Morphology, Structure, and Properties of Conductive Polylactide Fibers Prepared Using Polyvinyl Acetate and Multiwalled Carbon Nanotubes

Abstract

1. Introduction

2. Experimental Details

2.1. Materials

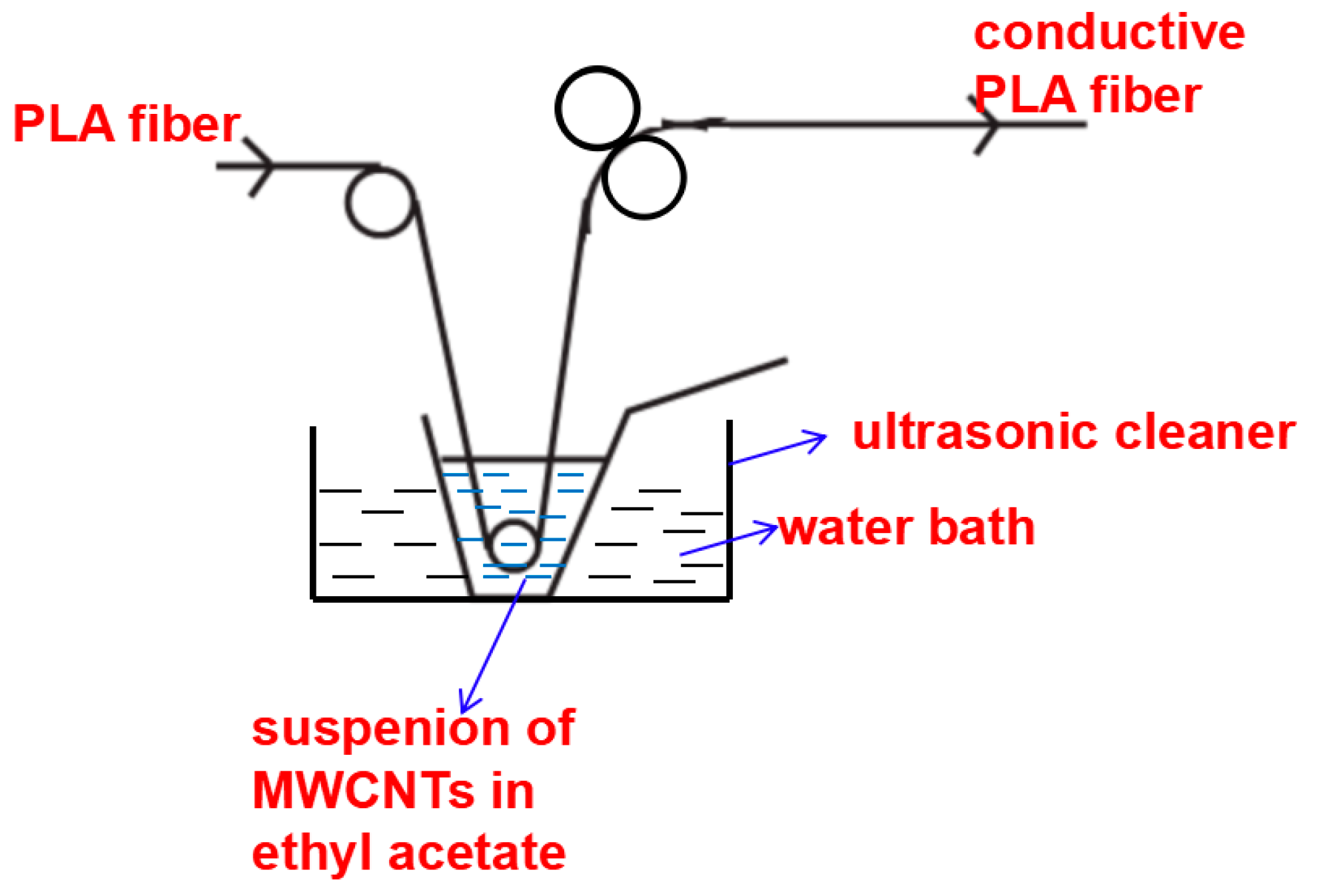

2.2. The Preparation of Conductive PLA Fiber

2.3. Differential Scanning Calorimetry

2.4. Scanning Electron Microscope

2.5. Fourier Transform Infrared-Attenuated Total Reflection Spectroscopy

2.6. Conductive Properties

2.7. Tensile Test

3. Results and Discussion

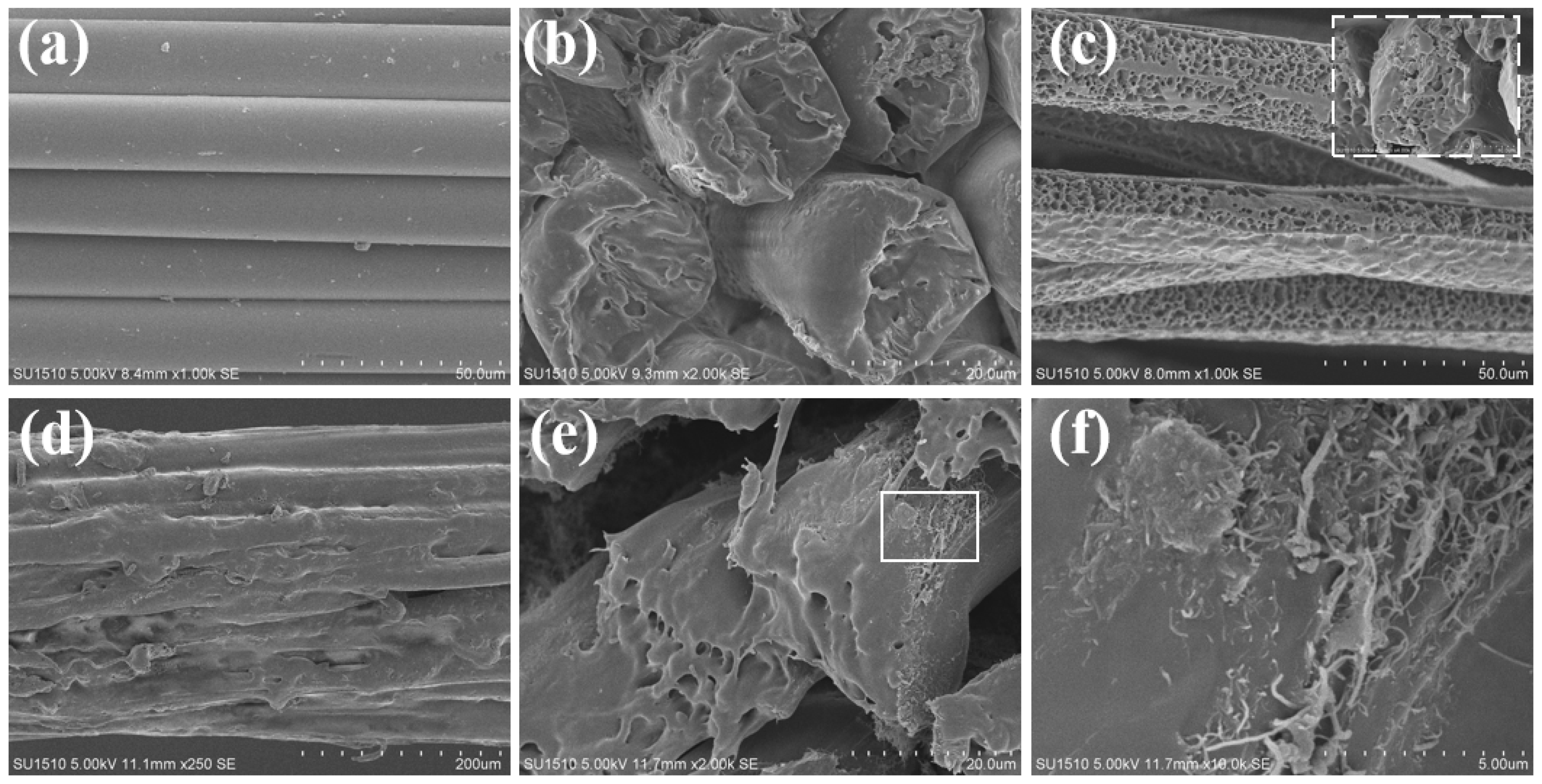

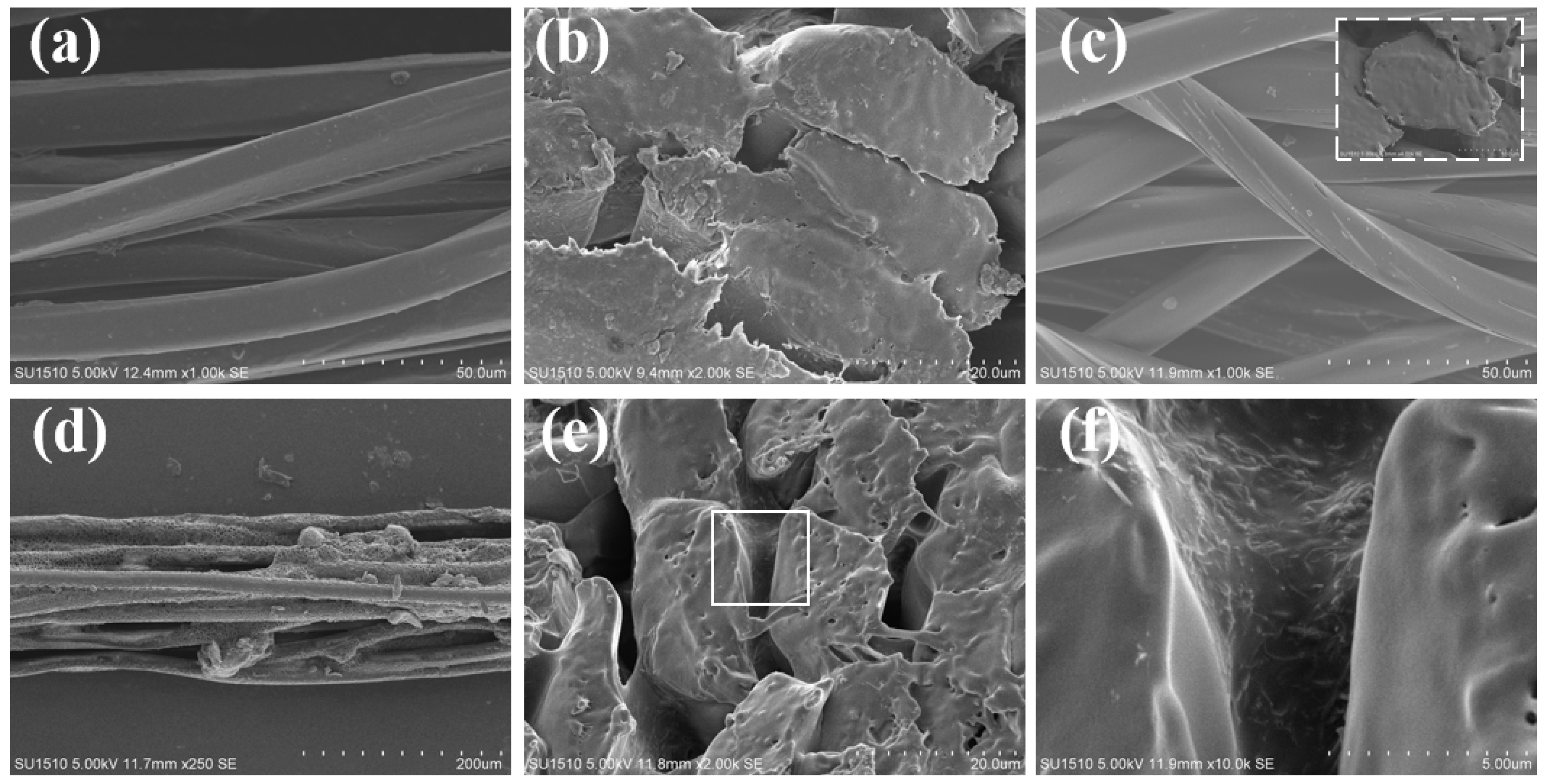

3.1. Morphology of PLA Fibers

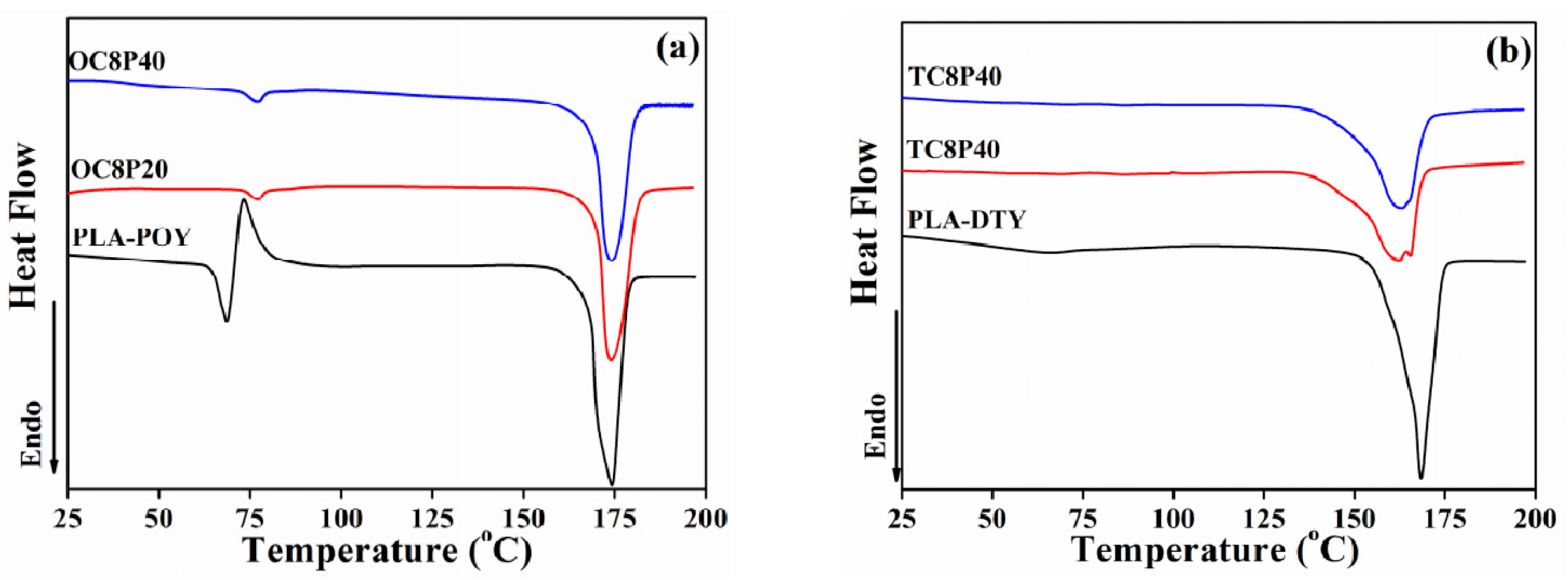

3.2. DSC Analysis

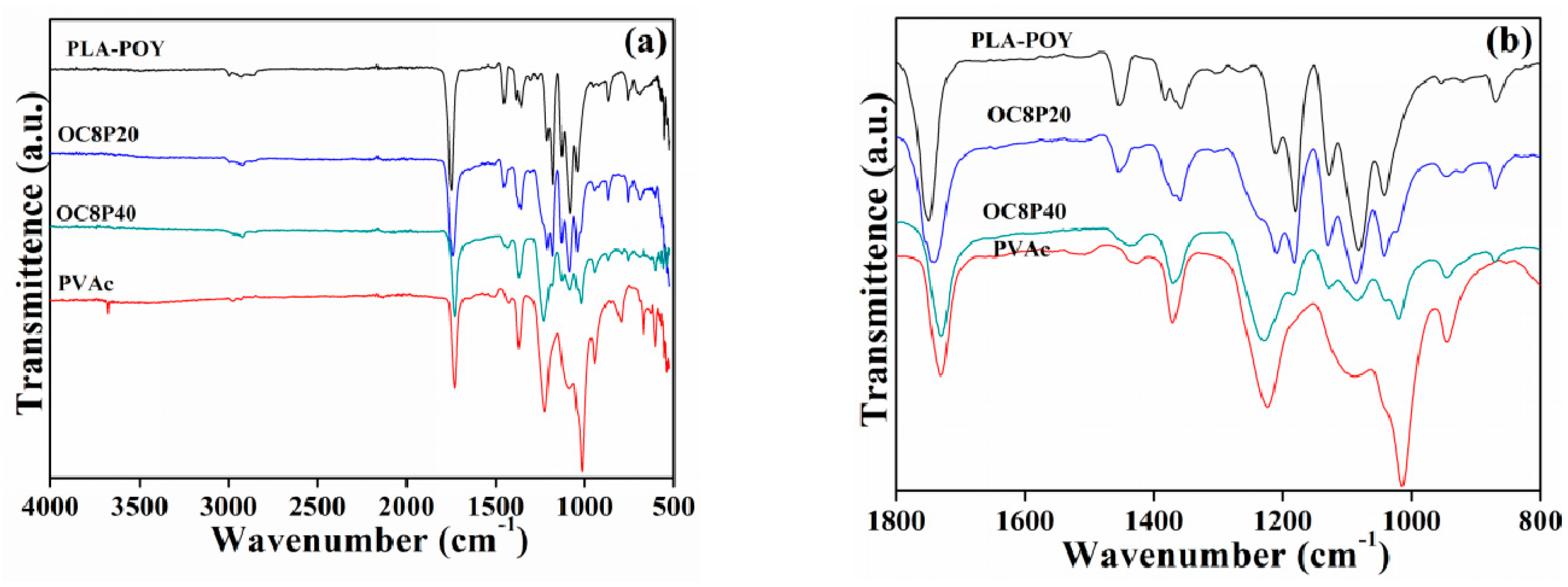

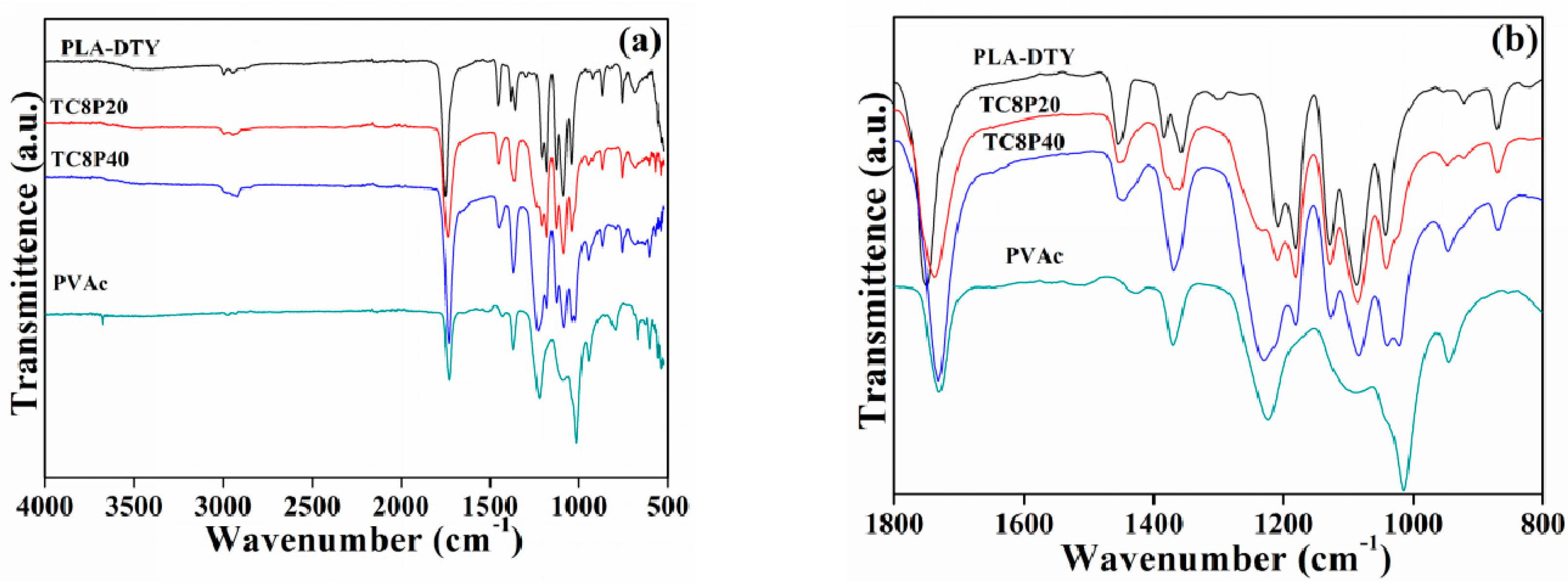

3.3. FTIR-ATR Analysis

3.4. Conductive Properties

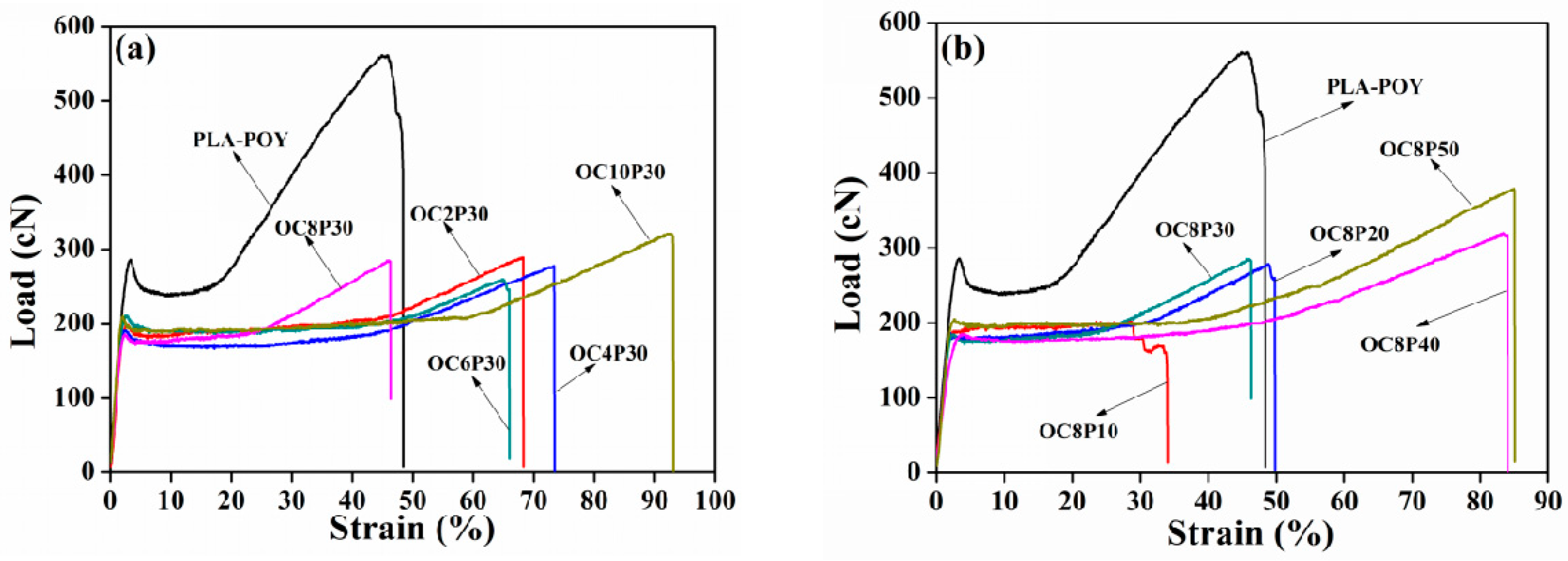

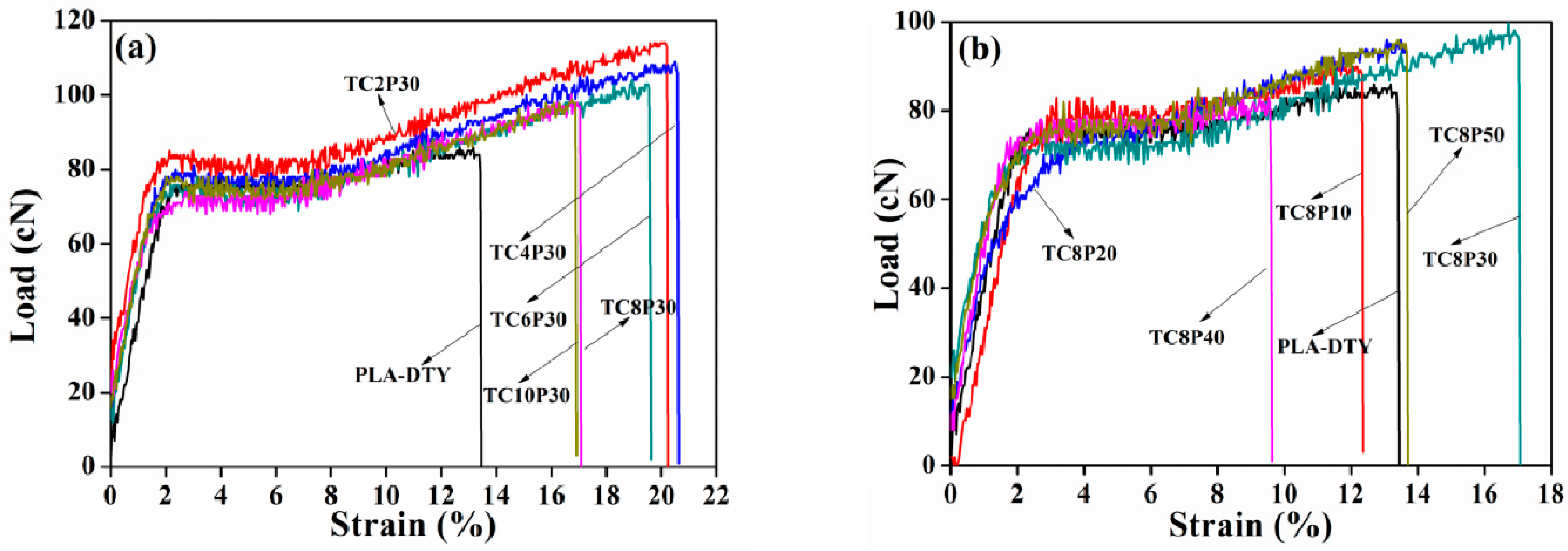

3.5. Tensile Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liu, Q.S.; Zhao, M.M.; Zhou, Y.Q.; Yang, Q.B.; Shen, Y.; Gong, R.H.; Zhou, F.L.; Deng, B.Y. Polylactide single-polymer composites with a wide melt-processing window based on core-sheath PLA fibers. Mater. Des. 2018, 139, 36–44. [Google Scholar] [CrossRef]

- Liu, Q.S.; Wu, C.; Zhang, H.X.; Deng, B.Y. Blends of polylactide and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with low content of hydroxyvalerate unit: Morphology, structure, and property. J. Appl. Polym. Sci. 2015, 132, 42689. [Google Scholar] [CrossRef]

- Liu, Q.S.; Sun, Y.Y.; Xia, S.N.; Zhang, H.X.; Tao, X.L.; Liu, Y.Y.; Deng, B.Y. Structure and mechanical property of polylactide fibers manufactured by air drawing. Text. Res. J. 2016, 86, 948–959. [Google Scholar] [CrossRef]

- Schmack, G.; Tändler, B.; Optiz, G.; Vogel, R.; Komber, H.; Häuβler, L.; Voigt, D.; Weinmann, S.; Heinemann, M.; Fritz, H.-G. High-speed melt spinning of various grades of polylactides. J. Appl. Polym. Sci. 2004, 91, 800–806. [Google Scholar] [CrossRef]

- Takasaki, M.; Ito, H.; Kikutani, T. Development of stereocomplex crystal of polylactide in high-speed melt spinning and subsequent drawing and annealing process. J. Macromol. Sci. Part B Phys. 2003, B42, 403–420. [Google Scholar] [CrossRef]

- Furuhashi, Y.; Kimura, Y.; Yamane, H. Higher order structural analysis of stereocomplex-type poly(lactic acid) melt-spun fibers. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 218–228. [Google Scholar] [CrossRef]

- Solarski, S.; Mahjoubi, F.; Ferreira, M.; Devaux, E.; Bachelet, P.; Bourbigot, S.; Delobel, R.; Coszach, P.; Murariu, M.; Ferreira, A.D.S.; et al. (Plasticized) Polylactide/clay nanocomposite textile: Thermal mechanical, shrinkage and fire properties. J. Mater. Sci. 2007, 42, 5105–5117. [Google Scholar] [CrossRef]

- Li, L.Z.; Huang, W.; Wang, B.J.; Wei, W.F.; Gu, Q. Properties and structure of polylactide/poly (3-hydroxybutyrate-co-3-hydroxyvalerate) (PLA/PHBV) blend fibers. Polymer 2015, 68, 183–194. [Google Scholar] [CrossRef]

- Hufenus, R.; Reifler, F.A.; Maniura-Weber, K.; Spierings, A.; Zinn, M. Biodegradable bicomponent fibers from renewable sources: Melt-spinning of poly(lactic acid) and poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)]. Macromol. Mater. Eng. 2012, 297, 75–84. [Google Scholar] [CrossRef]

- Zhang, H.X.; Bai, H.W.; Liu, Z.W.; Zhang, Q.; Fu, Q. Toward high-performance poly(L-lactide) fibers via tailoring crystallization with the aid of fibrillar nucleating agent. ACS Sustain. Chem. Eng. 2016, 4, 3939–3947. [Google Scholar] [CrossRef]

- Liu, Q.S.; Yang, Q.B.; Zhou, Y.Q.; Zhao, M.M.; Shen, Y.; Zhou, F.L.; Gong, R.H.; Deng, B.Y. A facile method of preparing highly porous polylactide microfibers. J. Appl. Polym. Sci. 2018, 135, 45860. [Google Scholar] [CrossRef]

- Rentenberger, R.; Cayla, A.; Villmow, T.; Jehnichen, D.; Campagne, C.; Rochery, M.; Devaux, E.; Pötschke, P. Multifilament fibres of poly(ε-caprolactone)/poly(lactic acid) blends with multiwalled carbon nanotubes as sensor materials for ethyl acetate and acetone. Sens. Actuat. B Chem. 2011, 160, 22–31. [Google Scholar] [CrossRef]

- Zhang, X.H.; Lu, W.B.; Zhou, G.H.; Li, Q.W. Understanding the Mechanical and Conductive Properties of Carbon Nanotube Fibers for Smart Electronics. Adv. Mater. 2019, 1902028. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.T.; Sun, X.T.; Zhao, H.T.; Tian, M.W.; Zhang, X.S.; Zhu, S.F. A simple and scalable production of conductive fibers with excellent washing resistance. Mater. Lett. 2019, 239, 9–12. [Google Scholar] [CrossRef]

- Liu, Q.S.; Jiang, J.Z.; Zhang, H.X.; Wang, J.C.; Li, X.M.; Li, Y.H.; Deng, B.Y. Miscibility and phase morphology of polylactide/poly(vinyl acetate-co-vinyl alcohol) blends obtained by melt mixing. Polym.-Plast. Technol. 2014, 53, 1590–1597. [Google Scholar] [CrossRef]

- Liu, Q.S.; Zhang, H.X.; Zhu, M.F.; Dong, Z.; Wu, C.; Jiang, J.Z.; Li, X.R.; Luo, F.; Gao, Y.X.; Deng, B.Y.; et al. Blends of polylactide/thermoplactic elastomer: Miscibility, physical aging and crystallization behaviors. Fibers Polym. 2013, 14, 1688–1698. [Google Scholar] [CrossRef]

| Samples | Electrical Conductivity | Samples | Electrical Conductivity |

|---|---|---|---|

| PLA-POY | 9.5 × 10−5 | OC6P30 | 22.7 |

| OC2P10 | 1.2 | OC6P40 | 181.8 |

| OC2P20 | 14.3 | OC6P50 | 204.1 |

| OC2P30 | 14.1 | OC8P10 | 6.8 |

| OC2P40 | 14.3 | OC8P20 | 14.1 |

| OC2P50 | 14.7 | OC8P30 | 245.2 |

| OC4P10 | 5.3 | OC8P40 | 409.6 |

| OC4P20 | 13.7 | OC8P50 | 371.4 |

| OC4P30 | 15.6 | OC10P10 | 7.7 |

| OC4P40 | 21.7 | OC10P20 | 14.1 |

| OC4P50 | 37.0 | OC10P30 | 129.1 |

| OC6P10 | 15.4 | OC10P40 | 270.3 |

| OC6P20 | 17.2 | OC10P50 | 526.3 |

| Samples | Electrical Conductivity | Samples | Electrical Conductivity |

|---|---|---|---|

| PLA-DTY | 1.1 × 10−4 | TC6P30 | 14.0 |

| TC2P10 | 0.7 | TC6P40 | 60.5 |

| TC2P20 | 8.3 | TC6P50 | 106.6 |

| TC2P30 | 8.8 | TC8P10 | 4.0 |

| TC2P40 | 8.9 | TC8P20 | 9.0 |

| TC2P50 | 8.9 | TC8P30 | 76.8 |

| TC4P10 | 2.7 | TC8P40 | 103.7 |

| TC4P20 | 8.5 | TC8P50 | 127.0 |

| TC4P30 | 9.4 | TC10P10 | 4.8 |

| TC4P40 | 39.2 | TC10P20 | 9.0 |

| TC4P50 | 73.9 | TC10P30 | 69.2 |

| TC6P10 | 3.6 | TC10P40 | 118.0 |

| TC6P20 | 9.7 | TC10P50 | 130.8 |

| Samples | Tensile Force (cN) | Elongation at Break (%) | Work of Rupture (J) |

|---|---|---|---|

| PLA-POY | 566 ± 9 | 46 ± 1 | 0.40 ± 0.02 |

| OC2P30 | 304 ± 60 | 67 ± 14 | 0.4 ± 0.1 |

| OC4P30 | 286 ± 13 | 73 ± 6 | 0.36 ± 0.04 |

| OC6P30 | 251 ± 67 | 61 ± 16 | 0.3 ± 0.1 |

| OC8P30 | 288 ± 32 | 49 ± 3 | 0.25 ± 0.03 |

| OC10P30 | 318 ± 20 | 95 ± 9 | 0.51 ± 0.05 |

| OC8P10 | 211 ± 10 | 41 ± 22 | 0.2 ± 0.1 |

| OC8P20 | 320 ± 53 | 53 ± 12 | 0.29 ± 0.08 |

| OC8P40 | 347 ± 35 | 81 ± 12 | 0.45 ± 0.09 |

| OC8P50 | 401 ± 54 | 87 ± 14 | 0.6 ± 0.1 |

| Samples | Tensile Force (cN) | Elongation at Break (%) | Work of Rupture (J) |

|---|---|---|---|

| PLA-DTY | 85.0 ± 0.8 | 12.6 ± 0.4 | 0.022 ± 0.001 |

| TC2P30 | 111 ± 6 | 19 ± 3 | 0.041 ± 0.009 |

| TC4P30 | 107 ± 4 | 19 ± 2 | 0.041 ± 0.006 |

| TC6P30 | 103 ± 2 | 19 ± 1 | 0.037 ± 0.002 |

| TC8P30 | 96 ± 5 | 16 ± 3 | 0.030 ± 0.006 |

| TC10P30 | 98 ± 6 | 16 ± 2 | 0.031 ± 0.005 |

| TC8P10 | 94 ± 4 | 13 ± 2 | 0.024 ± 0.005 |

| TC8P20 | 95 ± 7 | 15 ± 3 | 0.027 ± 0.007 |

| TC8P40 | 86 ± 4 | 10 ± 2 | 0.018 ± 0.004 |

| TC8P50 | 95 ± 4 | 14 ± 2 | 0.026 ± 0.005 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Zhou, Y.; Shen, Y.; Li, Y.; Guo, H.; Deng, B.; Li, Y. Morphology, Structure, and Properties of Conductive Polylactide Fibers Prepared Using Polyvinyl Acetate and Multiwalled Carbon Nanotubes. Coatings 2019, 9, 651. https://doi.org/10.3390/coatings9100651

Liu Q, Zhou Y, Shen Y, Li Y, Guo H, Deng B, Li Y. Morphology, Structure, and Properties of Conductive Polylactide Fibers Prepared Using Polyvinyl Acetate and Multiwalled Carbon Nanotubes. Coatings. 2019; 9(10):651. https://doi.org/10.3390/coatings9100651

Chicago/Turabian StyleLiu, Qingsheng, Yuqi Zhou, Ying Shen, Yuhao Li, Haiyang Guo, Bingyao Deng, and Yonggui Li. 2019. "Morphology, Structure, and Properties of Conductive Polylactide Fibers Prepared Using Polyvinyl Acetate and Multiwalled Carbon Nanotubes" Coatings 9, no. 10: 651. https://doi.org/10.3390/coatings9100651

APA StyleLiu, Q., Zhou, Y., Shen, Y., Li, Y., Guo, H., Deng, B., & Li, Y. (2019). Morphology, Structure, and Properties of Conductive Polylactide Fibers Prepared Using Polyvinyl Acetate and Multiwalled Carbon Nanotubes. Coatings, 9(10), 651. https://doi.org/10.3390/coatings9100651