Structure, Mechanical and Optical Properties of Silicon-Rich Al–Si–N Films Prepared by High Power Impulse Magnetron Sputtering

Abstract

1. Introduction

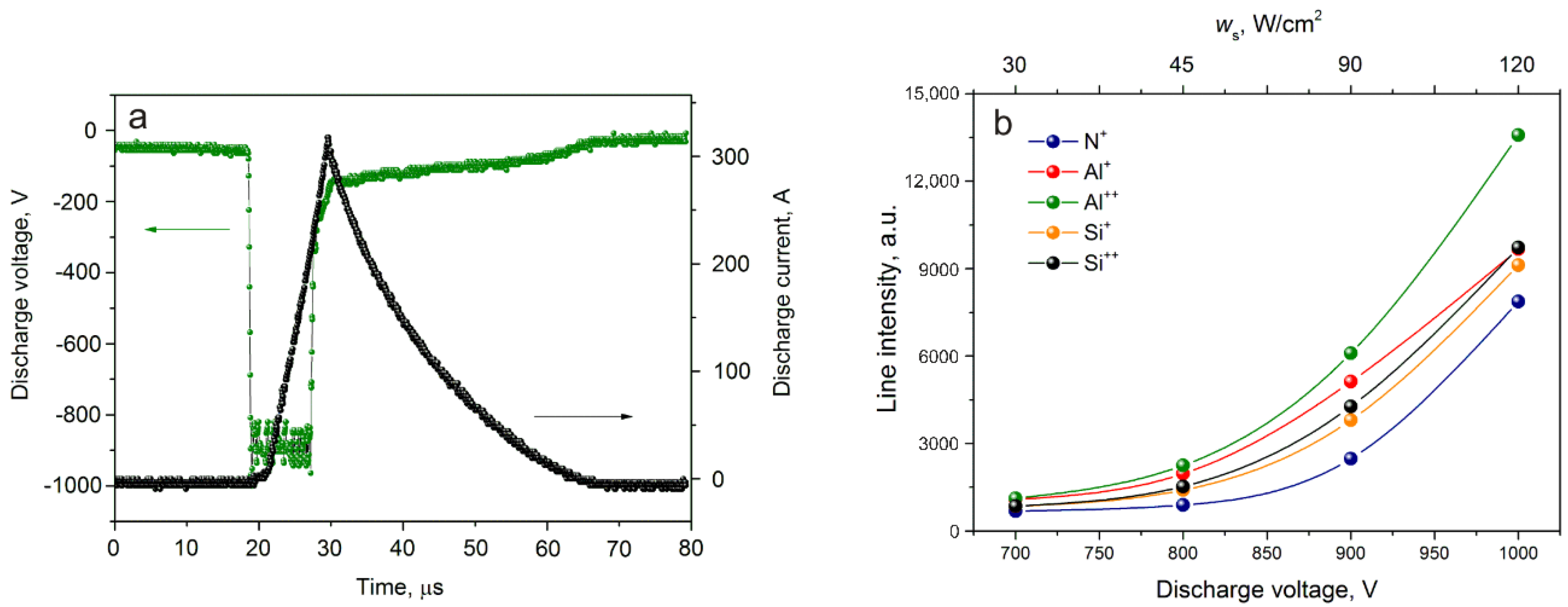

2. Materials and Methods

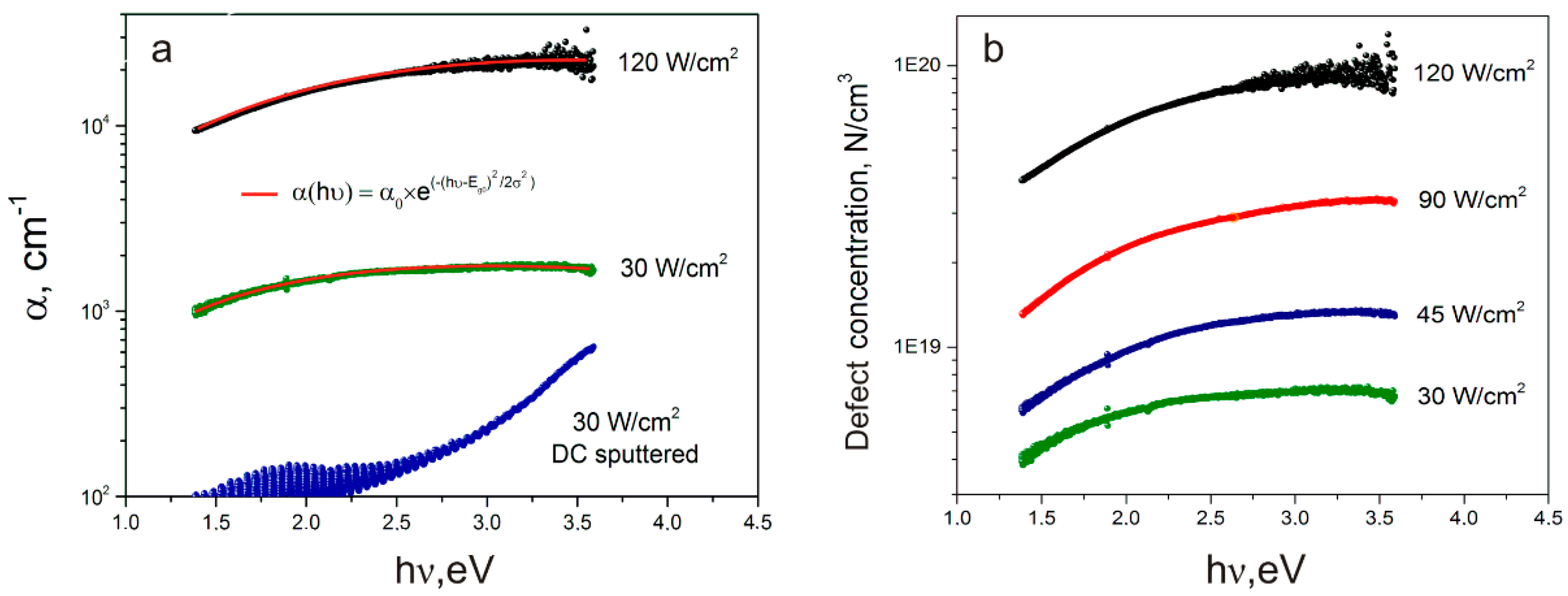

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yang, M.; Wang, H.; Ma, X.; Gao, H.; Wang, B. Effect of nitrogen-accommodation ability of electrodes in SiNx-based resistive switching devices. Appl. Phys. Lett. 2017, 111, 233510. [Google Scholar] [CrossRef]

- Guo, H.; Herkommer, C.; Billat, A.; Grassani, D.; Zhang, C.; Pfeiffer, M.H.P.; Weng, W.; Brès, C.; Kippenberg, T.J. Mid-infrared frequency comb via coherent dispersive wave generation in silicon nitride nanophotonic waveguides. Nat. Photonics 2018, 12, 330–335. [Google Scholar] [CrossRef]

- Souza, J.V.C.; Nono, M.C.A.; Ribeiro, M.V.; Machado, J.P.B.; Silva, O.M.M. Cutting forces in turning of gray cast iron using silicon nitride based cutting tool. Mater. Des. 2009, 30, 2715–2720. [Google Scholar] [CrossRef]

- Negro, L.D.; Yi, J.H.; Michel, J.; Kimerling, L.C.; Chang, T.-W.F.; Sukhovatkin, V.; Sargent, E.H. Light emission efficiency and dynamics in silicon-rich silicon nitride films. Appl. Phys. Lett. 2006, 88, 233109. [Google Scholar] [CrossRef]

- Musil, J.; Javdošňák, D.; Čerstvý, R.; Haviar, S.; Remnev, G.; Uglov, V. Effect of energy on the formation of flexible hard Al-Si-N films prepared by magnetron sputtering. Vacuum 2016, 133, 43–45. [Google Scholar] [CrossRef]

- Shen, Z.; Zhao, Z.; Peng, H.; Nygren, M. Formation of tough interlocking microstructures in silicon nitride ceramics by dynamic ripening. Nature 2002, 417, 266–269. [Google Scholar] [CrossRef] [PubMed]

- Nishiyama, N.; Ishikawa, R.; Ohfuji, H.; Marquardt, H.; Kurnosov, A.; Taniguchi, T.; Kim, B.; Yoshida, H.; Masuno, A.; Bednarcik, J.; et al. Transparent polycrystalline cubic silicon nitride. Sci. Rep. 2017, 7, 44755. [Google Scholar] [CrossRef]

- Musil, J.; Remnev, G.; Legostaev, V.; Uglov, V.; Lebedynskiy, A.; Lauk, A.; Procházka, J.; Haviar, S.; Smolyanskiy, E. Flexible hard Al–Si–N films for high temperature operation. Surf. Coat. Technol. 2016, 307, 1112–1118. [Google Scholar] [CrossRef]

- Sergeev, V.; Psakhie, S.; Chubik, P.; Cherniavsky, A.; Soloviev, V.; Solntsev, V.; Khristenko, Y. Magnetron sputtering of Si–Al–N nanocomposite coatings on quartz for protection against impacts of high speed microparticles. Vacuum 2017, 143, 454–457. [Google Scholar] [CrossRef]

- Pélisson, A.; Parlinska-Wojtan, M.; Hug, H.J.; Patscheider, J. Microstructure and mechanical properties of Al–Si–N transparent hard coatings deposited by magnetron sputtering. Surf. Coat. Technol. 2007, 202, 884–889. [Google Scholar] [CrossRef]

- Jiang, X.; Yang, F.; Chen, W.; Lee, J.; Chang, C. Effect of nitrogen-argon flow ratio on the microstructural and mechanical properties of AlSiN thin films prepared by high power impulse magnetron sputtering. Surf. Coat. Technol. 2017, 320, 138–145. [Google Scholar] [CrossRef]

- Ding, J.C.; Wang, Q.M.; Liu, Z.R.; Jeong, S.; Zhang, T.F.; Kim, K.H. Influence of bias voltage on the microstructure, mechanical and corrosion properties of AlSiN films deposited by HiPIMS technique. J. Alloy. Compd. 2019, 772, 112–121. [Google Scholar] [CrossRef]

- Anders, A. Tutorial: Reactive high power impulse magnetron sputtering (R-HiPIMS). J. Appl. Phys. 2017, 121, 171101. [Google Scholar] [CrossRef]

- Yang, Y.; Tanaka, K.; Liu, J.; Anders, A. Ion energies in high power impulse magnetron sputtering with and without localized ionization zones. Appl. Phys. Lett. 2015, 106, 124102. [Google Scholar] [CrossRef]

- Belosludtsev, A.; Houška, J.; Vlček, J.; Haviar, S.; Čerstvý, R.; Rezek, J.; Kettner, M. Structure and properties of Hf–O–N films prepared by high-rate reactive HiPIMS with smoothly controlled composition. Ceram. Int. 2017, 43, 5661–5667. [Google Scholar] [CrossRef]

- Cemin, F.; Abadias, G.; Minea, T.; Furgeau, C.; Brisset, F.; Solas, D.; Lundin, D. Benefits of energetic ion bombardment for tailoring stress and microstructural evolution during growth of Cu thin films. Acta Mater. 2017, 141, 120–130. [Google Scholar] [CrossRef]

- Pélisson-Schecker, A.; Hug, H.J.; Patscheider, J. Morphology, microstructure evolution and optical properties of Al–Si–N nanocomposite coatings. Surf. Coat. Technol. 2014, 257, 114–120. [Google Scholar] [CrossRef]

- Jouan, P.; le Brizoual, L.; Ganciu, M.; Cardinaud, C.; Tricot, S.; Djouadi, M. HiPIMS ion energy distribution measurements in reactive mode. IEEE Trans. Plasma Sci. 2010, 38, 3089–3094. [Google Scholar] [CrossRef]

- Kabyshev, A.V.; Konusov, F.V.; Lauk, A.L.; Lebedynskiy, A.M.; Legostaev, V.N.; Smolyanskiy, E.A. Optical absorption peculiarities of Al-Si-N coatings produced by magnetron sputtering. Key Eng. Mater. 2016, 712, 3–8. [Google Scholar] [CrossRef]

- Konusov, F.V.; Kabyshev, A.V.; Remnev, G.E. Optical properties of GaAs films deposited via pulsed ion ablation. J. Surf. Invest. 2011, 5, 228–235. [Google Scholar] [CrossRef]

- Wang, Q.; Ward, S.; Gedvilas, L.; Keyes, B.; Sanchez, E.; Wang, S. Conformal thin-film silicon nitride deposited by hot-wire chemical vapor deposition. Appl. Phys. Lett. 2004, 84, 338–340. [Google Scholar] [CrossRef]

| Target Power Density w (W/cm2) | Film Band Gap Eg0 (eV) | Band Gap Dispersion σ′ (eV) | Urbach Energy EU (eV) | Optical Gap Eg′ (eV) |

|---|---|---|---|---|

| 30 | 2.98 | 1.53 | 1.86 | 1.6 |

| 45 | 3.14 | 1.40 | 1.48 | 1.8 |

| 90 | 3.22 | 1.38 | 1.33 | 2.01 |

| 120 | 3.44 | 1.5 | 1.15 | 2.04 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zenkin, S.; Konusov, F.; Lauk, A.; Zelentsov, D.; Demchenko, S. Structure, Mechanical and Optical Properties of Silicon-Rich Al–Si–N Films Prepared by High Power Impulse Magnetron Sputtering. Coatings 2019, 9, 53. https://doi.org/10.3390/coatings9010053

Zenkin S, Konusov F, Lauk A, Zelentsov D, Demchenko S. Structure, Mechanical and Optical Properties of Silicon-Rich Al–Si–N Films Prepared by High Power Impulse Magnetron Sputtering. Coatings. 2019; 9(1):53. https://doi.org/10.3390/coatings9010053

Chicago/Turabian StyleZenkin, Sergei, Fedor Konusov, Aleksandr Lauk, Denis Zelentsov, and Stanislav Demchenko. 2019. "Structure, Mechanical and Optical Properties of Silicon-Rich Al–Si–N Films Prepared by High Power Impulse Magnetron Sputtering" Coatings 9, no. 1: 53. https://doi.org/10.3390/coatings9010053

APA StyleZenkin, S., Konusov, F., Lauk, A., Zelentsov, D., & Demchenko, S. (2019). Structure, Mechanical and Optical Properties of Silicon-Rich Al–Si–N Films Prepared by High Power Impulse Magnetron Sputtering. Coatings, 9(1), 53. https://doi.org/10.3390/coatings9010053