Paint Pull-Off Strength and Permeability in Nanosilver-Impregnated and Heat-Treated Beech Wood

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Procurement

2.2. Pull-Off Adhesion Strength Testing

2.3. Gas Permeability Measurement

2.4. Nanosilver Impregnation

2.5. Heat Treatment Process

2.6. SEM Imaging

2.7. Statistical Analysis

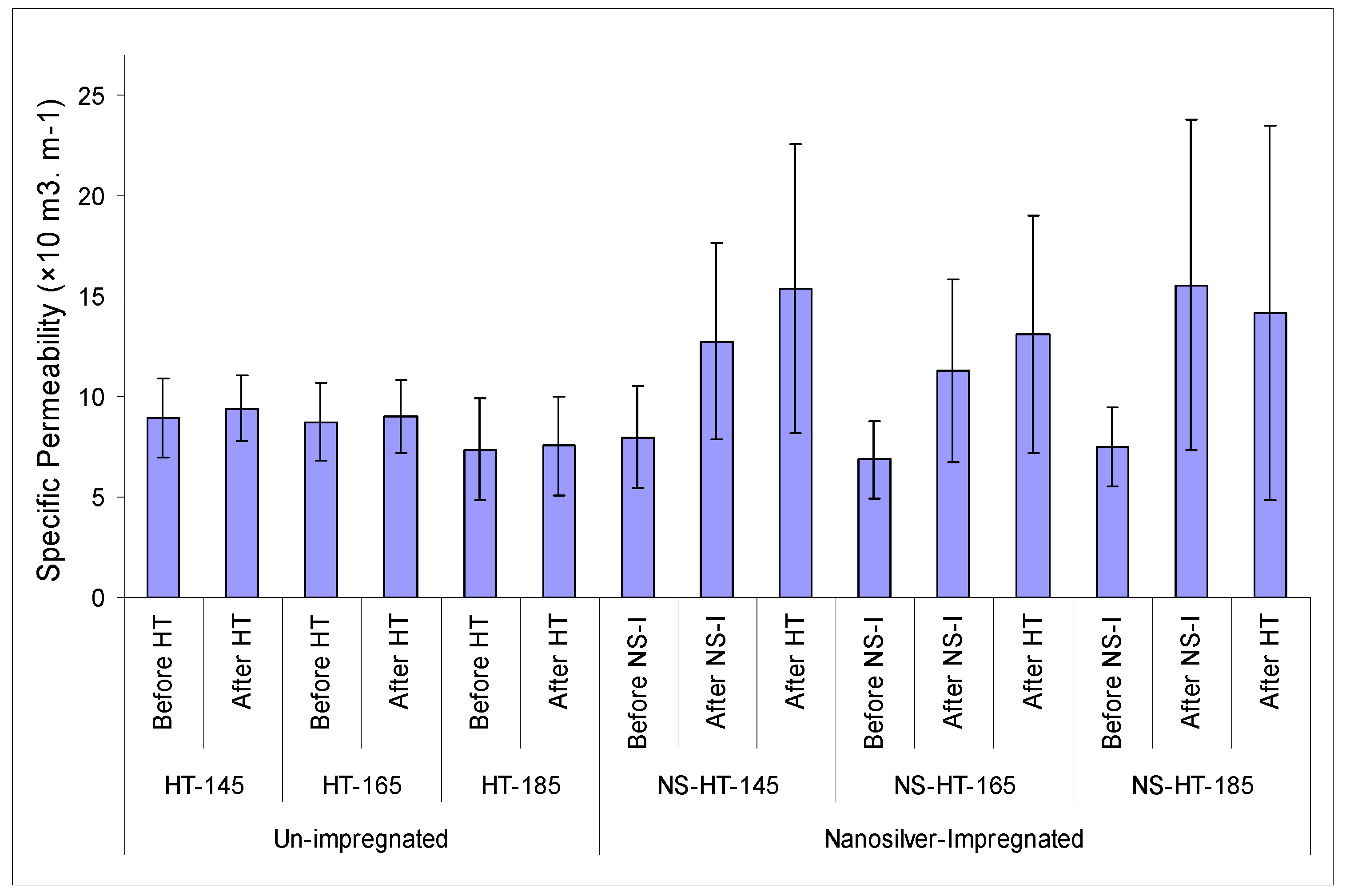

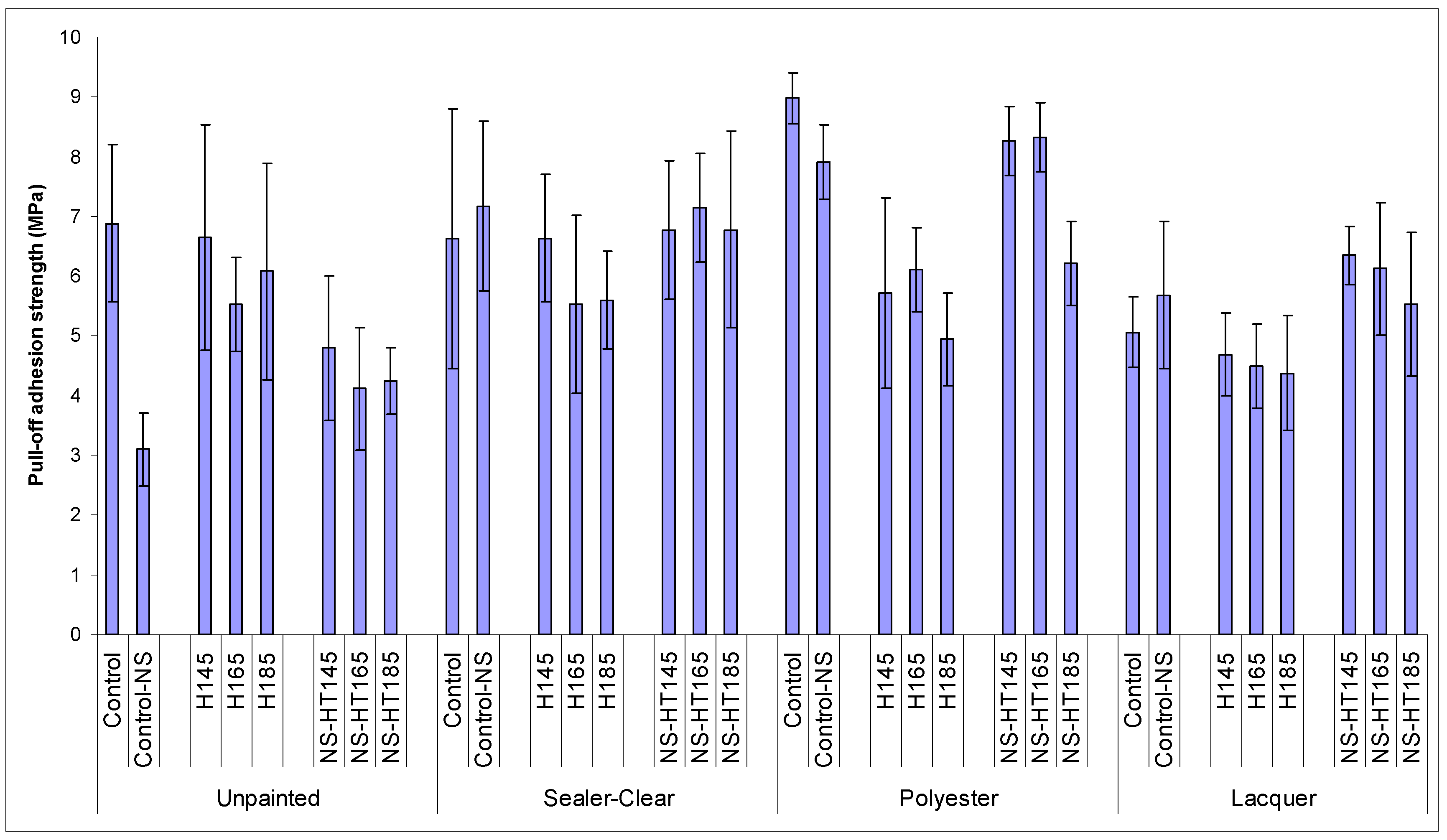

3. Results

4. Discussion

5. Conclusions

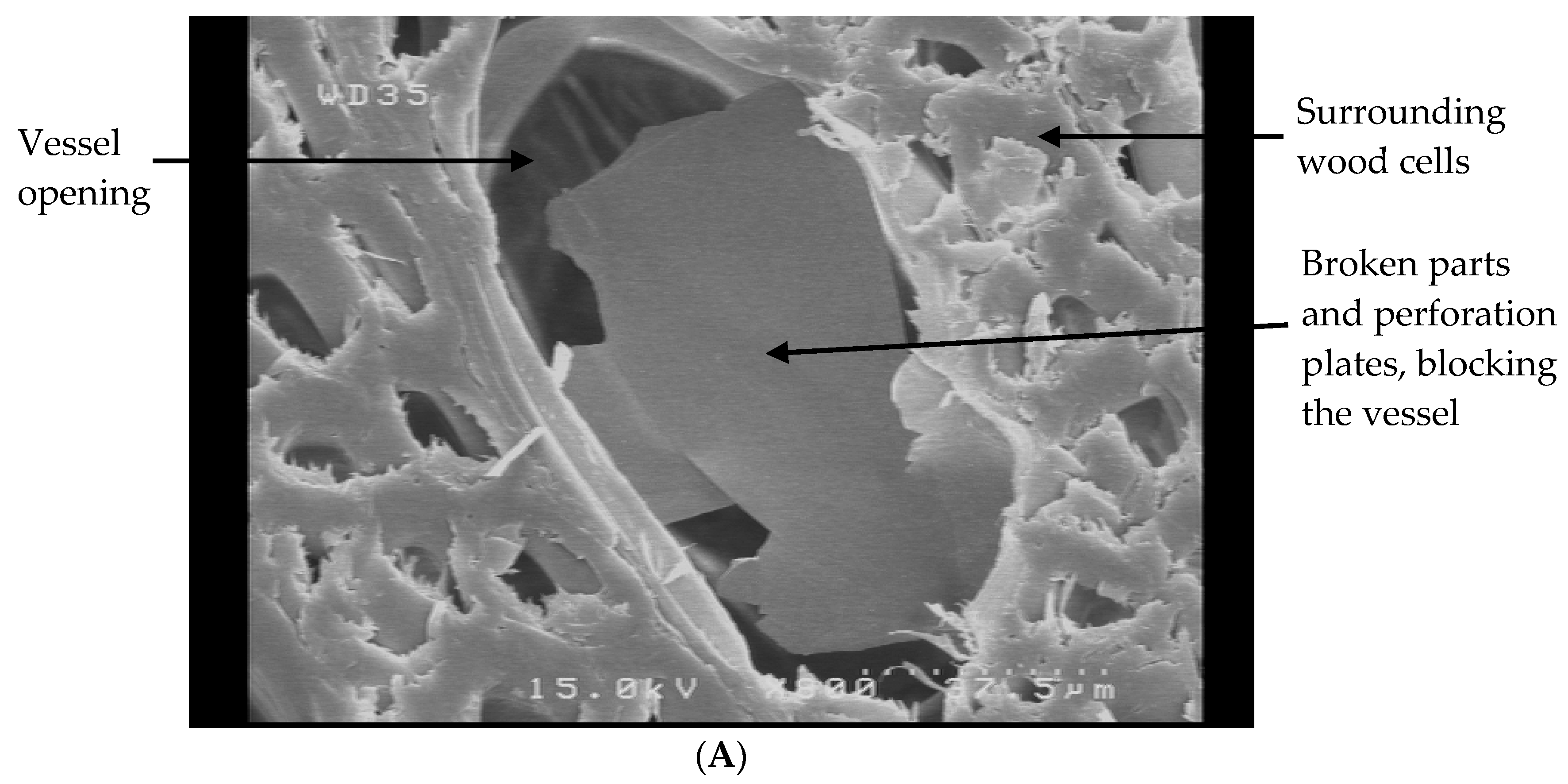

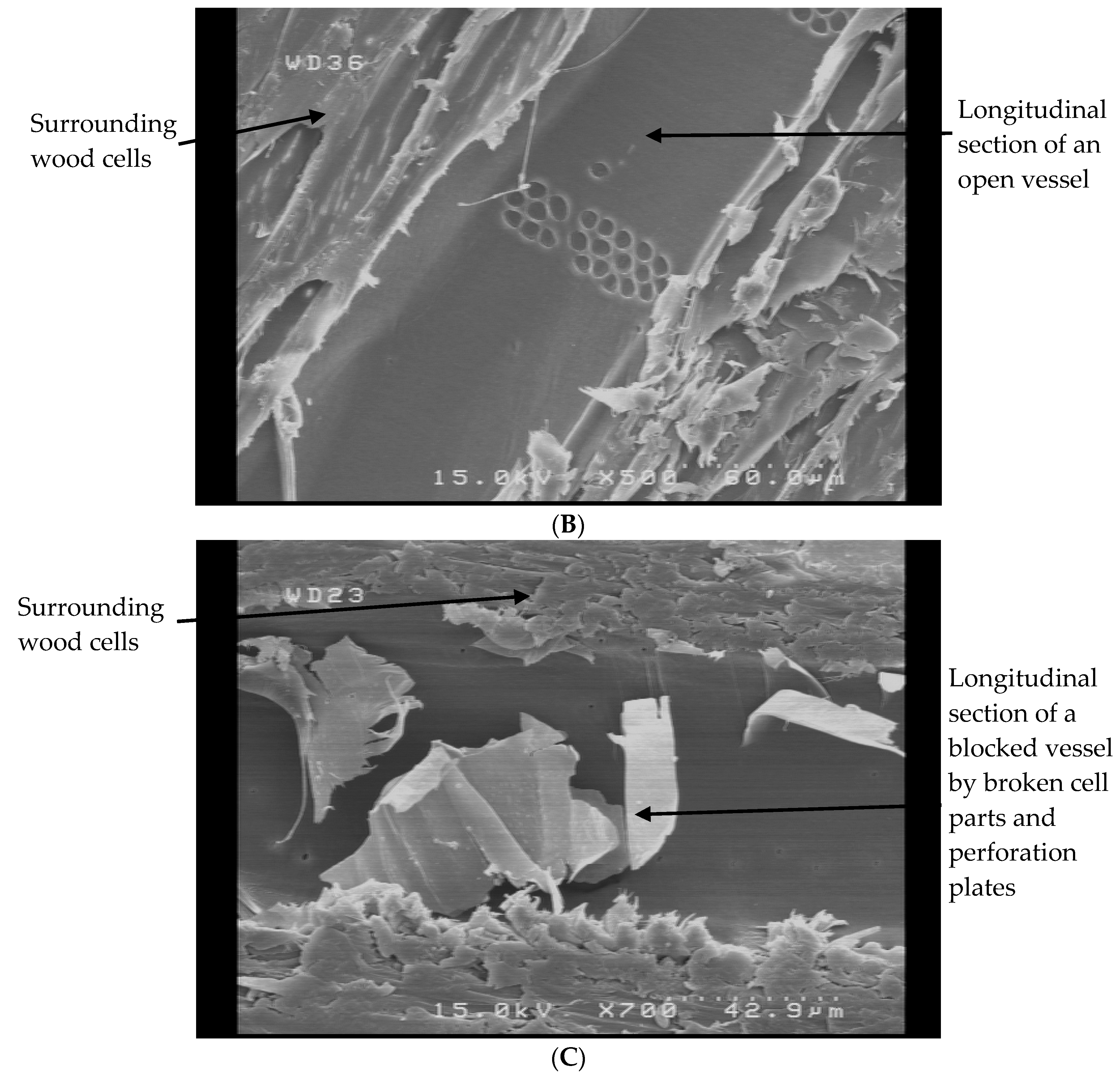

- Impregnating beech wood with nanosilver suspension results in the rupture of perforation plated and pit openings, and eventually permeability increases significantly.

- Higher permeability causes more adhesive being penetrated deep in to the pores of the wood substrate, being left out of the sticking process, eventually decreasing pull-off strength.

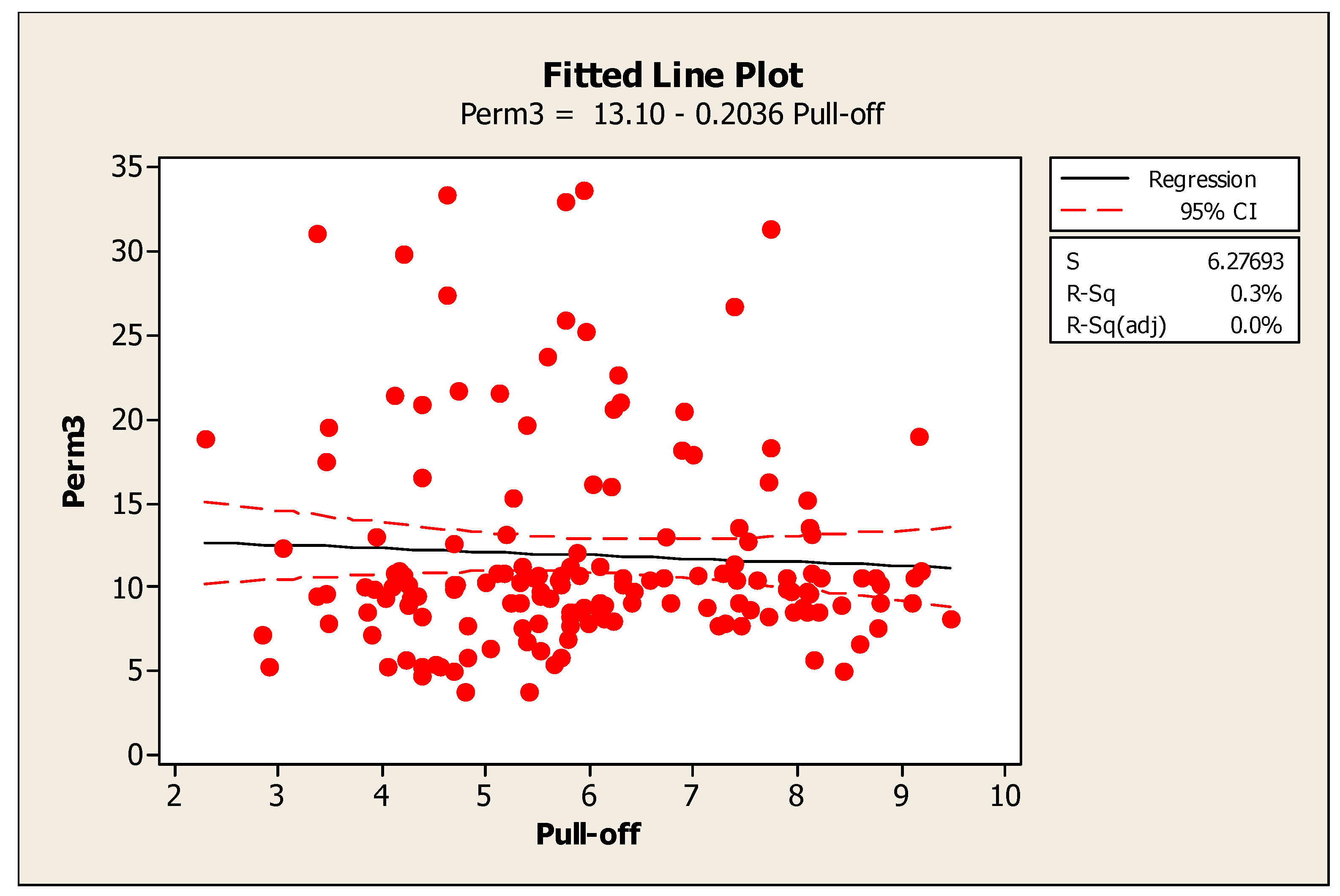

- Permeability depends on the continuous pore system. Pull-off adhesion strength, however, is dependent on the surface pore system of the wood substrate. Therefore, there is no significant correlation between pull-off adhesion strength versus air permeability.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Siau, J.F. Flow in Wood; Syracuse University Press: Syracuse, NY, USA, 1971. [Google Scholar]

- Siau, J.F. Wood: Influence of Moisture on Physical Properties; Blacksburg, V.A., Ed.; Department of Wood Science and Forest Products, Virginian Polytechnic Institute and State University: Blacksburg, VA, USA, 1995. [Google Scholar]

- Siau, J.F. Transport Processes in Wood; Springer: Berlin/Heidelbergh, Germany; GmbH & Co. KG: Berlin, Germany, 2011. [Google Scholar]

- Skaar, C. Wood-Water Relations; Springer: Berlin/Heidelberg, Germany, 1988. [Google Scholar]

- Oltean, L.; Teischinger, A.; Hansmann, C. Influence of temperature on cracking and mechanical properties of wood during wood drying—A review. BioResources 2008, 2, 789–811. [Google Scholar]

- Mosqueda, M.R.P.; Tabil, L.G.; Christensen, C. Effect of drying conditions and level of condensed distillers solubles on protein quality of what distillers dried grain with solubles. Dry. Technol. 2013, 31, 811–824. [Google Scholar] [CrossRef]

- Fernandez-Puratich, H.; Oliver-Villanueva, J.V. Quantification of biomass and energetic value of young natural regenerated stands of Quercus ilex under Mediterranean conditions. Bosque 2014, 35, 65–74. [Google Scholar]

- Borrega, M.; Karenlampi, P.P. Hygroscopicity of heat-treated norway spruce (Picea abies) wood. Eur. J. Wood Wood Prod. 2010, 68, 233–235. [Google Scholar] [CrossRef][Green Version]

- Hering, S.; Keunecke, D.; Niemz, P. Moisture-dependent orthotropic elasticity of beech wood. Wood Sci. Technol. 2012, 46, 927–938. [Google Scholar] [CrossRef]

- Barna, M. Natural regeneration of Fagus sylvatica L.: A Review. Austrian J. For. Sci. 2011, 128, 71–91. [Google Scholar]

- Hill, C. Wood Modification Chemical, Thermal and Other Processes; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Schmidt, O. Wood and Tree Fungi: Biology, Damage, Protection, and Use; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Maresi, G.; Oliveira Longa, C.M.; Turchetti, T. Brown rot on nuts of Castanea sativa Mill: An emerging disease and its causal agent. iForest Biogeosci. For. 2013, 6, 294–301. [Google Scholar] [CrossRef]

- Awoyemi, L. Determination of optimum borate concentration for alleviating strength loss during heat treatment of wood. Wood Sci. Technol. 2007, 42, 39–45. [Google Scholar] [CrossRef]

- Repellin, V.; Guyonnet, R. Evaluation of heat treated wood swelling by differential scanning calorimetry in relation with chemical composition. Holzforschung 2005, 59, 28–34. [Google Scholar] [CrossRef]

- Pati, R. Molecule for electronics: A myriad of opportunities comes with daunting challenges. J. Nanomater. Mol. Nanotechnol. 2012, 1. [Google Scholar] [CrossRef]

- Sadeghi, B.; Rastgo, S. Study of the shape controlling silver nanoplates by reduction process. Int. J. Bio-Inorg. Hybrid Nanomater. 2012, 1, 33–36. [Google Scholar]

- Saber, R.; Shakoori, Z.; Sarkar, S.; Tavoosidana, G.; Kharrazi, S.; Gill, P. Spectroscopic and microscopic analyses of rod-shaped gold nanoparticles interacting with single-stranded DNA oligonucleotides. IET Nanobiotechnol. 2013, 7, 42–49. [Google Scholar] [CrossRef] [PubMed]

- Tomic, S.L.; Micic, M.M.; Dokic, D.; Vasiljevic-Radvic, D.G.; Filipovic, J.M.; Suljovrujic, E.H. Preparation of silver (I) complexes with itaconic acid-based hydrogels for biomedical application. Mater. Manuf. Process. 2009, 24, 1197. [Google Scholar] [CrossRef]

- Nguyen, N.T.; Nguyen, B.H.; Ba, D.T.; Pham, D.G.; Khai, T.V.; Nguyen, L.T.; Tran, L.D. Microwave-assisted synthesis of silver nanoparticles using chitosan: A novel approach. Mater. Manuf. Process. 2014, 29, 418. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Enayati, A.; Gholamiyan, H. Effects of nano-silver impregnation on brittleness, physical and mechanical properties of heat-treated hardwoods. Wood Sci. Technol. 2013, 47, 467–480. [Google Scholar] [CrossRef]

- Taghiyari, H.R. Effects of heat-treatment on permeability of untreated and nanosilver-impregnated native hardwoods. Maderas Cienc. Y Tecnol. 2013, 15, 183–194. [Google Scholar] [CrossRef]

- Sönmez, A.; Budakci, M.; Huseyin, P. The effect of the moisture content of wood on the layer performance of water-borne varnishes. BioResources 2011, 6, 3166–3178. [Google Scholar]

- Figueroa, M.; Bustos, C.; Dechent, P.; Reyes, L.; Cloutier, A.; Giuliano, M. Analysis of rheological and thermo-hygro-mechanical behaviour of stress-laminated timber bridge deck in variable environmental conditions. Maderas Cienc. Y Tecnol. 2012, 14, 303–319. [Google Scholar]

- ASTM D 4541-02. Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers; ASTM: West Conshohocken, PA, USA, 2006.

- Taghiyari, H.R.; Kalantari, A.; Avramidis, S. Effect of wollastonite nanofibers and exposure to Aspergillus niger fungus on air flow rate in paper. Measurement 2019, 136, 307–313. [Google Scholar] [CrossRef]

- Shi, S.H.Q. Diffusion model based on Fick’s second law for the moisture absorption process in wood fiber-based composites: Is it suitable or not? Wood Sci. Technol. 2007, 41, 645–658. [Google Scholar] [CrossRef]

- Dermoe, D.; Zillig, W.; Carmeliet, J. Variation of measured cross-sectional cell dimensions and calculated water vapor permeability across a single growth ring of spruce wood. Wood Sci. Technol. 2012, 46, 827–840. [Google Scholar] [CrossRef]

- Shibata, H.; Hirohashi, Y. Effect of segment scale in a pore network of porous materials on drying periods. Dry. Technol. 2013, 31, 743–751. [Google Scholar] [CrossRef]

- Ghorbani, M.; Akhtari, M.; Taghiyari, H.R.; Kalantari, A. Effects of silver and zinc-oxide nanoparticles on gas and liquid permeability of heat-treated Paulownia wood. Austrian J. For. Sci. 2012, 129, 106–123. [Google Scholar]

- Esmailpour, A.; Taghiyari, H.R.; Golchin, M.; Avramidis, S. On the fluid permeability of heat treated paulownia wood. Int. Wood Prod. J. 2019, 10, 55–63. [Google Scholar] [CrossRef]

- Hernandez, V.; Avramidis, S.; Navarrete, J. Albino strains of Ophiostoma spp. Fungi effect on radiate pine permeability. Eur. J. Wood Wood Prod. 2012, 70, 551–556. [Google Scholar] [CrossRef]

- Choo, A.C.Y.; Tahir, M.P.; Karimi, A.; Bakar, E.S.; Abdan, K.; Ibrahim, A.; Balkis, F.A.B. Study on the longitudinal permeability of oil palm wood. Ind. Eng. Chem. Res. 2013, 52, 9405–9410. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Norton, J. Effect of silver nanoparticles on hardness in medium-density fiberboard (MDF). J. iForest Biogeosci. For. 2014, 8, 677–680. [Google Scholar] [CrossRef]

- Dashti, H.; Shahverdi, M.; Taghiyari, H.R.; Salehpur, S.; Heshmati, S. Effects of steaming and microwave pretreatments on mass transfer characteristics of Aleppe oak (Quercus infectoria). BioResources 2012, 7, 3262–3273. [Google Scholar]

- Taghiyari, H.R. Correlation between gas and liquid permeability in some nanosilver-impregnated and untreated hardwood. J. Trop. For. Sci. 2012, 24, 249–255. [Google Scholar]

- Korkut, S.; Budakci, M. Effect of high-temperature treatment on the mechanical properties of Rowan (Sorbus aucuparia L.) wood. Dry. Technol. 2009, 27, 1240–1247. [Google Scholar] [CrossRef]

- Bayani, S.; Taghiyari, H.R.; Papadopoulos, A.N. Physical and mechanical properties of thermally-modified beech wood impregnated with silver nano-suspension and their relationship with the crystallinity of cellulose. Polymers 2019, 11, 1538. [Google Scholar] [CrossRef] [PubMed]

- Bayani, S.; Bazyar, B.; Mirshokraie, S.A.; Taghiyari, H.R. Effects of heat treatment on the relative amounts of cellulose in nanosilver-impregnated and untreated poplar wood (Populus alba). Floresta E Ambiente 2019, 26, e20160398. [Google Scholar] [CrossRef]

| Treatments | R-Square | ||||

|---|---|---|---|---|---|

| Un-Painted | SC | Lacquer | Polyester | ||

| Un-heated | Control | 0.795 ns(-) | 0.191 ns(+) | 0.047 ns(+) | 0.732 ns(+) |

| NS-I | 0.304 ns(-) | 0.519 ns(+) | 0.443 ns(+) | 0.200 ns(+) | |

| HT-145 | Control | 0.004 ns(-) | 0.683 ns(+) | 0.503 ns(-) | 0.954 *(-) |

| NS-I | 0.004 ns(-) | 0.061 ns(+) | 0.034 ns(-) | 0.186 ns(-) | |

| HT-165 | Control | 0.111 ns(-) | 0.470 ns(+) | 0.105 ns(+) | 0.676 ns(+) |

| NS-I | 0.469 ns(-) | 0.135 ns(+) | 0.650 ns(-) | 0.284 ns(-) | |

| HT-185 | Control | 0.240 ns(+) | 0.638 ns(+) | 0.234 ns(+) | 0.438 ns(+) |

| NS-I | 0.551 ns(+) | 0.520 ns(-) | 0.246 ns(-) | 0.481 ns(+) | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taghiyari, H.; Esmailpour, A.; Papadopoulos, A. Paint Pull-Off Strength and Permeability in Nanosilver-Impregnated and Heat-Treated Beech Wood. Coatings 2019, 9, 723. https://doi.org/10.3390/coatings9110723

Taghiyari H, Esmailpour A, Papadopoulos A. Paint Pull-Off Strength and Permeability in Nanosilver-Impregnated and Heat-Treated Beech Wood. Coatings. 2019; 9(11):723. https://doi.org/10.3390/coatings9110723

Chicago/Turabian StyleTaghiyari, Hamid, Ayoub Esmailpour, and Antonios Papadopoulos. 2019. "Paint Pull-Off Strength and Permeability in Nanosilver-Impregnated and Heat-Treated Beech Wood" Coatings 9, no. 11: 723. https://doi.org/10.3390/coatings9110723

APA StyleTaghiyari, H., Esmailpour, A., & Papadopoulos, A. (2019). Paint Pull-Off Strength and Permeability in Nanosilver-Impregnated and Heat-Treated Beech Wood. Coatings, 9(11), 723. https://doi.org/10.3390/coatings9110723