Cavitation Erosion Resistance and Wear Mechanism Model of Flame-Sprayed Al2O3-40%TiO2/NiMoAl Cermet Coatings

Abstract

1. Introduction

2. Material and Methods

2.1. Coating Manufacturing

2.2. Characterization Techniques

2.3. Cavitation Erosion Testing

3. Results and Discussion

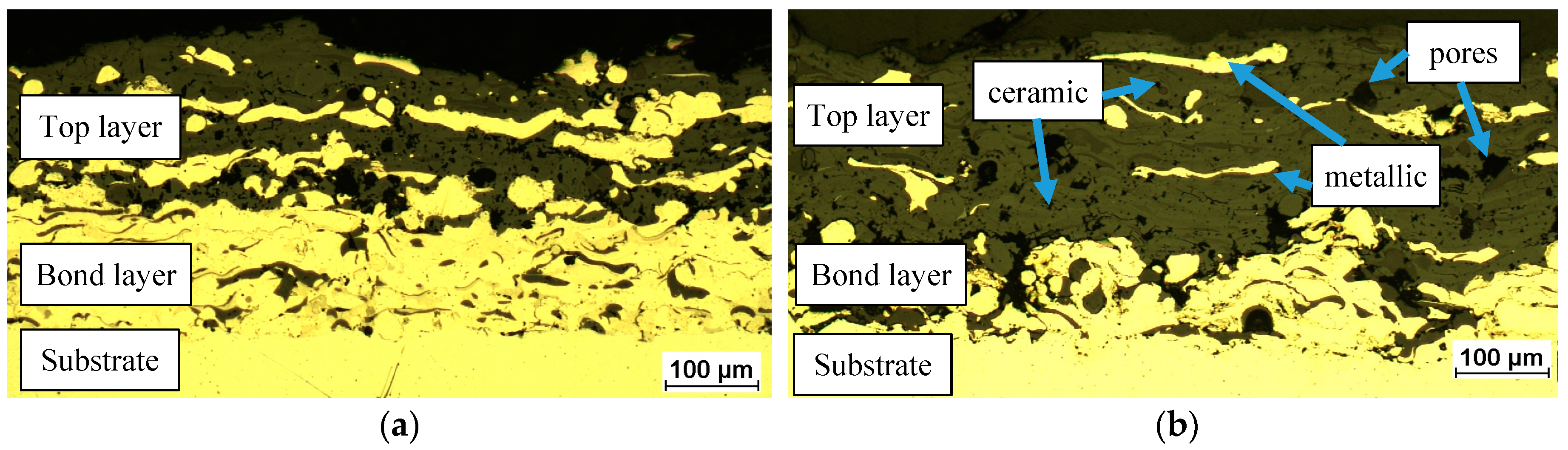

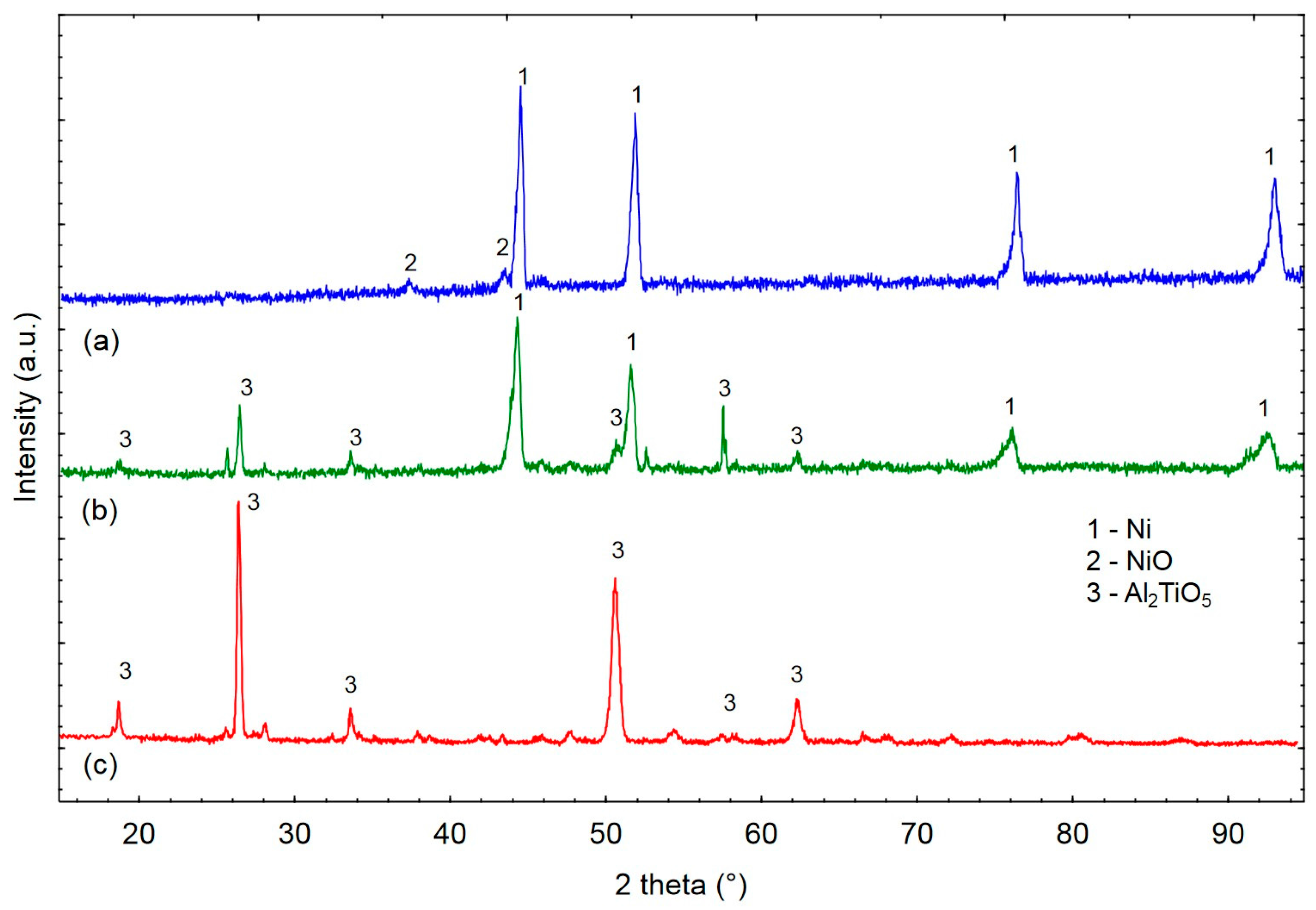

3.1. Microstructure and Properties

3.2. Cavitation Erosion

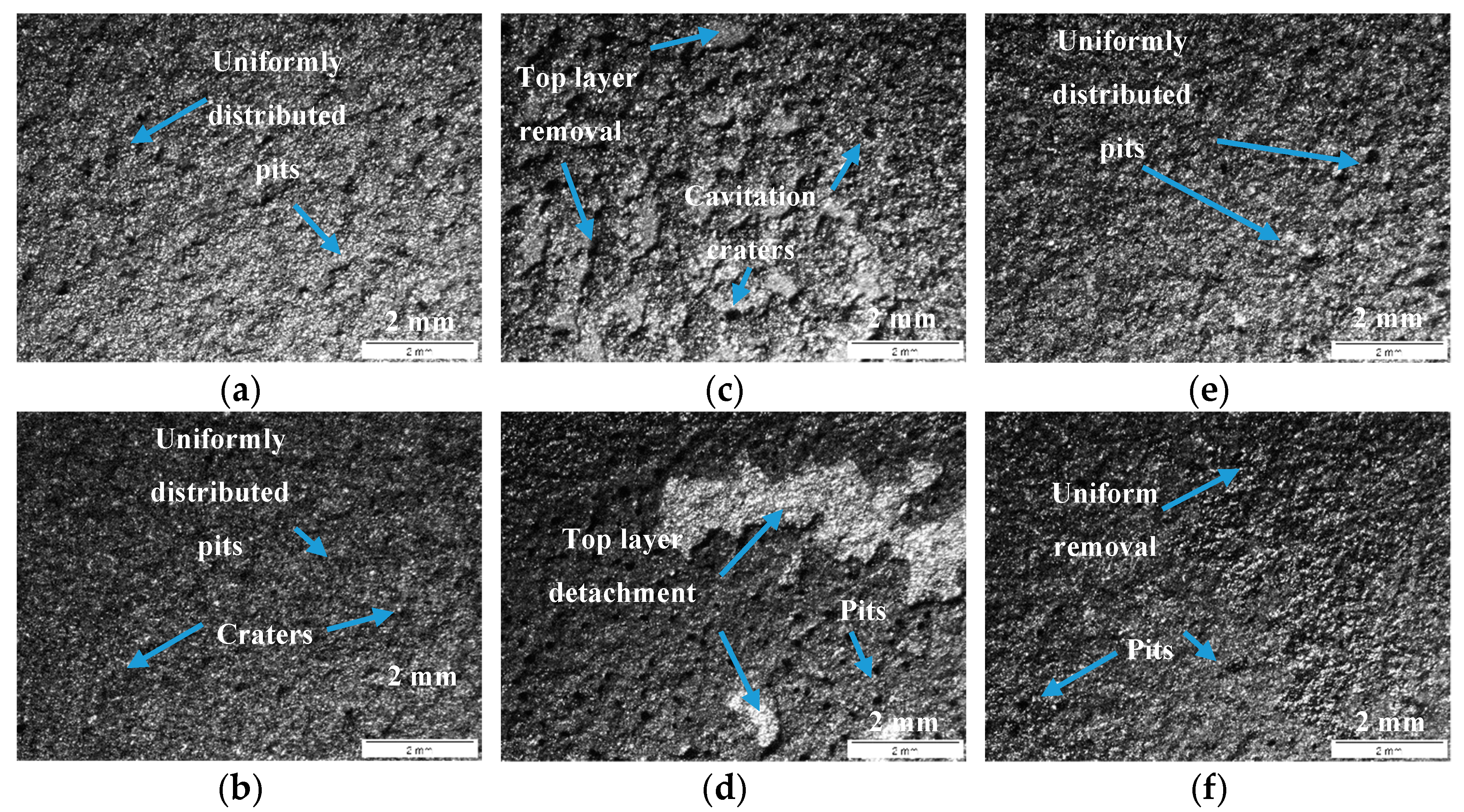

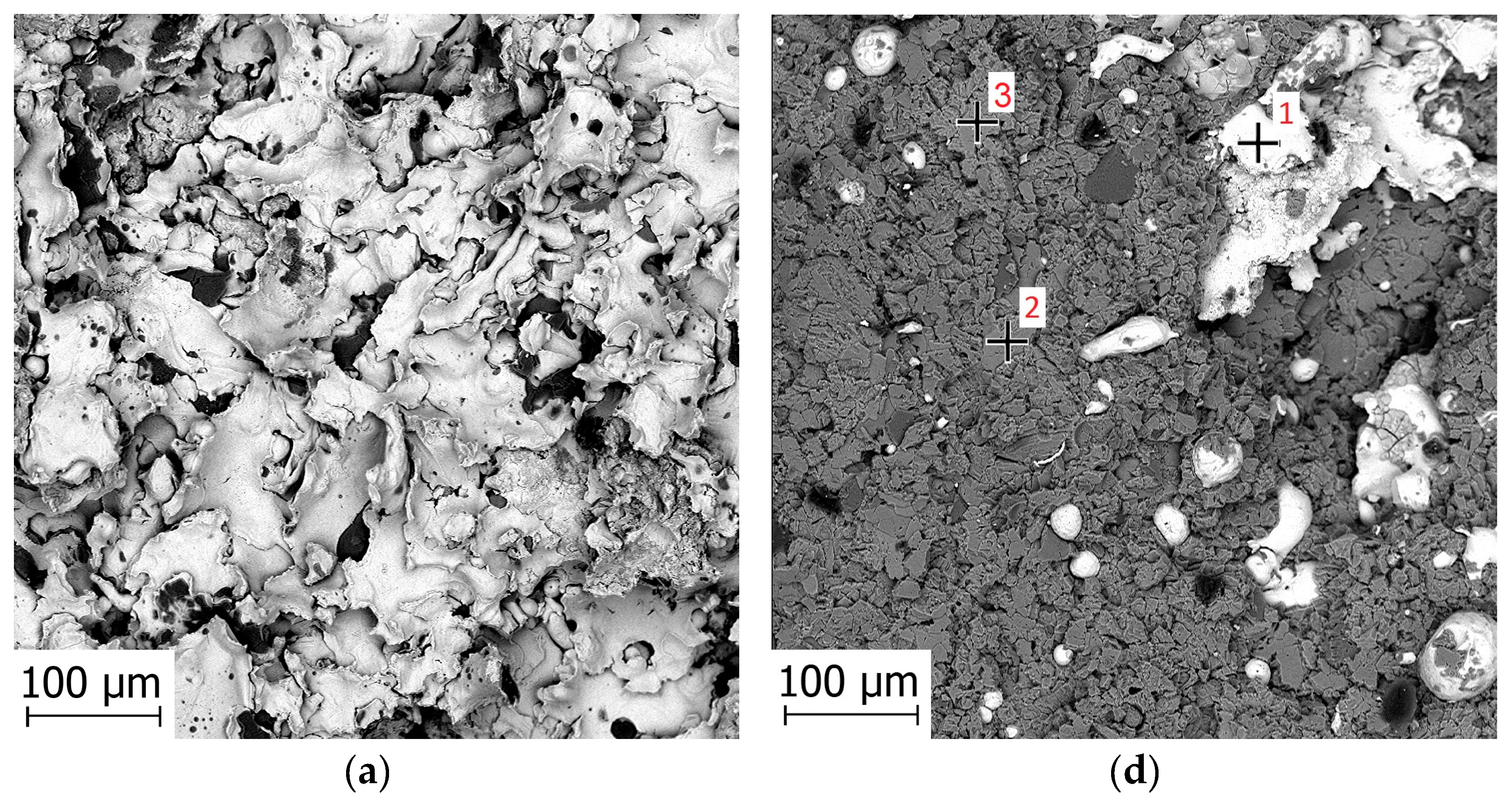

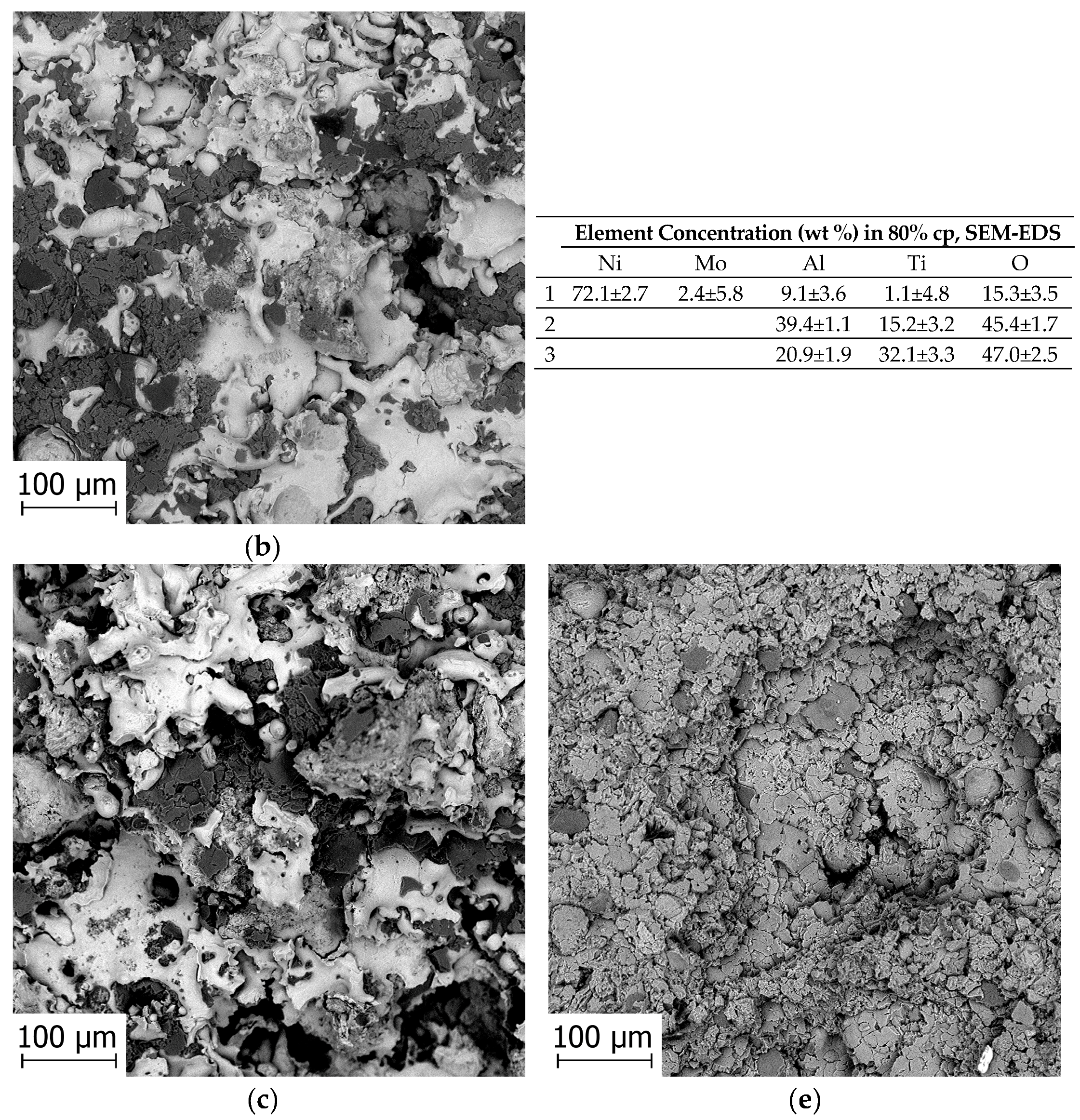

3.3. Cavitation Erosion Mechanism and the Phenomenological Model of Al2O3-40%TiO2/NiMoAl Coatings

4. Conclusions

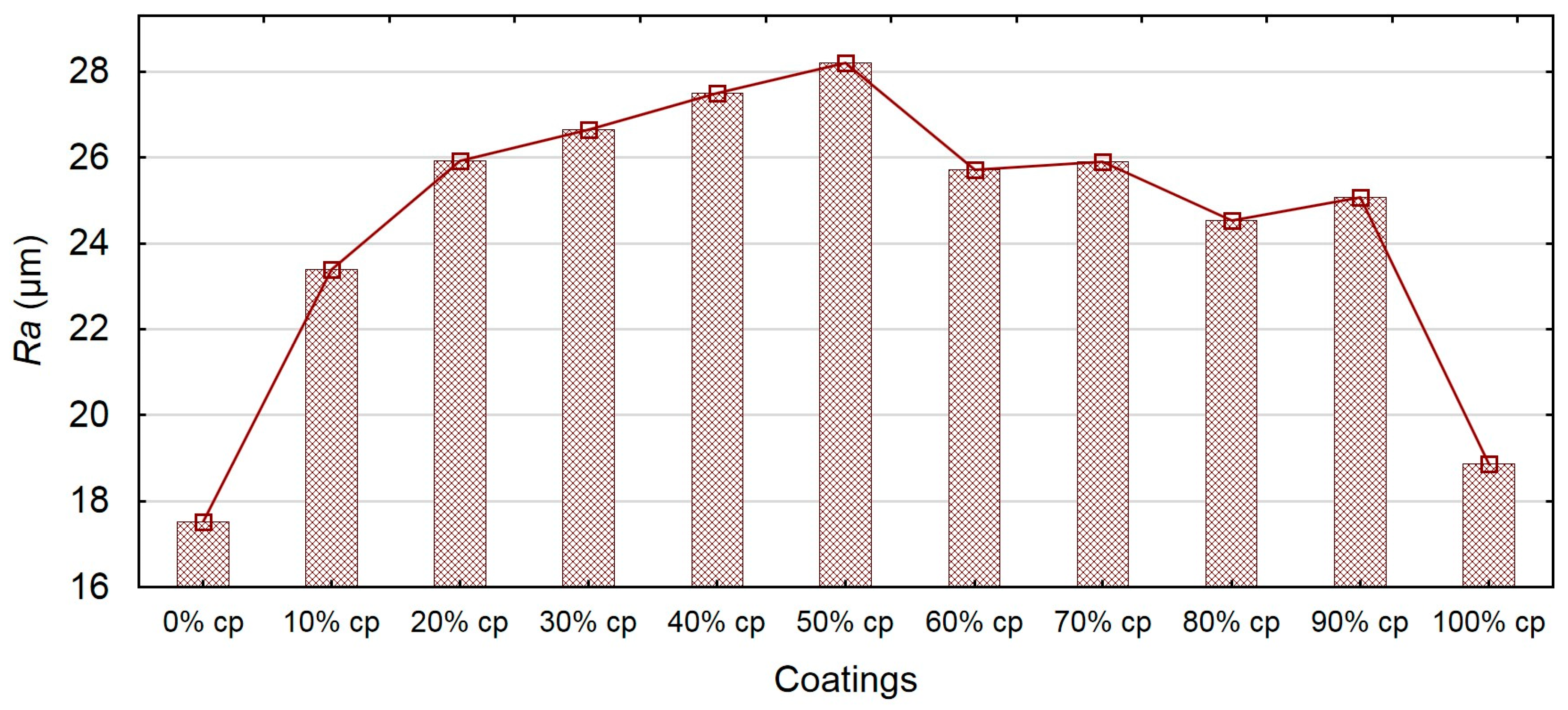

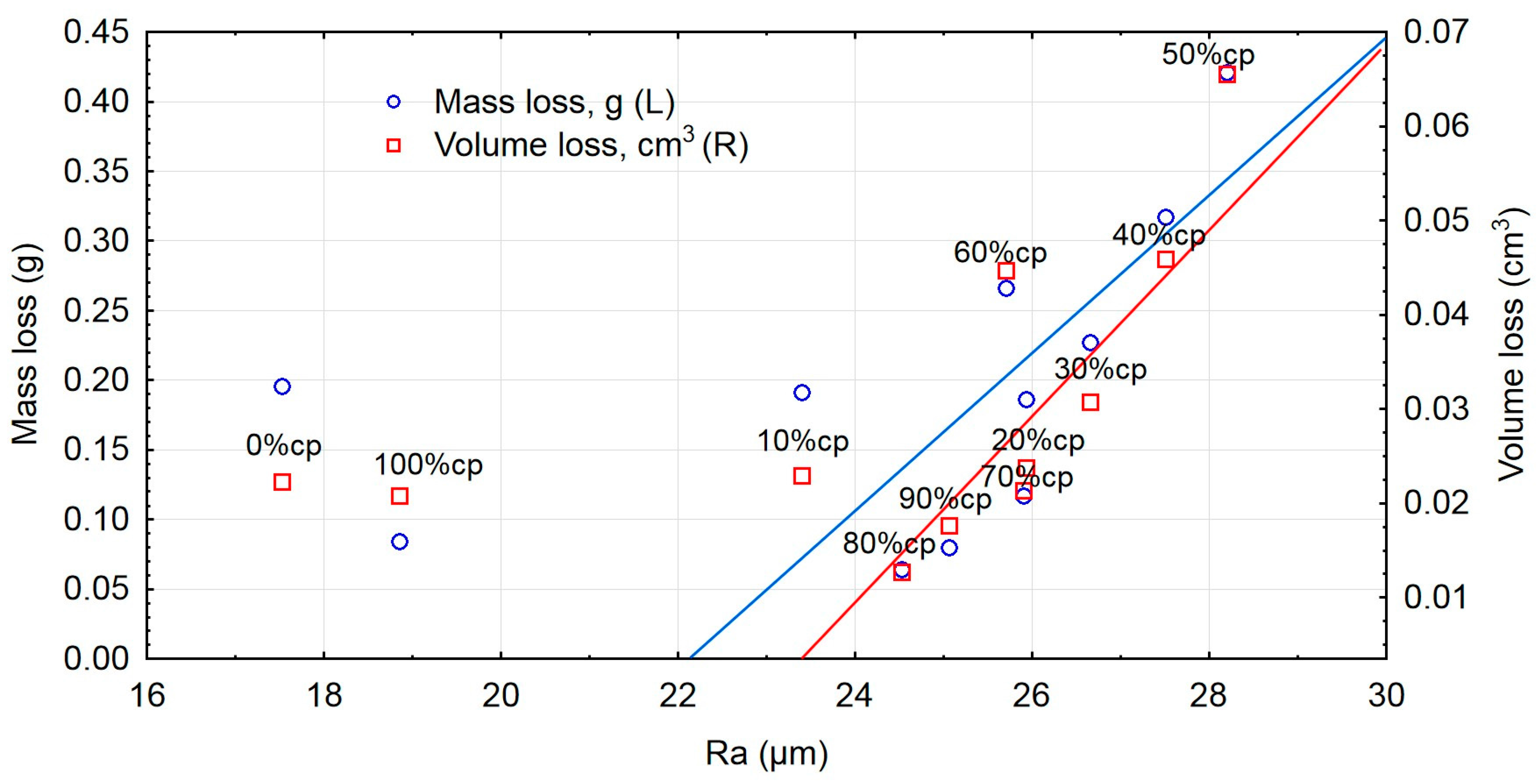

- Cermet coatings sprayed with the mixtures of Al2O3-40%TiO2 and NiMoAl feedstock powders were successfully deposited by LVOF spray. The microstructure of sprayed cermet contained unmelted particles, ceramic and metallic lamellas, lamella interfaces, porosity, oxide particles, and microcracks. The average hardnesses of ceramic and metallic lamellas were 727 HV and 327 HV, respectively. The porosity was in the range of 9.8–13.3%. The surface roughness Ra of as-sprayed cermet ranged from 23.4 µm to 28.2 µm.

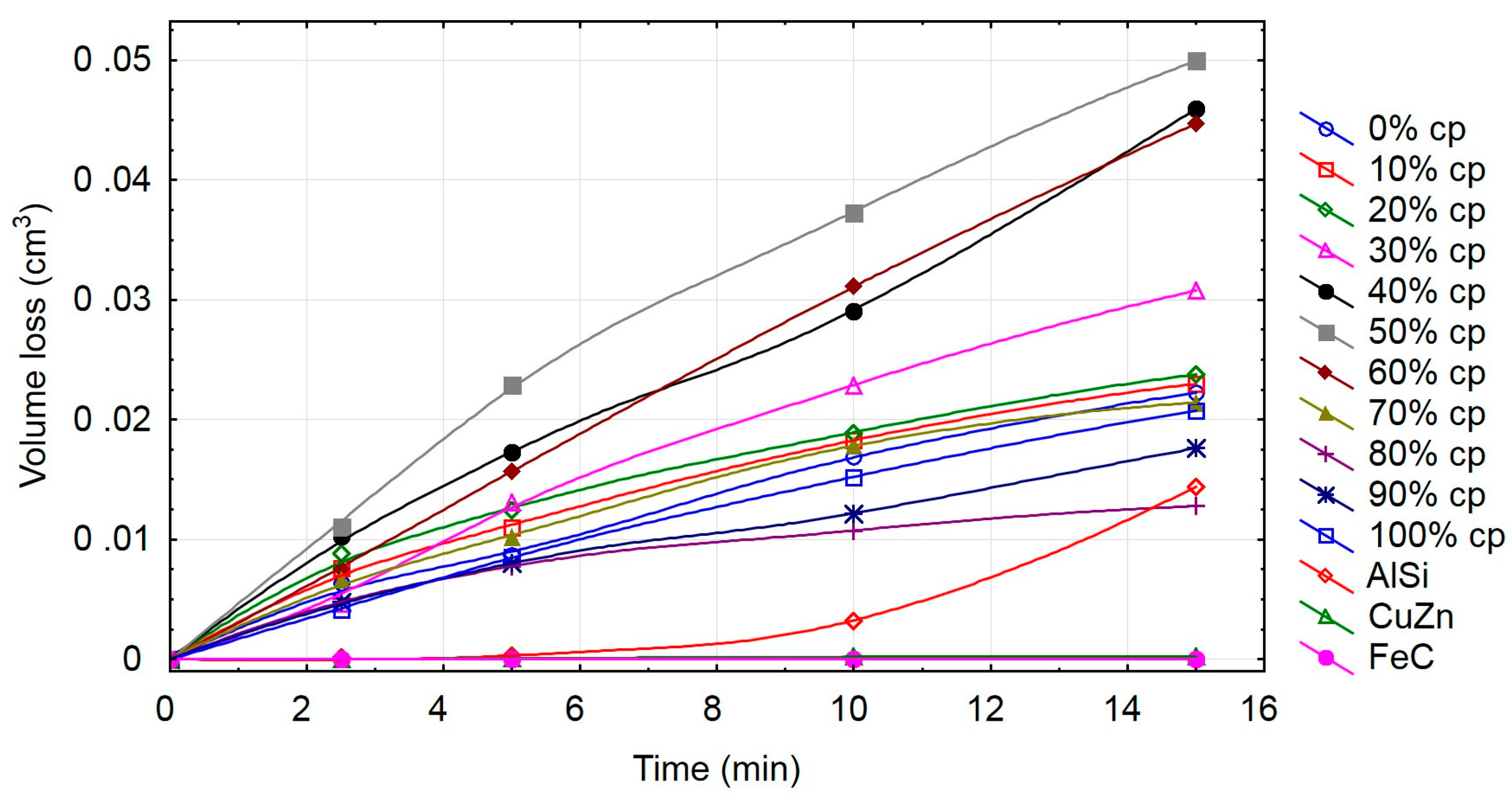

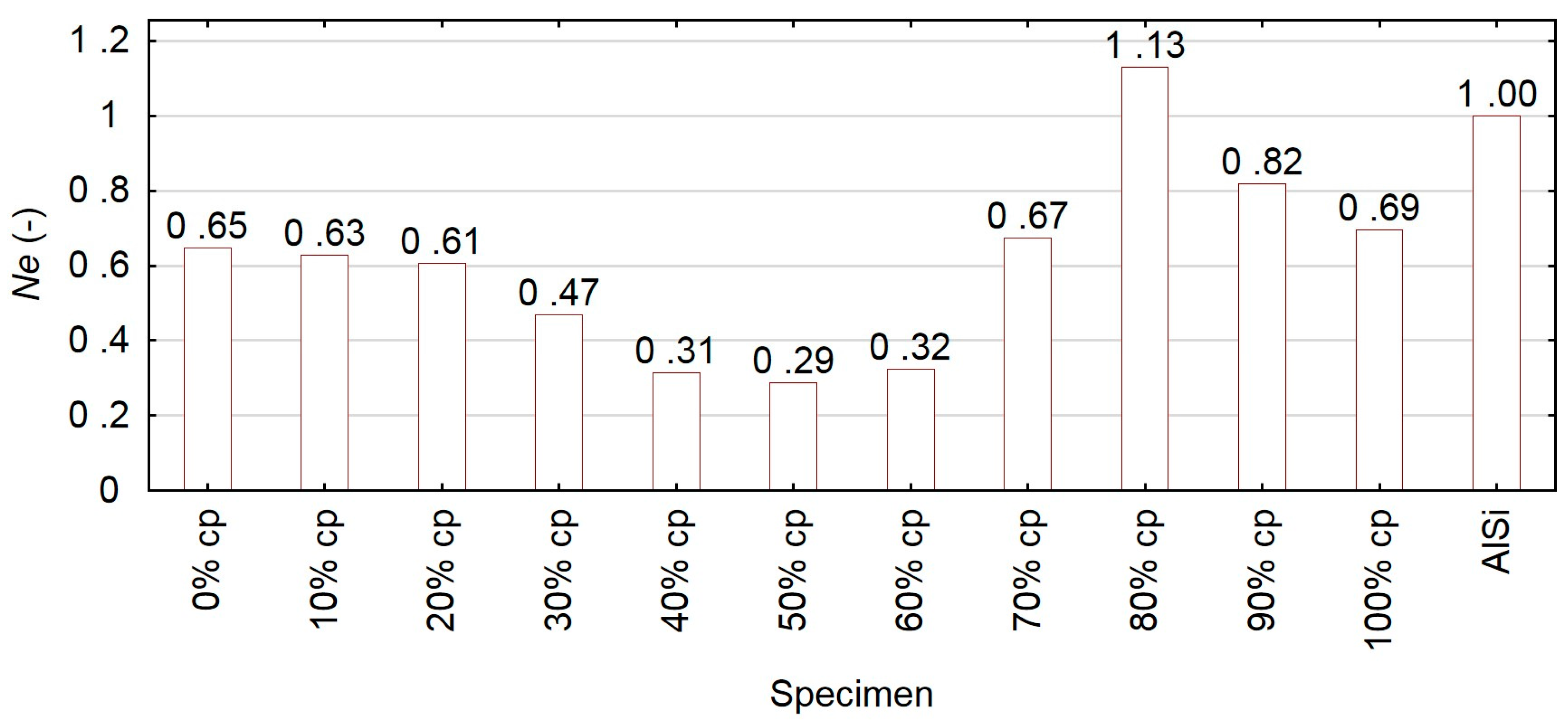

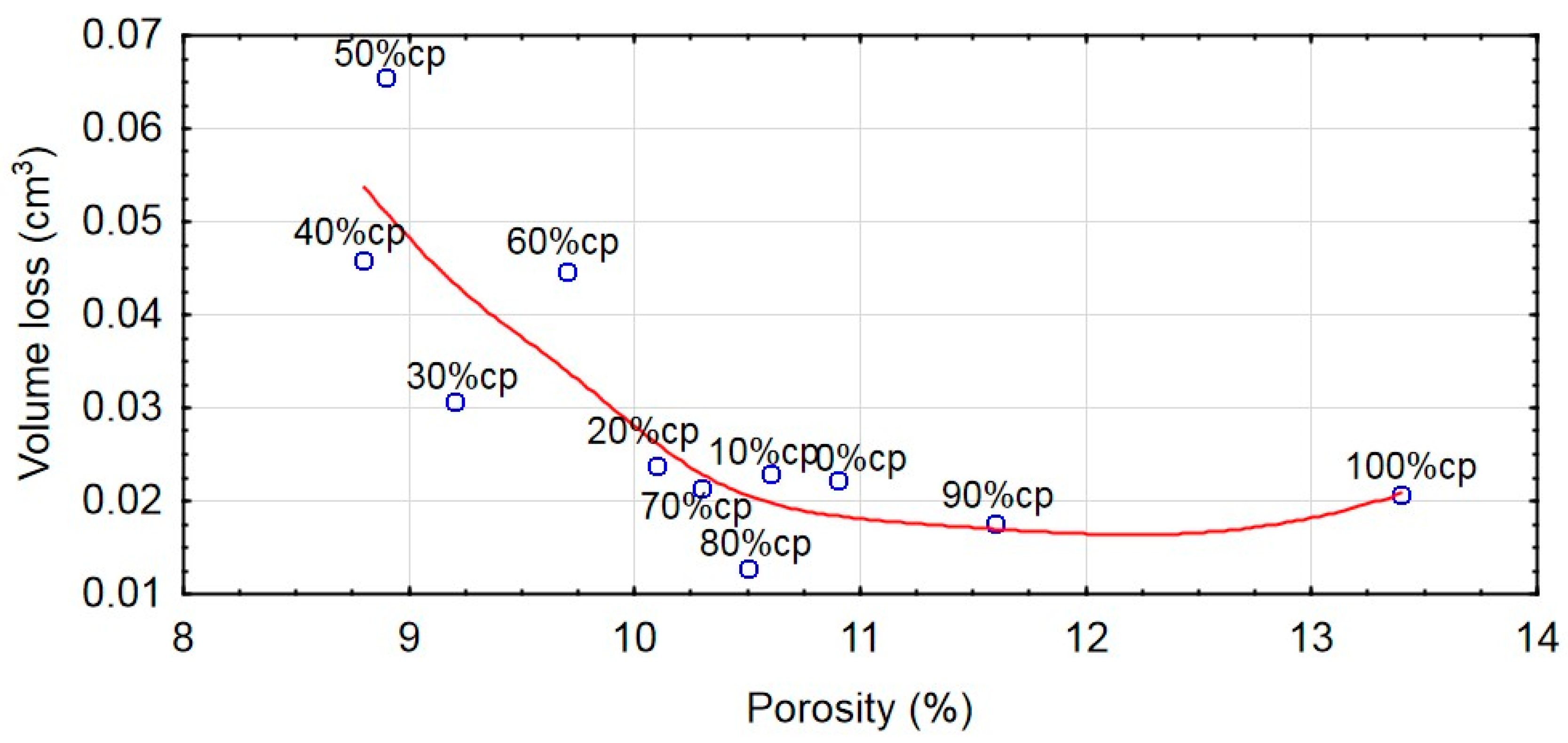

- The composition of the blend of the Al2O3-40%TiO2 and NiMoAl feedstock powders affects the cavitation erosion resistance of cermet coatings. The coating sprayed with the mixture containing 80 wt % of Al2O3-40%TiO2 exhibits a higher cavitation erosion resistance than other cermet.

- The cermet coating sprayed with the Al2O3-40%TiO2/NiMoAl mixture containing 80 wt % of Al2O3-40%TiO2 has more than 10% higher normalised cavitation erosion resistance than the reference aluminium alloy. By contrast, the cavitation wear rates of the cermet coatings were higher than those of the reference steel and brass samples.

- The main difference in the cavitation erosion process of the coatings and metal alloys consists of the evident incubation stage of cavitation erosion identified for reference materials and negligible incubation period of cavitation erosion as well as constant erosion rate acknowledged for thermally sprayed coatings.

- Porosity and surface roughness affect cavitation erosion resistance (CER). Large porosity or/and small surface roughness have a positive effect on the CER of cermet coatings.

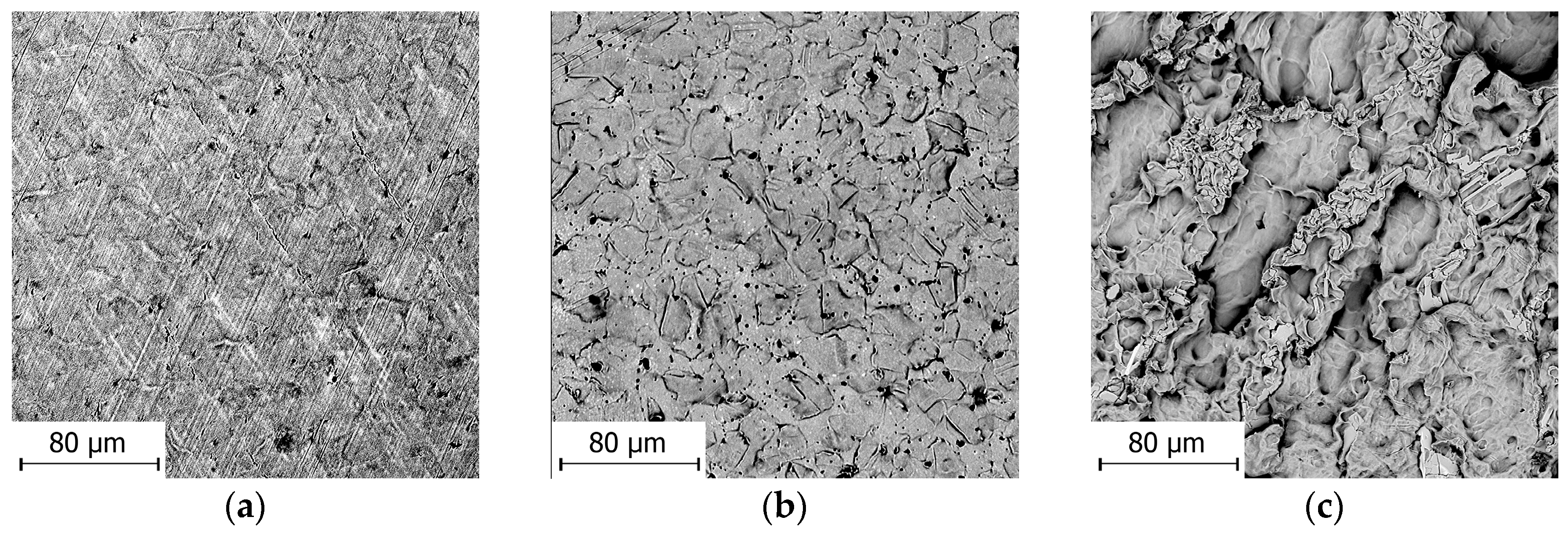

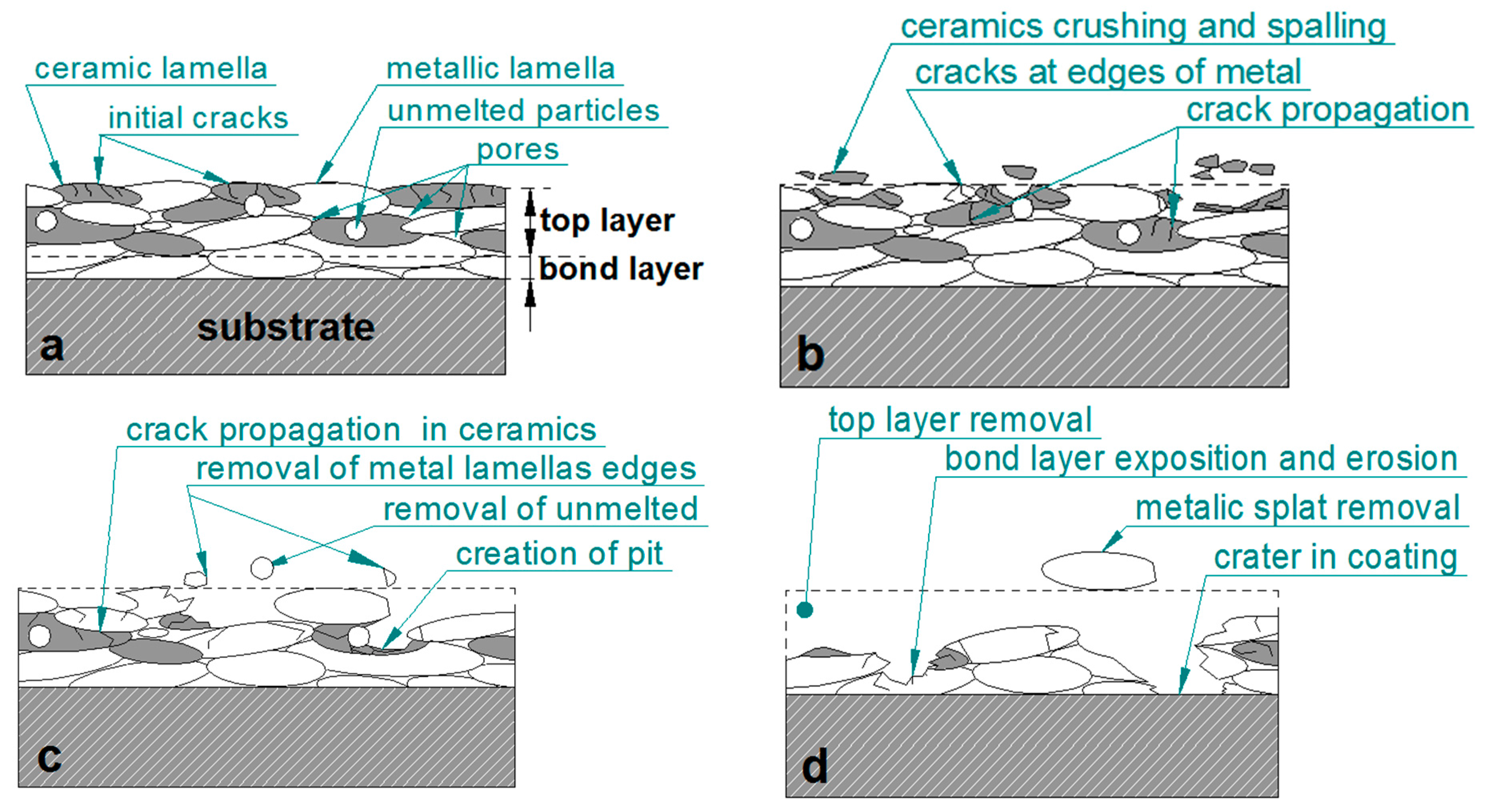

- The investigation revealed that the hard and brittle ceramic phase is more susceptible to cavitation erosion than are the metallic splats. The dominant mechanism of the cavitation erosion of composite coatings is brittle fracture initiated at primary microcracks present in ceramic lamellas, which results in ceramic splat removal. Then, exposed to cavitation, the metallic lamellas undergo erosion and the overlapping edges of splats are prone to erosion.

- The phenomenological model of the cavitation erosion of the Al2O3-40%TiO2/NiMoAl cermet coatings was elaborated. The erosion of cermet coatings starts with the removal of ceramic lamellas. The cavitation erosion is accelerated by cermet structural nonuniformities or discontinuities in the cermet coating microstructure such as crack networks, unmelted particles, and porosity. The progress of erosion depends on the differences in the mechanical properties of ceramic and metallic lamellas. The study confirmed that any inhomogeneity such as primary microcracks in ceramic lamellas plays a major role in the initiation of erosion, which leads to ceramic crushing and spalling.

Author Contributions

Funding

Conflicts of Interest

References

- Gao, X.; Tian, Z.; Liu, Z.; Shen, L. Interface characteristics of Al2O3-13%TiO2 ceramic coatings prepared by laser cladding. Trans. Nonferrous Met. Soc. China 2012, 22, 2498–2503. [Google Scholar] [CrossRef]

- Mishra, N.K.; Mishra, S.B. Hot corrosion performance of LVOF sprayed Al2O3-40% TiO2 coating on Superni 601 and Superco 605 superalloys at 800 and 900°C. Bull. Mater. Sci. 2015, 38, 1679–1685. [Google Scholar] [CrossRef]

- Cui, S.; Miao, Q.; Liang, W.; Zhang, Z.; Xu, Y.; Ren, B. Tribological Behavior of Plasma-Sprayed Al2O3-20 wt.%TiO2 Coating. J. Mater. Eng. Perform. 2017, 26, 2086–2094. [Google Scholar] [CrossRef]

- Davis, J.R. Handbook of Thermal Spray Technology; ASM International: Geauga County, OH, USA, 2004; ISBN 978-0-87170-795-6. [Google Scholar]

- Czupryński, A. Selected Properties of Thermally Sprayed Oxide Ceramic Coatings. Adv. Mater. Sci. 2015, 15, 17–32. [Google Scholar] [CrossRef]

- Szymański, K.; Hernas, A.; Moskal, G.; Myalska, H. Thermally sprayed coatings resistant to erosion and corrosion for power plant boilers—A review. Surf. Coat. Technol. 2015, 268, 153–164. [Google Scholar] [CrossRef]

- Yao, Y.; Lyckfeldt, O.; Tricoire, A.; Tricoire, A. Microstructure of Plasma Sprayed Al2O3-3wt%TiO2 Coating Using Freeze Granulated Powder. J. Mater. Sci. Chem. Eng. 2016, 04, 8. [Google Scholar] [CrossRef]

- Jia, S.; Zou, Y.; Xu, J.; Wang, J.; Yu, L. Effect of TiO2 content on properties of Al2O3 thermal barrier coatings by plasma spraying. Trans. Nonferrous Met. Soc. China 2015, 25, 175–183. [Google Scholar] [CrossRef]

- Mishra, N.K.; Mishra, S.B.; Kumar, R. Oxidation resistance of low-velocity oxy fuel-sprayed Al2O3-13TiO2 coating on nickel-based superalloys at 800°C. Surf. Coat. Technol. 2014, 260, 23–27. [Google Scholar] [CrossRef]

- Jafarzadeh, K.; Valefi, Z.; Ghavidel, B. The effect of plasma spray parameters on the cavitation erosion of Al2O3-TiO2 coatings. Surf. Coat. Technol. 2010, 205, 1850–1855. [Google Scholar] [CrossRef]

- Morks, M.F.; Akimoto, K. The role of nozzle diameter on the microstructure and abrasion wear resistance of plasma sprayed composite coatings. J. Manuf. Process. 2008, 10, 1–5. [Google Scholar] [CrossRef]

- Matikainen, V.; Niemi, K.; Koivuluoto, H.; Vuoristo, P. Abrasion, Erosion and Cavitation Erosion Wear Properties of Thermally Sprayed Alumina Based Coatings. Coatings 2014, 4, 18–36. [Google Scholar] [CrossRef]

- Żórawski, W.; Góral, A.; Bokuvka, O.; Lityńska-Dobrzyńska, L.; Berent, K. Microstructure and tribological properties of nanostructured and conventional plasma sprayed alumina–titania coatings. Surf. Coat. Technol. 2015, 268, 190–197. [Google Scholar] [CrossRef]

- Maruszczyk, A.; Dudek, A.; Szala, M. Research into Morphology and Properties of TiO2–NiAl Atmospheric Plasma Sprayed Coating. Adv. Sci. Technol. Res. J. 2017, 11, 204–210. [Google Scholar] [CrossRef]

- Hejwowski, T.; Łabacz-Kęcik, A. Mikrostruktura i odporność na zużycie powłok natryskiwanych metodą płomieniowo-proszkową mieszaninami proszków. Przegląd Spaw.-Weld. Technol. Rev. 2012, 9, 57–64. [Google Scholar] [CrossRef]

- Hejwowski, T. Comparative study of thermal barrier coatings for internal combustion engine. Vacuum 2010, 85, 610–616. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, H.; Zhao, X.; Chen, J.; An, Y.; Yan, F. Microstructural Characterization and Tribological Behavior of HVOF Sprayed NiMoAl Coating from 20 to 800 °C. J. Therm. Spray Technol. 2015, 24, 348–356. [Google Scholar] [CrossRef]

- Hou, G.; Zhao, X.; Zhou, H.; Lu, J.; An, Y.; Chen, J.; Yang, J. Cavitation erosion of several oxy-fuel sprayed coatings tested in deionized water and artificial seawater. Wear 2014, 311, 81–92. [Google Scholar] [CrossRef]

- Santa, J.F.; Espitia, L.A.; Blanco, J.A.; Romo, S.A.; Toro, A. Slurry and cavitation erosion resistance of thermal spray coatings. Wear 2009, 267, 160–167. [Google Scholar] [CrossRef]

- Ksiazek, M.; Boron, L.; Radecka, M.; Richert, M.; Tchorz, A. Mechanical and Tribological Properties of HVOF-Sprayed (Cr3C2-NiCr+Ni) Composite Coating on Ductile Cast Iron. J. Mater. Eng. Perform. 2016, 25, 3185–3193. [Google Scholar] [CrossRef]

- Kekes, D.; Psyllaki, P.; Vardavoulias, M.; Vekinis, G. Wear micro-mechanisms of composite WC-Co/Cr-NiCrFeBSiC coatings.Part II: Cavitation erosion. Tribol. Ind. 2014, 36, 375–383. [Google Scholar]

- Hejwowski, T. Wear resistance of graded coatings. Vacuum 2002, 65, 515–520. [Google Scholar] [CrossRef]

- ISO 4287:1997. Geometrical Product Specifications (GPS)—Surface texture: Profile method—Terms, definitions and surface texture parameters; International Organization for Standardization: Geneva, Switzerland, 1997. [Google Scholar]

- Steller, J. International Cavitation Erosion Test and quantitative assessment of material resistance to cavitation. Wear 1999, 233–235, 51–64. [Google Scholar] [CrossRef]

- Hattori, S.; Ishikura, R.; Zhang, Q. Construction of database on cavitation erosion and analyses of carbon steel data. Wear 2004, 257, 1022–1029. [Google Scholar] [CrossRef]

- ASTM G32-10: Standard Test Method for Cavitation Erosion Using Vibratory Apparatus; ASTM International: West Conshohocken, PA, USA, 2010.

- Tucker, R.C. ASM Handbook Volume 5A: Thermal Spray Technology; ASM International: Geauga County, OH, USA, 2013; ISBN 978-1-61503-996-8. [Google Scholar]

- Shaw, L.L.; Goberman, D.; Ren, R.; Gell, M.; Jiang, S.; Wang, Y.; Xiao, T.D.; Strutt, P.R. The dependency of microstructure and properties of nanostructured coatings on plasma spray conditions. Surf. Coat. Technol. 2000, 130, 1–8. [Google Scholar] [CrossRef]

- Szala, M. Application of computer image analysis software for determining incubation period of cavitation erosion – preliminary results. In ITM Web of Conferences, Proceedings of the II International Conference of Computational Methods in Engineering Science (CMES’17), Lublin, Poland, 23–25 November 2017; EDP Sciences: Reyulis, France, 2017; Volume 15, p. 06003. [Google Scholar] [CrossRef]

- Dybowski, B.; Szala, M.; Hejwowski, T.J.; Kiełbus, A. Microstructural phenomena occurring during early stages of cavitation erosion of Al-Si aluminium casting alloys. Solid State Phenom. 2015, 227, 255–258. [Google Scholar] [CrossRef]

- Tomlinson, W.J.; Kalitsounakis, N.; Vekinis, G. Cavitation erosion of aluminas. Ceram. Int. 1999, 25, 331–338. [Google Scholar] [CrossRef]

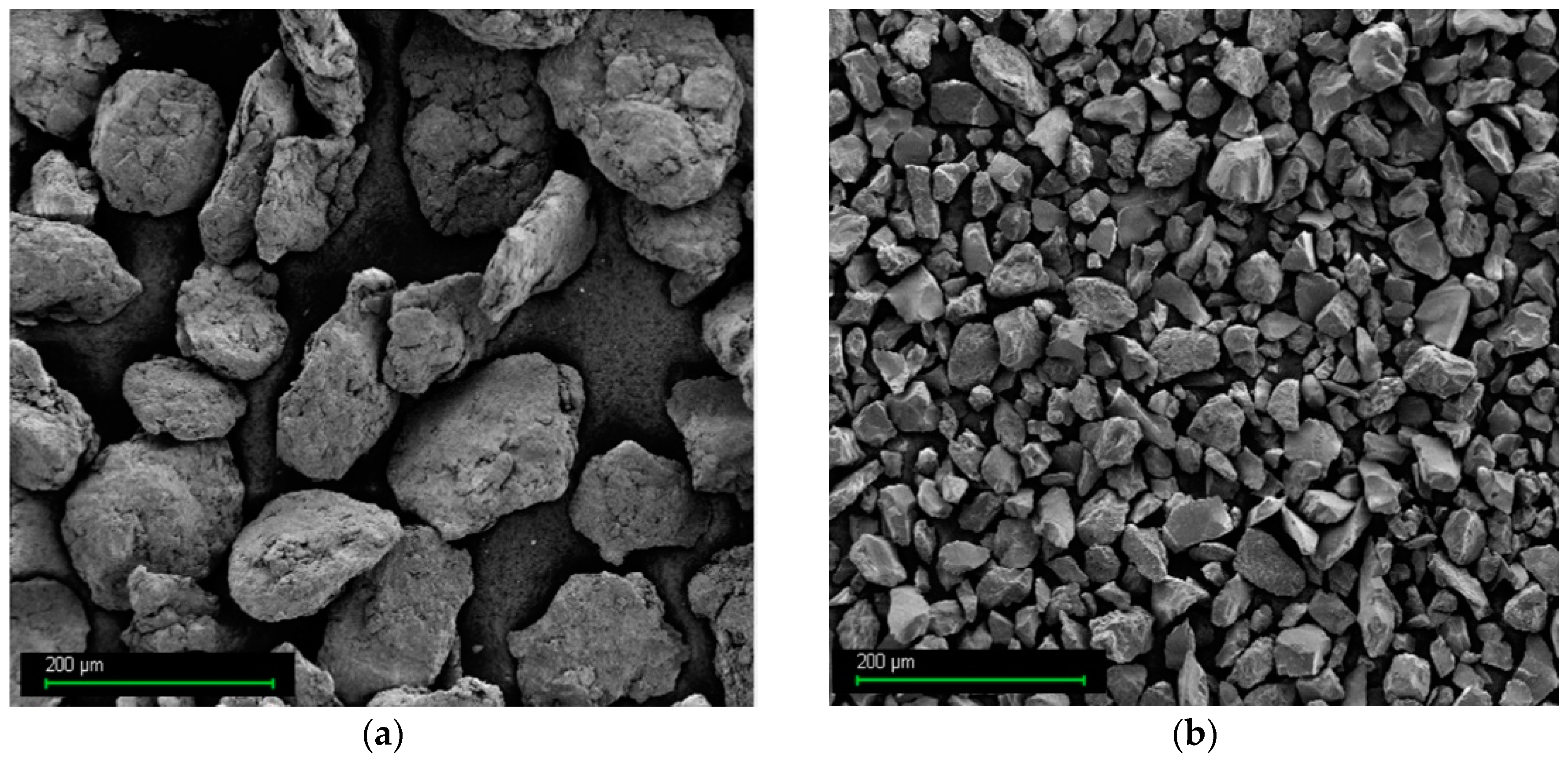

| Type of Powder (Description) | Powder Grade | Nominal Chemical Composition (wt %) | Grain Size (µm) |

|---|---|---|---|

| Metallic powder (mp) | AMI 3452.6 | Al = 5.2%; Mo = 4.9%; Fe = 0.8%; Si = 0.4%, Ni, bal. | −125 + 45 |

| Ceramic powder (cp) | MX 6-3018.2 | Al2O3-40%TiO2 | −40 + 15 |

| Sample Code | Grade | Main Chemical Element Composition (wt %) |

|---|---|---|

| AlSi | AlSi7Mg | Al base; Si 7.5%; Mg 6.5% |

| CuZn | CuZn40Pb2 | Cu base; Zn 40%; Pb 2% |

| FeC | C45 | Fe base; C 0.45% |

| Microstructure Phase | Nanohardness (HV) | Young’s Modulus (GPa) | ||

|---|---|---|---|---|

| Average | SD | Average | SD | |

| ceramic lamellas | 723.2 | 310.7 | 110.4 | 20.2 |

| metallic lamellas | 325.5 | 40.8 | 116.8 | 23.1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szala, M.; Hejwowski, T. Cavitation Erosion Resistance and Wear Mechanism Model of Flame-Sprayed Al2O3-40%TiO2/NiMoAl Cermet Coatings. Coatings 2018, 8, 254. https://doi.org/10.3390/coatings8070254

Szala M, Hejwowski T. Cavitation Erosion Resistance and Wear Mechanism Model of Flame-Sprayed Al2O3-40%TiO2/NiMoAl Cermet Coatings. Coatings. 2018; 8(7):254. https://doi.org/10.3390/coatings8070254

Chicago/Turabian StyleSzala, Mirosław, and Tadeusz Hejwowski. 2018. "Cavitation Erosion Resistance and Wear Mechanism Model of Flame-Sprayed Al2O3-40%TiO2/NiMoAl Cermet Coatings" Coatings 8, no. 7: 254. https://doi.org/10.3390/coatings8070254

APA StyleSzala, M., & Hejwowski, T. (2018). Cavitation Erosion Resistance and Wear Mechanism Model of Flame-Sprayed Al2O3-40%TiO2/NiMoAl Cermet Coatings. Coatings, 8(7), 254. https://doi.org/10.3390/coatings8070254