Microstructure, Properties, and Titanium Cutting Performance of AlTiN–Cu and AlTiN–Ni Coatings

Abstract

1. Introduction

2. Experimental Details

2.1. Coating Deposition

2.2. Coating Characterization

2.3. Cutting Experiments

3. Results and Discussion

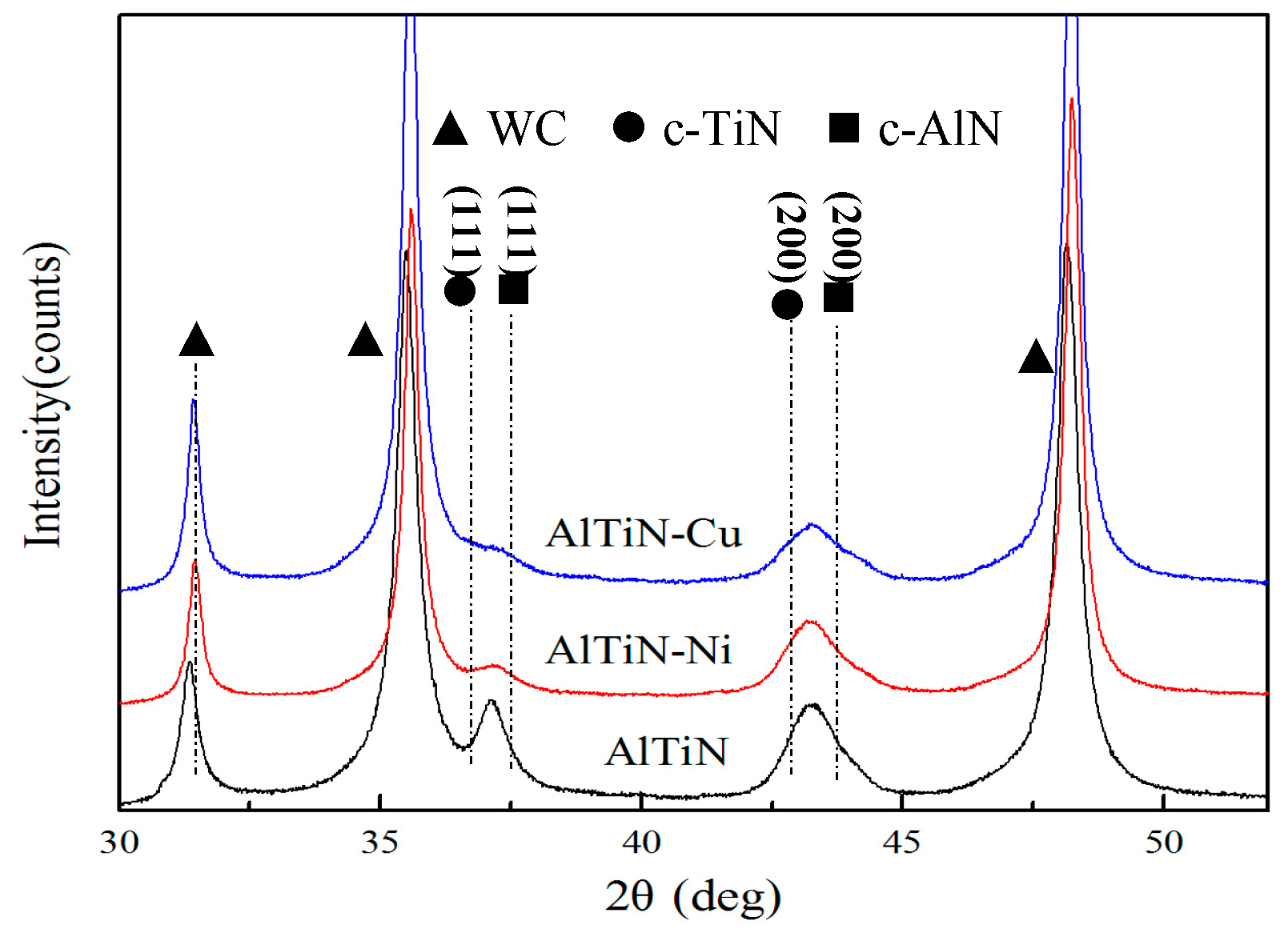

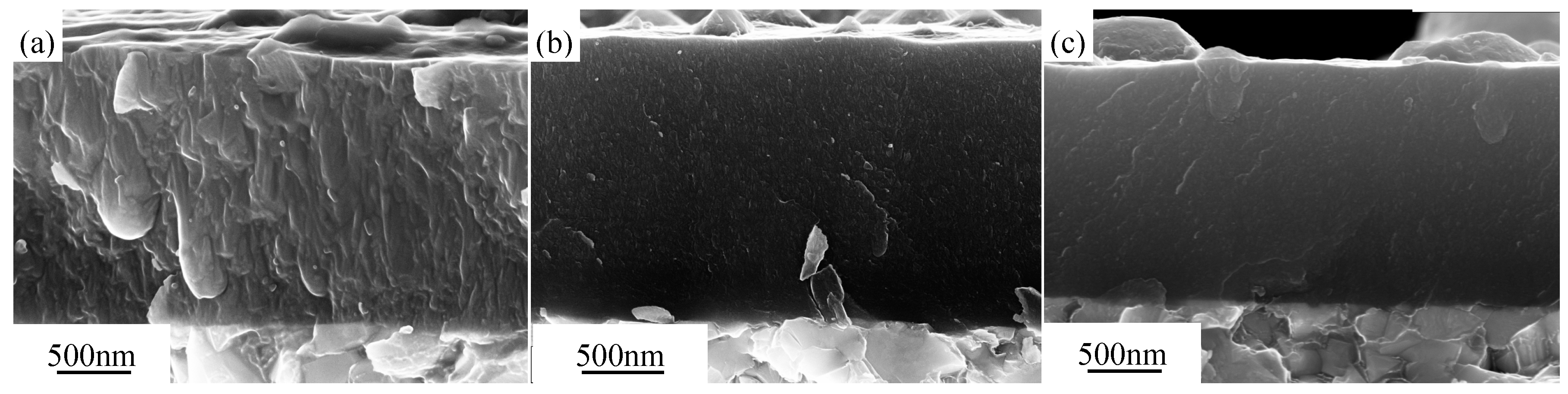

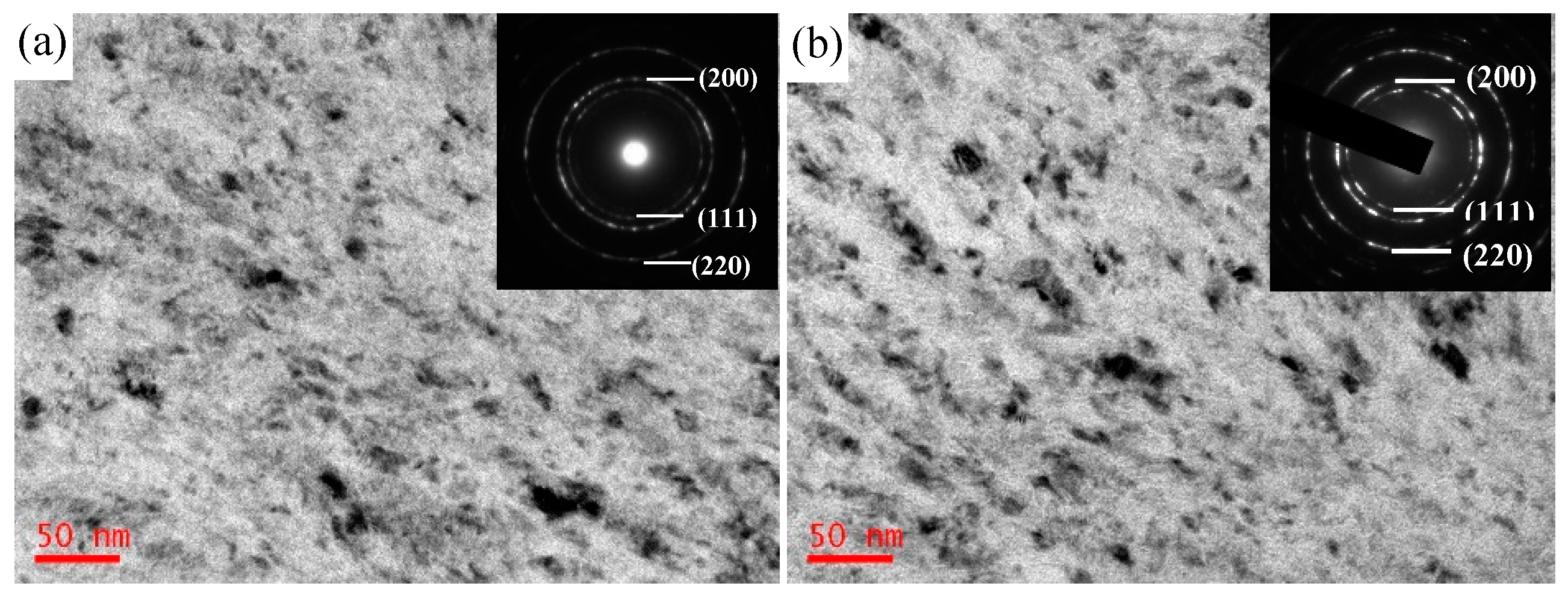

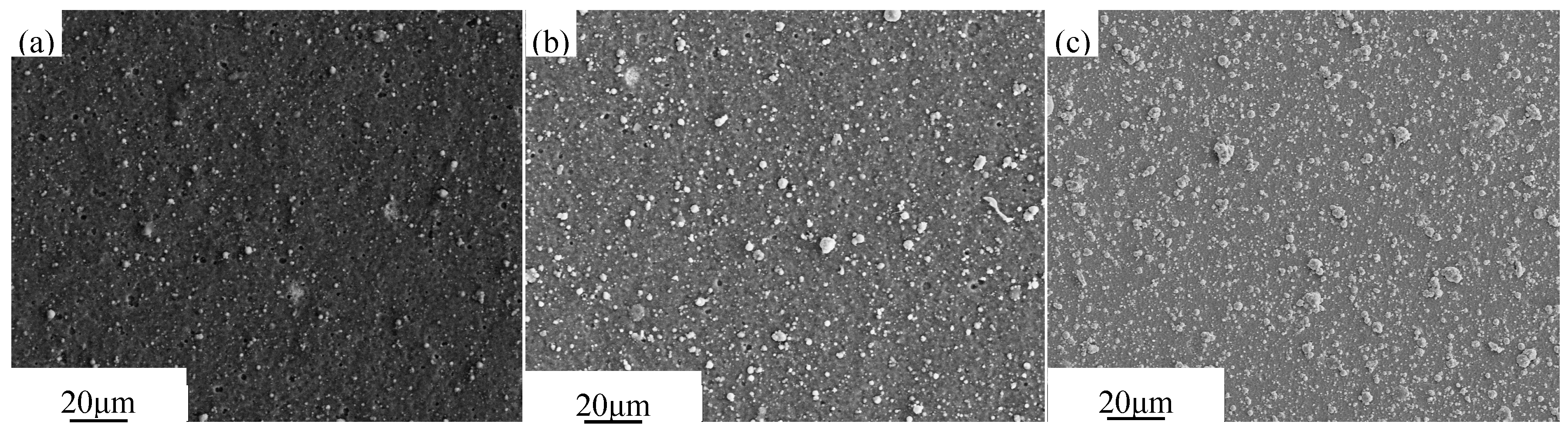

3.1. Microstructure and Composition

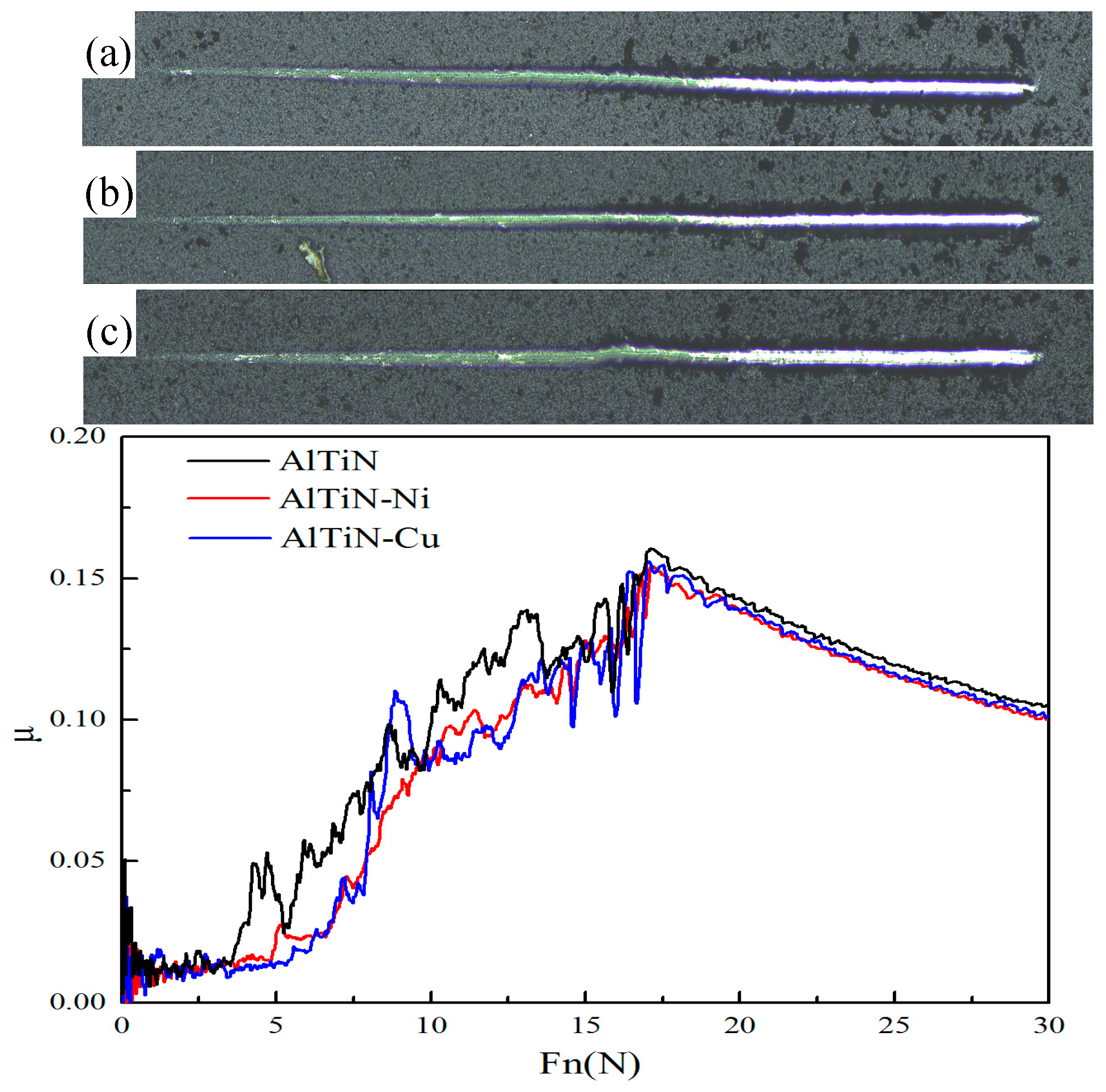

3.2. Mechanical Properties

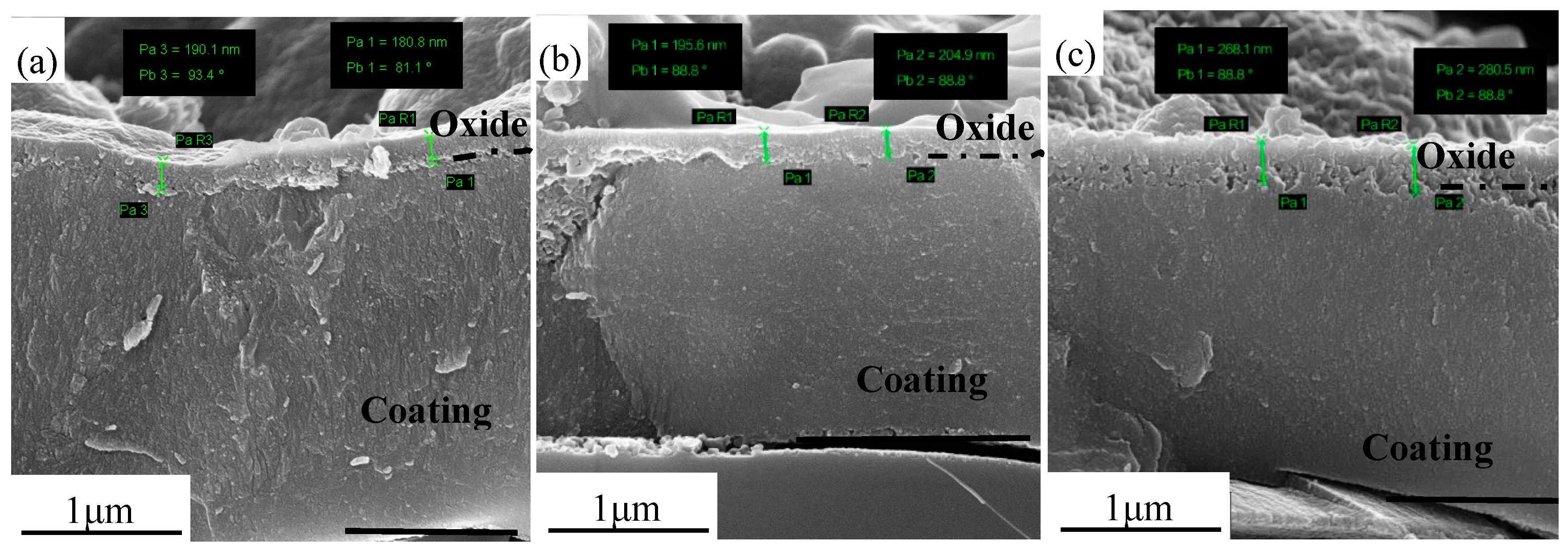

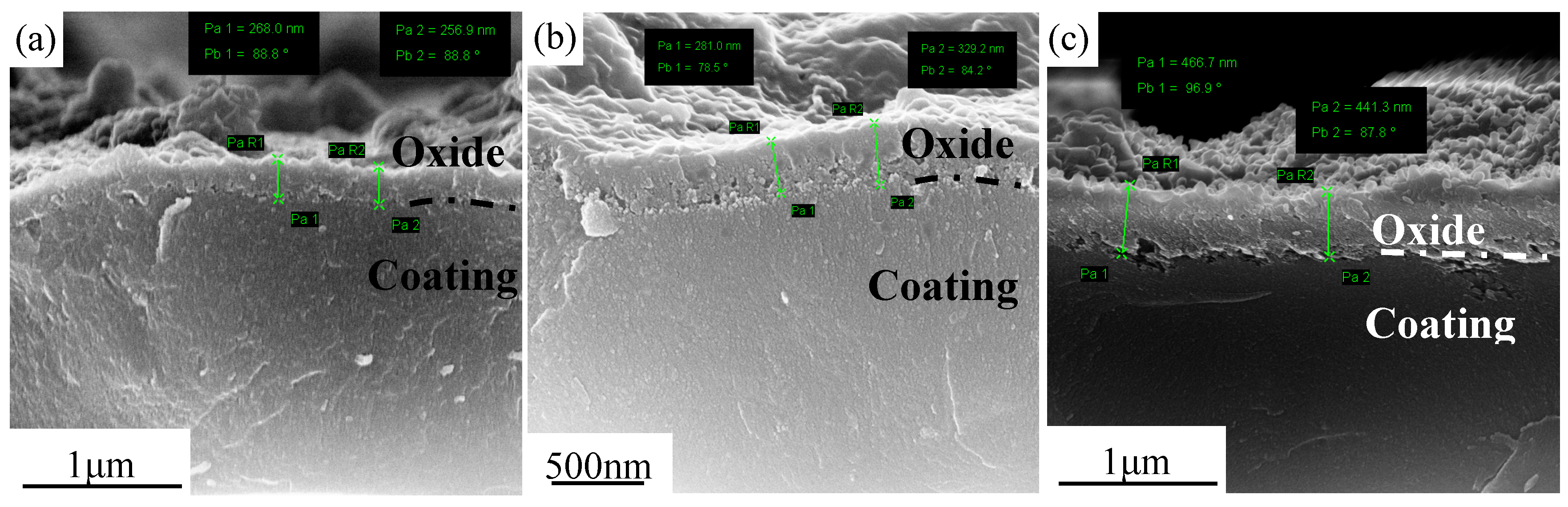

3.3. Oxidation Resistance

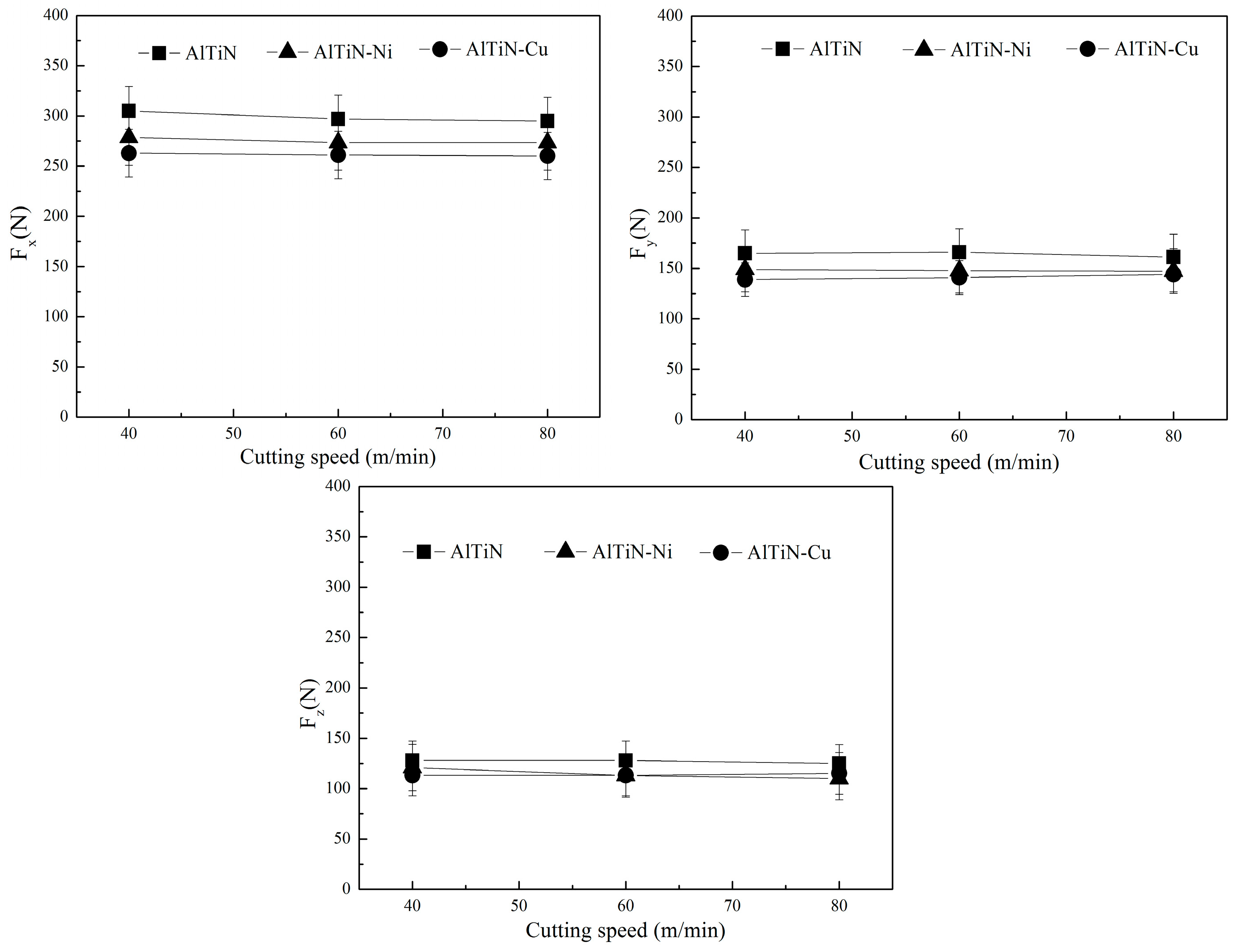

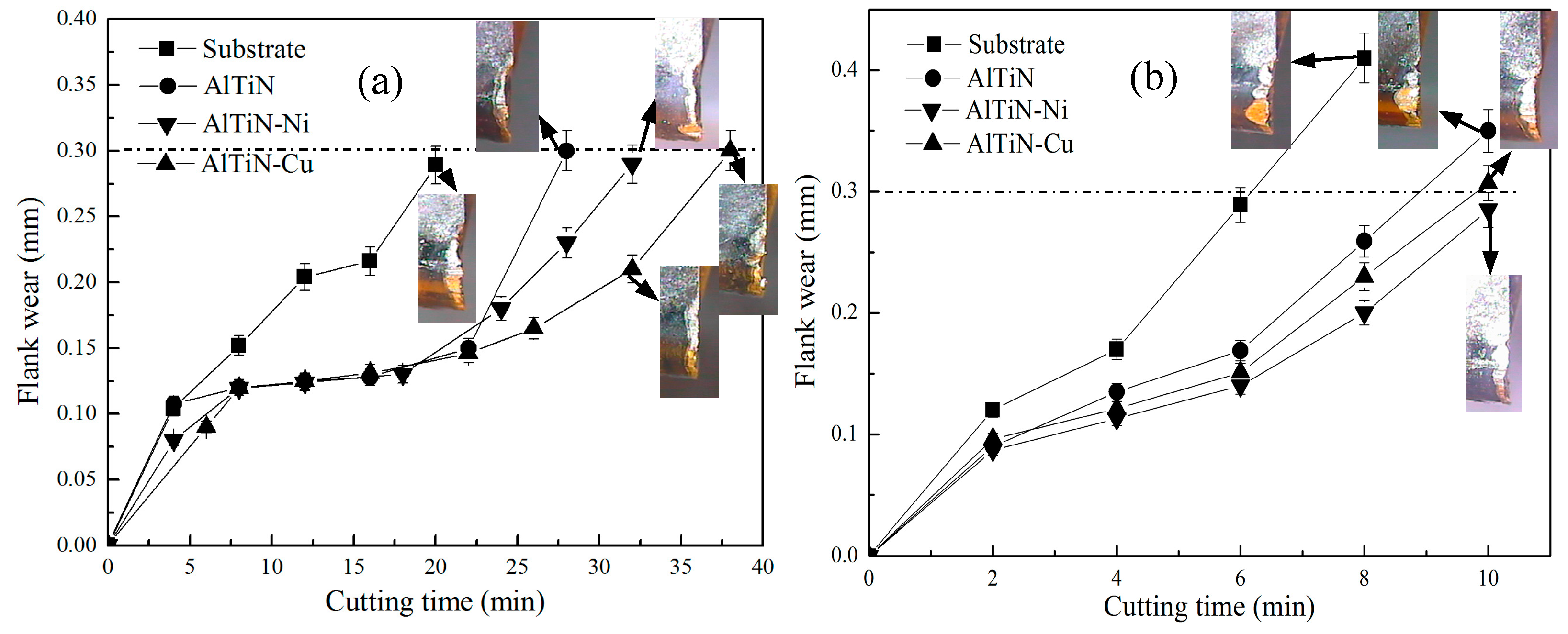

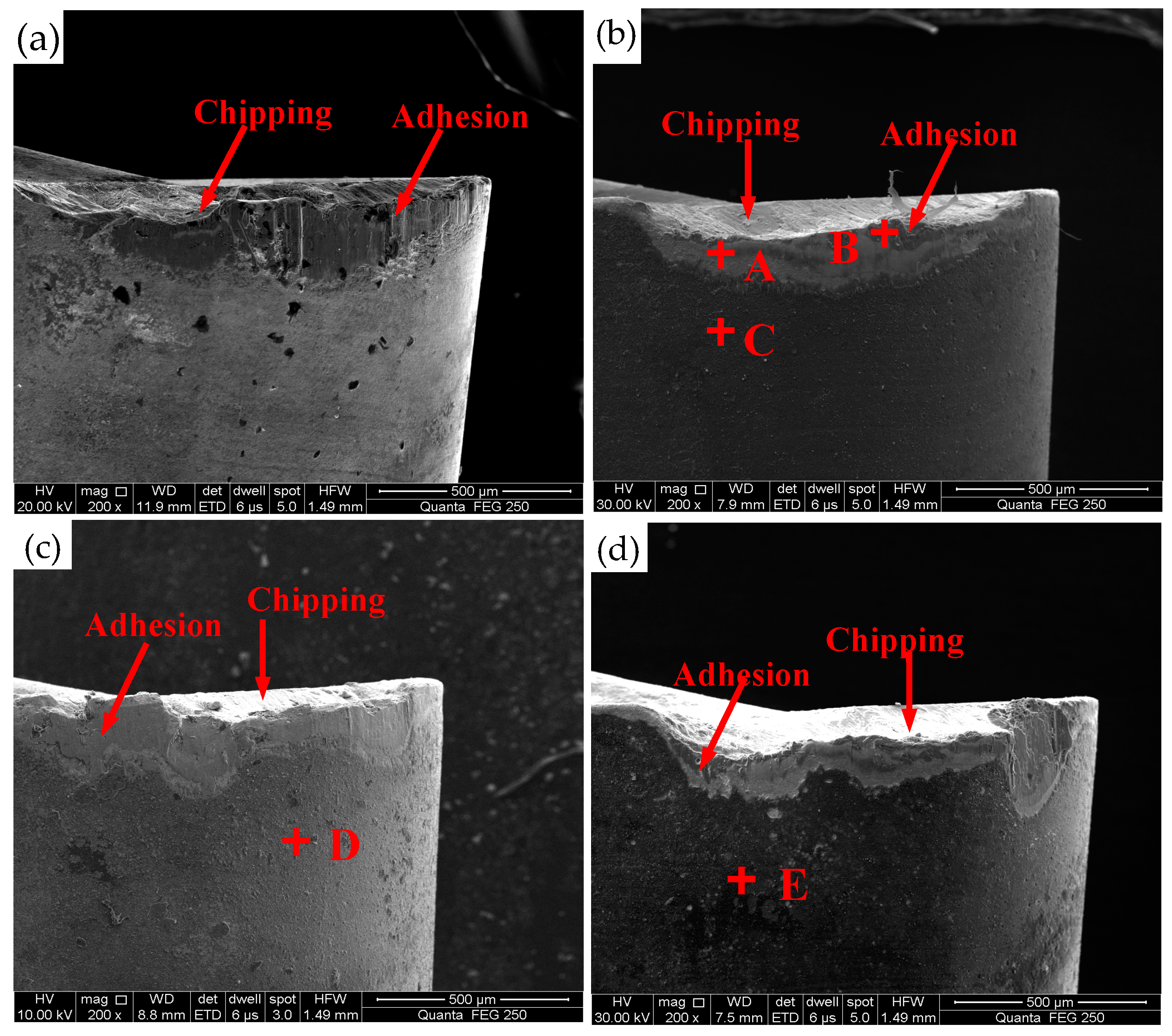

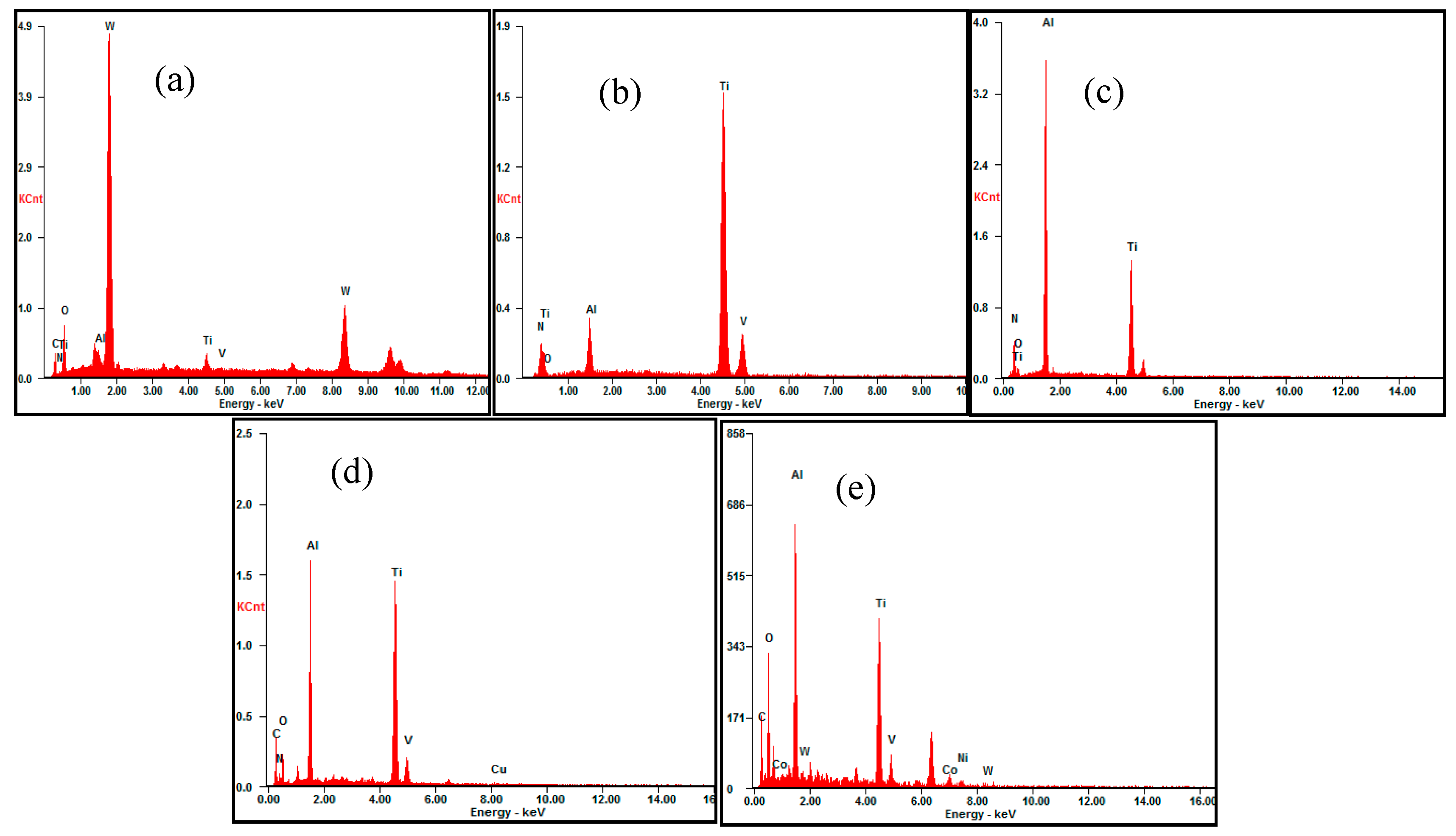

3.4. Cutting Experiments

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jindal, P.C.; Santhanam, A.T.; Schleinkofer, U.; Shuster, A.F. Performance of PVD TiN, TiCN, and TiAlN coated cemented carbide tools in turning. Int. J. Refract. Met. Hard Mater. 1999, 17, 163–170. [Google Scholar] [CrossRef]

- Deng, J.X.; Li, Y.S.; Song, W.L. Diffusion wear in dry cutting of Ti-6Al-4V with WC/Co carbide tools. Wear 2008, 265, 1776–1783. [Google Scholar]

- Kitagawa, T.; Kubo, A.; Maekawa, K. Temperature and wear of cutting tools in high-speed machining of Inconel 718 and Ti-6Al-6V-2Sn. Wear 1997, 202, 142–148. [Google Scholar] [CrossRef]

- Pervaiz, S.; Rashid, A.; Deiab, I.; Nicolescu, M. Influence of Tool Materials on Machinability of Titanium-and Nickel-Based Alloys: A Review. Mater. Manuf. Processes 2014, 29, 219–252. [Google Scholar] [CrossRef]

- Ezugwu, E.O. Key improvements in the machining of difficult-to-cut aerospace superalloys. Int. J. Mach. Tool. Manuf. 2005, 45, 1353–1367. [Google Scholar] [CrossRef]

- Beake, B.D.; Smith, J.F.; Gray, A.; Fox-Rabinovich, G.S.; Veldhuis, S.C.; Endrino, J.L. Investigating the correlation between nano-impact fracture resistance and hardness/modulus ratio from nanoindentation at 25–500 ℃ and the fracture resistance and lifetime of cutting tools with Ti1−xAlxN(x = 0.5 and 0.67) PVD coatings in milling operations. Surf. Coat. Technol. 2007, 201, 4585–4593. [Google Scholar] [CrossRef]

- Chen, L.; Paulitsch, J.; Du, Y.; Mayrhofer, P.H. Thermal stability and oxidation resistance of Ti–Al–N coatings. Surf. Coat. Technol. 2012, 206, 2954–2960. [Google Scholar] [CrossRef]

- Kutschej, K.; Mayrhofer, P.H.; Kathrein, M.; Polcikd, P.; Tessadrie, R.; Mittereret, C. Structure, mechanical and tribological properties of sputtered Ti1–xAlxN coatings with 0.5 ≤ x ≤ 0.75. Surf. Coat. Technol. 2005, 200, 2358–2365. [Google Scholar] [CrossRef]

- Sui, X.D.; Li, G.J.; Qin, X.S.; Yu, H.D.; Zhou, X.K.; Wang, K.; Wang, Q. Relationship of microstructure, mechanical properties and titanium cutting performance of TiAlN/TiAlSiN composite coated tool. Ceram. Int. 2016, 42, 7524–7532. [Google Scholar] [CrossRef]

- Chen, L.; Chang, K.K.; Du, Y.; Li, J.R.; Wu, M.J. A comparative research on magnetron sputtering and arc evaporation deposition of Ti–Al–N coatings. Thin Solid Films 2011, 519, 3762–3767. [Google Scholar] [CrossRef]

- Li, G.J.; Sui, X.D.; Jiang, C.J.; Gao, Y.; Wang, K.; Wang, Q.; Liu, D. Low adhesion effect of TaO functional composite coating on the titanium cutting performance of coated cemented carbide insert. Mater. Design. 2016, 110, 105–111. [Google Scholar] [CrossRef]

- Biksa, A.; Yamamoto, K.; Dosbaeva, G.; Veldhuis, S.C.; Fox-Rabinovich, G.S.; Elfizy, A.; Wagg, T.; Shuster, L.S. Wear behavior of adaptive nano-multilayered AlTiN/MexN PVD coatings during machining of aerospace alloys. Tribol. Int. 2010, 43, 1491–1499. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Yamamoto, K.; Aguirre, M.H.; Cahill, D.G.; Veldhuis, S.C.; Biksa, A.; Dosbaeva, G.; Shuster, L.S. Multi-functional nano-multilayered AlTiN/Cu PVD coating for machining of Inconel 718 superalloy. Surf. Coat. Technol. 2010, 204, 2465–2471. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Kovalev, A.I.; Aguirre, M.H.; Beake, B.D.; Yamamoto, K.; Veldhuis, S.C.; Endrino, J.L.; Wainstein, D.L.; Rashkovskiy, A.Y. Design and performance of AlTiN and TiAlCrN PVD coatings for machining of hard to cut materials. Surf. Coat. Technol. 2009, 204, 489–496. [Google Scholar] [CrossRef]

- Belov, D.S.; Blinkov, I.V.; Volkhonskii, A.O. The effect of Cu and Ni on the nanostructure and properties of arc-PVD coatings based on titanium nitride. Surf. Coat. Technol. 2014, 260, 186–197. [Google Scholar] [CrossRef]

- Blinkov, I.V.; Volkhonskii, A.O.; Laptev, A.I.; Sviridova, T.A.; Tabachkova, N.Y.; Belov, D.S.; Ershova, A.V. Ceramic-metallic (TiN-Cu) nanostructured ion-plasma vacuum-arc coatings for cutting hard-alloy tools. Russ. J. Non Ferr. Met. 2014, 55, 489–493. [Google Scholar] [CrossRef]

- Akbari, A.; Templier, C.; Beaufort, M.F.; Eyidi, D.; Riviere, J.P. Ion beam assisted deposition of TiN–Ni nanocomposite coatings. Surf. Coat. Technol. 2011, 206, 972–975. [Google Scholar] [CrossRef]

- Balashabadi, P.; Larijani, M.M.; Jafari-Khamse, E.; Seyedi, H. The role of Cu content on the structural properties and hardness of TiN-Cu nanocomposite film. J. Alloys Compd. 2017, 728, 863–871. [Google Scholar] [CrossRef]

- Belov, D.; Blinkov, I.; Volkhonskii, A.; Kuznetsov, D.; Kiryukhantsev-Korneev, F.; Pustov, Y.A.; Sergevnin, V.; Kuznetsov, D. Thermal stability and chemical resistance of (Ti,Al)N-Cu and (Ti,Al)N-Ni metal-ceramic nanostructured coatings. Appl. Surf. Sci. 2016, 388, 2–12. [Google Scholar] [CrossRef]

- Myung, H.S.; Lee, H.M.; Shaginyan, L.R.; Han, J.G. Microstructure and mechanical properties of Cu doped TiN superhard nanocomposite coatings. Surf. Coat. Technol. 2003, 163–164, 591–596. [Google Scholar] [CrossRef]

- He, C.L.; Xie, L.P.; Zhang, J.L.; Ma, G.F.; Du, Z.F.; Wang, J.M.; Zhao, D.L. Microstructure and mechanical properties of reactive sputtered nanocrystalline Ti-Al-Ni-N thin films. Surf. Coat. Technol. 2017, 320, 472–477. [Google Scholar] [CrossRef]

- Yi, J.; Chen, S.; Chen, K.; Xu, Y.; Chen, Q.; Zhu, C.; Liu, L. Effects of Ni content on microstructure, mechanical properties and Inconel 718 cutting performance of AlTiN-Ni nanocomposite coatings. Ceram. Int. 2019, 45, 471–480. [Google Scholar] [CrossRef]

- Chen, H.; Chen, K.-H.; Xu, Y.-C.; Pan, C.-X.; Yi, J.-Y.; Zhu, C.-J. Microstructure, mechanical properties, and milling performance of arc-PVD AlTiN-Cu and AlTiN/AlTiN-Cu coatings. J. Cent. South. Univ. 2018, 25, 506–515. [Google Scholar] [CrossRef]

- Chen, L.; Pei, Z.; Xiao, J.; Gong, J.; Sun, C. TiAlN/Cu Nanocomposite Coatings Deposited by Filtered Cathodic Arc Ion Plating. J. Mater. Sci. Technol. 2017, 33, 111–116. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, S.; Chen, Z.; Li, J.; Li, M. Influence of deposition parameters on hard Cr–Al–N coatings deposited by multi-arc ion plating. Appl. Surf. Sci. 2012, 258, 3629–3636. [Google Scholar] [CrossRef]

- Cai, F.; Zhang, S.; Li, J.; Chen, Z.; Li, M.; Wang, L. Effect of nitrogen partial pressure on Al–Ti–N films deposited by arc ion plating. Appl. Surf. Sci. 2011, 258, 1819–1825. [Google Scholar] [CrossRef]

- Yang, J.; Jiang, Y.; Yang, R.; Gao, Y.; Wang, X.; Fang, Q. Microstructure and mechanical properties of W–Ni–N coatings prepared by magnetron sputtering. Thin Solid Films 2014, 570, 249–255. [Google Scholar] [CrossRef]

- Koller, C.M.; Hollerweger, R.; Sabitzer, C.; Rachbauer, R.; Kolozsvári, S.; Paulitsch, J.; Mayrhofer, P.H. Thermal stability and oxidation resistance of arc evaporated TiAlN, TaAlN, TiAlTaN, and TiAlN/TaAlN coatings. Surf. Coat. Technol. 2014, 259, 599–607. [Google Scholar] [CrossRef]

- Chen, L.; He, L.Q.; Xu, Y.X.; Zhou, L.C.; Pei, F.; Du, Y. Influence of ZrN on oxidation resistance of Ti-Al-N coating. Surf. Coat. Technol. 2014, 244, 87–91. [Google Scholar] [CrossRef]

- Çalışkan, H.; Küçükköse, M.; Çaliskan, H. The effect of aCN/TiAlN coating on tool wear, cutting force, surface finish and chip morphology in face milling of Ti6Al4V superalloy. Int. J. Refract. Met. Hard Mater. 2015, 50, 304–312. [Google Scholar] [CrossRef]

| Coatings | H (GPa) | E (GPa) | Adhesion Strength (N) |

|---|---|---|---|

| AlTiN | 26.1 ± 2.9 | 337.5 ± 14.3 | 18.9 ± 1.1 |

| AlTiN–Ni | 24.3 ± 1.8 | 315.8 ± 11.9 | 18.3 ± 1.0 |

| AlTiN–Cu | 23.7 ± 1.7 | 300.2 ± 11.2 | 18.7 ± 1.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, J.; Chen, K.; Xu, Y. Microstructure, Properties, and Titanium Cutting Performance of AlTiN–Cu and AlTiN–Ni Coatings. Coatings 2019, 9, 818. https://doi.org/10.3390/coatings9120818

Yi J, Chen K, Xu Y. Microstructure, Properties, and Titanium Cutting Performance of AlTiN–Cu and AlTiN–Ni Coatings. Coatings. 2019; 9(12):818. https://doi.org/10.3390/coatings9120818

Chicago/Turabian StyleYi, Jiyong, Kanghua Chen, and Yinchao Xu. 2019. "Microstructure, Properties, and Titanium Cutting Performance of AlTiN–Cu and AlTiN–Ni Coatings" Coatings 9, no. 12: 818. https://doi.org/10.3390/coatings9120818

APA StyleYi, J., Chen, K., & Xu, Y. (2019). Microstructure, Properties, and Titanium Cutting Performance of AlTiN–Cu and AlTiN–Ni Coatings. Coatings, 9(12), 818. https://doi.org/10.3390/coatings9120818