Composition versus Wear Behaviour of Air Plasma Sprayed NiCr–TiB2–ZrB2 Composite Coating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Feedstock Materials

2.2. Powder Preparation

2.3. APS Spraying Experiments

2.4. Microstructural Characterisation

2.5. Performance Tests of Coatings

3. Results and Discussion

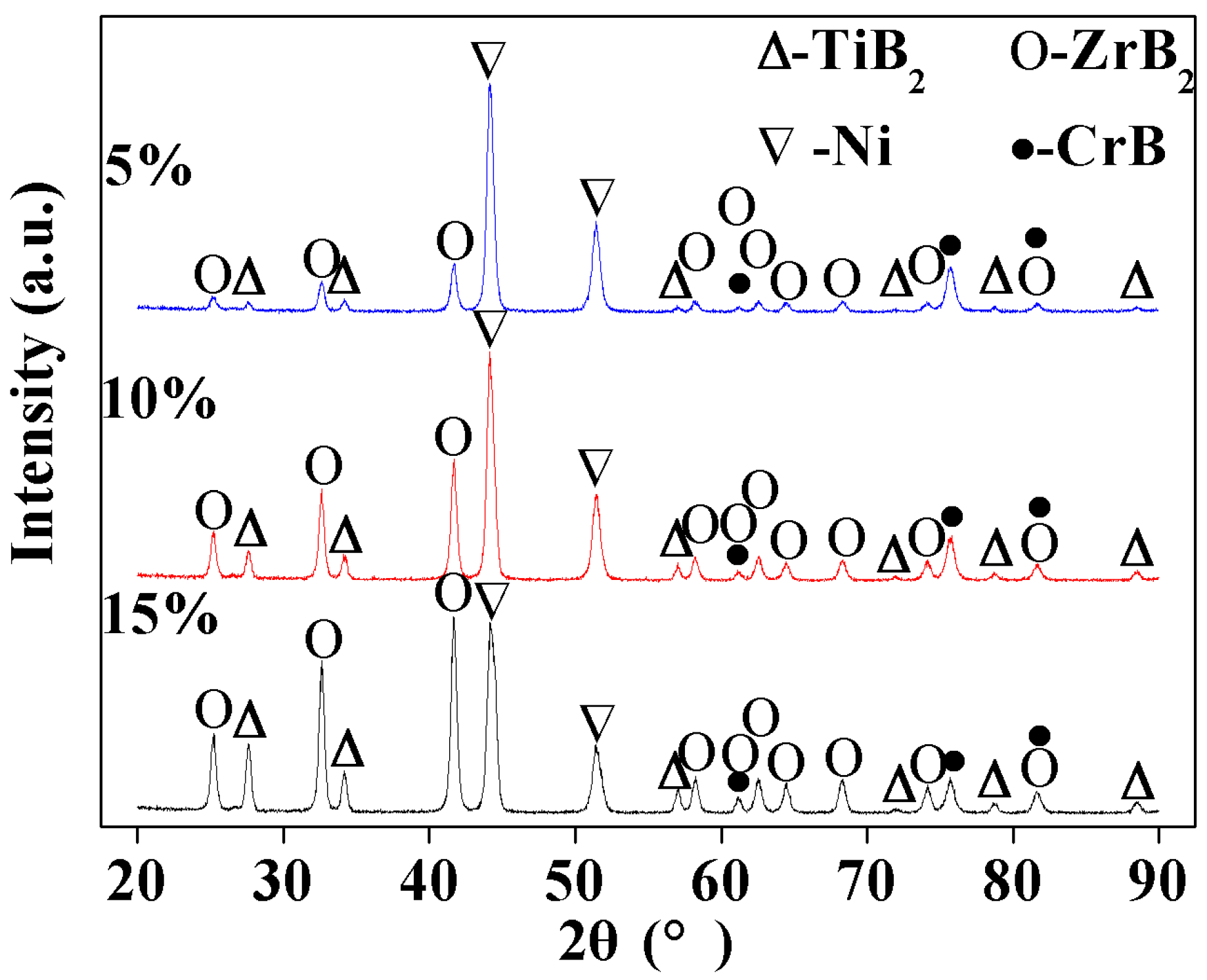

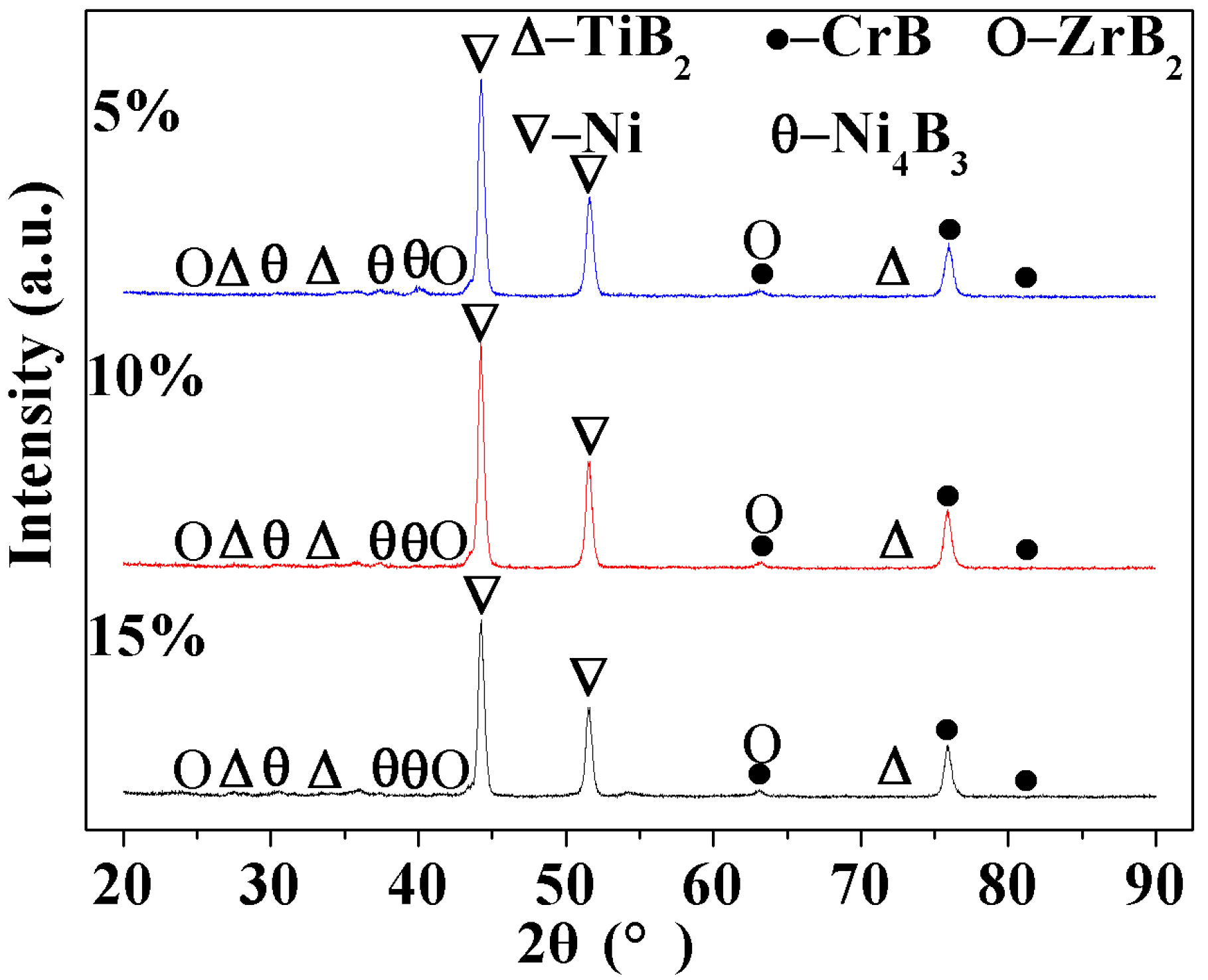

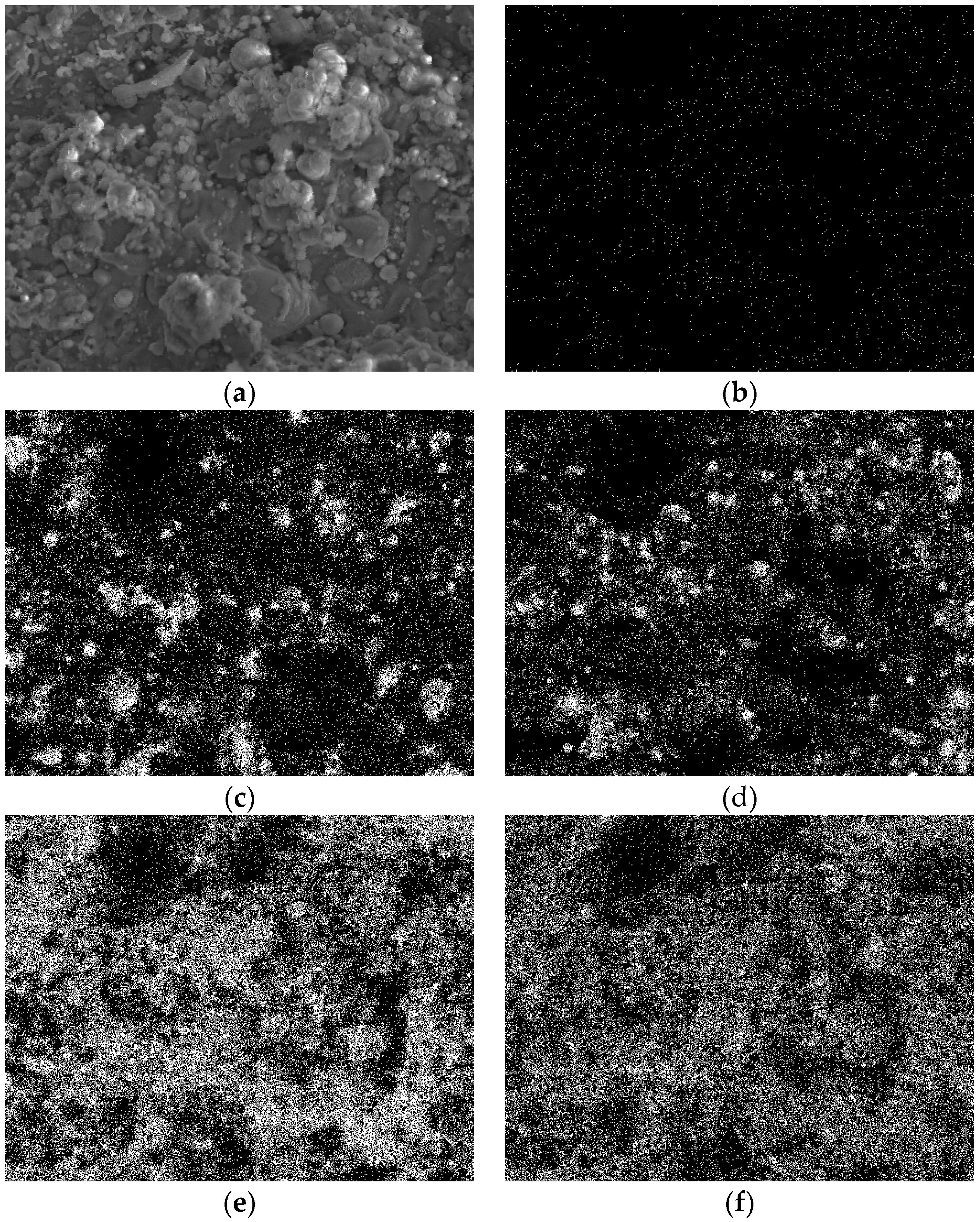

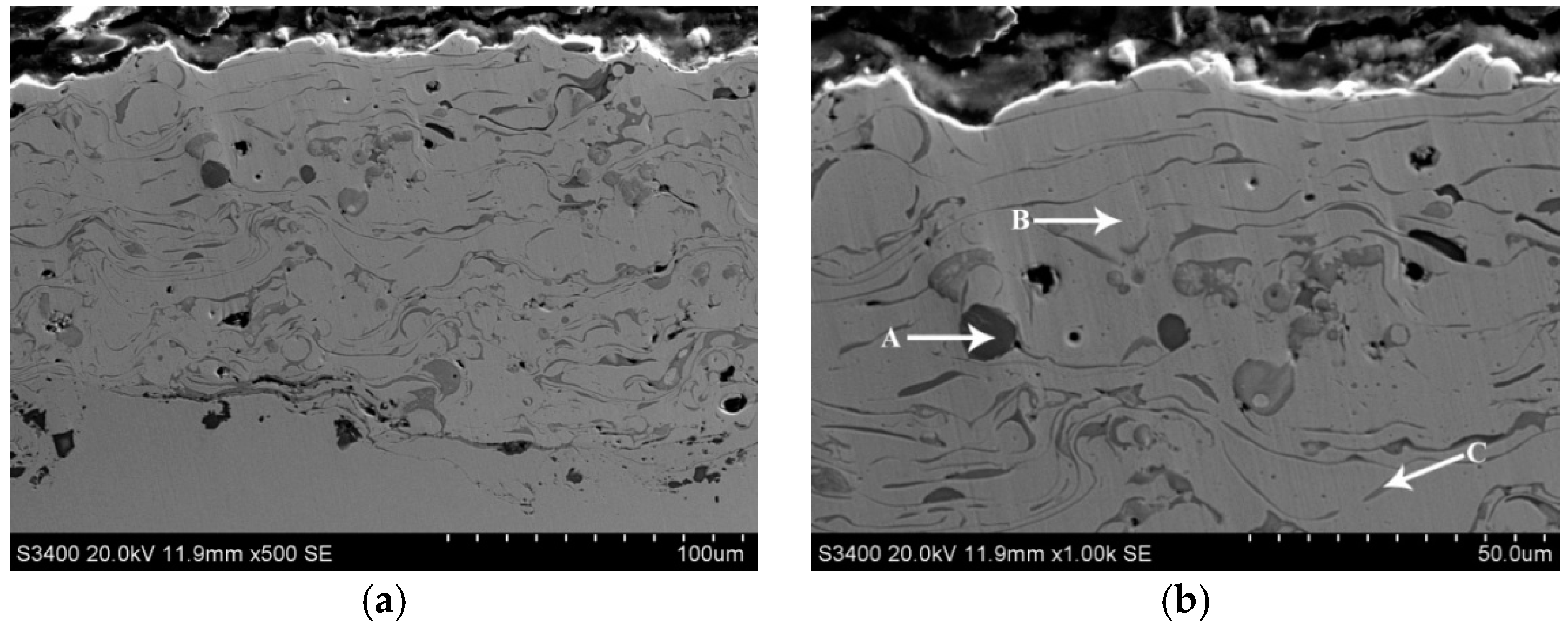

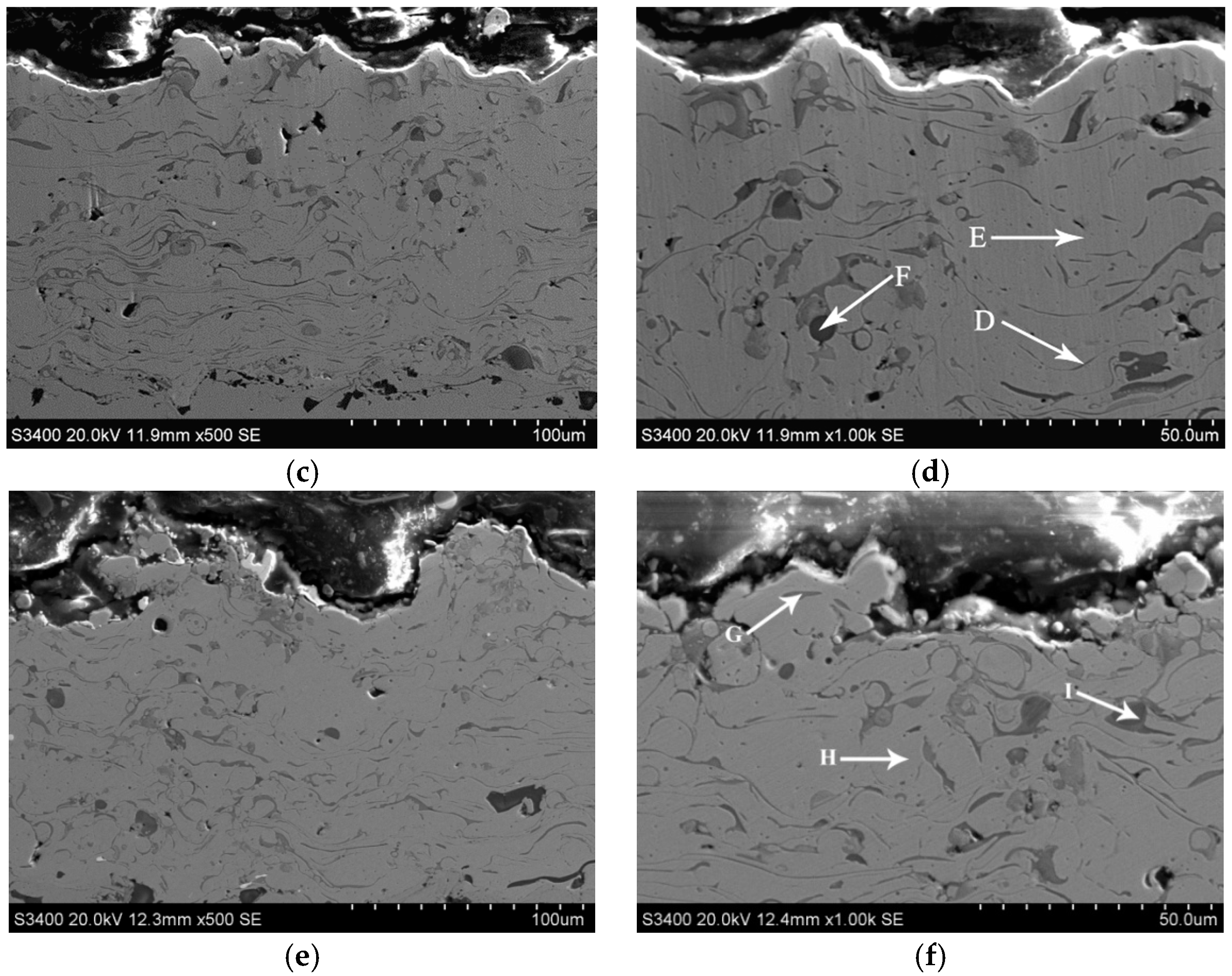

3.1. Microstructure and Phase Composition

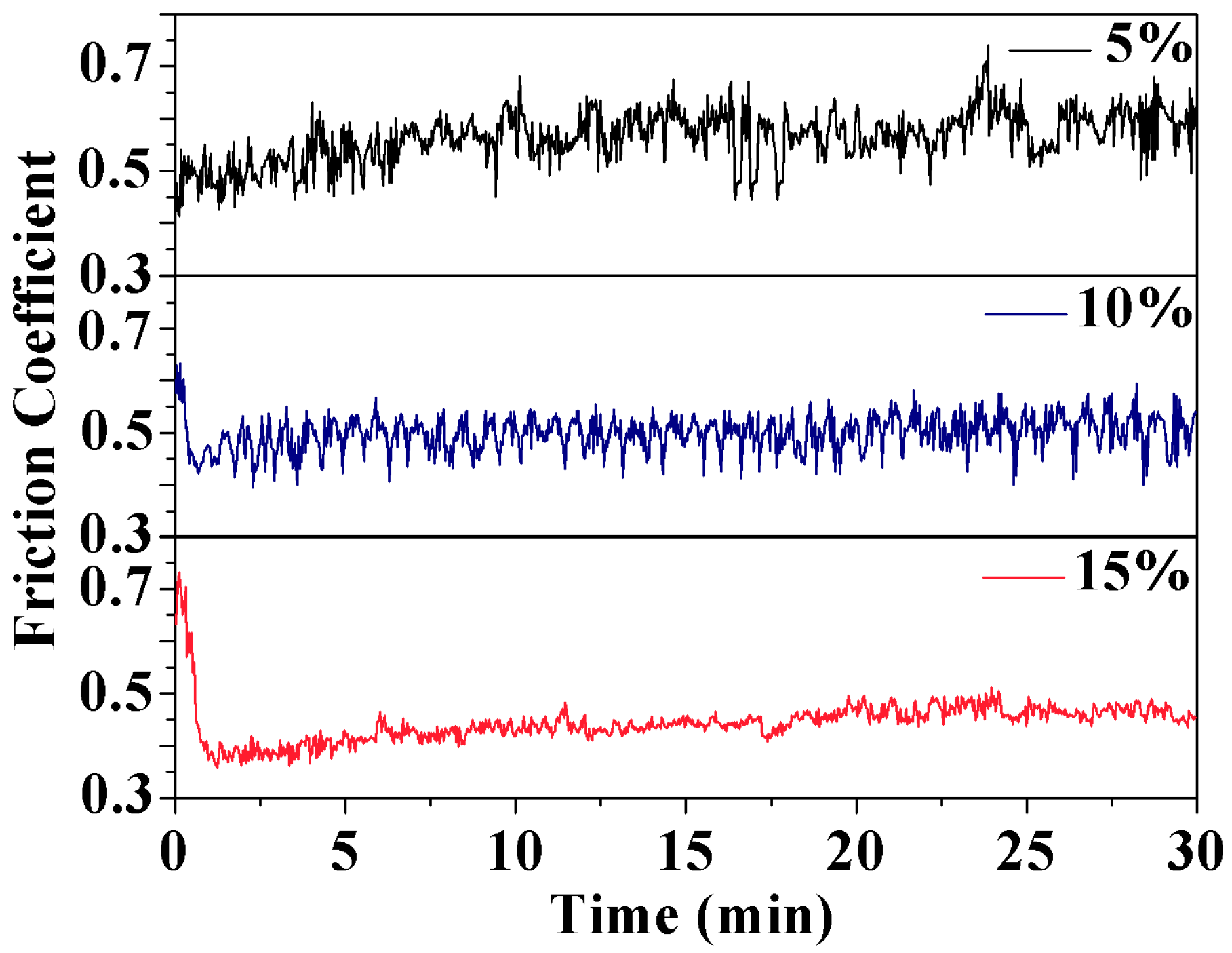

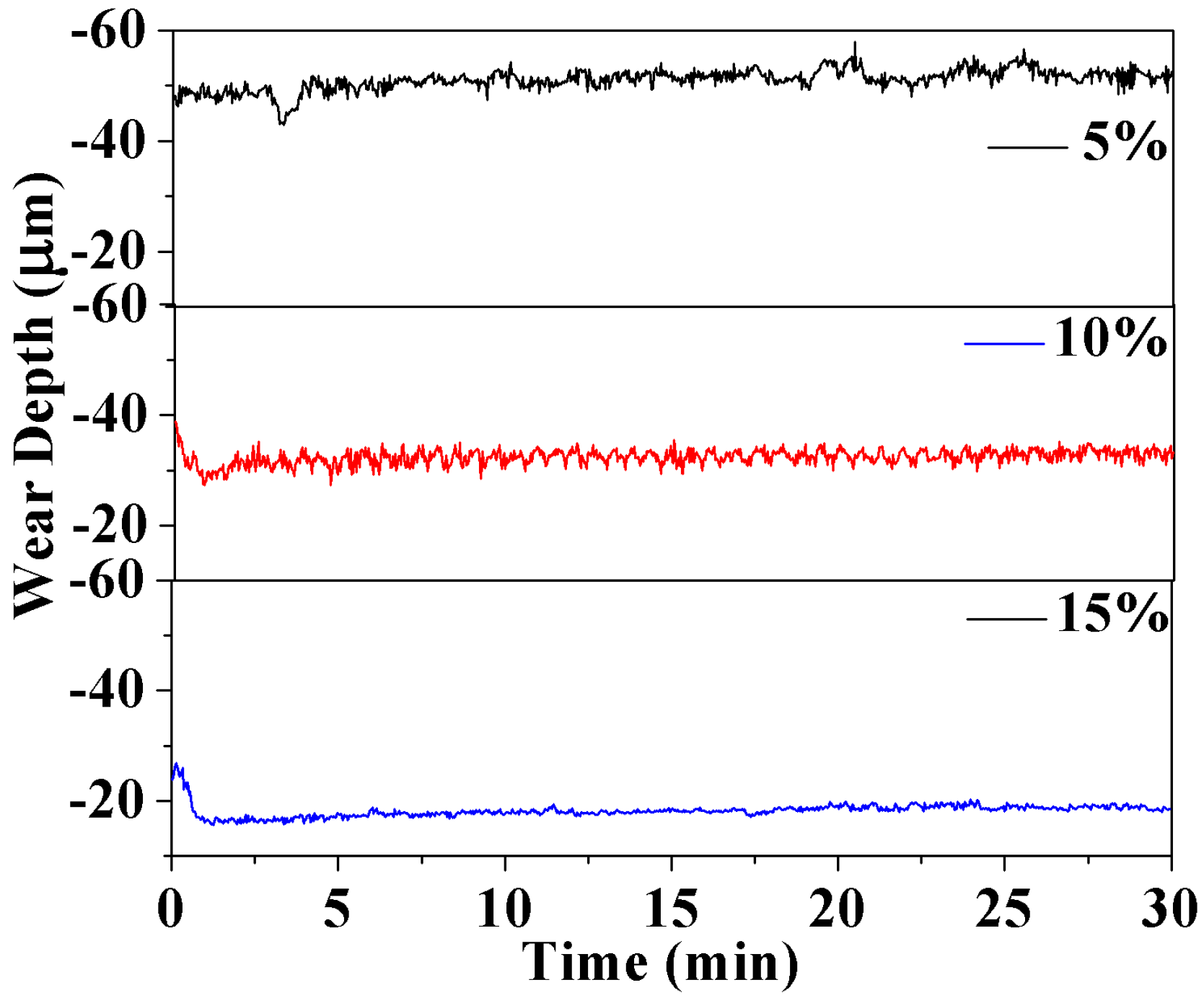

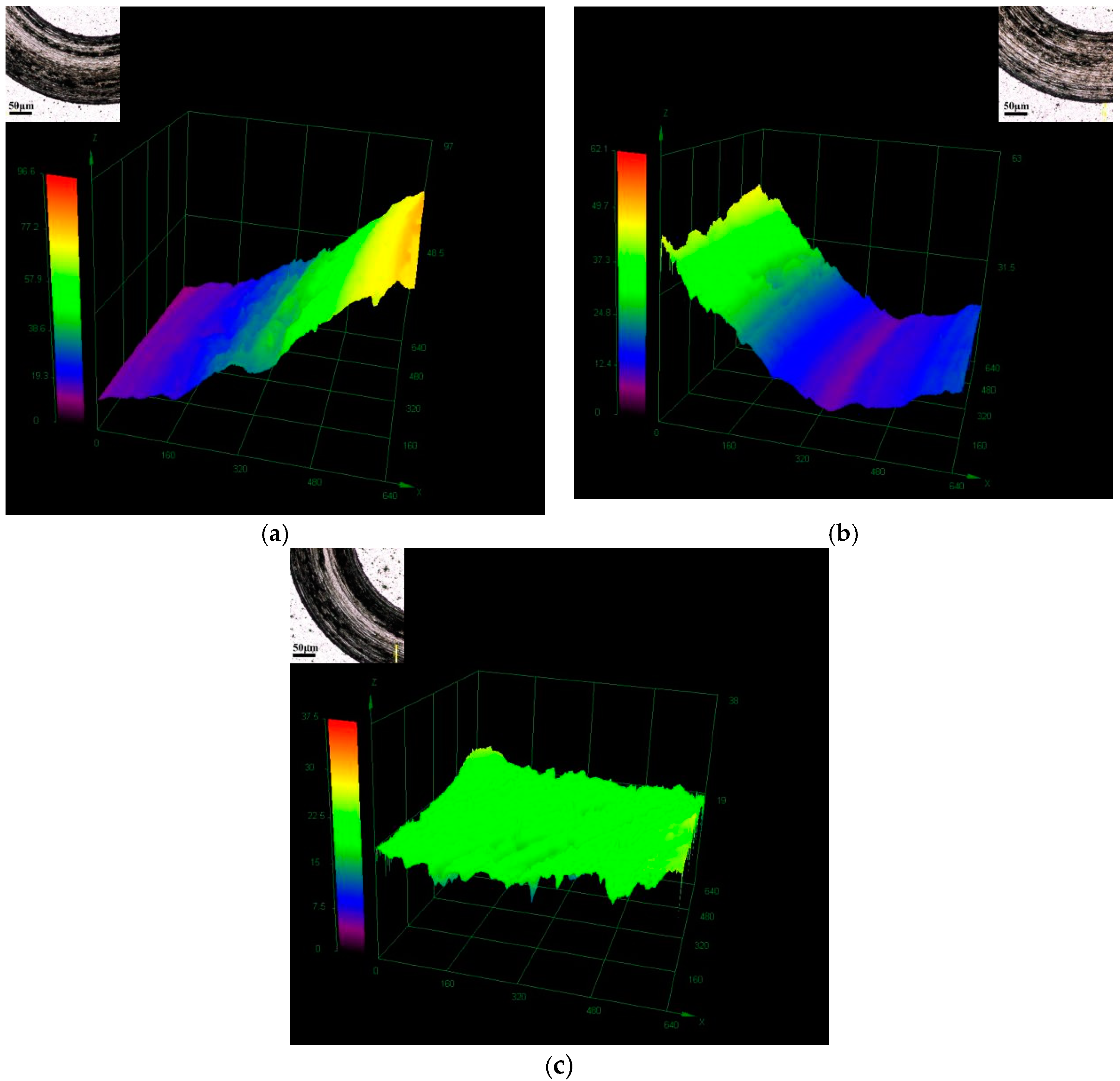

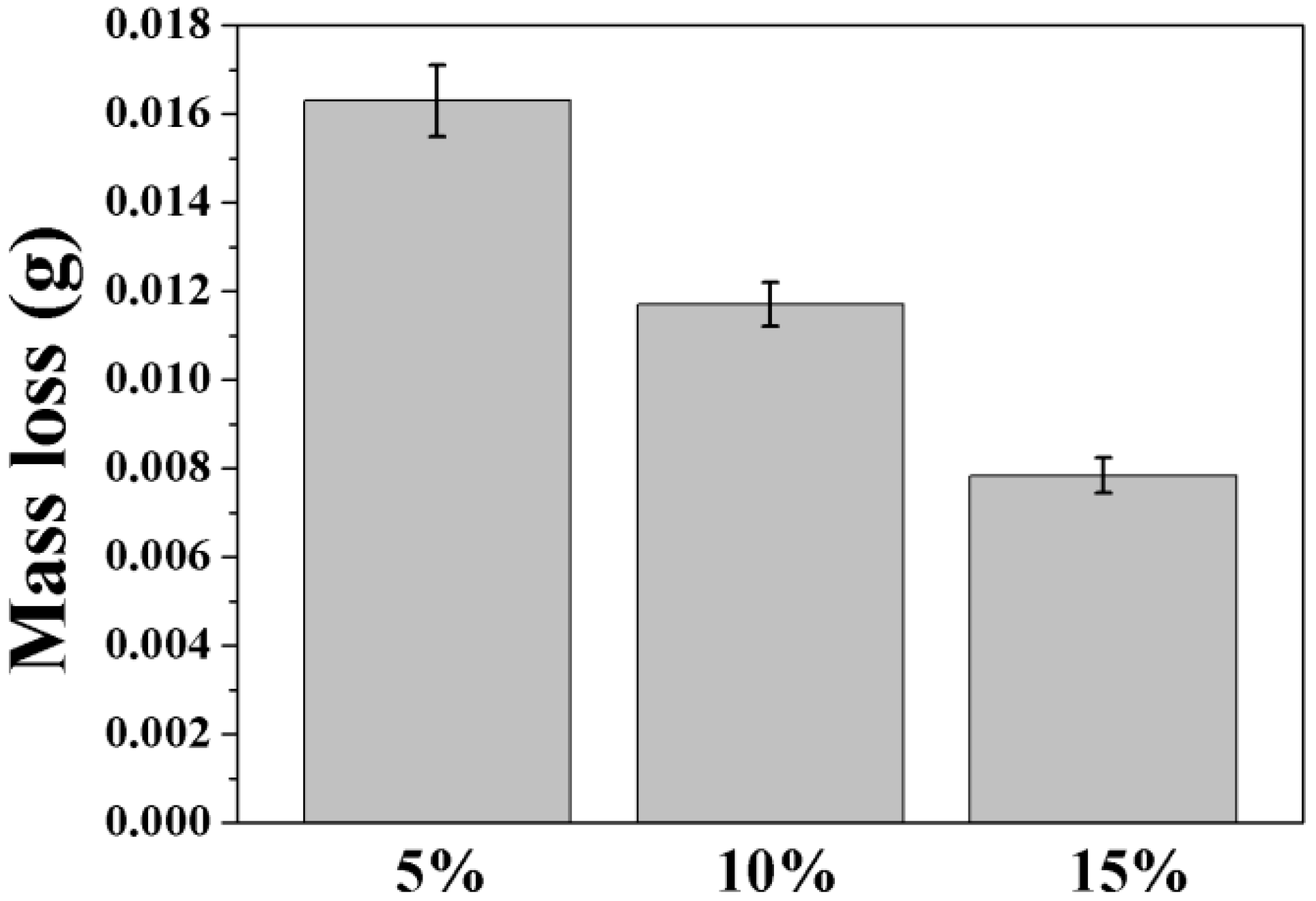

3.2. Performance Test of Coatings

4. Conclusions

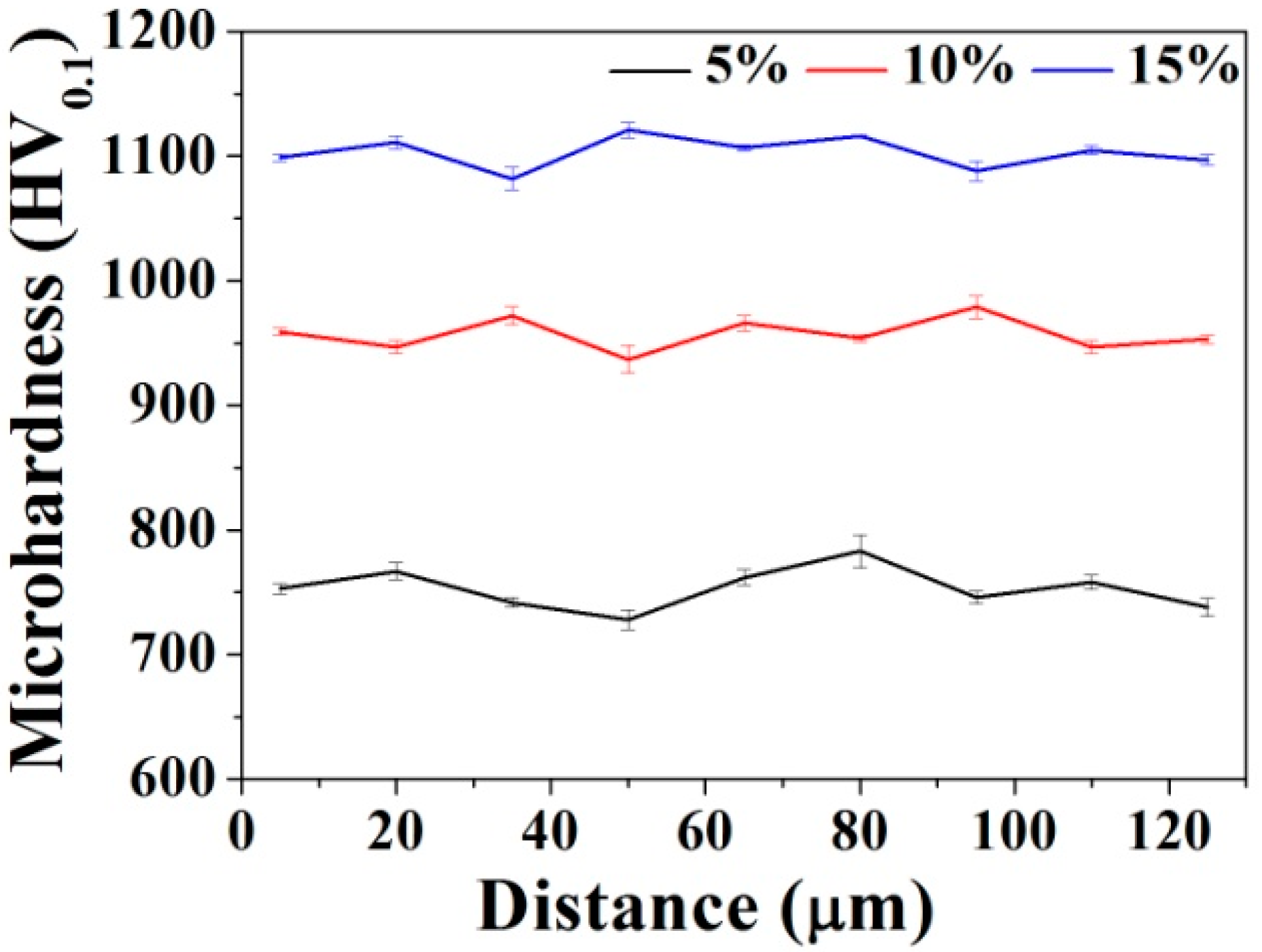

- With an increase in the proportion of ceramics, the microhardness of the composite coating gradually increased. The average hardness obtained on the coating cross-section was 753, 957, and 1102 HV0.1 for NiCr (5 wt.%)–TiB2 (5 wt.%)–ZrB2, NiCr (10 wt.%)–TiB2 (10 wt.%)–ZrB2, and NiCr (15 wt.%)–TiB2 (15 wt.%)–ZrB2 coatings.

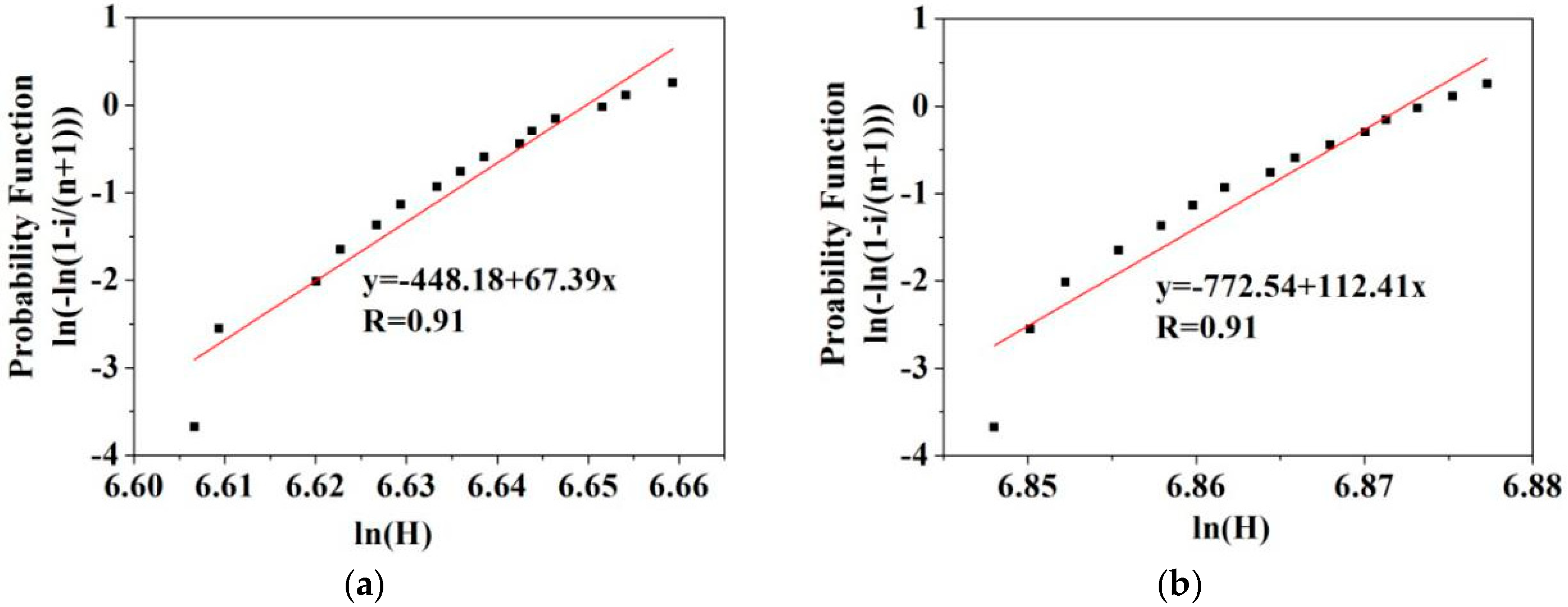

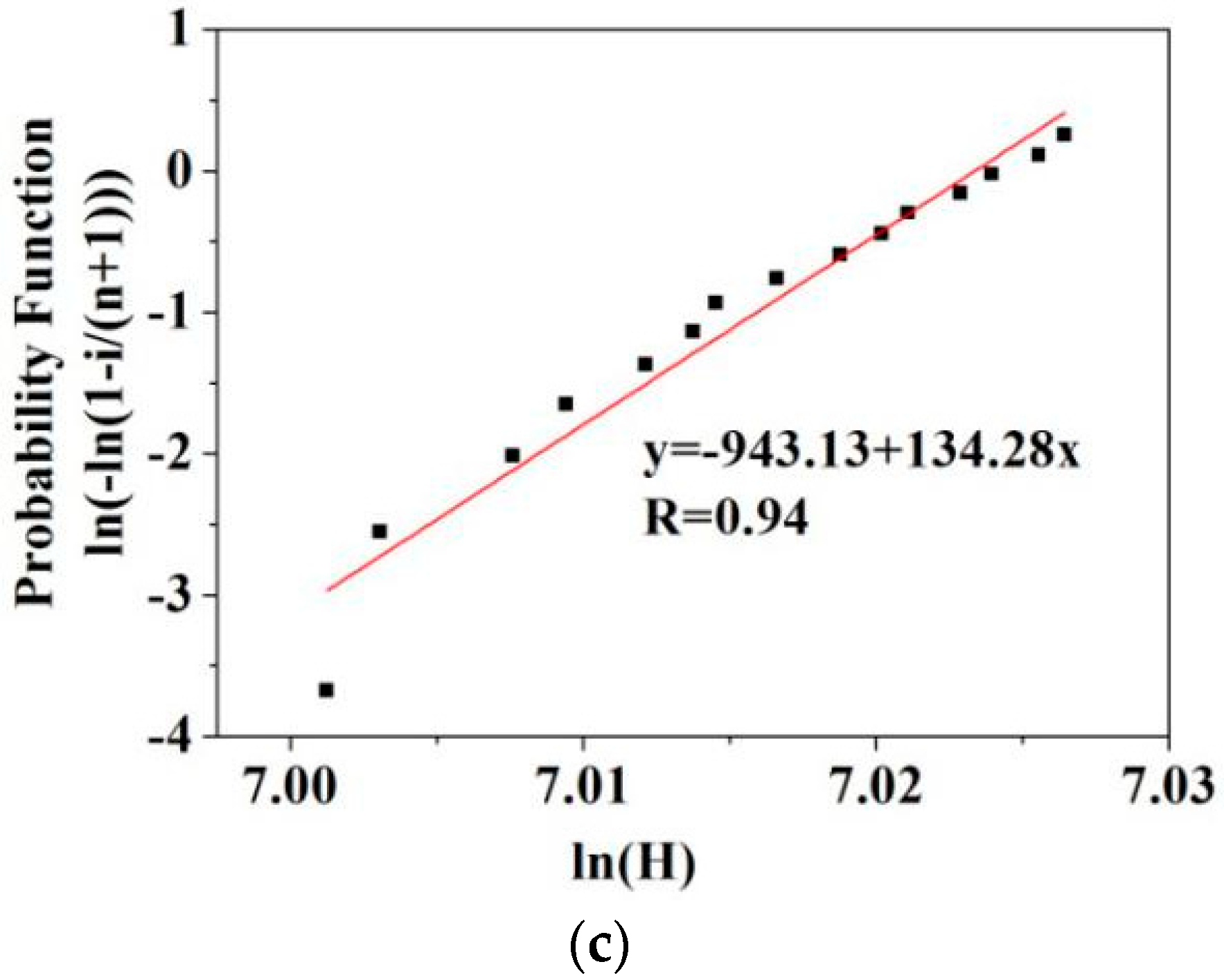

- From the analyses of the Weibull distributions, the R value of all of the coatings was greater than 0.9 and there was little overall change of the coatings. With the addition of the ceramic phases (TiB2 and ZrB2), the β-values of the coatings rose from 67.39 to 134.28, implying that the coating had a minimal variation when the content of the ceramic phases (TiB2 and ZrB2) increased.

- The wear mechanism of the coatings was mixed, involving abrasive wear, adhesive wear, oxidation wear, and fatigue wear. The ceramic phases in the coatings gave outstanding resistance to wear and oxidation. The NiCr–15TiB2–15ZrB2 composite coating had the best tribological properties.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alam, P.; Toivakka, M. Deflection and plasticity of soft-tip bevelled blades in paper coating operations. Mater. Design 2009, 30, 871–877. [Google Scholar] [CrossRef]

- Hua, Y.; Xu, L.; Hua, W. Development of tungsten carbide blade. Chin. Pulp. Pap. 2013, 32, 49–52. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Zhu, H.; Cheng, F.; Wang, D.; Li, Z. A comparative study of plasma sprayed TiB2-NiCr and Cr3C2-NiCr composite coatings. Mater. Lett. 2015, 153, 110–113. [Google Scholar] [CrossRef]

- Zhang, C.; Luo, G.; Zhang, J.; Dai, Y.; Shen, Q.; Zhang, L. Synthesis and thermal conductivity improvement of W-Cu composites modified with WC interfacial layer. Mater. Design 2017, 127, 233–242. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, J. Tungsten carbide ceramics. In Practical Handbook of Ceramic Materials, 1st ed.; Chemical Industry Press: Beijing, China, 2006; pp. 390–399. ISBN 7-5025-8469-2. (In Chinese) [Google Scholar]

- Vashishtha, N.; Khatirkar, R.K.; Sapate, S.G. Tribological behaviour of HVOF sprayed WC-12Co, WC-10Co-4Cr and Cr3C2-25NiCr coatings. Tribol. Int. 2017, 105, 55–68. [Google Scholar] [CrossRef]

- Zhu, H.B.; Li, H.; Li, Z.X. Plasma sprayed TiB2-Ni cermet coatings: Effect of feedstock characteristics on the microstructure and tribological performance. Surf. Coat. Technol. 2013, 235, 620–627. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, F.; Hao, S.; Dong, F.; Xu, Y.; Geng, W.; Zhang, N.; Gey, N.; Grosdidier, T.; Dong, C. Evolution of nanostructure and metastable phases at the surface of a HCPEB-treated WC-6% Co hard alloy with increasing irradiation pulse numbers. Coatings 2017, 7, 178. [Google Scholar] [CrossRef]

- Zhang, M.; Qu, K.; Luo, S.; Liu, S. Effect of Cr on the microstructure and properties of TiC-TiB2 particles reinforced Fe-based composite coatings. Surf. Coat. Technol. 2017, 316, 131–137. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, P.; Yu, Z.; Lu, Q.; Yang, S.; Li, C. Microstructure and tribological properties of laser-clad Ni-Cr/TiB2, composite coatings on copper with the addition of CaF2. Surf. Coat. Technol. 2012, 206, 4046–4053. [Google Scholar] [CrossRef]

- Lotfi, B.; Shipway, P.H.; Mccartney, D.G.; Edris, H. Abrasive wear behaviour of Ni(Cr)-TiB2 coatings deposited by HVOF spraying of SHS-derived cermet powders. Wear 2003, 254, 340–349. [Google Scholar] [CrossRef]

- Jones, M.; Horlock, A.J.; Shipway, P.H.; McCartney, D.G.; Wood, J.V. A comparison of the abrasive wear behavior of HVOF sprayed titanium carbide-and titanium boride-based cermet coatings. Wear 2001, 251, 1009–1016. [Google Scholar] [CrossRef]

- Xu, J.; Zou, B.; Zhao, S.; Hui, Y.; Huang, W.; Zhou, X.; Wang, Y.; Cai, X.; Cao, X. Fabrication and properties of ZrC-ZrB2/Ni cermet coatings on a magnesium alloy by atmospheric plasma spraying of SHS powders. Ceram. Int. 2014, 40, 1537–15544. [Google Scholar] [CrossRef]

- Umanskyi, O.; Poliarus, O.; Ukrainets, M.; Antonov, M.; Hussainova, I. High temperature sliding wear of NiAl-based coatings reinforced by borides. Mater. Sci. 2016, 22, 49–53. [Google Scholar] [CrossRef]

- Farhadinia, F.; Sedghi, A. Wear behaviour of Al/(Al2O3 + ZrB2 + TiB2) hybrid composites fabricated by hot pressing. Int. J. Mater. Res. 2015, 106, 160–165. [Google Scholar] [CrossRef]

- Chakraborty, S.; Debnath, D.; Mallick, A.R.; Das, P.K. Mechanical and thermal properties of hot pressed ZrB2, system with TiB2. Int. J. Refract. Met. Hard Mater. 2014, 46, 35–42. [Google Scholar] [CrossRef]

- Li, B. Effect of ZrB2 and SiC addition on TiB2-based ceramic composites prepared by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2014, 46, 84–89. [Google Scholar] [CrossRef]

- Luo, P.; Xiong, C.; Wang, C.; Qin, F.; Xiao, Y.; Li, Z.; Liu, K.; Guan, X.; Dong, S. Comparative failure analysis of electrodes coated with TiB2-ZrB2 and TiB2-ZrB2/Ni layers. Surf. Coat. Technol. 2017, 317, 83–94. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, C.; Qian, S.; Yu, Q.; Dong, C. Microstructure and wear resistance of laser-clad (Co,Ni)61.2B26.2Si7.8Ta4.8 coatings. Metals 2017, 7, 419. [Google Scholar] [CrossRef]

- Wu, Y.; Zeng, D.; Liu, Z.; Qiu, W.; Zhong, X.; Yu, H.; Li, S. Microstructure and sliding wear behavior of nanostructured Ni60–TiB2 composite coating sprayed by HVOF technique. Surf. Coat. Technol. 2011, 206, 1102–1108. [Google Scholar] [CrossRef]

- Zhang, N.; Lin, D.; He, B.; Zhang, G.; Li, D. Effect of oxyacetylene flame remelting on wear behaviour of supersonic air-plasma sprayed NiCrBSi/h-BN composite coatings. Surf. Rev. Lett. 2017, 24, 83–90. [Google Scholar] [CrossRef]

- Pawlowski, L. Coating growth. In The Science and Engineering of Thermal Spray Coatings, 1st ed.; Li, H., He, D., Eds.; China Machine Press: Beijing, China, 2011; pp. 135–136. ISBN 978-7-111-32163-7. (In Chinese) [Google Scholar]

- Zhang, N.; Zhang, N.; Wei, X.; Zhang, Y.; Li, D. Microstructure and tribological performance of TiB2-NiCr composite coating deposited by APS. Coatings 2017, 7, 238. [Google Scholar] [CrossRef]

- Zhu, H.; Li, H.; Yang, H.; Li, Z. Microstructure and sliding wear performance of plasma-sprayed TiB2-Ni coating deposited from agglomerated and sintered powder. J. Therm. Spray. Technol. 2013, 22, 1310–1319. [Google Scholar] [CrossRef]

- An, Y.; Li, S.; Hou, G.; Zhao, X.; Zhou, H.; Chen, J. Mechanical and tribological properties of nano/micro composite alumina coatings fabricated by atmospheric plasma spraying. Ceram. Int. 2017, 43, 5319–5328. [Google Scholar] [CrossRef]

- Zhang, F.; He, J.; Chen, K.; Qin, Y.; Li, C.; Yin, F. Microstructure evolution and mechanical properties of TiCN-Cr nano/micro composite coatings prepared by reactive plasma spraying. Appl. Surf. Sci. 2017, 427, 905–914. [Google Scholar] [CrossRef]

- Kliagua, A.M.; Travessa, D.; Ferrante, M. Al2O3/Ti interlayer/AISI 304 diffusion bonded joint: Microstructural characterization of the two interfaces. Mater. Charact. 2001, 46, 65–74. [Google Scholar] [CrossRef]

- Tian, L.; Feng, Z.; Xiong, W. Microstructure, microhardness, and wear resistance of AlCoCrFeNiTi/Ni60 coating by plasma spraying. Coatings 2018, 8, 112. [Google Scholar] [CrossRef]

- Lu, Z.; Zhou, Y.; Rao, Q.; Jin, Z. An investigation of the abrasive wear behavior of ductile cast iron. J. Mater. Process. Technol. 2001, 116, 176–181. [Google Scholar] [CrossRef]

| Materials | Purity | Zr | Ti | B | Cr | Ni | Fe | C | Others |

|---|---|---|---|---|---|---|---|---|---|

| NiCr | 99.0 | – | – | – | 19.86 | 80.08 | – | 0.01 | Bal. |

| TiB2 | 99.5 | – | 68.23 | 30.75 | – | – | 0.14 | 0.13 | Bal. |

| ZrB2 | 99.9 | 79.27 | – | 19.30 | – | – | 0.09 | 0.15 | Bal. |

| SUS304 | – | – | – | – | 18.65 | 9.73 | 68.54 | 0.07 | Bal. |

| Parameters | Value |

|---|---|

| Current (A) | 600 |

| Voltage (V) | 40 |

| Ar (dm3/s) | 0.67 |

| H2 (dm3/s) | 0.17 |

| Powder feed rate (g/s) | 0.58–0.75 |

| Gun traverse speed (mm/s) | 90 |

| Spray distance (mm) | 100 |

| Pre-heating temperature (°C) | 120 |

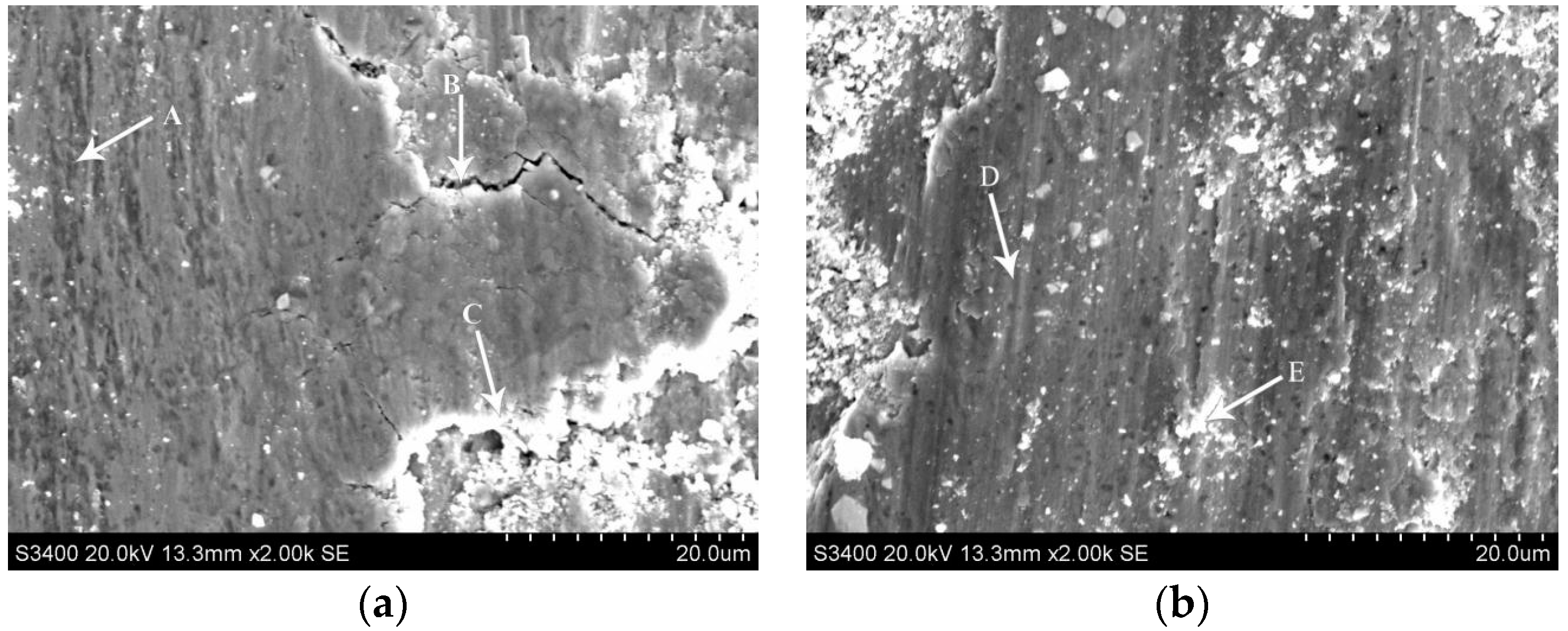

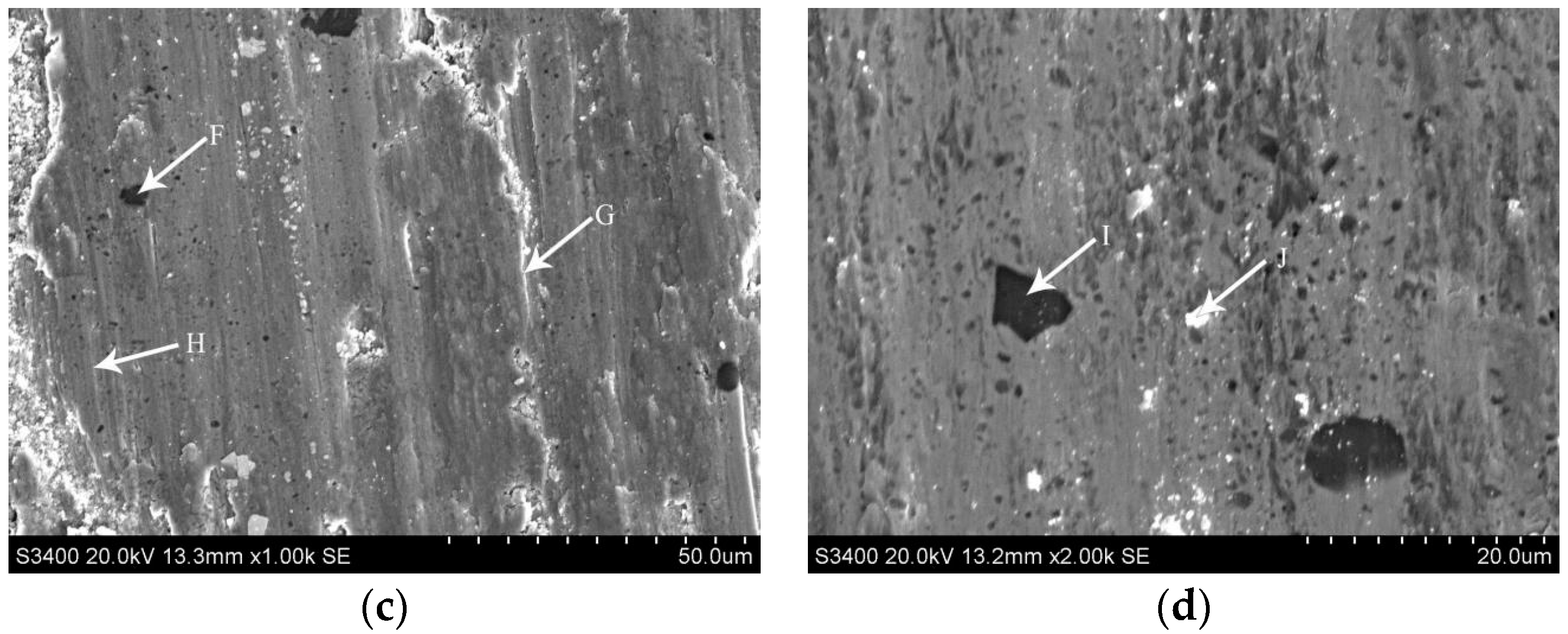

| Zone | Ni | Cr | Zr | Ti | B |

|---|---|---|---|---|---|

| A | – | – | – | 34.21 | 65.79 |

| B | 72.43 | 15.98 | 0.24 | 0.62 | 10.73 |

| C | 15.93 | 19.98 | 10.07 | 12.41 | 41.61 |

| D | 29.95 | 14.95 | 10.71 | 7.82 | 36.57 |

| E | 61.13 | 17.64 | 0.62 | 1.25 | 19.36 |

| F | – | – | – | 36.47 | 63.53 |

| G | 20.68 | 12.06 | 5.73 | 13.70 | 47.83 |

| H | 65.43 | 14.91 | 0.11 | 0.83 | 18.72 |

| I | – | – | – | 33.52 | 66.48 |

| Zone | Ni | Cr | Ti | Zr | B | O |

|---|---|---|---|---|---|---|

| C | 47.86 | 12.69 | 2.86 | 1.29 | 18.36 | 16.94 |

| E | 42.89 | 10.43 | 4.07 | 3.11 | 25.87 | 13.63 |

| F | – | – | 33.54 | – | 66.46 | – |

| I | – | – | 34.73 | – | 65.27 | – |

| J | 35.97 | 8.54 | 5.66 | 3.29 | 34.72 | 11.82 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, N.; Zhang, N.; Guan, S.; Li, S.; Zhang, G.; Zhang, Y. Composition versus Wear Behaviour of Air Plasma Sprayed NiCr–TiB2–ZrB2 Composite Coating. Coatings 2018, 8, 273. https://doi.org/10.3390/coatings8080273

Zhang N, Zhang N, Guan S, Li S, Zhang G, Zhang Y. Composition versus Wear Behaviour of Air Plasma Sprayed NiCr–TiB2–ZrB2 Composite Coating. Coatings. 2018; 8(8):273. https://doi.org/10.3390/coatings8080273

Chicago/Turabian StyleZhang, Ning, Nannan Zhang, Sheng Guan, Shumei Li, Guangwei Zhang, and Yue Zhang. 2018. "Composition versus Wear Behaviour of Air Plasma Sprayed NiCr–TiB2–ZrB2 Composite Coating" Coatings 8, no. 8: 273. https://doi.org/10.3390/coatings8080273

APA StyleZhang, N., Zhang, N., Guan, S., Li, S., Zhang, G., & Zhang, Y. (2018). Composition versus Wear Behaviour of Air Plasma Sprayed NiCr–TiB2–ZrB2 Composite Coating. Coatings, 8(8), 273. https://doi.org/10.3390/coatings8080273