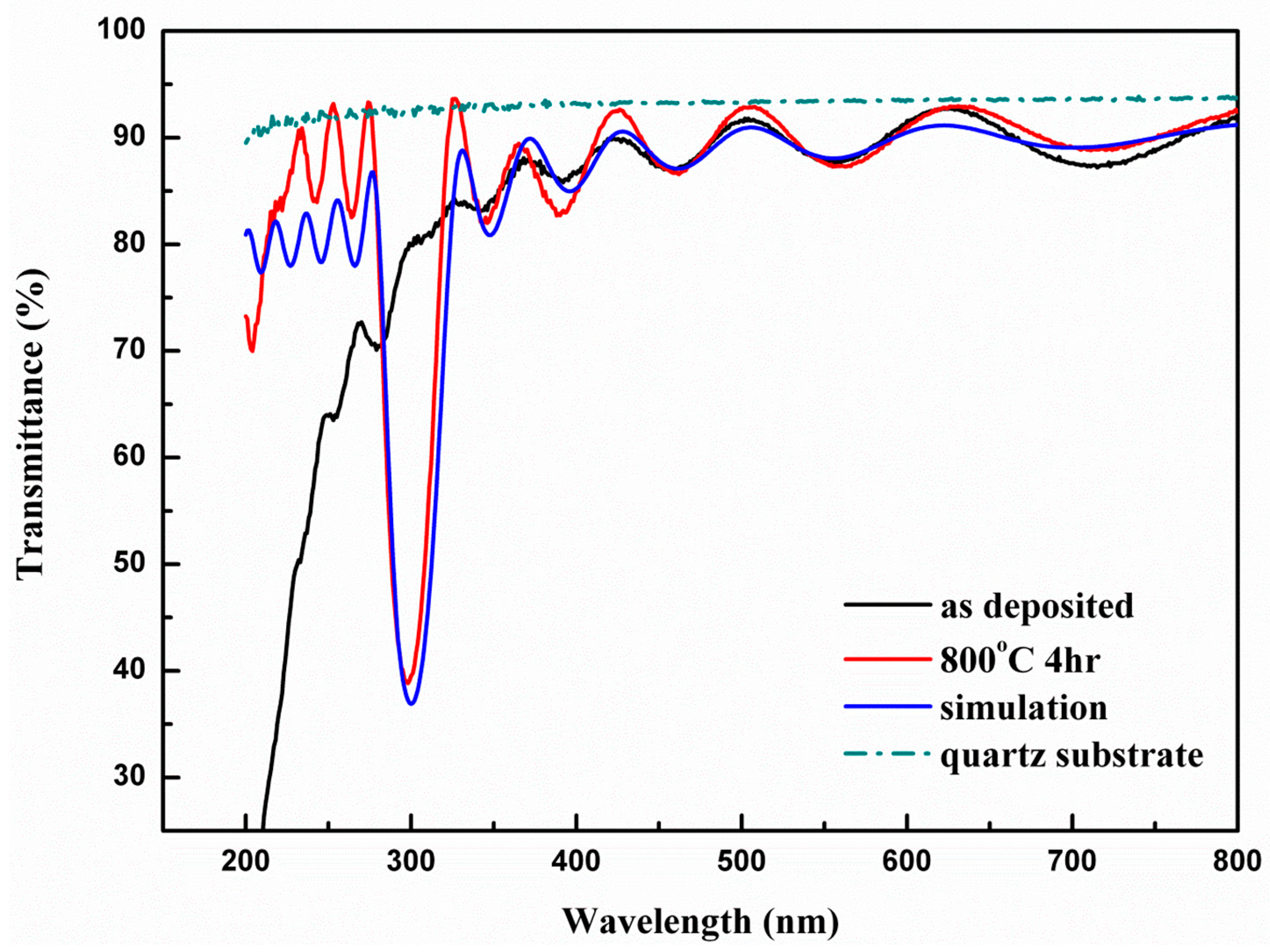

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lee, C.C.; Hsu, J.C. Technique for Deposition Multiplayer Interference Thin films Using Silicon as the Only Coating Material. US Patent 6425978B1, 30 July 2002. [Google Scholar]

- Lee, C.C.; Tang, C.J.; Hsu, J.C.; Wu, J.Y. Rugate filter made with composite thin film by ion beam sputtering. Appl. Opt. 2006, 45, 1333–1337. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.C.; Hsu J., C. Technique for Deposition of Multiplayer Interference Thin Film Using Only One Coating Material. ROC Patent Invention No. 137551, 23 June 2001. [Google Scholar]

- Hodgkinson, I.; Wu, Q.H.; Brett, M.; Robbie, K. Vacuum deposition of biaxial film with surface-aligned principal axes and large birefringence Δn. Opt. Soc. Am. Tech. Digest 1998, 9, 104–106. [Google Scholar]

- Cho, W.H.; Lee, C.C. Low-refractive-index oxide thin films originated from the Kirkendall effect. Appl. Opt. 2014, 53, A175–A178. [Google Scholar] [CrossRef] [PubMed]

- Xi, J.-Q.; Schubert, M.F.; Kim, J.K.; Schubert, E.F.; Chen, M.; Lin, S.-Y.; Liu, W.; Smart, J.A. Optical thin-film materials with low refractive index for broadband elimination of Fresnel reflection. Nat. Photonics 2007, 1, 176–179. [Google Scholar] [CrossRef]

- Chen, J.; Wang, B.; Yang, Y.; Shi, Y.; Xu, G.; Cui, P. Porous anodic alumina with low refractive index for broadband graded-index antireflection coatings. Appl. Opt. 2012, 51, 6839. [Google Scholar] [CrossRef] [PubMed]

- Van Dal, M.J.H.; Gusak, A.M.; Cserháti, C.; Kodentsov, A.A.; van Loo, F.J.J. Microstructural stability of the Kirkendall plane in solid state diffusion. Phys. Rev. Lett. 2001, 86, 3352. [Google Scholar] [CrossRef] [PubMed]

- Schubert, E.F.; Kim, J.K.; Xi, J.Q. Low-refractive-index materials: A new class of optical thin-film materials. Phys. Status Solidi (B) 2007, 244, 3002–3008. [Google Scholar] [CrossRef]

- Kuo, Y. Etch mechanism in the low refractive index silicon nitride plasma enhanced chemical vapor deposition process. Appl. Phys. Lett. 1993, 63, 144–146. [Google Scholar] [CrossRef]

- Carter, R.E. Mechanism of Solid-state Reaction Between Magnesium Oxide and Aluminum Oxide and Between Magnesium Oxide and Ferric Oxide. J. Am. Ceram. Soc. 1961, 44, 116–120. [Google Scholar] [CrossRef]

- Rao, C.N.R.; Gopalakrishnan, J. New Directions in Solid State Chemistry; Cambridge University Press: Cambridge, UK, 1997; pp. 488–490. [Google Scholar]

- Wicht, G.; Ferrini, R.; Schüttel, S.; Zuppiroli, L. Nanoporous Films with Low Refractive Index for Large-Surface Broad-Band Anti-Reflection Coatings. Macromol. Mater. Eng. 2010, 295, 628–636. [Google Scholar] [CrossRef]

- Redel, E.; Mirtchev, P.; Huai, C.; Petrov, S.; Ozin, G.A. Nanoparticle Films and Photonic Crystal Multilayers from Colloidally Stable, Size-Controllable Zinc and Iron Oxide Nanoparticles. ACS Nano 2011, 5, 2861–2869. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Garcia, F.J.; Gil-Rostra, J.; Terriza, A.; González, J.C.; Cotrino, J.; Frutos, F.; Ferrer, F.J.; González-Elipe, A.R.; Yubero, F. Low refractive index SiOF thin films prepared by reactive magnetron sputtering. Thin Solid Films 2013, 542, 332–337. [Google Scholar] [CrossRef]

- Streubel, K.; Rapp, S.; André, J.; Chitica, N. 1.26 mu m vertical cavity laser with two InP/air-gap reflectors. Electron. Lett. 1996, 32, 1369. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.-P.; Cho, W.-H.; Chen, W.-C.; Lee, C.-T.; Lee, C.-C. The Fabrication of a UV Notch Filter by Using Solid State Diffusion. Coatings 2019, 9, 208. https://doi.org/10.3390/coatings9030208

Chen H-P, Cho W-H, Chen W-C, Lee C-T, Lee C-C. The Fabrication of a UV Notch Filter by Using Solid State Diffusion. Coatings. 2019; 9(3):208. https://doi.org/10.3390/coatings9030208

Chicago/Turabian StyleChen, Hung-Pin, Wen-Hao Cho, Wei-Chun Chen, Chao-Te Lee, and Cheng-Chung Lee. 2019. "The Fabrication of a UV Notch Filter by Using Solid State Diffusion" Coatings 9, no. 3: 208. https://doi.org/10.3390/coatings9030208

APA StyleChen, H.-P., Cho, W.-H., Chen, W.-C., Lee, C.-T., & Lee, C.-C. (2019). The Fabrication of a UV Notch Filter by Using Solid State Diffusion. Coatings, 9(3), 208. https://doi.org/10.3390/coatings9030208