Effect of Interlayer Thickness on Nano-Multilayer Coating Performance during High Speed Dry Milling of H13 Tool Steel

Abstract

1. Introduction

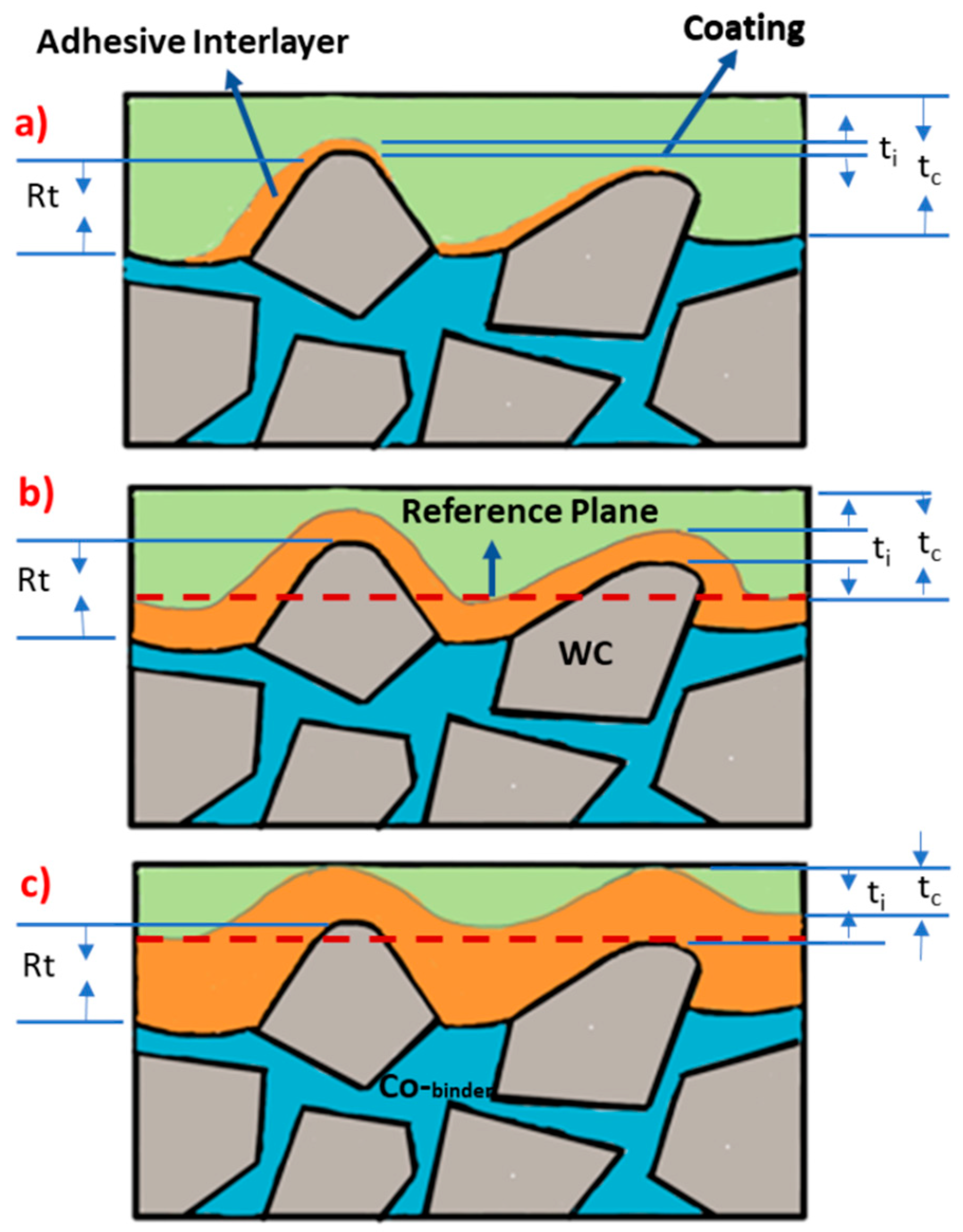

2. Experimental Details

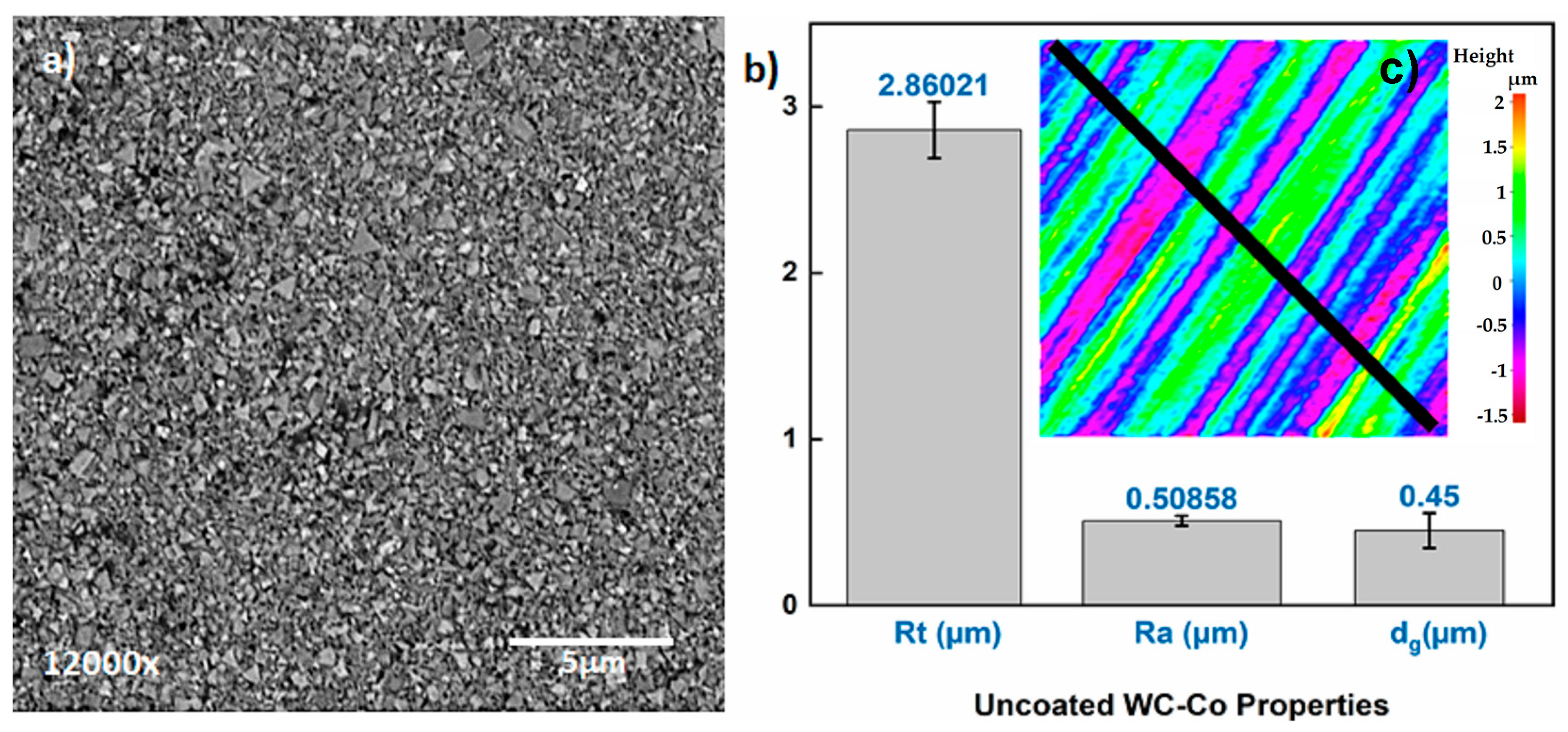

2.1. Substrate Specification

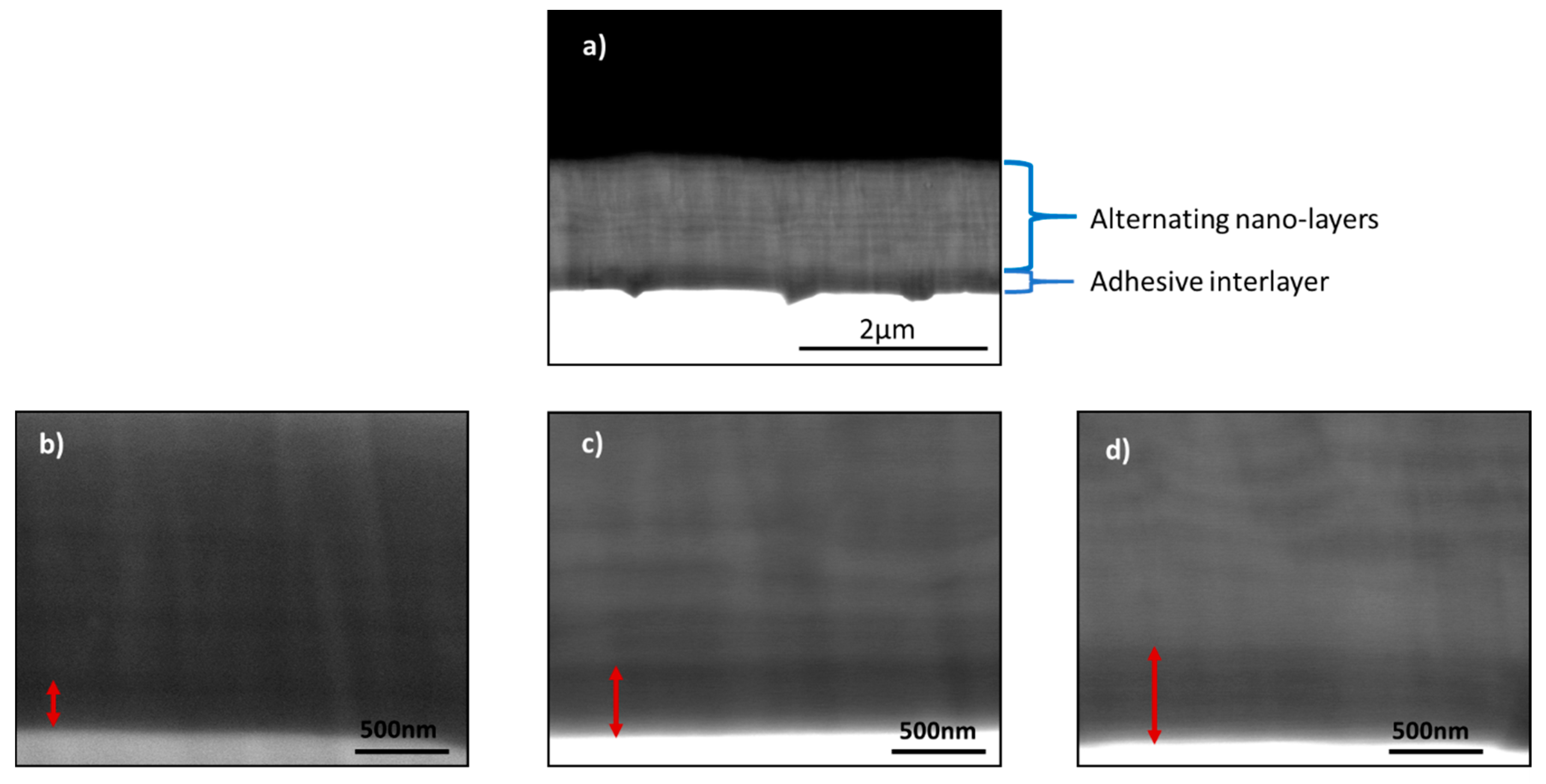

2.2. Coating Deposition

2.3. Determination of Micro-Mechanical Properties of Coatings

2.4. Cutting Performance of Coated Tools

3. Results and Discussion

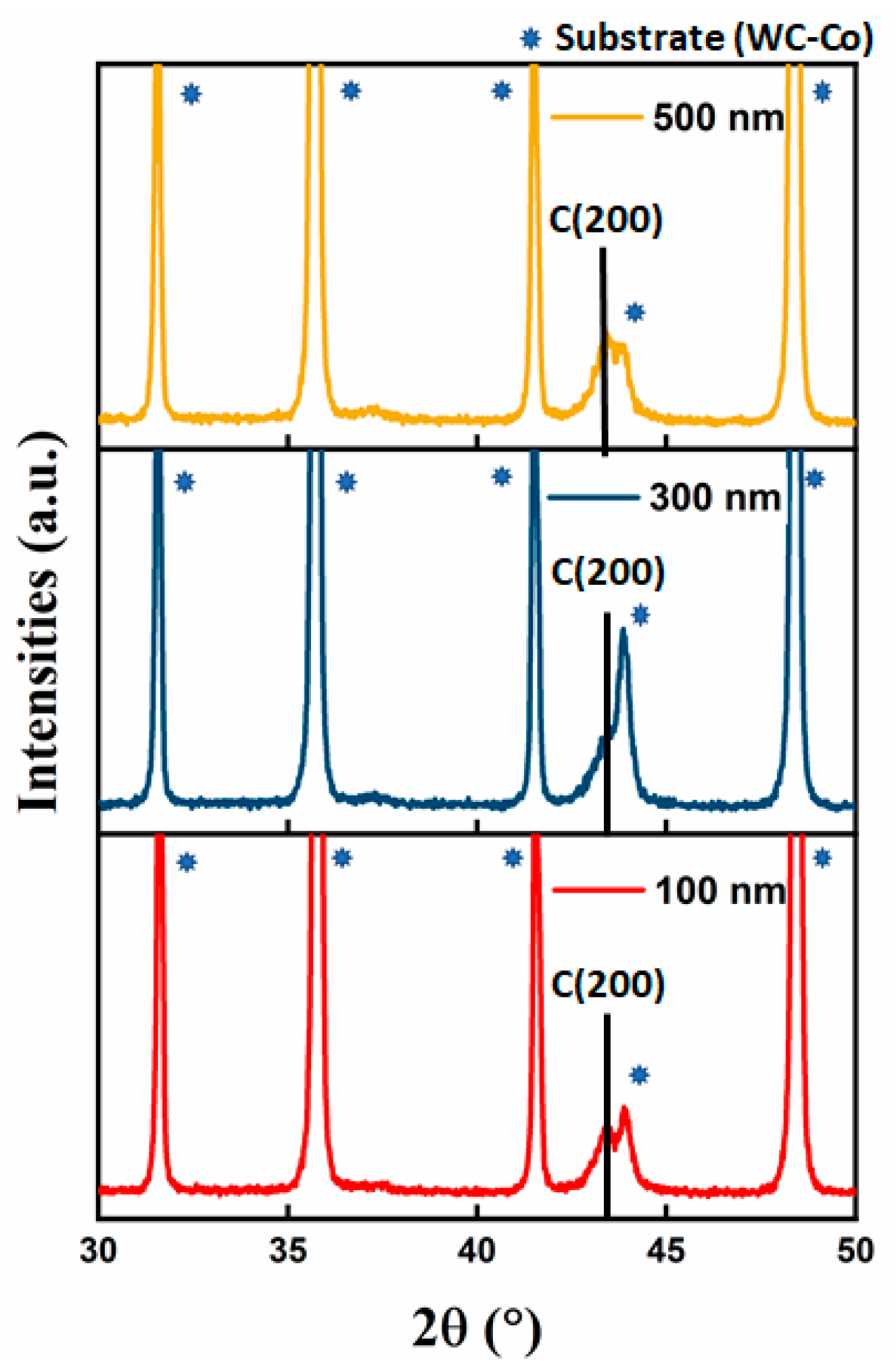

3.1. Structural Analysis

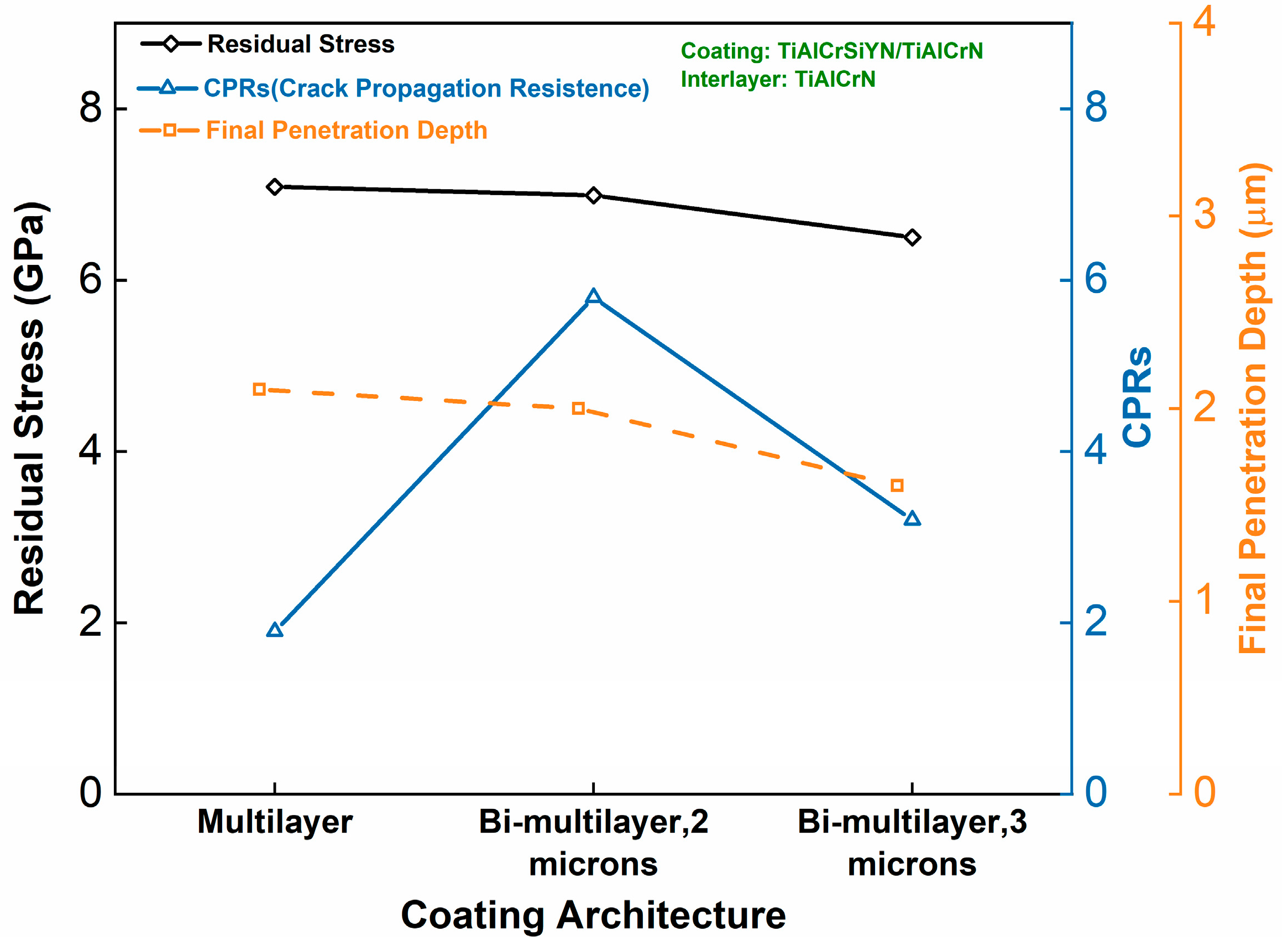

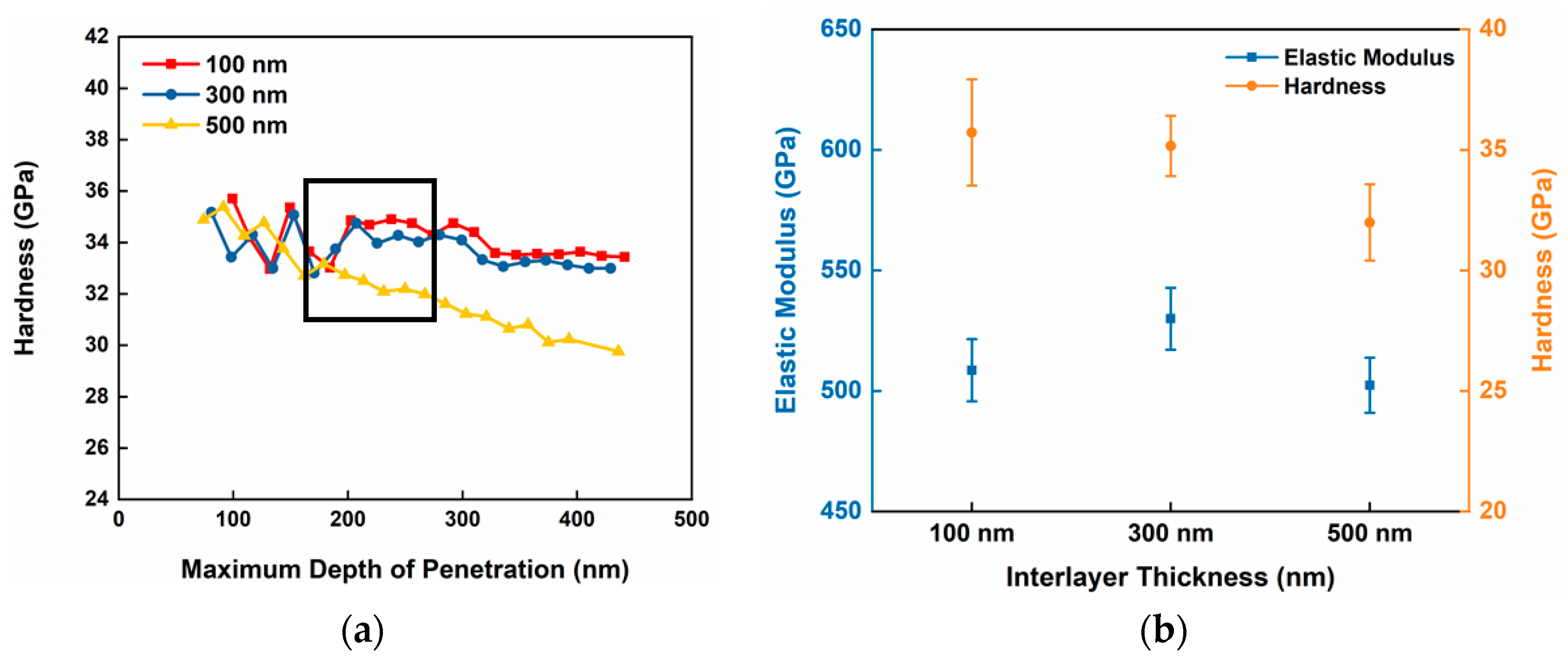

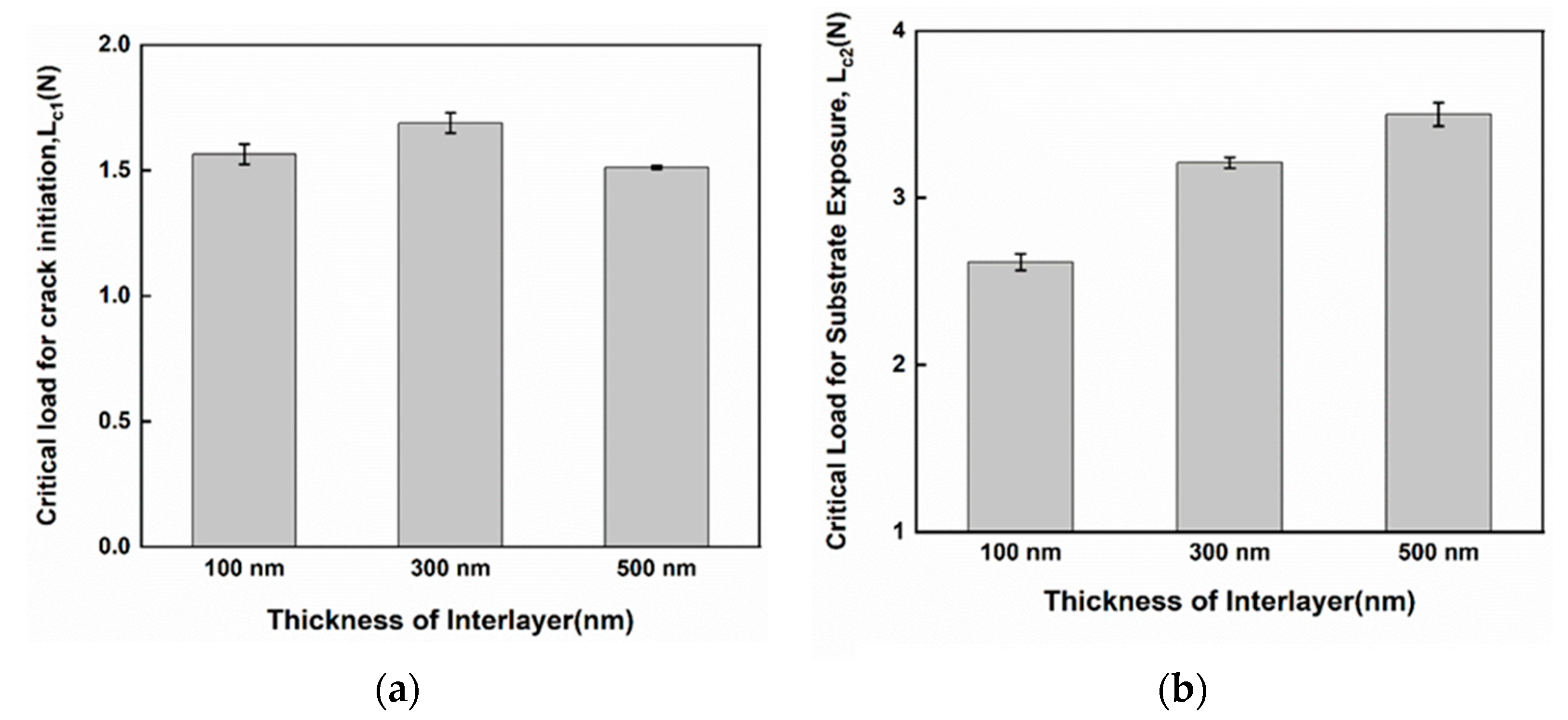

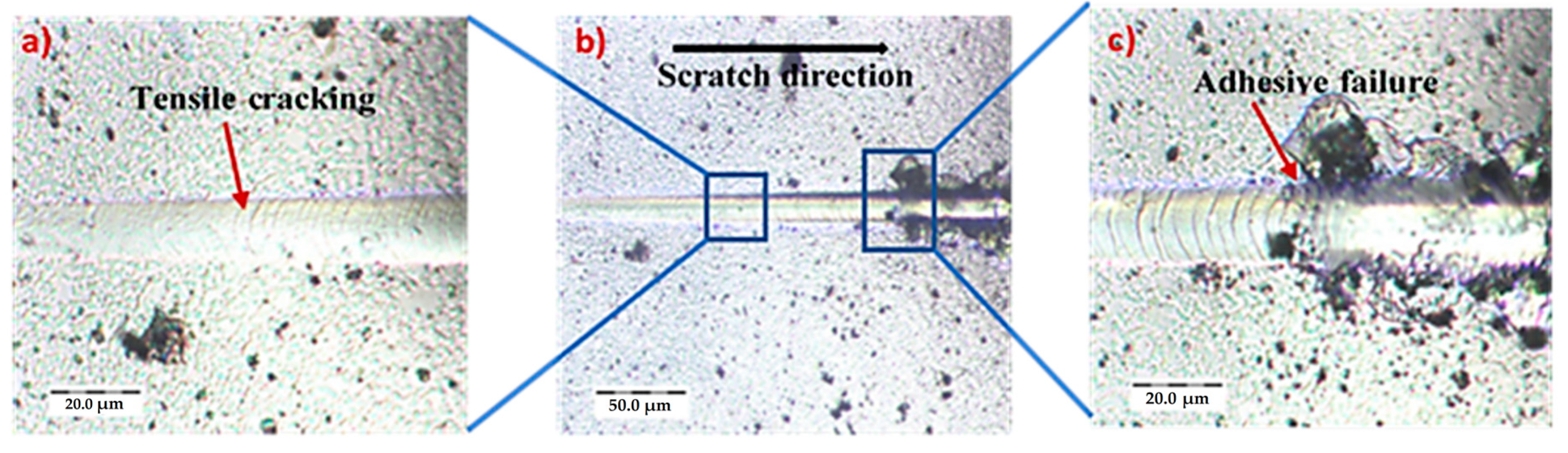

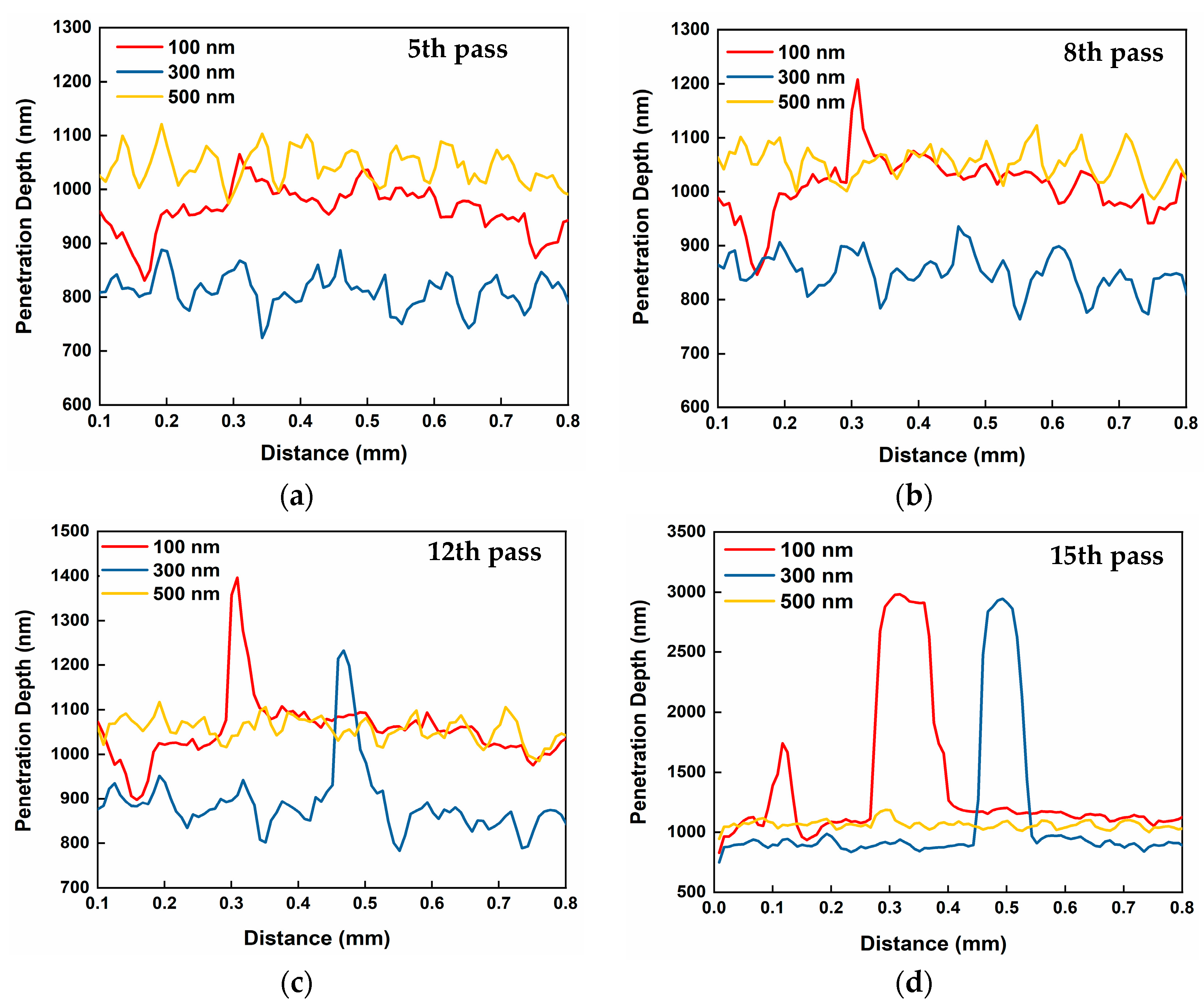

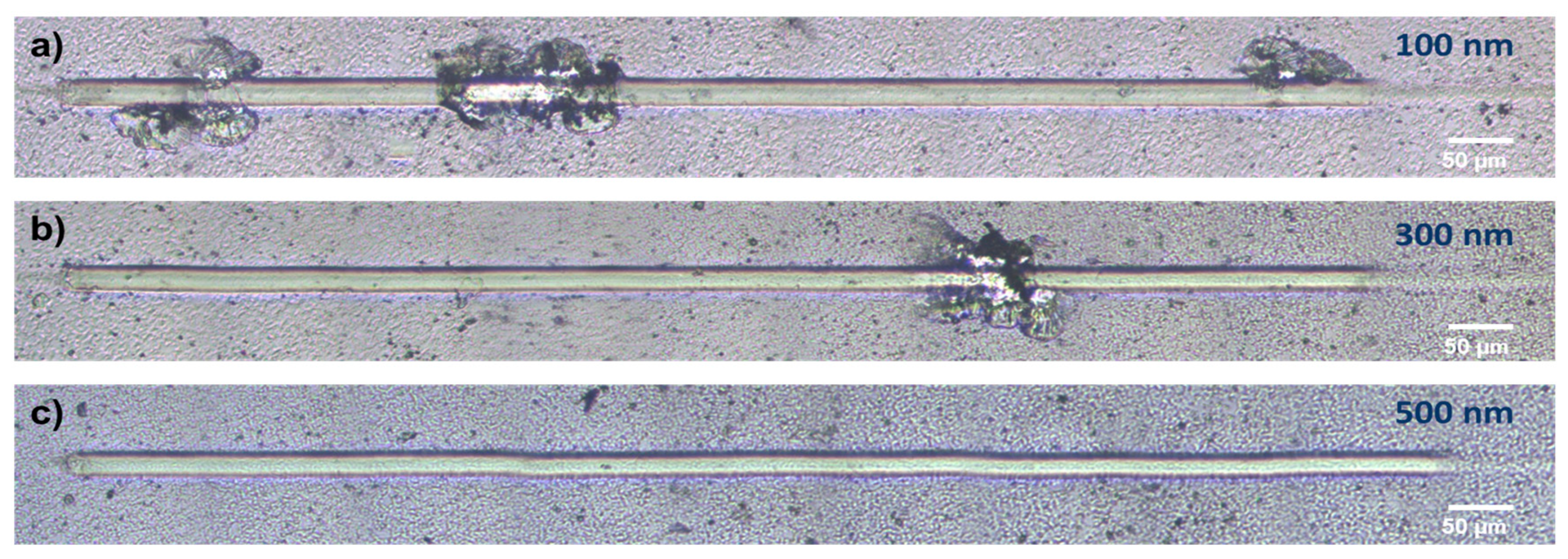

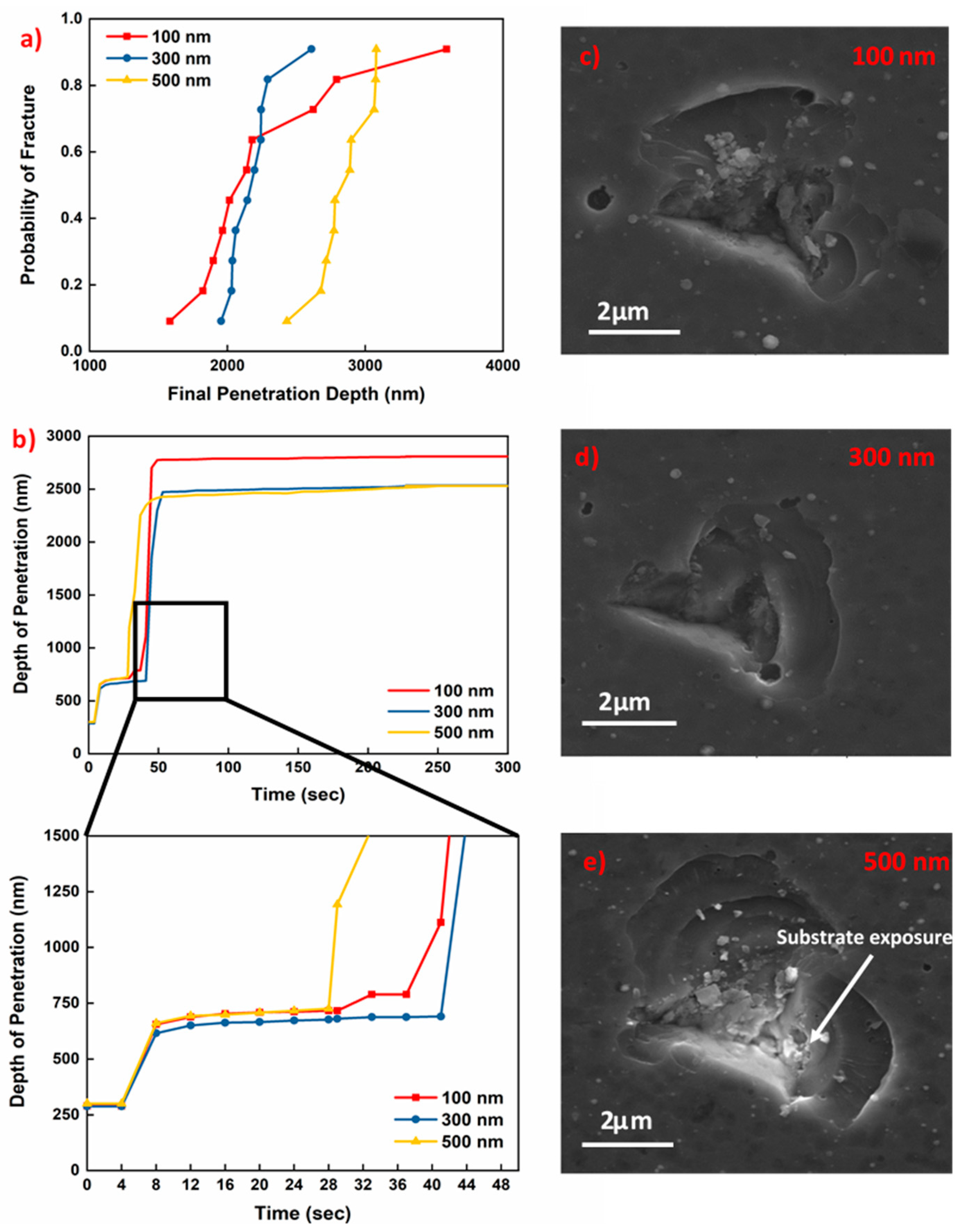

3.2. Micro-Mechanical Property Analysis

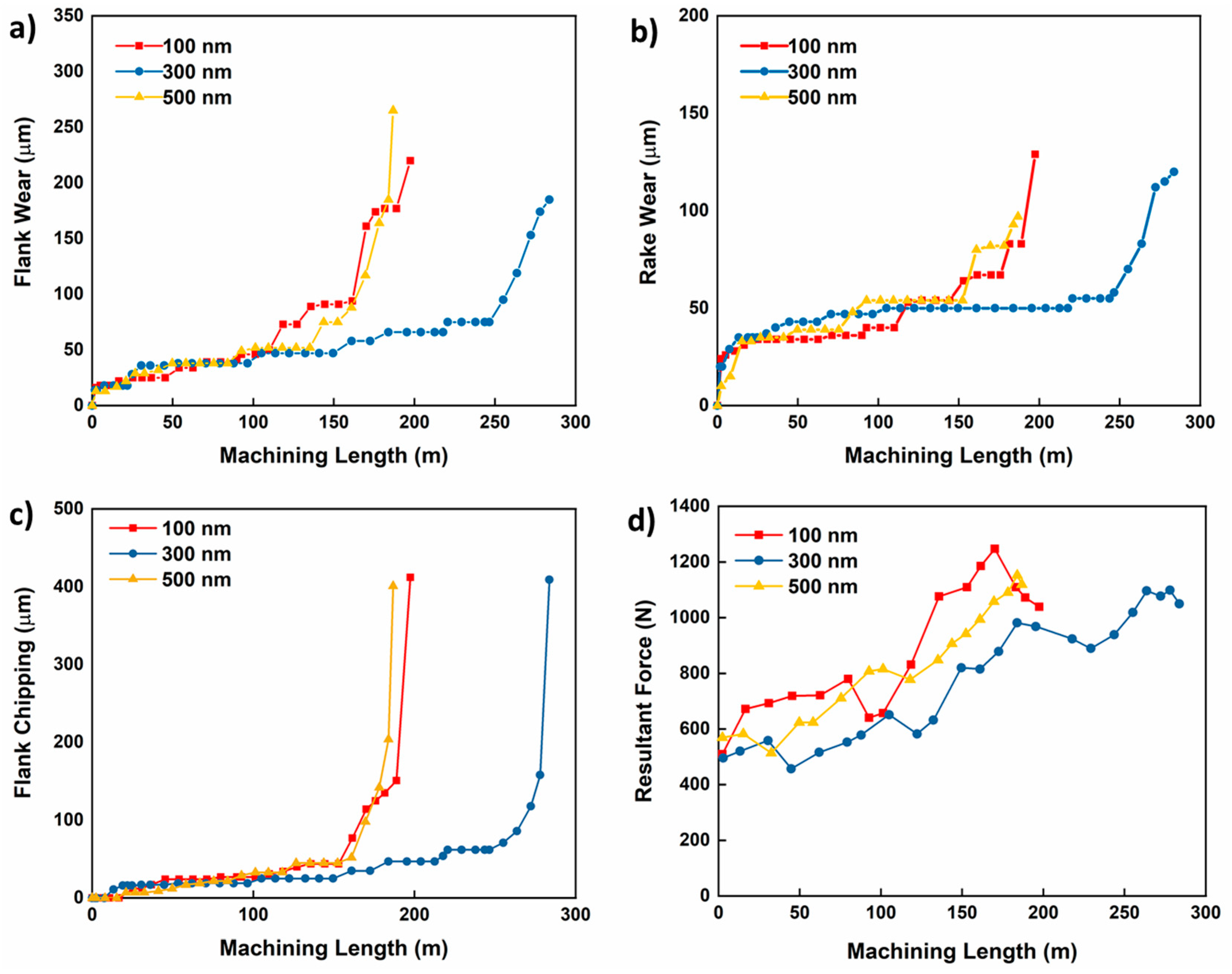

3.3. Tool Life Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fallböhmer, P.; Rodríguez, C.; Özel, T.; Altan, T. High-speed machining of cast iron and alloy steels for die and mold manufacturing. J. Mater. Process. Technol. 2000, 98, 104–115. [Google Scholar] [CrossRef]

- Tönshoff, H.; Bussmann, W.; Stanske, C. Requirements on tools and machines when machining hard materials. In Proceedings of the Twenty-Sixth International Machine Tool Design and Research Conference, Manchester, UK, 17th–18th September 1986; pp. 349–357. [Google Scholar]

- Nelson, S.; Schueller, J.; Tlusty, J. Tool wear in milling hardened die steel. J. Manuf. Sci. Eng. 1998, 120, 669–673. [Google Scholar] [CrossRef]

- Cui, X.; Zhao, J.; Tian, X. Cutting forces, chip formation, and tool wear in high-speed face milling of AISI H13 steel with CBN tools. Int. J. Adv. Manuf. Technol. 2013, 64, 1737–1749. [Google Scholar] [CrossRef]

- Elbestawi, M.; Chen, L.; Becze, C.; El-Wardany, T. High-speed milling of dies and molds in their hardened state. CIRP Ann. 1997, 46, 57–62. [Google Scholar] [CrossRef]

- Beake, B.; Ning, L.; Gey, C.; Veldhuis, S.; Komarov, A.; Weaver, A.; Khanna, M.; Fox-Rabinovich, G. Wear performance of different PVD coatings during hard wet end milling of H13 tool steel. Surf. Coat. Technol. 2015, 279, 118–125. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Choudhury, S. Machining of hardened steel—Experimental investigations, performance modeling and cooling techniques: A review. Int. J. Mach. Tools Manuf. 2015, 89, 95–109. [Google Scholar] [CrossRef]

- Mativenga, P.; Hon, K. A study of cutting forces and surface finish in high-speed machining of AISI H13 tool steel using carbide tools with TiAIN based coatings. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2003, 217, 143–151. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Michailidis, N.; Skordaris, G.; Bouzakis, E.; Biermann, D.; M’Saoubi, R. Cutting with coated tools: Coating technologies, characterization methods and performance optimization. CIRP Ann. Manuf. Technol. 2012, 61, 703–723. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Yamamoto, K.; Beake, B.D.; Gershman, I.S.; Kovalev, A.I.; Veldhuis, S.C.; Aguirre, M.H.; Dosbaeva, G.; Endrino, J.L. Hierarchical adaptive nanostructured PVD coatings for extreme tribological applications: The quest for nonequilibrium states and emergent behavior. Sci. Technol. Adv. Mater. 2012, 13, 043001. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Beake, B.; Yamamoto, K.; Aguirre, M.; Veldhuis, S.; Dosbaeva, G.; Elfizy, A.; Biksa, A.; Shuster, L. Structure, properties and wear performance of nano-multilayered TiAlCrSiYN/TiAlCrN coatings during machining of Ni-based aerospace superalloys. Surf. Coat. Technol. 2010, 204, 3698–3706. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Zabinski, J.S.; Muratore, C. Recent advances in hard, tough, and low friction nanocomposite coatings. Tsinghua Sci. Technol. 2005, 10, 665–679. [Google Scholar] [CrossRef]

- Chan, K.; He, M.; Hutchinson, J. Cracking and stress redistribution in ceramic layered composites. Mater. Sci. Eng. A 1993, 167, 57–64. [Google Scholar] [CrossRef]

- He, M.Y.; Evans, A.G.; Hutchinson, J.W. Crack deflection at an interface between dissimilar elastic materials: Role of residual stresses. Int. J. Solids Struct. 1994, 31, 3443–3455. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Reinhard, C.; Ehiasarian, A. CrAlYN/CrN superlattice coatings deposited by the combined high power impulse magnetron sputtering/unbalanced magnetron sputtering technique. Surf. Coat. Technol. 2006, 201, 4105–4110. [Google Scholar] [CrossRef]

- Chen, J.; Li, H.; Beake, B.D. Load sensitivity in repetitive nano-impact testing of TiN and AlTiN coatings. Surf. Coat. Technol. 2016, 308, 289–297. [Google Scholar] [CrossRef]

- Skordaris, G.; Bouzakis, K.-D.; Charalampous, P.; Bouzakis, E.; Paraskevopoulou, R.; Lemmer, O.; Bolz, S. Brittleness and fatigue effect of mono-and multi-layer PVD films on the cutting performance of coated cemented carbide inserts. CIRP Ann. Manuf. Technol. 2014, 63, 93–96. [Google Scholar] [CrossRef]

- Davim, J.P. Machining: Fundamentals and Recent Advances; Springer Science & Business Media: Berlin, Germany, 2008. [Google Scholar]

- Hong, Y.S.; Kwon, S.H.; Tiegang, W.; Doo-In, K.; Jihwan, C.; Kim, K.H. Effects of Cr interlayer on mechanical and tribological properties of Cr–Al–Si–N nanocomposite coating. Trans. Nonferr. Met. Soc. China 2011, 21, 62–67. [Google Scholar] [CrossRef]

- Fernandes, C.; Popovich, V.; Matos, M.; Senos, A.; Vieira, M. Carbide phases formed in WC–M (M = Fe/Ni/Cr) systems. Ceram. Int. 2009, 35, 369–372. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Makrimallakis, S.; Katirtzoglou, G.; Skordaris, G.; Gerardis, S.; Bouzakis, E.; Leyendecker, T.; Bolz, S.; Koelker, W. Adaption of graded Cr/CrN-interlayer thickness to cemented carbide substrates’ roughness for improving the adhesion of HPPMS PVD films and the cutting performance. Surf. Coat. Technol. 2010, 205, 1564–1570. [Google Scholar] [CrossRef]

- Klocke, F.; Bouzakis, K.-D.; Georgiadis, K.; Gerardis, S.; Skordaris, G.; Pappa, M. Adhesive interlayers’ effect on the entire structure strength of glass molding tools’ Pt–Ir coatings by nano-tests determined. Surf. Coat. Technol. 2011, 206, 1867–1872. [Google Scholar] [CrossRef]

- Chowdhury, S.; Beake, B.; Yamamoto, K.; Bose, B.; Aguirre, M.; Fox-Rabinovich, G.; Veldhuis, S. Improvement of wear performance of nano-multilayer PVD coatings under dry hard end milling conditions based on their architectural development. Coatings 2018, 8, 59. [Google Scholar] [CrossRef]

- Bull, S.; Berasetegui, E. An overview of the potential of quantitative coating adhesion measurement by scratch testing. Tribol. Int. 2006, 39, 99–114. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Skordaris, G.; Gerardis, S.; Katirtzoglou, G.; Makrimallakis, S.; Pappa, M.; Bolz, S.; Koelker, W. The effect of substrate pretreatments and HPPMS-deposited adhesive interlayers’ materials on the cutting performance of coated cemented carbide inserts. CIRP Ann. 2010, 59, 73–76. [Google Scholar] [CrossRef]

- Ning, L.; Veldhuis, S.; Yamamoto, K. Investigation of wear behavior and chip formation for cutting tools with nano-multilayered TiAlCrN/NbN PVD coating. Int. J. Mach. Tools Manuf. 2008, 48, 656–665. [Google Scholar] [CrossRef]

- Welzel, U.; Ligot, J.; Lamparter, P.; Vermeulen, A.; Mittemeijer, E. Stress analysis of polycrystalline thin films and surface regions by X-ray diffraction. J. Appl. Cryst. 2005, 38, 1–29. [Google Scholar] [CrossRef]

- Vermeulen, A.C. Accurate absolute peak positions for multiple {hkl} residual stress analysis by means of misalignment corrections. Z. Krist. Suppl. 2006, 23, 49–54. [Google Scholar] [CrossRef]

- Schwarzer, N.; Duong, Q.-H.; Bierwisch, N.; Favaro, G.; Fuchs, M.; Kempe, P.; Widrig, B.; Ramm, J. Optimization of the scratch test for specific coating designs. Surf. Coat. Technol. 2011, 206, 1327–1335. [Google Scholar] [CrossRef]

- Yamamoto, K.; Sato, T.; Takahara, K.; Hanaguri, K. Properties of (Ti, Cr, Al) N coatings with high Al content deposited by new plasma enhanced arc-cathode. Surf. Coat. Technol. 2003, 174, 620–626. [Google Scholar] [CrossRef]

- Carvalho, N.; Zoestbergen, E.; Kooi, B.; De Hosson, J.T.M. Stress analysis and microstructure of PVD monolayer TiN and multilayer TiN/(Ti, Al) N coatings. Thin Solid Film. 2003, 429, 179–189. [Google Scholar] [CrossRef]

- Yamamoto, K.; Kujime, S.; Fox-Rabinovich, G. Effect of alloying element (Si, Y) on properties of AIP deposited (Ti, Cr, Al) N coating. Surf. Coat. Technol. 2008, 203, 579–583. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Mitterer, C.; Hultman, L.; Clemens, H. Microstructural design of hard coatings. Prog. Mater. Sci. 2006, 51, 1032–1114. [Google Scholar] [CrossRef]

- Bielawski, M. Residual stress control in TiN/Si coatings deposited by unbalanced magnetron sputtering. Surf. Coat. Technol. 2006, 200, 3987–3995. [Google Scholar] [CrossRef]

- Hassani, S.; Bielawski, M.; Beres, W.; Martinu, L.; Balazinski, M.; Klemberg-Sapieha, J. Predictive tools for the design of erosion resistant coatings. Surf. Coat. Technol. 2008, 203, 204–210. [Google Scholar] [CrossRef]

- Bruet, B.J.; Song, J.; Boyce, M.C.; Ortiz, C. Materials design principles of ancient fish armour. Nat. Mater. 2008, 7, 748–756. [Google Scholar] [CrossRef] [PubMed]

- Fox-Rabinovich, G.; Beake, B.; Endrino, J.; Veldhuis, S.; Parkinson, R.; Shuster, L.; Migranov, M. Effect of mechanical properties measured at room and elevated temperatures on the wear resistance of cutting tools with TiAlN and AlCrN coatings. Surf. Coat. Technol. 2006, 200, 5738–5742. [Google Scholar] [CrossRef]

- Bull, S. Failure mode maps in the thin film scratch adhesion test. Tribol. Int. 1997, 30, 491–498. [Google Scholar] [CrossRef]

- Zeng, X.; Zhang, S.; Ding, X.; Teer, D. Comparison of three types of carbon composite coatings with exceptional load-bearing capacity and high wear resistance. Thin Solid Film. 2002, 420, 366–370. [Google Scholar] [CrossRef]

- Beake, B.; Vishnyakov, V.; Harris, A. Nano-scratch testing of (Ti, Fe) Nxthin films on silicon. Surf. Coat. Technol. 2017, 309, 671–679. [Google Scholar] [CrossRef]

- Beake, B.; Shi, B.; Sullivan, J. Nanoscratch and nanowear testing of TiN coatings on M42 steel. Tribol. Mater. Surf. Interfaces 2011, 5, 141–147. [Google Scholar] [CrossRef]

- Beake, B.; Endrino, J.L.; Kimpton, C.; Fox-Rabinovich, G.; Veldhuis, S. Elevated temperature repetitive micro-scratch testing of AlCrN, TiAlN and AlTiN PVD coatings. Int. J. Refract. Met. Hard Mater. 2017, 69, 215–226. [Google Scholar] [CrossRef]

- Beake, B.D.; Smith, J.F. Nano-impact testing—An effective tool for assessing the resistance of advanced wear-resistant coatings to fatigue failure and delamination. Surf. Coat. Technol. 2004, 188, 594–598. [Google Scholar] [CrossRef]

- Musil, J.; Jirout, M. Toughness of hard nanostructured ceramic thin films. Surf. Coat. Technol. 2007, 201, 5148–5152. [Google Scholar] [CrossRef]

- Pei, Y.; Galvan, D.; De Hosson, J.T.M. Nanostructure and properties of TiC/aC: H composite coatings. Acta Mater. 2005, 53, 4505–4521. [Google Scholar] [CrossRef]

- Trent, E.M.; Wright, P.K. Metal. Cutting; Butterworth-Heinemann: Oxford, UK, 2000. [Google Scholar]

- Fox-Rabinovich, G.; Yamamoto, K.; Beake, B.; Kovalev, A.; Aguirre, M.; Veldhuis, S.; Dosbaeva, G.; Wainstein, D.; Biksa, A.; Rashkovskiy, A. Emergent behavior of nano-multilayered coatings during dry high-speed machining of hardened tool steels. Surf. Coat. Technol. 2010, 204, 3425–3435. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Kovalev, A.; Aguirre, M.; Yamamoto, K.; Veldhuis, S.; Gershman, I.; Rashkovskiy, A.; Endrino, J.; Beake, B.; Dosbaeva, G. Evolution of self-organization in nano-structured PVD coatings under extreme tribological conditions. Appl. Surf. Sci. 2014, 297, 22–32. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Kovalev, A.; Veldhuis, S.; Yamamoto, K.; Endrino, J.; Gershman, I.; Rashkovskiy, A.; Aguirre, M.; Wainstein, D. Spatio-temporal behaviour of atomic-scale tribo-ceramic films in adaptive surface engineered nano-materials. Sci. Rep. 2015, 5, 8780. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Endrino, J.; Aguirre, M.; Beake, B.; Veldhuis, S.; Kovalev, A.; Gershman, I.; Yamamoto, K.; Losset, Y.; Wainstein, D. Mechanism of adaptability for the nano-structured TiAlCrSiYN-based hard physical vapor deposition coatings under extreme frictional conditions. J. Appl. Phys. 2012, 111, 064306. [Google Scholar] [CrossRef]

- Giuliani, F.; Goruppa, A.; Lloyd, S.; Teer, D.; Clegg, W. Indentation of AlN/CrN Multilayers from Room Temperature to 400 °C. Mater. Sci. Forum 2005, 492–493, 335–340. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Veldhuis, S.; Dosbaeva, G.; Yamamoto, K.; Kovalev, A.; Wainstein, D.; Gershman, I.; Shuster, L.; Beake, B. Nanocrystalline coating design for extreme applications based on the concept of complex adaptive behavior. J. Appl. Phys. 2008, 103, 083510. [Google Scholar] [CrossRef]

- Rovere, F.; Music, D.; Schneider, J.; Mayrhofer, P. Experimental and computational study on the effect of yttrium on the phase stability of sputtered Cr–Al–Y–N hard coatings. Acta Mater. 2010, 58, 2708–2715. [Google Scholar] [CrossRef]

| Overall Thickness | Interlayer Thickness | Deposition Time (Interlayer) |

|---|---|---|

| 2 µm | 100 nm | 1 min |

| 2 µm | 300 nm | 3 min |

| 2 µm | 500 nm | 5 min |

| Cutting Parameters | ||||

|---|---|---|---|---|

| Speed, m/min | Feed, mm/tooth | Axial Depth, mm | Radial Depth, mm | Coolant |

| 600 | 0.06 | 5 | 0.6 | Dry condition |

| Coating | TiAlCrN Interlayer Thickness (nm) | Residual Stress (GPa) |

|---|---|---|

| TiAlCrSiYN/TiAlCrN multilayer | 100 | −8.21 ± 1.39 |

| 300 | −8.64 ± 1.65 | |

| 500 | −8.71 ± 1.47 |

| Coating | Multilayer | Multilayer | Multilayer |

|---|---|---|---|

| Interlayer Thickness | 100 nm | 300 nm | 500 nm |

| H3/E2(Resistance to Plastic Deformation) | 0.1761 | 0.1547 | 0.1298 |

| H/E | 0.070223 | 0.0664 | 0.0636 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chowdhury, S.; Bose, B.; Yamamoto, K.; Veldhuis, S.C. Effect of Interlayer Thickness on Nano-Multilayer Coating Performance during High Speed Dry Milling of H13 Tool Steel. Coatings 2019, 9, 737. https://doi.org/10.3390/coatings9110737

Chowdhury S, Bose B, Yamamoto K, Veldhuis SC. Effect of Interlayer Thickness on Nano-Multilayer Coating Performance during High Speed Dry Milling of H13 Tool Steel. Coatings. 2019; 9(11):737. https://doi.org/10.3390/coatings9110737

Chicago/Turabian StyleChowdhury, Shahereen, Bipasha Bose, Kenji Yamamoto, and Stephen C. Veldhuis. 2019. "Effect of Interlayer Thickness on Nano-Multilayer Coating Performance during High Speed Dry Milling of H13 Tool Steel" Coatings 9, no. 11: 737. https://doi.org/10.3390/coatings9110737

APA StyleChowdhury, S., Bose, B., Yamamoto, K., & Veldhuis, S. C. (2019). Effect of Interlayer Thickness on Nano-Multilayer Coating Performance during High Speed Dry Milling of H13 Tool Steel. Coatings, 9(11), 737. https://doi.org/10.3390/coatings9110737